Patents

Literature

100results about How to "Enables automatic alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

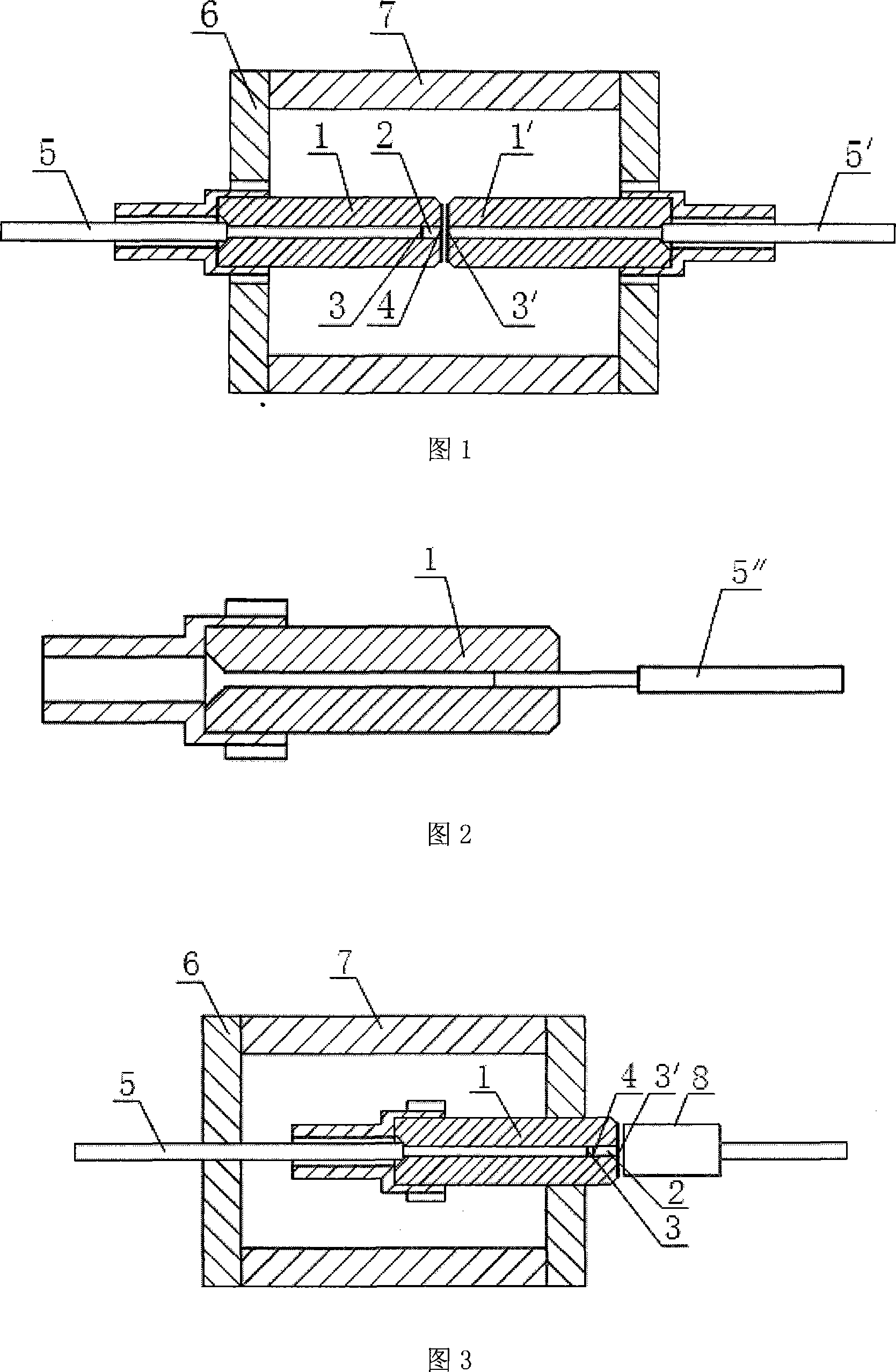

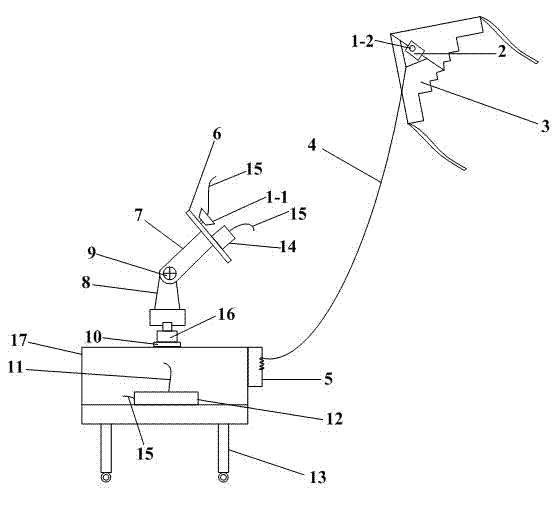

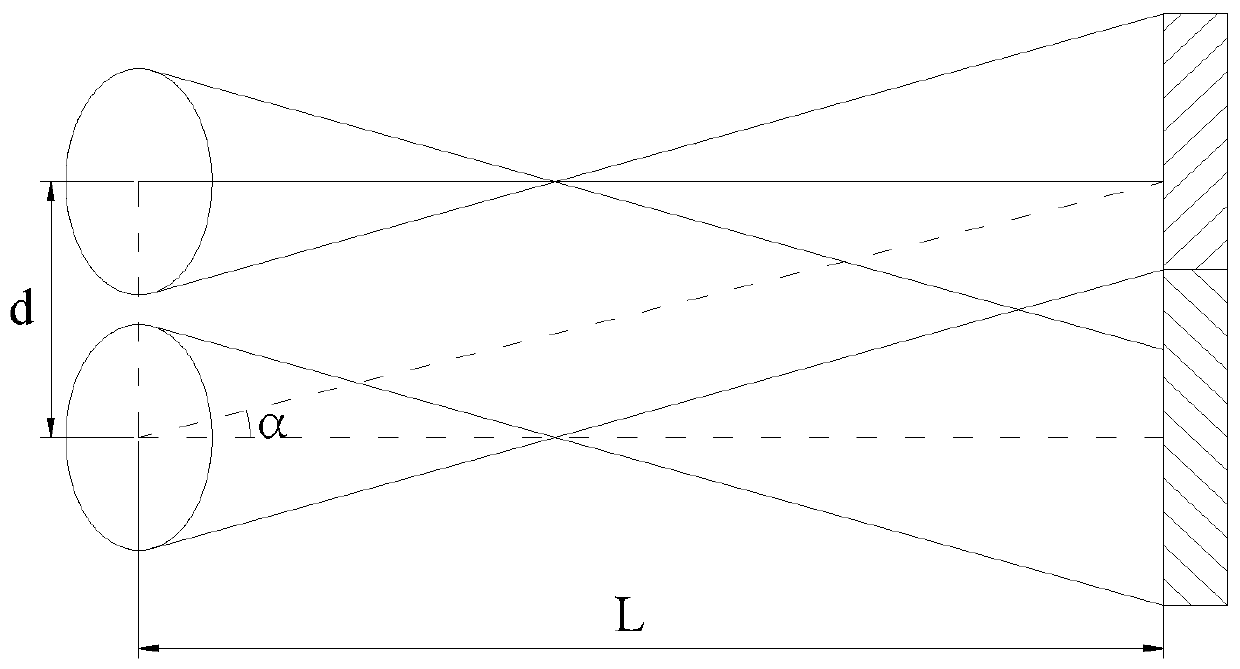

Turnning optical fibre method Fabry-perot filter

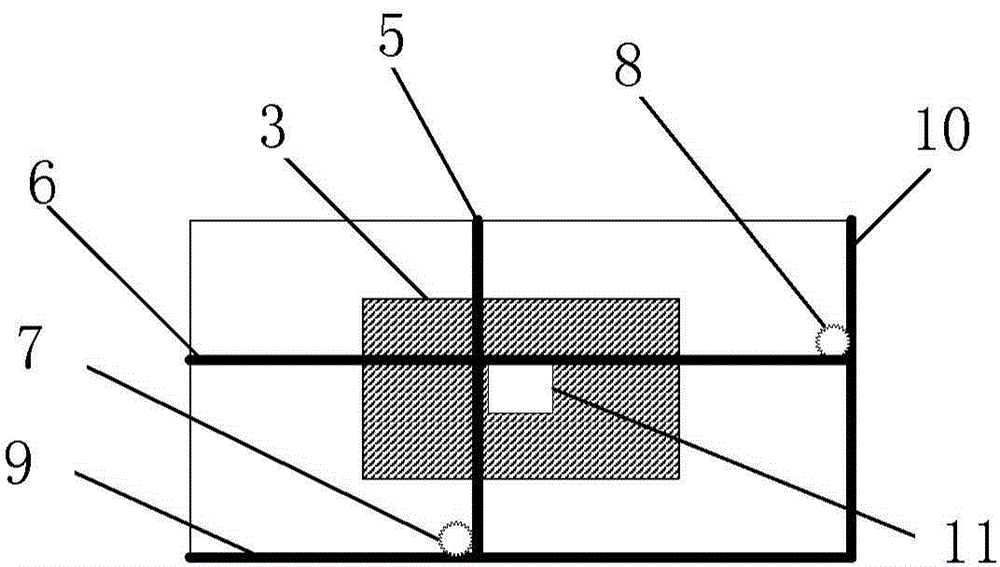

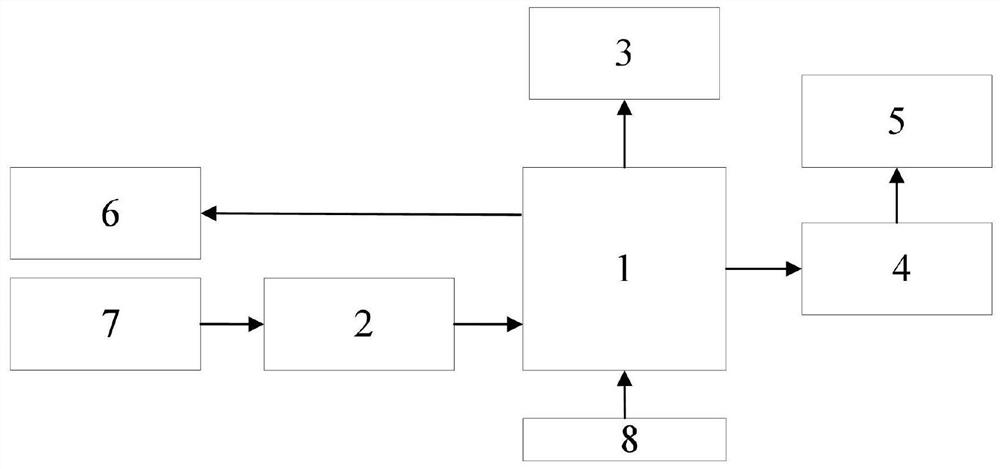

The present invention discloses a tunable optical fiber Fabry-Pero filter. The object is to provide the tunable optical fiber Fabry-Pero filter with a Fabry cavity optical fiber waveguide, easy manufacturing and low cost. The present invention comprises a core inset (1), the optical fiber waveguide (2), a high reflecting coating (3), an antireflection coating (4), an optical fiber (5), a support (6), a piezoelectric ceramics (7) and a fiber collimator (8); the optical fiber waveguide is fixed in one inner hole of the core insert. One end surface is placed in the inner hole of the core insert and the other end surface is placed on the same flat with the core insert end surface. The inner hole of the core insert which fixes the optical fiber waveguide is also inserted by the optical fiber. The optical fiber and the optical fiber waveguide are automatically aligned through the inner hole of the core insert. One of the two adjacent end surfaces of the optical fiber and the optical fiber waveguide is coated with the high reflecting coating. The end surface of the core insert or the other end surface of the core insert with optical fiber is coated with the high reflecting coating, so the optical fiber Fabry-Pero filter is formed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

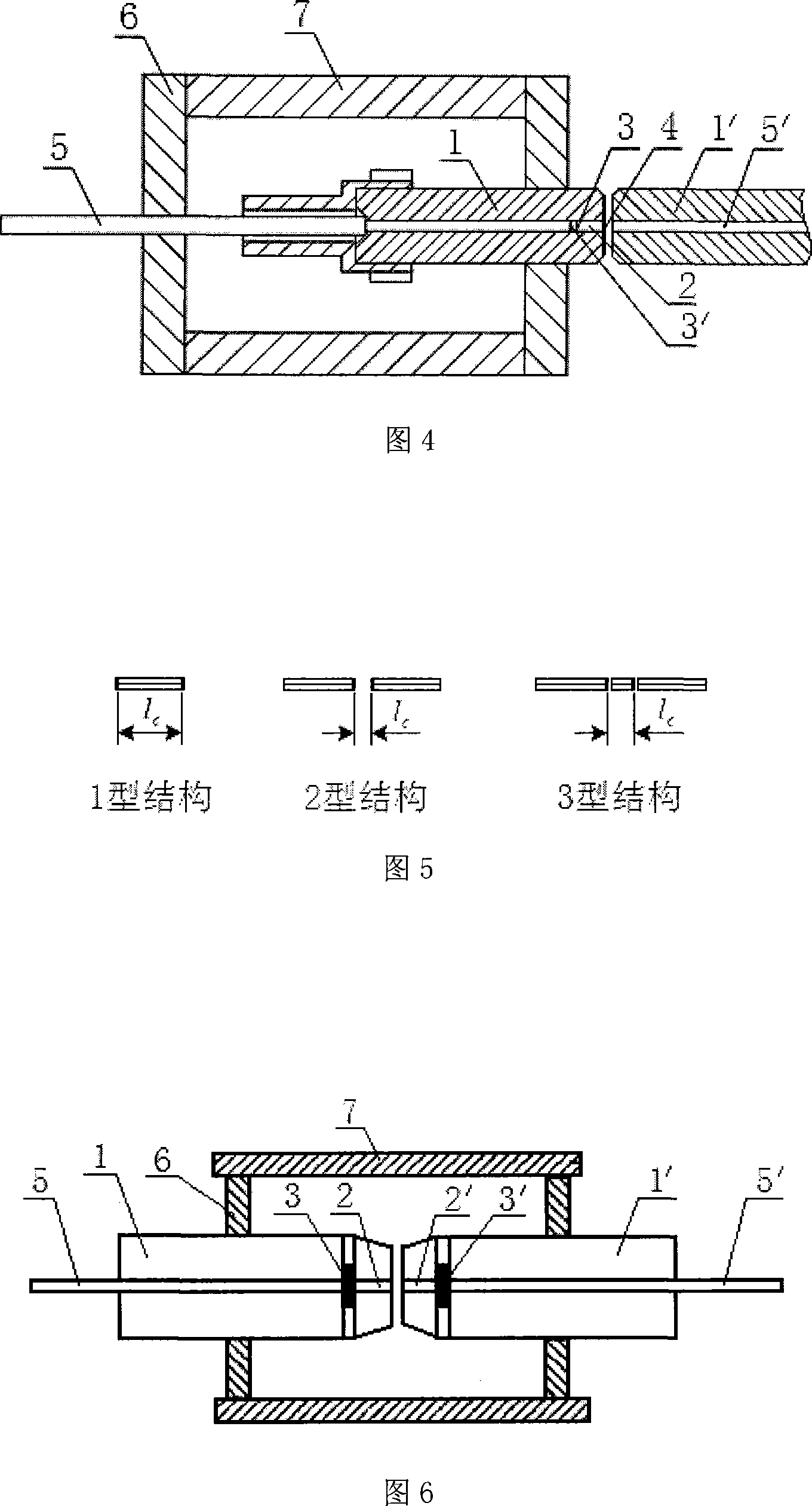

Automatic charge aligning method for robots

InactiveCN107134836APrecise alignmentEnables automatic alignmentBatteries circuit arrangementsElectric powerAutomatic processingLaser

The invention discloses an automatic charge aligning method for robots. The automatic charge aligning method includes arranging infrared transmitting devices and laser signal transmitting devices on charge piles; mounting infrared receiving devices and laser signal receiving devices on robot sides; switching on the infrared receiving devices when the robots need to be charged and adjusting attitudes of the robots; allowing the robots to switch on the laser signal receiving devices and adjusting the attitudes; keeping the robots in the current left-right location attitudes, and allowing the robots to advance towards the charge piles until charge plates of the robots are in contact with charge plates of the charge piles and the robots start to be charged. The automatic charge aligning method has the advantages that the robots can be assuredly accurately aligned with the charge piles owing to infrared and laser double-alignment modes; different types of anomaly are handled, accordingly, the robots can be assuredly automatically aligned with the charge piles to the greatest extent, the manual handing time can be shortened for management personnel, and the efficiency can be improved; the automatic charge aligning method is high in automatic alignment efficiency, and good automatic alignment effects can be realized; abnormal states can be automatically handled, and the automatic charge aligning method is high in efficiency.

Owner:长沙万为机器人有限公司

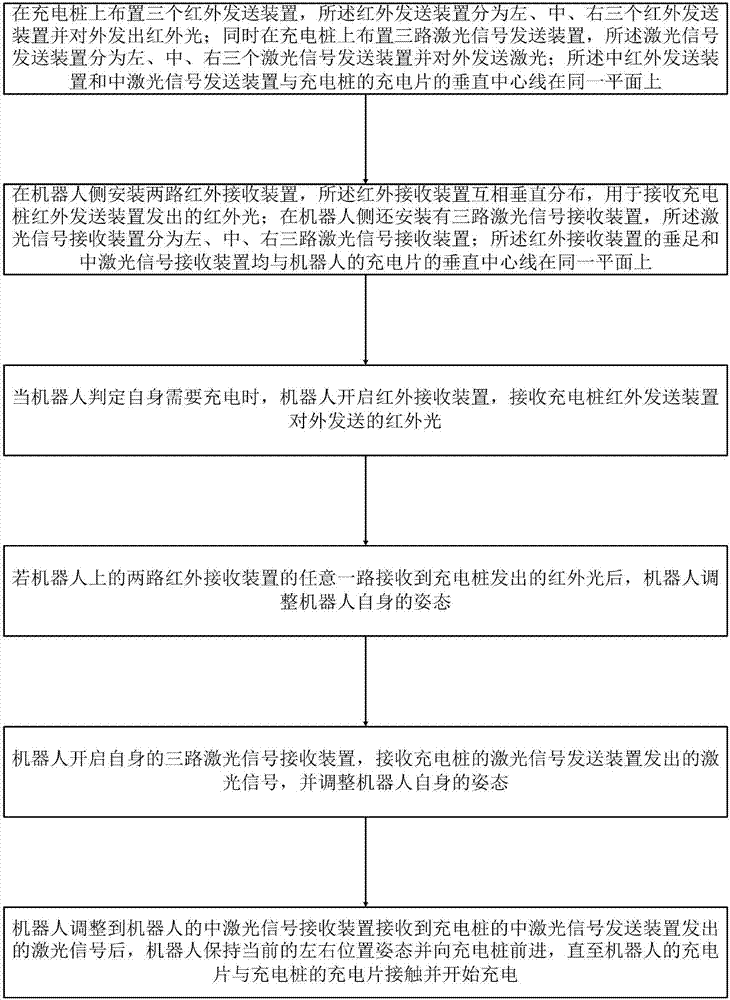

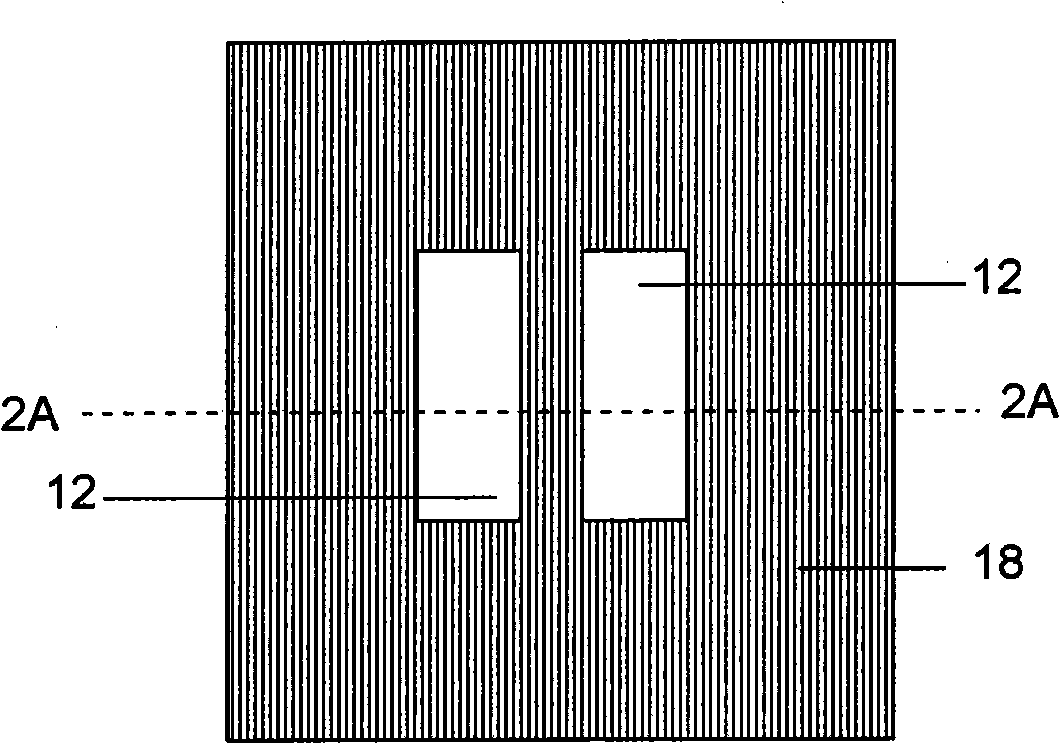

Electrical vehicle wireless charging transmitting and receiving automatic alignment system

InactiveCN104977944AAlgorithm comparison is simpleQuick calculationControl using feedbackElectric vehicleWireless

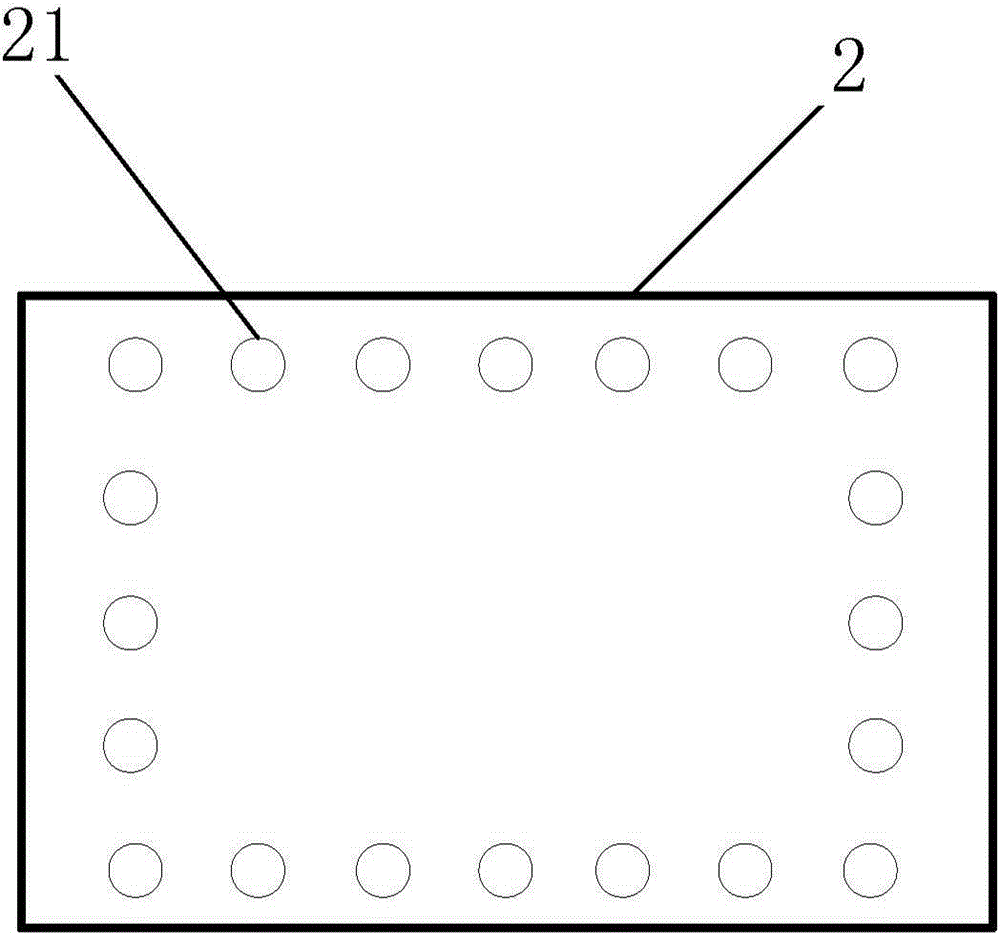

The present invention discloses an electrical vehicle wireless charging transmitting and receiving automatic alignment system which comprises a wireless receiving device and a wireless transmitting device. The communication connection is established by the wireless receiving device and the wireless transmitting device in a certain distance. The automatic alignment system also comprises an image recognition automatic positioning device and a motor positioning driving device arranged at the bottom of an electric vehicle. The wireless receiving device is arranged on the motor positioning driving device and is driven by the motor positioning driving device to move back and forward and left and right. Wired or wireless communication connection is established by the image recognition automatic positioning device and a motor positioning driving device. The image recognition automatic positioning device comprises a collection unit which collects a wireless transmitting device position image, an analysis unit which analyzes the wireless transmitting device position image collected by the collection unit, a control unit which controls the analysis result of the analysis unit and drives the motor positioning driving device to move.

Owner:XIAMEN NEWYEA SCI & TECH

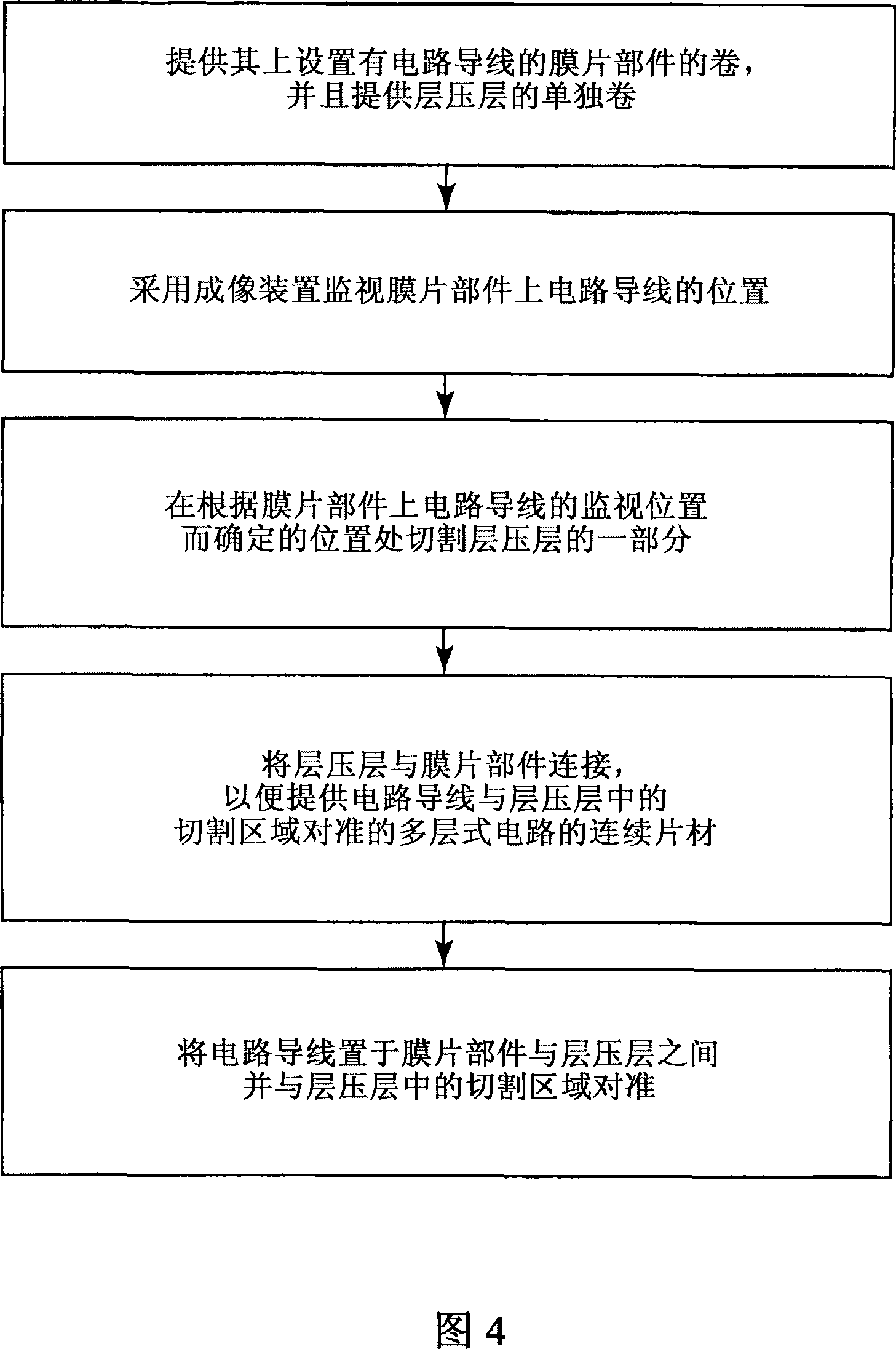

Registered lamination of webs using laser cutting

InactiveCN101095099AEliminate needEnables automatic alignmentLamination ancillary operationsLaminationEngineeringLaser cutting

