Patents

Literature

863results about How to "High communication rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Illuminative light communication device

InactiveUS7583901B2Possible to separateWeaken influenceTransmission/receiving by modifying power source wavePoint-like light sourceMultiplexingSignal on

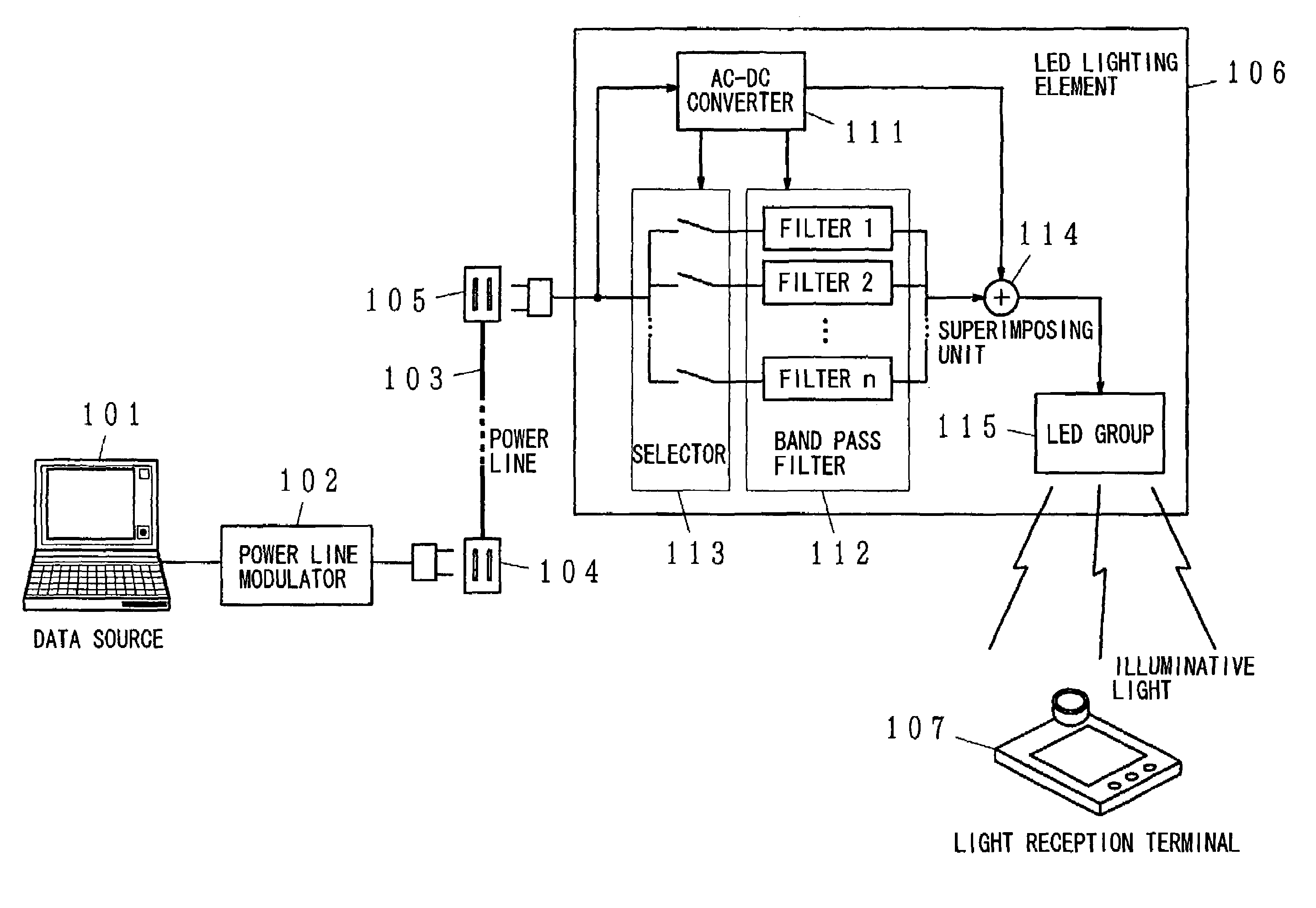

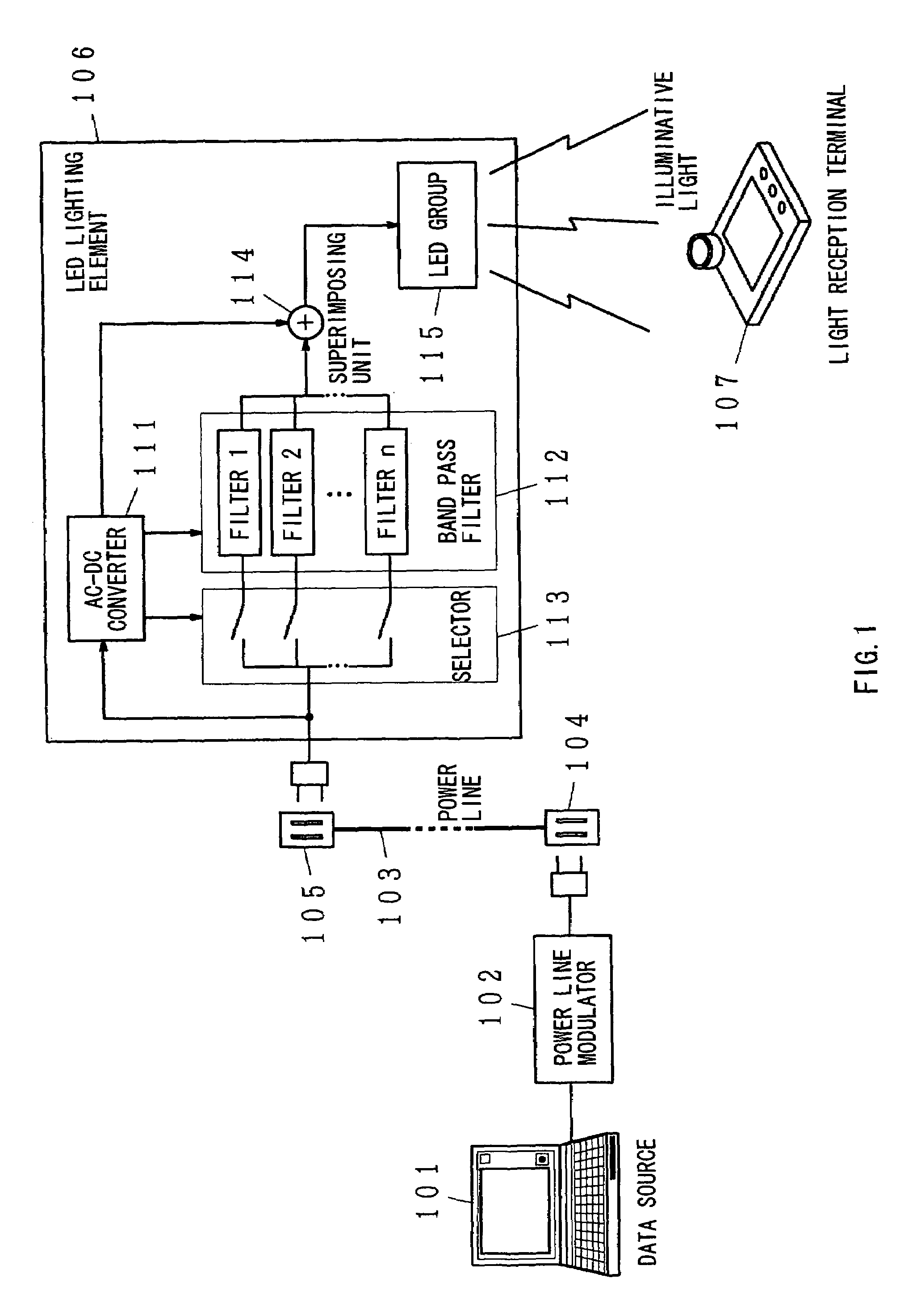

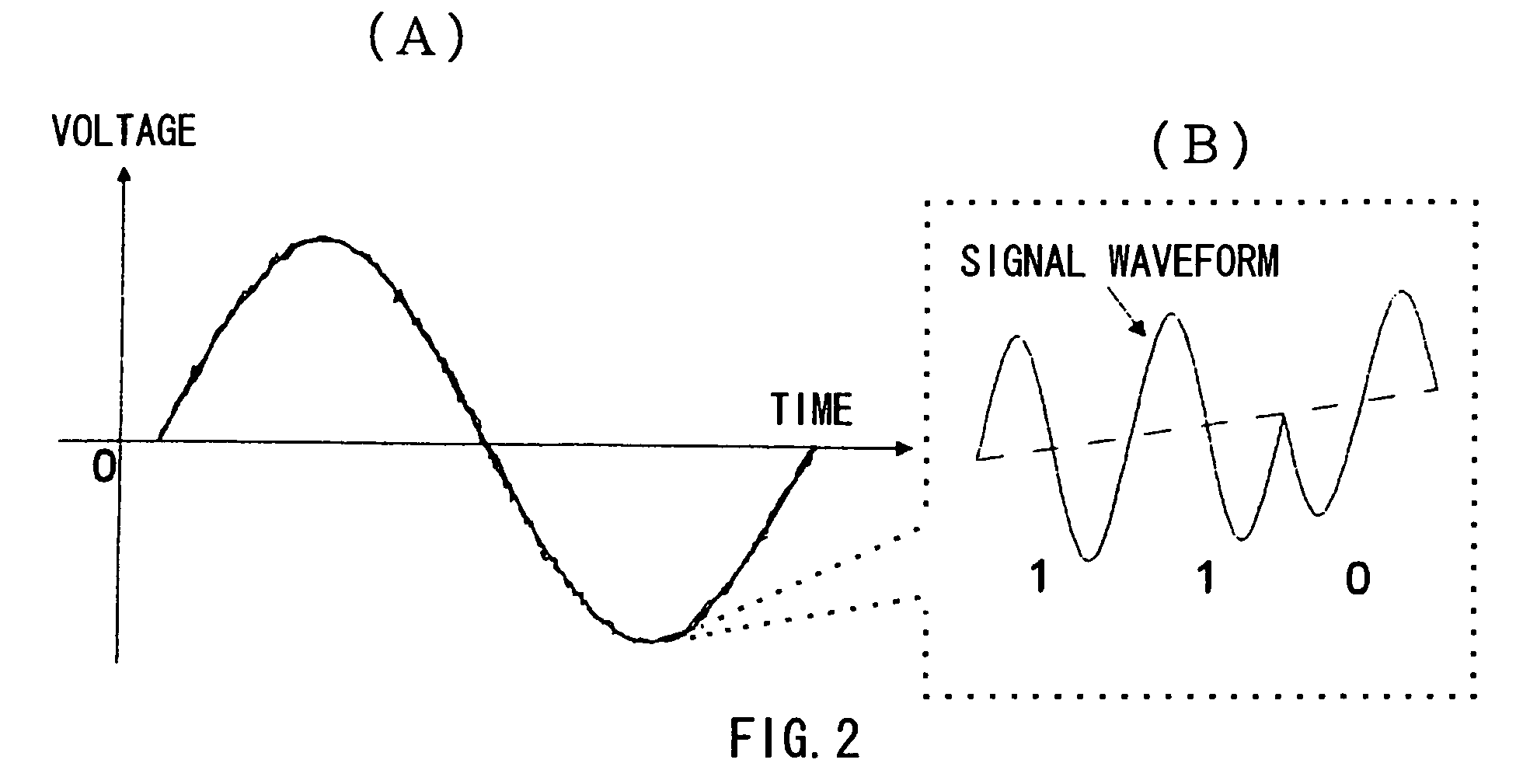

The present invention has been developed considering the above-described problems and aims to provide various structures and applications for illuminative light communication. According to the first aspect of the prevent invention, a broadcast system includes an LED light source 115 for lighting, a power line 103 that supplies electric power to the LED light source 115, a data modulator 102 that modulates and multiplexes a plurality of pieces of data, superimposes the resulting signal on an electric power waveform, and then transmits the resulting superimposed signal waveform to the power line 103, and a filter 112 that selectively separates one or more of a plurality of pieces of modulated data on the power line so as to control light intensity or blinking of the LED light source. Data is transmitted through changes in light intensity or blinking of the LED light source.

Owner:ICHIMARU

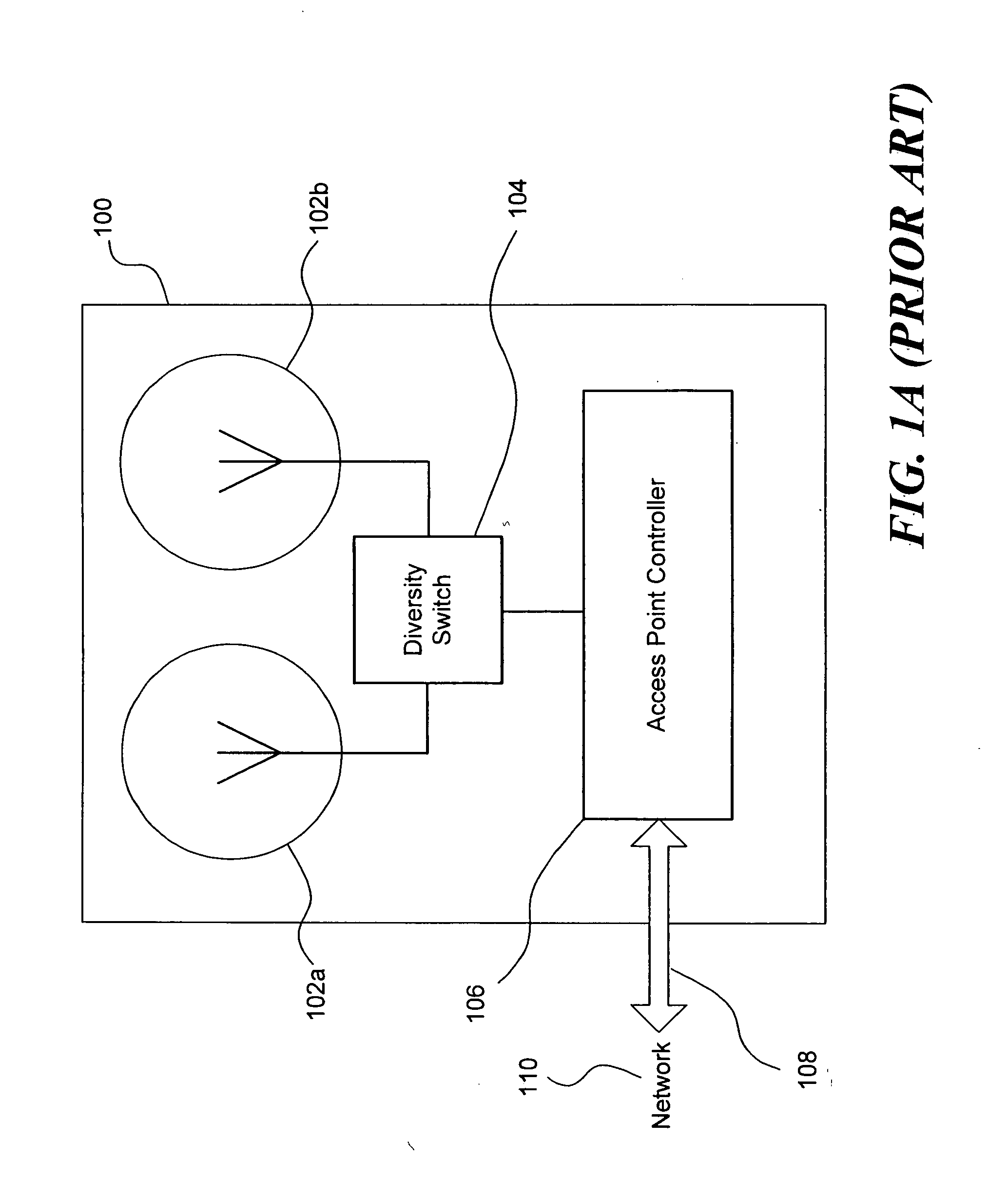

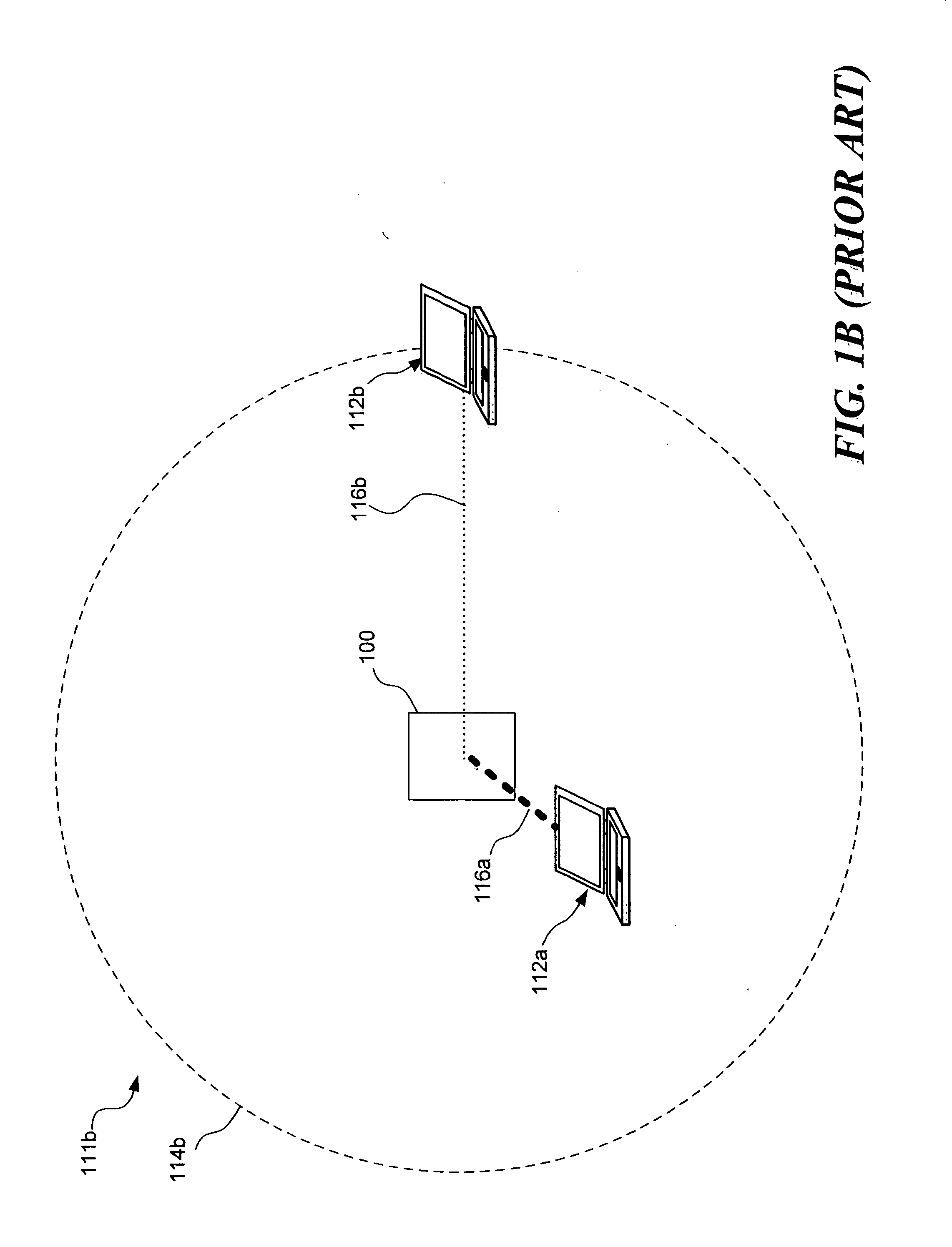

Multi-access system and method using multi-sectored antenna

InactiveUS20060172711A1Increased gainFast communication rateDiversity/multi-antenna systemsTransmission noise suppressionOmnidirectional antennaClient-side

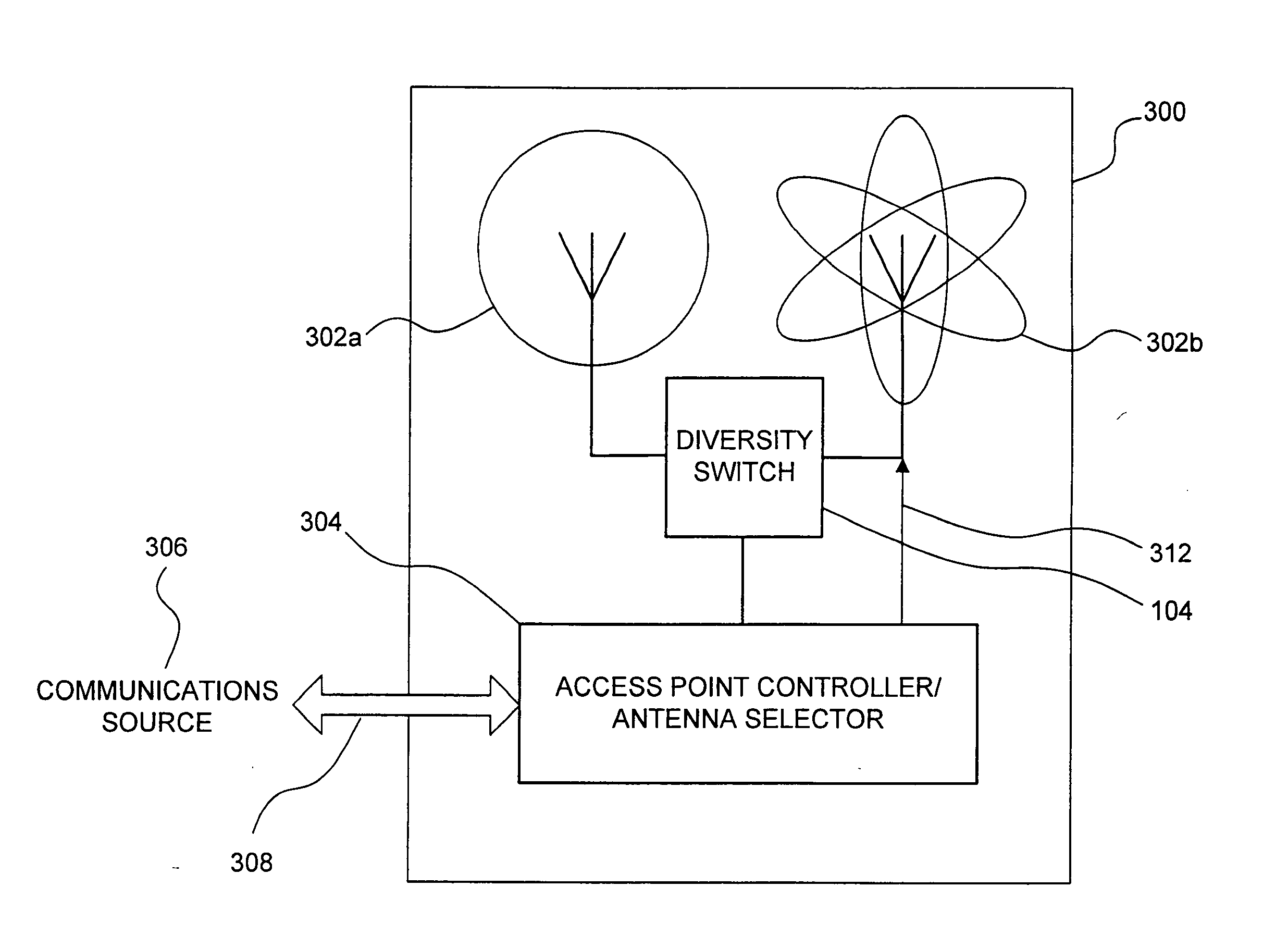

A wireless access point is equipped with both an omnidirectional antenna and a directable antenna that can be selectively directed to any of a plurality of directional spaces overlapping the network space served by the omnidirectional antenna. The directable antenna is directed to an optimal directional space for a client when the access point is communicating with the client at a high data rate. The access point can intermittently exchange information with other clients using the omnidirectional antenna. The omnidirectional antenna enables broadcast signals to be transmitted to any client in the entire network space, but at a lower data rate. A preferred data rate and an optimal client directional space are re-determined periodically or as necessary based on parameters such as the data rate, signal strength, and rate of success in communicating data.

Owner:MICROSOFT TECH LICENSING LLC

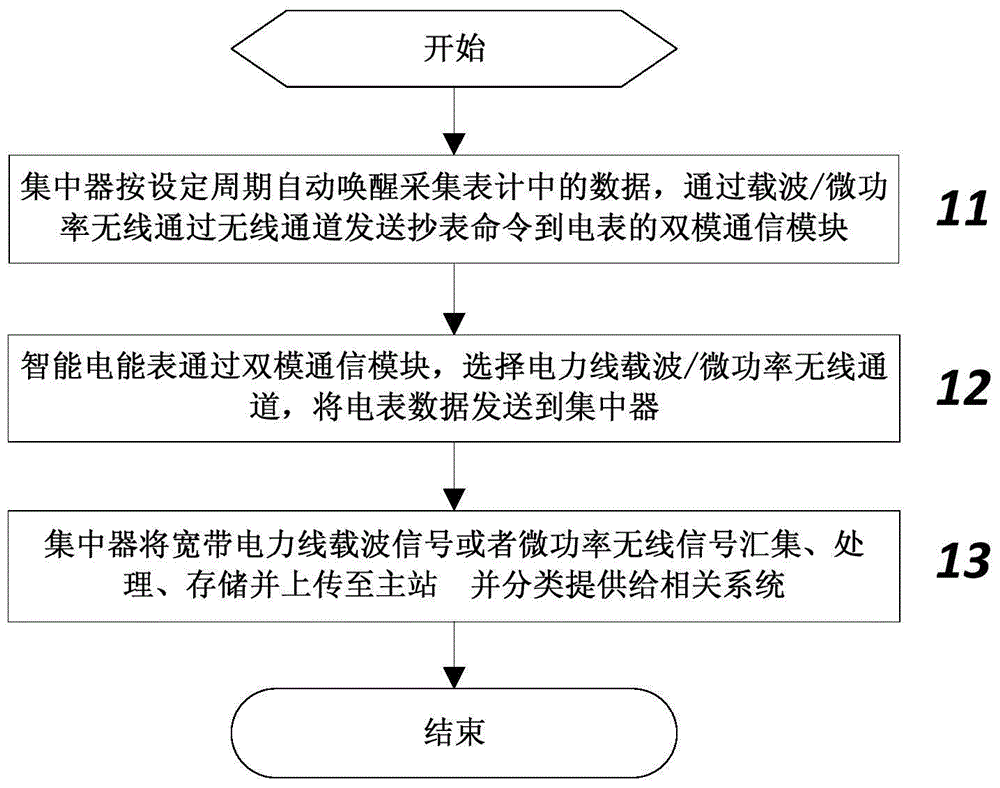

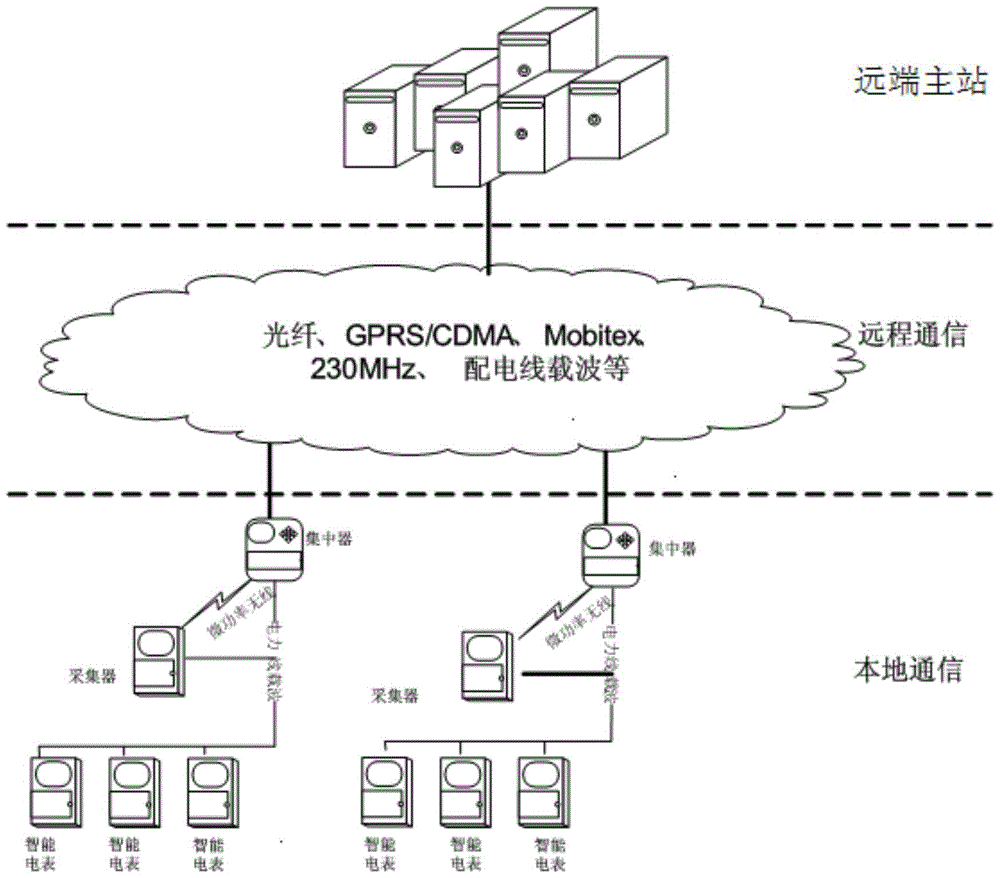

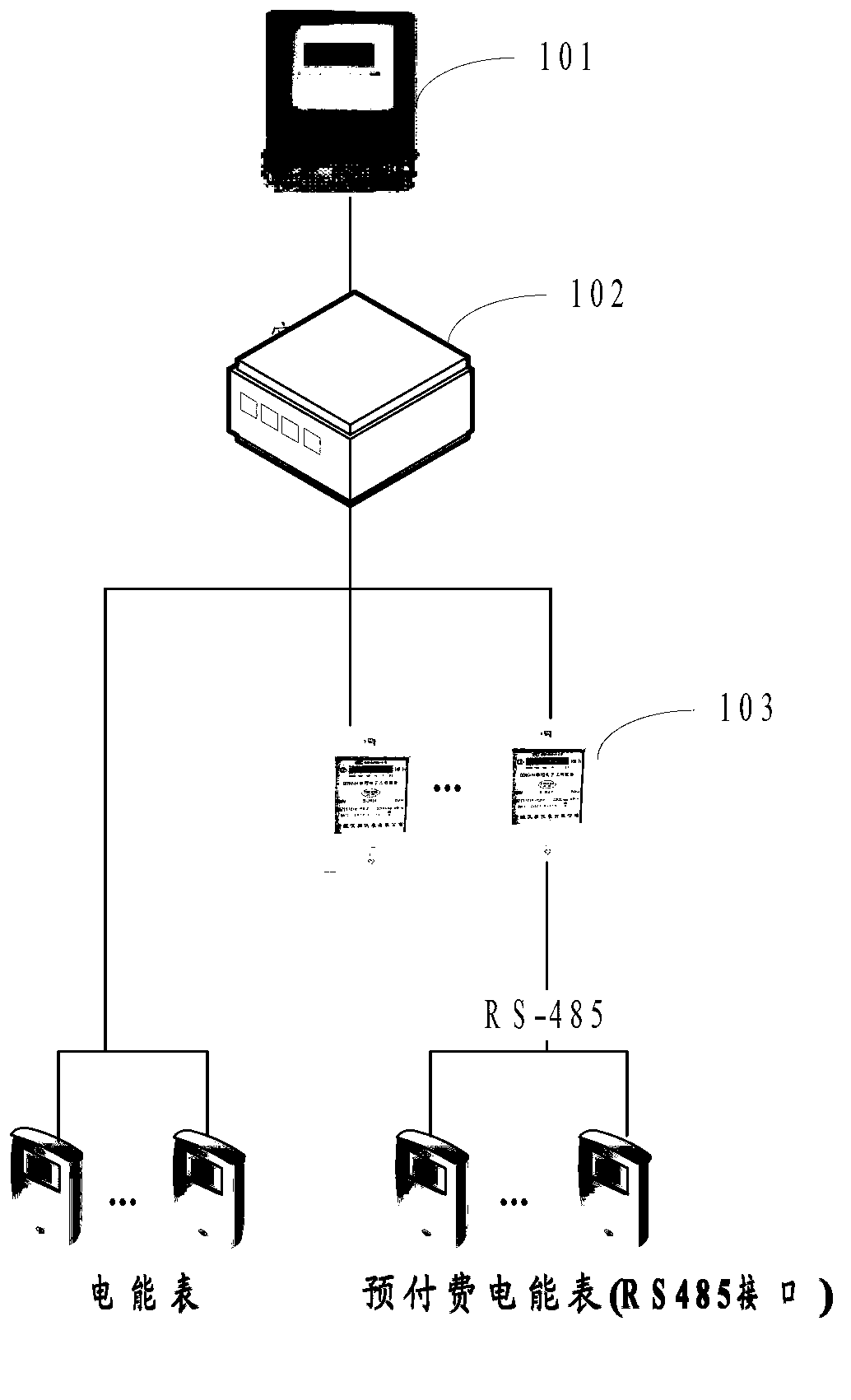

Electricity information acquisition system based on dual-mode communication and method thereof

