Embedded field bus protocol interface device and implementation method

A protocol interface and fieldbus technology, applied in the field of Profibus-DP fieldbus intelligent slave interface module, can solve the problems of poor versatility, single function, inconvenient porting, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

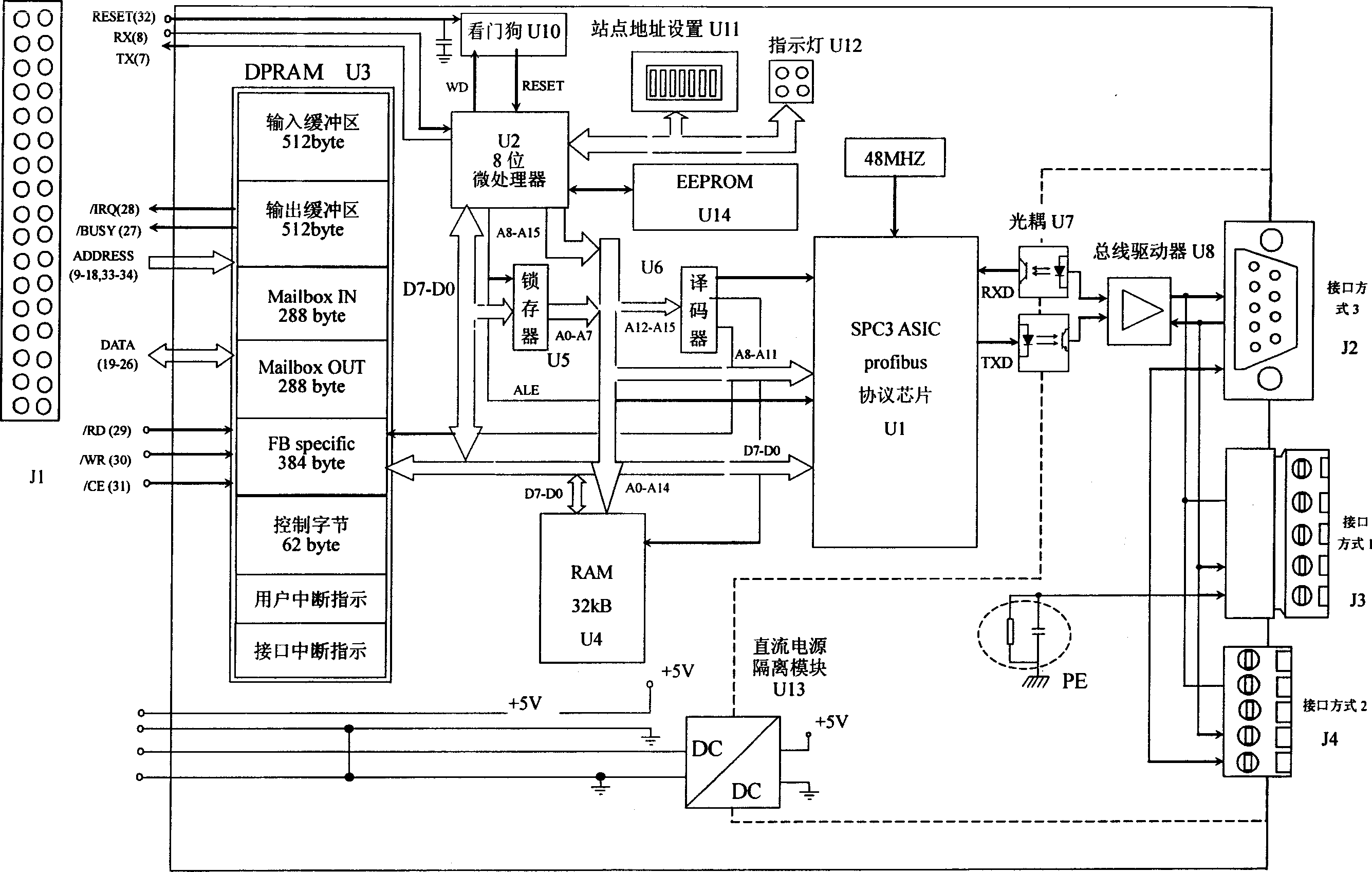

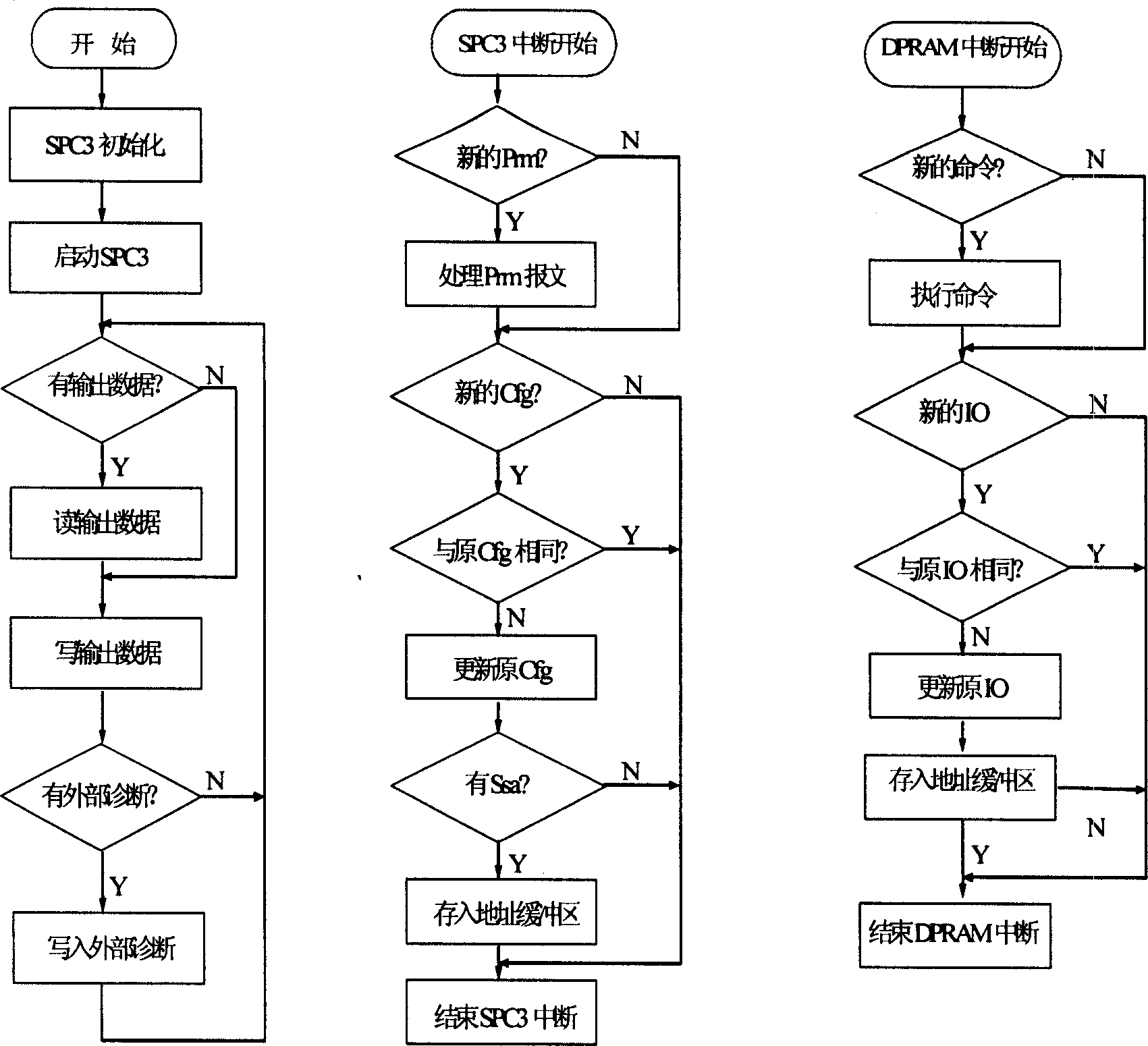

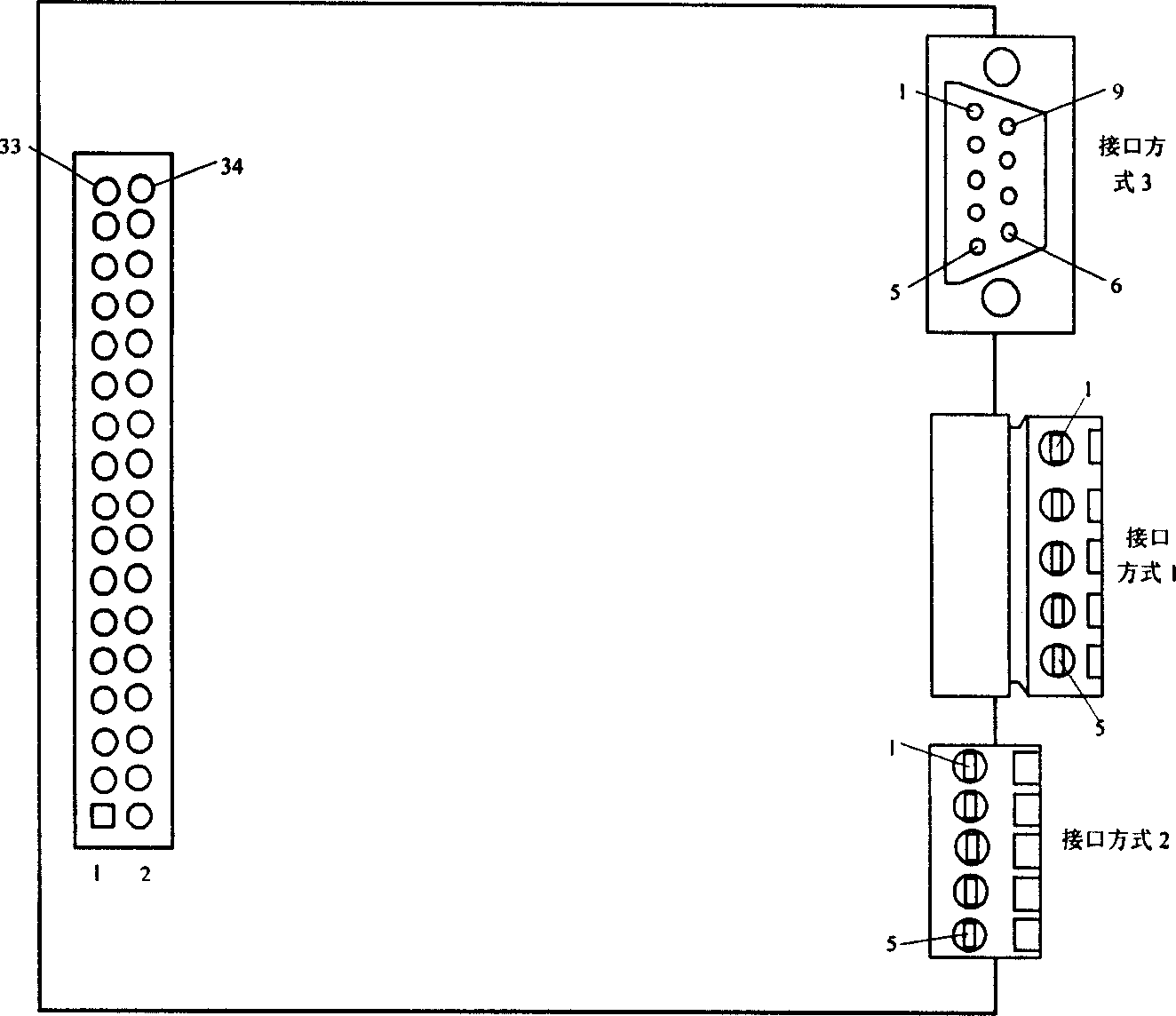

[0038] figure 1 It is a schematic diagram of the Profibus-DP field bus slave station interface device of the present invention: it mainly includes: Profibus-DP protocol processing chip (SPC3) (U1). Bus driver (U8), high-speed optical isolation (U7), DC / DC converter (U13), DB9 pin type (J2), 5-pin pluggable socket (J3) and 5-pin screw-fixed socket (J4) ;Microcontroller (U2), serial EEPROM (U14), power monitoring, watchdog chip (U10), latch (U5), decoder (U6), slave station address setting dial switch (U11) And working status indicator light (U12); 32K external data memory (U4), dual-port RAM (U3), 34-pin socket (J1).

[0039]Dual-port RAM parallel bus is used to realize high-speed repeated data exchange without handshake between two processors, which can improve system transmission speed and efficiency. Dual-port RAM has two sets of independent address, data, and read-write control lines, which can be connected to two different CPUs at the same time. As long as the same stora...

Embodiment 2

[0047] Figure 5 The second connection method to realize the Profibus field bus interface for the user product circuit template. In this connection mode, user product circuit template A and Profibus protocol conversion interface B realize data information exchange through TTL asynchronous serial port. This method is characterized by fewer connecting lines, simple structure, and slower speed. When the user product needs to communicate with the master station device of the field bus, it only needs to connect the CPU ⑦ of the user product circuit template A and the CPU ① on the Profibus protocol conversion interface B through two asynchronous transceiver data lines. When user product circuit template A sends data to the master device of the Profibus field bus, first CPU⑦ transmits the data to CPU① through the asynchronous serial port UART, and after receiving the data, CPU① performs Profibus-DP protocol conversion through SPC3③ and becomes fieldbus capable The identified data f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com