Registered lamination of webs using laser cutting

A membrane and lamination layer technology, applied in the direction of lamination, lamination device, lamination auxiliary operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

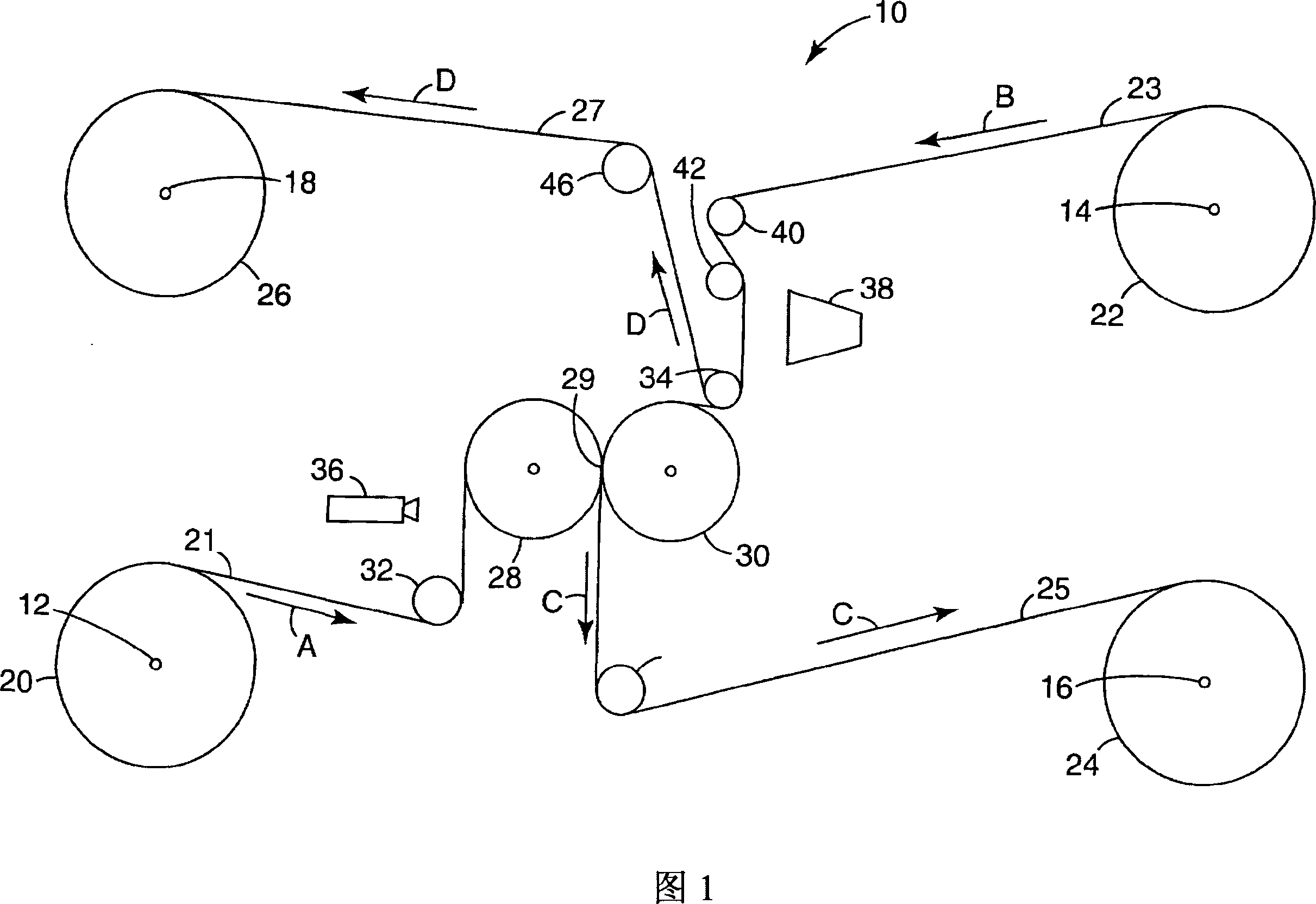

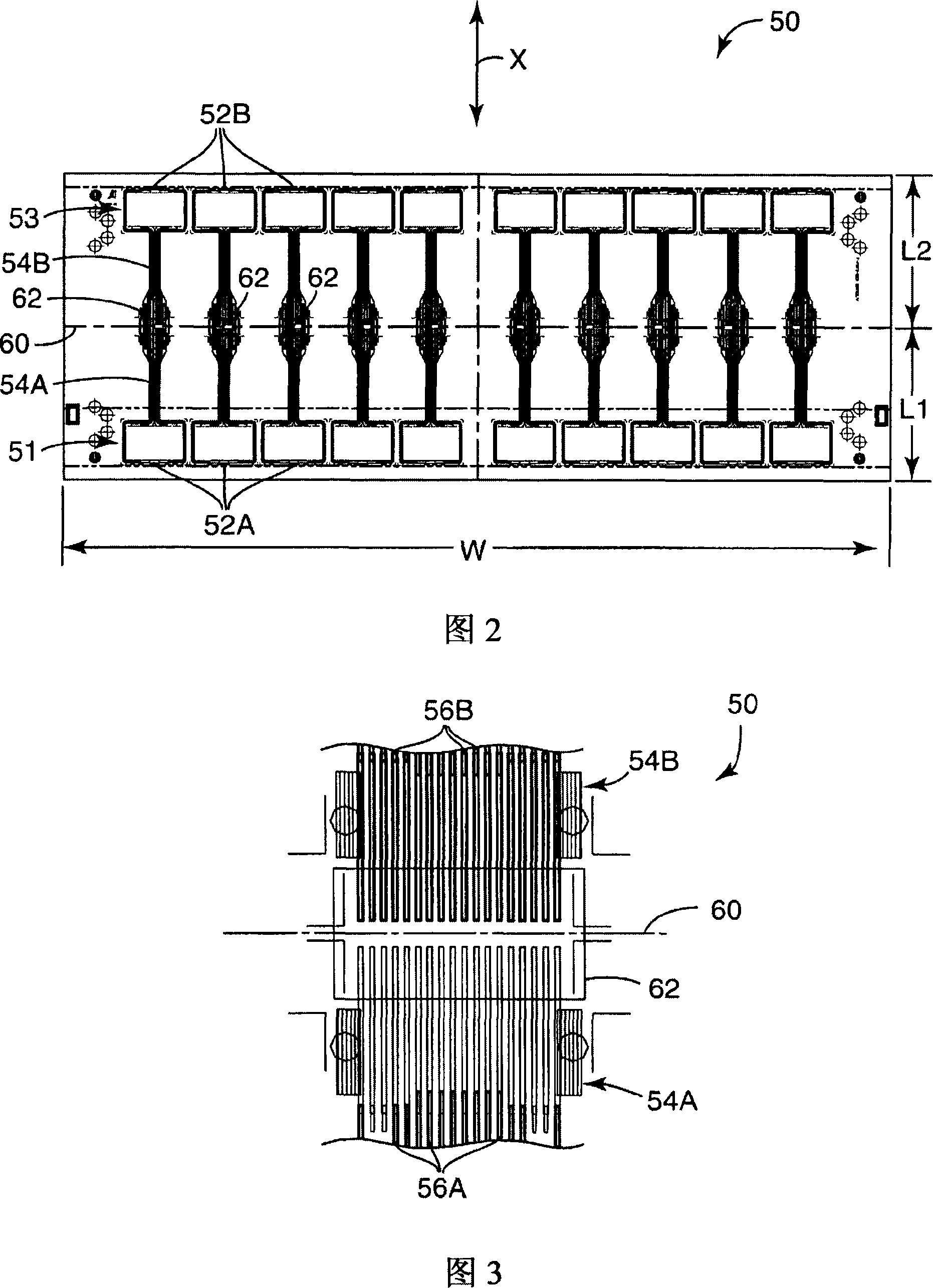

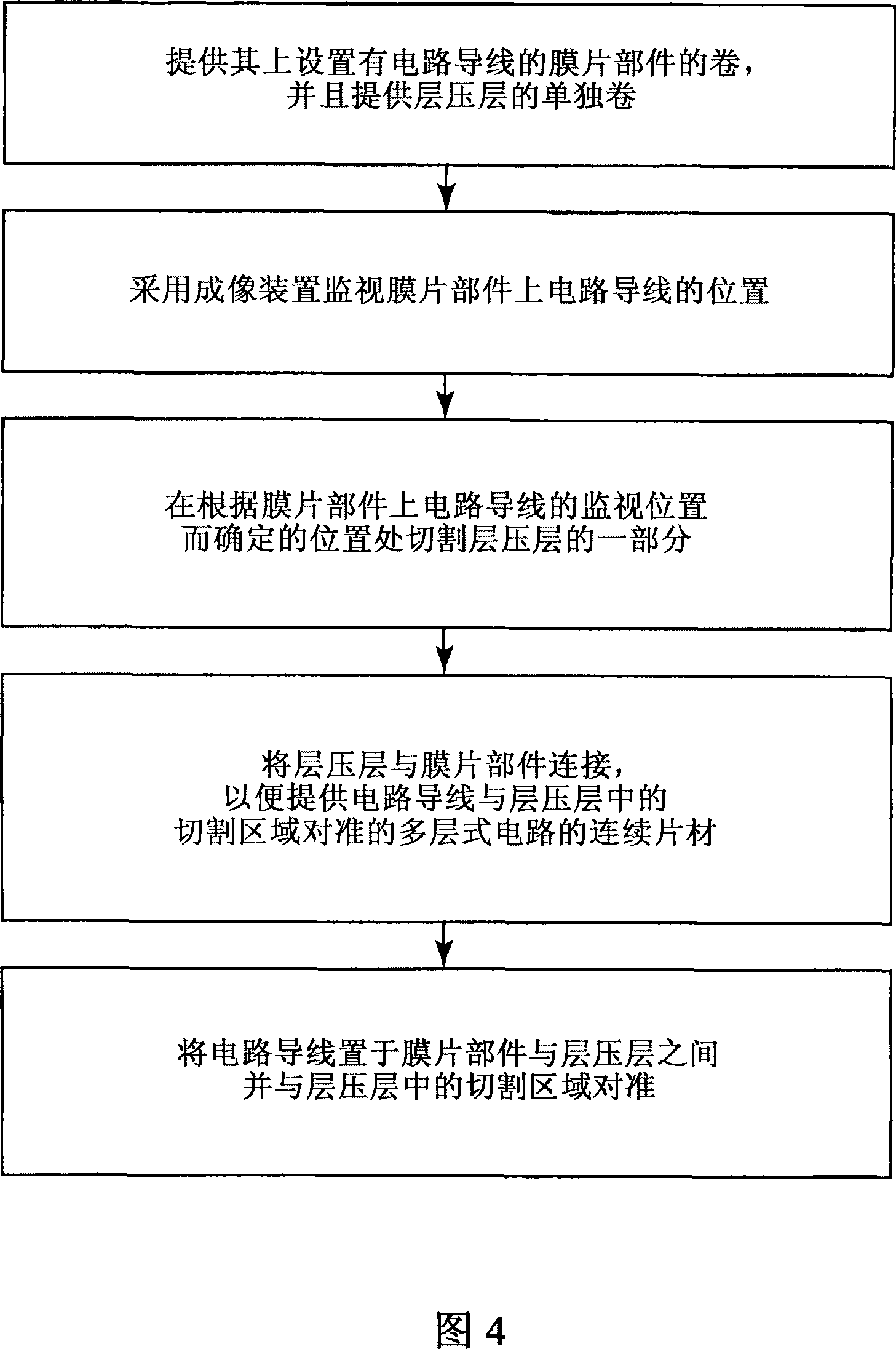

[0018] The present invention provides novel methods and apparatus that enable the formation of multilayer circuits on a membrane such that the electrical connections to the layers of the multilayer circuit can be exposed for subsequent connection to each other or to external circuits . In one aspect, the present invention provides a method for machine vision aligned cuts during lamination to expose critical areas of circuitry that would otherwise be covered by laminate layers.

[0019] The present invention also provides an efficient solution to the problem of offset that arises when attempting to manufacture multilayer circuits in the form of membranes. If the two circuit layers are formed on two separate films, each with a series of images, image shift problems can arise when the two films are laminated together in registration. This is due to the fact that the spacing between images is not maintained exactly, and any small error will cause misalignment after accumulation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com