A sawing equipment and sawing method for heavy and extra-large structural parts

A structural part and sawing technology, which is applied in the field of large-scale CNC sawing equipment, to achieve the effect of promoting chip breaking and chip removal, improving service life, reducing volume and height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

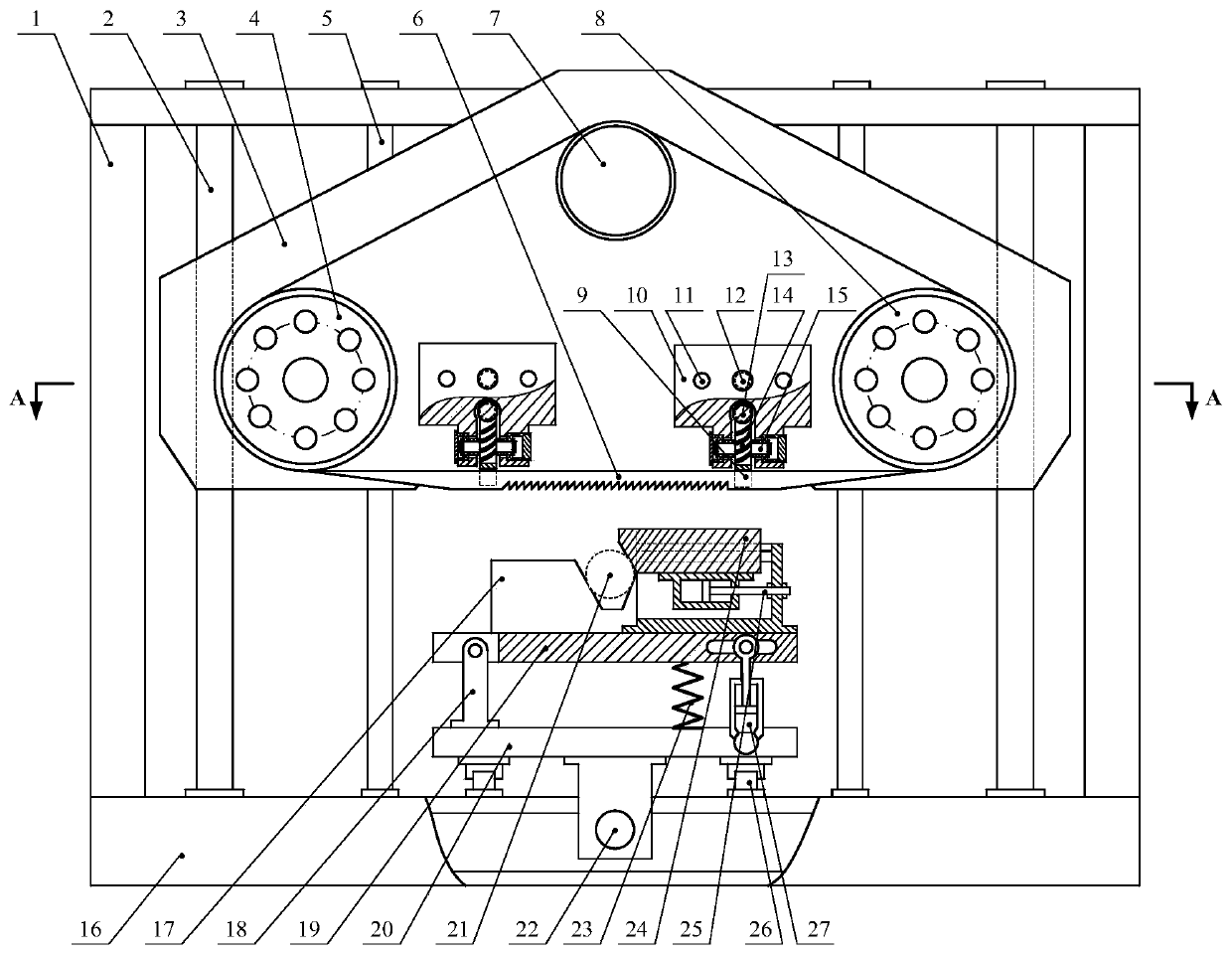

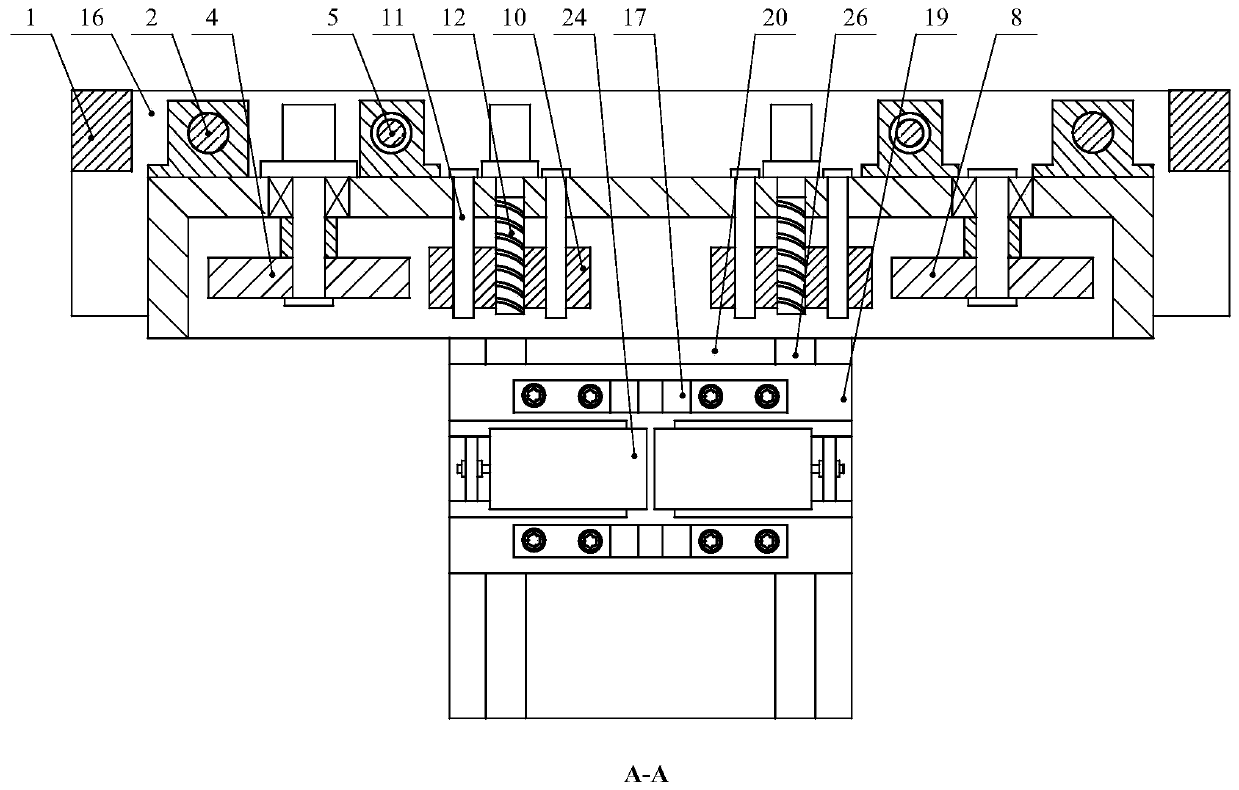

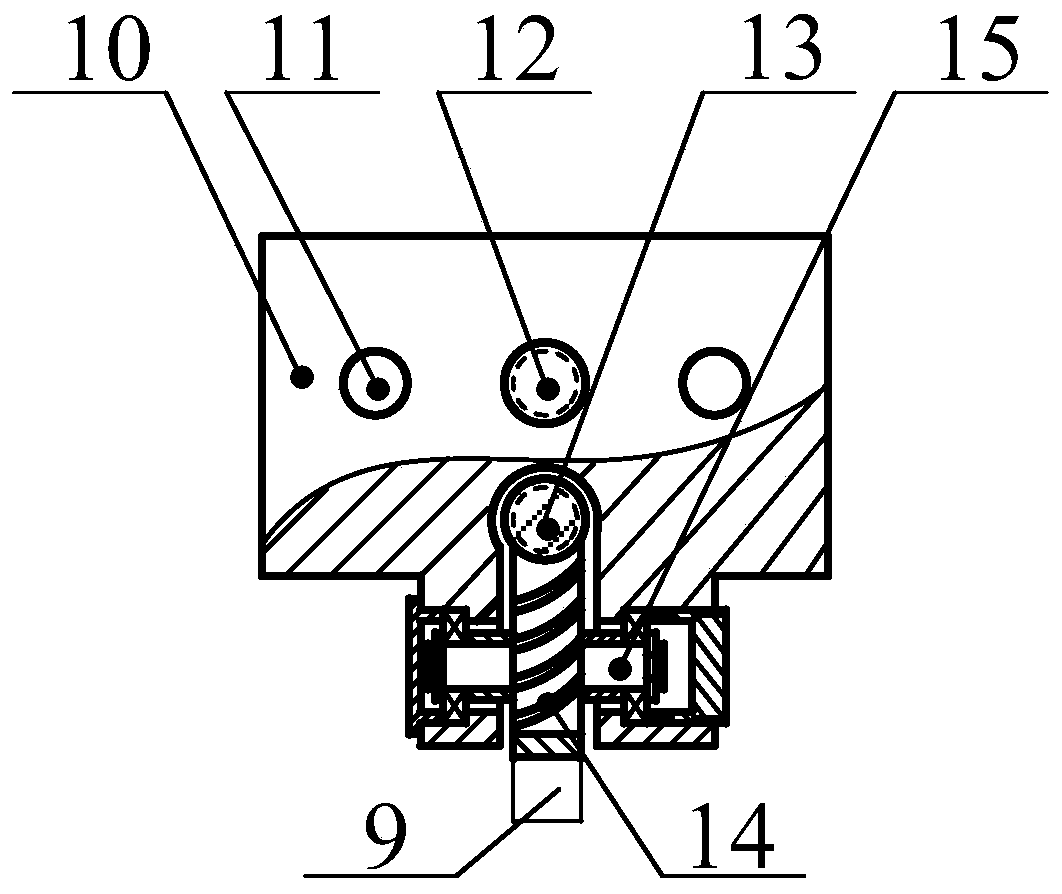

[0037] The present invention will be further described below in conjunction with accompanying drawing.

[0038] Such as figure 1 As shown, a sawing equipment for heavy and large structural parts includes a frame 1, a guide column 2, a three-wheel sawing mechanism, a feed hydraulic cylinder 5, a machine base 16, a workbench, a guide correction mechanism, a workbench, and a clamping mechanism. components and controllers. The frame 1 is fixed on the machine base 16 . Two guide columns 2 are all fixed on the frame 1 and the support 16. The three-wheel sawing mechanism includes a saw frame 3 , a driving band saw wheel 4 , a saw band 6 , an intermediate band saw wheel 7 and a driven band saw wheel 8 . The saw frame 3 and the two guide columns 2 form a sliding pair. The two feeding hydraulic cylinders 5 are centrally arranged on the machine base 16 . Feed hydraulic oil cylinder 5 adopts double rod oil cylinder. The two ends of the piston rod on the feeding hydraulic oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com