InactiveCN105788206AImprove reliabilityEasy to implementElectric signal transmission systemsSingle useAutomatic control

The invention discloses an electricity information acquisition system based on dual-mode communication and a method thereof; the system includes a far-end master station, a concentrator and an intelligent electric energy meter; the far-end master station is used for acquisition and management of system electric power user electricity information through various wired or wireless communication channels, and is used for data exchange with the concentrator through a remote communication module; the concentrator is provided with a dual-mode communication module, and is used for acquiring intelligent electric energy meter data information and operation states through the dual-mode communication module, achieving local acquisition and monitoring of the electricity information, and uploading the local electric meter data information to the far-end master station through the remote communication module; the intelligent electric energy meter is provided with a dual-mode communication module and is responsible for electricity information measurement, data processing, real-time monitoring, automatic control and information exchange. The communication problem generated when a fault occurs due to single use of a micro power wireless or power line is avoided, the consumed power of a dual-mode communication chip is reduced, and the reliability of the communication is ensured.

Owner:ELECTRIC POWER SCI RES INST OF JIANGSU ELECTRIC POWER +2

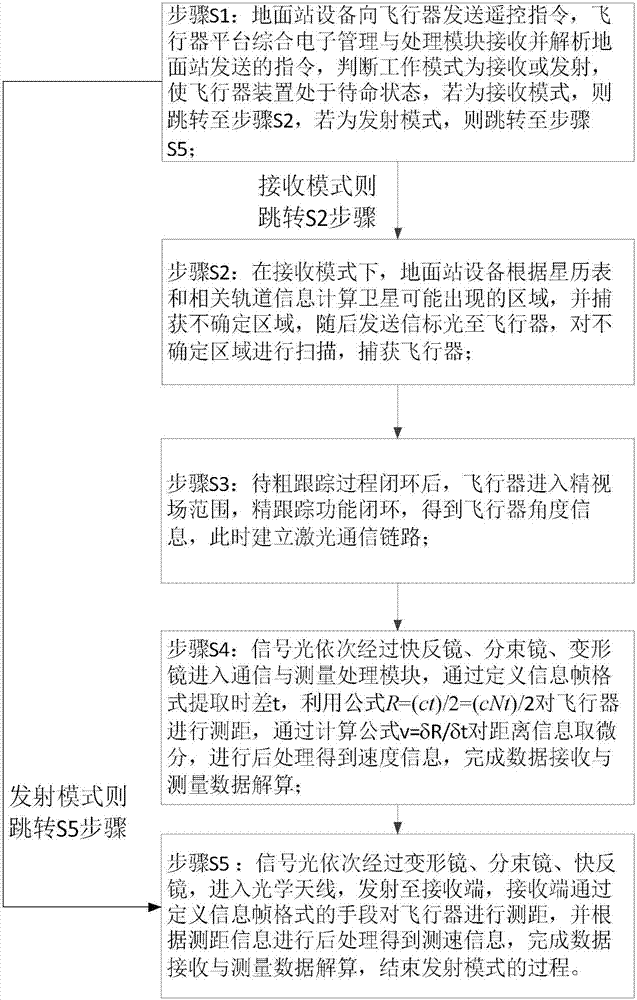

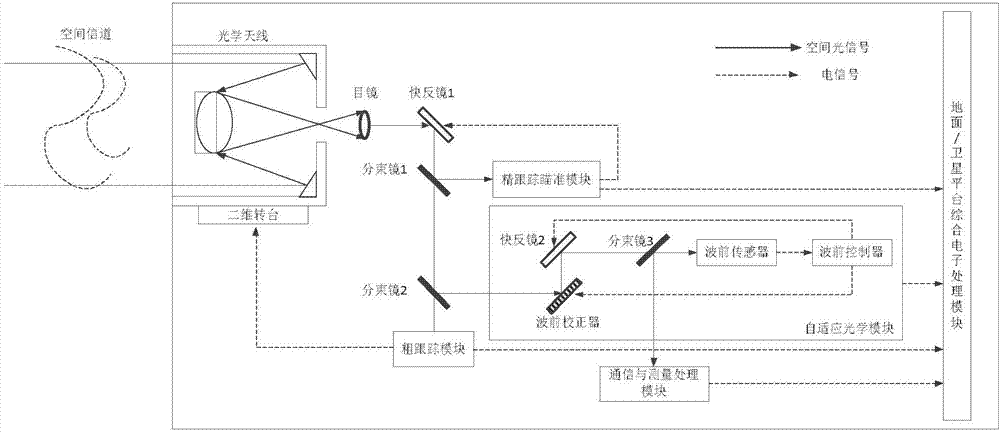

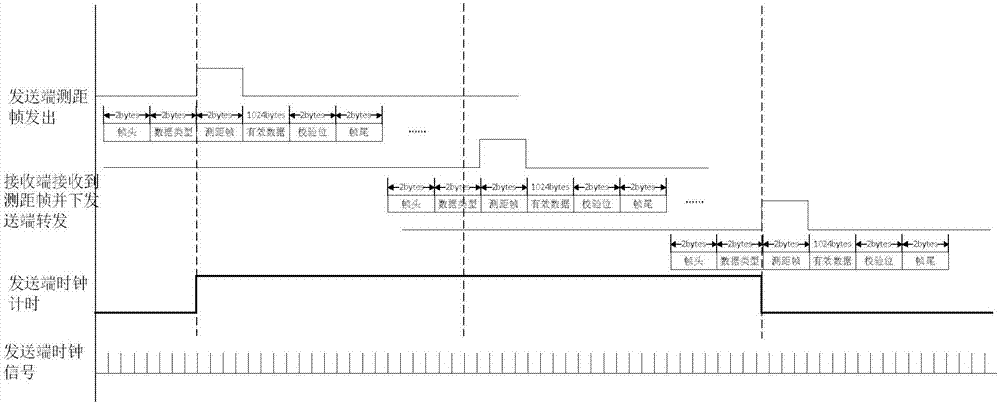

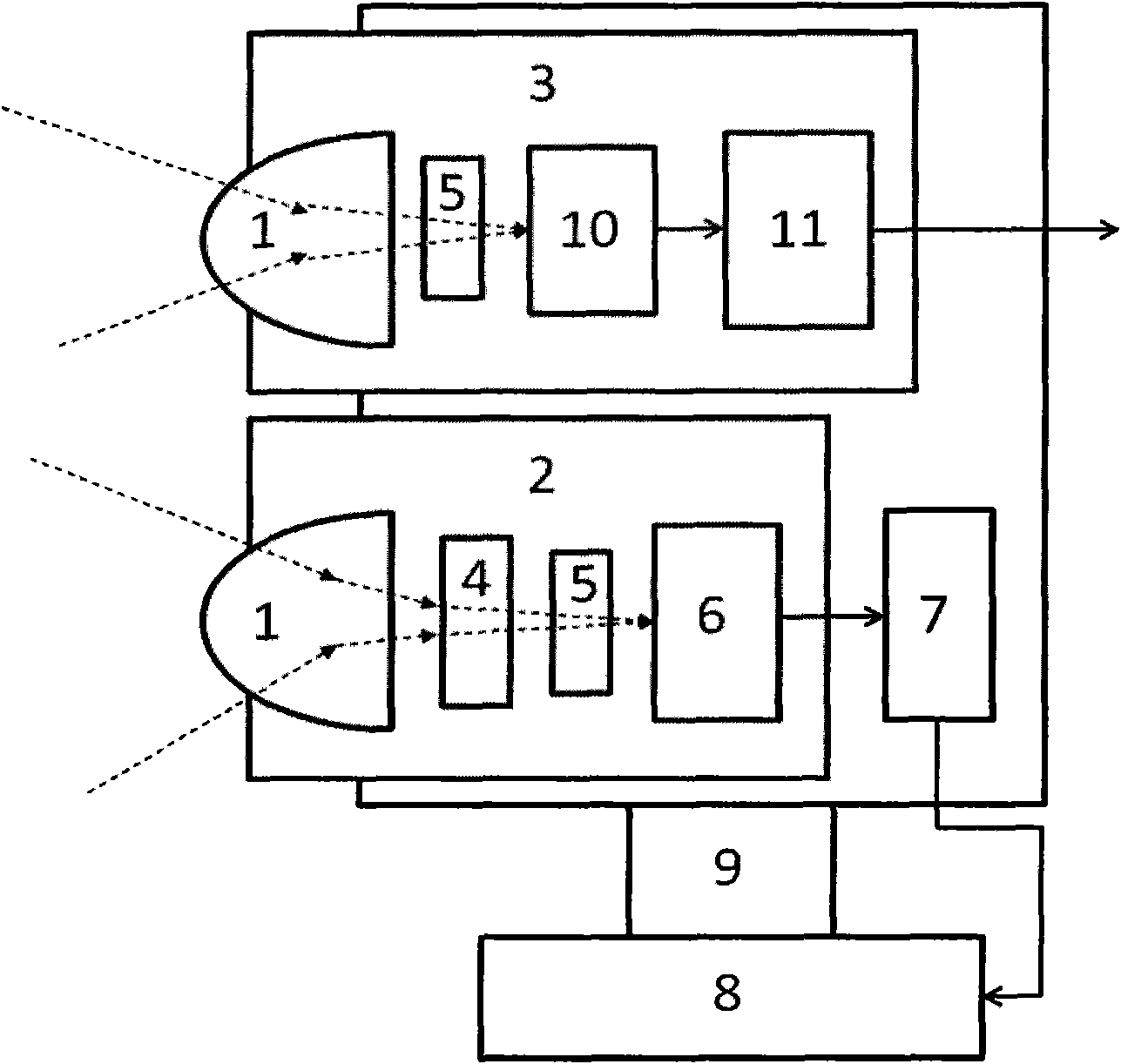

Laser link communication-measurement composite system

InactiveCN106911381AIncrease profitReduce weightOptical rangefindersFree-space transmissionTelecommunications linkBeam splitter

The invention discloses a laser link communication-measurement composite system. Through adoption of the laser link communication-measurement composite system, the payload weight, size and power consumption can be lowered. The laser link communication-measurement composite system is implemented by the following technical scheme: an optical antenna transmits a comprehensive optical signal to a rapid reflecting mirror through an eye lens at a transmitting end; reflected light splits a light beam of the comprehensive optical signal into two paths through a beam splitter; one path is transmitted into another beam splitter through the beam splitter to transmit the light beam into a coarse tracking module in order to extract a target position coarse miss distance, and a control voltage is applied to a two-dimensional turntable according to an embedded control algorithm; the other path of comprehensive optical signal is introduced into the field range of a fine tracking module through the beam splitter, and transmitted into the fine tracking module to extract a target position fine miss distance, the overall offset of fine field light spots is controlled, the light spots are introduced into the center of a fine tracking field to obtain target angle information, and the extracted target position fine miss distance is transmitted into a ground / satellite platform comprehensive electronic management and processing module to finish target capture and an aiming function and establish a communication link.

Owner:10TH RES INST OF CETC

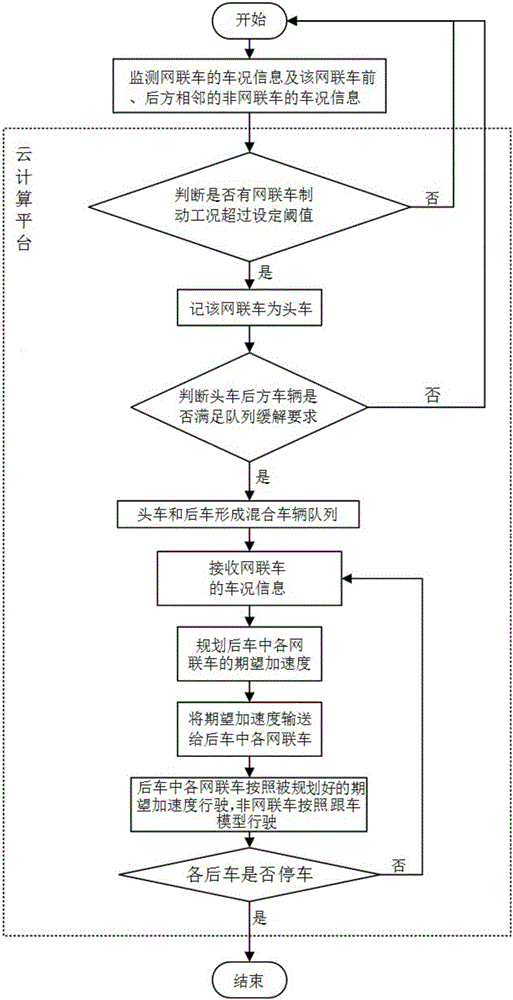

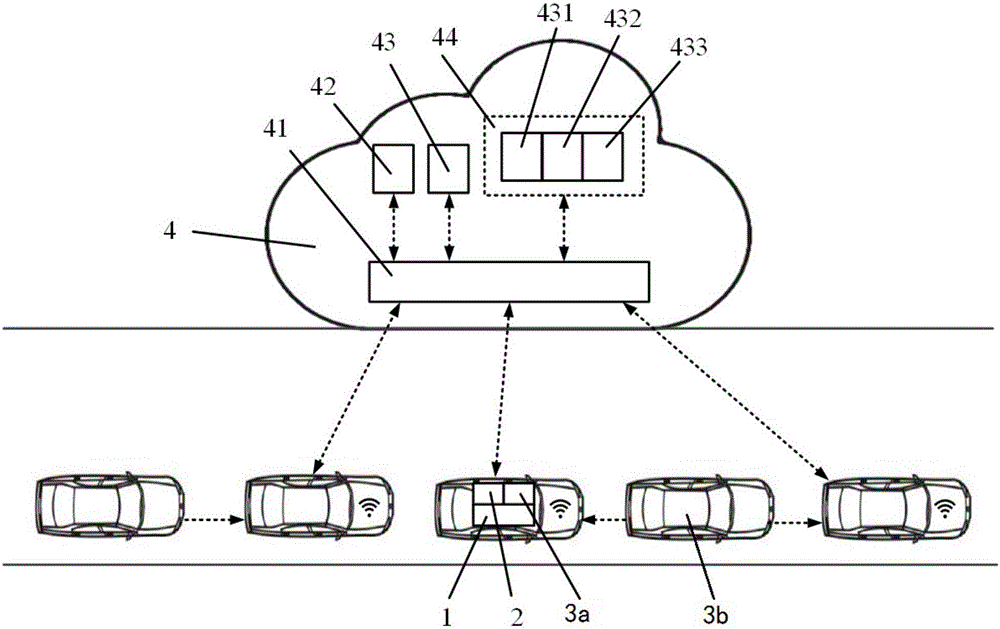

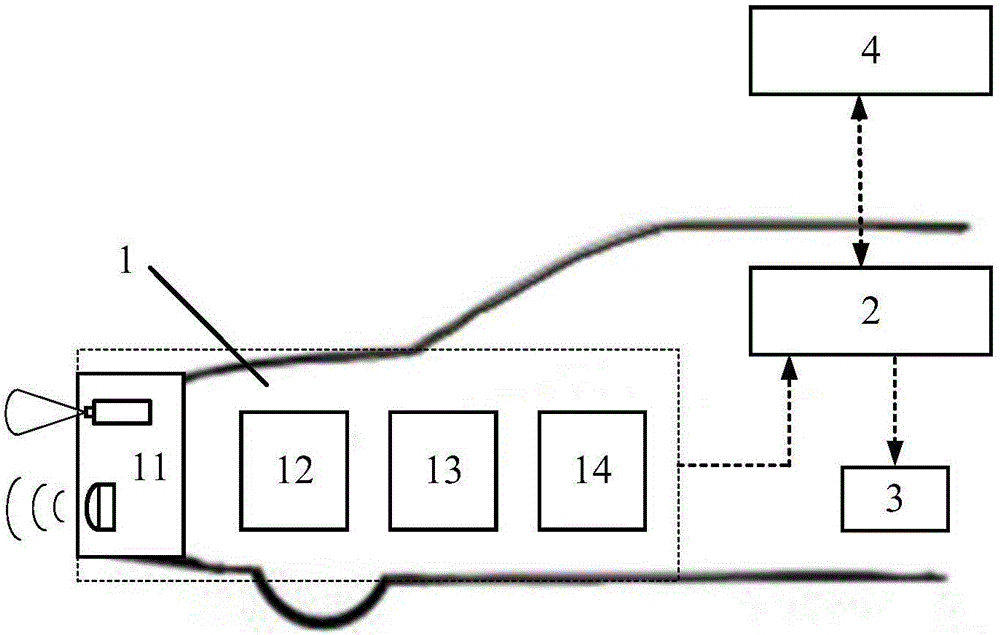

Collision relieving method and device between vehicles in hybrid vehicle queue

ActiveCN105774800AImprove access delayHigh communication rateTransmissionNetwork connectionHybrid vehicle

The invention discloses a collision relieving method and device between vehicles in a hybrid vehicle queue. The collision relieving method between the vehicles in the hybrid vehicle queue includes the following steps that firstly, vehicle condition information of the network-connection vehicles and vehicle condition information of the non-network-connection vehicles in front of and behind the network-connection vehicles are acquired; secondly, the head vehicle and the rear vehicles in the hybrid vehicle queue are sequentially judged, if the corresponding network-connection vehicle is the head vehicle or the rear vehicles, the third step is executed, and if the corresponding network-connection vehicle is neither the head vehicle nor the rear vehicles, the first step is executed again, wherein the head vehicle is the network-connection vehicle with the braking working condition exceeding a set threshold value, and the rear vehicles are vehicles meeting the queue collision relieving requirement behind the head vehicle; thirdly, the vehicle condition information of the network-connection vehicles is received; fourthly, the expected acceleration of each network-connection vehicle in the rear vehicles is planned; fifthly, each network-connection vehicle in the rear vehicles travels according to the planned expected acceleration, and the each network-connection vehicle in the rear vehicles travels according to a vehicle following mode; and sixthly, whether each of the rear vehicles is parked or not is judged, if certain rear vehicles are parked, control is stopped, and if no rear vehicles are parked, the third step is executed again. By the adoption of the method and device, the braking space between the vehicles in the hybrid vehicle queue can be used for control.