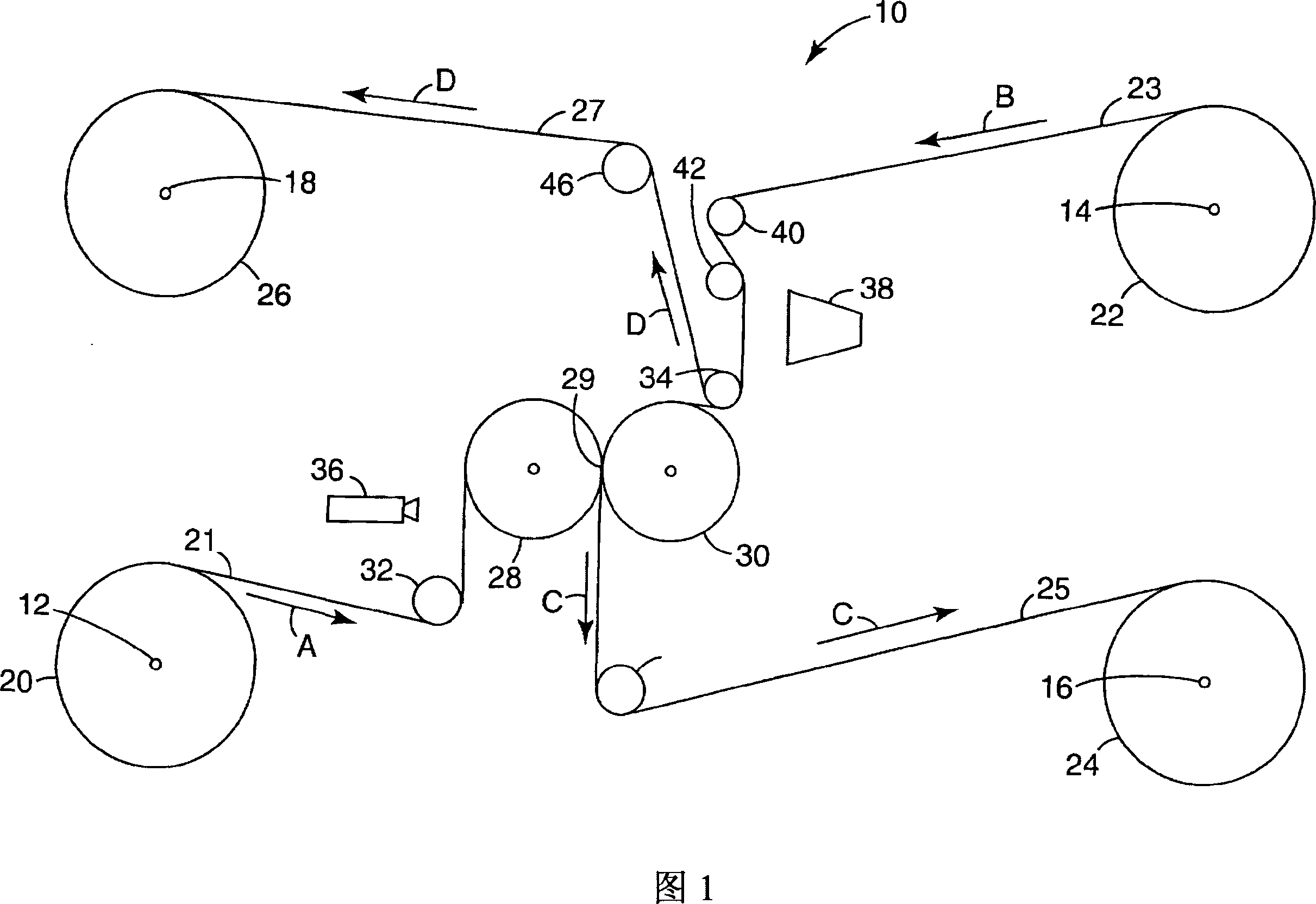

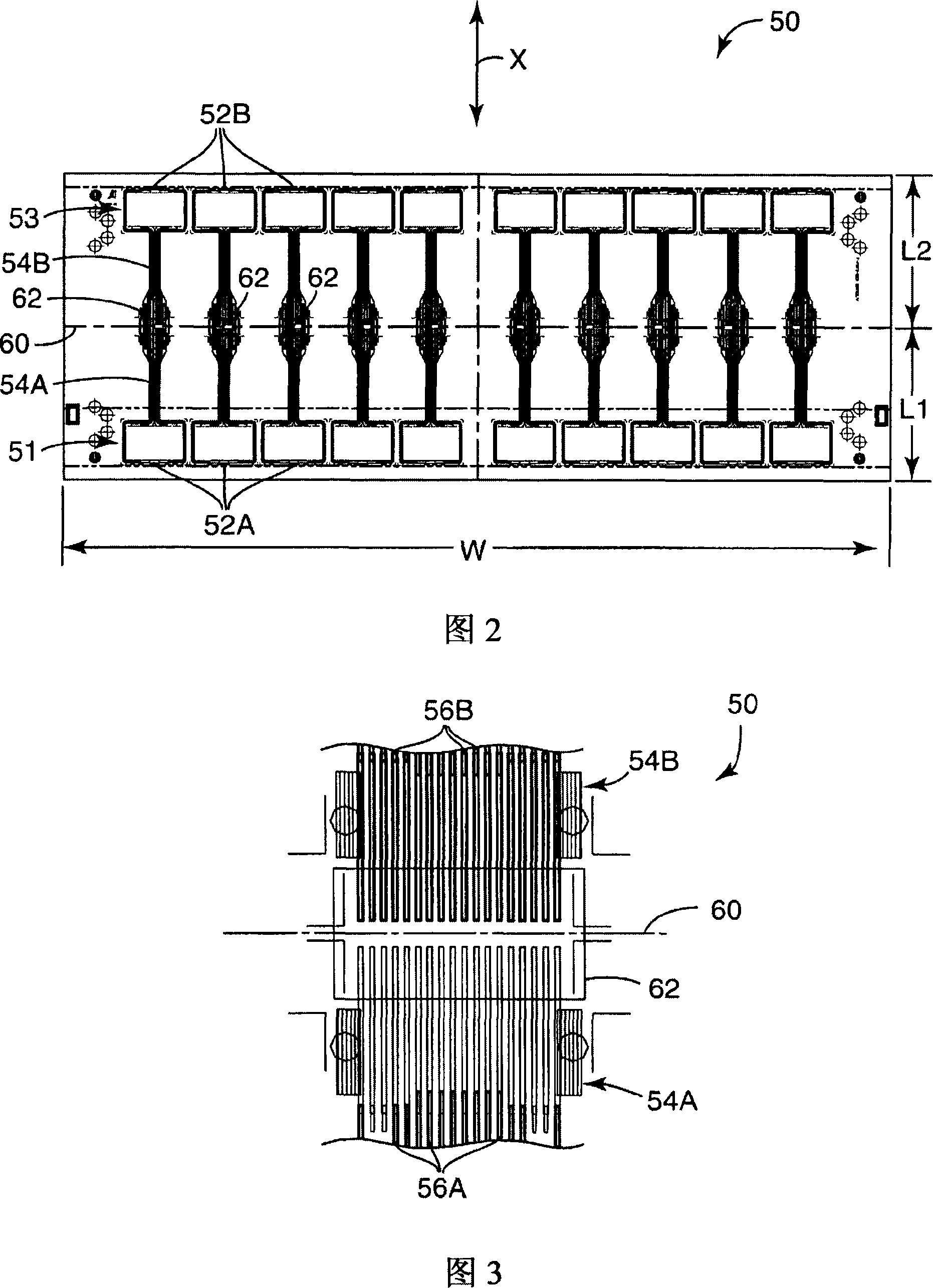

A system and method for manufacturing a multi-layered circuit assembly. The assembly includes a webbing member, a component, and a laminate layer. The method includes providing a roll of the webbing member with the component positioned thereon and a separate roll of the laminate layer, and monitoring a position of the component on the webbing member with an imaging device. The method also includes modifying a portion of the laminate layer at a location that is based on the monitored position of the component on the webbing member, and coupling the laminate layer to the webbing member to provide a continuous sheet of multi-layered circuit. The multi-layered circuit is formed with the component positioned between the webbing member and the laminate layer and aligned with the modification in the laminate layer.

Owner:3M INNOVATIVE PROPERTIES CO

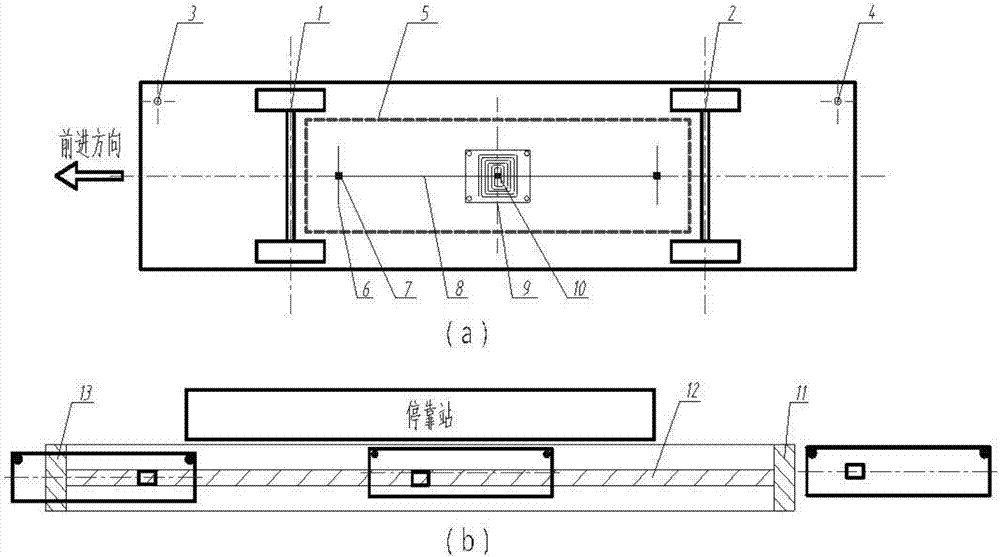

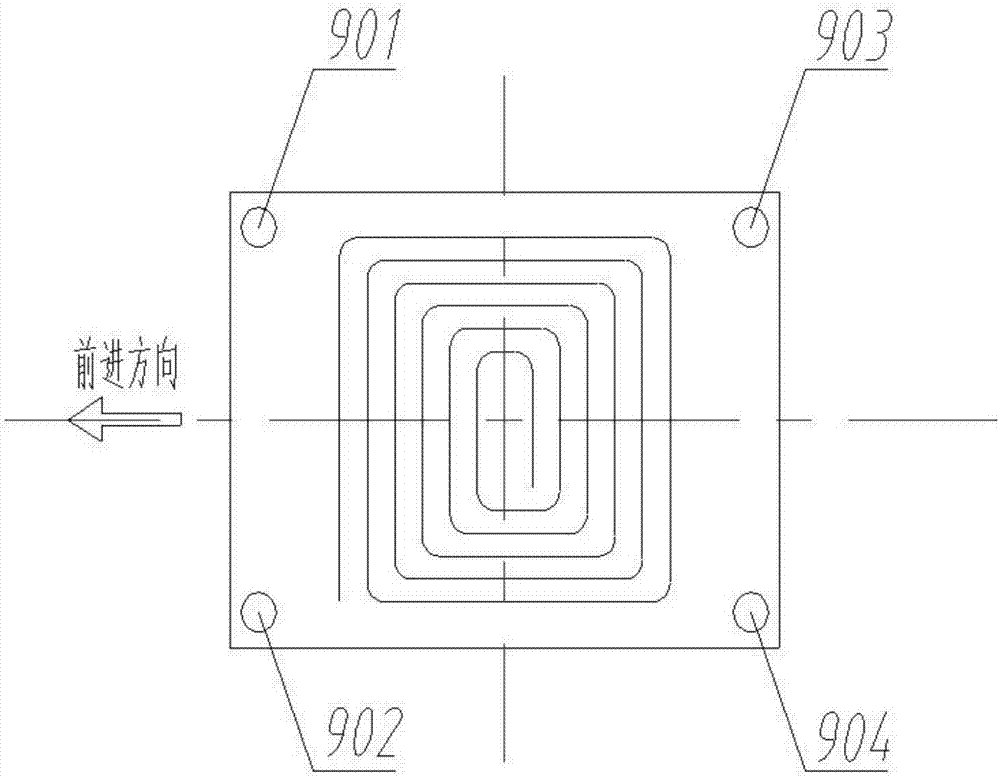

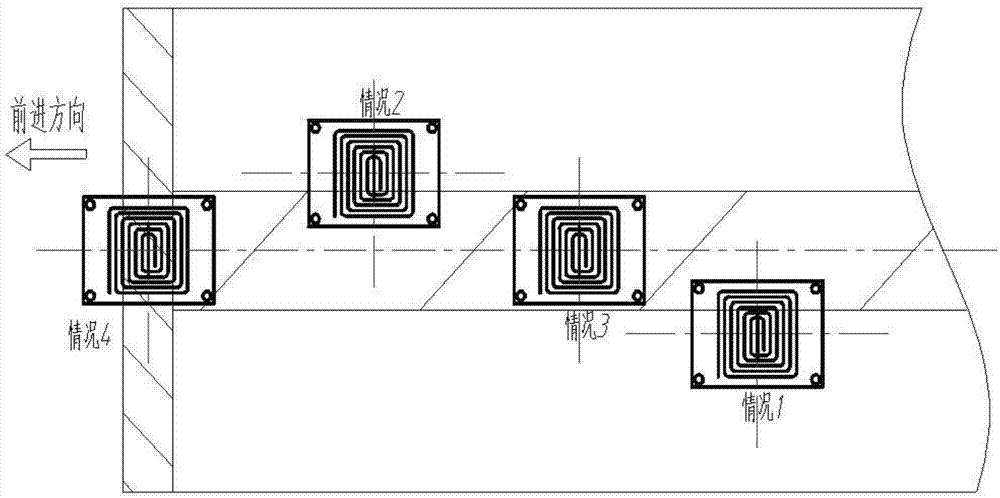

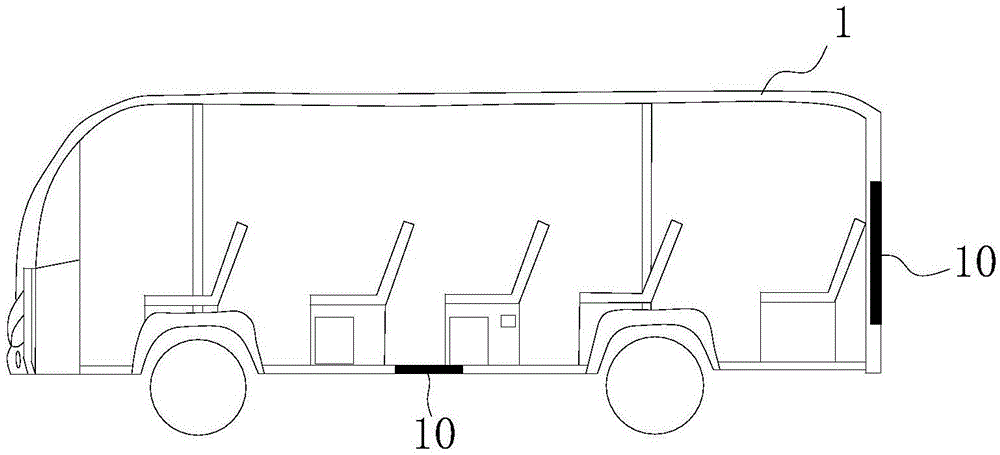

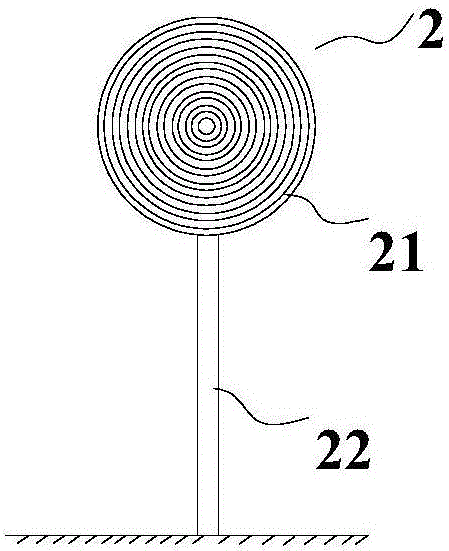

Dynamic wireless charging automatic alignment system based on electric bus stopping process and controlling method thereof

ActiveCN107571753AEfficient wireless chargingEnables automatic alignmentElectric vehicle charging technologyVehicular energy storageMicrocontrollerElectrical battery

The invention provides a dynamic wireless charging automatic alignment system based on the electric bus stopping process and a controlling method thereof. Automatic alignment of vehicle-mounted wireless charging equipment with a ground charging coil group is achieved in the dynamic processes of pulling in a station, stopping and pulling out the station of an electric bus, and high-efficiency wireless charging is conducted. Through receiving and transmitting signals of a high-frequency coil group, a motor is controlled after the signals are analyzed through a single chip computer to drive the vehicle-mounted wireless charging equipment to move, automatic alignment of the wireless charging equipment is achieved, wireless charging with the maximum efficiency is pursued, the cruising ability is further improved, the number of batteries carried is reduced, and the vehicle body is lightweight. At the same time, through a pulling-in and pulling-out sensing coil group, the single chip computerconducts calculating and analysis and controls timely opening and closing of the alignment system, energy saving and environmental protection are achieved, and safety of the charging system is improved.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

