Floating electrical connector

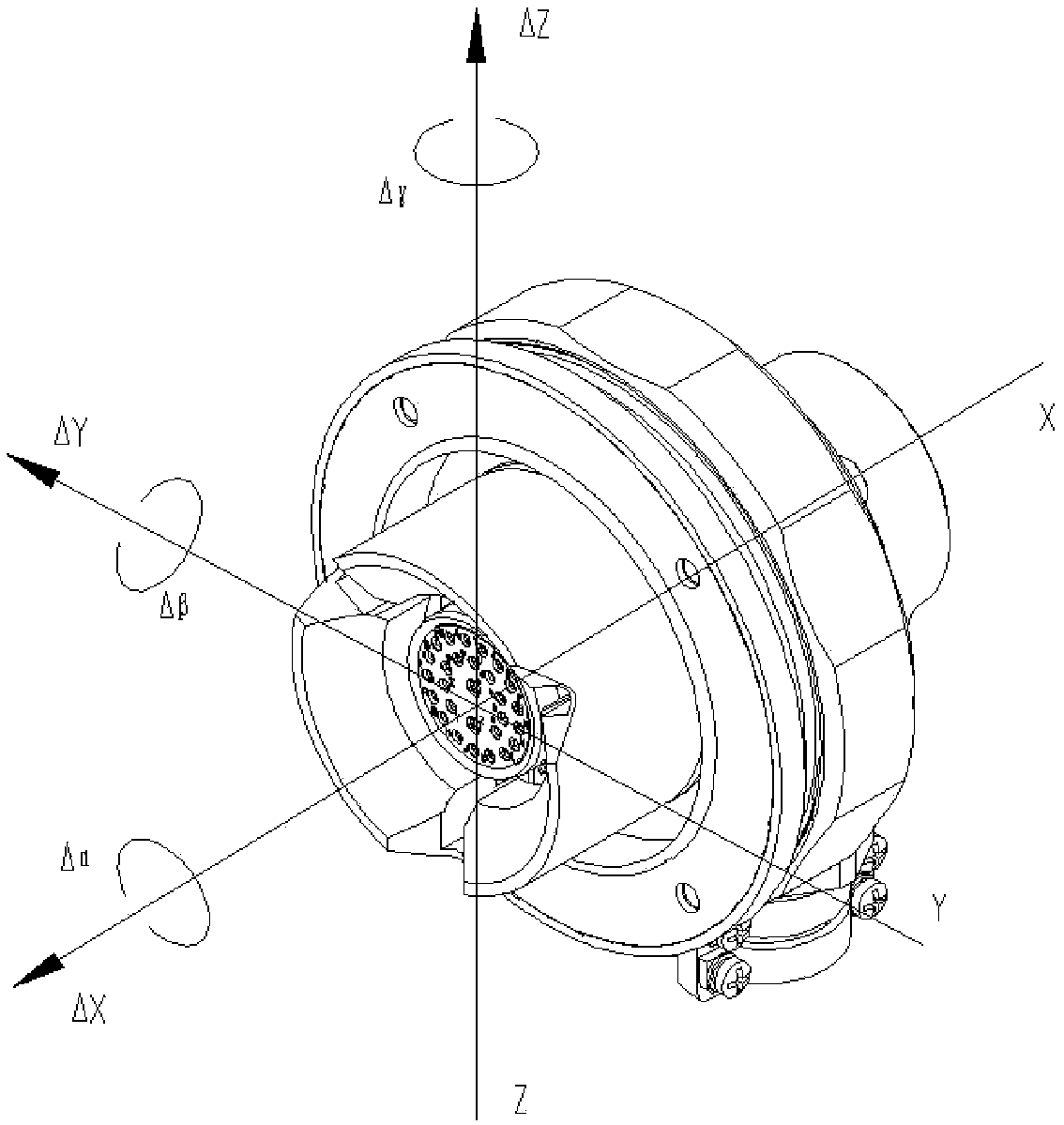

An electrical connector, floating sleeve technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problem of increasing product size and production cost, unable to achieve 360° force, high processing surface requirements, etc. problems, to achieve the effect of compact structure, meeting watertight requirements, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the floating electrical connector may specifically include: a plug and a socket. Wherein, the plug includes: floating sleeve 2 and plug housing 3 ; the socket includes: roller 31 and socket housing 33 .