Owner:TSINGHUA UNIV

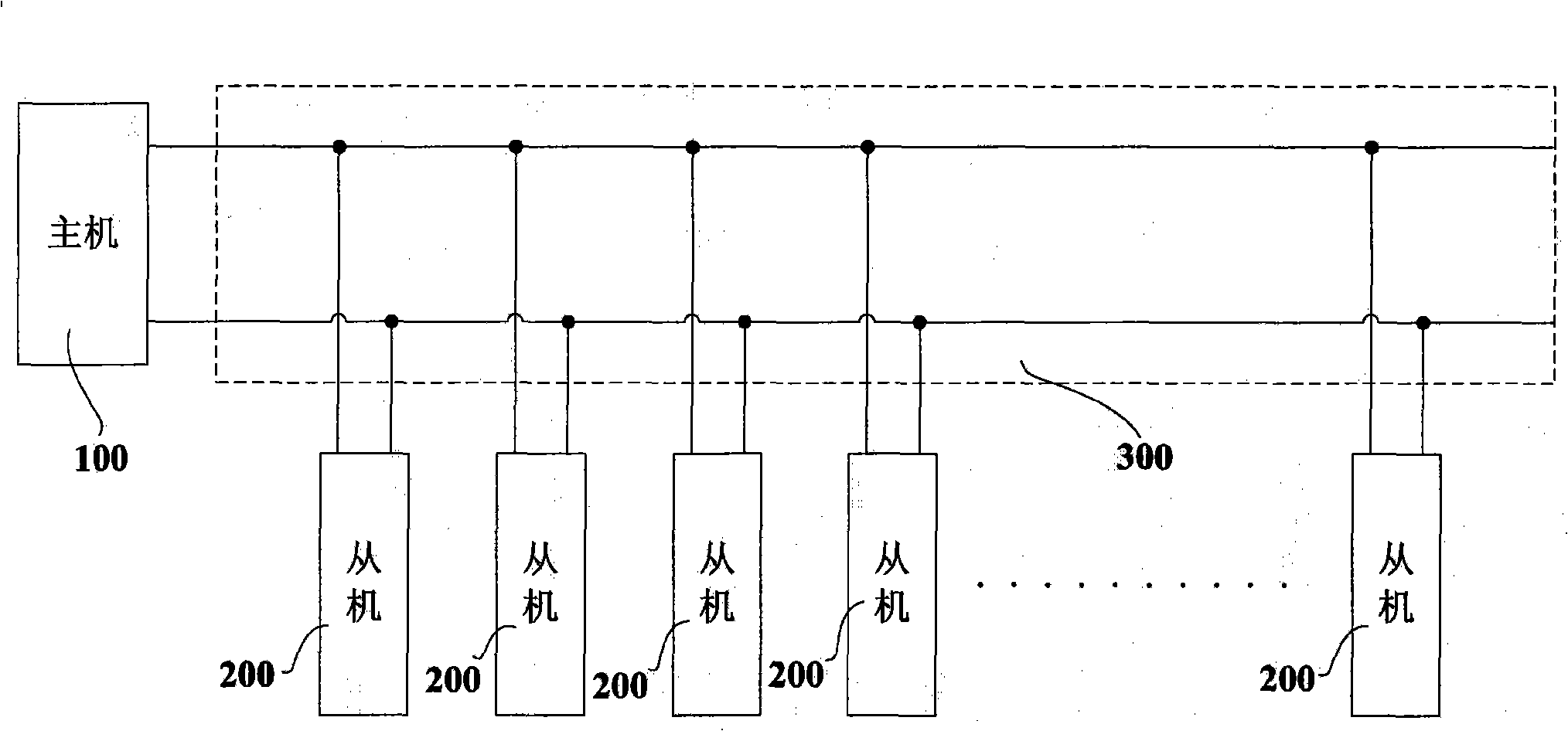

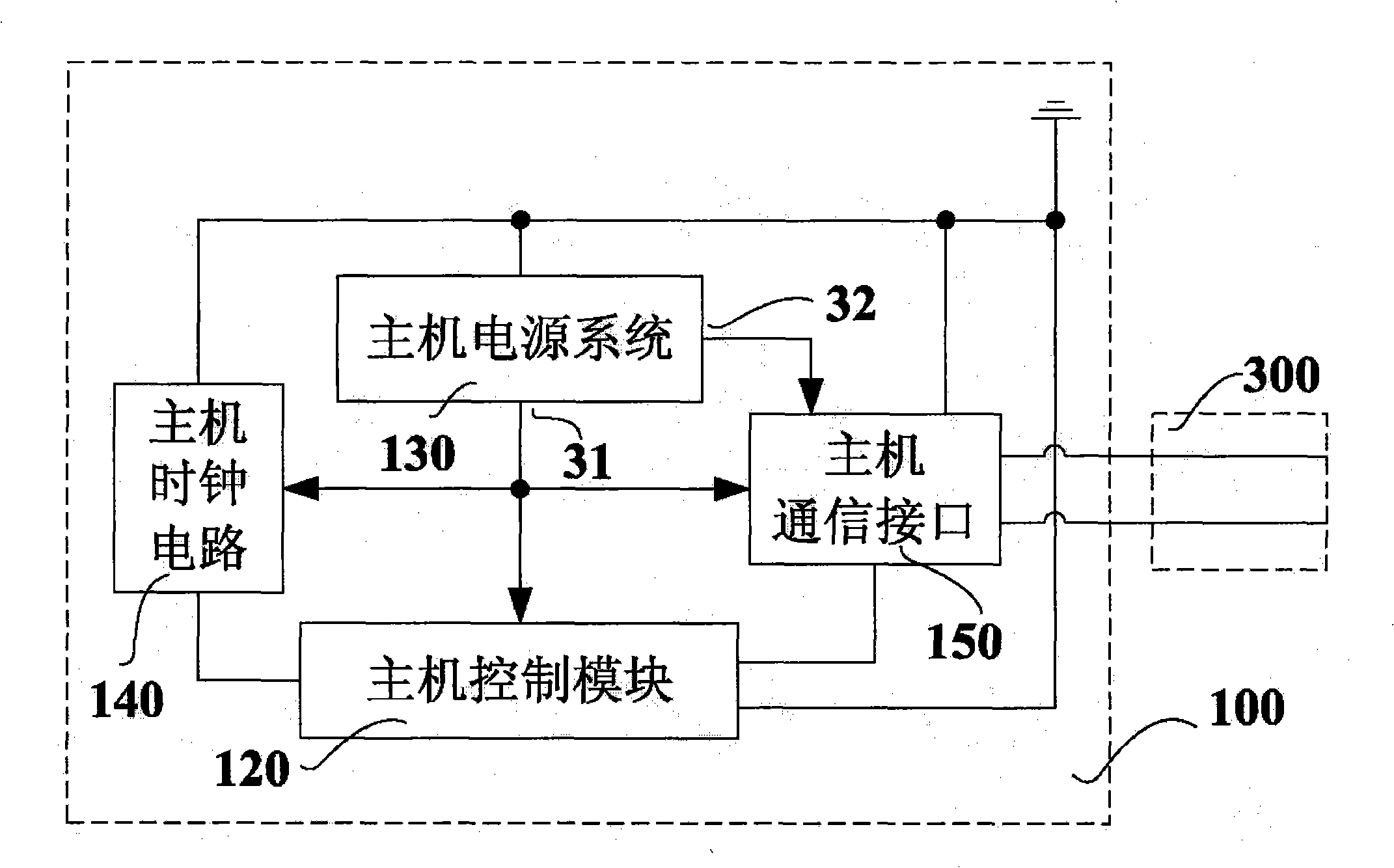

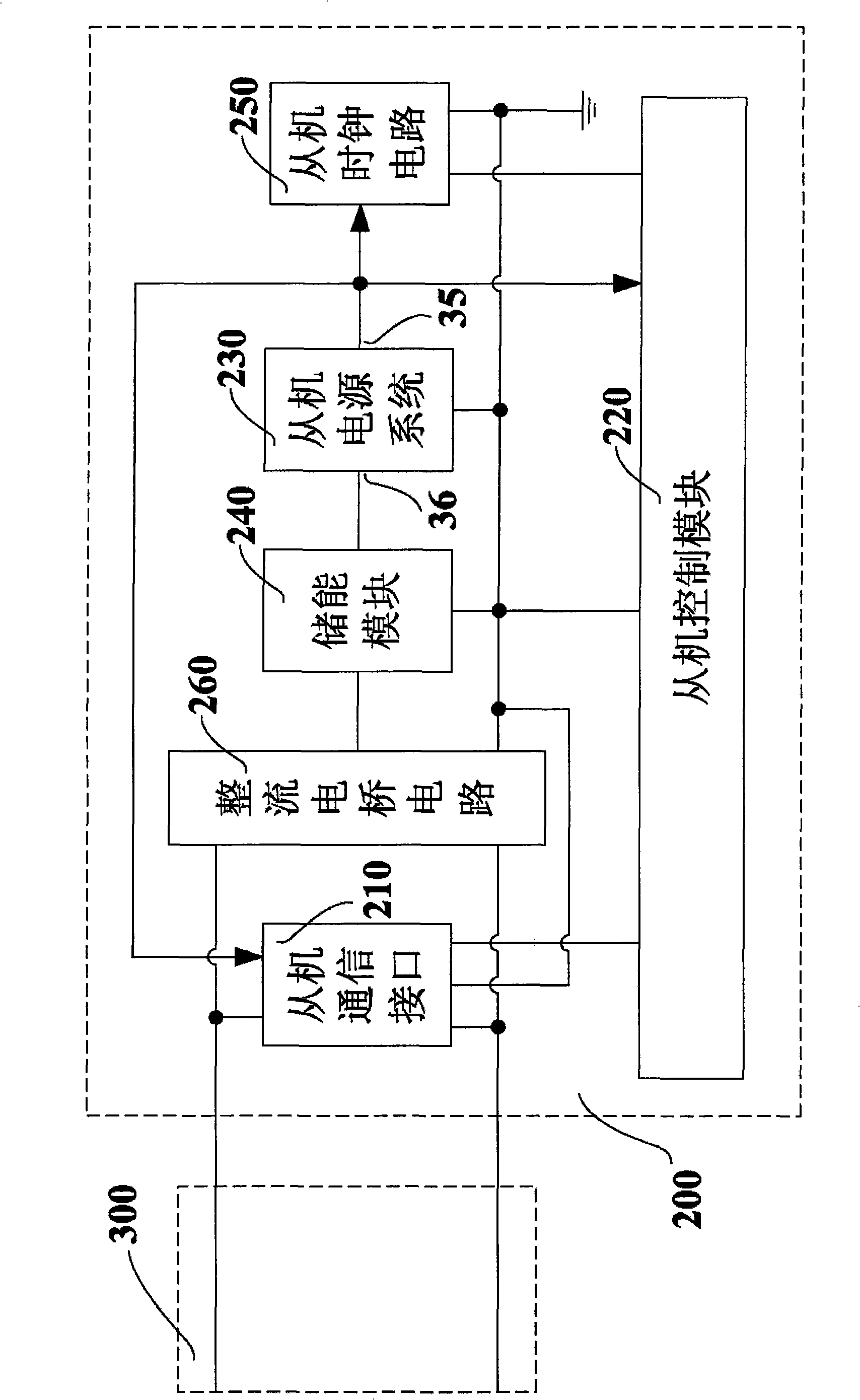

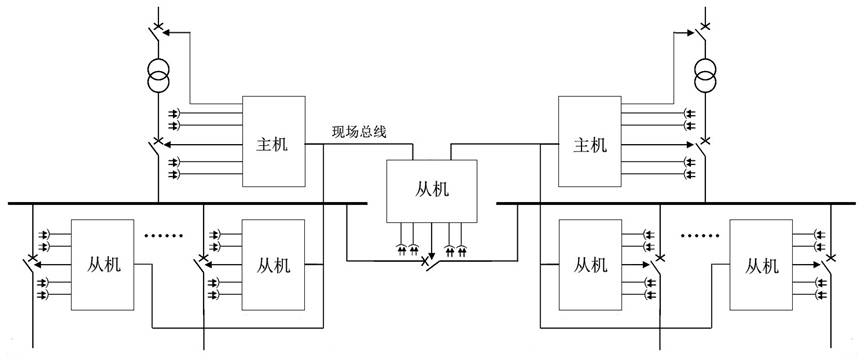

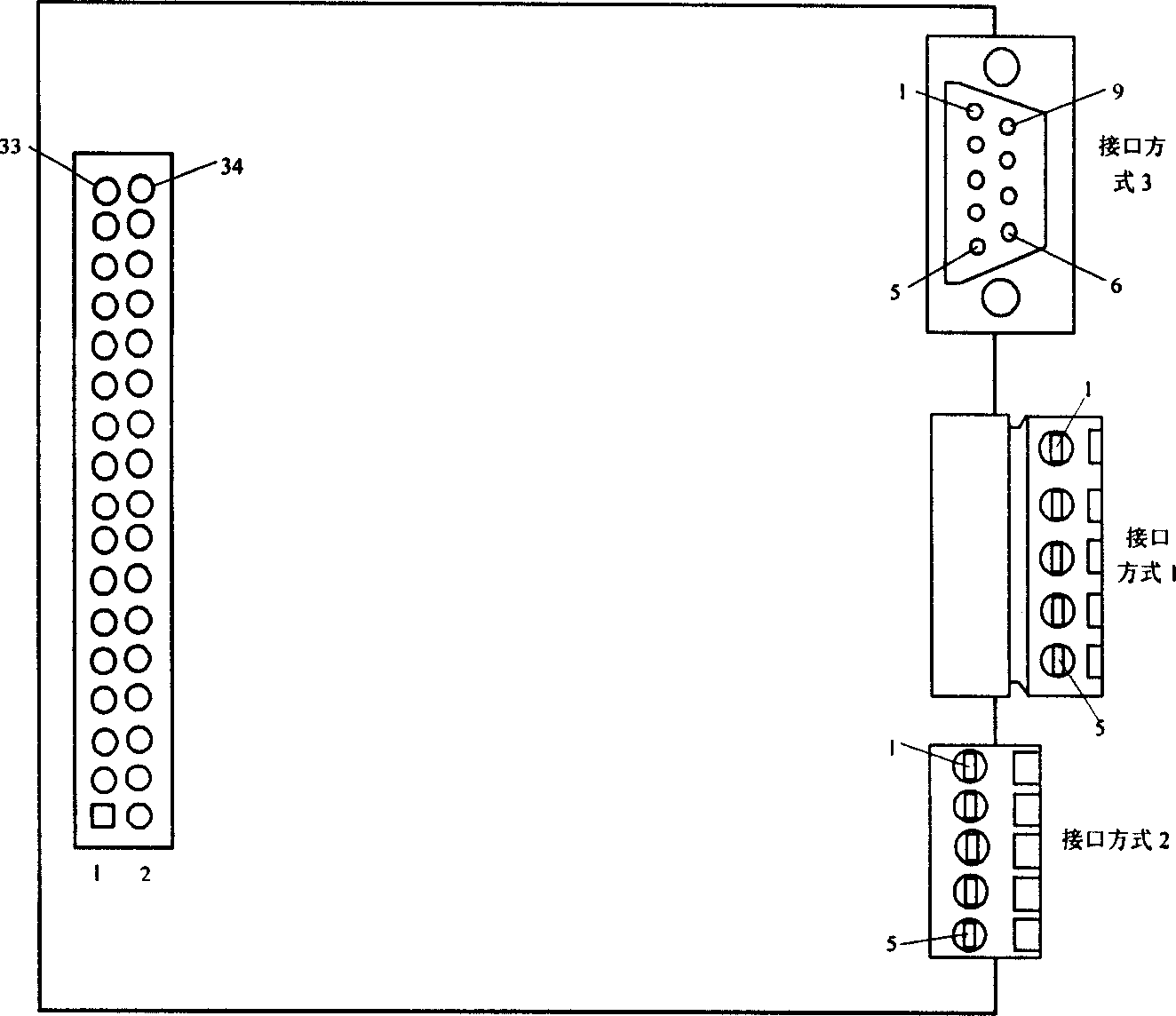

Master-slave mode direct current carrier communication system and its control flow

ActiveCN101404521AAvoid influenceImprove reliabilityPower distribution line transmissionTotal factory controlDetonatorEngineering

The invention provides a master-slave mode DC carrier communication system; wherein, a master machine comprises the clock circuit of the master machine, the power system of the master machine, the communication interface of the master machine and the control module of the master machine; a slave machine comprises the communication interface of the slave machine, a rectifier bridge circuit, an energy storage module, the power system of the slave machine, the clock circuit of the slave machine and the control module of the slave machine. The master machine can be the initiation device of an electronic detonator; the slave machine can be the electronic detonator. A unipolarity communication interface consisting of a unipolarity data modulating module and a unipolarity data demodulating module or a bipolar communication interface consisting of a bipolar date modulating module and a bipolar data demodulating module can be selected as the communication interface of the master machine; the communication interface of the slave machine can comprise the data modulating module and the data demodulating module of the slave machine. The invention also provides a control method for the master machine and the slave machine in the system. The technical scheme realizes the bidirectional data alternation between the master machine and the slave machine when the master machine supplies a working power to the slave machine, thereby improving the maintainability of the system.

Owner:南通炜天电子科技有限公司

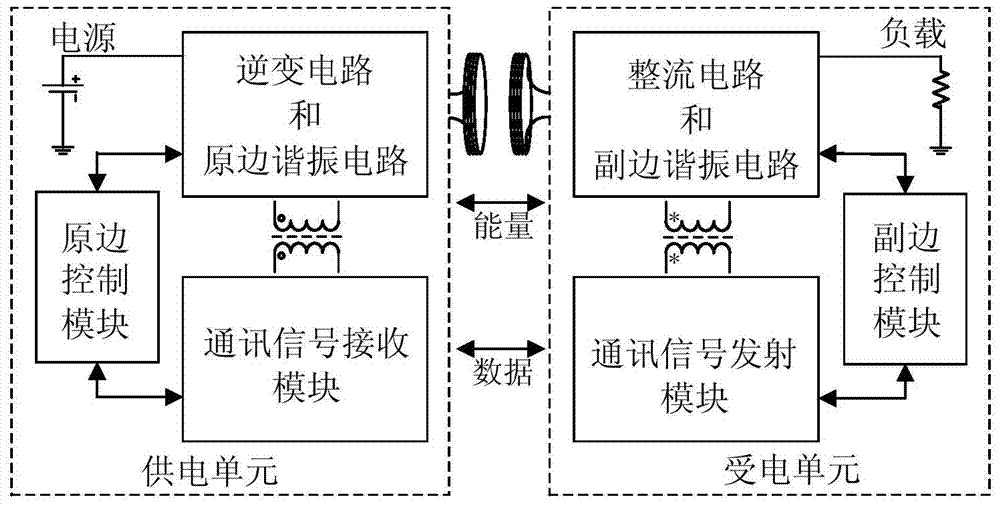

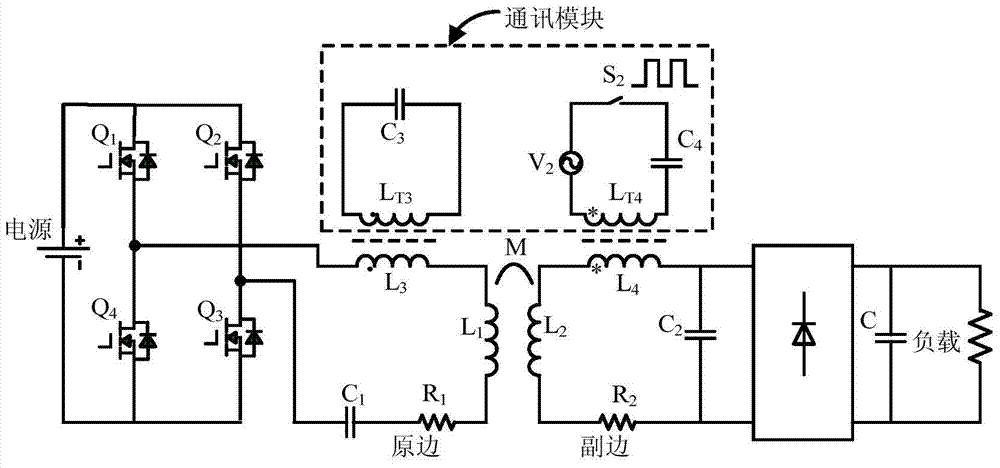

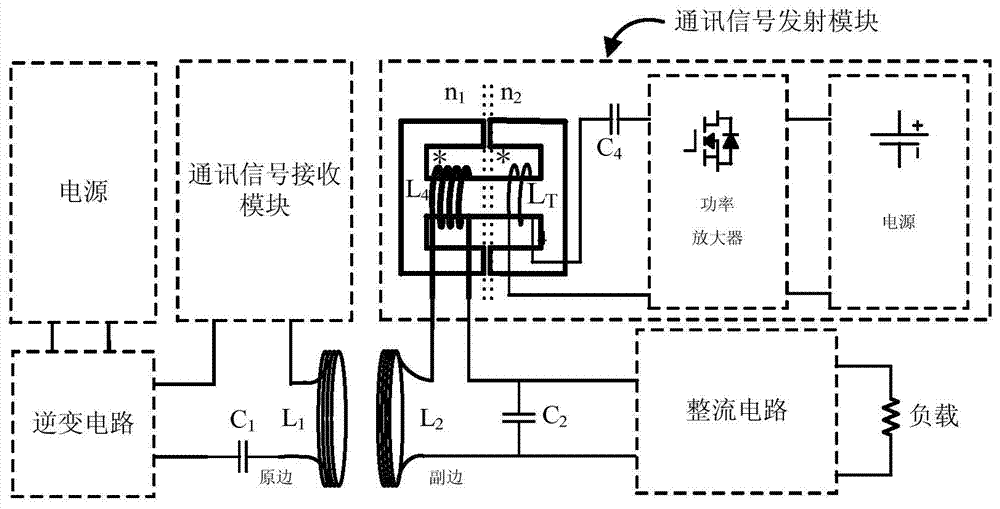

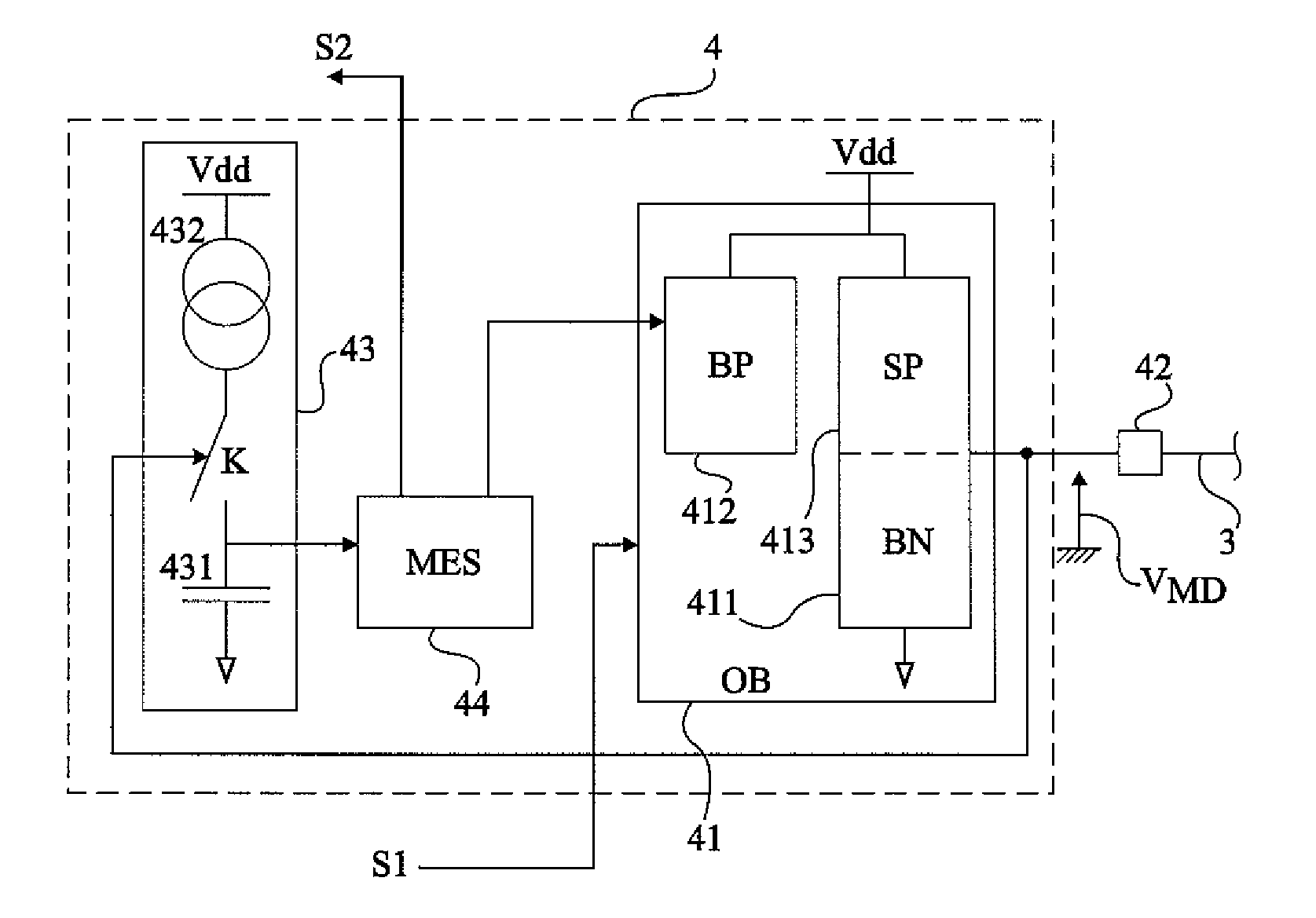

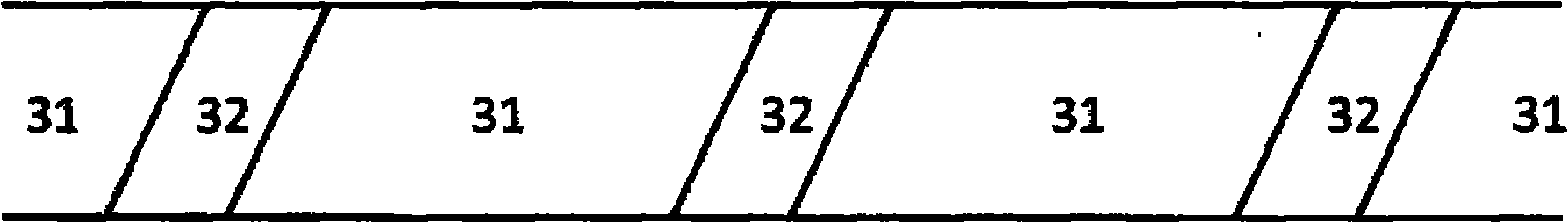

System for achieving high-speed communication and wireless energy transmission on basis of public inductive coupling

ActiveCN103595145ANo change in controlAffects power transfer efficiencyElectromagnetic wave systemCircuit arrangementsElectricityControl manner

The invention discloses a system for achieving high-speed communication and wireless energy transmission on basis of public inductive coupling. The system comprises a powering unit and a powered unit, wherein the powering unit comprises a power transmission module and a communication signal receiving module, and the powered unit comprises a power receiving module and a communication signal emitting module; the power transmission module is coupled with the power receiving module on the basis of public inductance; the power transmission module is coupled with the communication signal receiving module, the power receiving module is coupled with the communication signal emitting module, and power transmission and communication signal transmission are based on different kinds of transmission frequency. Compared with a traditional wireless energy transmission circuit without a communication function, the system has the advantages that the communication function is increased, meanwhile, cost and the size are basically not increased, and a control mode of the traditional wireless energy transmission circuit is not changed; the communication speed is high.

Owner:ZHEJIANG UNIV

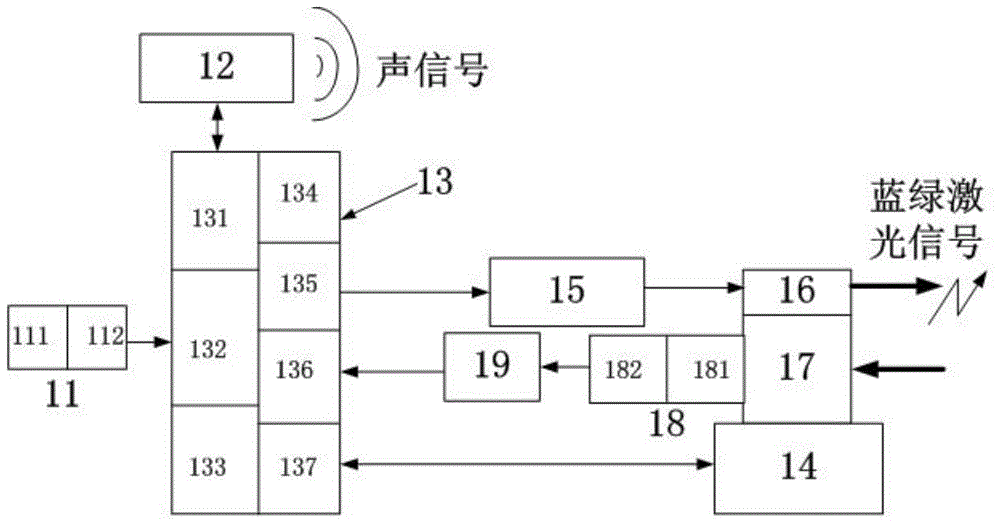

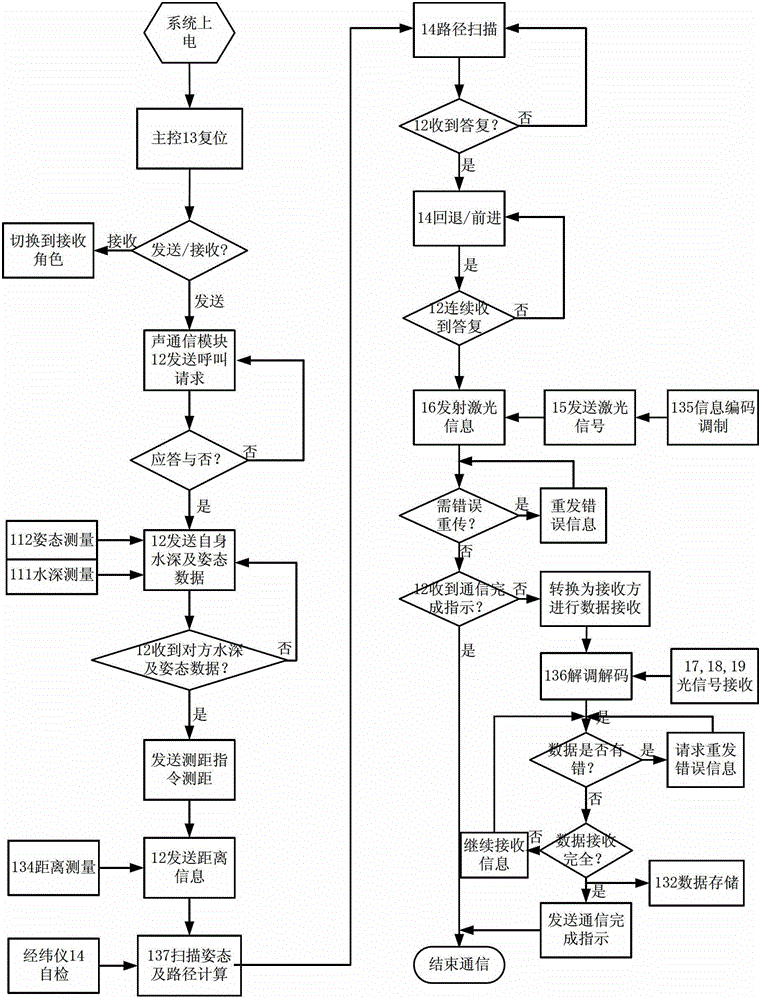

Underwater wireless acousto-optic communication device and method

ActiveCN103338079AIncrease speedReduce power consumptionFibre transmissionTheodoliteData acquisition

The invention discloses an underwater wireless acousto-optic communication device and method. The underwater wireless acousto-optic communication device comprises a water depth and posture measurement module, an acoustic communication module, a main control panel, a theodolite, a pulse blue-green laser, a laser emission telescope, a receiving telescope, a photoelectric detection and signal conditioning module and a high-speed data acquisition module. The underwater wireless acousto-optic communication device comprehensively utilizes the characteristics of an acoustic signal which is low in rate, but large in sidelobe and long in transmission distance and the characteristics of an optic signal which is high in communication rate, good in directivity and longer in transmission distance, realizes underwater high-speed information transmission in a longer distance, and has the characteristics of small size, light weight, high integration level, good reliability and high performance-cost ratio.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