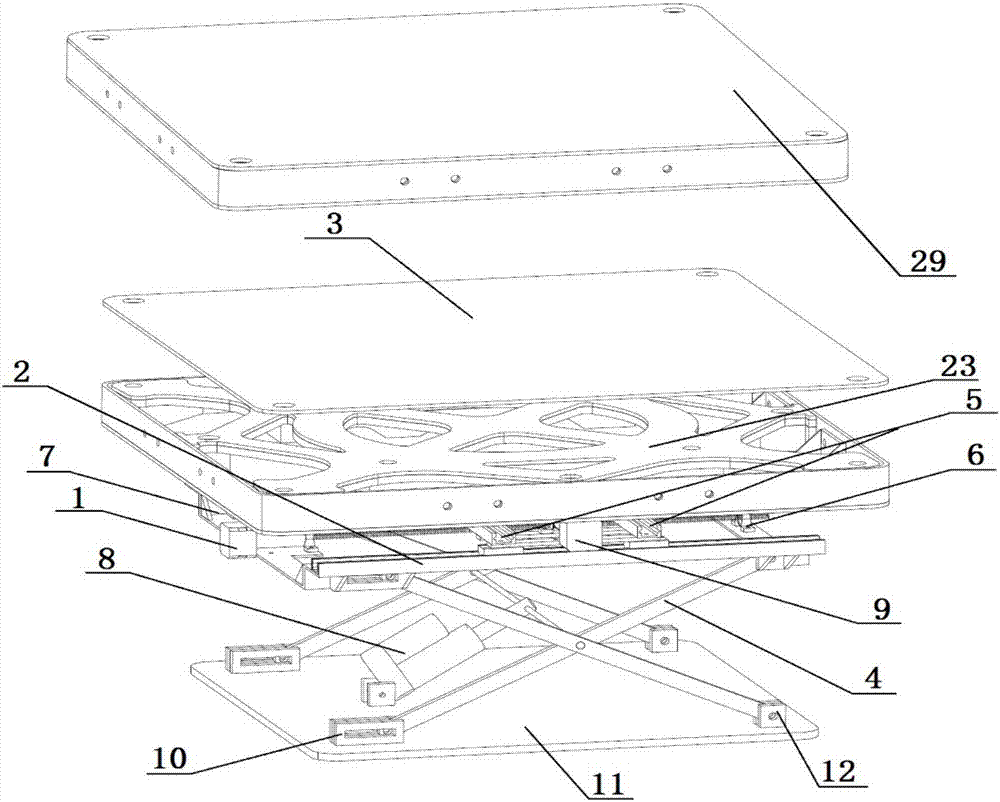

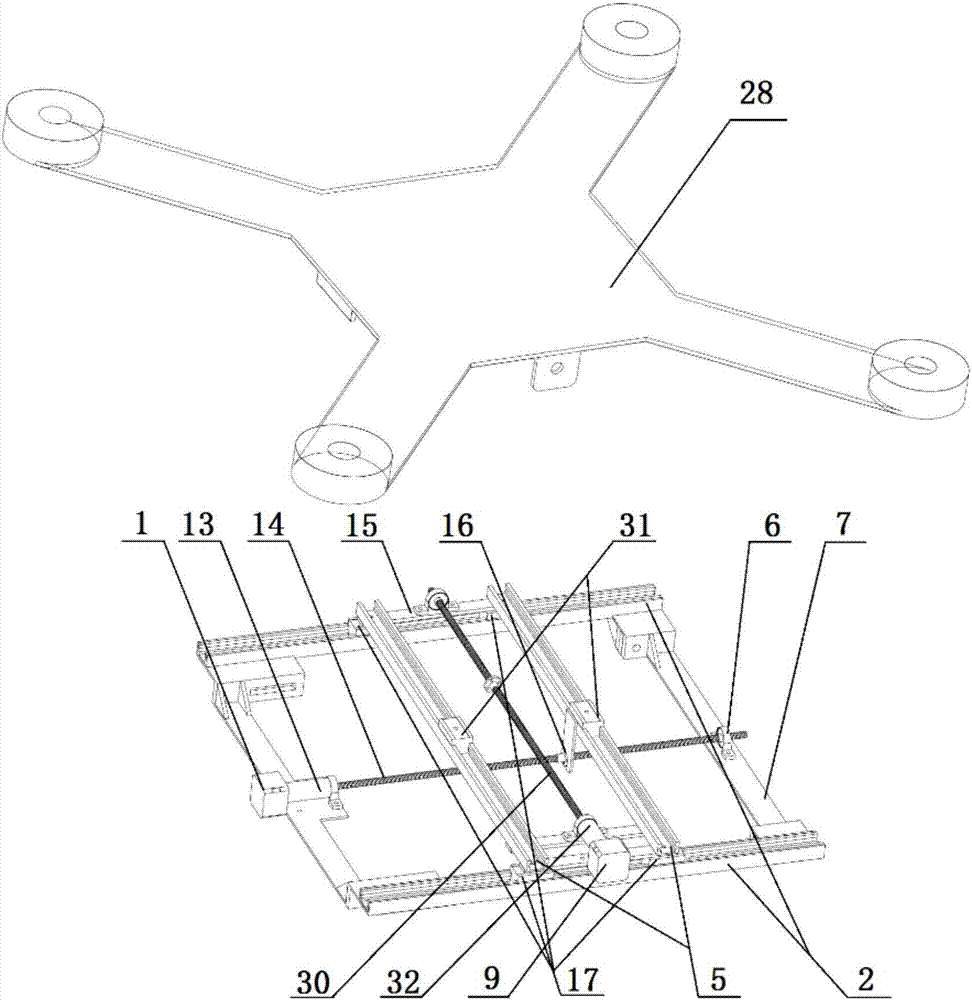

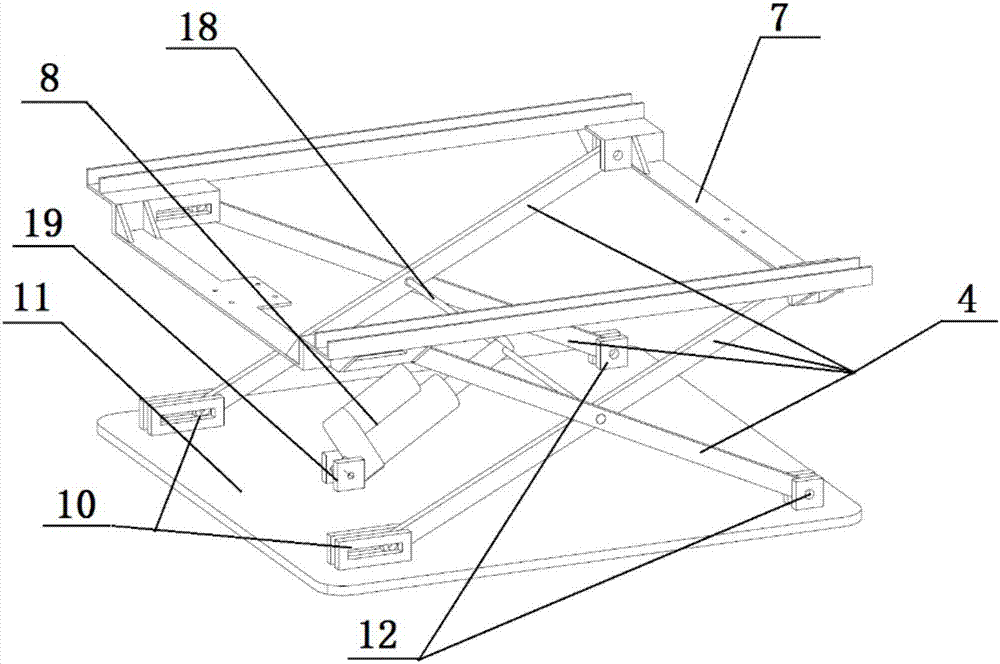

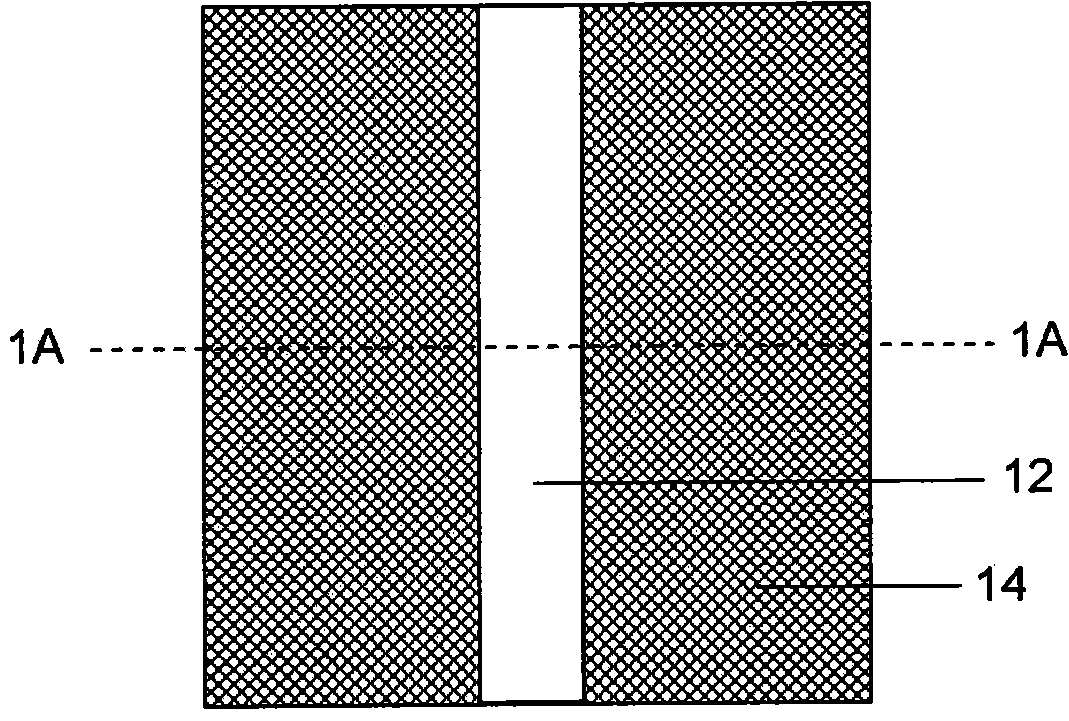

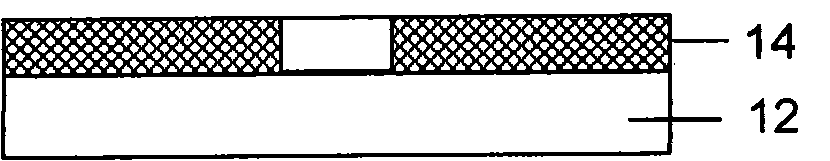

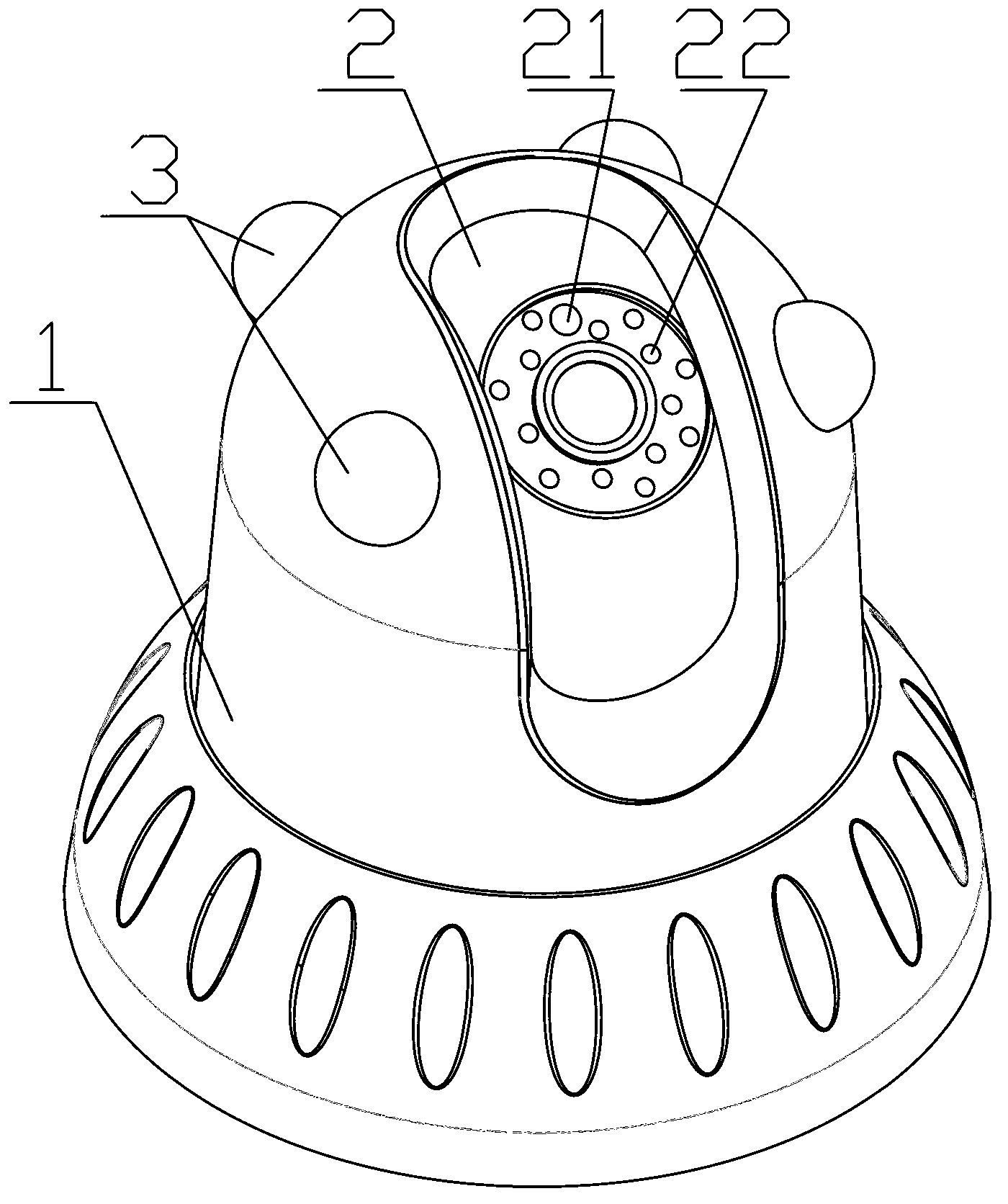

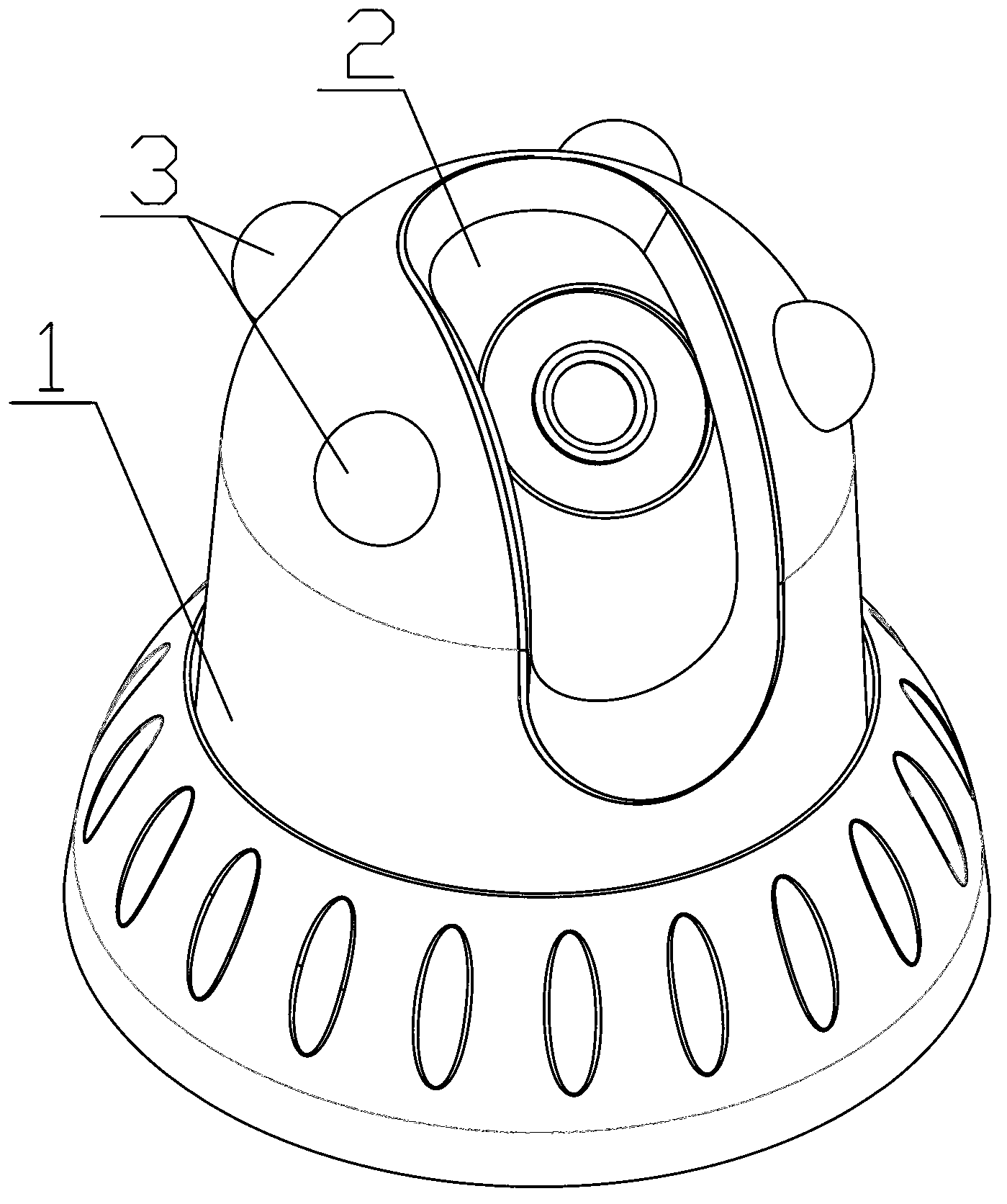

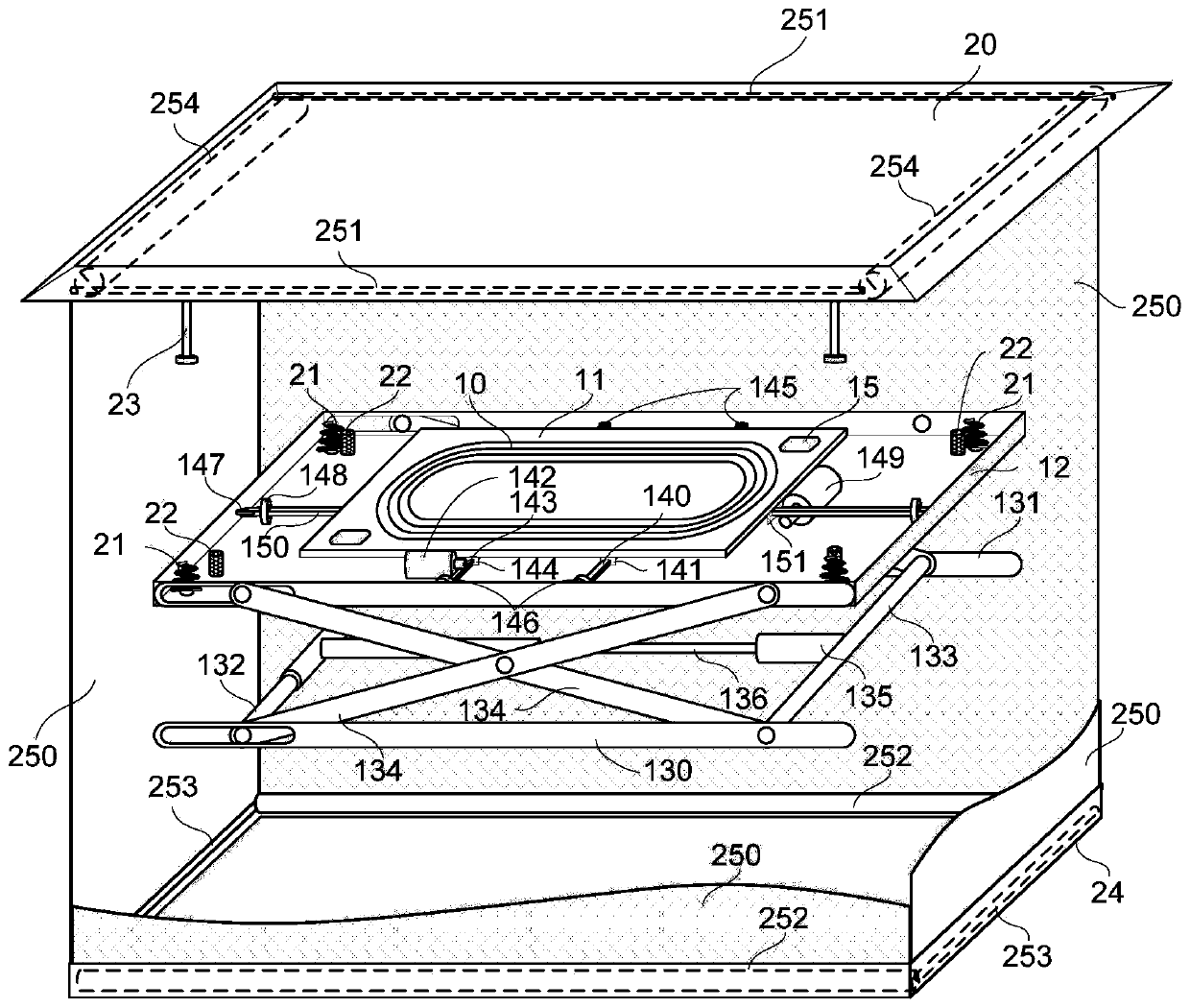

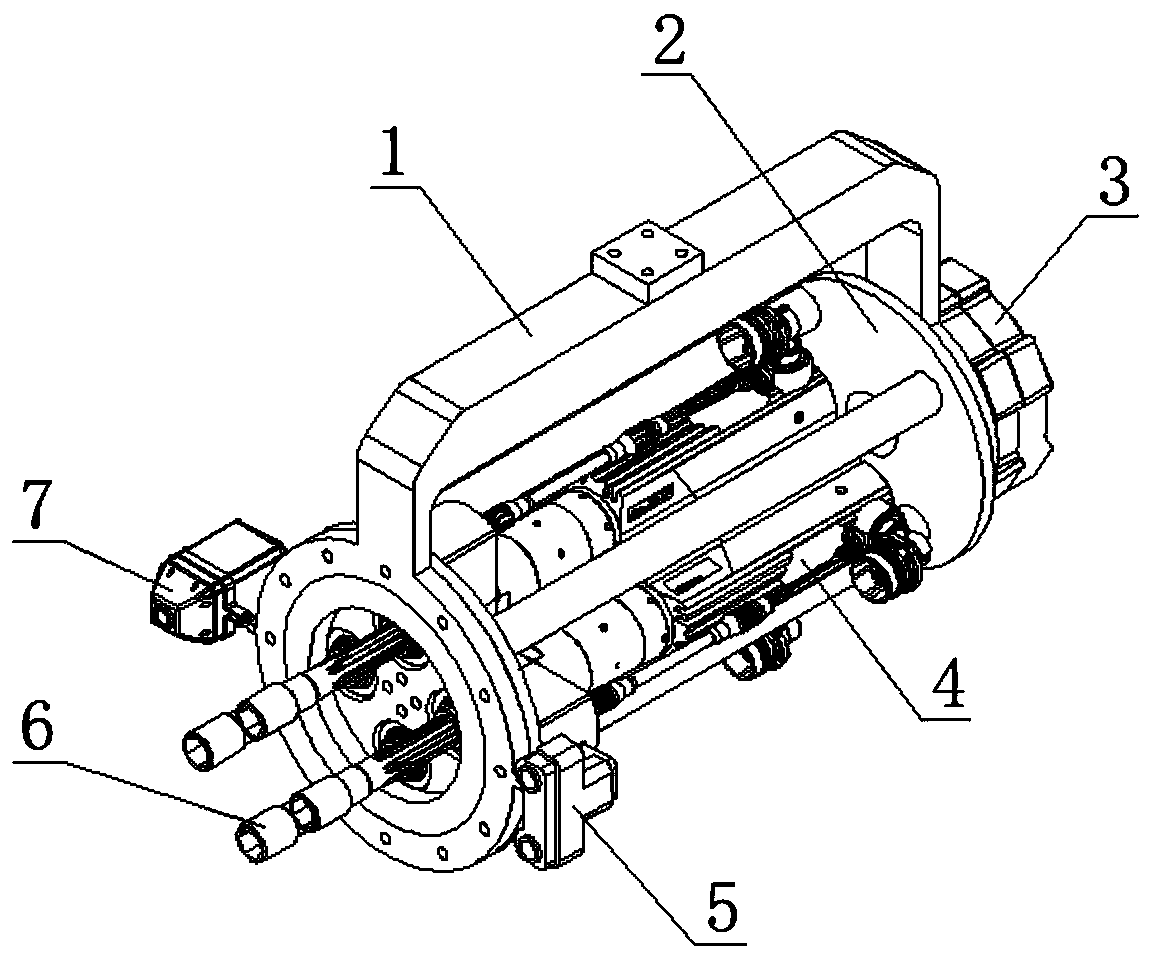

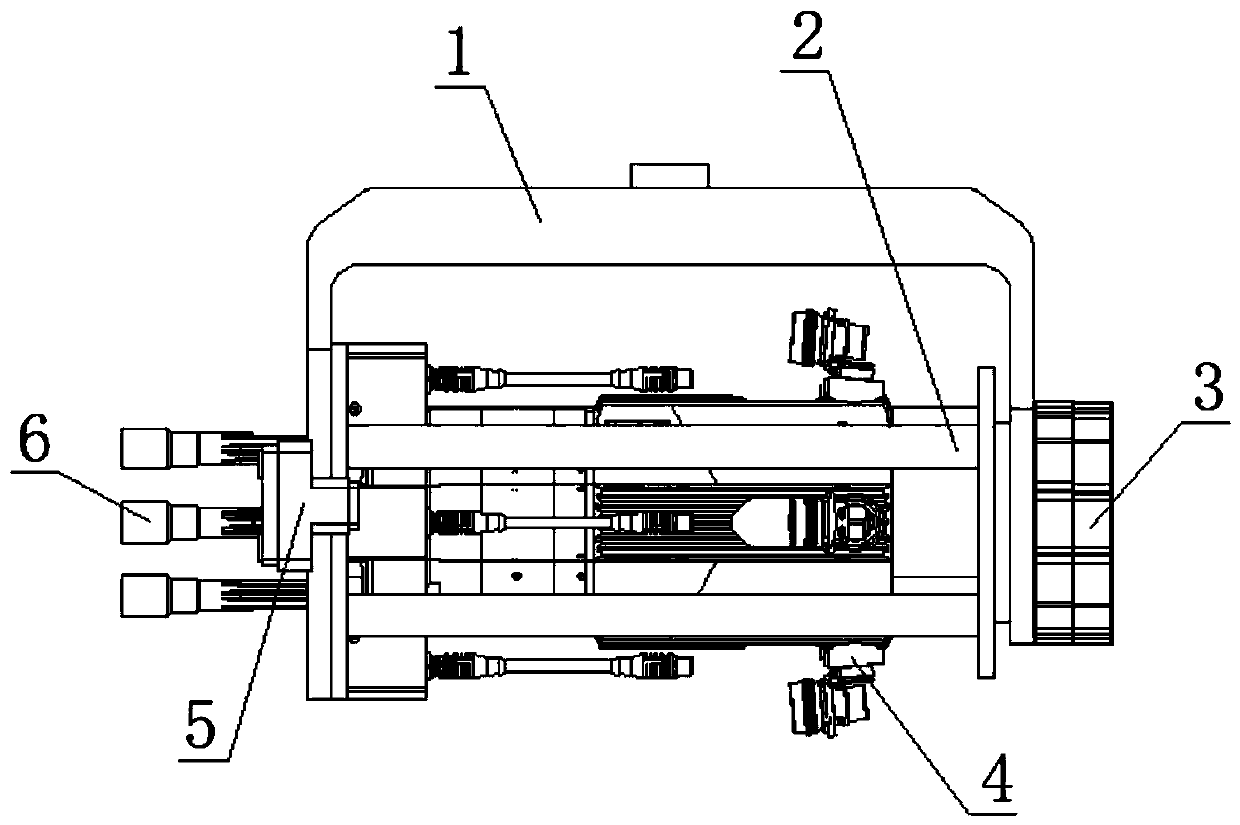

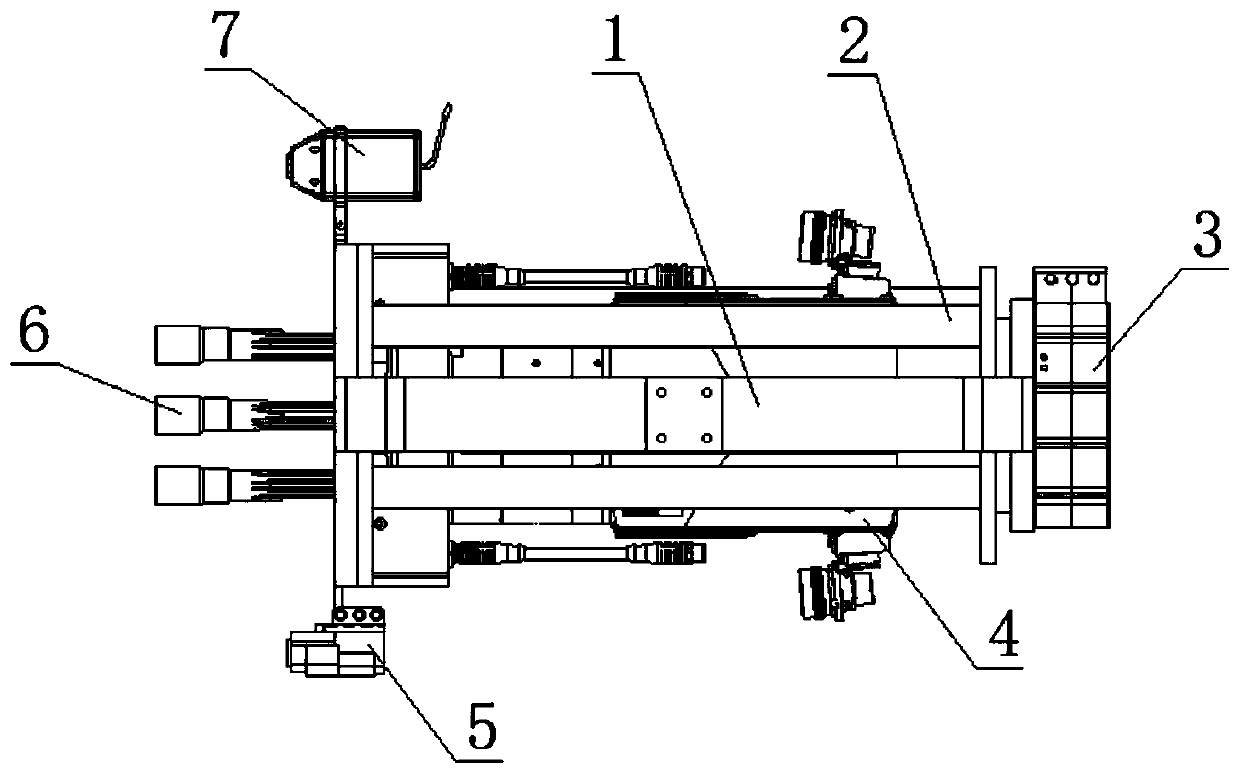

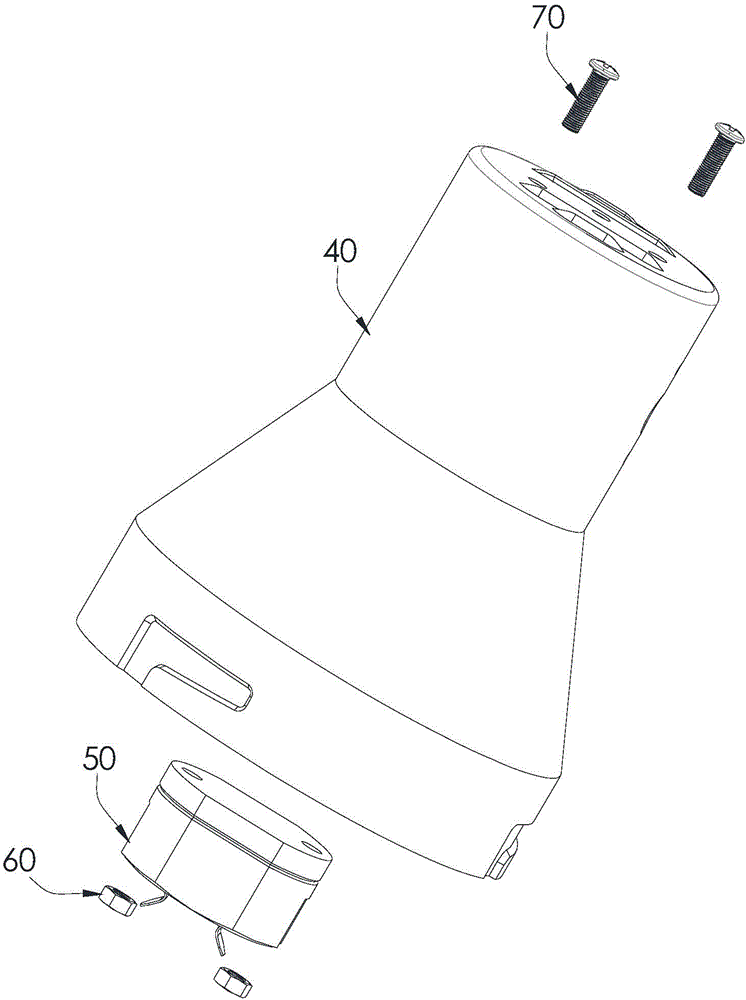

Wireless charging coil aligning mechanism

InactiveCN107089161AOvercoming non-automatic alignmentEnables automatic alignmentCharging stationsElectric vehicle charging technologyElectric vehicleInductive charging

The invention discloses a wireless charging coil aligning mechanism, belonging to the technical field of wireless power transmission. The wireless charging coil aligning mechanism comprises a secondary side coil protection shell, a primary side coil protection shell, an X-direction driving mechanism, a Y-direction driving mechanism, a Z-direction lifting mechanism, a connecting bracket, a base and electric control and sensor assemblies, wherein the X-direction driving mechanism, the Y-direction driving mechanism, the Z-direction lifting mechanism and the sensor and electric control assemblies constitute a mobile resistance device with spatial three degrees of freedom; and a square shell and a special-shaped support plate constitute the primary side coil protection shell. The wireless charging coil aligning mechanism disclosed by the invention overcomes the defect that primary and secondary side coils of a traditional wireless charging device for an electric vehicle can not be automatically aligned; automatic aligning of the primary and secondary side coils when the vehicle is parked is realized through the mobile structure with three degrees of freedom; and meanwhile, by designing the special-shaped support plate with a special shape, the pressure-resisting degree of the primary side coil is improved so as to prevent the primary side coil from being crushed by vehicle tires. The wireless charging coil aligning mechanism disclosed by the invention can better adapt to the working condition of the electric vehicle for wireless charging.

Owner:SHANGHAI JIAO TONG UNIV

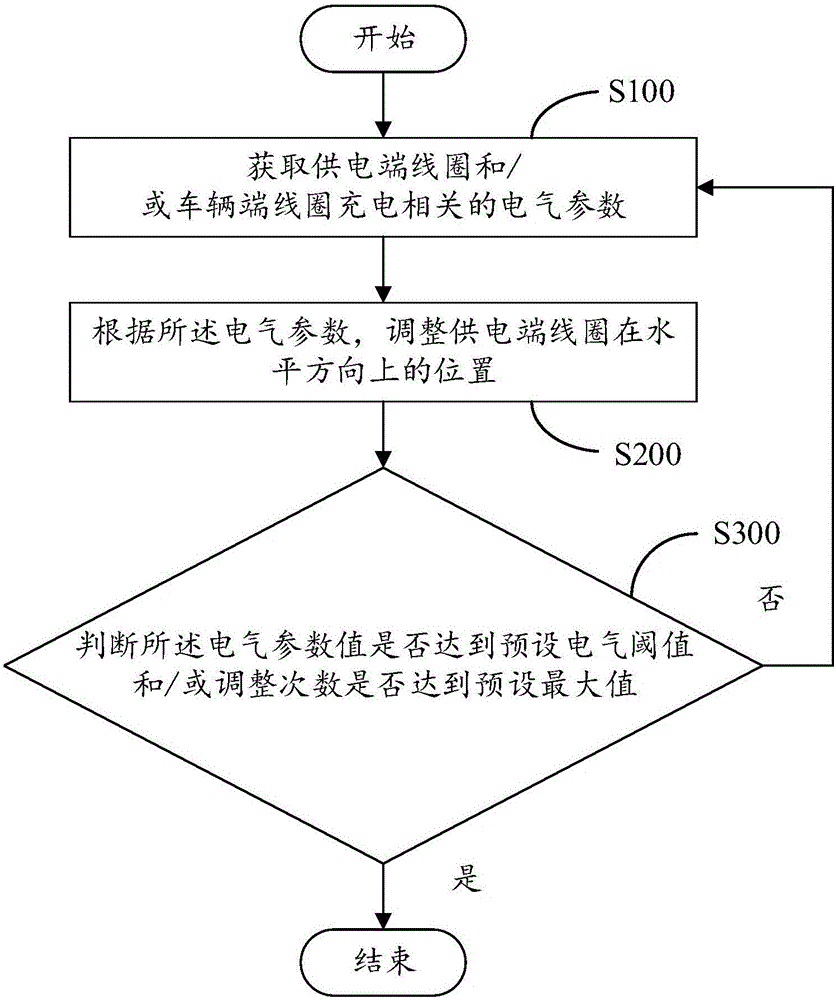

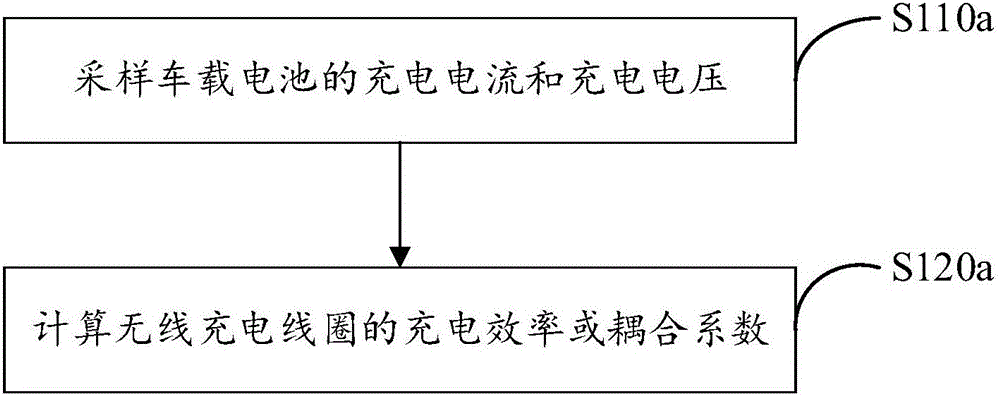

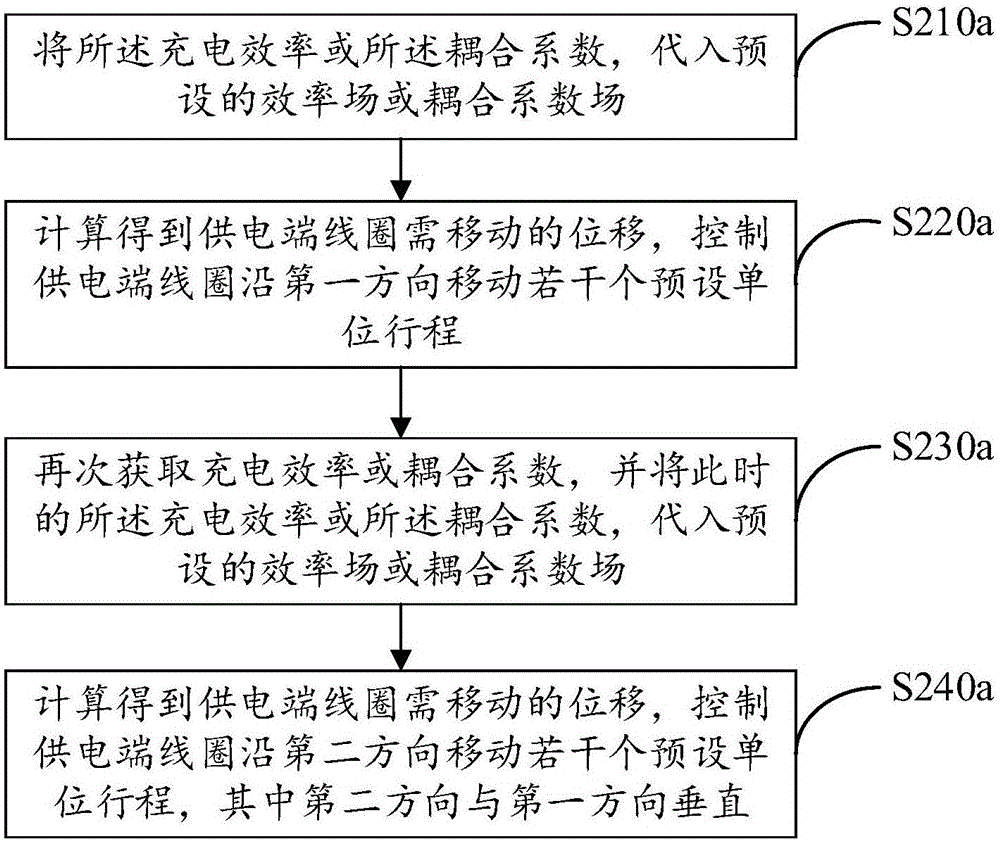

Alignment method for wireless charging coil, device and system

ActiveCN106541844AHigh speedHigh precisionCharging stationsElectric vehicle charging technologyEngineeringElectrical threshold

The invention discloses an alignment method for a wireless charging coil, a device and a system. The alignment method for the wireless charging coil comprises the following steps: acquiring charging-related electrical parameters of a power supply end coil and / or a vehicle end coil; adjusting the position of the power supply end coil in a horizontal direction according to the electrical parameters; judging whether an electrical parameter value reaches a preset electrical threshold and / or adjustment times reach a preset maximum value or not; and if so, finishing the alignment of the charging coil, and otherwise, circulating the steps. According to the technical scheme, the alignment speed of the wireless charging coil is improved, and the charging efficiency is improved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +2

Process using colored mask combined with selective area deposition

InactiveCN101868761AEnables automatic alignmentReduce the numberSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsVisible spectrum

The invention relates to a process for forming a structure comprising (a) providing a transparent support; (b) forming a color mask on a first side of the transparent support; (c) applying a first layer comprising a deposition inhibitor material that is sensitive to visible light; (d) patterning the first layer by exposing the first layer through the color mask with visible light to form a first pattern and developing the deposition inhibitor material to provide selected areas of the first layer effectively not having the deposition inhibitor material; and (e) depositing a second layer of functional material over the transparent support; wherein the second layer of functional material is substantially deposited only in selected areas over the transparent support not having the deposition inhibitor material.

Owner:EASTMAN KODAK CO

Safety protection monitoring camera

InactiveCN102857683AEnables automatic alignmentRealize unmanned on-dutyTelevision system detailsColor television detailsSurveillance cameraIntelligent control

The invention relates to a safety protection monitoring camera which comprises a shell, a camera arranged on the shell, a driving component for driving the camera to move, at least three infrared probes for performing infrared detection on an object in an invaded detected region, and an intelligent control module, wherein the intelligent control module controls the driving component to work according to data acquired by the infrared probes, so that the camera can shoot an invasion object by being aligned with the object. According to the safety protection monitoring camera, the invasion object outside the sight line of the camera can be found by the infrared probes arranged on the camera shell, and the camera can be automatically aligned with the invasion object, so that the intelligence of equipment is improved, and unmanned monitoring is realized.