[0045]The floating sleeve 2 is rigidly fixed to the plug housing 3, and the roller 31 is rigidly connected to the socket housing 33 by riveting; the floating sleeve 2 is provided with guide chamfers and notch chamfers, when the plug is mated with the socket, the floating sleeve 2 The guide chamfers of the socket contact with the socket and advance gradually. The guide chamfers make the plug move axially and radially along the socket to adjust the position and achieve the purpose of alignment; during the mating process of the plug and the socket, the rollers of the socket and the floating The chamfering of the notch on the sleeve 2 contacts, and the floating sleeve 2 drives the plug housing to rotate along the socket to achieve the mating rough guide...

Embodiment 2

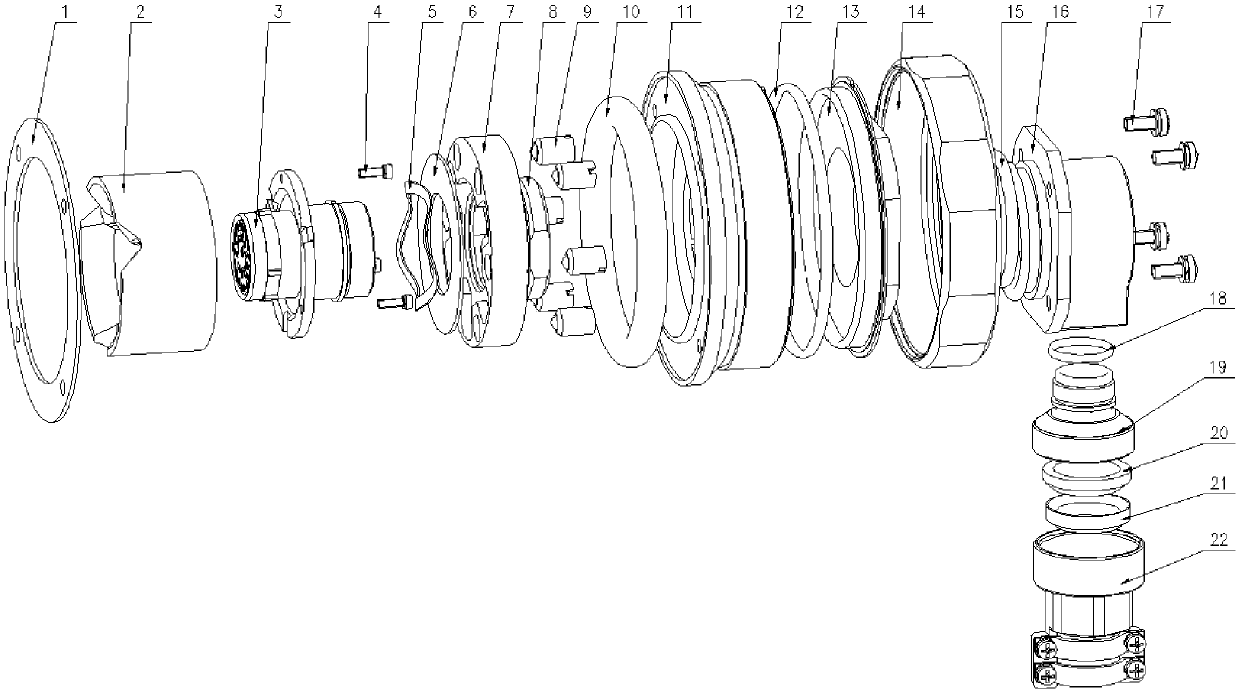

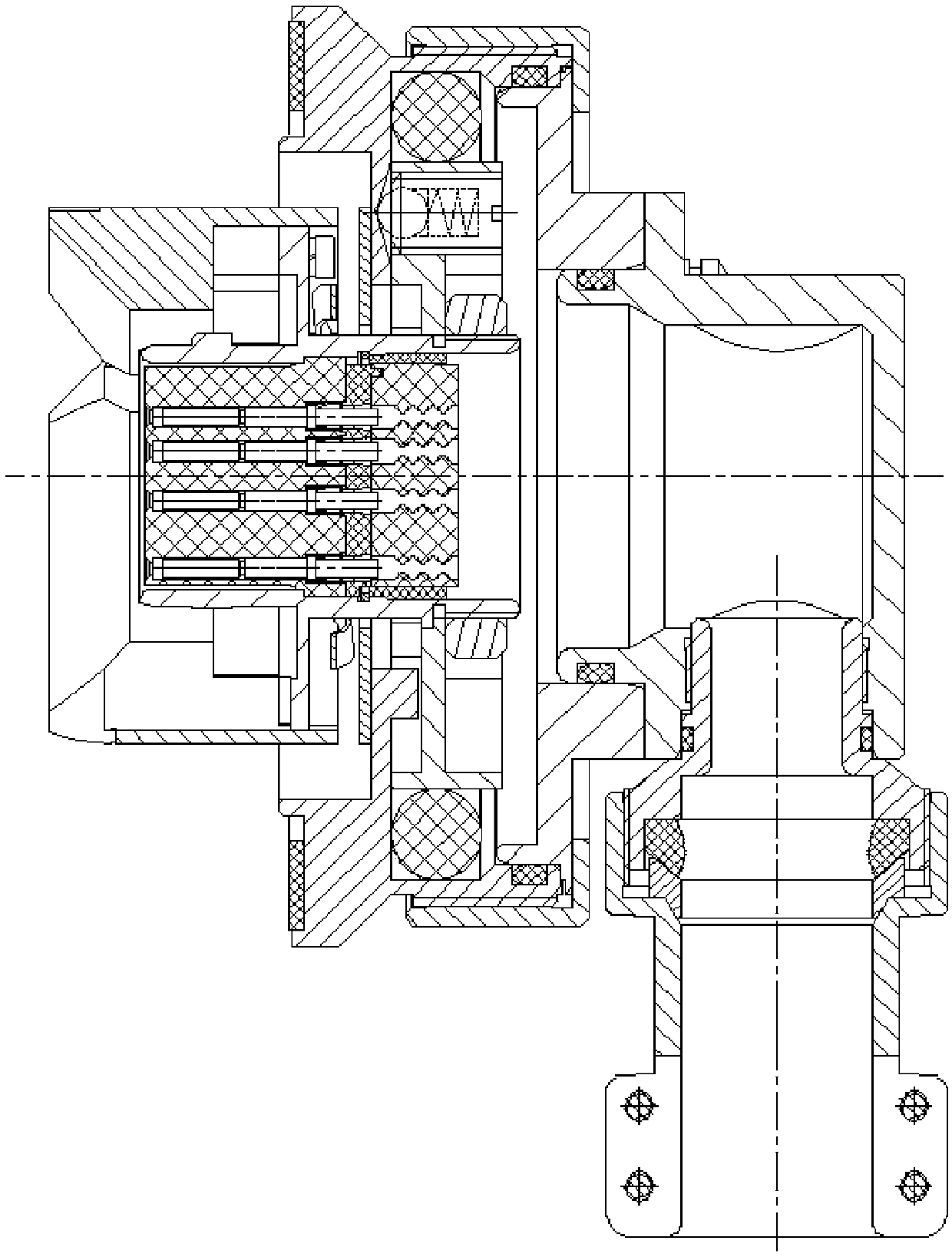

[0047] Such as Figure 2-6 , The plug can also include: a wave reed 5, a ball plunger 9, a rubber piece 10, a plug housing fixing frame 7, a tightening ring 8 and a plug cable cover fixing frame 11.

[0048] The wave reed 5 is arranged between the plug housing 3 and the plug housing fixing bracket 7; the ball plunger 9 is assembled on the plug housing fixing bracket 7 through screw fit; the plug housing fixing bracket 7 is connected with the plug housing 3 The rib groove structure between them is positioned, and is rigidly fixed on the plug housing 3 through the tightening ring 8; the plug