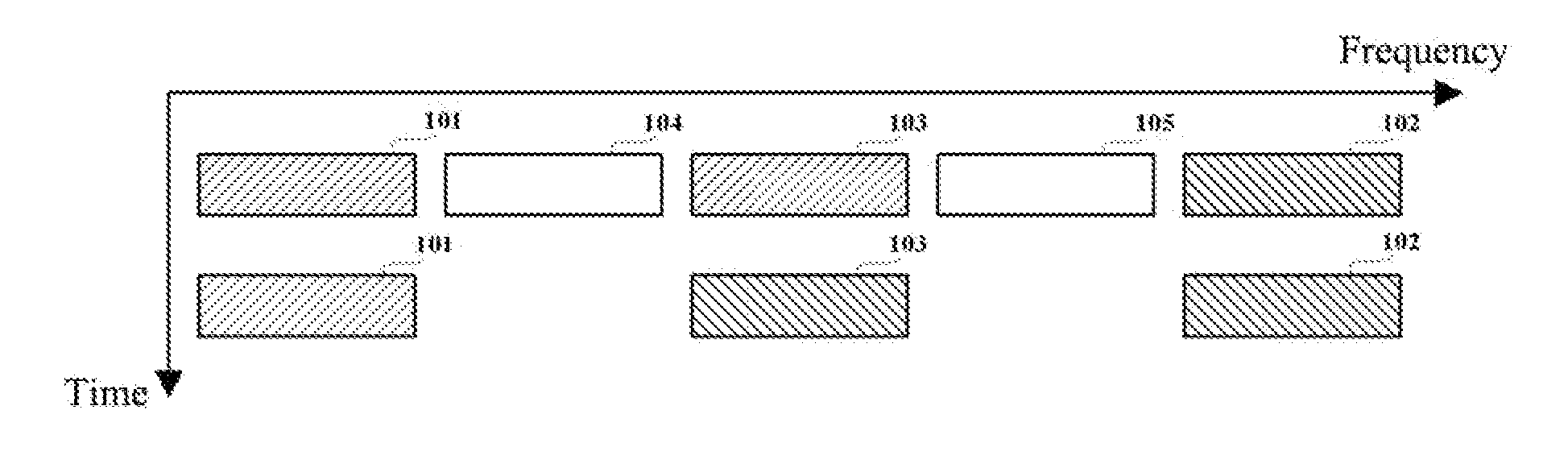

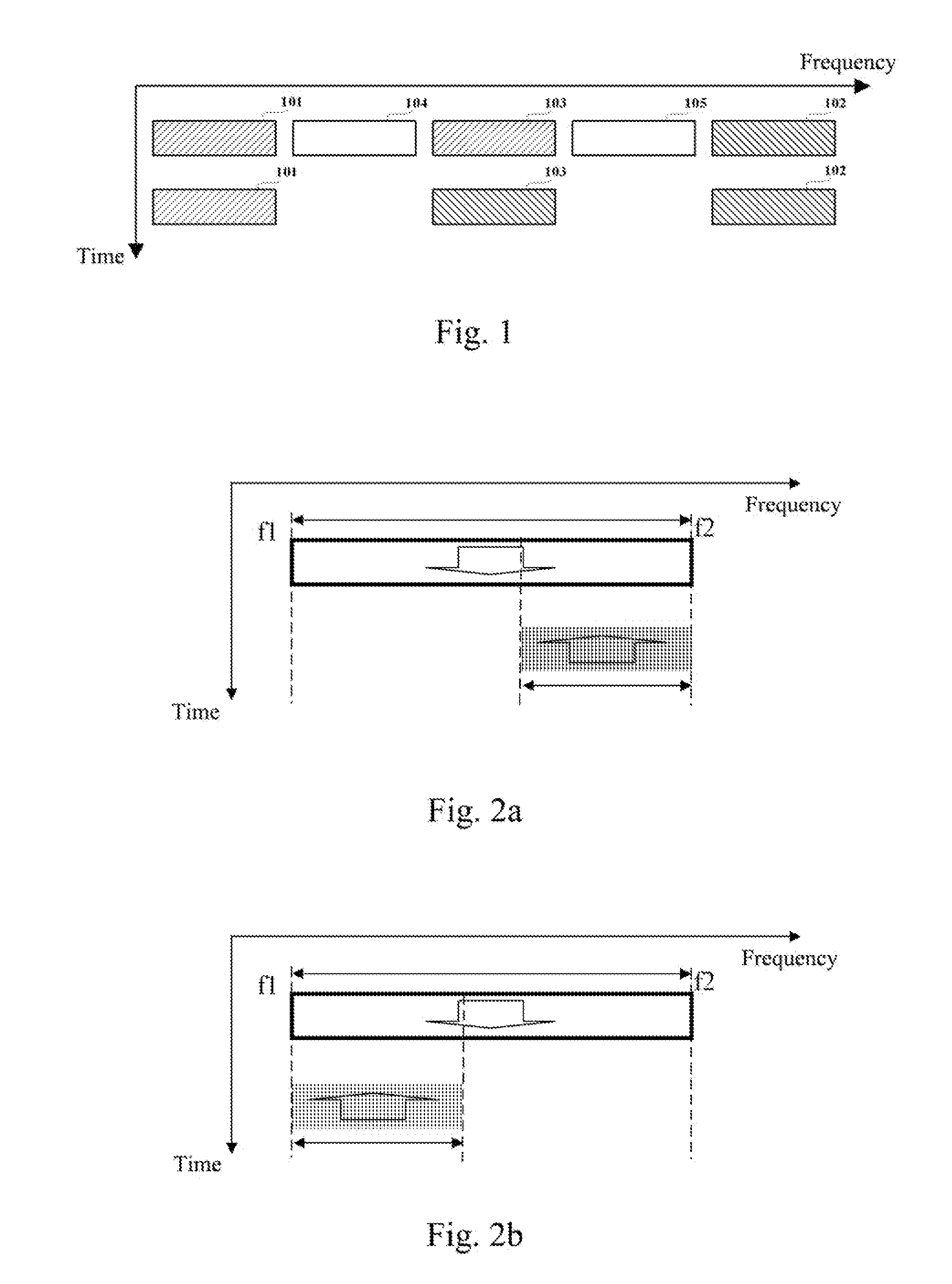

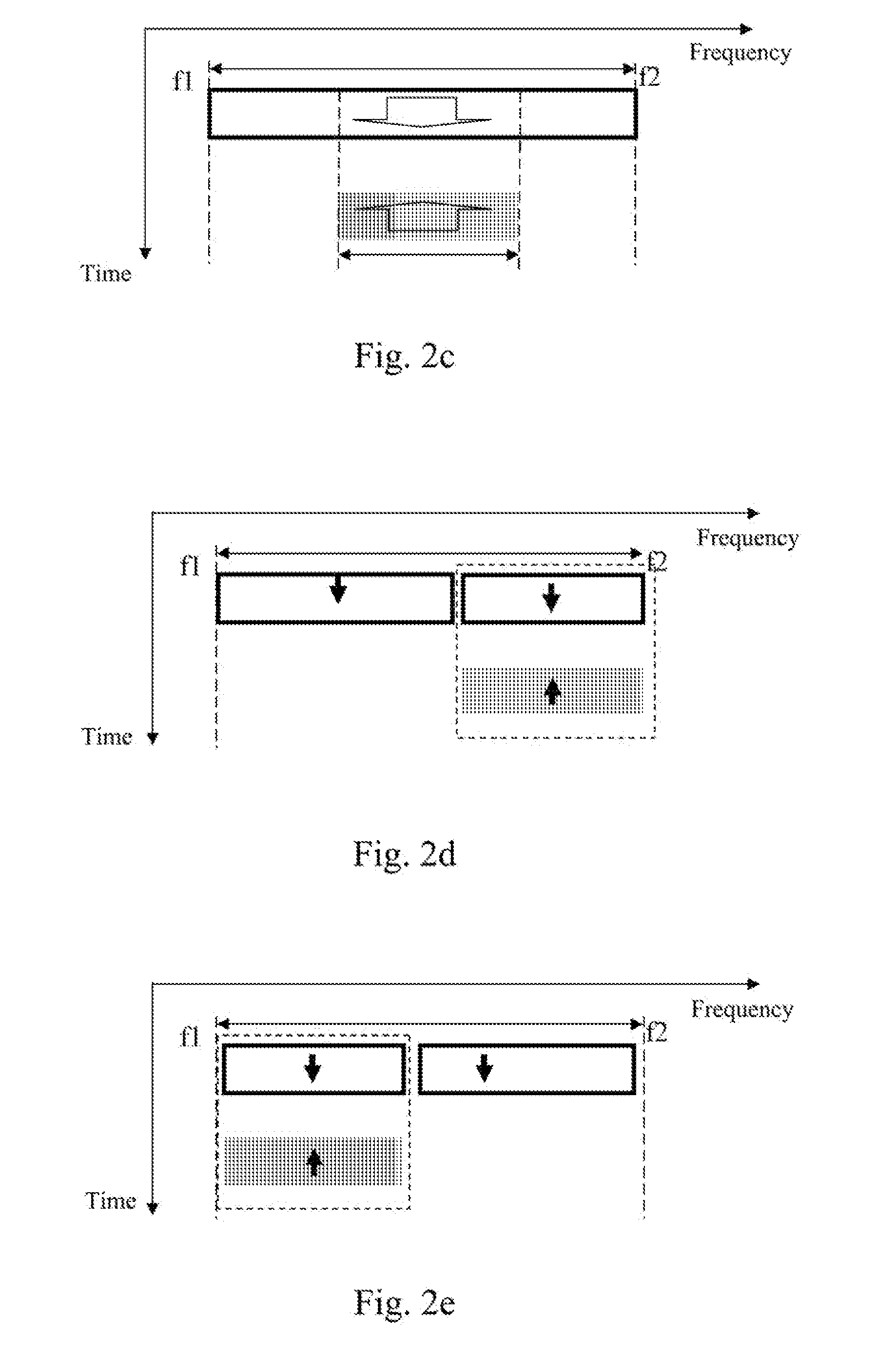

Duplex Communication Method, Terminal Scheduling Method and System

InactiveUS20120257551A1Improve communication efficiencyHigh communication rateTime-division multiplexWireless communicationComputer terminalFrequency band

The present invention provides a method for duplexing communication, and a method and a system for scheduling a terminal. The method for scheduling a terminal includes: determining capability information of the terminal when the terminal makes a request for a service; allocating a band resource for the terminal according to the capability information of the terminal and the currently available band resources, and sending information of the allocated band resource to the terminal in the band currently used by the terminal, wherein the allocated band resource includes a bidirectionally used band, and at least one of the uplink band and downlink band includes a unidirectional band; and communicating with the terminal in the manner of time division duplexing by way of the allocated band resource. The present invention makes the best of the band resources near the TDD licensed band and improves the communication efficiency.

Owner:ZTE CORP

Underwater short-distance high-speed wireless optical information transparent transmission device

InactiveCN104038292ALow costSmall transmission attenuationElectromagnetic transmission optical aspectsPhysicsOptical path

An underwater short-distance high-speed wireless optical information transparent transmission device comprises a transmitting module and a receiving module, wherein the transmitting module sequentially comprises an LED modulation drive circuit, a blue-green mixed LED array, a transmitting light path, a beam expanding mirror and a homogenizing piece in the direction of an electrical signal to be transmitted, and the receiving module sequentially comprises a large-view-field receiving light path, a light filter, a Fresnel lens, a photoelectric detector and a photoelectric detection conditioning circuit. The underwater short-distance high-speed information transparent transmission problem can be solved, the lake, river and ocean environment application requirements are met, and the underwater short-distance high-speed wireless optical information transparent transmission device is especially suitable for connection of multiple sensors at deep position under the ocean, underwater data collection, ROV data interaction and continuous communication occasions for water surface platforms and underwater devices and has important significance in the ocean application field.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

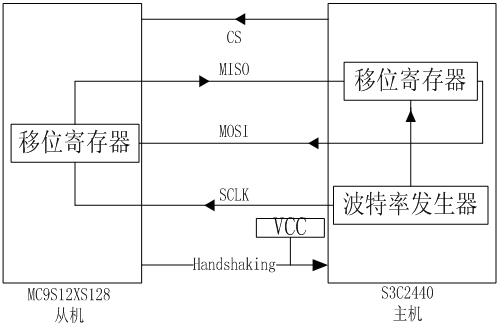

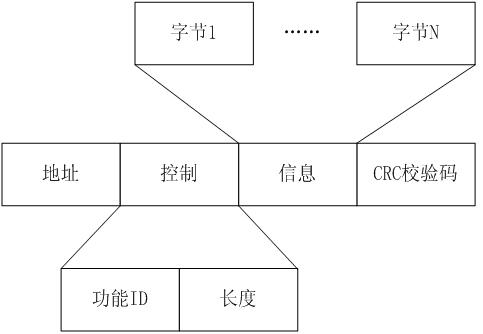

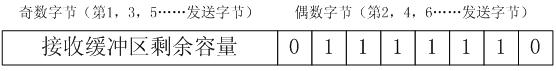

Dual-processor communication method based on SPI (serial peripheral interface) bus

InactiveCN102508812AMeet the requirements of high-speed communicationImprove scalabilityDigital computer detailsElectric digital data processingComputer architectureMulti processor

The invention relates to a dual-processor communication method based on an SPI (serial peripheral interface) bus, which is used for high-speed two-way communication between double processors by the aid of the SPI bus. The method includes: adding a handshaking wire based on a four-wire system of a physical layer of the SPI bus to form a five-wire SPI bus capable of being used for two-way communication; completing mechanism synchronization of the five-wire SPI bus on a data link layer by using the '0-bit interpolation method' and combining CS (chip select) signals, handshaking signals and feedback information; controlling flow of the five-wire SPI bus by using 'receiving buffer zone residual capacity' in the feedback information; and using CRC (cyclic redundancy check) and confirm character'0x7F' in the feedback information to complete error processing of the five-wire SPI bus. The method has the advantages of simplicity in expansion, convenience in application and compatibility to other buses, and meanwhile, extremely high communication rate can be obtained to meet requirements of high-speed communication between the double processors, and the method is widely applicable to designof multi-processor systems.

Owner:SHANGHAI UNIV

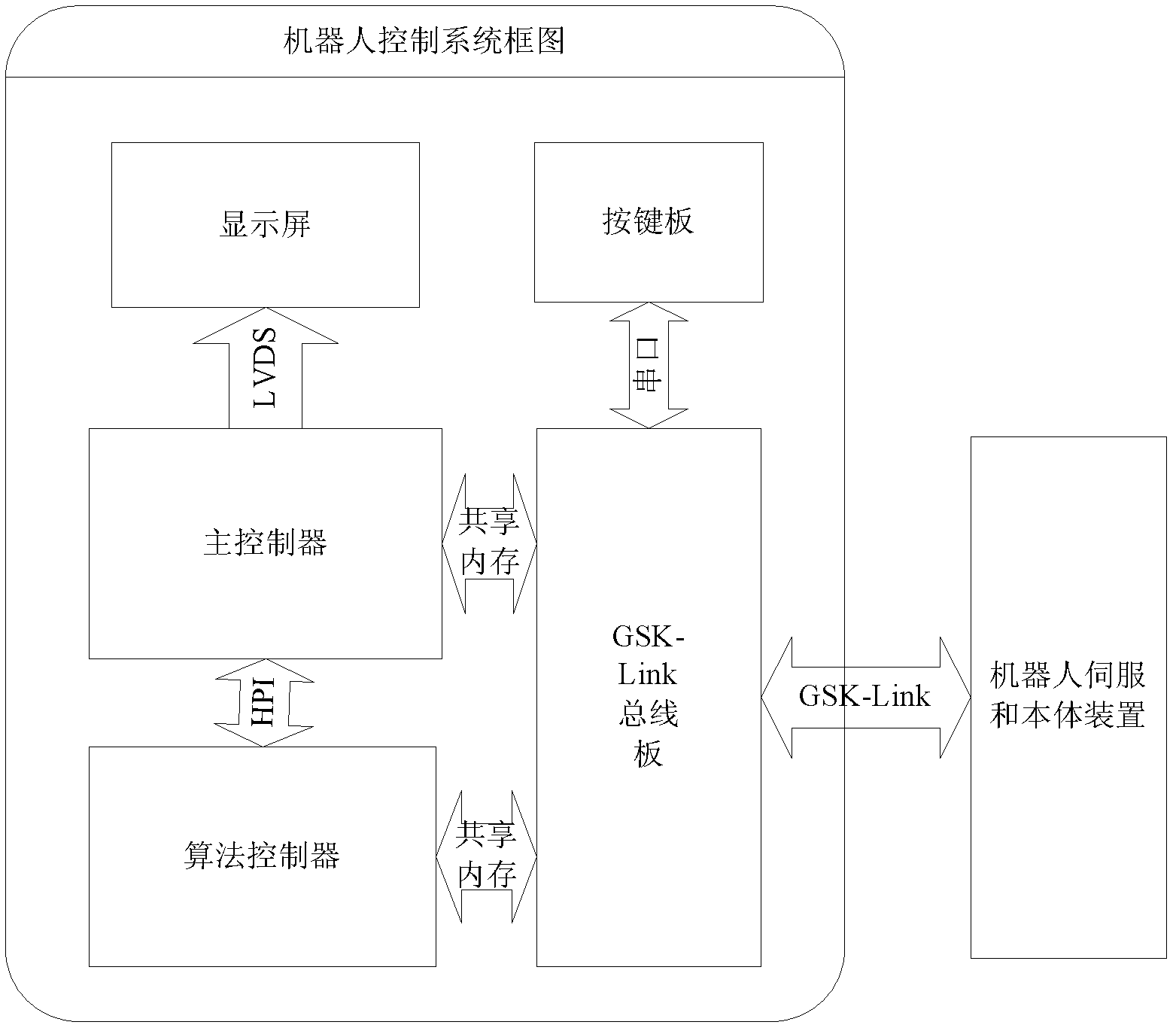

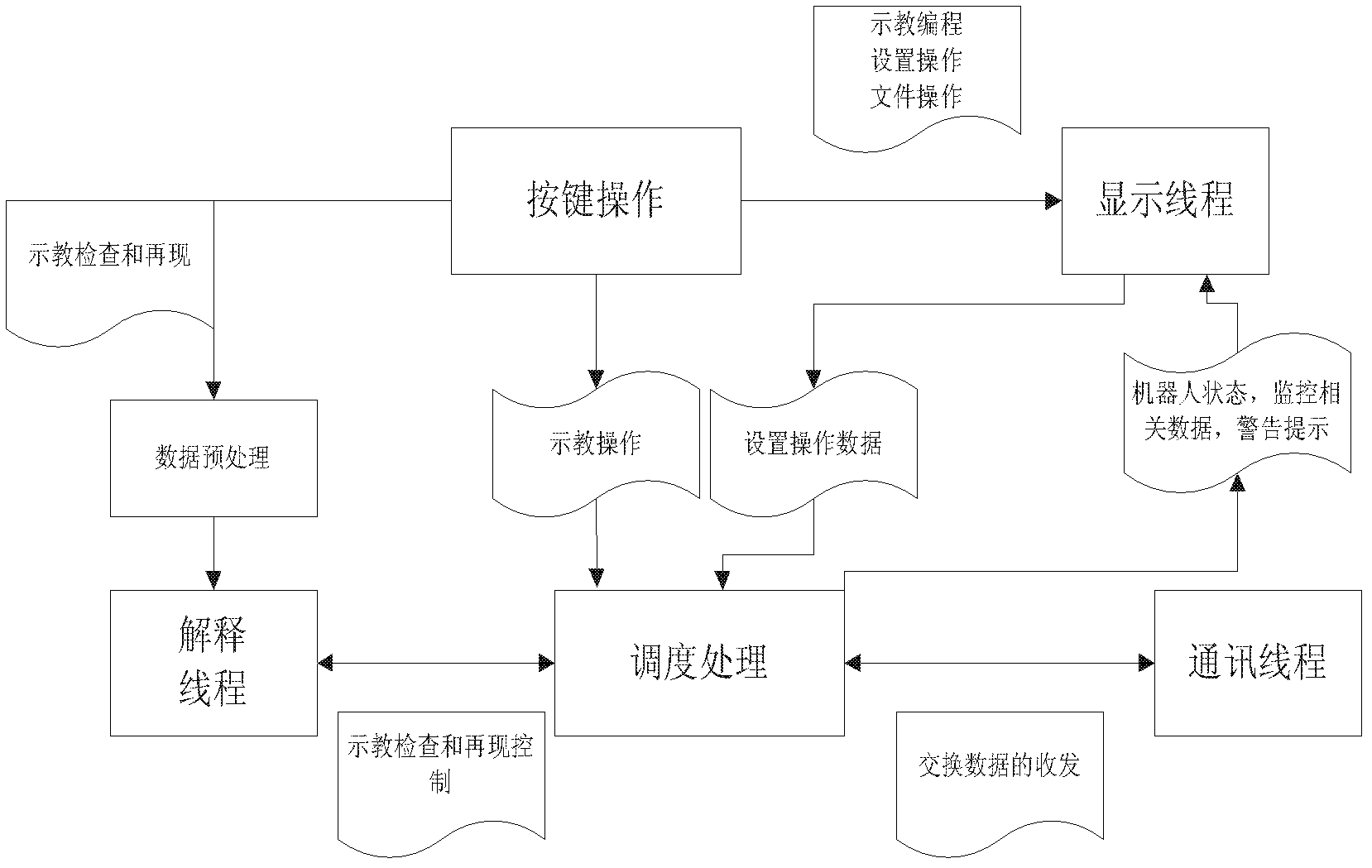

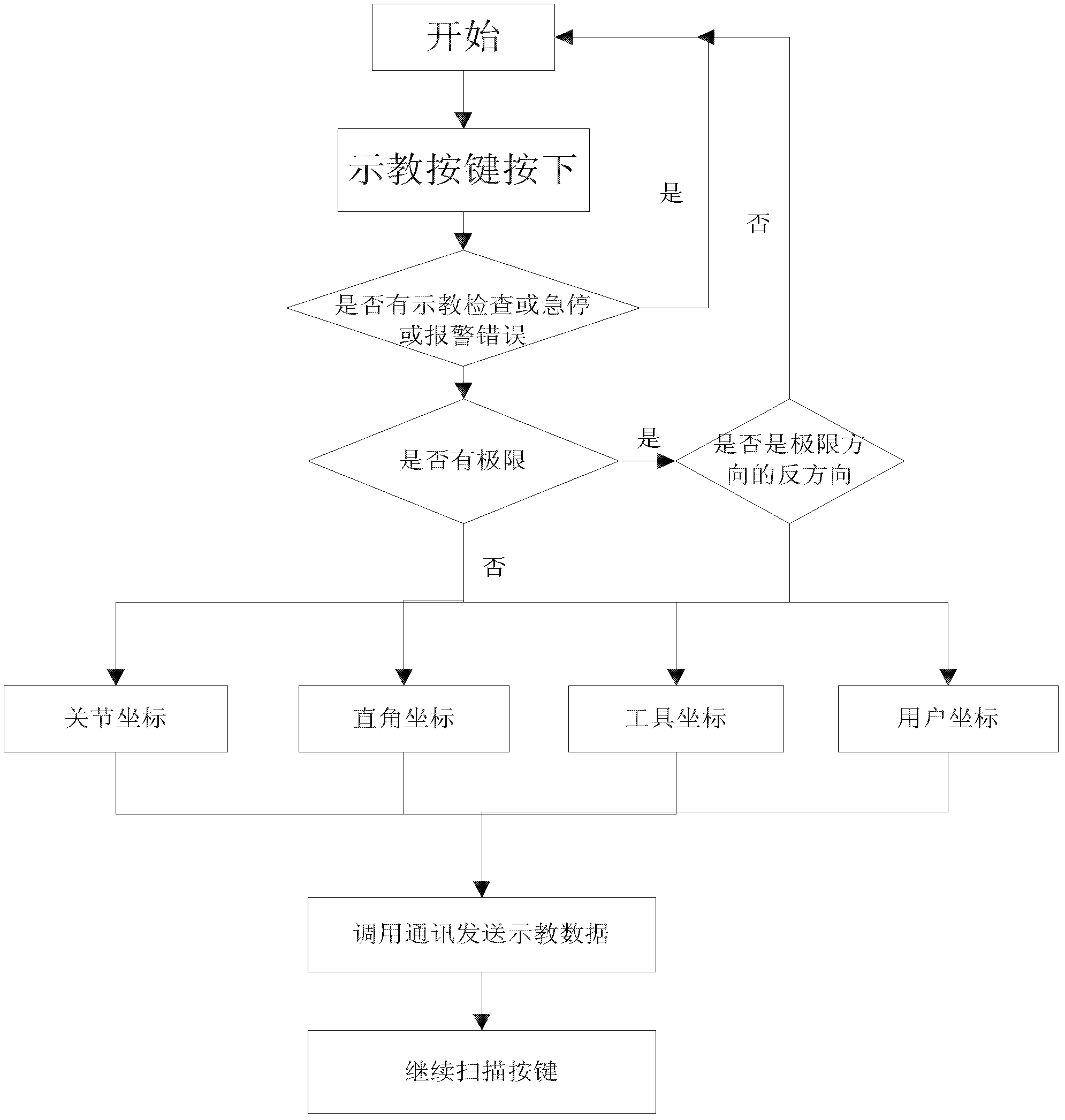

GSK-Link bus based modular robot control device and control method

ActiveCN102581850AHigh communication rateImprove stabilityProgramme-controlled manipulatorComputer moduleMovement control

Owner:GSK CNC EQUIP

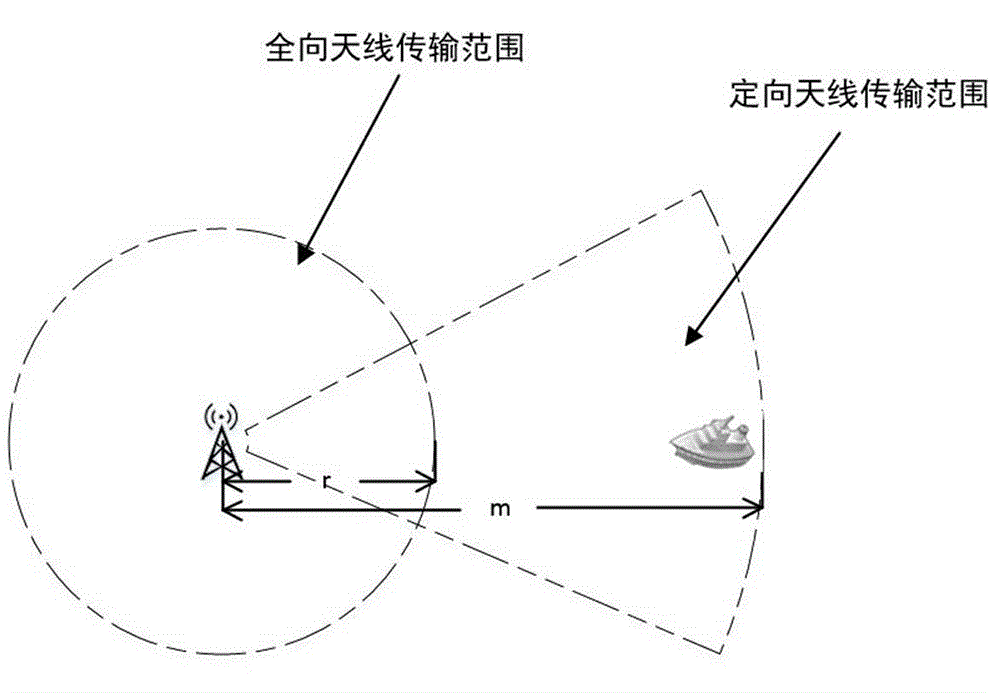

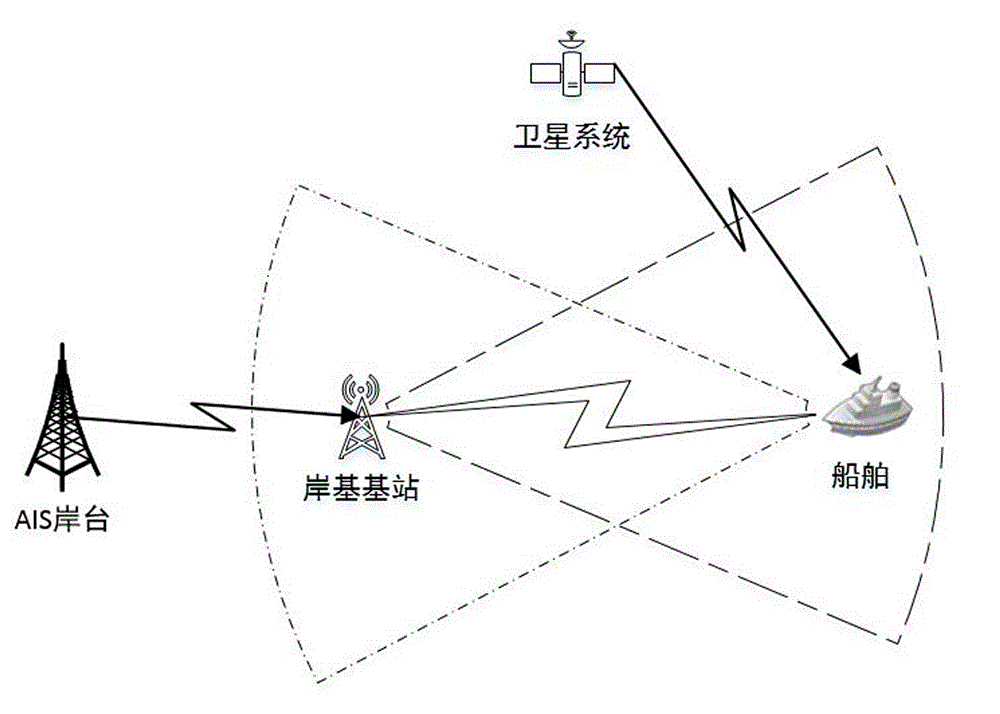

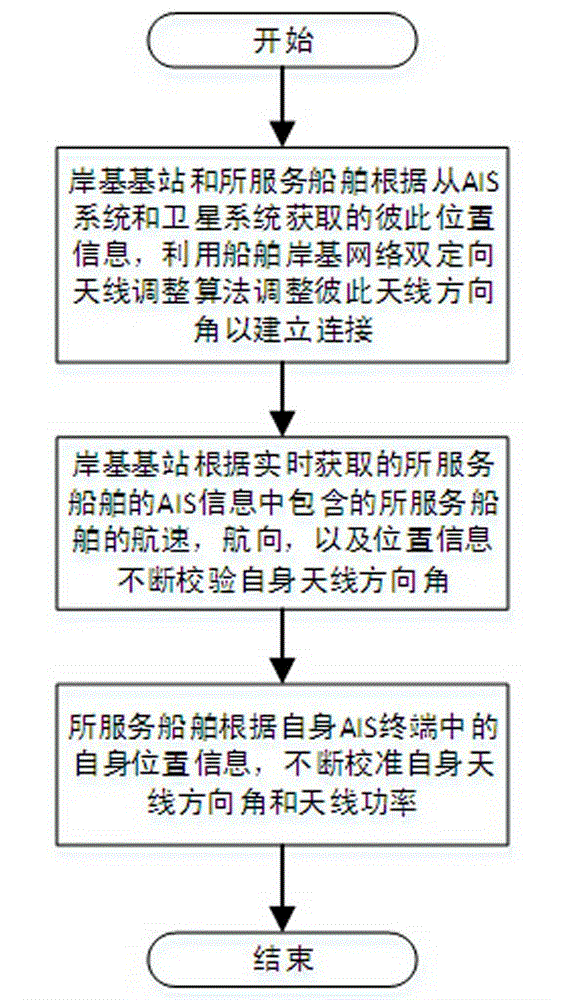

Dynamic antenna adjustment and communication method by utilizing shore-based base station and ship location information

ActiveCN104679032AImprove space utilizationReduce distractionsControl using feedbackDirectional antennaWireless network

The invention discloses a dynamic antenna adjustment and communication method by utilizing a shore-based base station and ship location information, and mainly solves the problems that in a ship and shore-based wireless network, the shore-based base station and the ship serviced by the base station both use directional antennas, so that in the neighborhood discovery phase, the shore-based base station and the ship serviced by the base station cannot find each other and further cannot perform communication. The dynamic antenna adjustment and communication method comprises three steps of establishing connection, calibrating the shore-based base station and calibrating the ship serviced by the base station. The dynamic antenna adjustment and communication method disclosed by the invention is suitable for the dedicated ship and shore-based wireless network of the directional antennas arranged on the shore-based base station and the ship, simple in antenna adjustment method, and capable of realizing communication between the shore-based base station and the ship at the near-shore channel.