Owner:浙江赛安电气科技有限公司

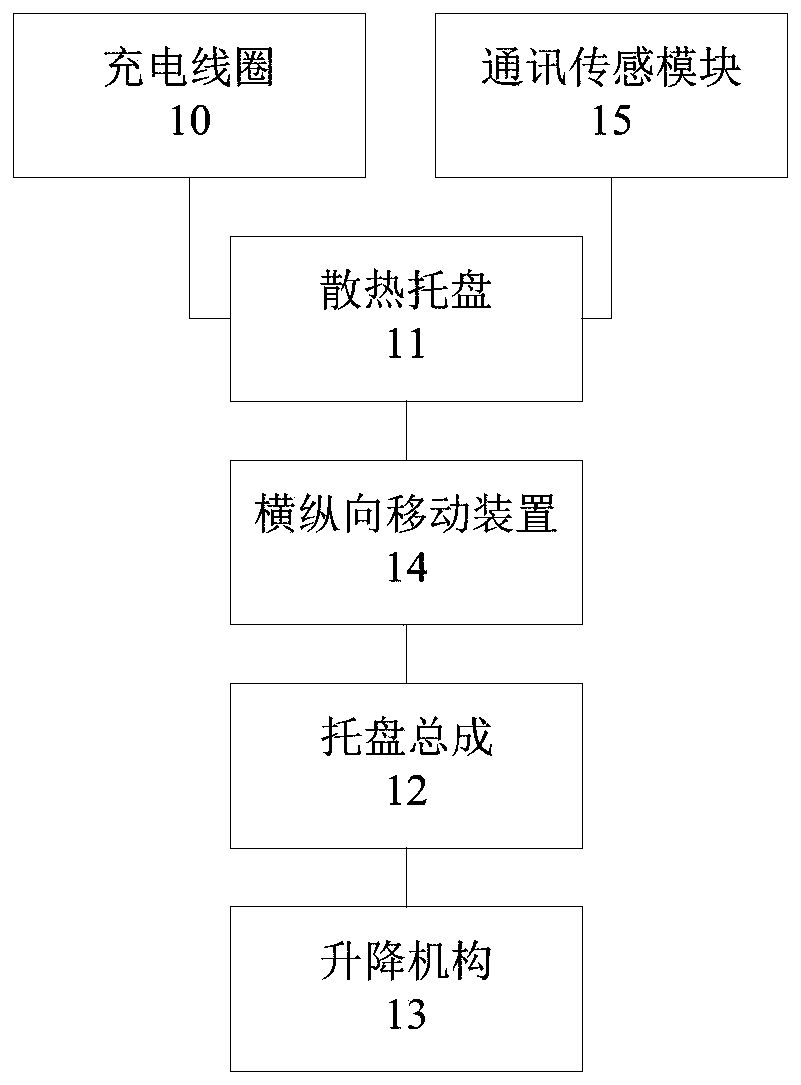

Wireless charging device, system and method

ActiveCN110053499AEnables automatic alignmentImprove charging efficiencyCharging stationsElectric vehicle charging technologyElectricityEngineering

The invention provides a wireless charging device, system and method. The wireless charging device includes a charging coil, a heat dissipation tray, a tray assembly, a lifting mechanism, a transverseand longitudinal moving device and a communication sensing module; the lifting mechanism drives the tray assembly to rise or fall so as to drive the charging coil to rise or fall; the communication sensing module judges whether the charging coil is aligned with an electric receiving coil of an electric vehicle or not; if the charging coil is not aligned with the electric receiving coil of the electric vehicle, the transverse and longitudinal moving device drives the heat dissipation tray to move so that the charging coil on the heat dissipation tray is aligned with the electric receiving coil; and when the charging coil is aligned with the electric receiving coil of the electric vehicle, the charging coil charges the electric receiving coil. According to the wireless charging device, system and method, the automatic alignment of the charging coil and the electric receiving coil can be realized through the transverse and longitudinal moving device, and meanwhile the efficiency of wireless charging is improved.

Owner:上海爱驱汽车技术有限公司

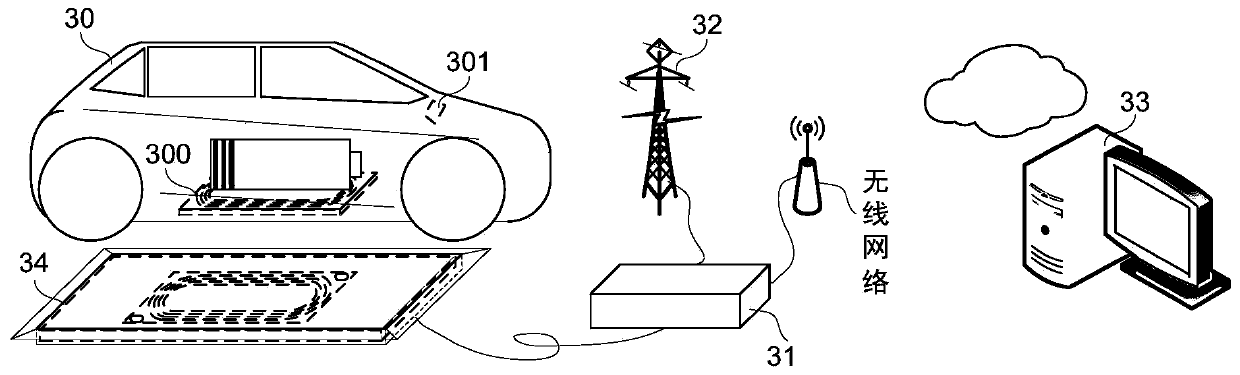

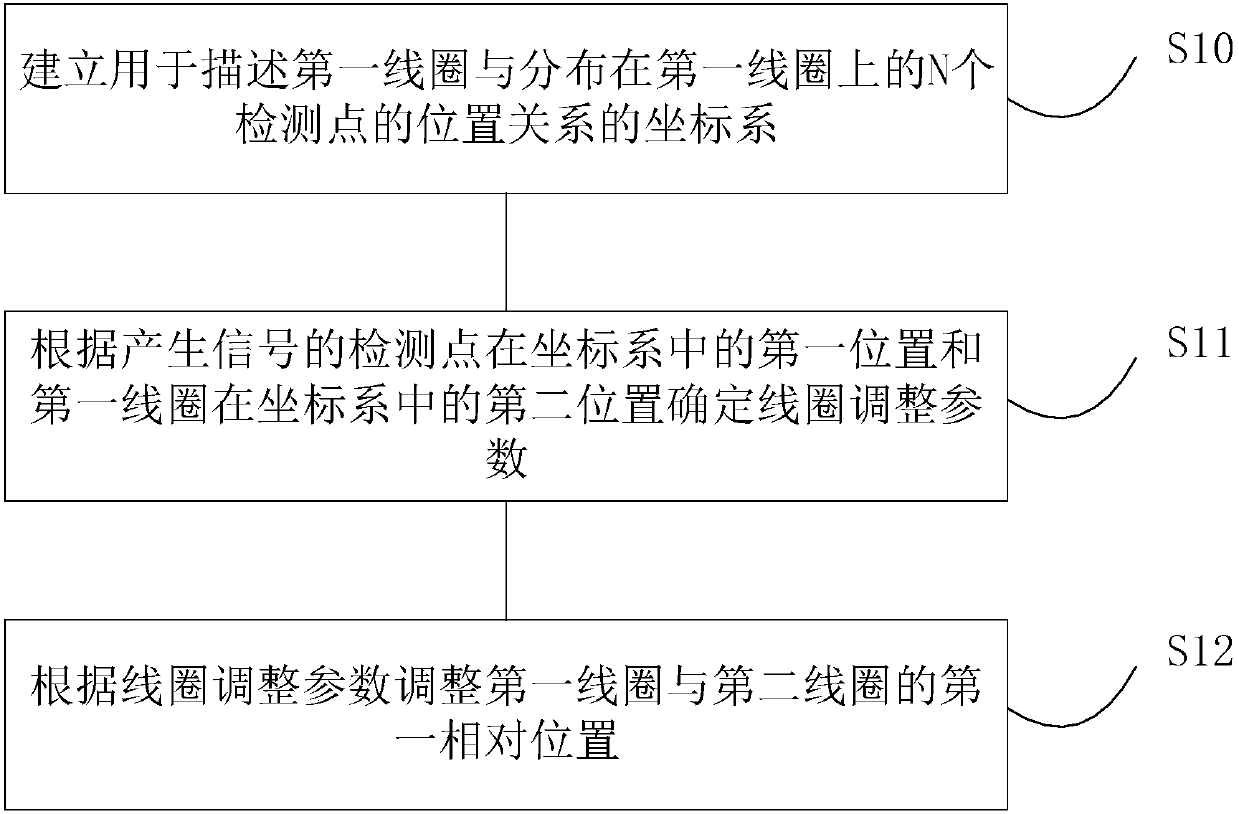

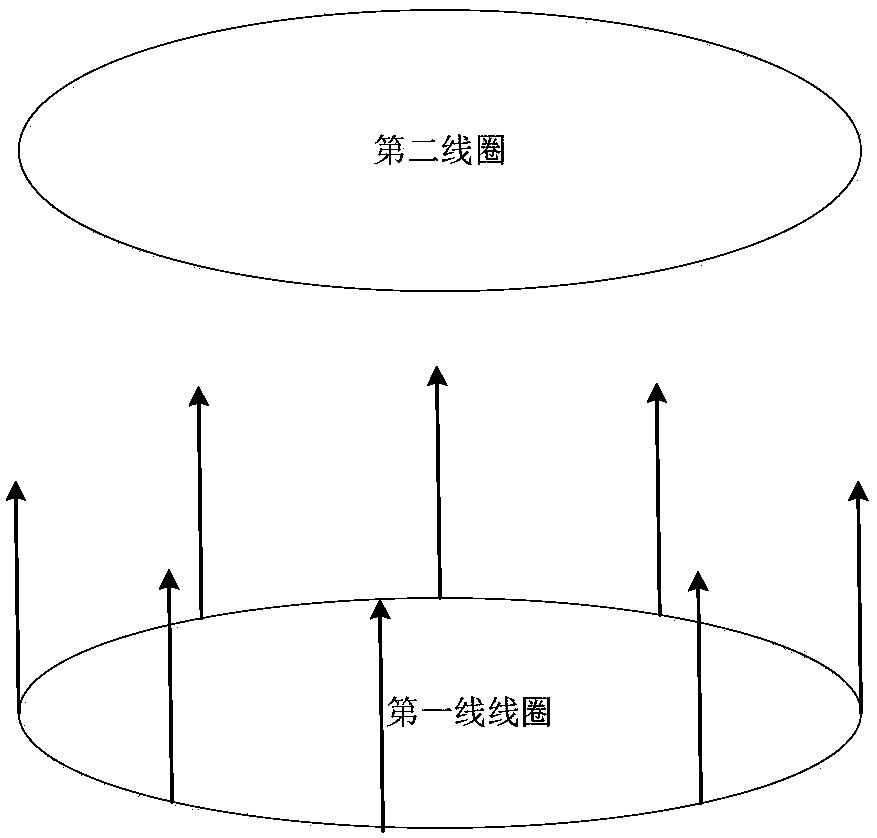

Wireless charging aligning method and apparatus

ActiveCN107591905AEnables automatic alignmentBatteries circuit arrangementsElectric powerComputer scienceInductive charging

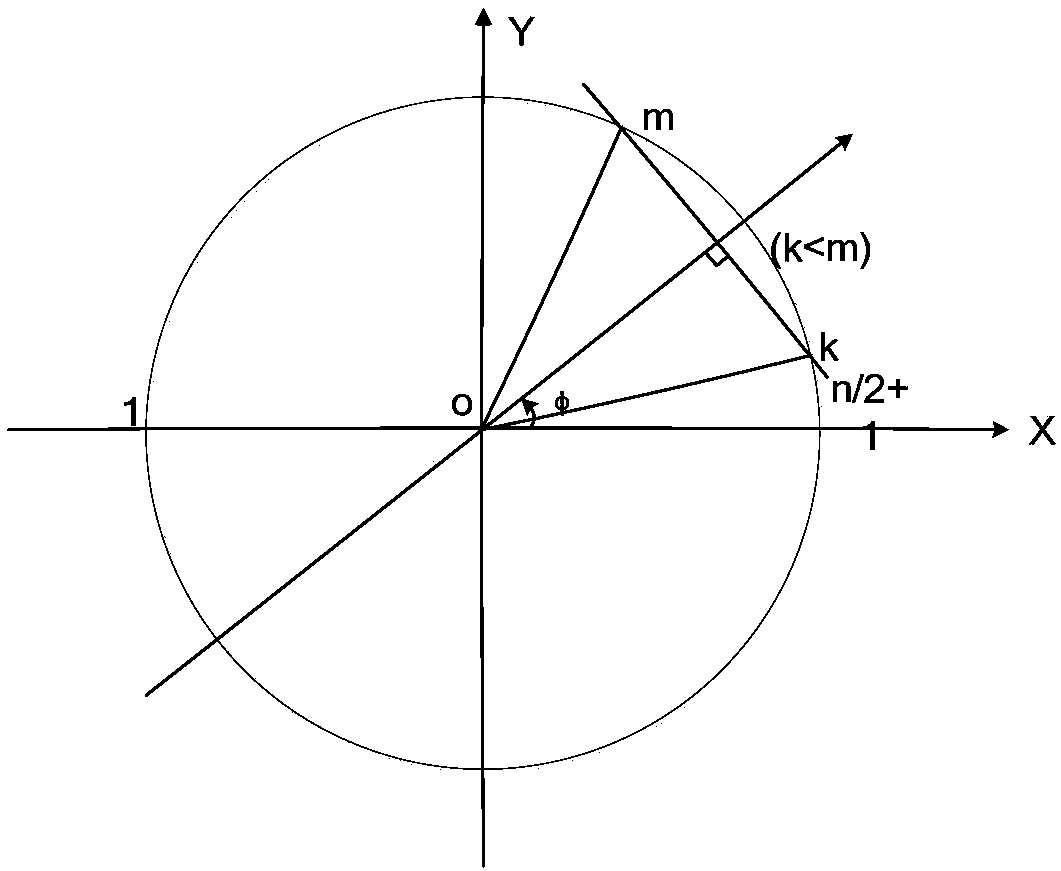

The invention discloses a wireless charging aligning method and apparatus. The wireless charging aligning method includes the steps: establishing a coordinate system for describing the positional relation between a first coil and N detection points on the first coil, wherein each detection point gives a response to a second coil to generate a signal; and according to the position of the detectionpoint generating the signal in the coordinate system and the position of the first coil in the coordinate system, adjusting parameters so as to align with the first coil and the second coil, and according to the coil adjusting parameters, adjusting the relative positions of the first coil and the second coil. The wireless charging aligning method and apparatus can solve the technical problem thatthe wireless charging coil is not convenient to be aligned.

Owner:GREE ELECTRIC APPLIANCES INC

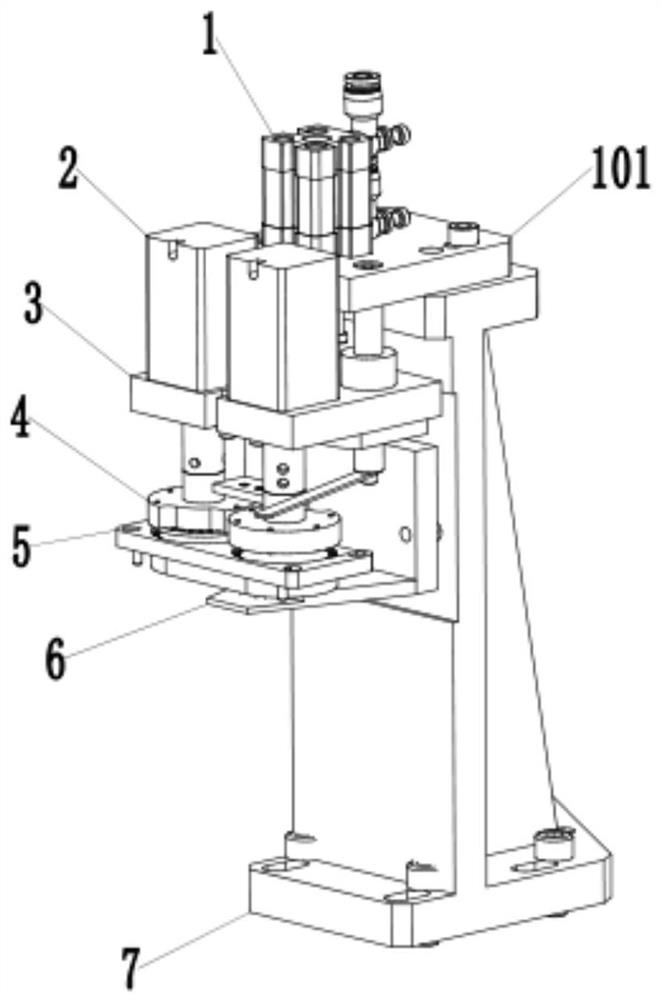

Automatic alignment device and method

ActiveCN110961907ASave on alignmentSave stepsMetal working apparatusControl engineeringElectric machinery

The invention discloses an automatic alignment device. The device comprises an axle box fixing and supporting hanging frame, a tightening axle fixing rotary box, an axle box servo driving motor, a tightening axle box real-time image pick-up position feedback module, a positioning device and a center control cabinet, wherein the axle box servo driving motor is connected with the axle box fixing andsupporting hanging frame and can drive the tightening axle fixing rotary box to rotate, the tightening axle box real-time image pick-up position feedback module is connected with the axle box fixingand supporting hanging frame and can shoot a hole site image of a wheel set moving under a sliding rail, the positioning device is connected with the axle box fixing and supporting hanging frame and can acquire the position information of the wheel set, and the center control cabinet matches the acquired actual hole site with the shot hole site image of the wheel set, and controls the axle box servo driving motor to act so as to realize the automatic alignment of the tightening axle fixing rotary box and the hole site of the wheel set. The invention further discloses an automatic alignment method. With the automatic alignment device of the invention adopted, addressing and positioning operation of multiple wheel sets are automatically completed, the automatic tightening operation of the wheel sets is achieved, manpower is saved, and operation efficiency and precision are improved.

Owner:LOTEEM BEIJING RAIL TRANSIT TECH CO LTD

Workpiece auto-collimation method and system in laser engraving

ActiveCN106903439AEnables automatic alignmentImprove work efficiencyLaser beam welding apparatusLaser engravingGalvanometer

The invention discloses a workpiece auto-collimation method and system in laser engraving. The method includes the steps that an electromagnetic field transmitting coil on a base is rotated to upwards transmit an electromagnetic field, a first magnetic field sensor and a second magnetic field sensor which are arranged on a dynamic convergence laser galvanometer module in a spaced manner in the length direction of a lead screw are used for detecting the electromagnetic field strength; a controller controls starting and stopping of a first servo motor and the rotating direction of an output shaft according to detecting signals output by the first magnetic field sensor and the second magnetic field sensor; when the electromagnetic field strength detected by the first magnetic field sensor and the second magnetic field sensor is larger than a preset value, the controller controls the first servo motor to stop rotating, automatic collimation of a workpiece and a protection window of the dynamic convergence laser galvanometer module is achieved; and the beneficial effect of greatly improving the laser engraving overall working efficiency and the collimation accuracy is achieved.

Owner:浙江创新激光设备有限公司

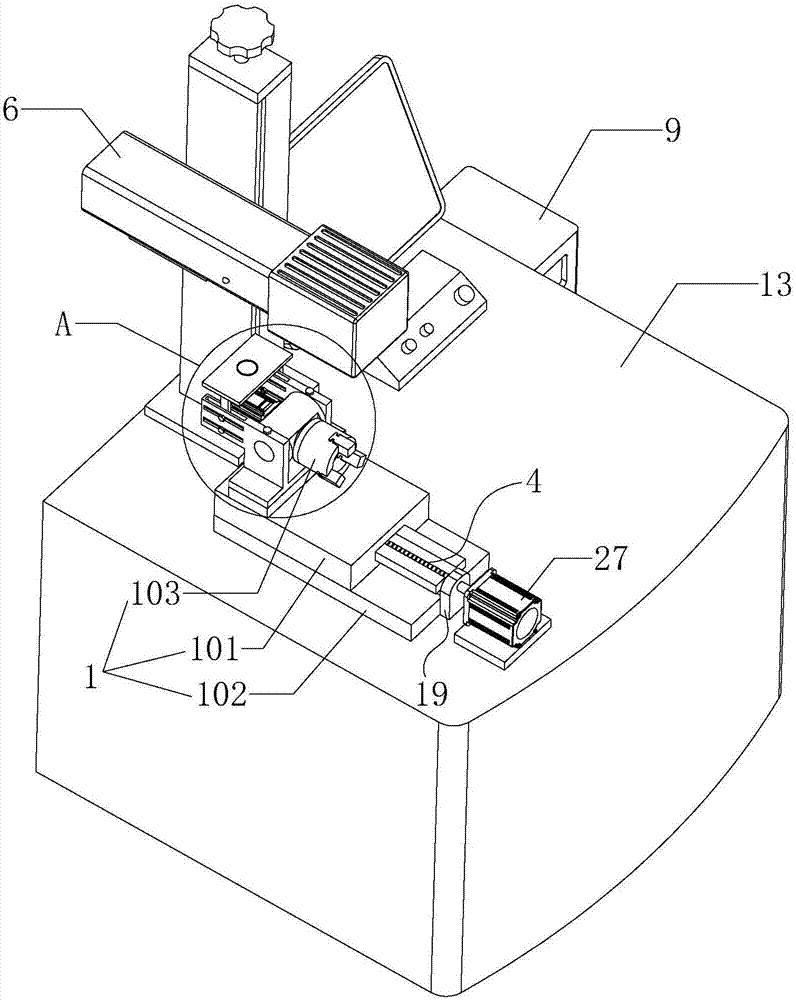

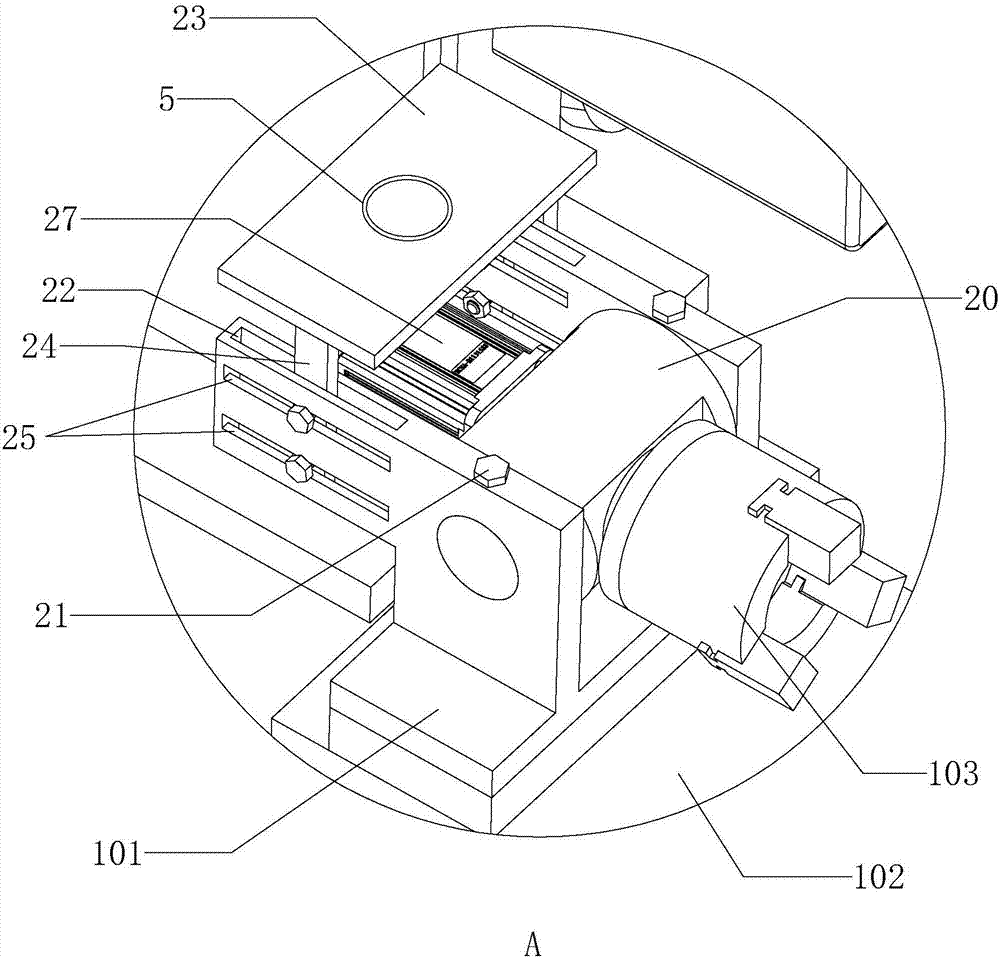

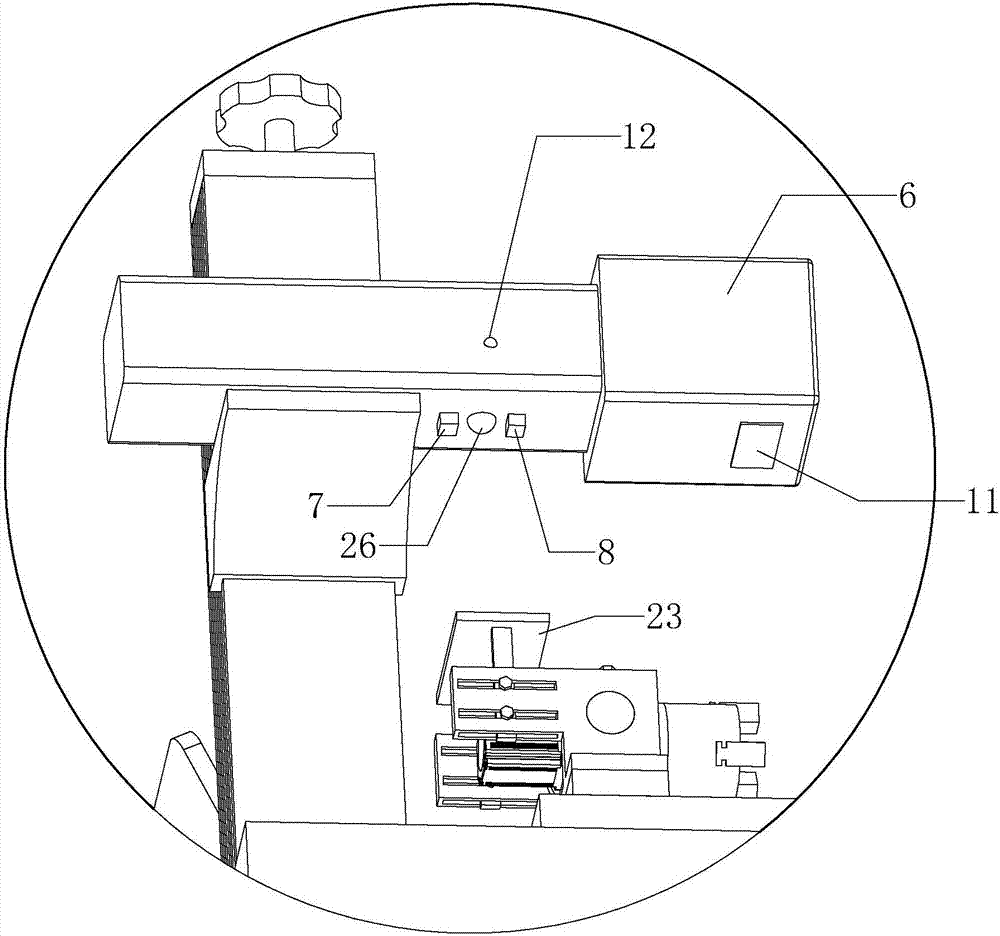

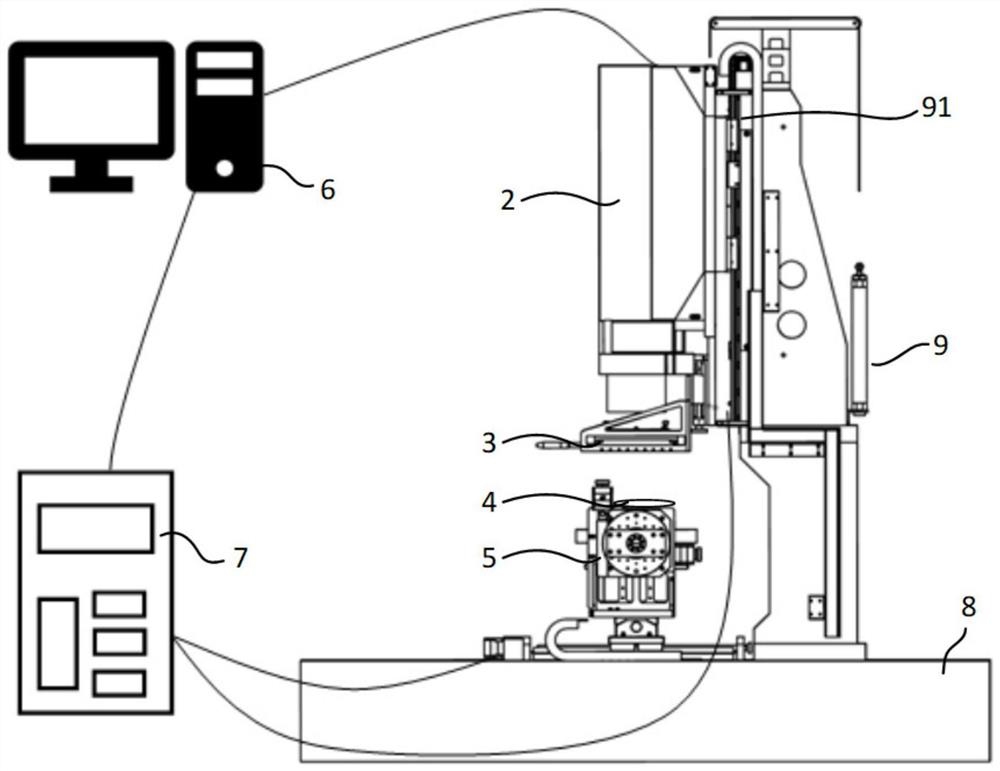

Multifunctional vertical zero overlapping scanning interferometry device

ActiveCN112504177ASave time and costSave economic costUsing optical meansAutomatic controlEngineering

The invention discloses a multifunctional vertical zero overlapping scanning interferometry device which comprises a main control unit, a drive control circuit and an air floatation vibration isolation base. A stand column and a four-dimensional motion adjusting platform are arranged on the air floatation vibration isolation base, a vertical lifting shaft is arranged on the stand column, and a laser wave surface interferometer is arranged on the vertical lifting shaft. A detachable CGH five-dimensional motion combination adjusting platform is arranged on a light output path of the laser wave surface interferometer, the CGH five-dimensional motion combination adjusting platform is located over the four-dimensional motion adjusting platform, and the control end of the CGH five-dimensional motion combination adjusting platform and the control end of the four-dimensional motion adjusting platform are connected with the main control unit through the drive control circuit. And the control end of the laser wave surface interferometer is connected with the main control unit. According to the invention, high-precision and high-efficiency measurement of a large-aperture plane, a spherical surface and a convex aspheric surface can be realized, zero measurement of the plane, the spherical surface and the aspheric surface can be flexibly carried out, and high-efficiency and high-precision detection of a large-aperture optical surface shape is realized in combination with automatic control.