cable cover fixing frame 11 is assembled between the wave reed 5 and the plug housing fixing frame 7, and the plug cable cover fixing frame 11 The fixed frame 7 of the plug housing is limited by the groove structure, and the fixed frame 11 of the plug cable cover is provided with a pit structure uniformly distributed on the circumference; the rubber part 10 is assembled under the fixed frame...

Embodiment 3

[0054] Such as Figure 7-9 , The socket may also include: a socket cable cover 35, a screw III 36, a socket tail cover connecting ring 38 and a socket tail cover 311. The socket cable cover body 35 is assembled with the socket housing 33 through screw III 36; the socket tail cover connecting ring 38 is assembled with the socket cable cover body 35 through threaded connection; the socket tail cover connecting ring 38 and the socket tail cover 311 are threaded.

[0055] Preferably, the socket may further include: O-ring IV 32 , O-ring V 34 , O-ring VI 37 , socket waterproof sealing ring 39 and socket pressure sleeve 310 . O-ring IV 32 is set at the front end of socket housing 33; O-ring V 34 is radially sealed between socket cable cover 35 and socket housing 33; O-ring is used between socket cable cover 35 and socket tail cover connecting ring 38 Ring Ⅴ 37 is radially sealed; the socket tail cover connecting ring 38 and the socket tail cover 311 are equipped with a socket water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com