Owner:SHANGHAI MARITIME UNIVERSITY

Method and system for quantum communication security

InactiveCN101820343AHighlight substantiveSignificant progressKey distribution for secure communicationCommunications securityPhoton emission

The invention relates to a method and a system for quantum communication security. An Alice terminal comprises a watchdog detector, an optical attenuator, a phase modulator, a reflector, a controller and a photon emitter; and a Bob terminal comprises a laser, a time division multiplex / demultiplex system, a phase modulator, a single photon detector, a controller, an optical switch and a reflector. The method and the system have the advantages that: (1) the two-way, stable and safe distribution of quantum keys is realized, the polarization and phase change of a single photon can be automatically compensated, and the aim of stable long-distance transmission is achieved; (2) the Alice terminal adopts the watchdog detector, on one hand, Trojan attack and intermediary attack can be detected by measuring the number of weak pulses reaching or leaving the Alice terminal, so that the communication security is improved greatly, and on the other hand, the communication speed and communication distance of the system are improved greatly; and (3) the Alice terminal and the Bob terminal can be adjusted and corrected respectively, can select mu independently without transmitting photons by means of unsafe optical fiber lines so as to ensure the system security.

Owner:BEIJING UNIV OF POSTS & TELECOMM

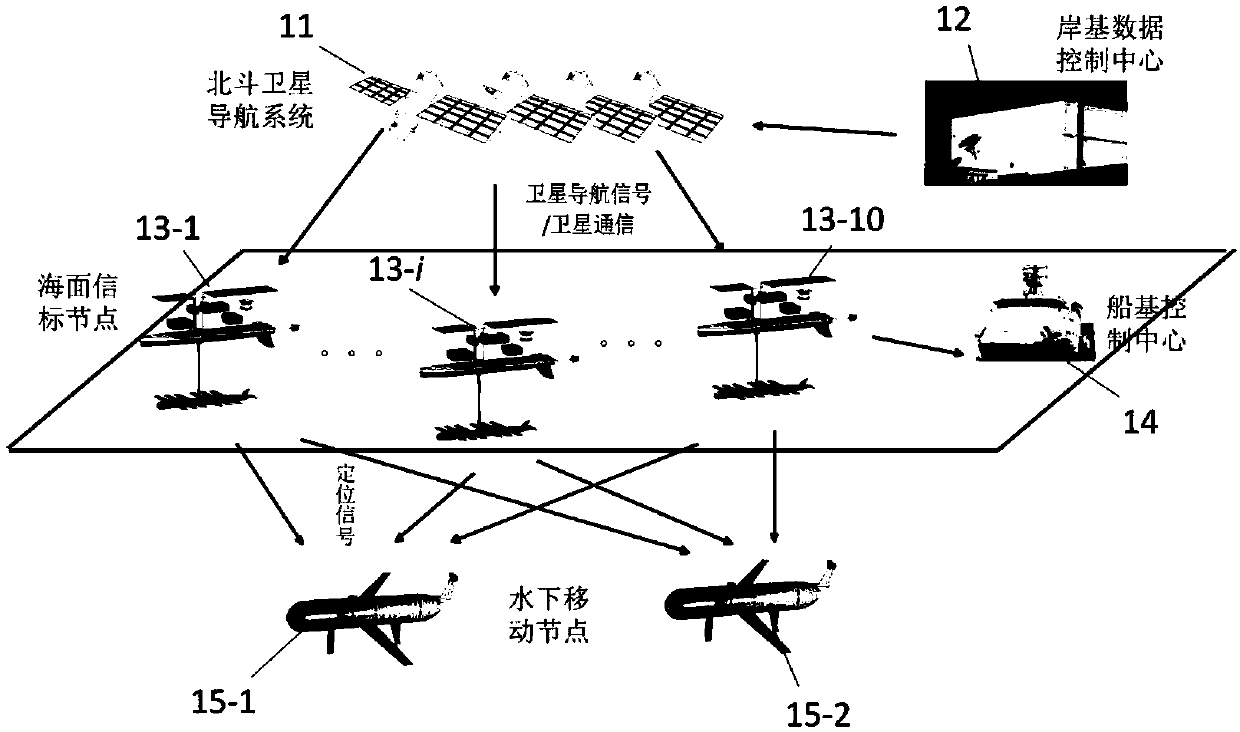

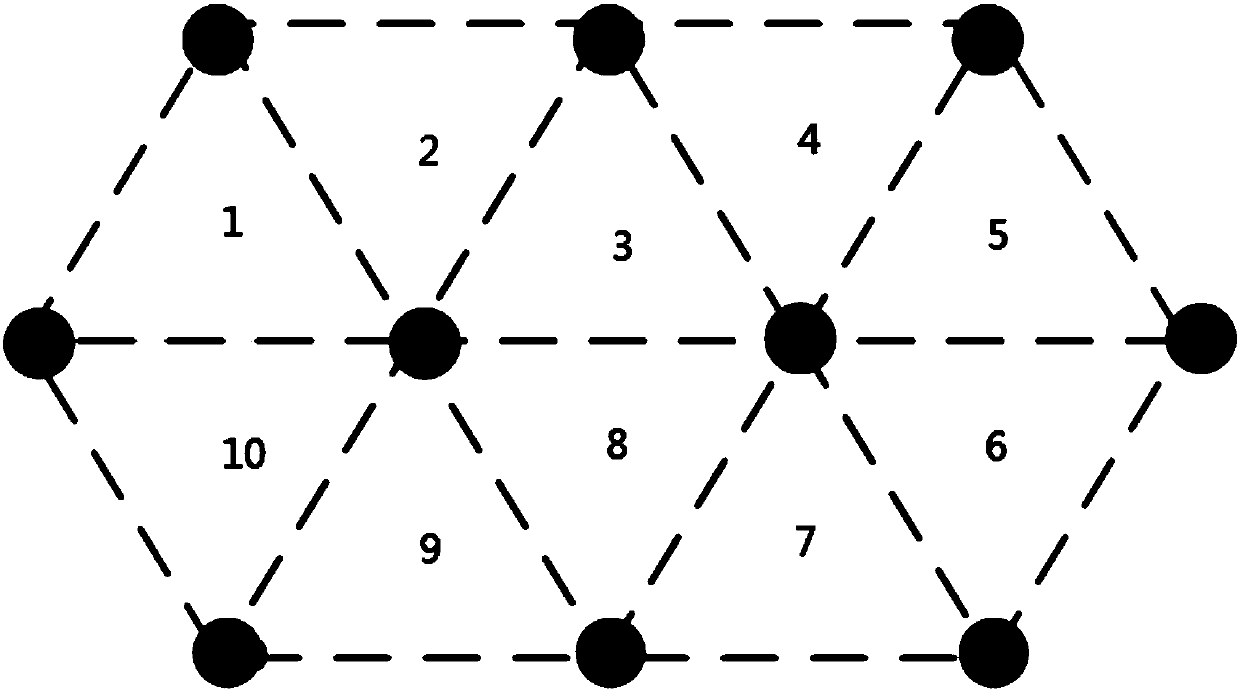

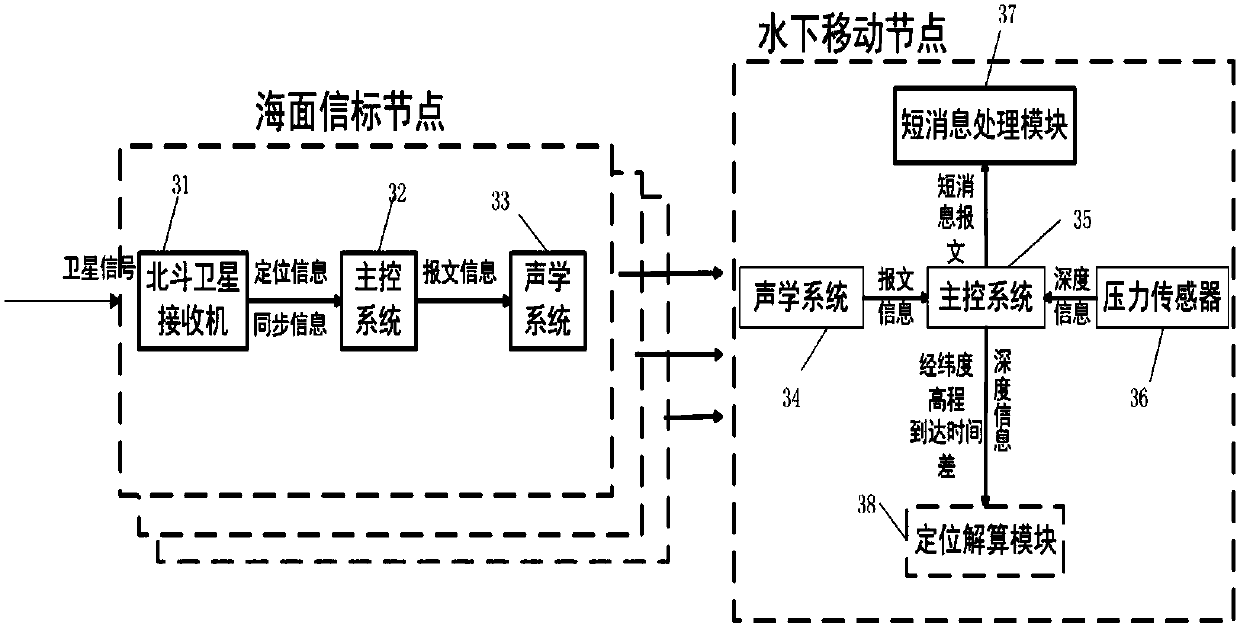

Passive location method for underwater moving node based on Beidou beacons and system

ActiveCN108303715AReduce positioning errorsHigh communication ratePosition fixationSatellite radio beaconingUnderwaterFilter algorithm

The invention relates to a passive location method for an underwater moving node based on Beidou beacons, which comprises the steps that 1, a sea surface beacon node receives a location and navigationsignal broadcast by a Beidou satellite navigation system, updates the position in real time and keep pace with the Beidou clock; three sea surface beacons located at vertexes of a triangular grid combine information such as the position and serial number into location messages and broadcast the location messages to the underwater moving node at the same time according to a time sequence table oftransmitting the location messages; and 2, if the underwater moving node receives the location messages, the position of the underwater moving node at the current moment is calculated by using a filtering algorithm according to the arrival time and message content of the three location messages, and if the underwater moving node does not receive the location messages, the position of the underwater moving node at the current moment can also calculated by using the filtering algorithm. The invention further relates to a system used for implementing the passive location method.

Owner:ZHEJIANG UNIV

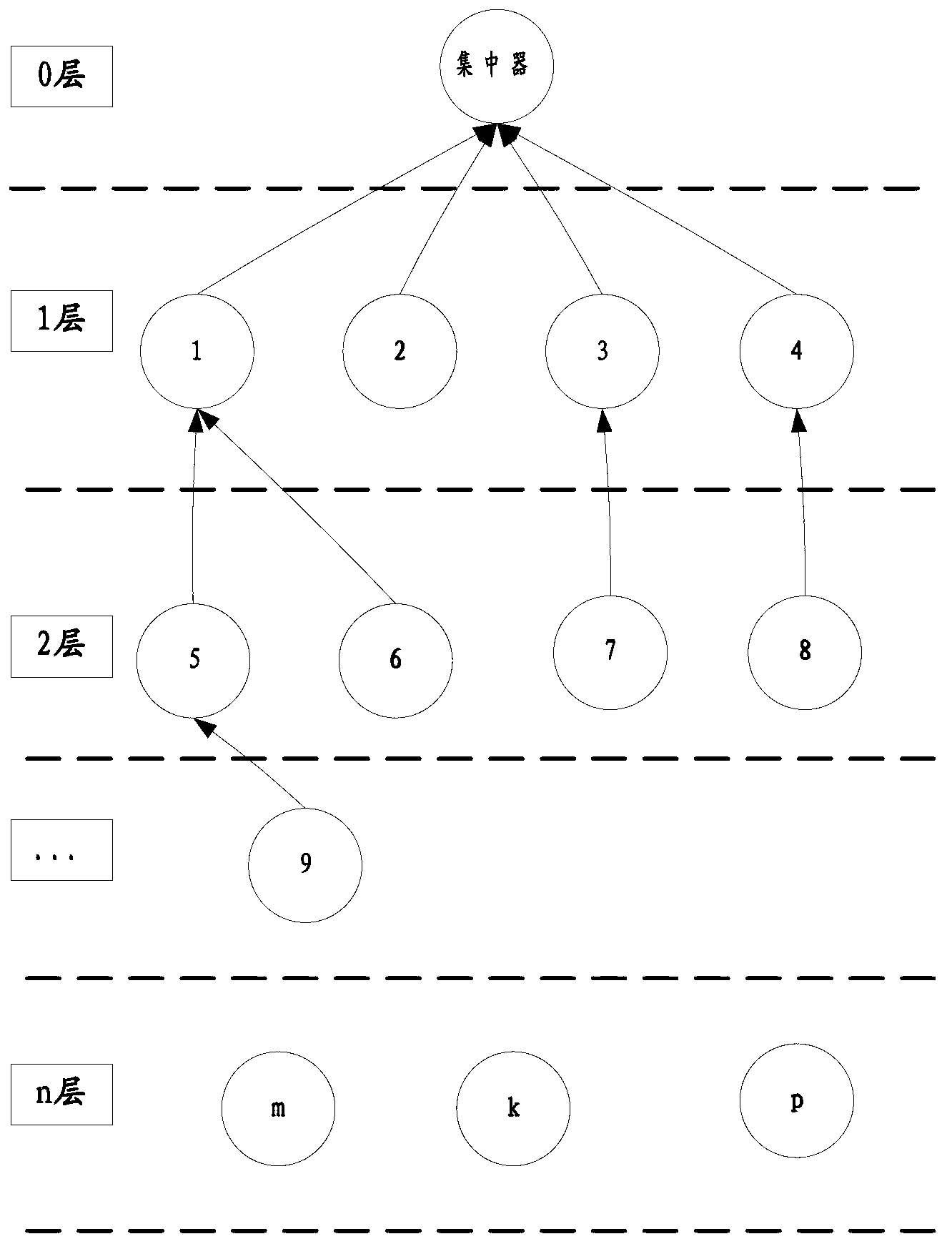

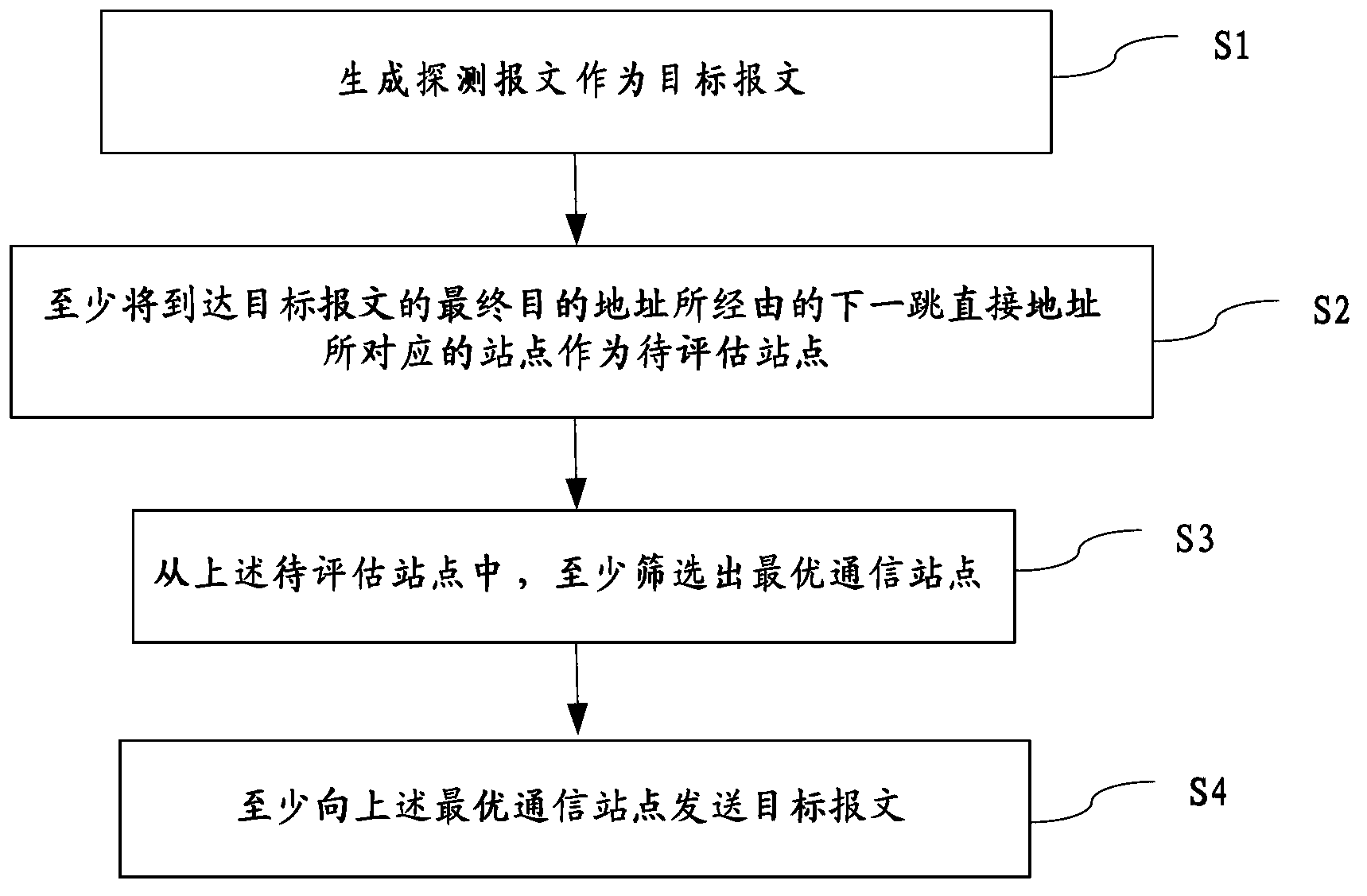

Communication method, communication device and communication system

ActiveCN103312547AImprove adaptabilityHigh communication rateData switching networksCommunications systemRouting table

An embodiment of the invention discloses a communication method, a communication device and a communication system. The communication method includes dynamically detecting communication paths and dynamically maintaining a local routing table by each station in a power line carrier communication network, wherein the local routing table records at least one routing table item, each routing table item at least contains a through path for reaching an ultimate destination address, and each path contains a next-hop direct address; processes for dynamically detecting the communication paths include: generating a detecting message bringing a source address and the ultimate destination address to serve as a target message; at least taking stations corresponding to the through next-hop direct addresses for reaching the ultimate destination address as to-be-evaluated stations; at least screening an optimal communication station in the to-be-evaluated stations; at least sending the target message to the optimal communication station; taking the received detecting message and the target message when the detecting message is received; and executing a transmitting strategy.

Owner:HUAWEI TECH CO LTD

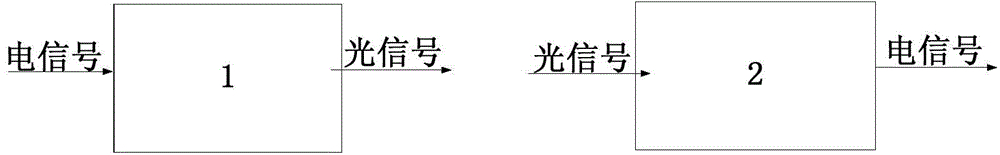

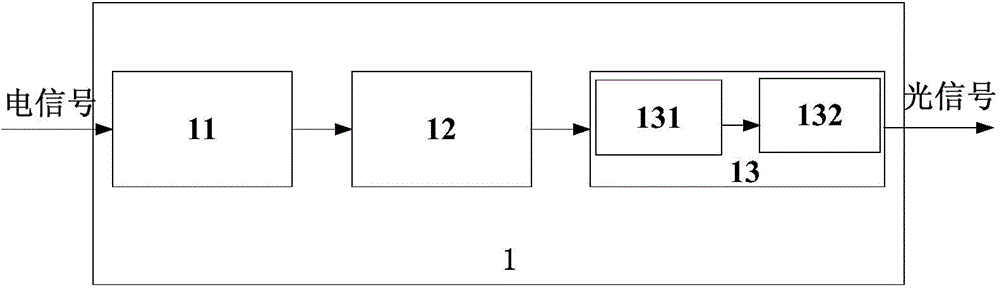

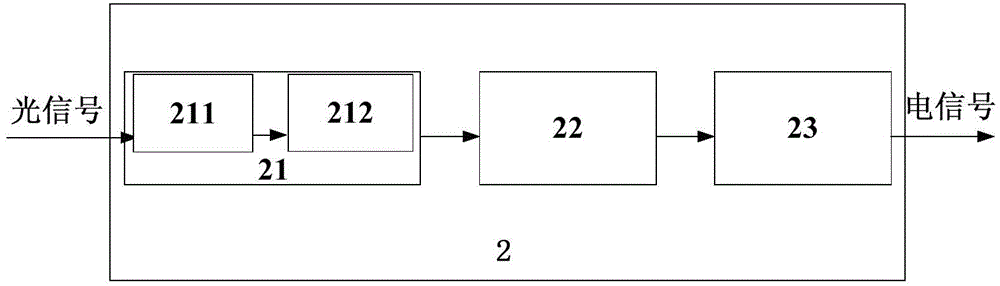

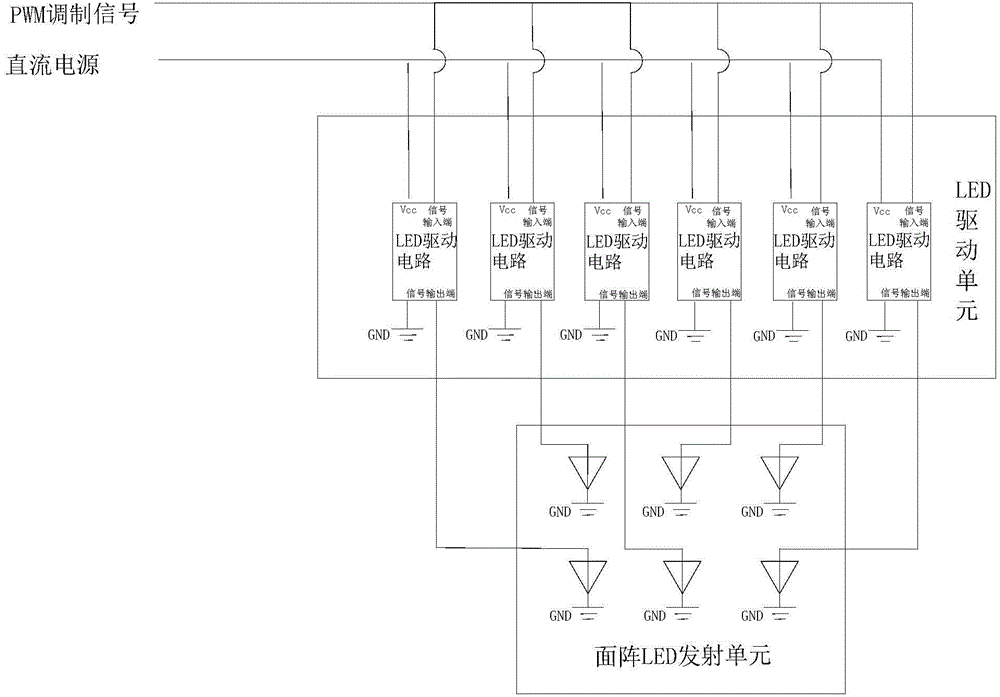

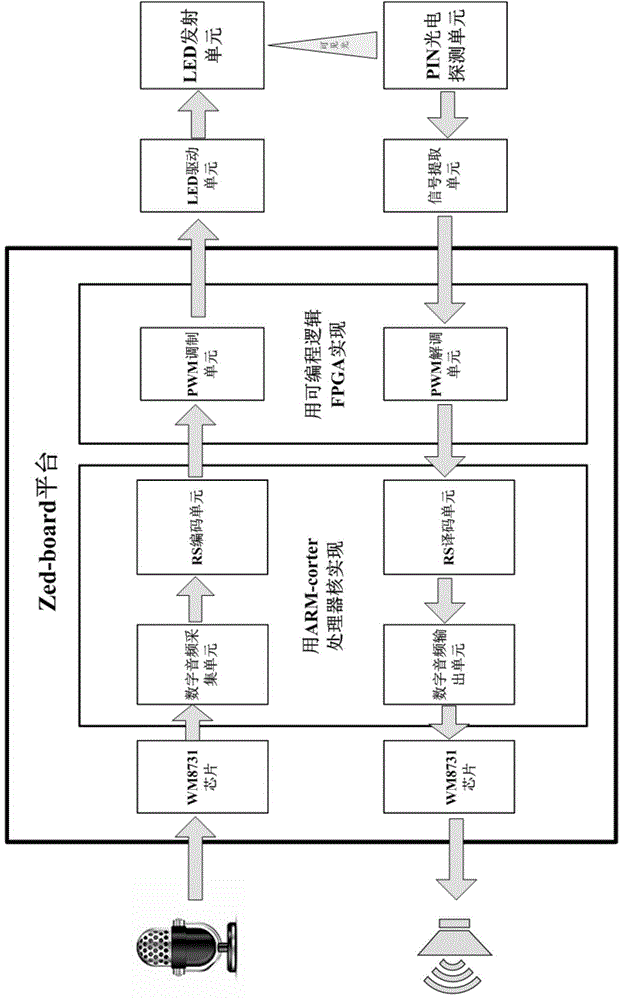

Vehicular visible light wireless digital voice communication system

InactiveCN104485993AImplement instant voice communication technologySave spaceClose-range type systemsFrequency spectrumVoice communication

The invention discloses a vehicular visible light wireless digital voice communication system. The vehicular visible light wireless digital voice communication system comprises a sending module and a receiving module. The sending module comprises a digital audio acquisition unit, an RS coding unit, a PWM (pulse width modulation) unit, an LED (light emitting diode) drive unit and an LED transmitting unit, which are connected successively in circuit; the receiving module comprises a PIN photoelectric detection unit, a signal extraction unit, a PWM modulation unit, an RS decoding unit and a digital audio output unit, which are connected successively in circuit. The wireless digital voice communication system realizes instant voice communication between strange vehicles; an LED-based lamp is integrated with automobile lighting and communication without the need of an additional signal emission source installation space and occupation of scarce frequency spectrum resource. The voice signal transmission is high-speed and reliable, high in integration level, strong in anti-interference ability and low in cost, and bigger communication distance and more reliable communication are realized; moreover, a detector has high accuracy, high responsivity, low dark current, higher communication rate, stronger anti-interference ability and high reliability of a transmission channel.