Owner:NAT UNIV OF DEFENSE TECH

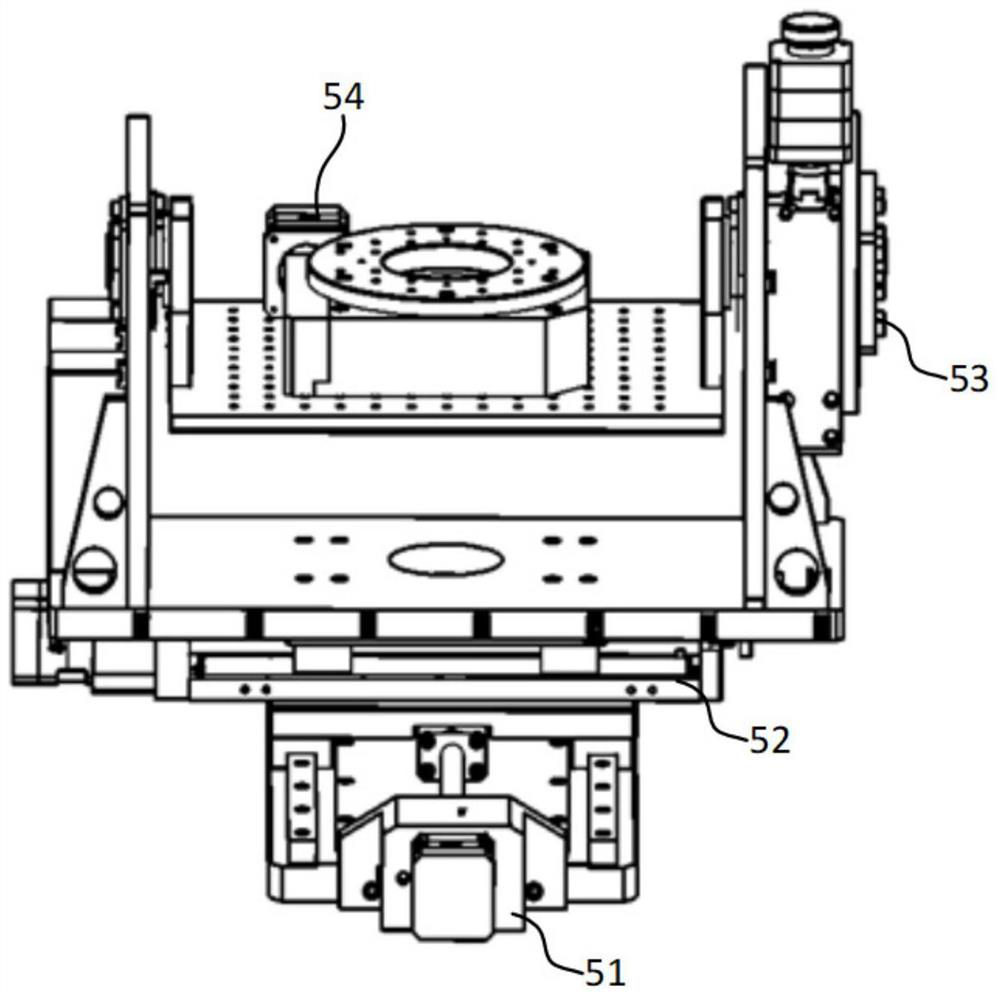

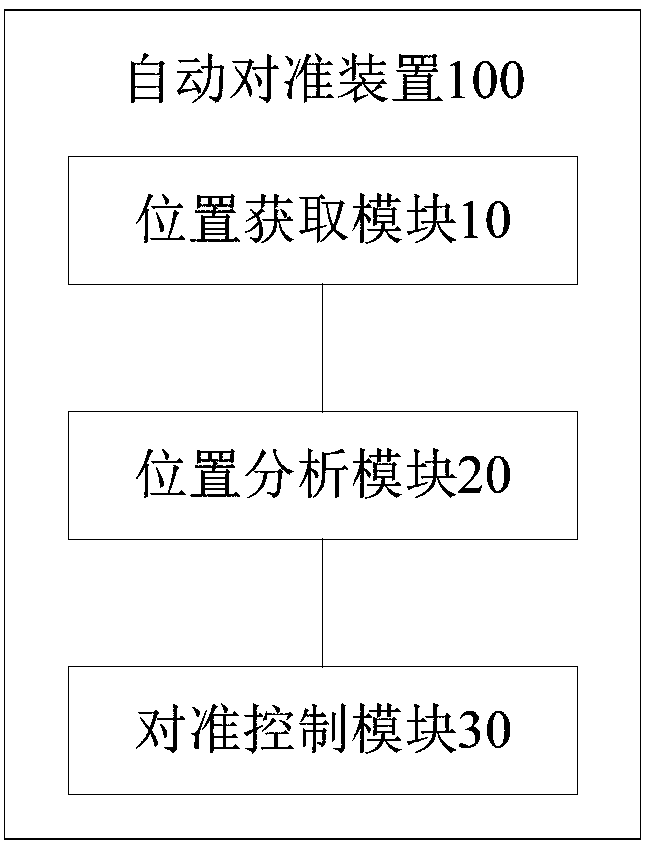

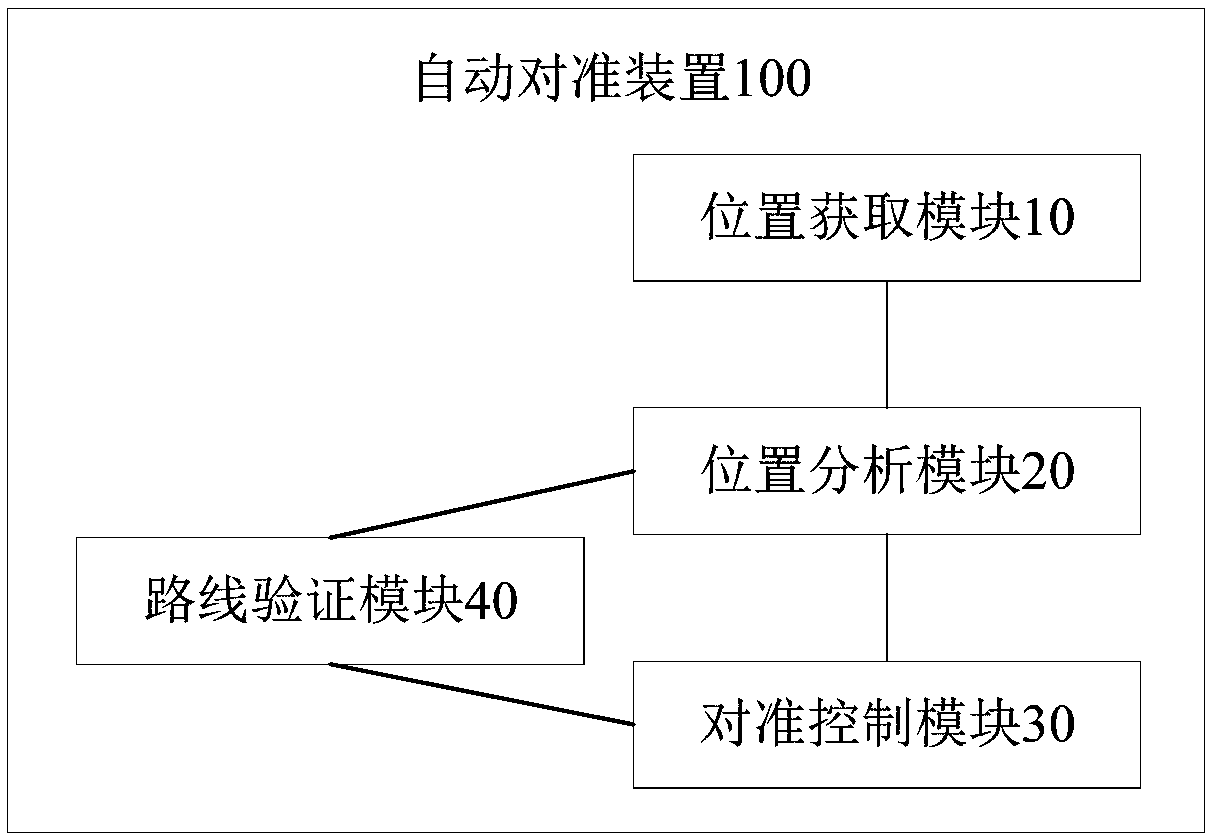

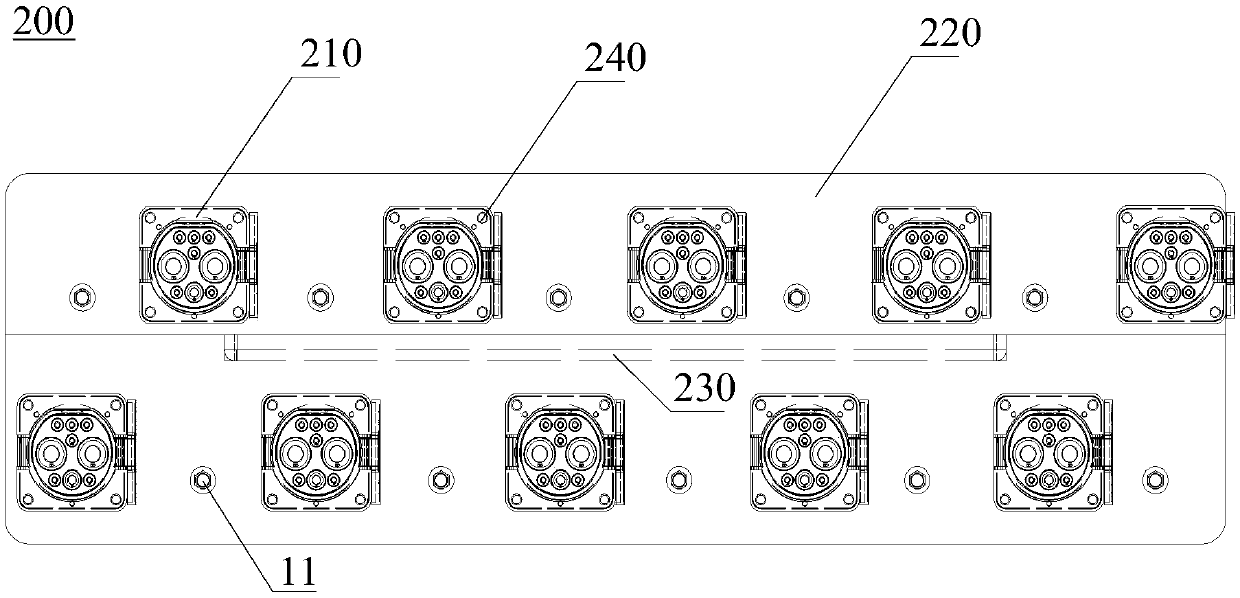

Vehicle and automatic alignment device and method of vehicle charging interfaces

ActiveCN110015069AGuaranteed normal chargingAvoid damageCharging stationsDriver interactionsComputer moduleElectric vehicle

The invention discloses a vehicle and an automatic alignment device and method of vehicle charging interfaces. The vehicle comprises a charging interface assembly, and the charging interface assemblycomprises the N charging interface. The automatic alignment device comprises a position obtaining module, a position analyzing module and an alignment control module; the position obtaining module isused for obtaining position information of each charging gun when the electric vehicle receives a charging instruction, wherein a charging pile used for charging the vehicle comprises the M charging guns, and each of N and M is an integer greater than one; the position analyzing module is used for obtaining position information of the charging interfaces needing to be connected with the charging guns, and determining a moving line of each of the charging interfaces needing to be connected with the corresponding charging gun according to the position information of the charging interfaces needing to be connected with the charging guns and the position information, obtained by the position obtaining module, of each charging gun; and the alignment control module is used for controlling each of the charging interfaces needing to be connected with the charging guns to move according to the corresponding moving line determined by the position analyzing module, so that each of the charging interfaces needing to be connected with the charging guns is controlled to be aligned with the corresponding charging gun.

Owner:BYD CO LTD

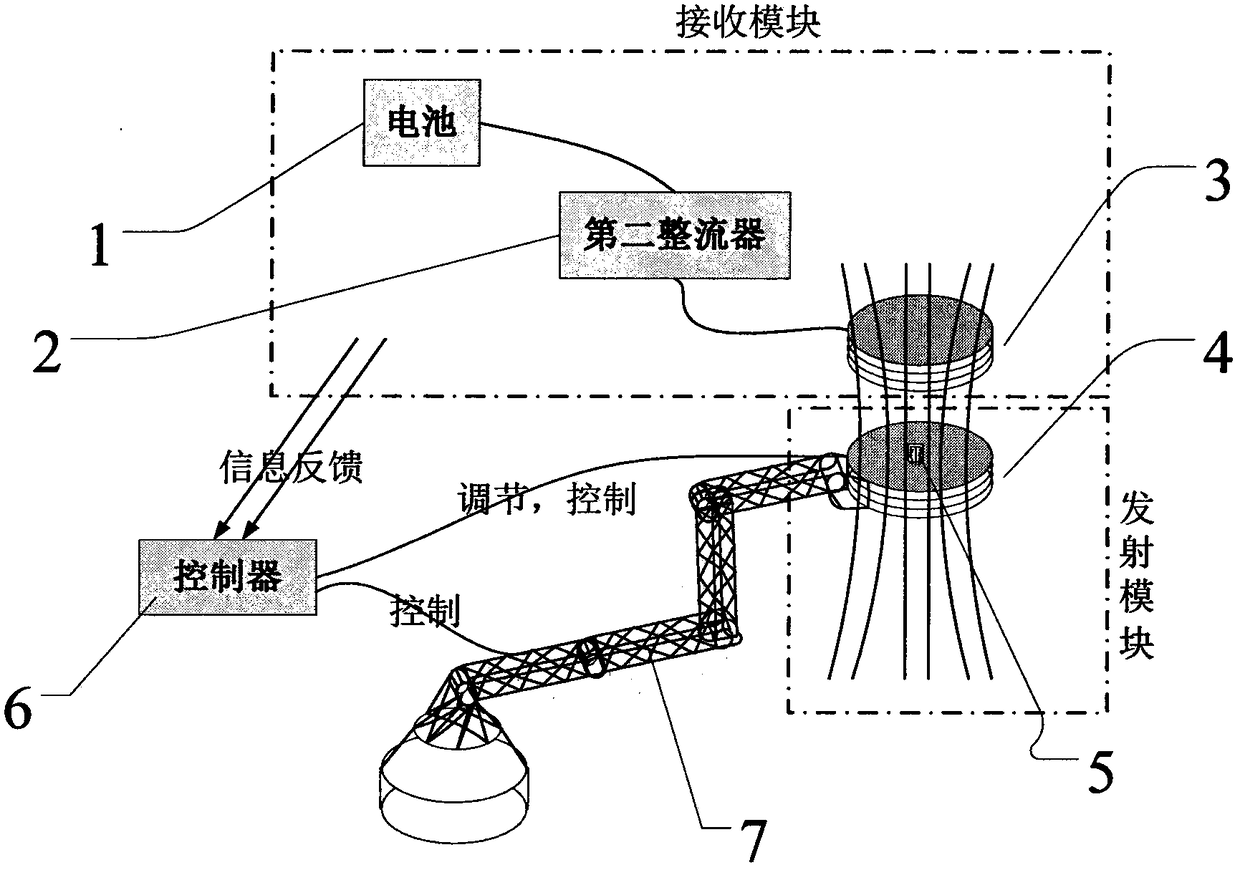

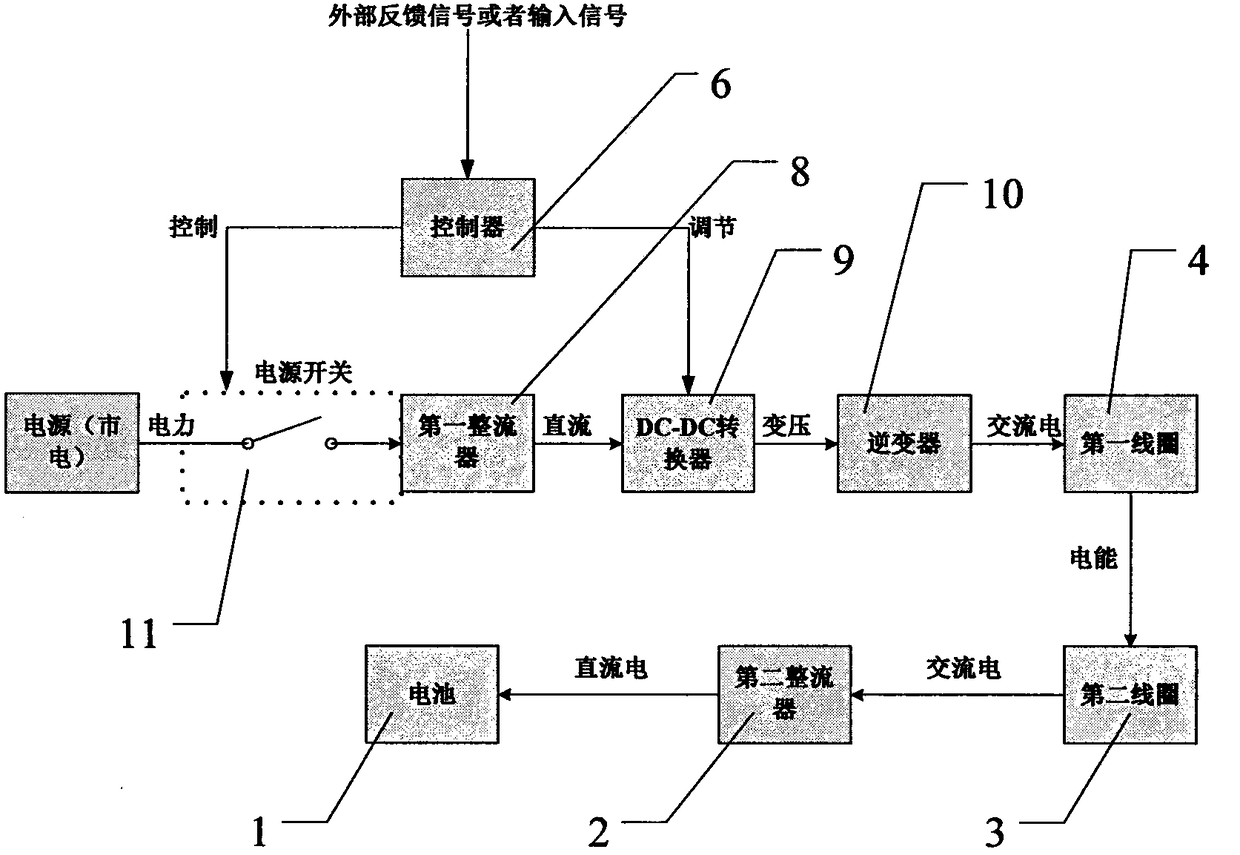

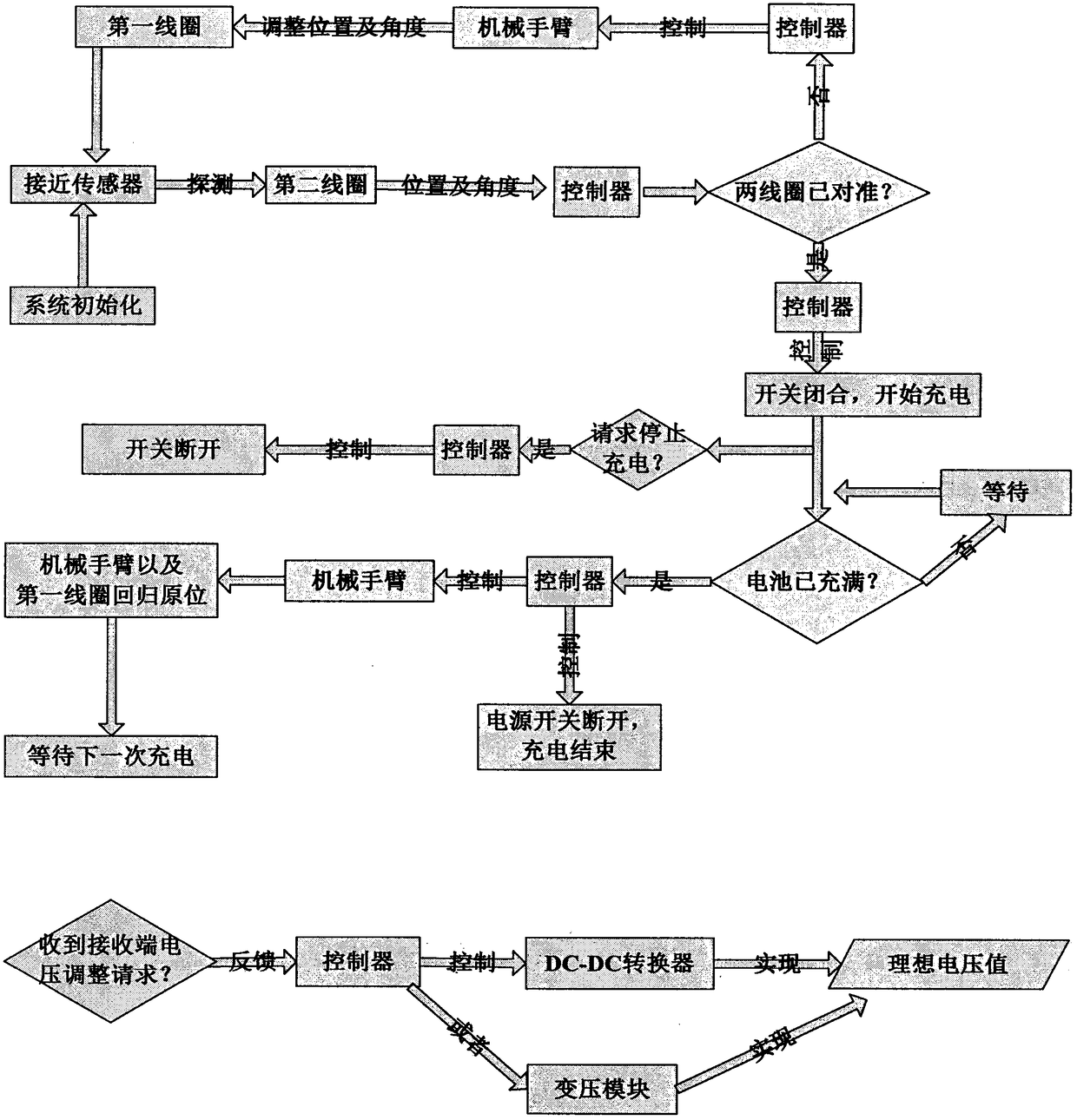

Intelligent wireless charging system

PendingCN108711949ARealize transmissionEnables automatic alignmentBatteries circuit arrangementsElectric powerAuto regulationAutomatic control

The invention discloses an intelligent wireless charging system. The system is characterized by comprising a transmitting module, a receiving module, a controller, and an automatic alignment module; the controller can control a mechanical arm, and then adjusts the location and inclination angle of a first coil; the controller can control the starting, stopping and ending of the charging; the controller can regulate the voltage of the charging; after the charging is finished, the controller can control the mechanical arm to return to the original location and the first coil to return to the original location to wait for next charging. The current frequency is equal to the inherent frequency of the transmitting module, the inherent frequency of the transmitting module is equal to the inherent frequency of the receiving module, thereby realizing the magnetic coupling resonant wireless electric energy transmission to the receiving module from the transmitting module, and receiving the efficient wireless electric energy transmission. The system disclosed by the invention has the advantages of realizing the automatic alignment of the transmitting end coil and the receiving end coil of the wireless charging system, the automatic control of the power-on / off, and the automatic regulation of the voltage; and the system is high in automation degree, high in electric energy transmission efficiency and convenient for use.

Owner:闵应昌

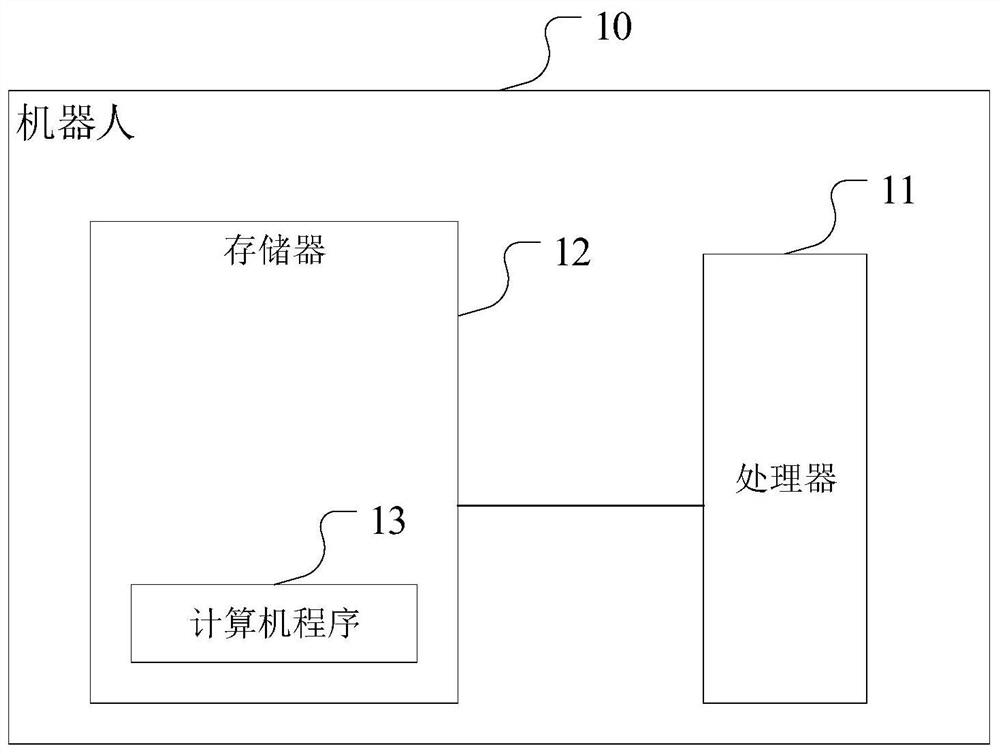

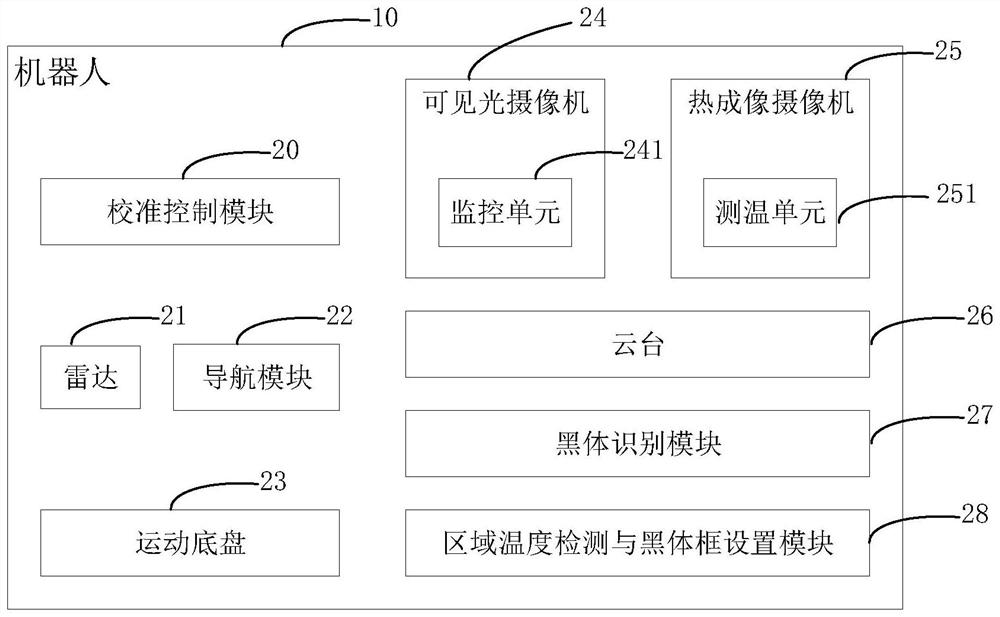

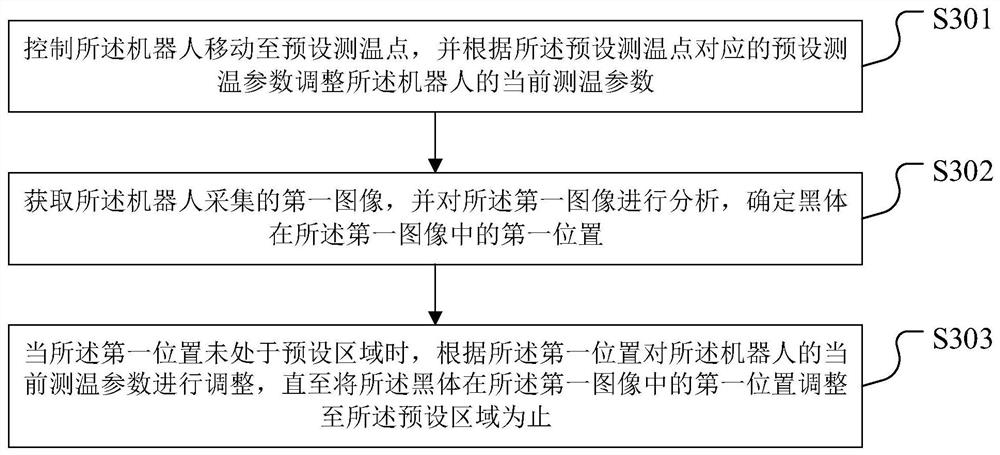

Blackbody alignment method and device, robot and computer readable storage medium

ActiveCN112033543AImprove temperature measurement efficiencyImprove temperature measurement accuracySensing radiation from moving bodiesPyrometry for temperature profileSimulationImage pair

The invention is applicable to the technical field of robots, and particularly relates to a blackbody alignment method and device, a robot and a storage medium. The method comprises the steps of controlling the robot to move to a preset temperature measurement point, and adjusting current temperature measurement parameters of the robot according to preset temperature measurement parameters corresponding to the preset temperature measurement point; acquiring a first image acquired by the robot, analyzing the first image, and determining a first position of the black body in the first image; andwhen the first position is not in the preset area, adjusting the current temperature measurement parameter of the robot according to the first position until the first position of the black body in the first image is adjusted to the preset area. In this way, the current temperature measurement parameters of the robot can be automatically and preliminarily adjusted according to the preset temperature measurement parameters corresponding to the preset temperature measurement points, then the first image can be obtained through the preliminarily adjusted robot, the current temperature measurement parameters of the robot can be accurately adjusted according to the obtained first image, automatic alignment of a black body is achieved; and the alignment efficiency is improved.

