Method for controlling working track of aerial work platform

A high-altitude work platform and trajectory control technology, which is applied in the direction of non-electric variable control, position/direction control, control/adjustment system, etc., can solve the problems of inability to realize actions, affect work efficiency, consume manpower and material resources, etc., and reduce frequent positioning The effect of reducing trouble, reducing collision accidents, and smooth working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

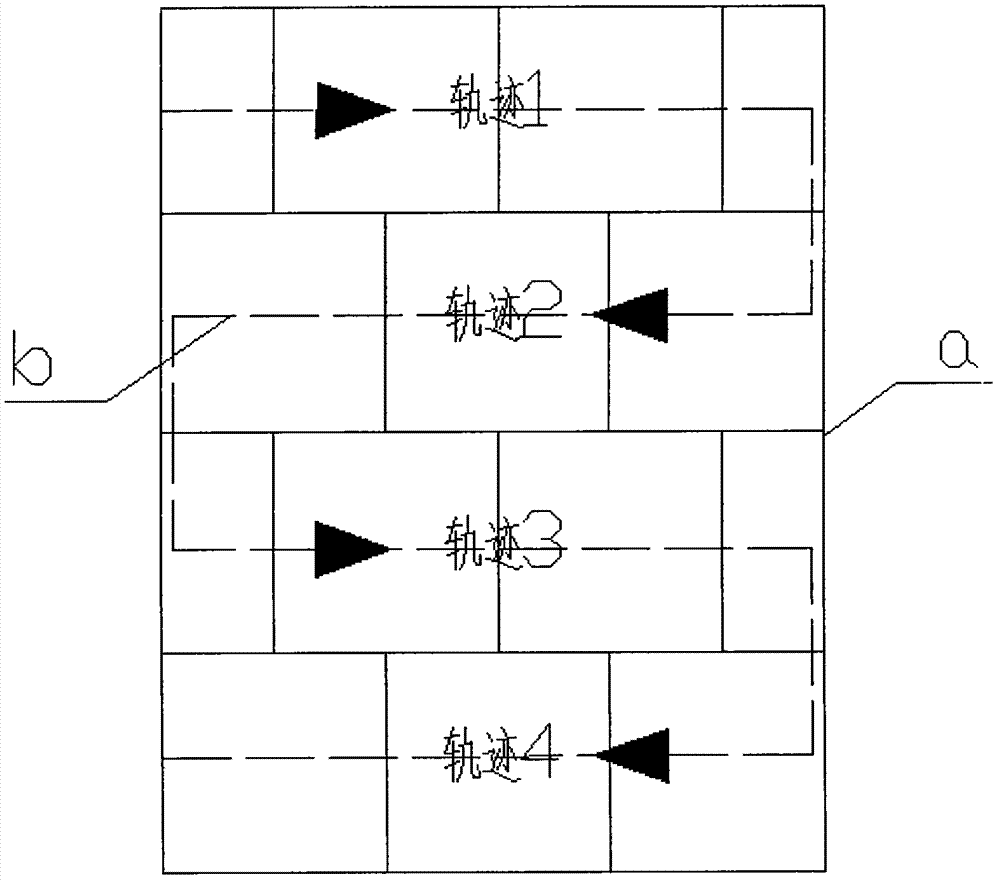

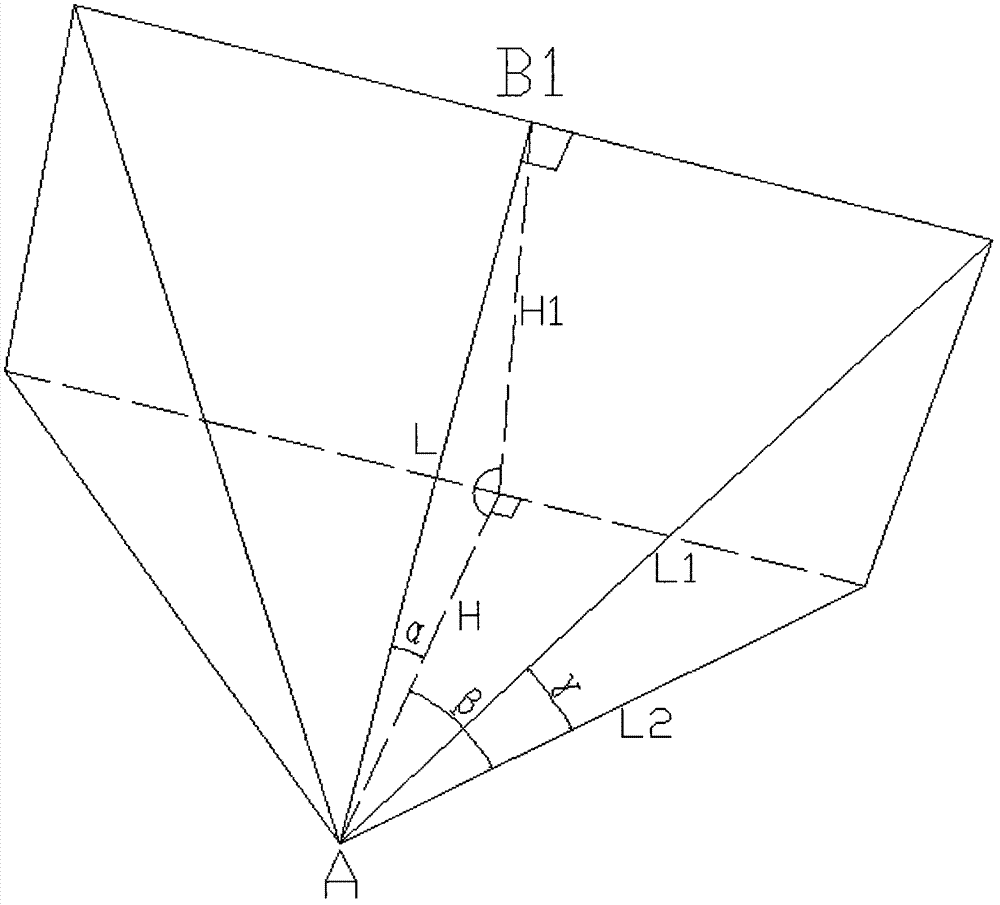

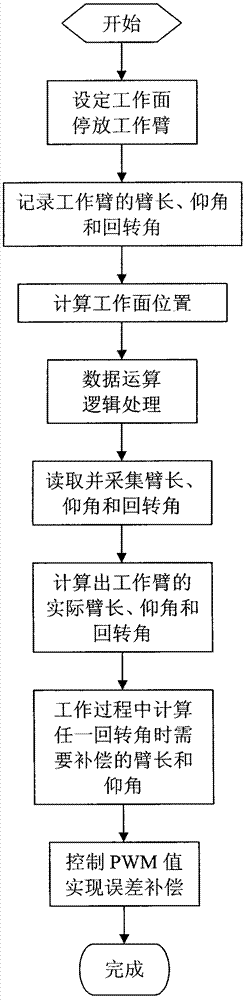

[0028] Such as figure 1 , figure 2 and image 3 As shown, a working trajectory control method of an aerial work platform, the specific steps are:

[0029] (1) Park the working arm at a position perpendicular to the preset working track surface. When entering the track control working mode, record the initial arm length, working arm elevation angle and rotation angle through the data recording module, and automatically calculate the working the position of the trajectory surface;

[0030] (2) When the slewing action starts, the controller performs data calculation and logic processing to automatically record the angle, length and slewing angle of the working arm;

[0031] (3) Collect the length signal value of the working arm through the length sensor, the angle sensor collects the elevation angle of the working arm, and the rotary encoder collects the rotation angle va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com