Oil pipe and casing pipe comprehensive flaw detection system

A casing and tubing technology, which is applied in the field of comprehensive inspection systems for tubing and casing, can solve the problems of increased inspection costs, single data, and inability to fully reflect the tubing and casing, and achieves flexible use, high communication speed, and applicable wellbore range. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

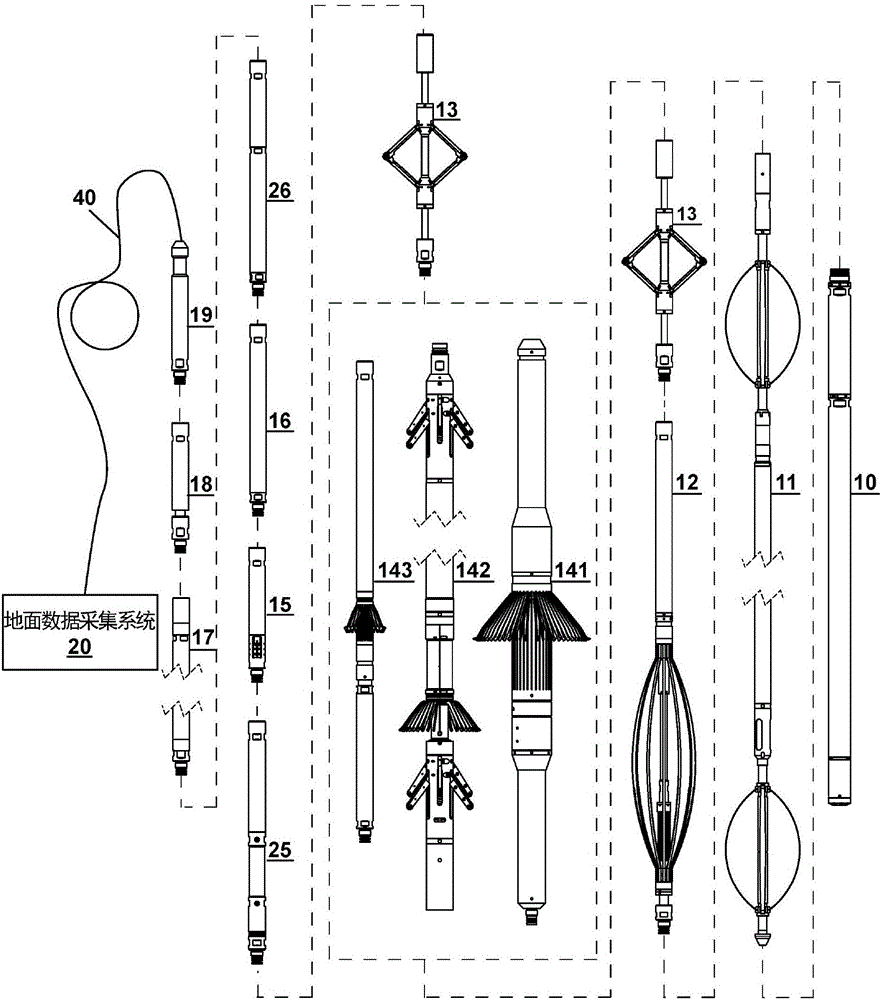

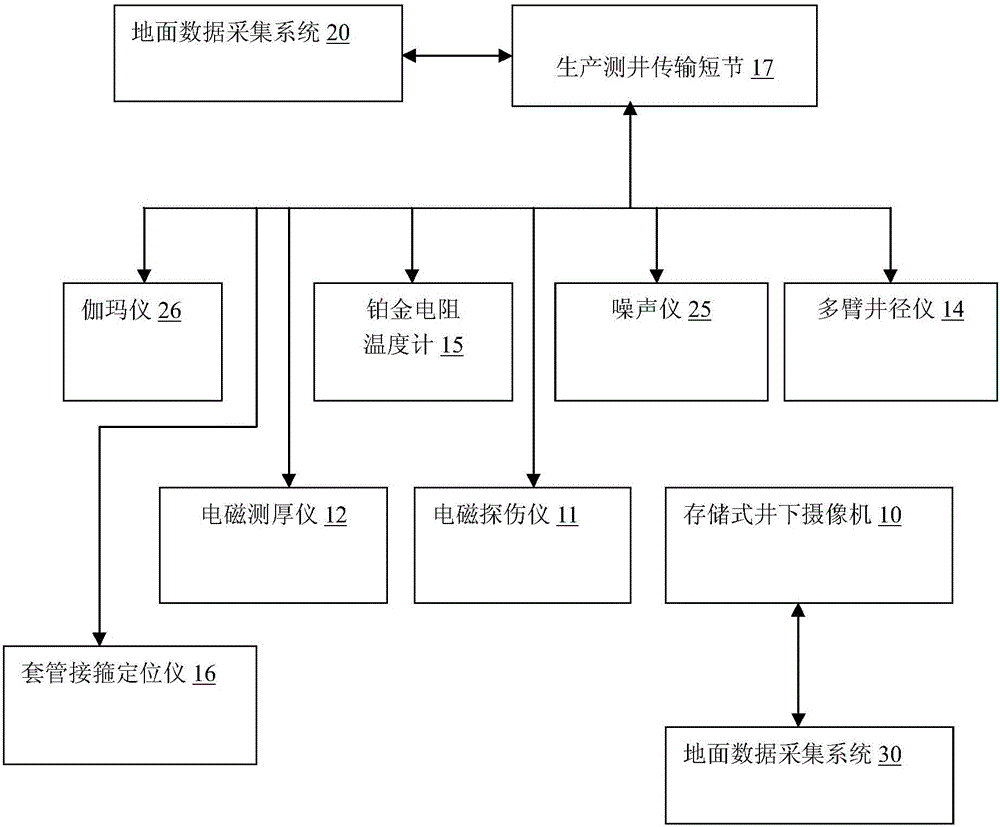

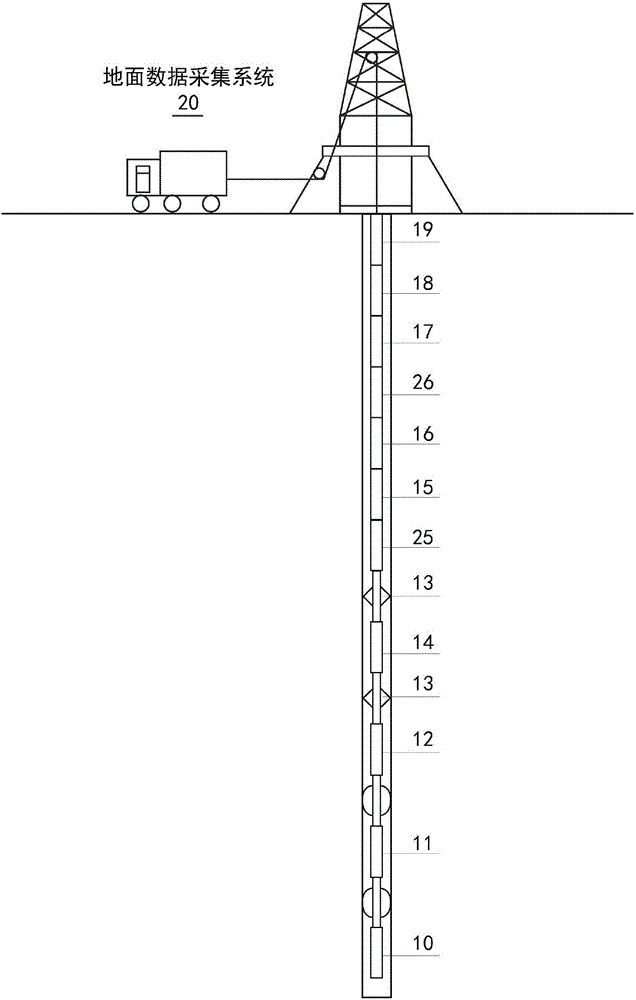

[0019] Such as figure 1 As shown, the present invention is a comprehensive flaw detection method for tubing and casing. The instrument string used mainly includes a production logging rotary sub (SWS-P) 18, a production logging transmission sub (PTS) sequentially connected from top to bottom. 17. Gamma meter (GRT-P) 26, casing collar locator (CCL-P) 16, platinum resistance thermometer (PTT) 15, noise meter (NLT) 25, centralizer (TCS-R) 13, multiple Boom caliper (MFI) 14, centralizer (CTT-C2) 13, electromagnetic thickness gauge (MCI) 12, electromagnetic flaw detector (MTT) 11, storage downhole camera (DHT-M) 10, among which, the dobby Caliper 14 mainly includes 24-arm caliper (MFI-24) 143, 40-arm caliper (MFI-40) 142, and 60-arm caliper (MFI-60) 141, which can be selected according to needs A sort of.

[0020] The uppermost instrument in the downhole instrument string is connected to the cable head 19 , and the signals output by each instrument in the downhole instrument stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com