Owner:UBTECH ROBOTICS CORP LTD

Experiment method and apparatus for studying mapping relation between signal strength indication and distance

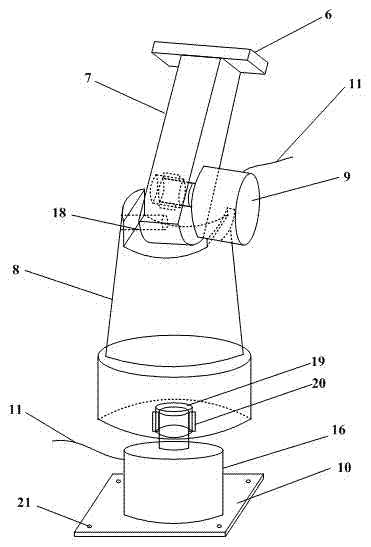

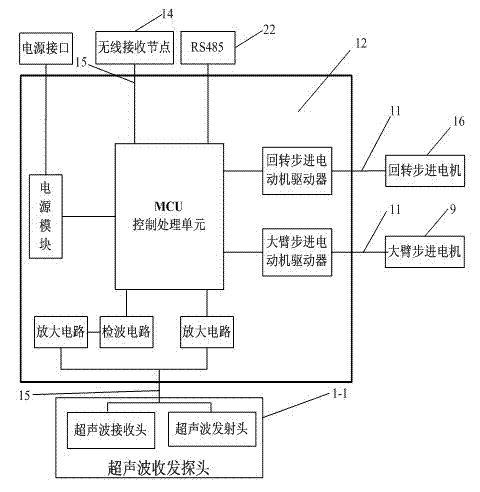

InactiveCN103763042ASatisfy the spatial propagation characteristicsImprove stabilityReceivers monitoringTransceiverIndustrial robotics

The invention discloses an experiment method and apparatus for studying a mapping relation between signal strength indication and a distance. An industrial robot execution mechanism is fixed at the upper portion of a box body structure on the ground; a first ultrasonic receiving-transmitting probe and a receiving node are fixed at the top end of the industrial robot execution mechanism; an emission node is fixed at one side, facing the ground, of a kite; and a second ultrasonic receiving-transmitting probe is arranged at the emission node. The industrial robot execution mechanism is rotated and is processed by fine tuning, so that the two ultrasonic receiving-transmitting probes are aligned automatically; the distance of the two ultrasonic receiving-transmitting probes is changed by changing the height of the kite; a control circuit board carries out data fitting on multiple groups of signal strength indication values and the corresponding distances and carries out analyzing to obtain a mapping relation between the signal strength indication and the distance. According to the invention, a wireless signal can be effectively prevented from being interfered by various factors like reflection and blocking by an obstacle during ground propagation; and thus the stability and the measuring precision are improved.

Owner:JIANGSU UNIV

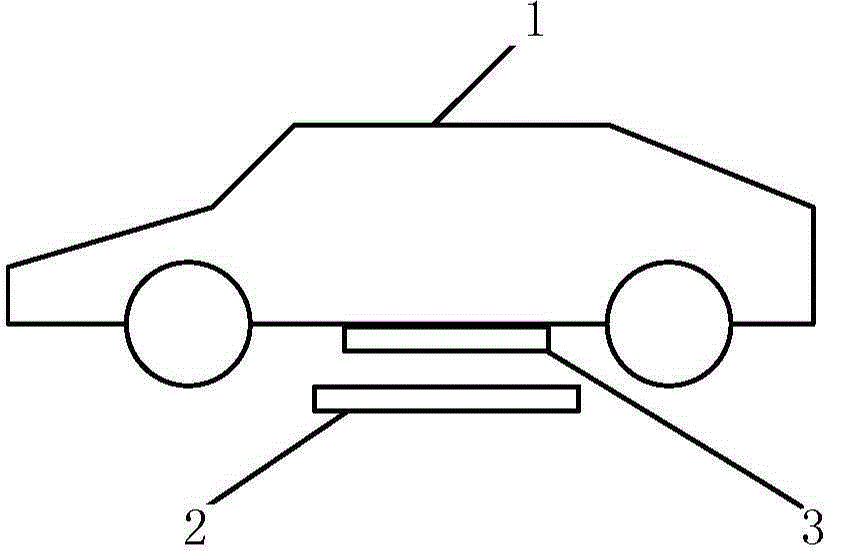

Wireless charging device used for electric vehicle and control system of wireless charging device

InactiveCN106696751AEnables automatic alignmentRealize automatic adjustmentCharging stationsElectric vehicle charging technologyElectricityControl system

The invention provides a wireless charging device used for an electric vehicle and a control system of the wireless charging device. The charging device comprises the electric vehicle, a receiving coil arranged at the bottom of the electric vehicle and a charging pile used for providing charging power supply for the electric vehicle, the charging pile comprises an adjusting mechanism and a transmitting coil arranged on the adjusting mechanism, and a receiving coil matched with the transmitting coil is further arranged at the tail of the electric vehicle; the control system is composed of a power supply system and a power receiving system. By the arrangement, technical problems about low charging efficiency during charging and potential safety hazard in operation with an existing wireless charging structure are solved; a wireless charging launcher is placed on the ground, automatic adjusting in vertical and horizontal positions is realized, self aligning of the transmitting coil and the receiving coil can be achieved, and when the receiving coil and the transmitting coil are perfectly fit on the same horizontal line, efficient charging during operation is realized.

Owner:吴文钦

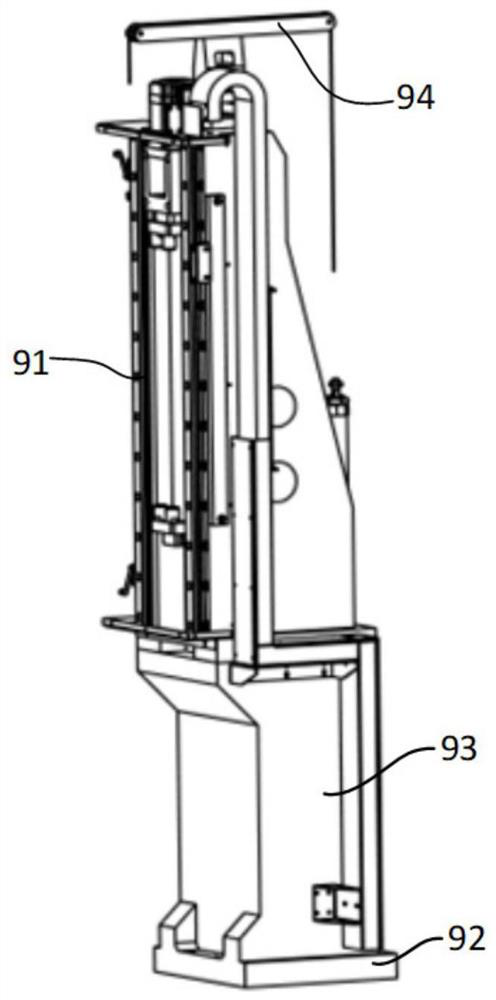

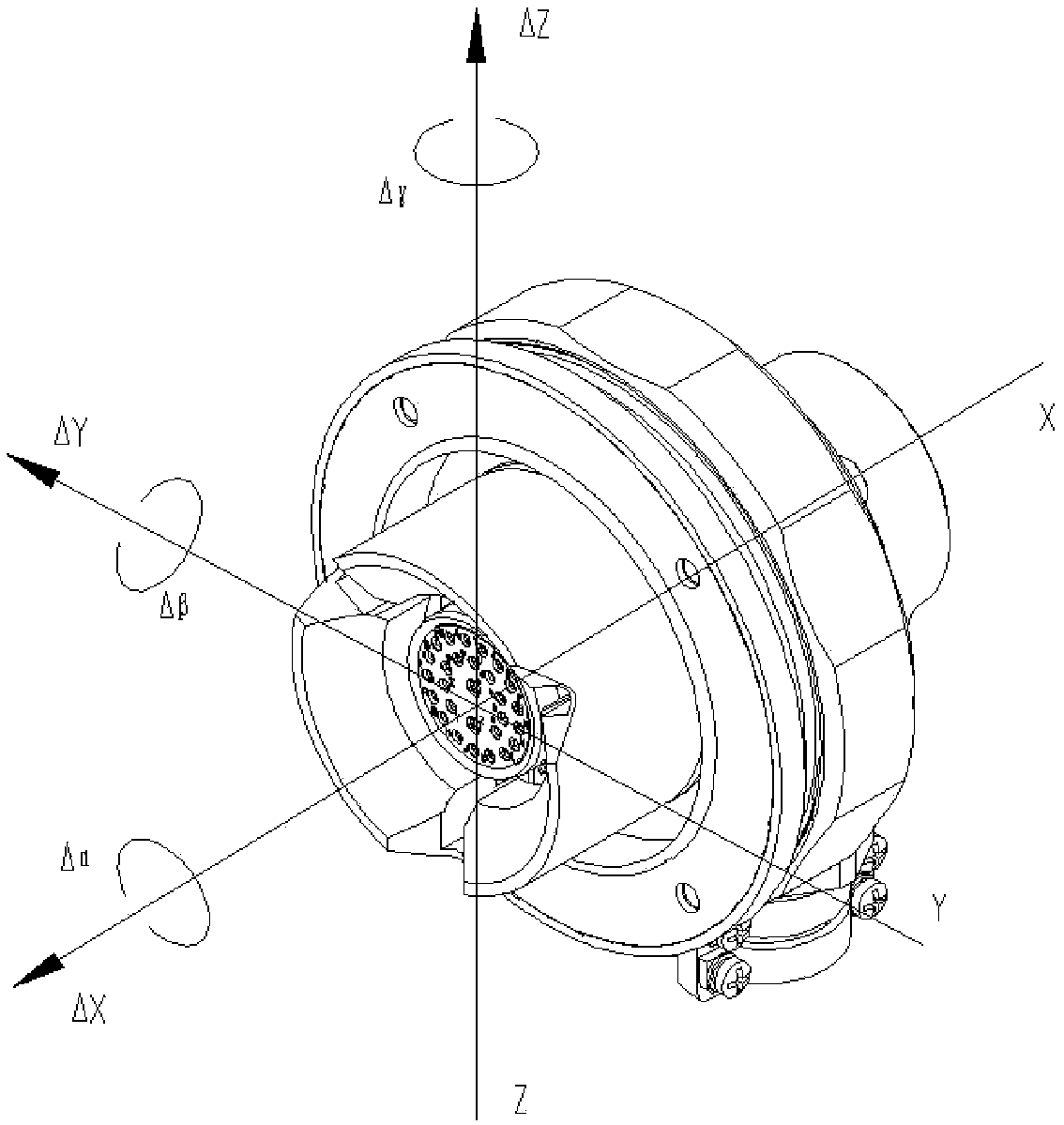

Nine-degree-of-freedom robot tightening control method for assembling thin-wall large threaded part

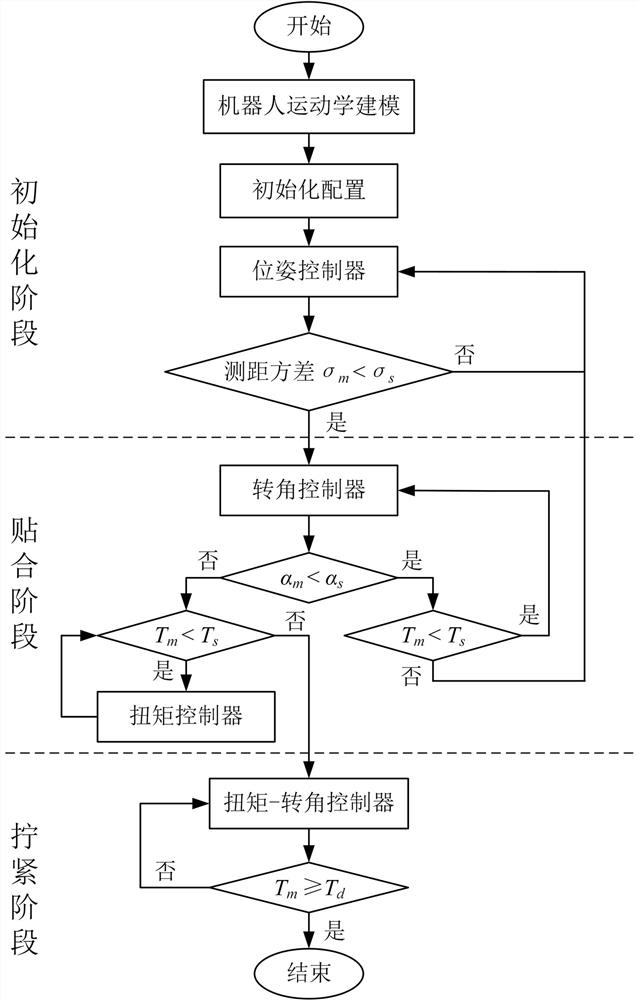

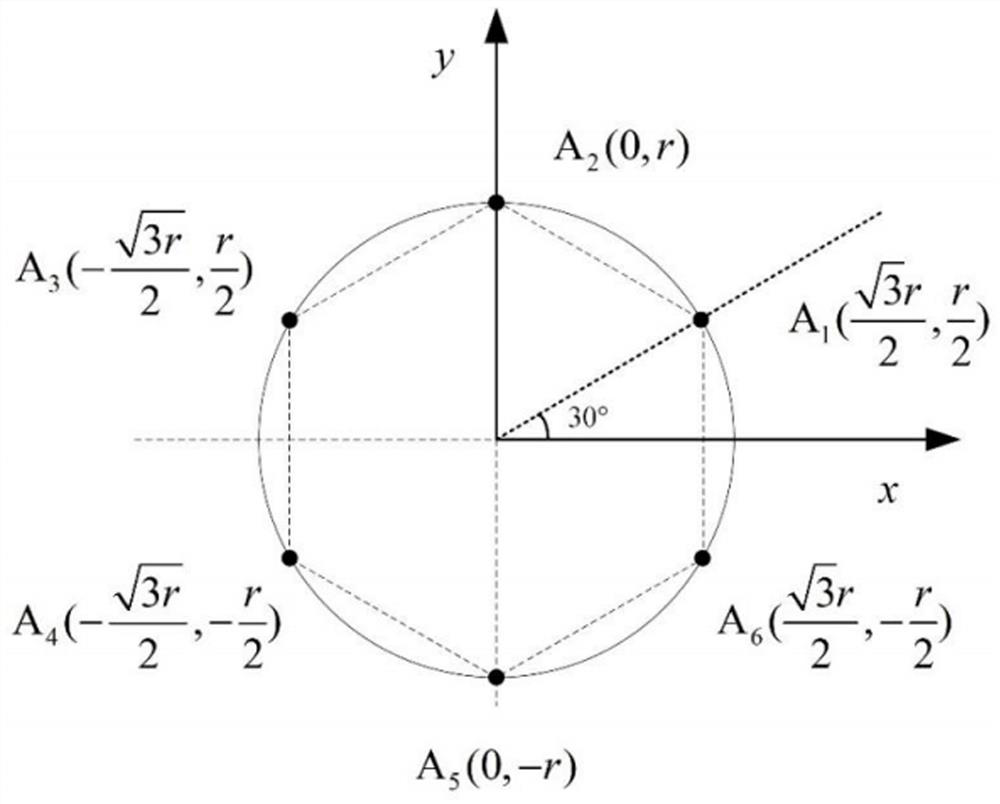

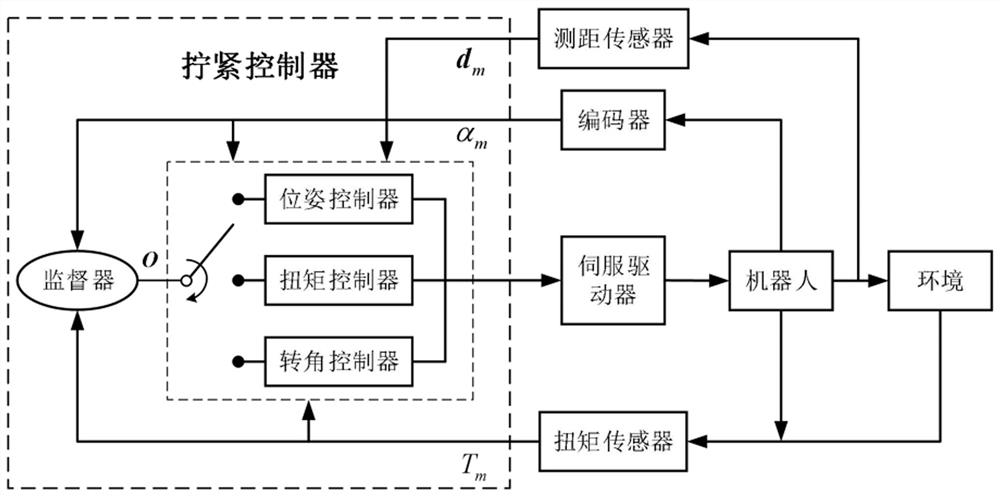

ActiveCN112720473AEnables automatic alignmentTo achieve error compensationProgramme-controlled manipulatorLaser rangingHandoff control

The invention discloses a nine-degree-of-freedom robot tightening control method for assembling a thin-wall large threaded part. The robot tightening control system comprises a tightening controller, a six-degree-of-freedom Stewart platform and a three-degree-of-freedom series mechanism, wherein the six-degree-of-freedom Stewart platform is located at the bottom and used for adjusting the pose of an upper platform tightening mechanism; the three-degree-of-freedom series mechanism is fixed to the six-degree-of-freedom Stewart platform and used for executing tightening control; a laser ranging module is used for collecting information about the distance between a shell and a to-be-assembled bolt piece, and axial alignment of the bolt piece and the shell and pose error correction in the fitting stage are achieved through a pose compensation algorithm; and a switching control method based on a pose / torque / corner controller is used, and a segmented switching control strategy is executed according to feedback information of various heterogeneous sensors. According to the method, automatic alignment, error compensation and tightening control operations in the assembly of the thin-wall large-thread part are realized, the occurrence probability of the thread pair jamming phenomenon can be reduced, and the assembly efficiency and quality of the thin-wall large-thread part are effectively improved.

Owner:HENAN UNIV OF SCI & TECH

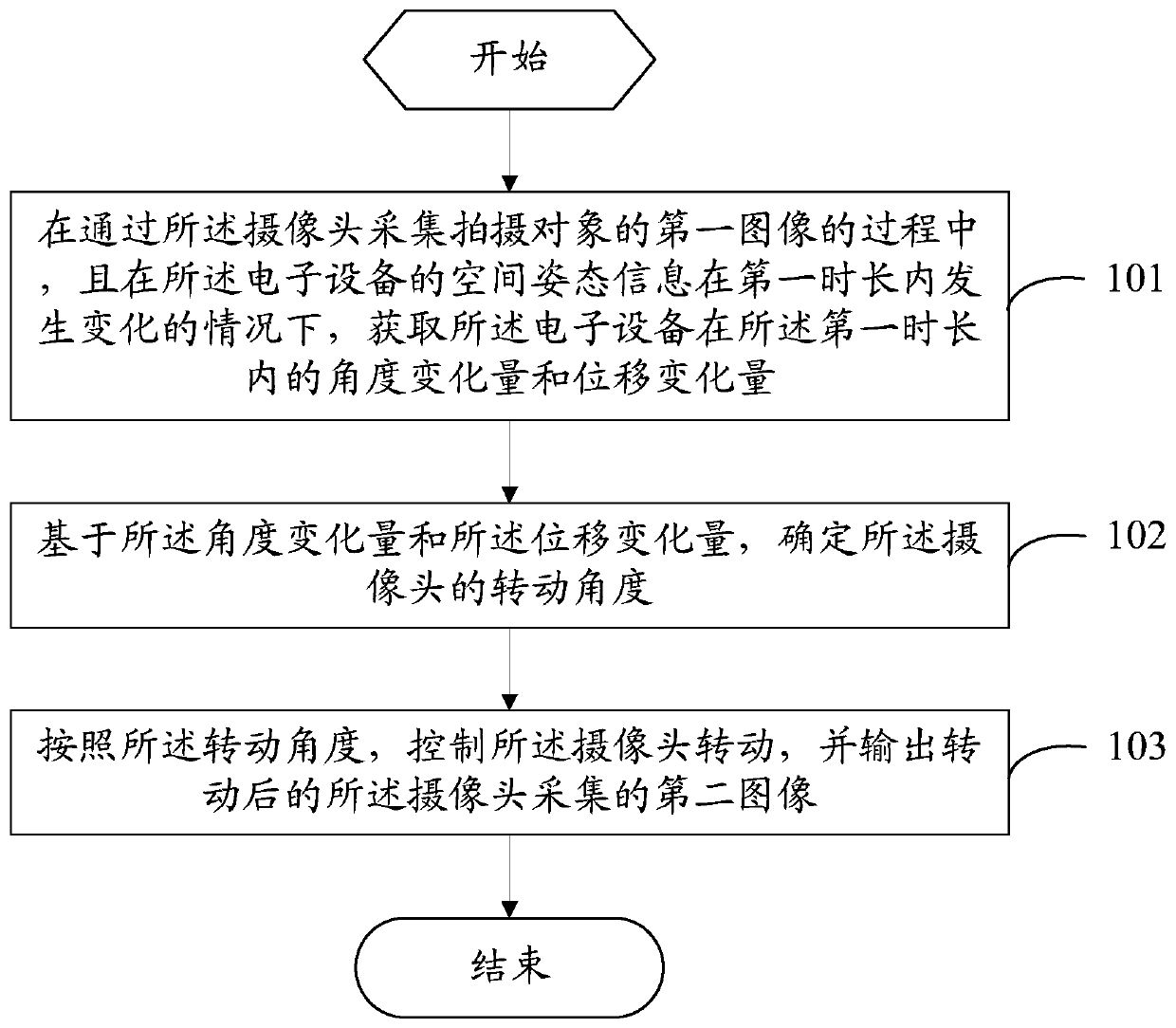

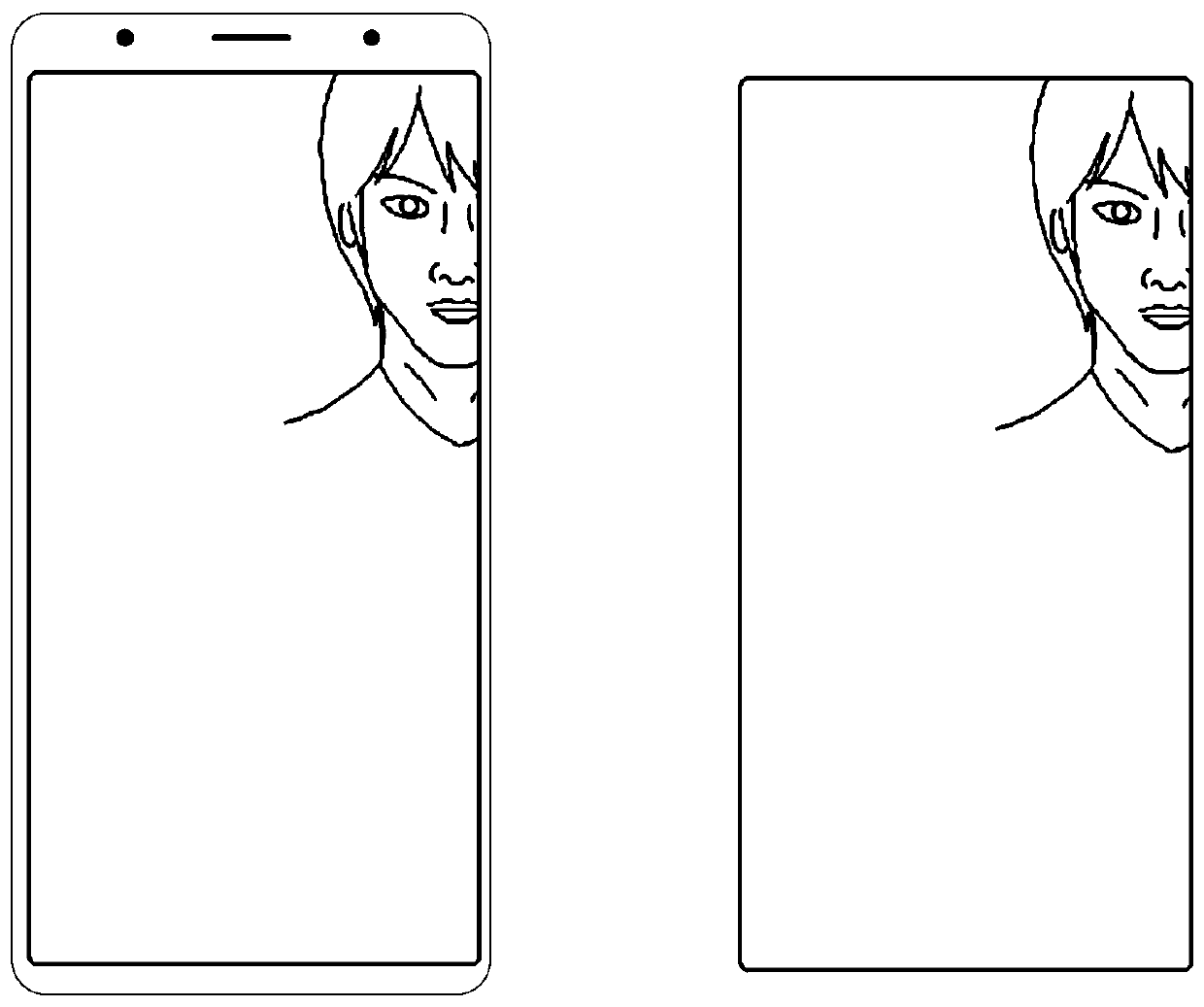

Shooting method and electronic equipment

InactiveCN111031246AEnables automatic alignmentSimplify shooting operationsTelevision system detailsColor television detailsComputer graphics (images)Engineering

The invention provides a shooting method and electronic equipment. The electronic equipment comprises a rotatable camera, and the method comprises the steps that in the process of collecting a first image of a shooting object through the camera, under the condition that space attitude information of the electronic equipment changes within a first duration, acquiring the angle change amount and thedisplacement change amount of the electronic equipment within the first duration; determining a rotation angle of the camera based on the angle variation and the displacement variation; controlling the camera to rotate according to the rotation angle, and outputting a second image acquired by the rotated camera, wherein the position of the shooting object in the second image is the same as the position of the shooting object in the first image. Therefore, the shooting operation of the user can be effectively simplified, and the shooting effect of long-focus shooting can be improved.