Owner:NANCHANG UNIV

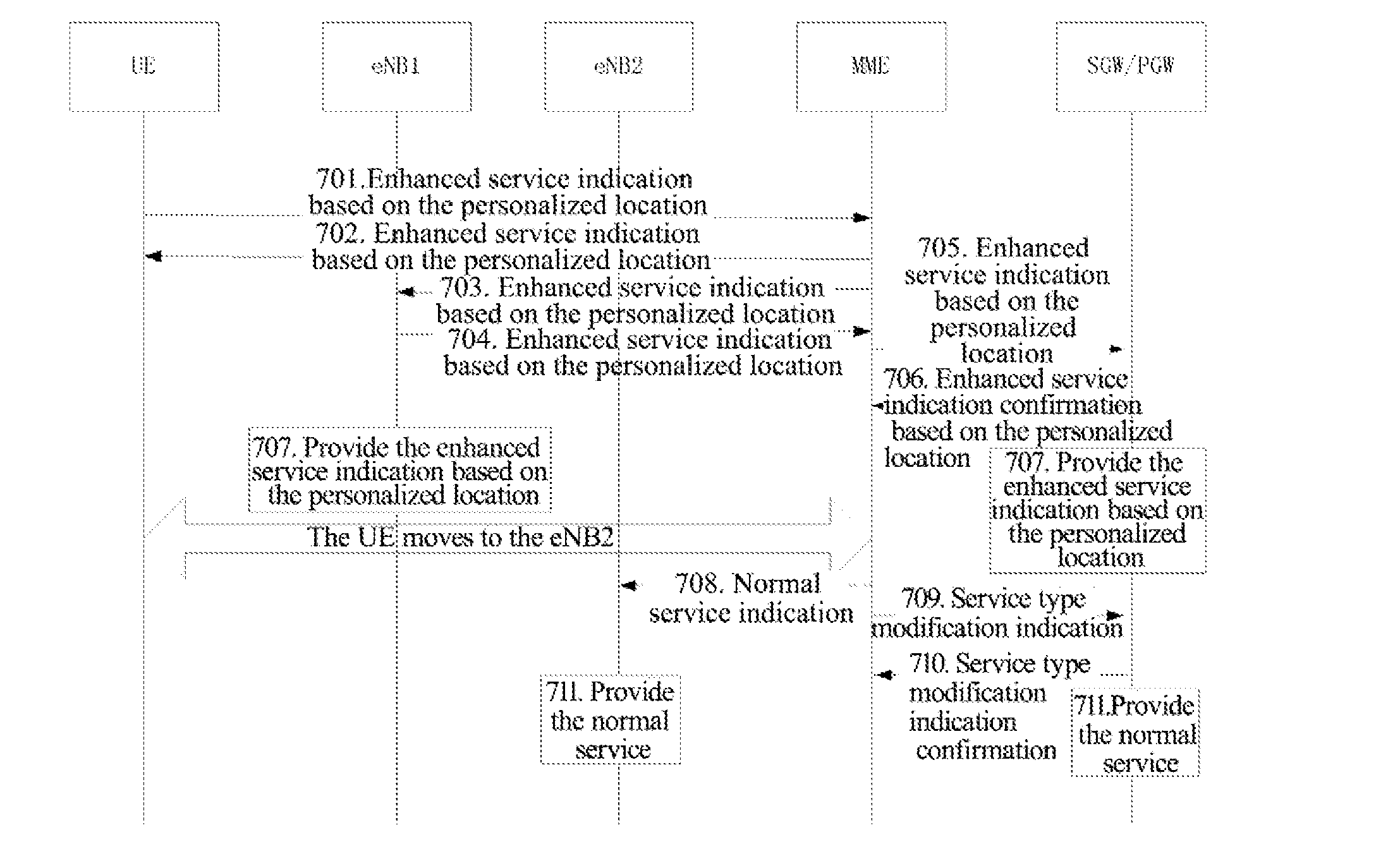

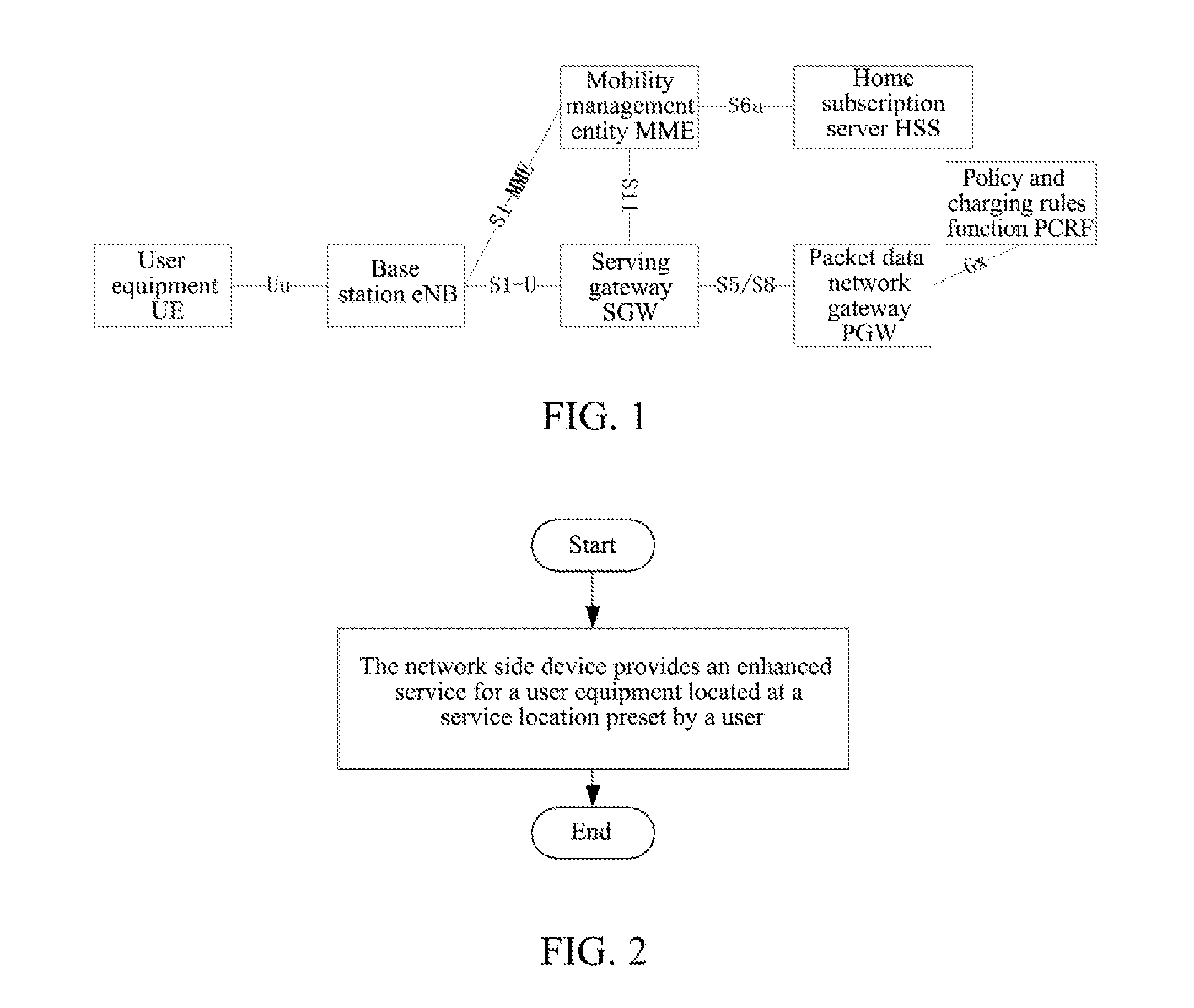

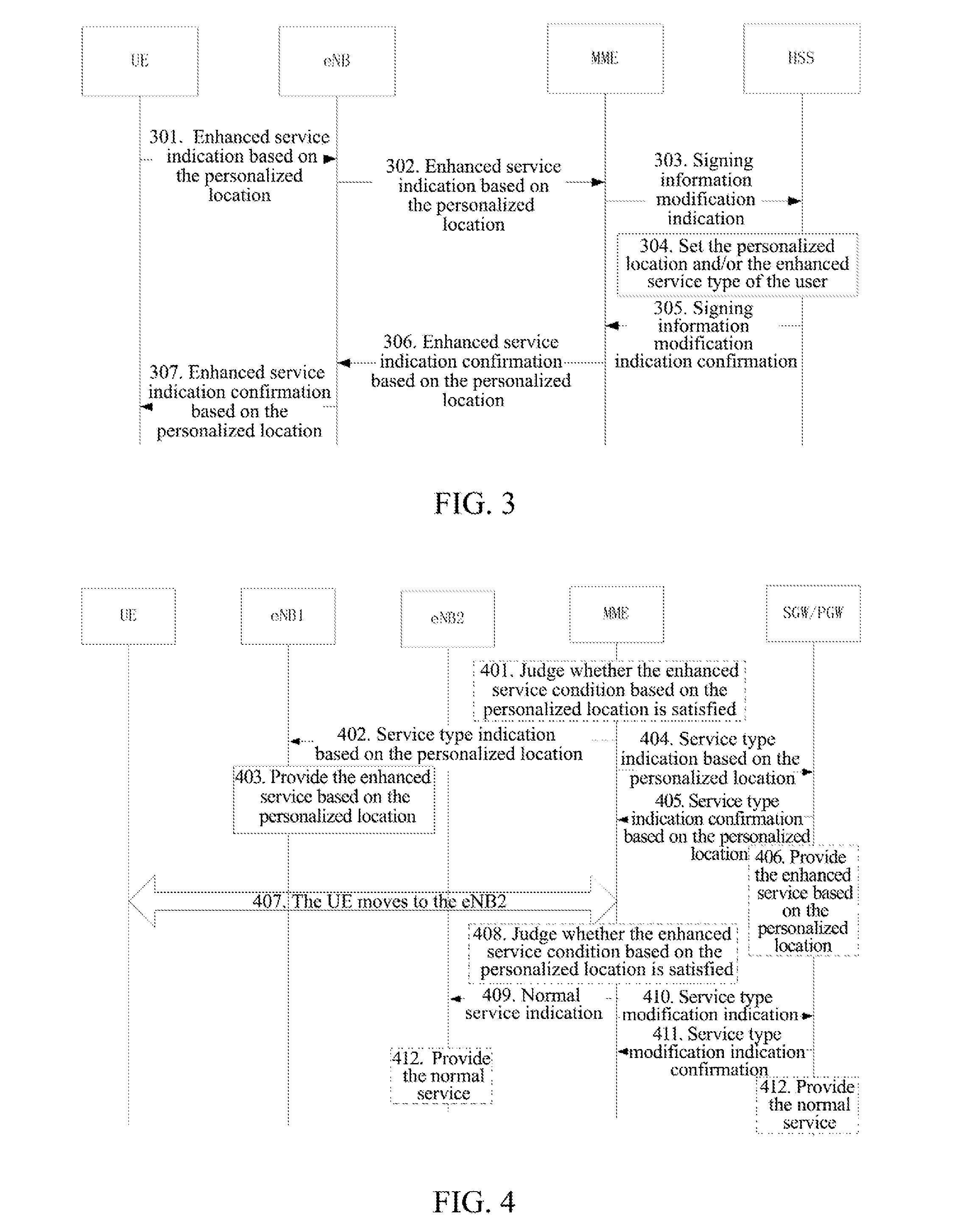

Personalized Method for Enhancing Service, Network Side Device, and Mobile User Equipment

ActiveUS20150181373A1Improve user experienceHigh communication rateAccounting/billing servicesTelephonic communicationPersonalizationService control

A personalized method for enhancing a service, a network side device and a mobile user equipment are provided. The network side device provides an enhanced service for a user equipment located at a service location preset by a user. The network side device comprises a service location determination module and an enhanced service control module. The service location determination module is configured to maintain the service location preset by the user. The enhanced service control module is configured to indicate to provide the enhanced service for the user equipment located at the service location preset by the user. The mobile user equipment comprises an enhanced service indication module. The enhanced service indication module is configured to send a user indication to the network side device to enable the network side device to provide the enhanced service for the user equipment located at the service location preset by the user.

Owner:ZTE CORP

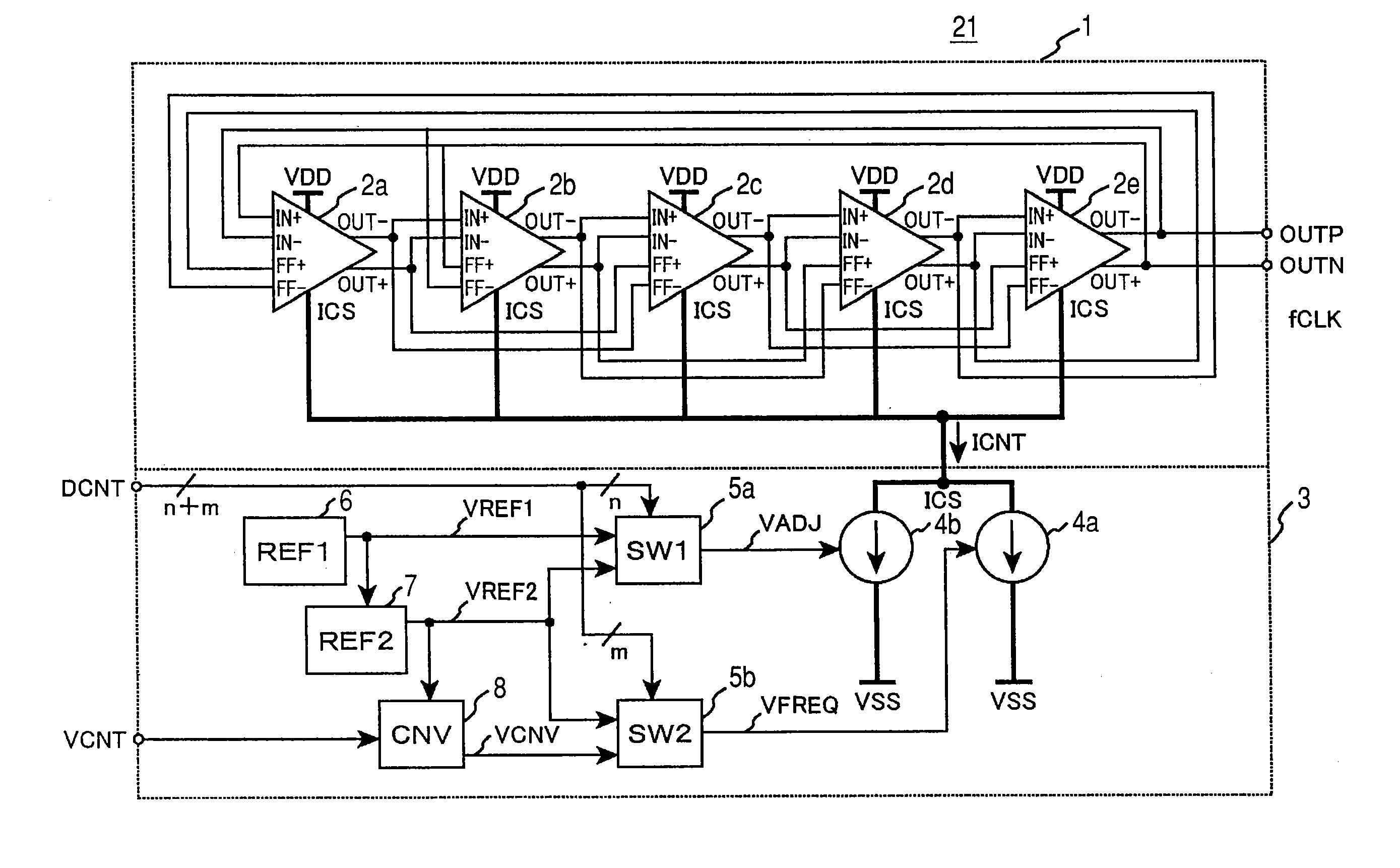

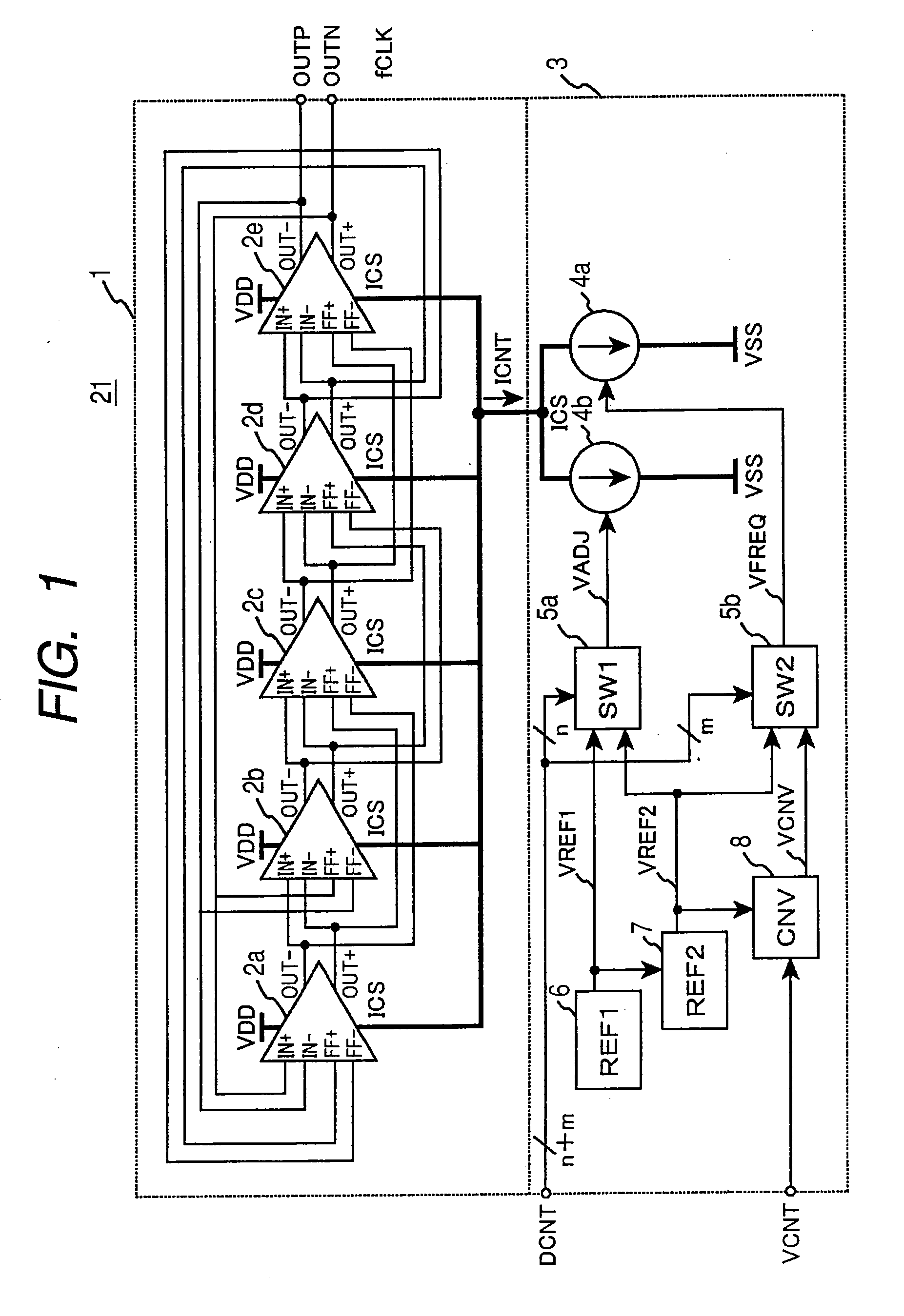

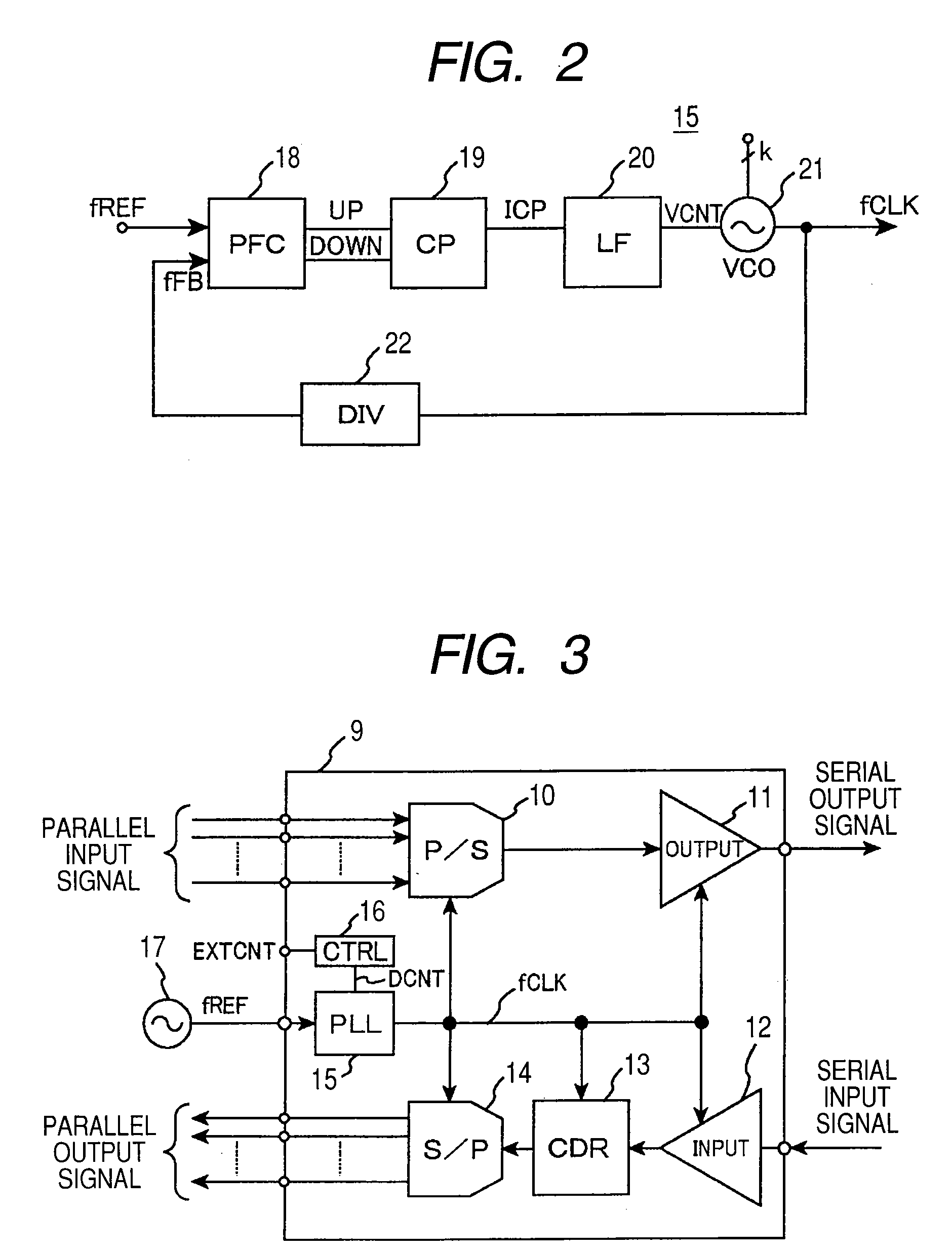

Variable frequency oscillator and communication circuit with it

InactiveUS20080122546A1Reduce phase noiseShorten the length of timeParallel/series conversionPulse automatic controlInput controlEngineering

In a variable frequency oscillator in a semiconductor device, as the variation of an oscillation frequency caused by the variation of temperature and supply voltage and process variation is large, it is difficult to reduce the conversion ratio of control voltage dependent upon phase noise and the oscillation frequency and therefore, phase noise is large. The variation of the oscillation frequency is suppressed and phase noise is reduced by connecting a voltage-to-current conversion circuit that converts input control voltage to control current of a ring oscillator to the ring oscillator where delay circuits a delay time of which increases and decreases according to the amplitude of input control current are cascade-connected by a plurality of stages in a ring and increasing / decreasing current dependent upon any of temperature, supply voltage and the threshold voltage of a transistor inside the voltage-to-current conversion circuit.

Owner:HITACHI LTD

Detection of data received by a master device in a single-wire communication protocol

ActiveUS20090252068A1High communication rateLess sensitiveError preventionTransmission systemsReal-time computing

A method of determining, by a first device capable of transmitting a two-state signal over a single-wire connection to a second device, the binary state of data transmitted by the second device over said connection, the state being determined according to the slope of a rising edge of the two-state signal.

Owner:STMICROELECTRONICS (ROUSSET) SAS

Four-color LED light mixing method based on visible light communication

ActiveCN104053278ASpectrum richColor temperature adjustablePoint-like light sourceElectric lightingColor rendering indexSpectrograph

The invention discloses a four-color LED light mixing method based on visible light communication. The method comprises the steps that spectral power distribution of all monochromatic light is obtained through a spectrograph, and the tristimulus value of each corresponding monochromatic light is calculated; the target color temperature of mixed light is determined, and a corresponding reference light source is selected and used for obtaining the tristimulus value of a mixed color; according to the color addition principle, the sum of the tristimulus values of all the monochromatic light should be equal to the tristimulus value of the mixed color, and a color mixing equation set is obtained; the spectral power distribution of the mixed light can be obtained according to the light mixing coefficient of all the monochromatic light in the color mixing equation set, and the color rendering index Ra of the mixed light is calculated according to the spectral power distribution of the mixed light, wherein Ra is larger than or equal to epsilon; the range of the channel capacity C of the mixed light is calculated, and the maximum capacity Cmax is solved within the range; the ratio of all the colored light with the maximum capacity is output.

Owner:SOUTHEAST UNIV

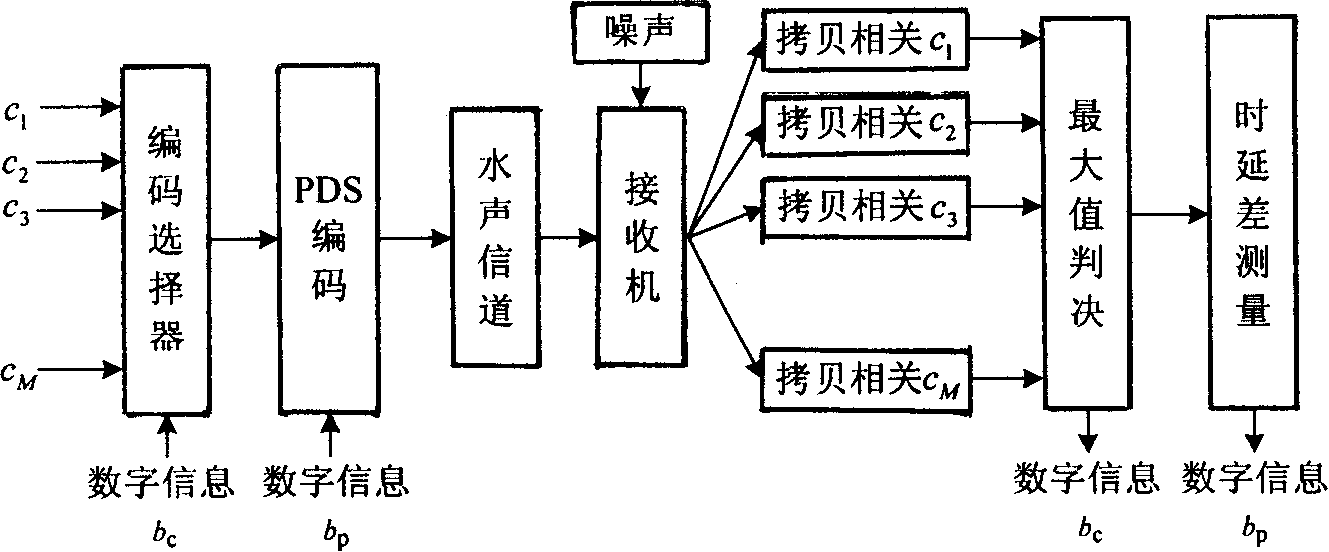

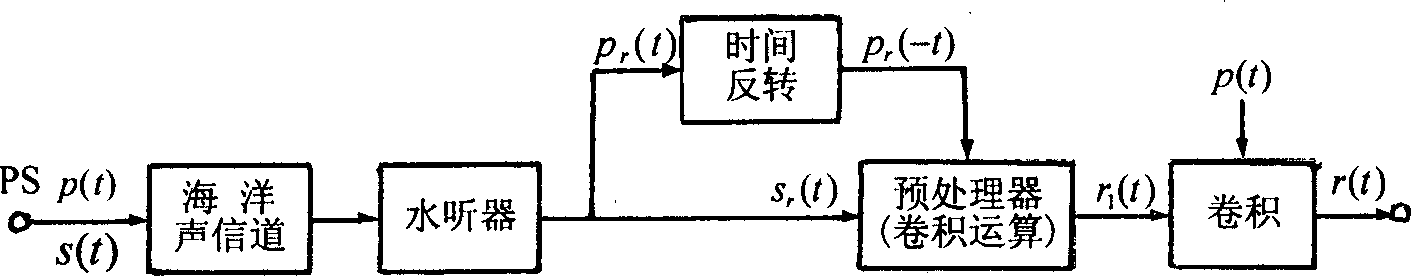

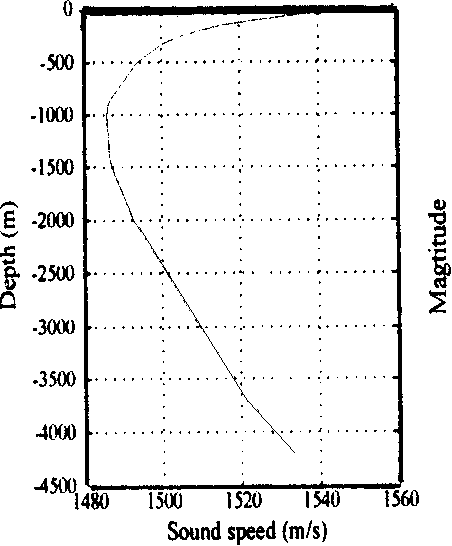

Deep sea remote water sound communication method

InactiveCN101166065ASuppress interferenceHigh communication rateTransmitter/receiver shaping networksSound sourcesSignal-to-noise ratio (imaging)

This invention provides a blue water remote underwater communication method including: 1, combining frequency-expansion communication with a Pattern time delay difference coding underwater communication system and applying a work mode of M members, 2, applying a single array element PTRM channel balance technology at the receiving end, 3, analyzing character of blue-water tracks and pointing out that when a sound source is near a track shaft, regions along the shaft are gathered regions. Advantages: 1, communication rate is increased due to the frequency-expansion and the Pattern time delay difference coding method, 2, the single array element passive time reversing mirror can use multi-use expansion signals to suppress interference among codes and get gathered gain , 3, realizing stable remote communication by the character of blue-water communication.

