Automatic charge aligning method for robots

A technology of automatic charging and robotics, which is applied in the direction of instruments, current collectors, electric vehicles, etc., can solve the problems of troublesome management of monitoring personnel, low alignment efficiency, and reduced efficiency, so as to reduce human processing time, improve efficiency, and achieve high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

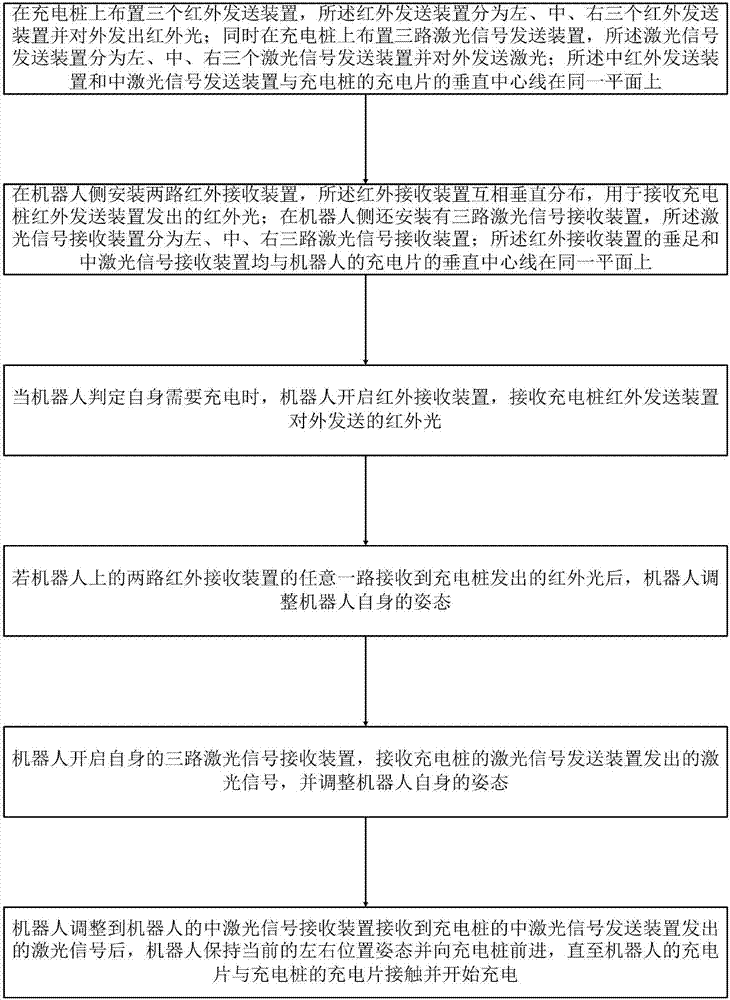

[0027] Such as figure 1 Shown is the method flow chart of the present invention: the robot automatic charging alignment method provided by the present invention includes the following steps:

[0028] S1. Arrange three infrared sending devices on the charging pile. The infrared sending devices are divided into three infrared sending devices: left, middle and right, and emit infrared light to the outside; at the same time, arrange three-way laser signal sending devices on the charging pile. The laser signal sending device is divided into three laser signal sending devices, left, middle and right, and sends laser light to the outside; the mid-infrared sending device and the middle laser signal sending device are on the same plane as the vertical centerline of the charging sheet of the charging pile;

[0029] S2. Install two infrared receiving devices on the side of the robot. The infrared receiving devices are arranged perpendicular to each other and are used to receive the infra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com