Owner:VIVO MOBILE COMM CO LTD

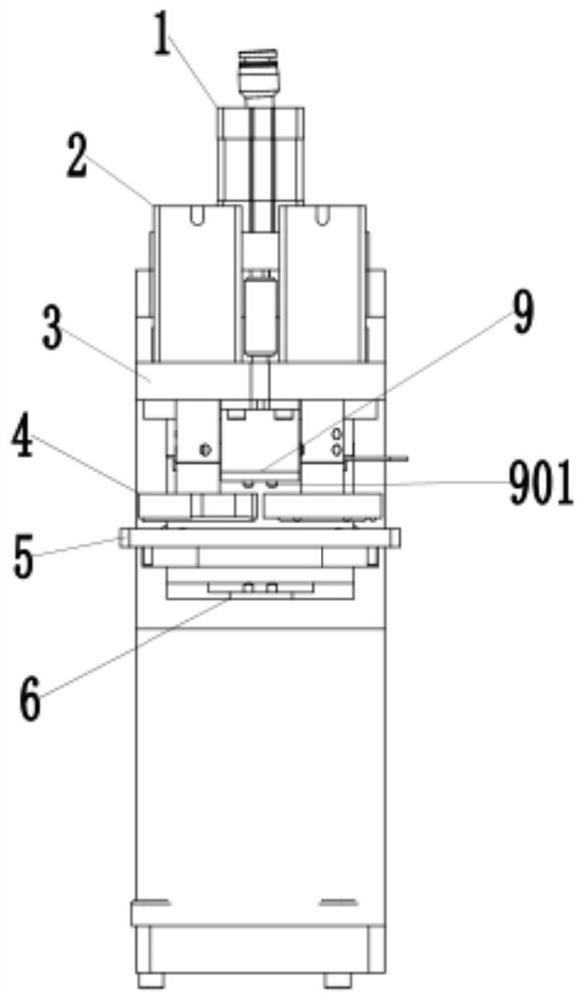

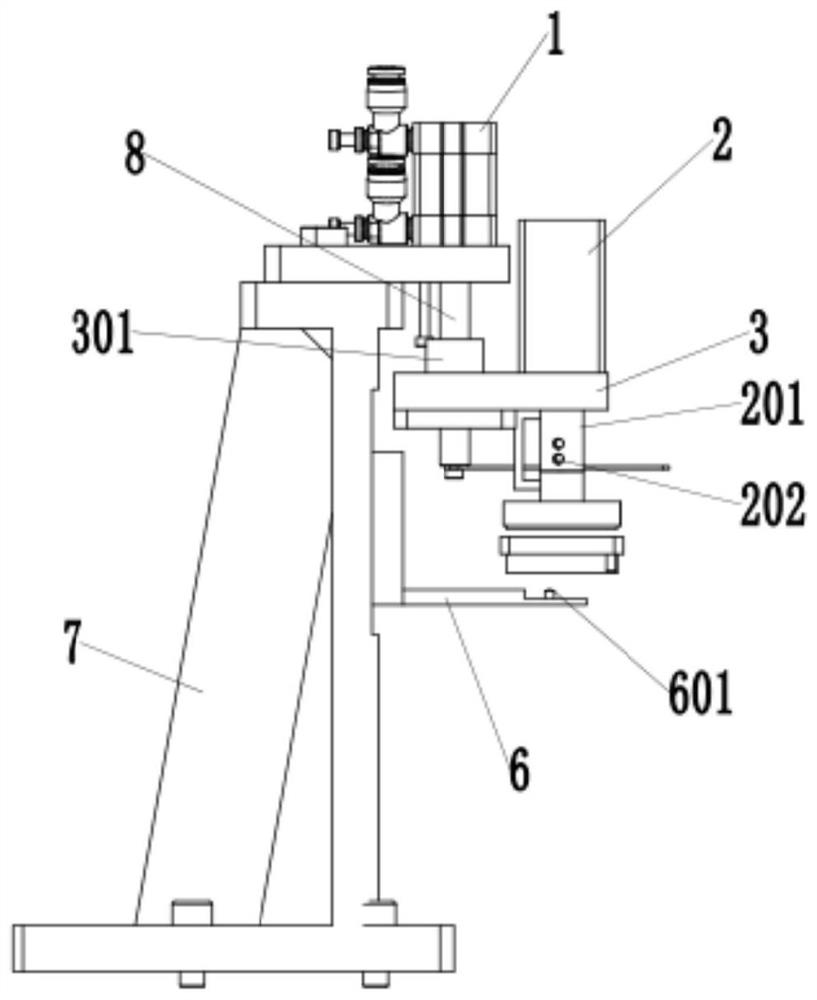

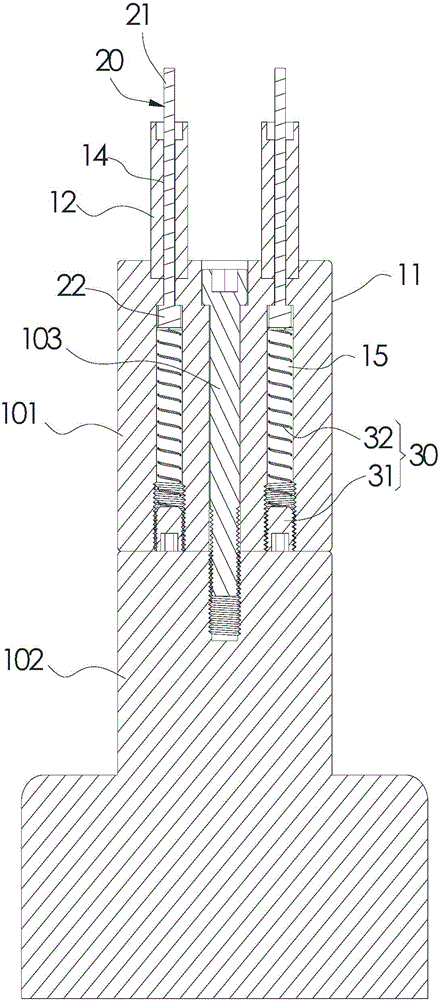

Correction mechanism and method for rubber ring annular hole

PendingCN112108864ASolving the Alignment DilemmaEnables automatic alignmentMetal working apparatusRubber ringPhotoswitch

The invention discloses a correction mechanism and method for a rubber ring annular hole. The correction mechanism comprises a positioning air cylinder, a stepping motor, a positioning pressing disc,a die, a supporting seat and a correlation type photoelectric switch. The positioning air cylinder is fixed to the upper end of the supporting seat, a lifting plate is connected to a piston rod of thepositioning air cylinder, the stepping motor is arranged at the upper end of the lifting plate, and the positioning pressing disc connected with an output shaft of the stepping motor is arranged on the lower part of the lifting plate. The die is arranged below the positioning pressing disc, a mounting groove for mounting a rubber ring is formed in the upper end of the die, and a die annular holecorresponding to the rubber ring annular hole is formed in the mounting groove. The correlation type photoelectric switch comprises an emitter and a receiver, the emitter and the receiver are correspondingly located on the two sides of the die, and light between the emitter and the receiver penetrates through the die annular hole. Optical fiber detection is adopted, a detection result is accurate,the problem that the rubber ring annular hole and the die annular hole are difficult to align is solved, automatic alignment of hole sites is achieved, and the requirement for automatic bead installation is met.

Owner:JINAN FIRST MACHINE TOOL GROUP

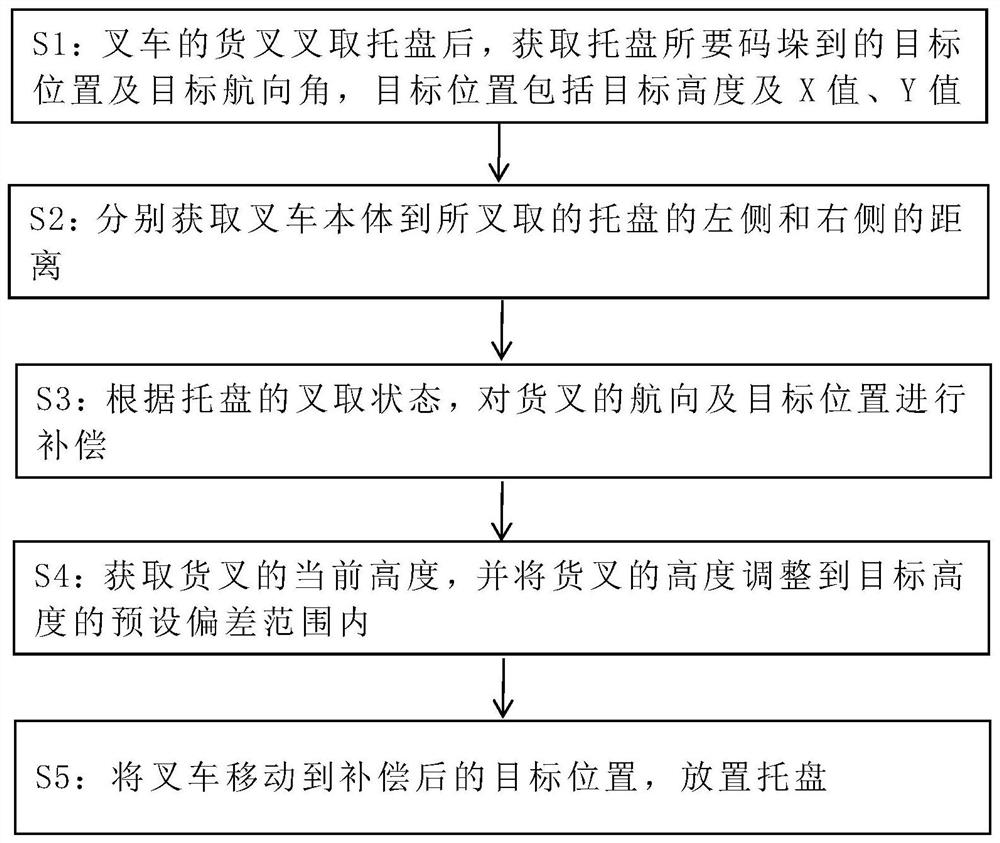

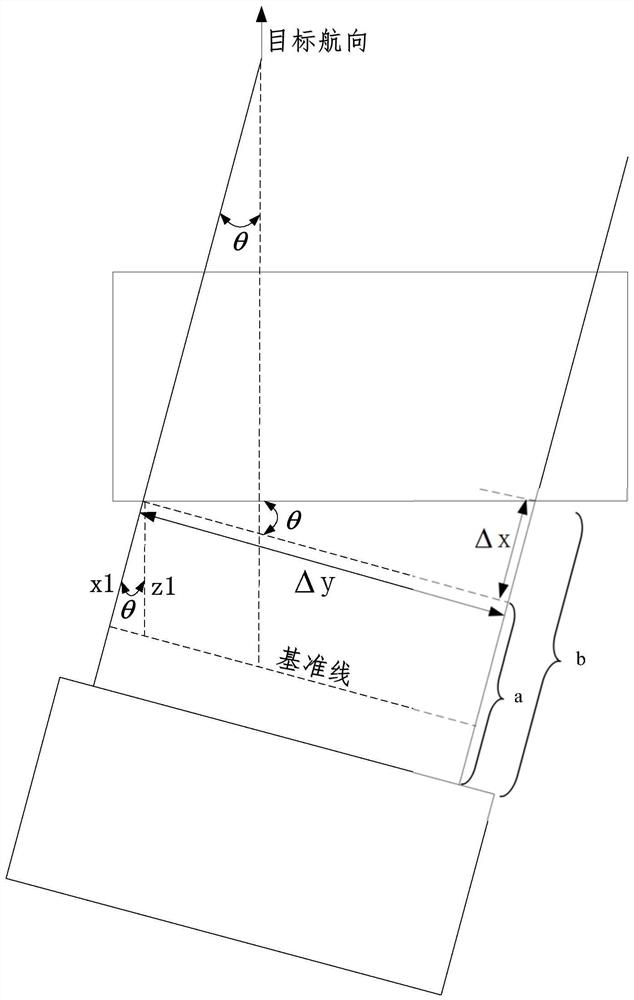

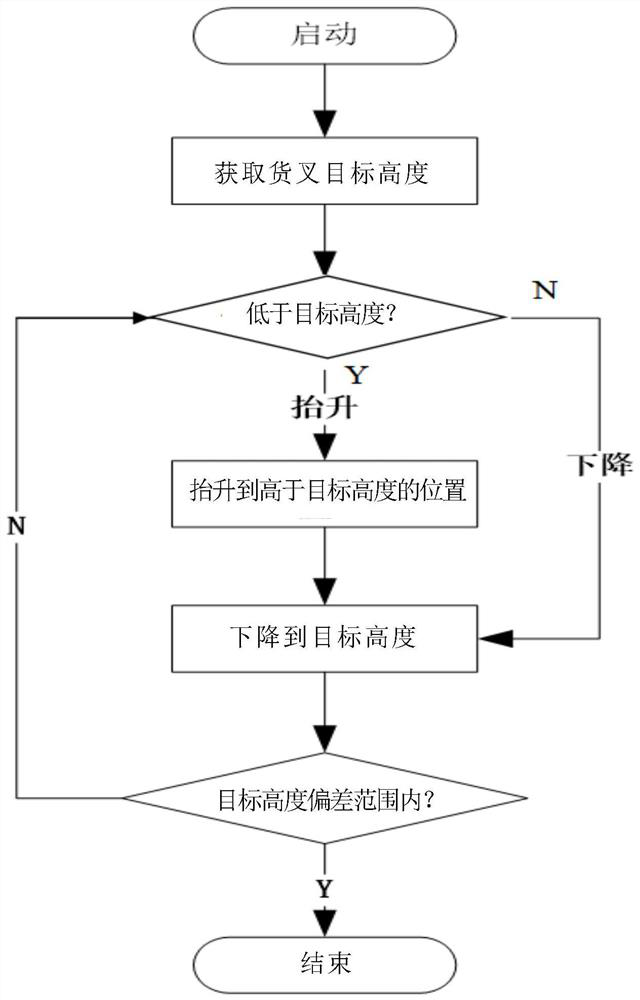

Automatic alignment control method and device for hydraulic pallet fork

ActiveCN112357836AEnables automatic alignmentHigh palletizing accuracyLifting devicesStructural engineeringControl theory

The invention discloses an automatic alignment control method for a hydraulic pallet fork. The automatic alignment control method comprises the following steps that S1, after a pallet fork of a forklift forks a pallet, the target position and the target course angle of the pallet to be stacked are obtained, and the target position comprises the target height; S2, the distance between a forklift body and the left side of the forked pallet and the distance between the forklift body and the right side of the forked pallet are obtained; S3, the course and the target position of the forklift are compensated according to the forking state of the pallet; S4, the current height of the pallet fork is obtained, and the height of the pallet fork is adjusted to be within the preset deviation range ofthe target height; and S5, the forklift is moved to the compensated target position, and the pallet is placed. According to the control method, the target position and the target course angle of the forklift can be compensated based on the forking state of the pallet, and therefore automatic alignment of the pallet fork is achieved, the stacking precision is improved, and accumulative errors are eliminated. The invention further discloses an automatic alignment control device for the hydraulic pallet fork.

Owner:ZHONG CHAO GREAT WALL FINANCIAL EQUIP HLDGCO +1

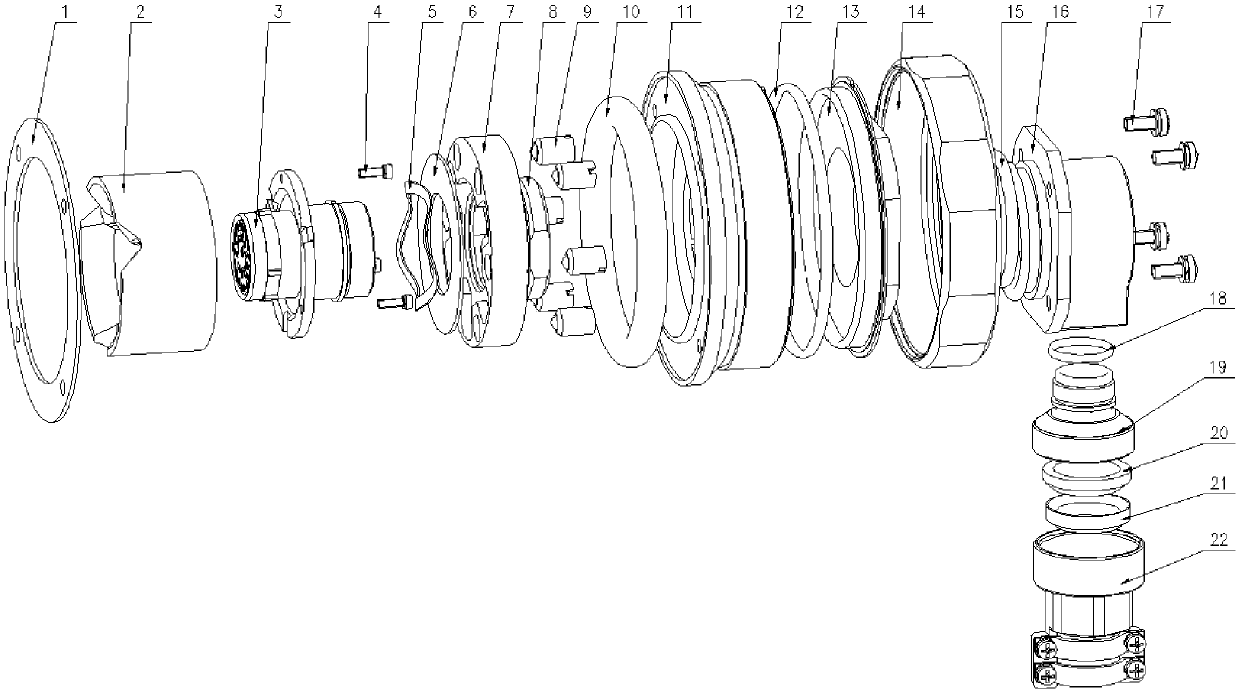

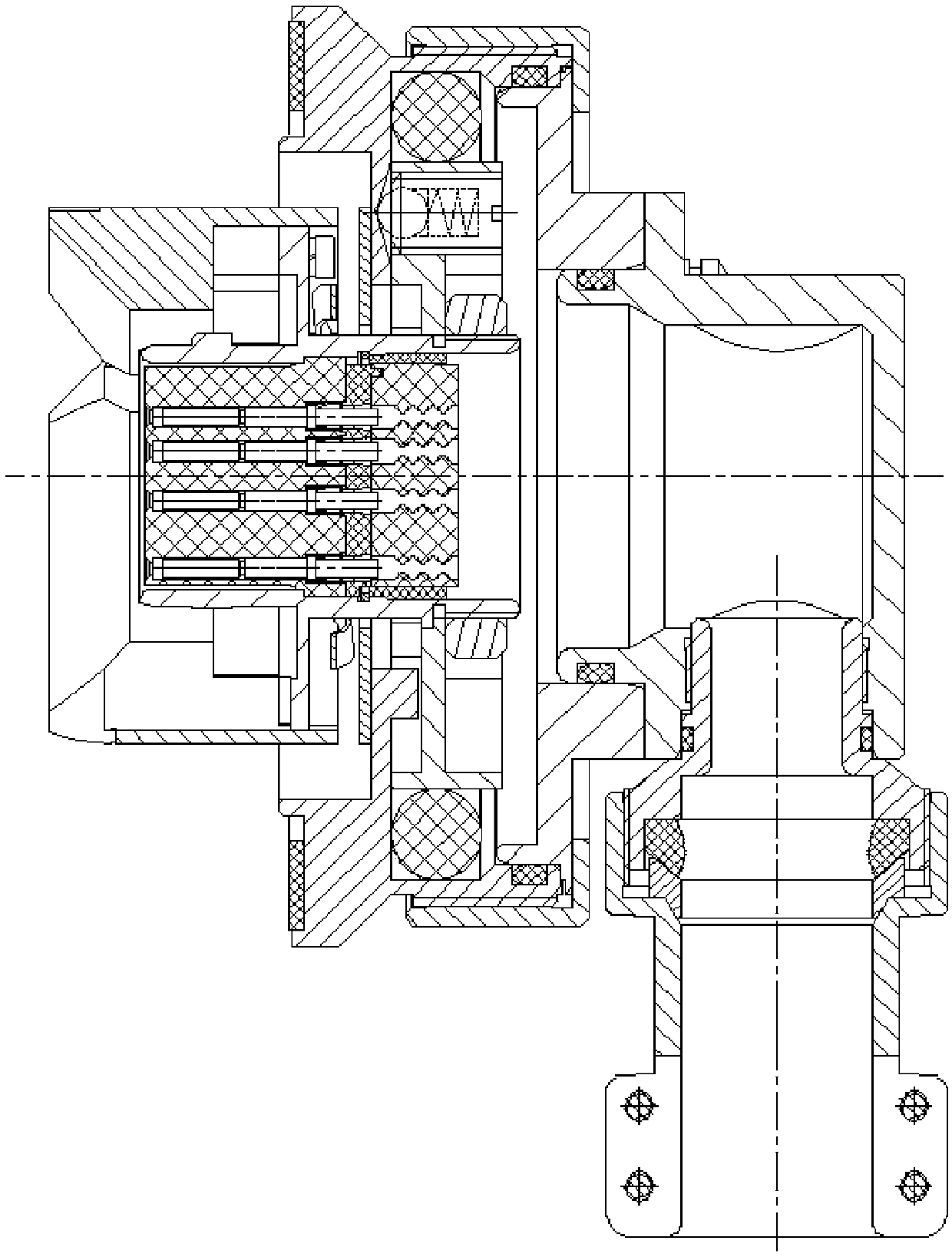

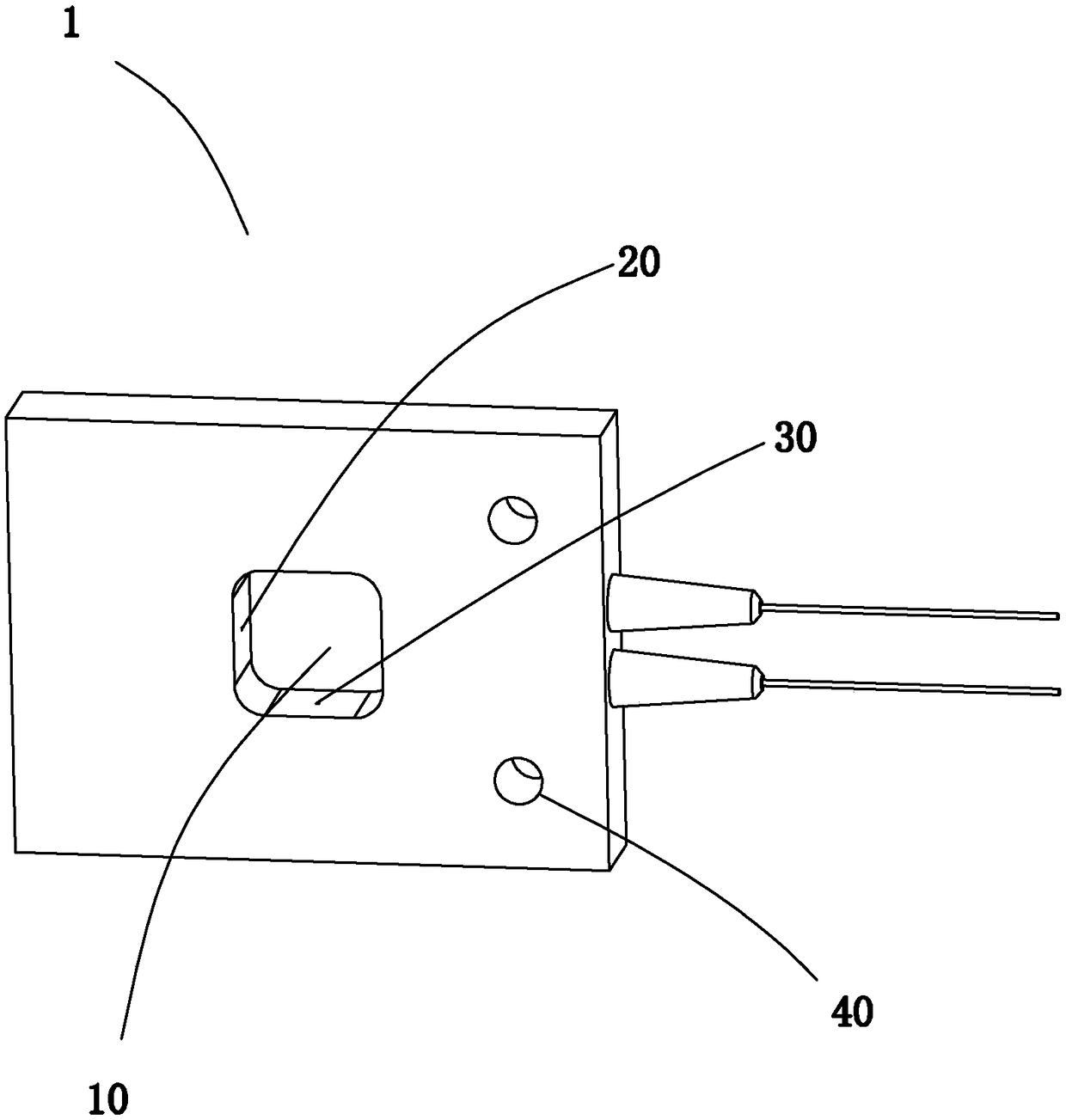

Floating electrical connector

ActiveCN109560424AConvenient three-dimensional space postureImprove reliabilityCouplings bases/casesTwo-part coupling devicesElectricityEngineering

The invention discloses a floating electrical connector, comprising: a plug and a socket; the plug comprises: a floating sleeve and a plug housing; the socket comprises: a roller and a socket housing;the floating sleeve is rigidly fixed with the plug housing, and the roller is rigidly connected with the socket housing by riveting; the floating sleeve is provided with a guiding chamfer and a notchchamfer; the front end of the plug housing is provided with a guiding key, and the front end of the socket housing is provided with a corresponding key slot. The floating electrical connector realizes a three-dimensional six-degree-of-freedom floating function of mechanically docking the electrical connector, has a centering reset function in an unplugged state, and has the advantages of compactstructure and small size.

Owner:杭州航天电子技术有限公司

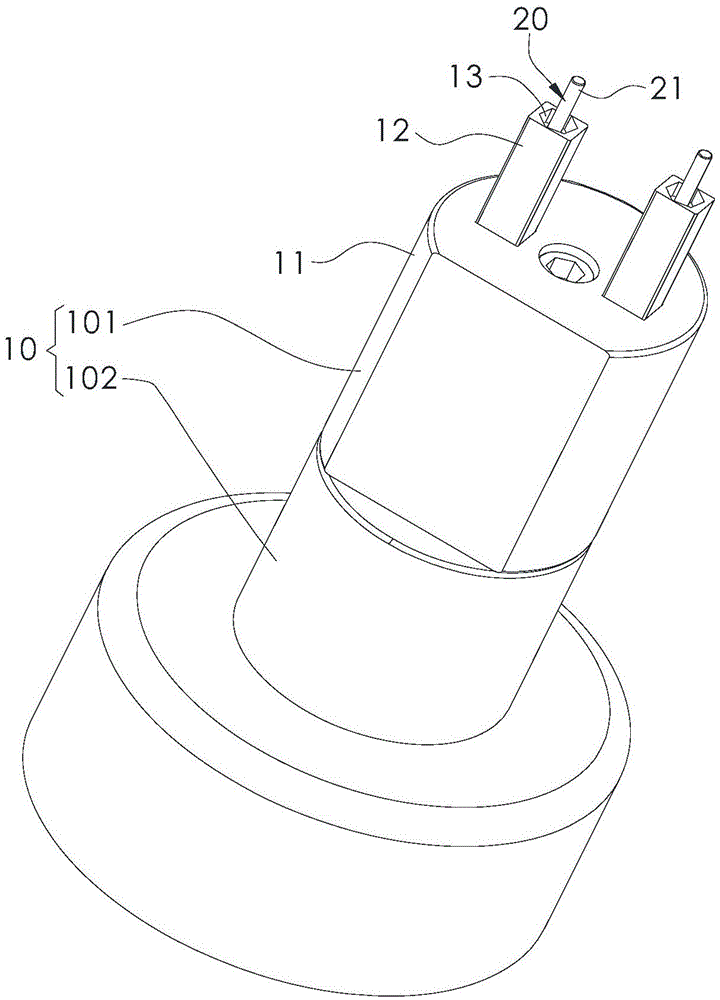

Lamp holder assembly fixture and lamp holder assembly method

ActiveCN104552085APlay a guiding roleEnables automatic alignmentWork holdersMetal-working hand toolsBiomedical engineeringAssembly structure

The invention relates to a lamp holder assembly fixture and a lamp holder assembly method. The lamp holder assembly fixture comprises a mounting seat, a floating needle and an elastic mechanism, wherein the upper end of the mounting seat is provided with a positioning end, a lamp head fixing part is arranged above the positioning end, a nut mounting groove is formed in the upper end surface of the lamp head fixing part, a floating needle through hole is downwards formed in the middle part of the nut mounting groove, the floating needle is arranged in the floating needle through hole in a penetrating way, and the upper end of the floating needle is provided with a guide end. The lamp holder assembly fixture has the advantages that when a lamp holder is mounted, the lamp head can be fixedly arranged on the lamp head fixing part, a lamp holder housing sleeves the positioning end of the mounting seat, and the guide end of the floating needle sequentially passes through the mounting through hole of the lamp head and the mounting through hole of the lamp holder housing, and is exposed out of one side, away from the lamp head, of the lamp holder housing, so the guide function on a bolt is realized, the mounting positions of the nut, the lamp head, the lamp holder housing and the bolt are automatically aligned, and the artificial error is effectively avoided; the assembly structure is reliable and convenient, the assembly time is saved, the error rate of assembly is reduced, and the production efficiency is improved.

Owner:佛山市南海嘉美时代照明有限公司

Reference position automatic alignment method and device of glue dispensing needle of glue dispensing machine

PendingCN109174561ASimple structureIngenious designLiquid surface applicatorsCoatingsManipulatorBiomedical engineering

The invention relates to a reference position automatic alignment method and device of a glue dispensing needle of a glue dispensing machine. The method comprises the following steps: a position detecting sensor is provided; a square hole is formed in the position detecting sensor; an X-directional light emitter and an X-directional light receiver, and a Y-directional light emitter and a Y-directional light receiver are arranged in the center positions of each pair of opposite inner walls of the square hole; the glue dispensing needle moves in the square hole through a multiaxis manipulator inan X direction; the Y-directional light receiver generates a pulse signal; positions corresponding to an ascending edge and a descending edge of the pulse signal are recorded as X1 and X2; an X-directional reference position X of the glue dispensing needle is (X1+X2) / 2; the glue dispensing needle moves in a Y direction in the square hole through the multiaxis manipulator; the X-directional lightreceiver generates another pulse signal; positions corresponding to an ascending edge and a descending edge of the pulse signal are recorded as Y1 and Y2; an Y-directional reference position Y of theglue dispensing needle is (Y1+Y2) / 2; and the glue dispensing needle automatically moves to a reference position (X, Y) through the multiaxis manipulator.