Owner:HARBIN ENG UNIV

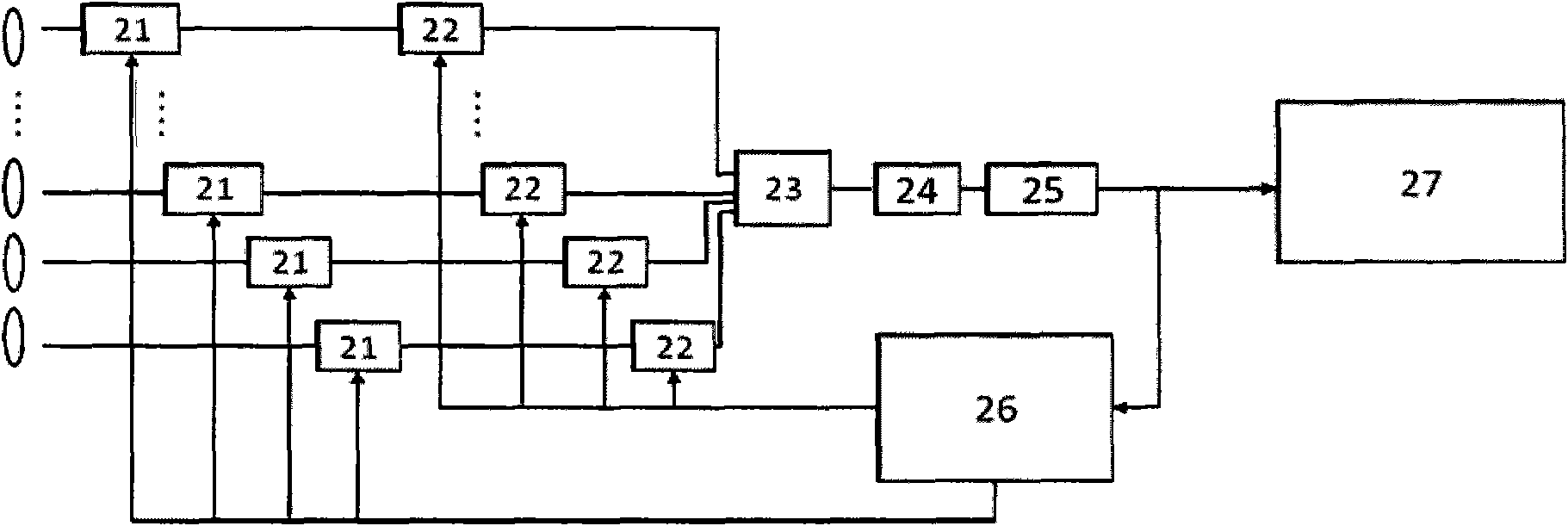

Receiving system in wireless optical communication and signal receiving method thereof

InactiveCN101873169AHigh sensitivityHighly integratedCoupling light guidesElectromagnetic receiversOptical couplerOpto electronic

The invention relates to a receiving system in wireless optical communication and a signal receiving method thereof, and belongs to the field of optical communication. The system comprises a group of focusing lenses, a group of fiber or waveguide array, a group of optical signal delayers, a group of optical phase modulators, an optical coupler, an optical filter, a photoelectric detector, an analysis and calculation control module and a decoding and sampling judgment module. The method comprises the following steps of: 1) focusing and feeding spacial optical signals into a fiber array by adopting the group of focusing lenses; 2) performing phase delay and phase modulation on each path of the fiber array, and coupling-out a path of optical signals; 3) filtering the optical signals, converting the optical signals into electric signals, and outputting the electric signals to the decoding and sampling judgment module and the analysis and calculation control module respectively; and 4) in a communication time slot, restoring original information from the received electric signals by using the decoding and sampling judgment module, and in a reference time slot, performing feedback adjustment on each path of received optical signals by using the analysis and calculation control module. The receiving system and the signal receiving method thereof have the advantages of easy implementation and high precision.

Owner:PEKING UNIV

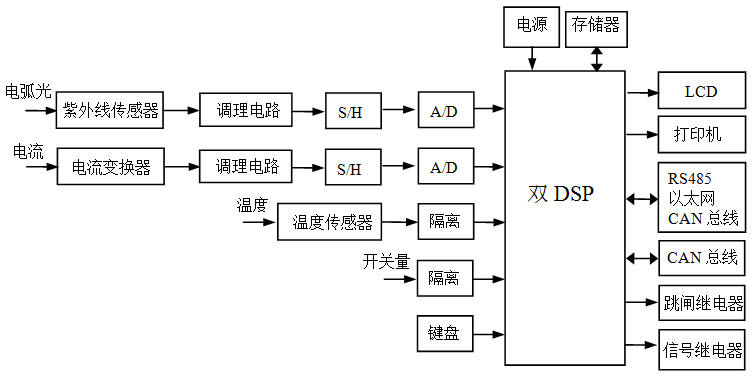

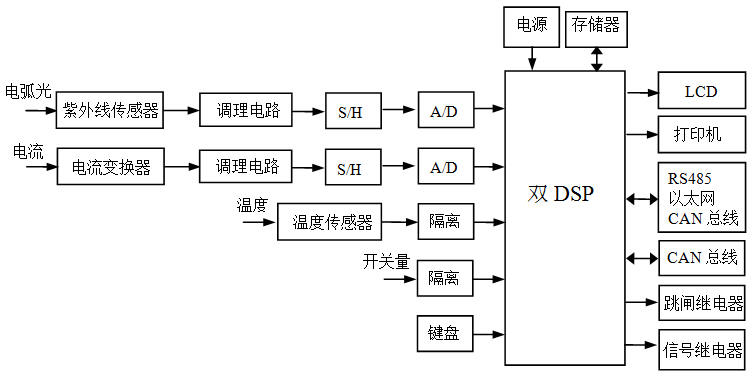

Monitoring and arc protecting system for switch cabinet

InactiveCN102694372AHigh communication rateAutomatic real-time monitoring of temperatureEmergency protective circuit arrangementsSustainable buildingsUltravioletSwitchgear

The invention relates to a running state monitoring and arc protecting system for a switch cabinet, which belongs to the monitoring and relay protection field of electric equipment. The system consists of a host machine and a slave machine which are both controlled by a DSP (Digital Signal Processor) and adopt field bus communication. A digital temperature sensor is used for monitoring the temperature in the switch cabinet; and an ultraviolet sensor is used for detecting partial discharge in the switch cabinet and ultraviolet rays emitted by short circuit arcs. The system has the characteristics that temperature rise or partial discharge caused by abnormal operation of the switch cabinet can be detected and a warning signal can be given out immediately to prevent the switch cabinet from short troubles. If the switch cabinet is suddenly short-circuited, the system can immediately detect the ultraviolet rays emitted by the arcs, rapidly transmit information through an advanced field bus and quickly and selectively clear faults.

Owner:NANJING NORMAL UNIVERSITY

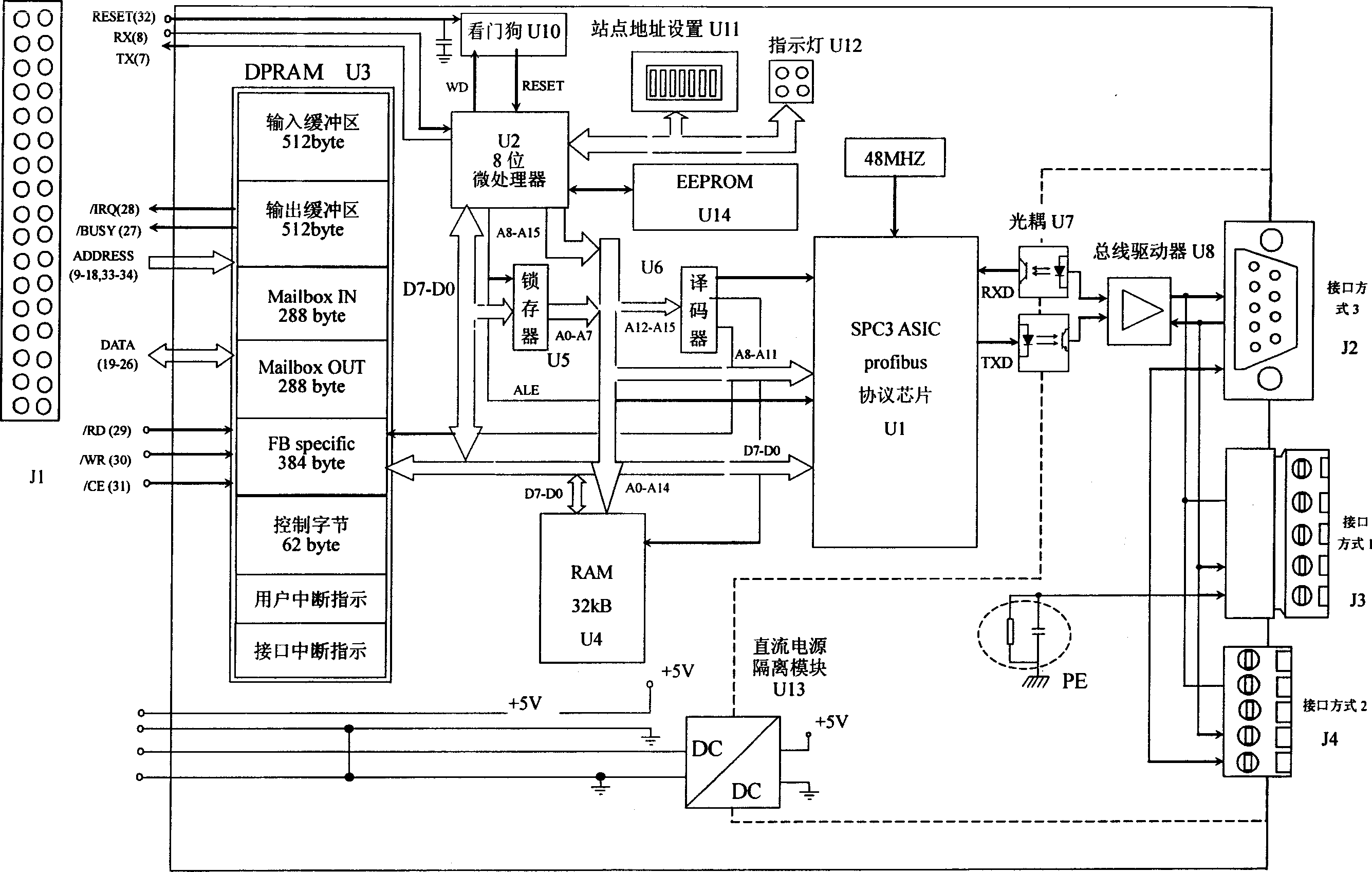

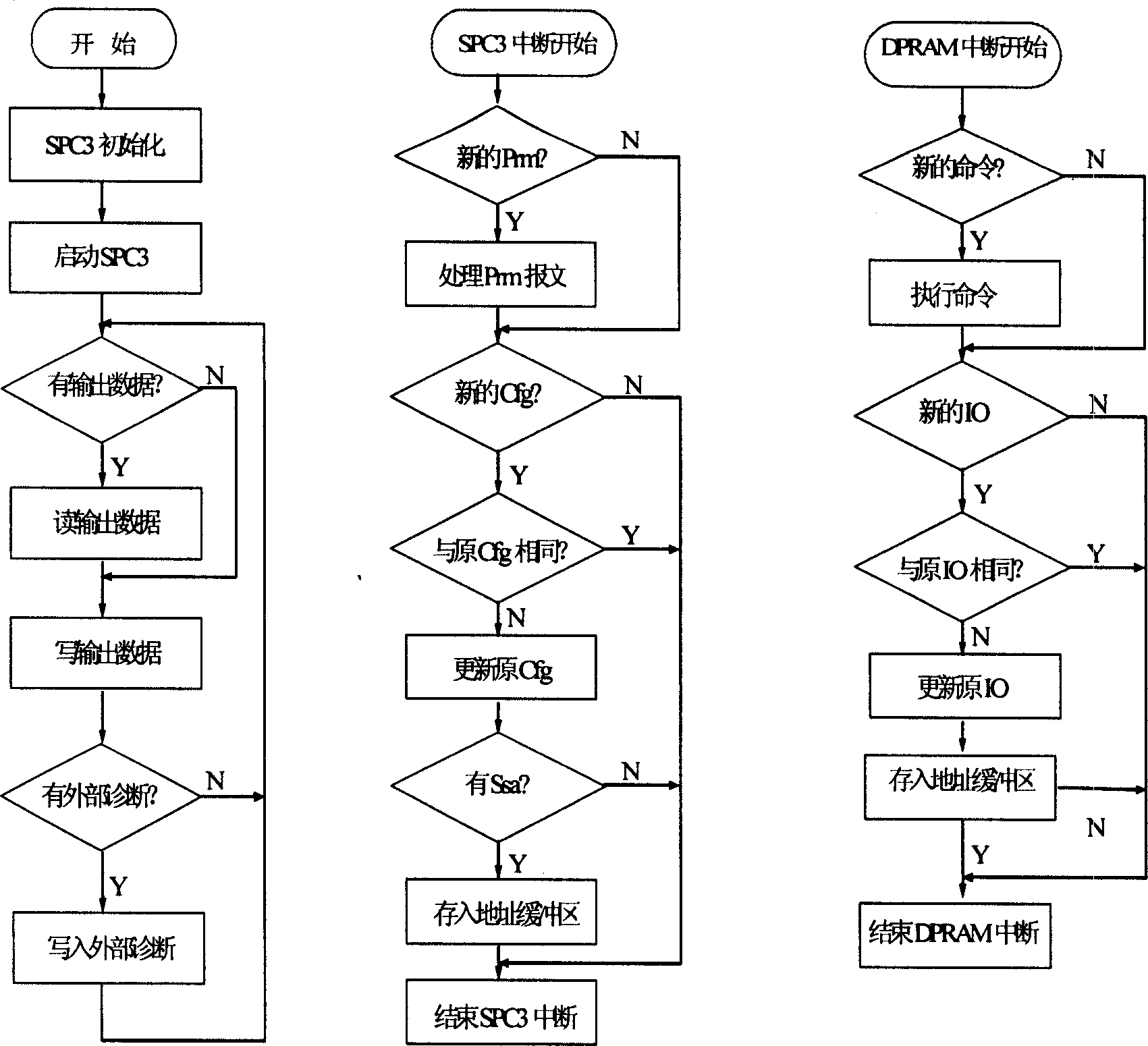

Embedded field bus protocol interface device and implementation method

InactiveCN1801020AReduce distractionsReliable communicationTransmissionTotal factory controlComputer moduleMovement control

The invention discloses a flush-type on-site bus protocol interface device and method, which connects instrument or equipment with PROFBUS to accomplish DP passive station communication function in the on-site PROFBUS. One end of interface mode exchanges data with 8-byte or 16-byte microprocessor as intelligent controller through two-port RAM or asynchronous serial port of TTL electrical level, which can be embedded in the circuit of intelligent instrument equipment; the other end displays standard Profibus-DP passive station interface, which communicates with other equipments through the switch-in bus of Profibus-DP passive station. The invention is fit for Profibus interface of high speed and moving control device, which brings significant social and economical benefit.

Owner:HEBEI UNIV OF TECH

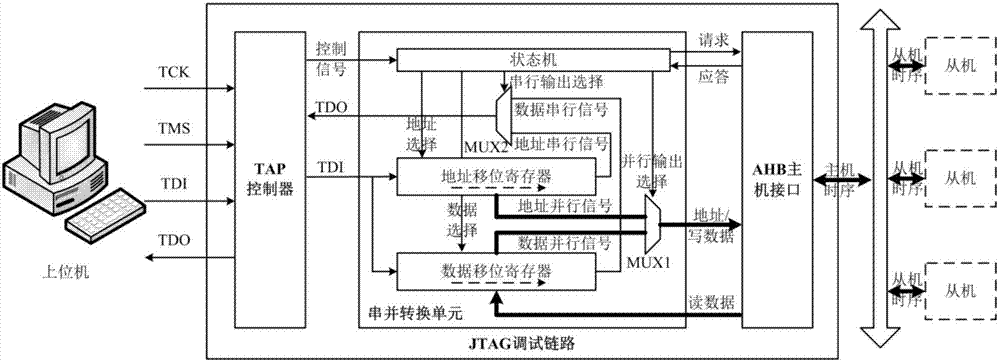

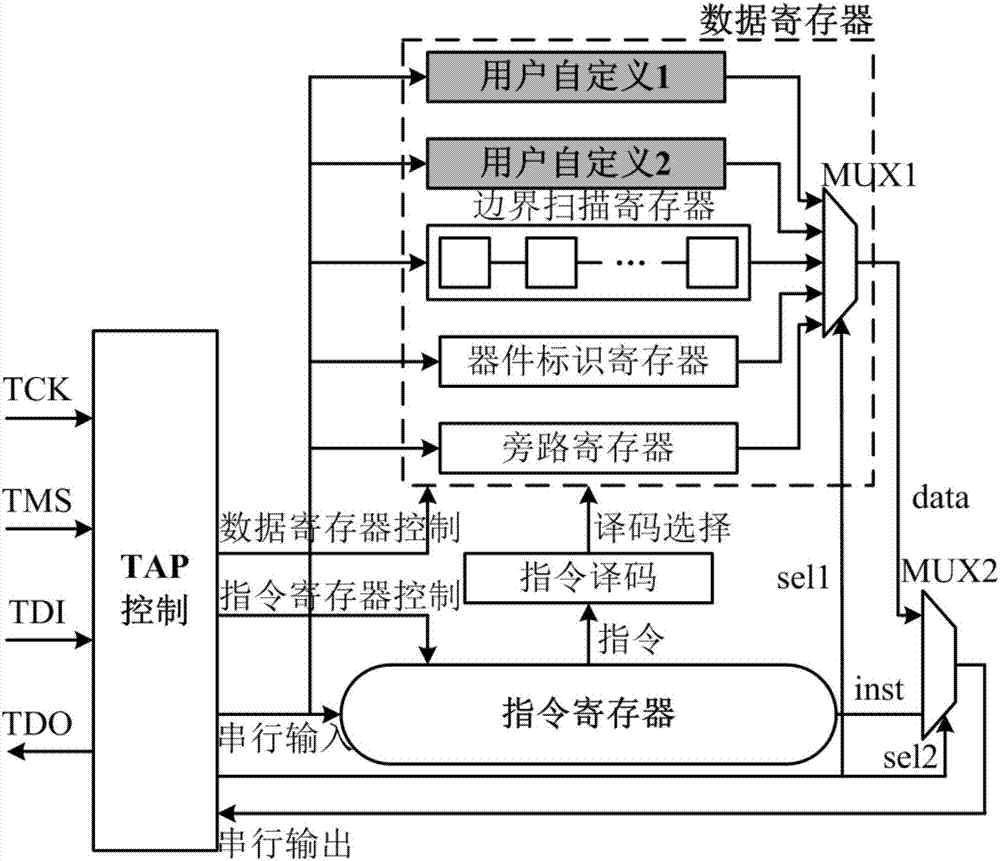

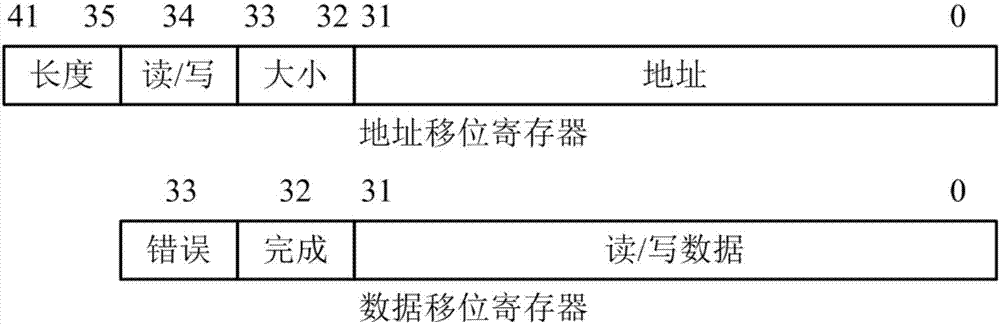

Non-handshake-type JTAG debugging link compatible to AHB protocol and debugging method thereof

ActiveCN107577635AImprove stabilityUniversal goodElectric digital data processingComputer hardwareJoint Test Action Group

The invention discloses a non-handshake-type JTAG debugging link compatible to an AHB protocol and a debugging method thereof. The link comprises a deserializing unit which is provided with an external JTAG standard interface on one side and an AHB standard host interface on the other side, and the deserializing unit utilizes a user-defined TAP controller instruction of an IEEE 1149.1 protocol toachieve seamless connection with the AHB protocol through an extension instruction; on the basis of mutual parsing of information, a high-speed serial debugging command sent by an upper computer is mapped onto communication channels of the interior of a chip, an access command is sent to the whole system of the chip to simulate the behaviors of a host, and then the key status information about system running is converted into serial data again and sent back to the upper computer. Compared with traditional debugging approaches, the method has the advantages of being higher in speed and better in stability, since the JTAG interface of standard DFT is repeatedly used, pin resources of the chip are saved, and by establishing a conversion channel between the standard JTAG interface and an on-chip AMBA bus, the method has high practical value and universality.

Owner:XIAN MICROELECTRONICS TECH INST

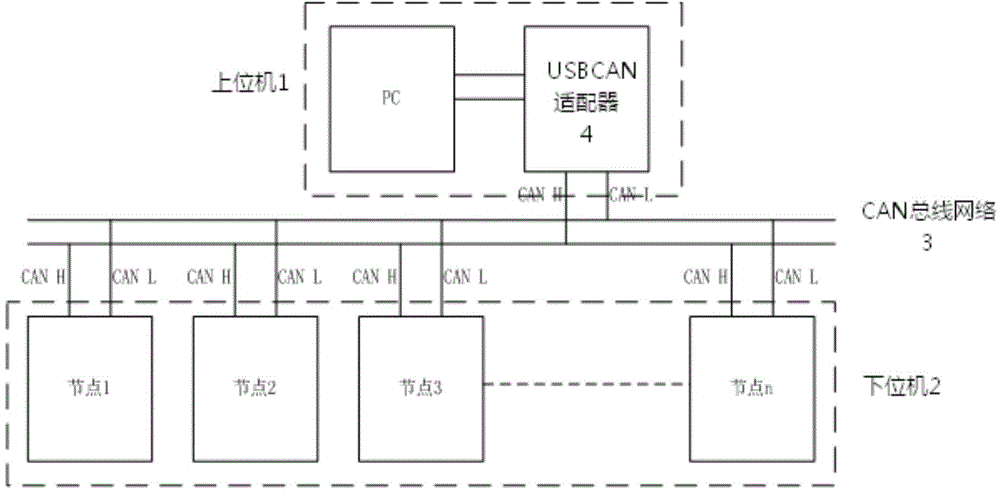

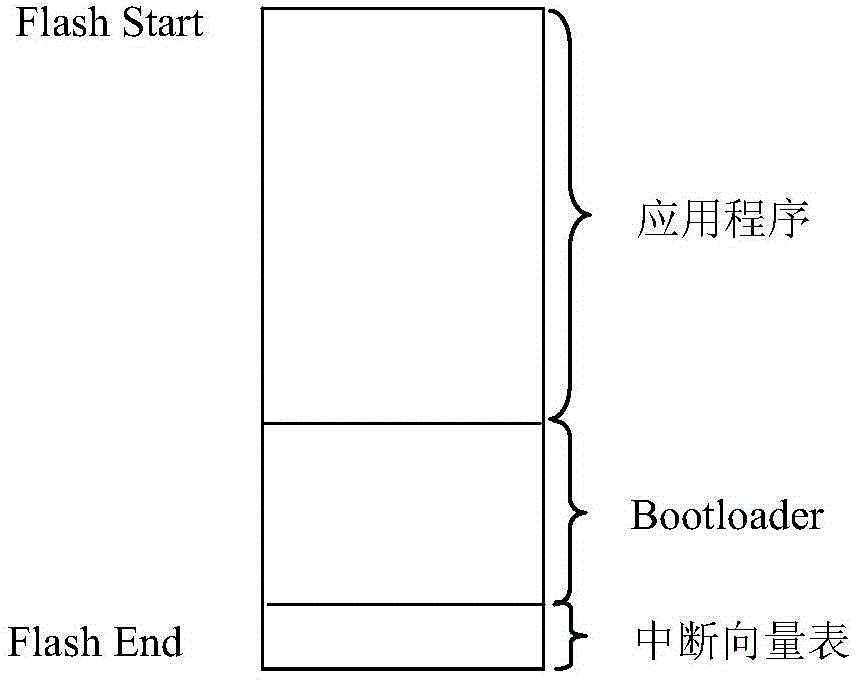

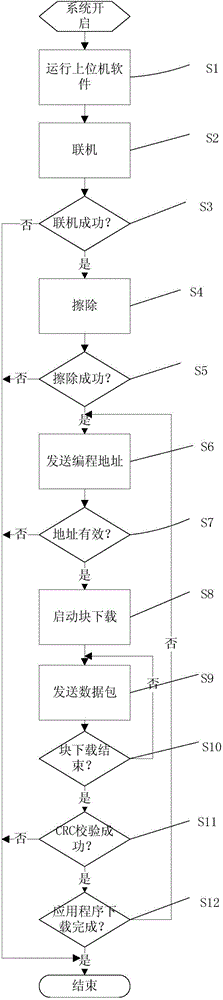

CANOPEN-protocol-based embedded software upgrading method

ActiveCN103559066AStrong anti-drying abilityHigh communication rateProgram loading/initiatingTransmissionNetwork connectionCANopen

The invention relates to a CANOPEN-protocol-based embedded software upgrading method. The method is applied to a system formed by an upper computer and a lower computer which are in network connection through a CAN bus. The method comprises the following steps: connecting the upper computer and the lower computer, and confirming the effectiveness of the programming address after the successful connection; adopting a block transmission mechanism in an SDO protocol when the effectiveness is ensured; sending the block data in a subpackage way until all data of the application program are sent; afterwards, skipping to the application program area of a storer to implement the application program to complete the program upgrading. Compared with the prior art, the method has the advantages of strong anti-interference ability, high transmission rate, wide application range, convenience in follow-up development, and the like.

