GSK-Link bus based modular robot control device and control method

A control device and robot technology, applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve problems such as system failure, high cost, and poor bus scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

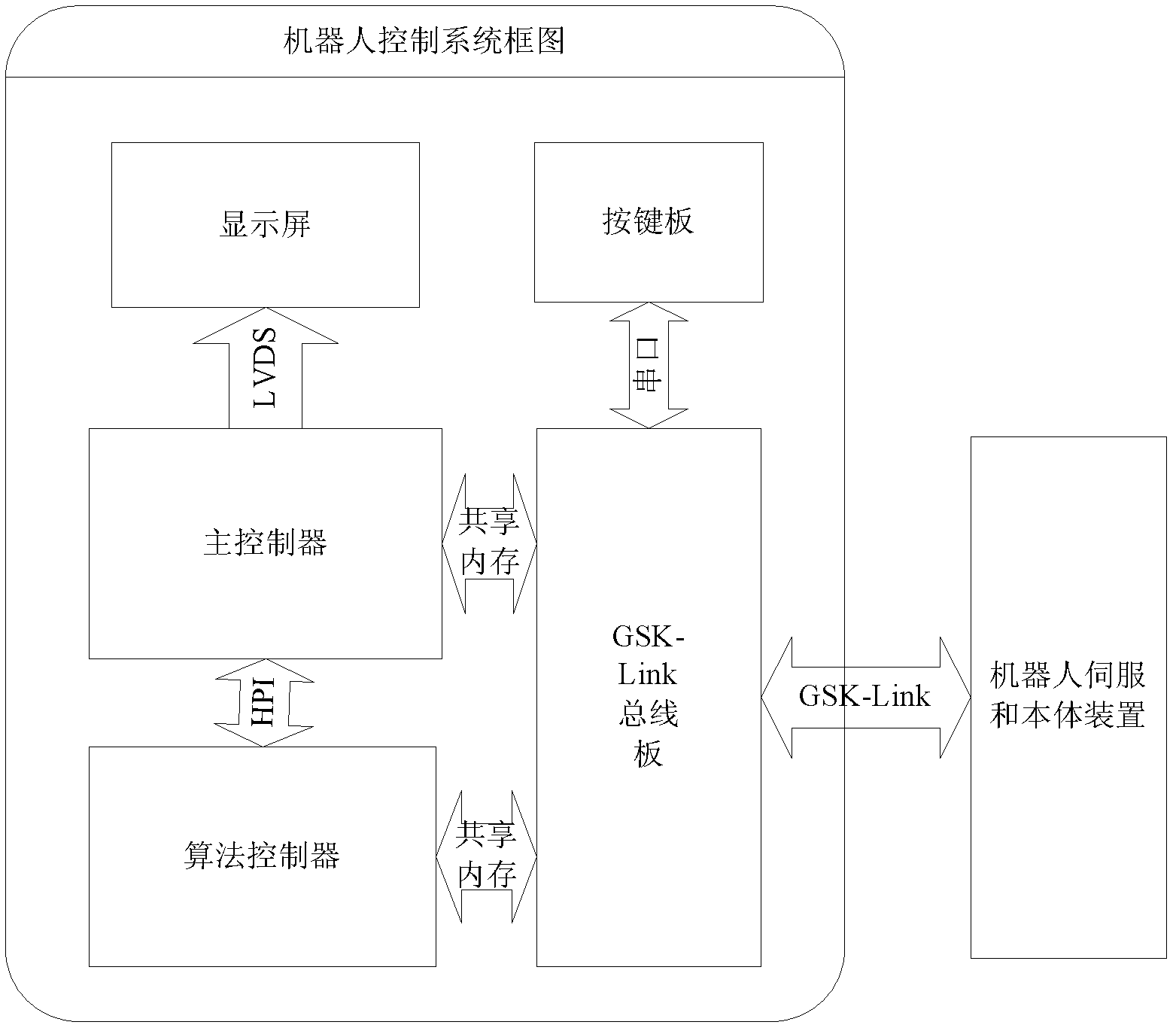

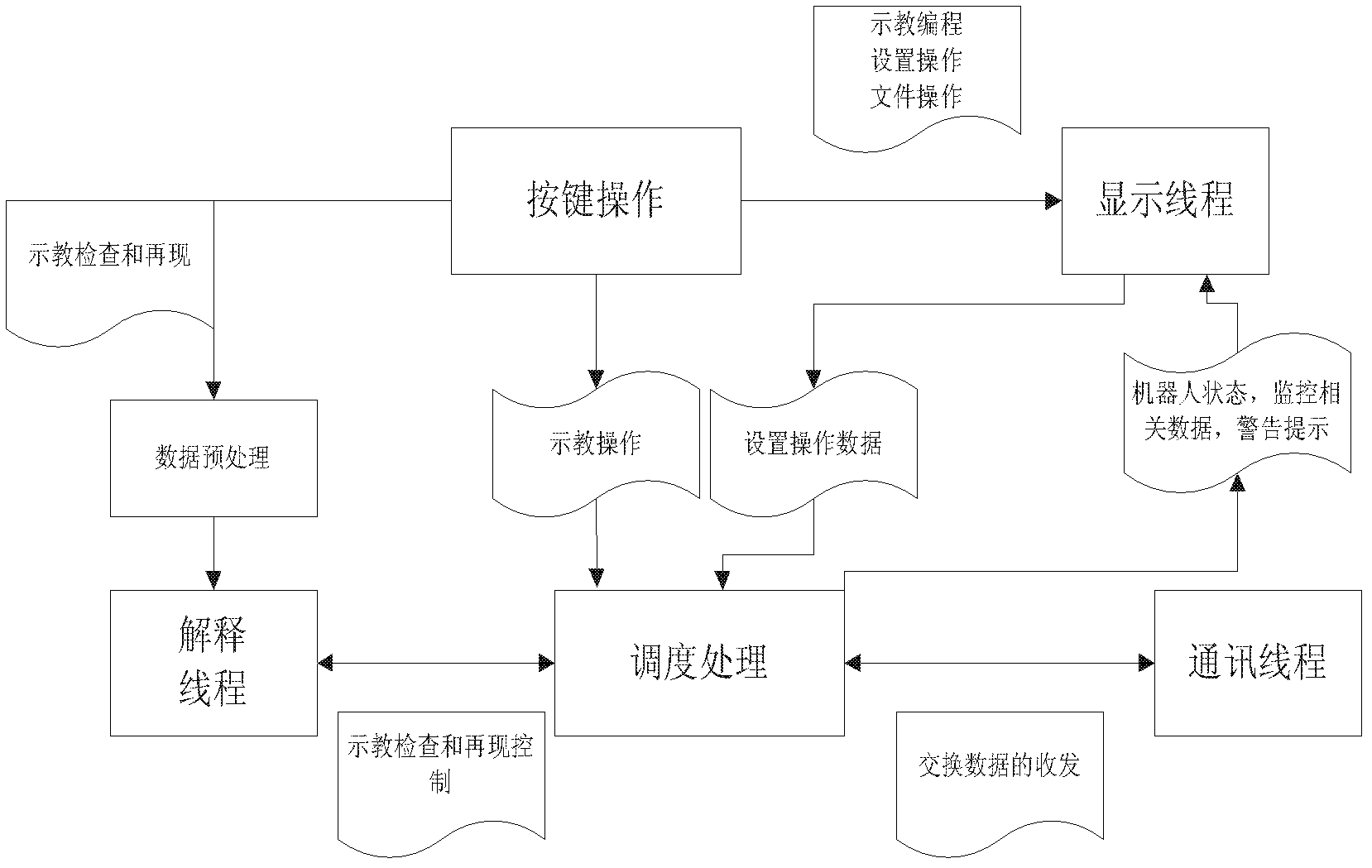

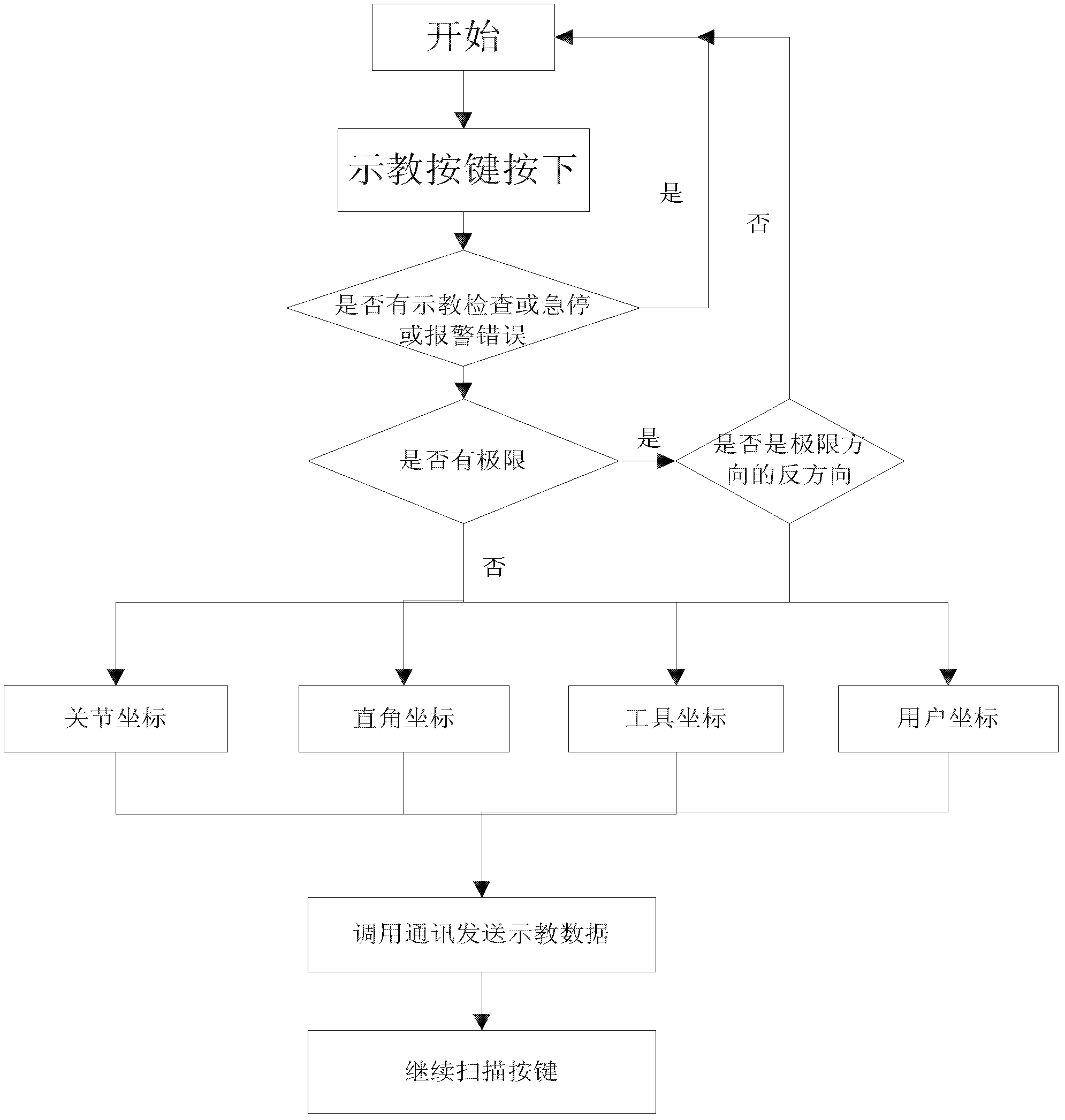

[0098] In this embodiment, a modular robot control device based on the GSK-Link bus, such as figure 1 As shown, it includes a main controller, an algorithm controller, a GSK-Link bus board, a display screen, and a key board; the main controller mainly completes robot teaching, teaching inspection, reproduction motion control, teaching programming, program explanation, Preprocessing and parameter setting functions; the algorithm controller mainly performs forward and reverse solution algorithms, interpolation algorithms, speed control, and trajectory planning operations on robot motion data; the GSK-Link bus board is used as a GSK-Link bus controller, mainly Complete the control of the GSK-Link bus; it sends the received motion data and parameter data to the servo device, and transmits the servo status data and the status data of the GSK-Link bus to the host computer for corresponding control; the display screen It is used to display program editing and robot status, which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com