Owner:VISION XIAMEN AUTOMATION TECH CO LTD

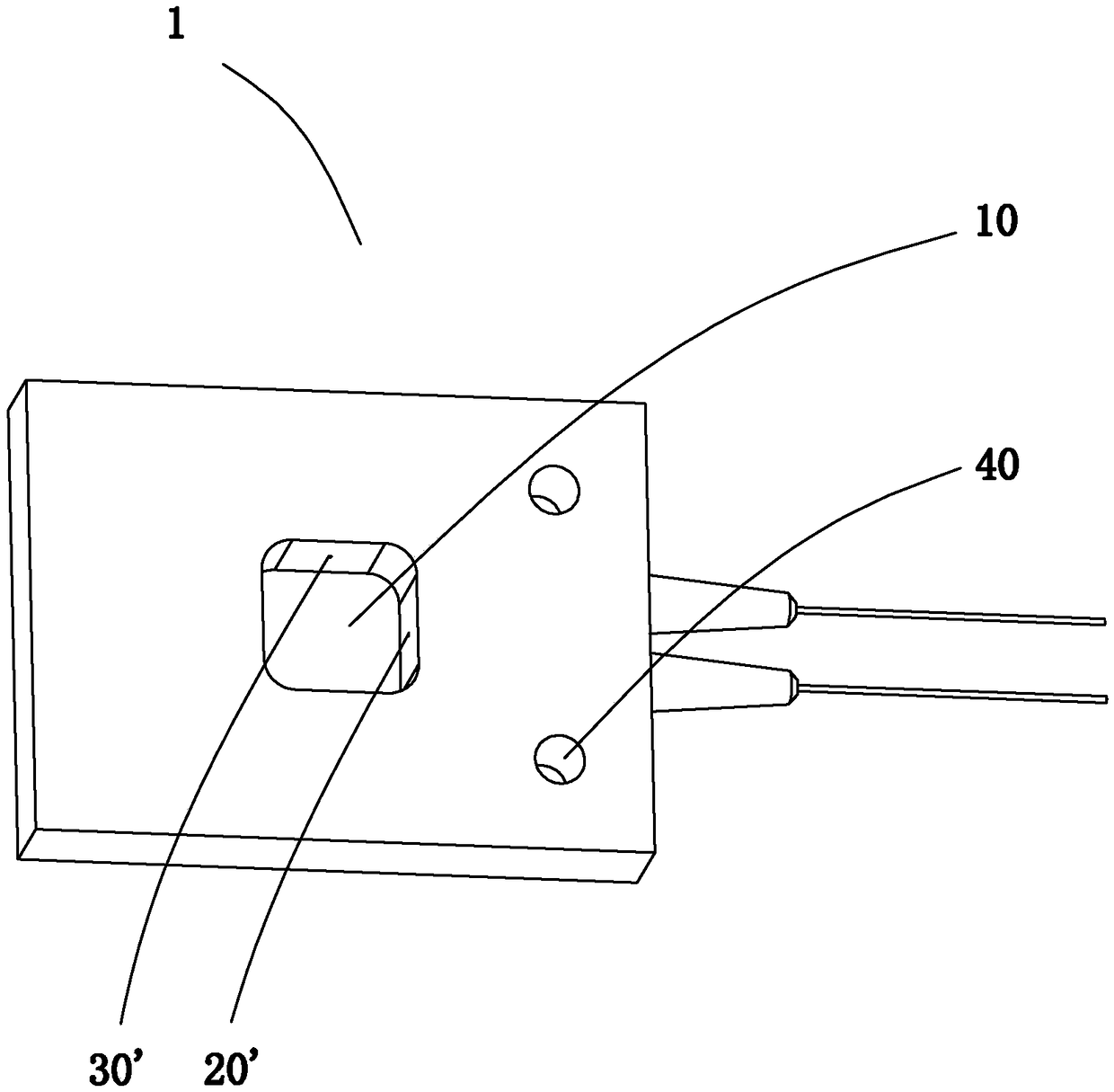

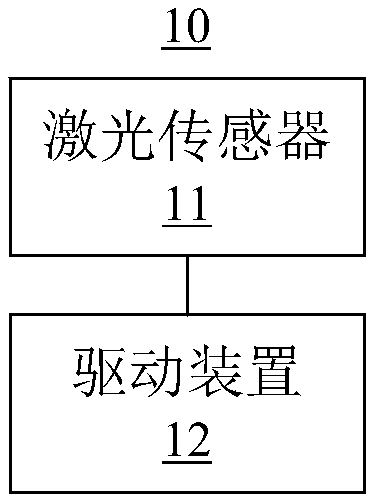

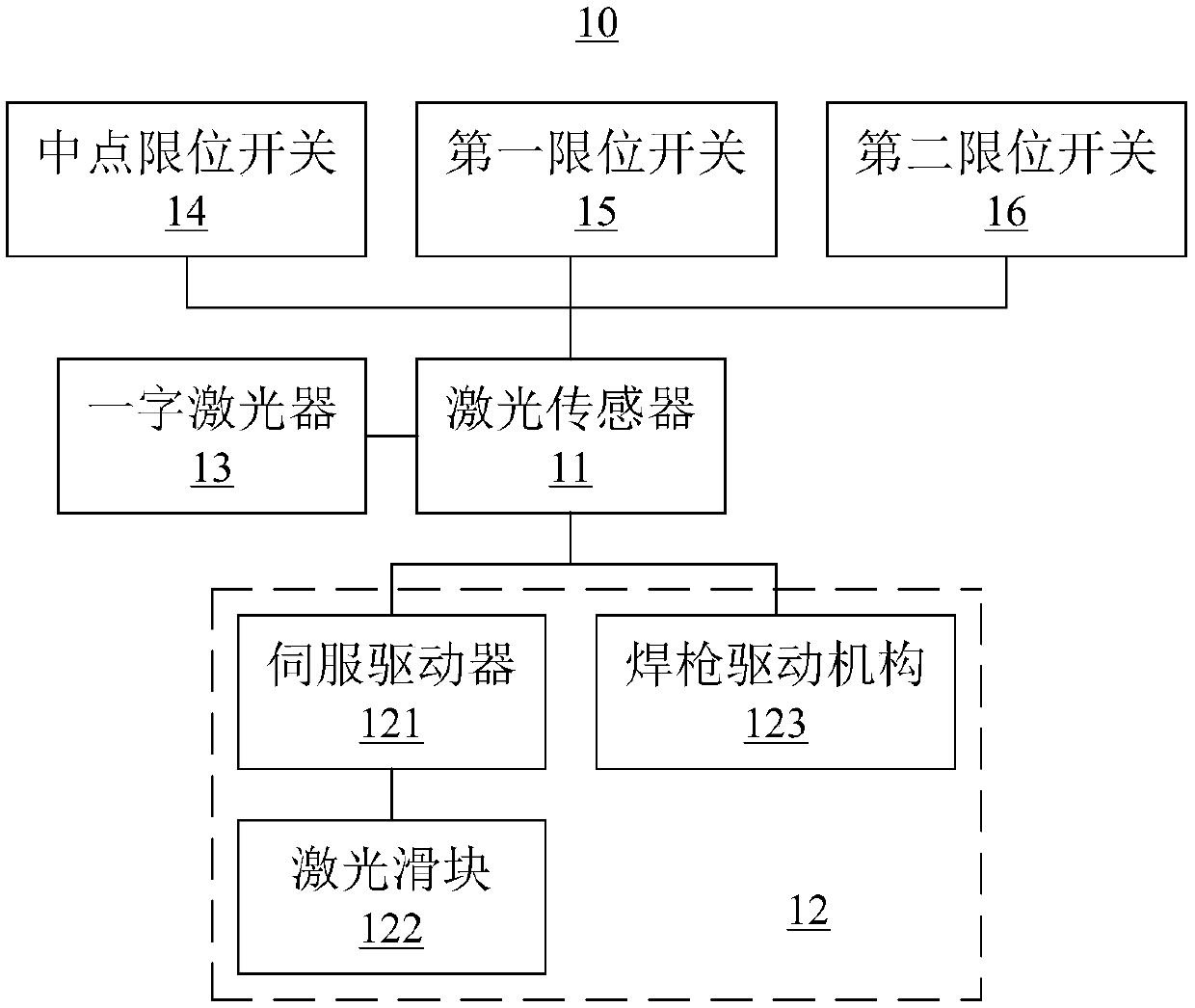

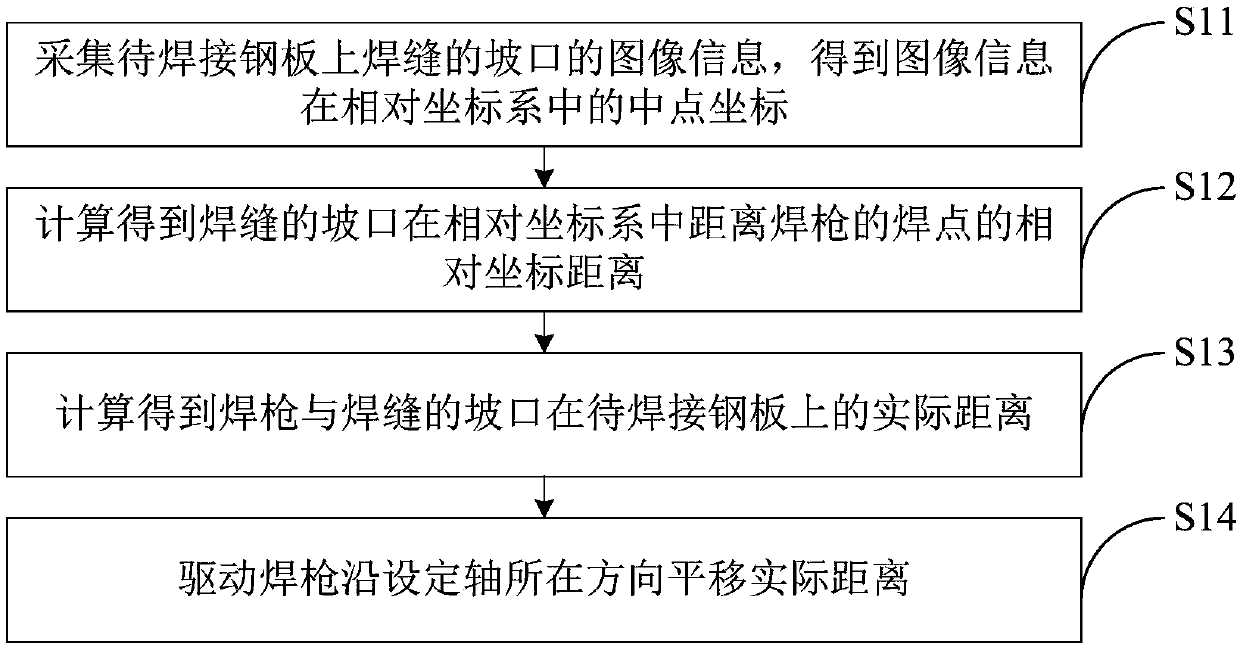

Automatic aligning system and method for welding spot

ActiveCN109514137AEnables automatic alignmentAutomatic alignment is convenientWelding/cutting auxillary devicesAuxillary welding devicesTransverse axisEngineering

The invention provides an automatic aligning system and method for a welding spot and relates to the technical field of welding. The system comprises a laser sensor and a driving device. The method comprises the following steps: pre-establishing a relative coordinate system in the laser sensor for collecting image information of a groove of a weld joint on a to-be-welded steel plate to obtain a center point coordinate of the image information in the relative coordination system; calculating the relative coordinate distance from the groove of the weld joint to the welding spot of a weld gun inthe relative coordinate system, wherein in the relative coordinate system, the connecting line of the coordinate information of the welding spot of the weld gun and the center point coordinate of theimage information of the groove is parallel to a set axis of the relative coordinate system, and the set axis comprises a transverse axis or a vertical axis; calculating the actual distance from the weld gun to the groove of the weld joint on a to-be-welded steel plate according to the relative coordinate distance and a preset specific value; and driving the weld gun to move actually translationally in the direction of the set axis by a driving device. The welding spot is calibrated automatically.

Owner:BEIJING BO TSING TECH CO LTD

Laser signal recovery module, multipoint alignment underwater laser communication system and multipoint alignment underwater laser communication method

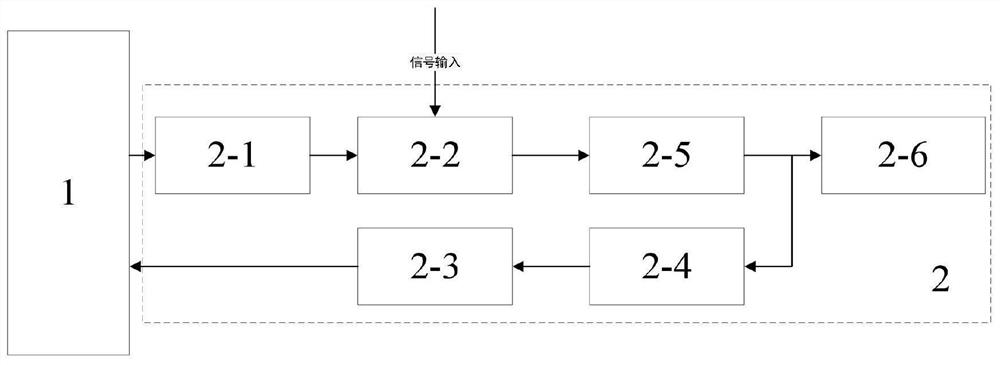

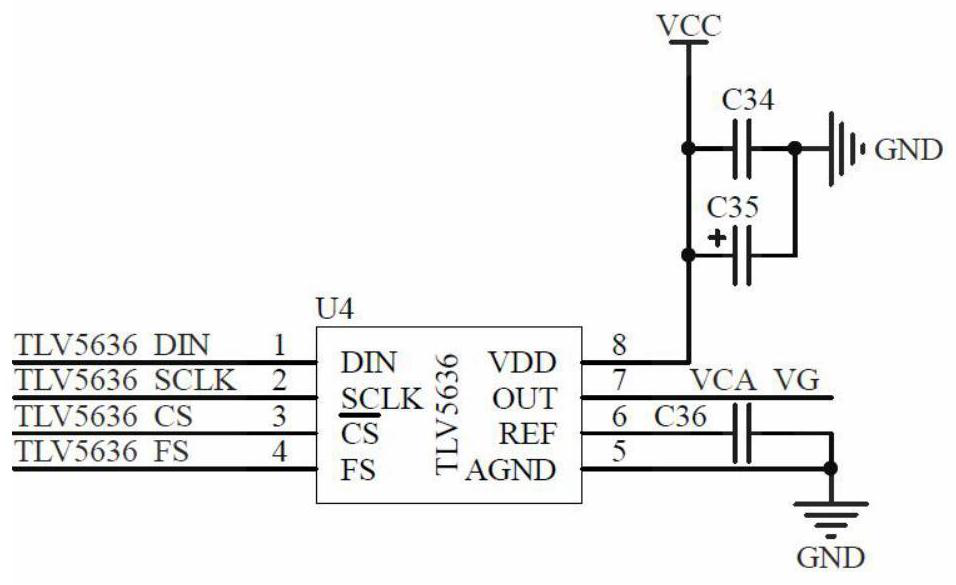

ActiveCN111934779AHigh communication rateEnables automatic alignmentElectromagnetic transmittersElectromagnetic receiversInterference (communication)Video transmission

The invention discloses a laser signal recovery module, a multipoint alignment underwater laser communication system and a multipoint alignment underwater laser communication method. A complex underwater environment is a main factor influencing underwater laser communication distance and bit error rate. The laser signal recovery module comprises a DAC circuit, a voltage-controlled amplification circuit, an ADC sampling circuit, a pulse peak holding circuit, an autocorrelation circuit and an adjustable threshold comparator circuit, wherein the DAC circuit, the voltage-controlled amplification circuit, the ADC sampling circuit and the pulse peak holding circuit form an automatic gain control circuit; laser signals subjected to water attenuation and scattering interference are recovered through a signal conditioning technology, so that a relatively high communication rate is achieved under a longer communication distance, and a technical guarantee is provided for underwater wireless videotransmission and other applications. According to the laser signal recovery module disclosed in the invention, automatic alignment of any two underwater laser communication systems is realized by using the holder, and therefore laser communication among a plurality of spatially separated underwater targets can be realized.

Owner:HANGZHOU DIANZI UNIV

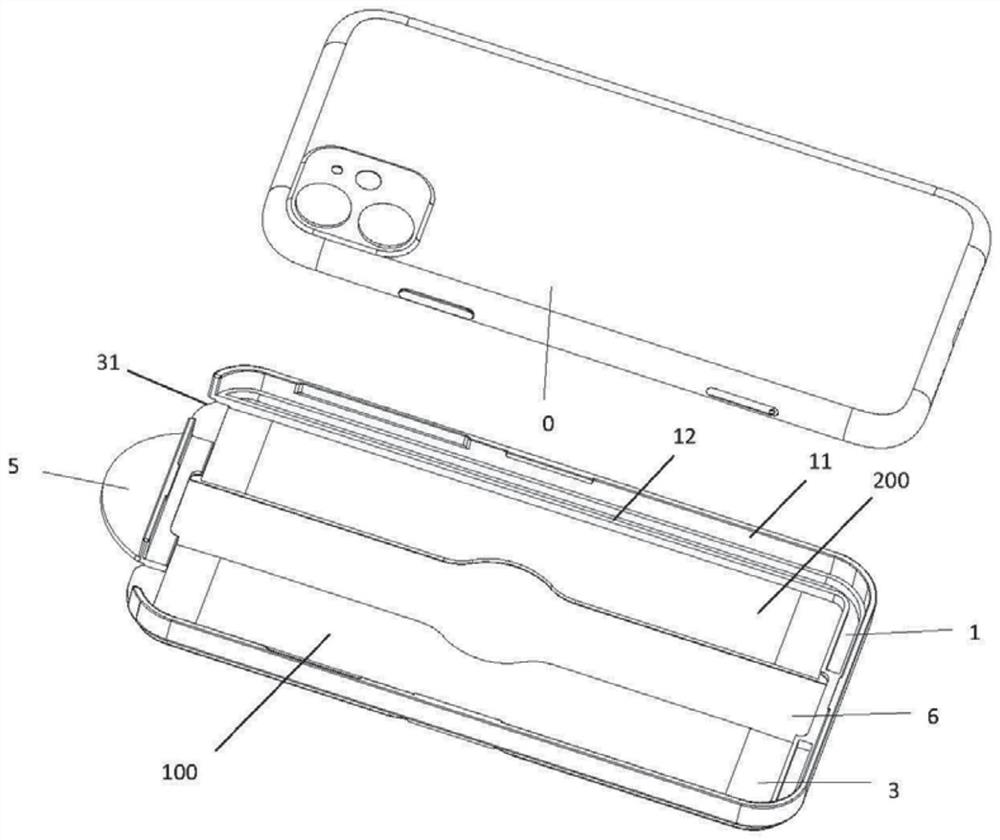

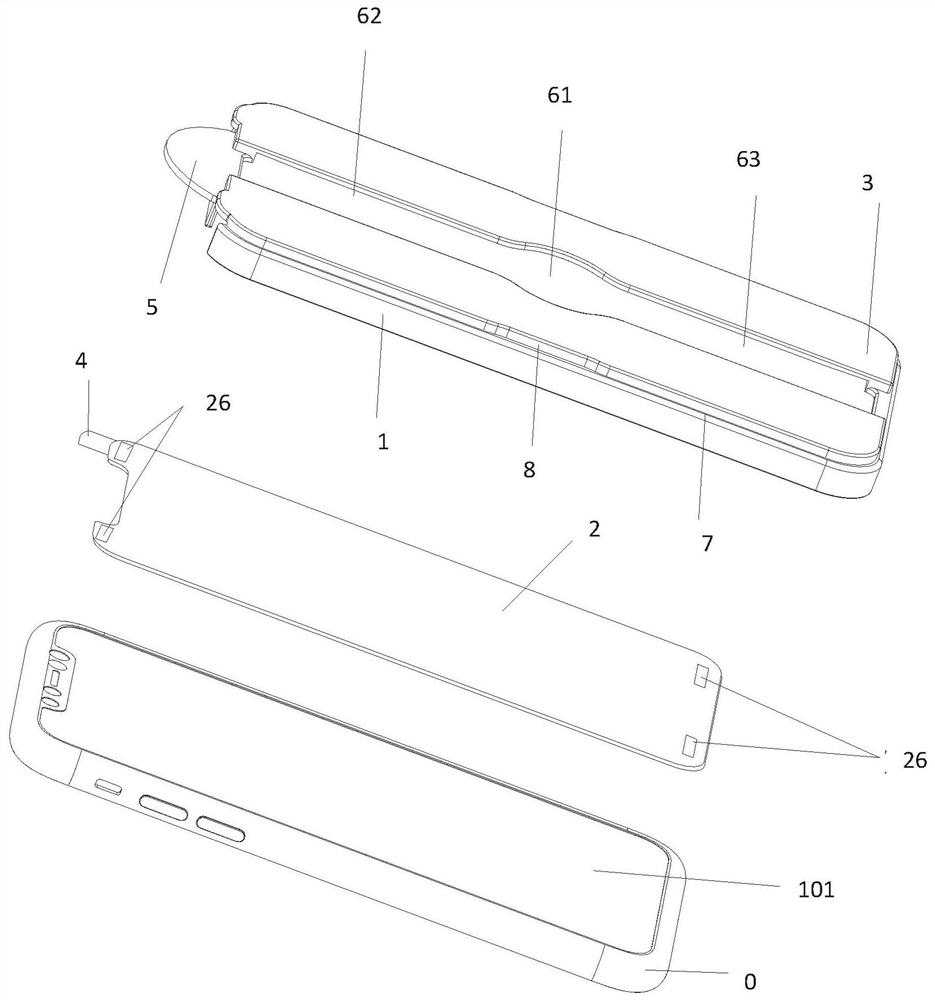

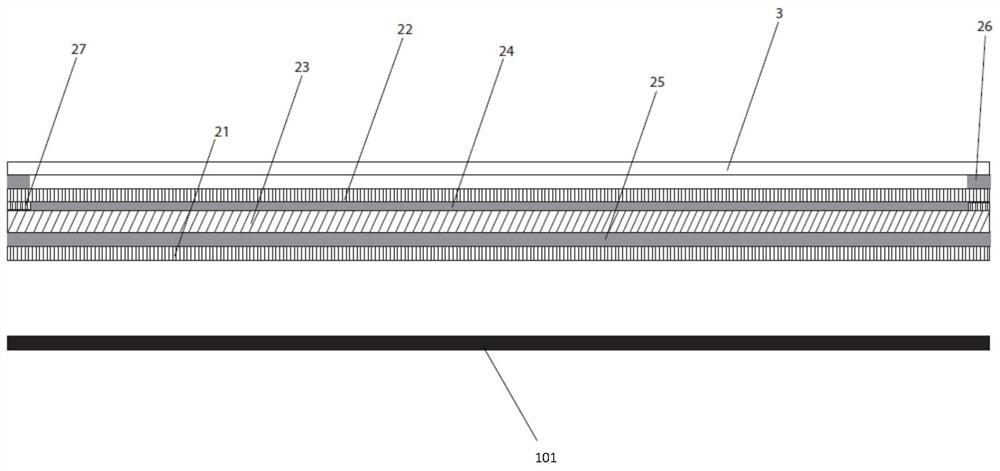

Screen protection film assembly and film sticking device for screen protection film

PendingCN112140523ASimple structureEasy to operateProtective equipmentFilm/foil adhesivesMechanical engineeringScreen protector

The invention belongs to the field of equipment accessories, and discloses a screen protection film assembly and a film sticking device for a screen protection film. The film sticking device comprisesthe screen protection film assembly and a film sticking device tray. The screen protection film assembly comprises a covering layer, a screen protection film layer and a retaining layer. The coveringlayer is adhered to a first surface of the screen protection film layer through a first adhesive layer arranged on the screen protection film layer. The retaining layer is adhered to a second surfaceof the screen protection film layer through a second adhesive layer arranged on the retaining layer. An interlayer is arranged between the retaining layer and the screen protection film layer. The film sticking device for the screen protection film has a simple structure, and can store and protect the screen protection film assembly before the screen protection film layer is sticked on the screen. In the film sticking process of the screen protection film, the operation method is simple and convenient.

Owner:张平

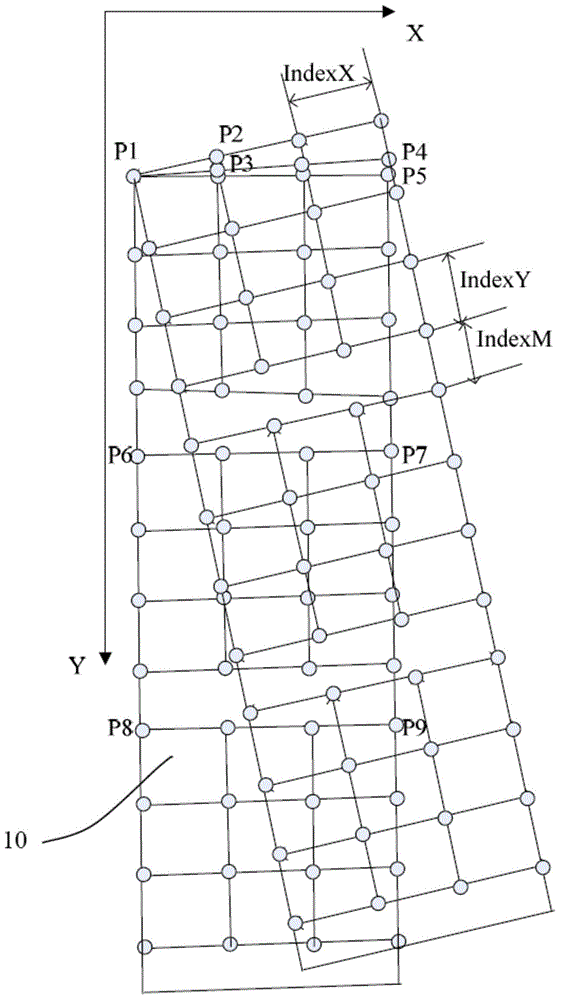

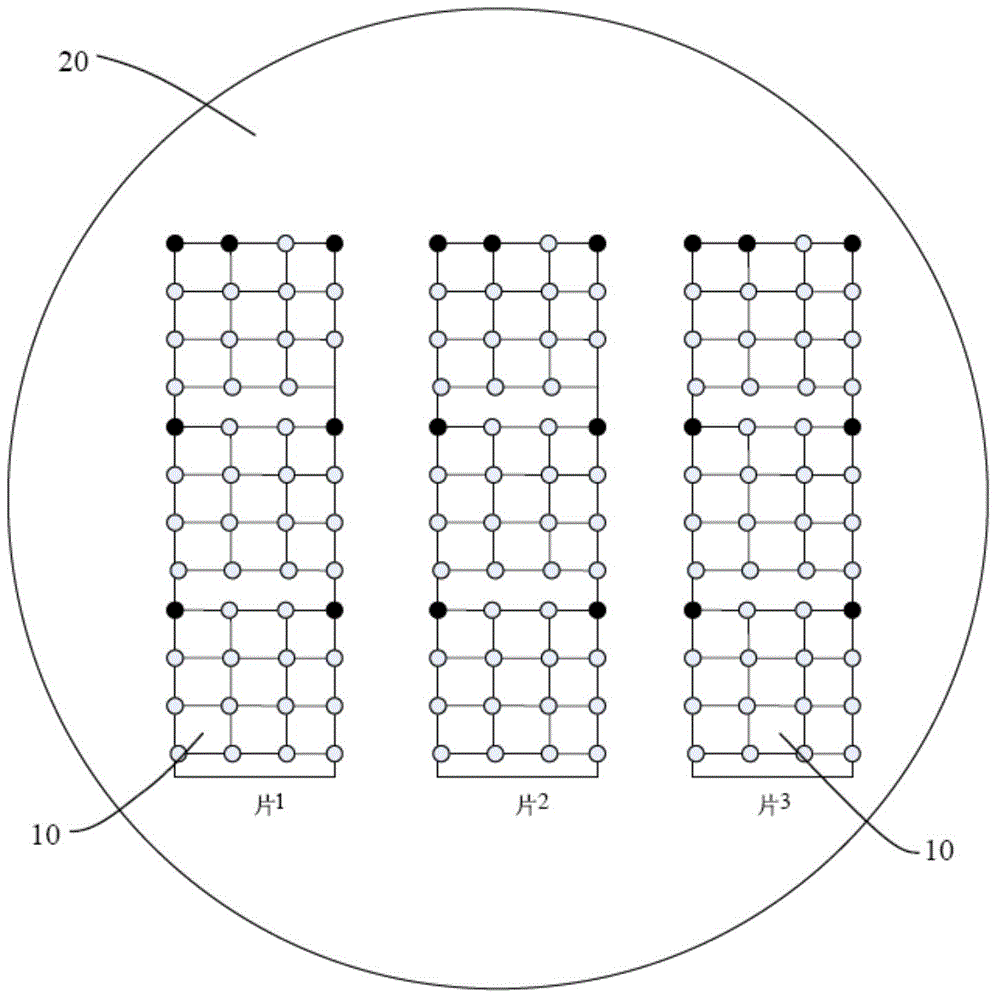

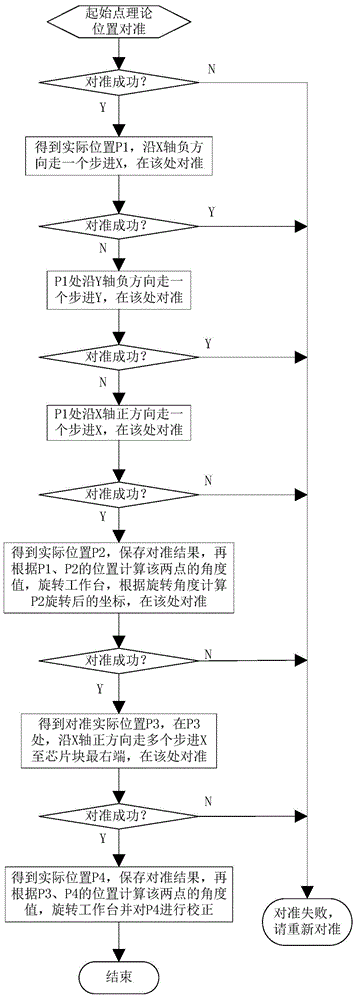

Quad flat no-lead (QFN) package image sheet automatic alignment method

ActiveCN106158686AEnables automatic alignmentImprove alignment accuracySemiconductor/solid-state device testing/measurementComputer sciencePositive direction

The invention provides a quad flat no-lead (QFN) package image sheet automatic alignment method, which is used for a scribing machine to cut chip blocks on a QFN package image sheet. The QFN package image sheet automatic alignment method mainly comprises the following steps: S1) defining X-axis and Y-axis directions, defining stepping X and stepping Y of each chip block in the X-axis direction and Y-axis direction respectively, moving the QFN package image sheet along the X-axis and Y-axis directions to a starting point theoretic alignment position for alignment, and after alignment, obtaining a starting point alignment actual position and defining the starting point alignment actual position as a P1 point; S2) moving from the P1 point along the X-axis positive direction by at least one stepping X and carrying out alignment, obtaining an alignment actual position and defining the alignment actual position as a P2 point, and keeping the alignment result; and S3) calculating angle values of the two points according to the positions of the P1 point and the P2 point, rotating a working platform and calculating the coordinate of the P2 obtained after rotation, and carrying out alignment on the P2 at the coordinate to obtain an alignment actual position and keeping the alignment result.

Owner:SUZHOU VEGA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com