Owner:上海创程车联网络科技有限公司

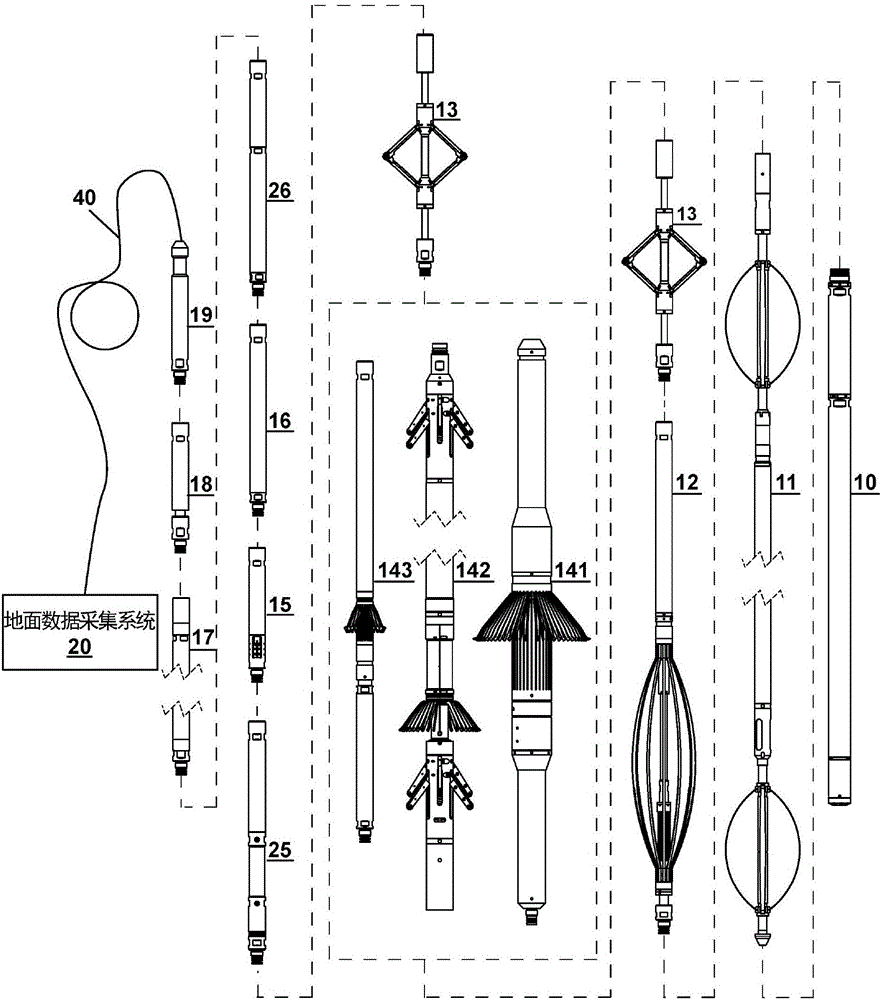

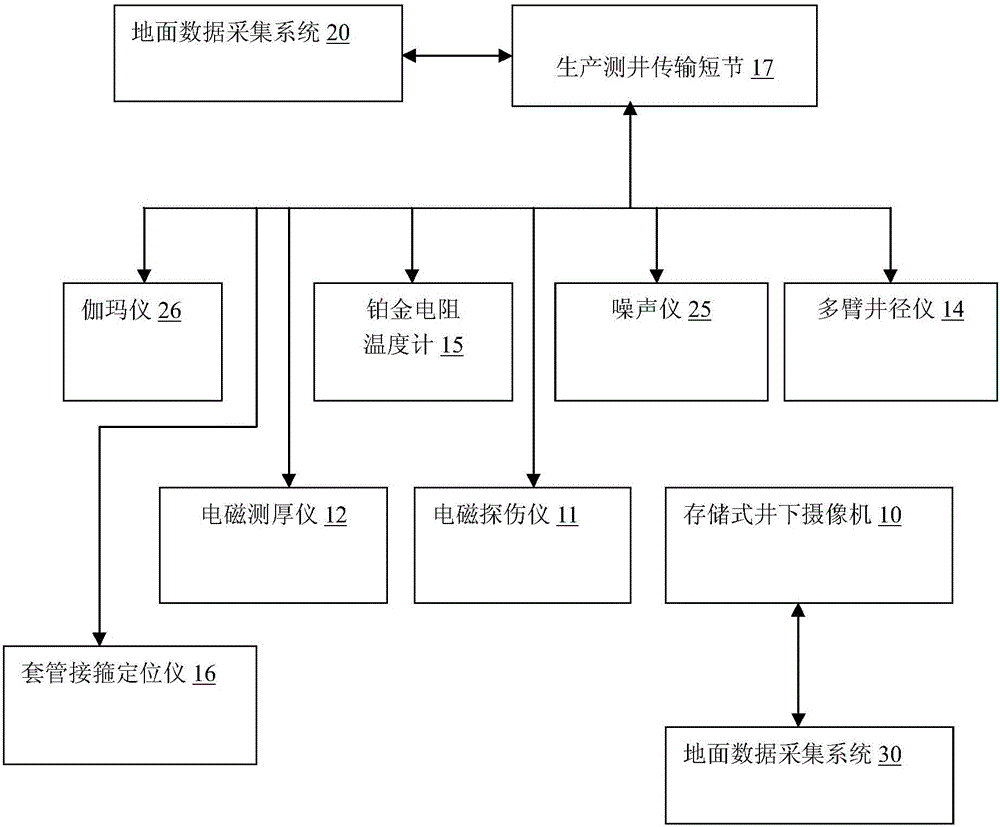

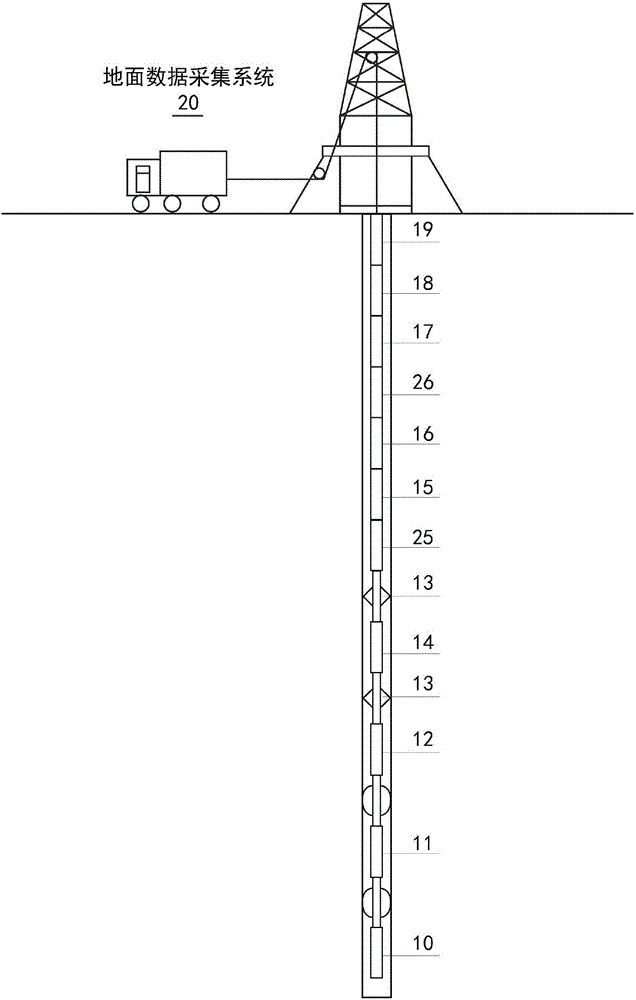

Oil pipe and casing pipe comprehensive flaw detection system

InactiveCN106194158AImprove reliabilityFlexible useSurveyConstructionsCable transmissionElectrical resistance and conductance

The invention relates to an oil pipe and casing pipe comprehensive flaw detection system (MultiCIS). The downhole flaw detection system is a downhole instrument set formed by connecting a plurality of flaw detection instruments and auxiliary instruments in series up and down. The downhole instrument set is mainly composed of a rotary short section, a transmission short section, a platinum resistance thermometer, a gamma instrument, a casing pipe collar positioning instrument, centering devices, a multi-arm caliper device, an electromagnetic thickness meter, the electromagnetic flaw detectors, a storage type downhole camera and a noise meter, wherein the multi-arm caliper device mainly refers to a 24-arm caliper device or a 40-arm caliper device or a 60-arm caliper device. The instrument at the uppermost end of the downhole instrument set is connected with a cable head, and signals transmitted out by the instruments in the downhole instrument set are transmitted to a ground data acquisition system through the production logging transmission short section by means of a cable. According to the downhole flaw detection system, after being connected, the downhole instrument set comprising the flaw detection instruments is released into a well at a time so as to comprehensively detect an oil pipe and a casing pipe, multiple sets of logging data are obtained through one-time logging, mutual complementation and verification can be conducted between the obtained logging data, and operation efficiency and reliability are greatly improved. Comprehensive assessment can be conducted on oil pipe and casing pipe flaw detection.

Owner:BEIJING JIEWEISITE TECH CO LTD

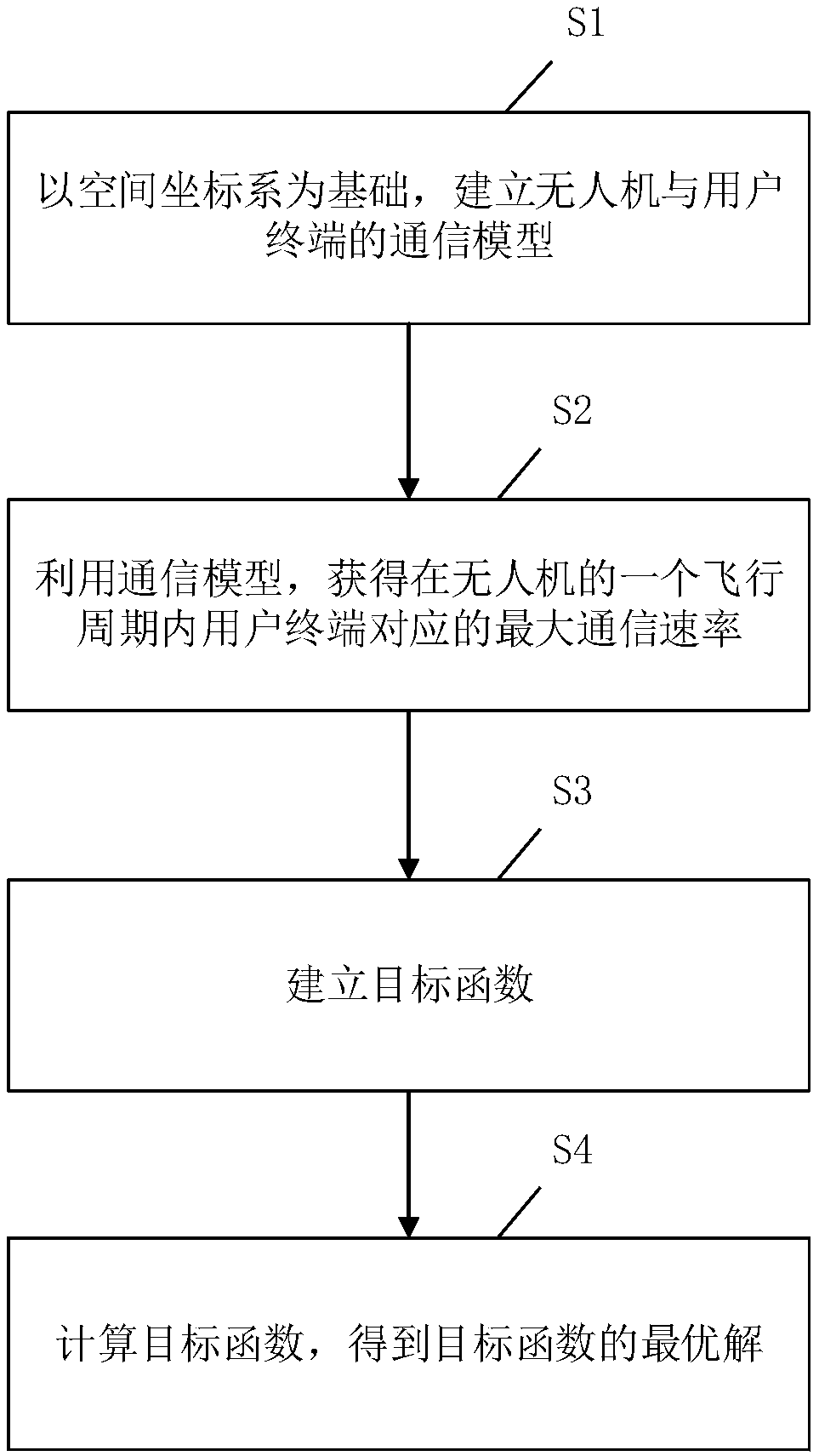

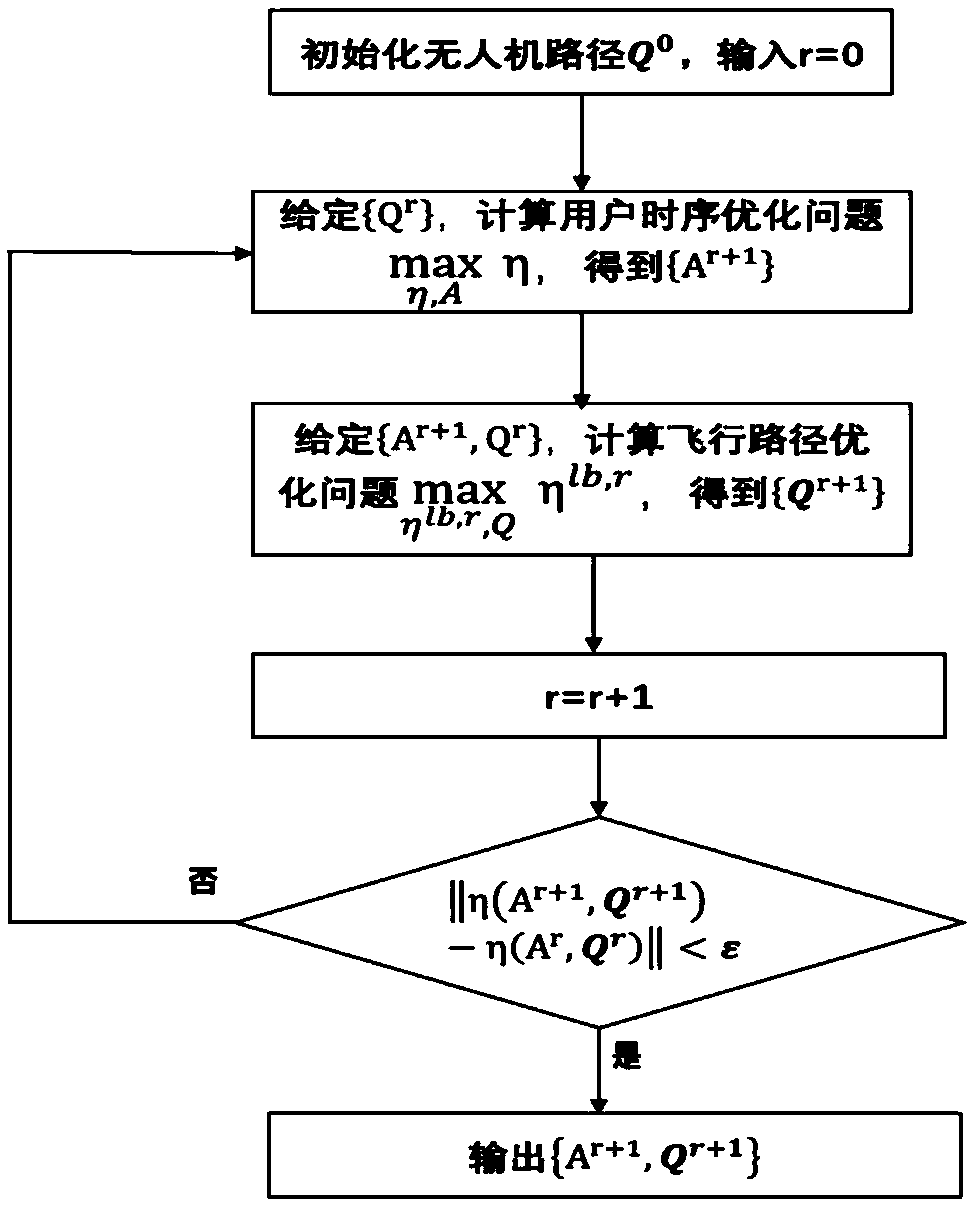

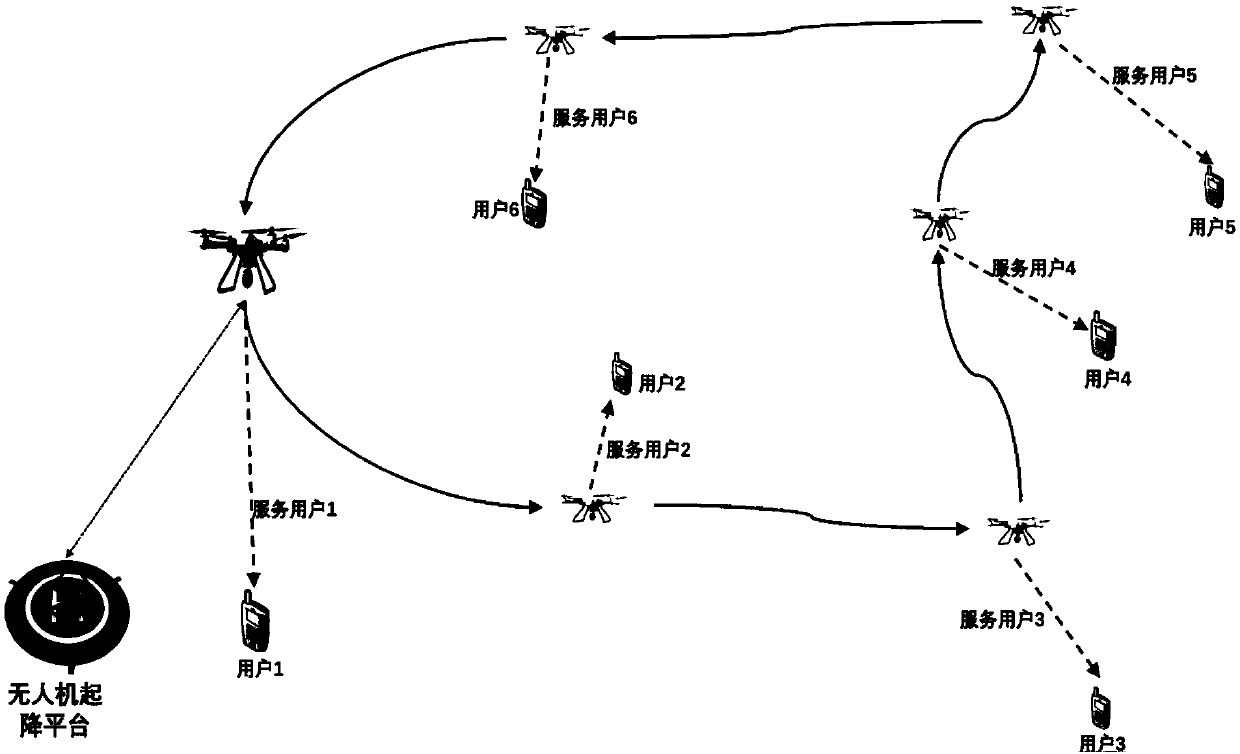

Control method, system and device of unmanned aerial vehicle base station communication system and storage medium

ActiveCN108616303AHigh communication rateGet the most out of mobile flexibilityRadio transmissionPosition/course control in three dimensionsCommunications systemUncrewed vehicle

The invention discloses a control method of an unmanned aerial vehicle base station communication system and a storage medium. The method comprises steps of establishing a communication model of an unmanned aerial vehicle and a user terminal, wherein the communication model comprises a flight path shown in the description in a flight period of the unmanned aerial vehicle and a communication time sequence shown in the description of the user terminal and the unmanned aerial vehicle in the flight period; by use of the communication model, acquiring the biggest communication speed corresponding to the user terminal in the flight period, wherein the biggest communication speed corresponding to the ith user terminal; and establishing a target function shown in the description, wherein a formulais shown in the description, and calculating the target function so as to obtain an optimal solution of the target function. According to the invention, the optimal solution of the target function isfinally obtained and comprises an optimal selection of the flight path of the unmanned aerial vehicle and the communication time sequence; the target function is used for controlling the unmanned aerial vehicle base station; according to the flight routes of the unmanned aerial vehicle, the accessing sequence and duration of the user can be flexibly dispatched; and performance of the communication system can be optimized by use of the mobility of the unmanned aerial vehicle.

Owner:佛山国防科技工业技术成果产业化应用推广中心

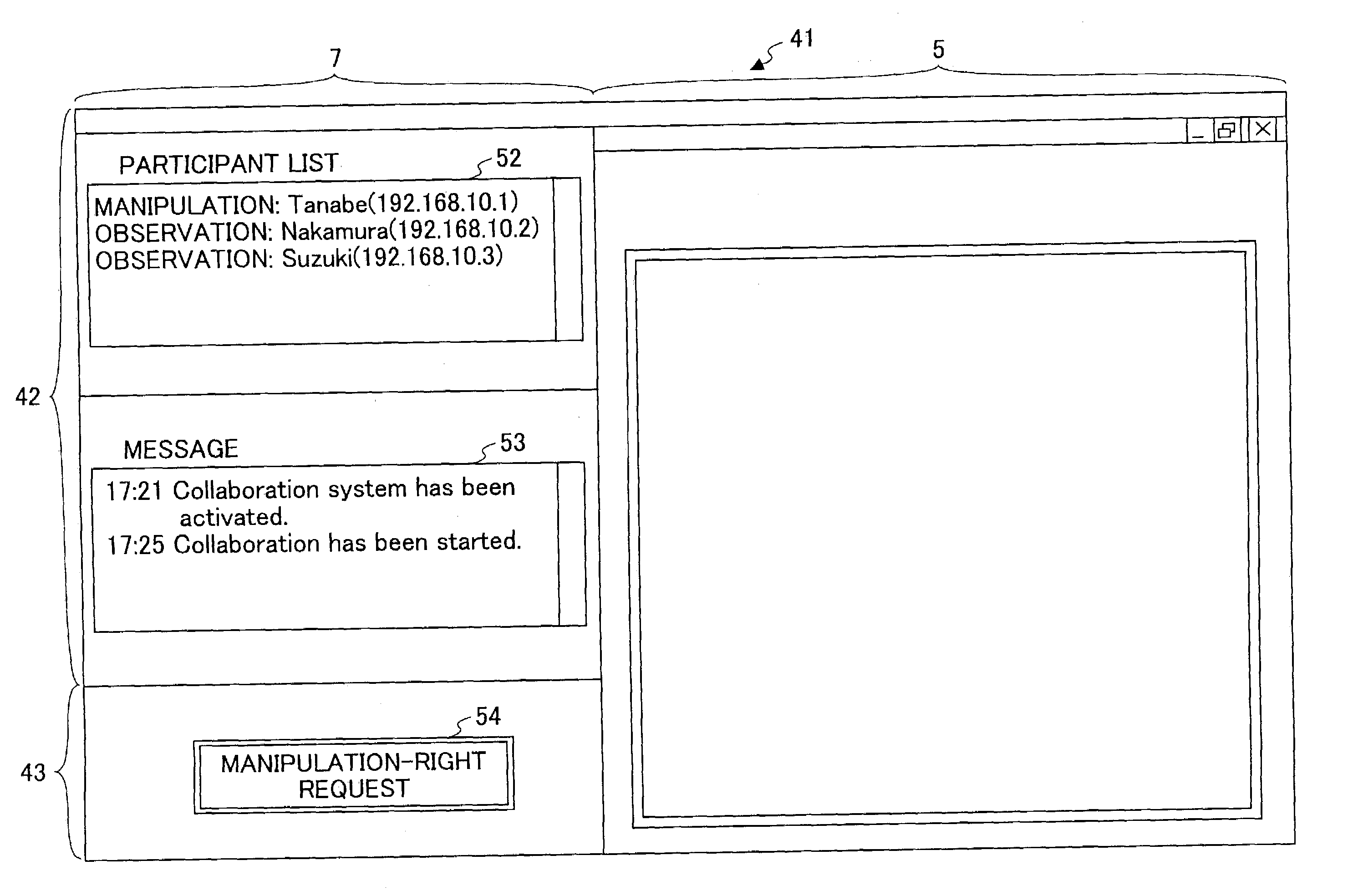

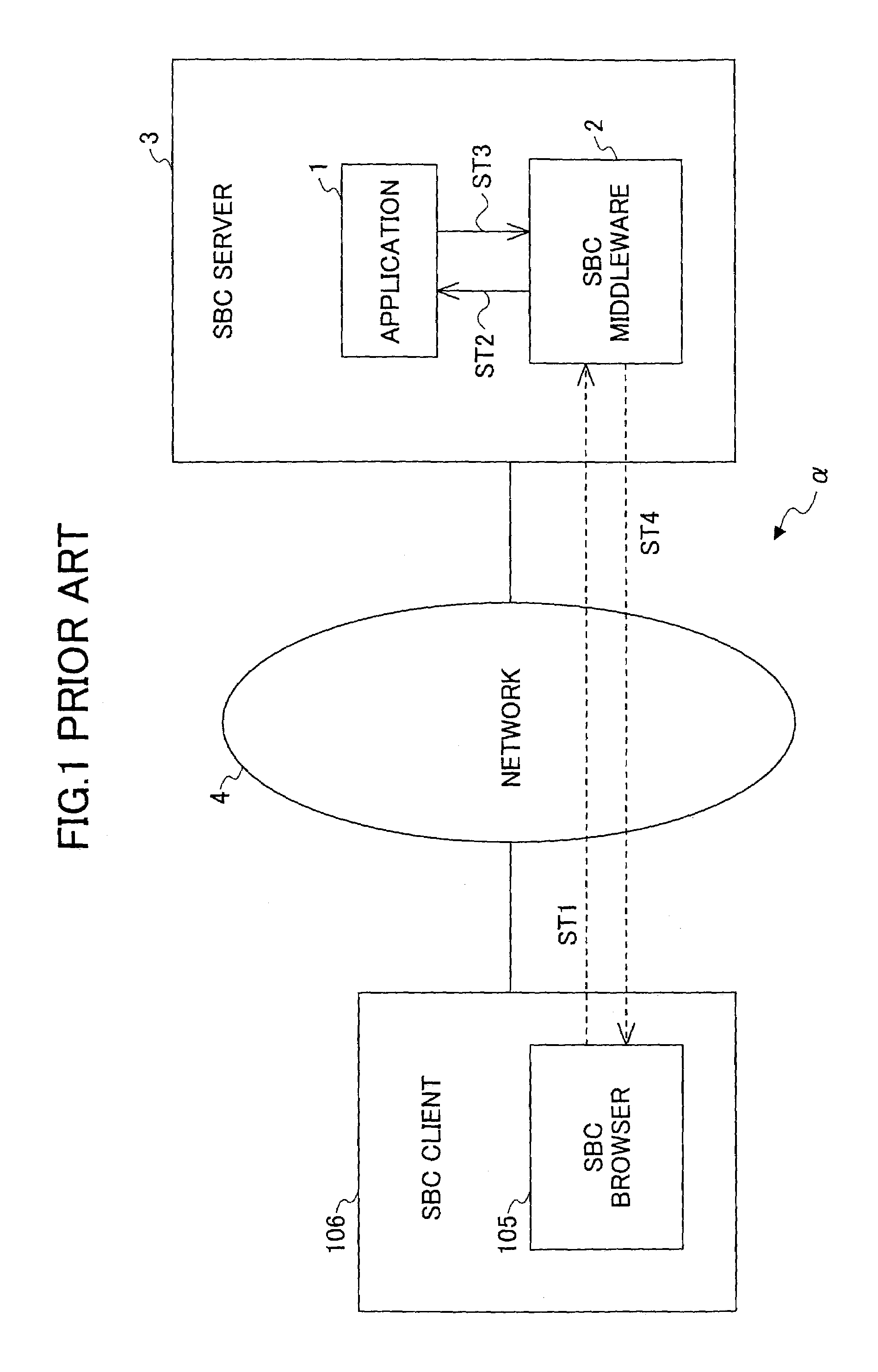

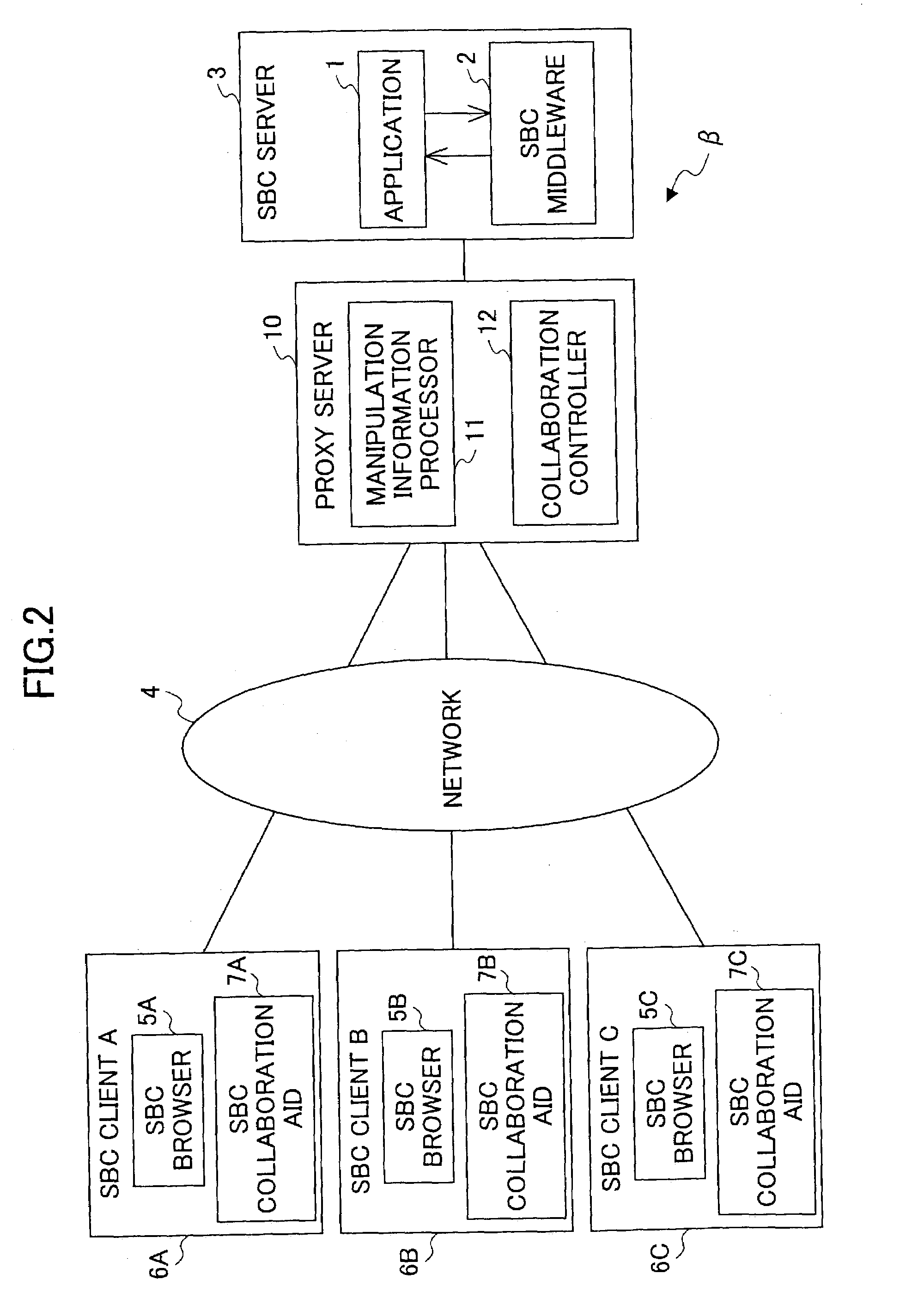

Distributed server-based collaborative computing

InactiveUS7191217B2Evenly distributedHigh communication rateMultiple digital computer combinationsTransmissionNetwork connectionDistributed servers

A proxy server is inserted between an SBC server, which is furnished with SBC middleware capable of installation of an application, and a plurality of SBC clients connected to the SBC server via a network in a server-based computing system. The proxy server comprises a manipulation right controller that gives a manipulation right to execute the application to a first SBC client, a manipulation information relay unit that receives first input manipulation information for executing the application from the first SBC client and transmits the first input manipulation information to the SBC server to cause the application to be executed, and an execution screen distributor that receives an execution screen of the application from the SBC server and distributes the execution screen to each of the SBC clients.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com