Screen protection film assembly and film sticking device for screen protection film

A screen protector and film applicator technology, which is applied in the direction of film/sheet adhesive, protective clothing, protective equipment, etc., can solve the problem of not being able to temporarily store and protect the mobile phone protective film, etc., and achieve the operation method and convenient operation. The effect of simple method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

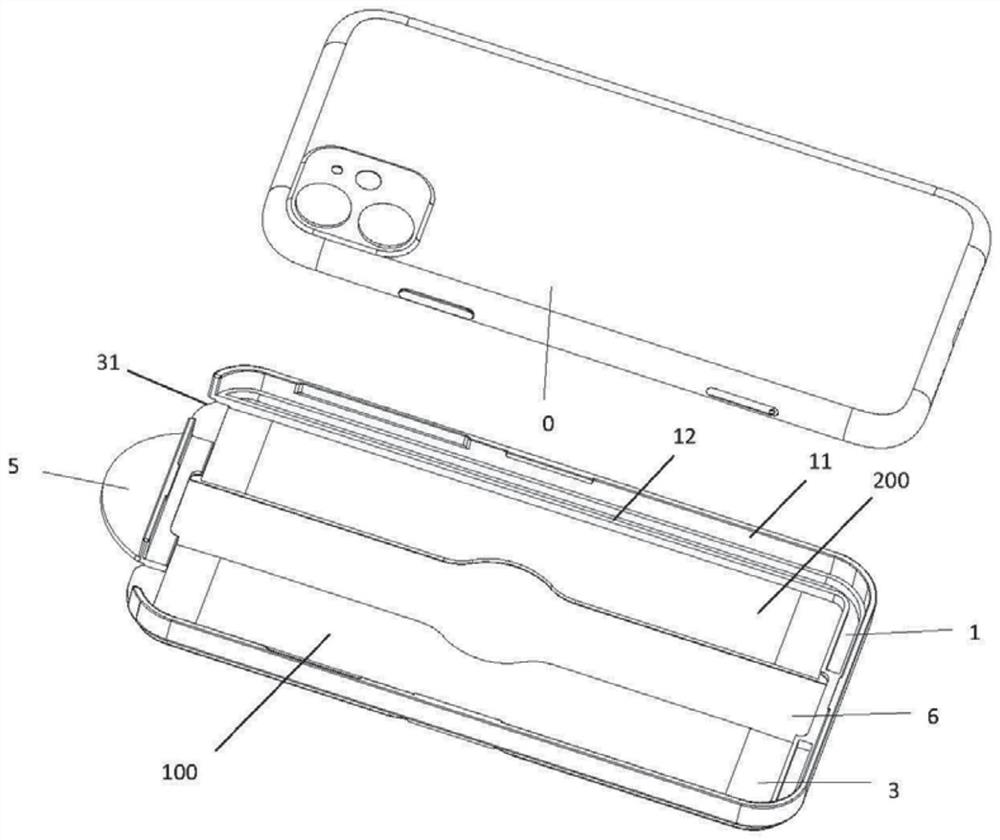

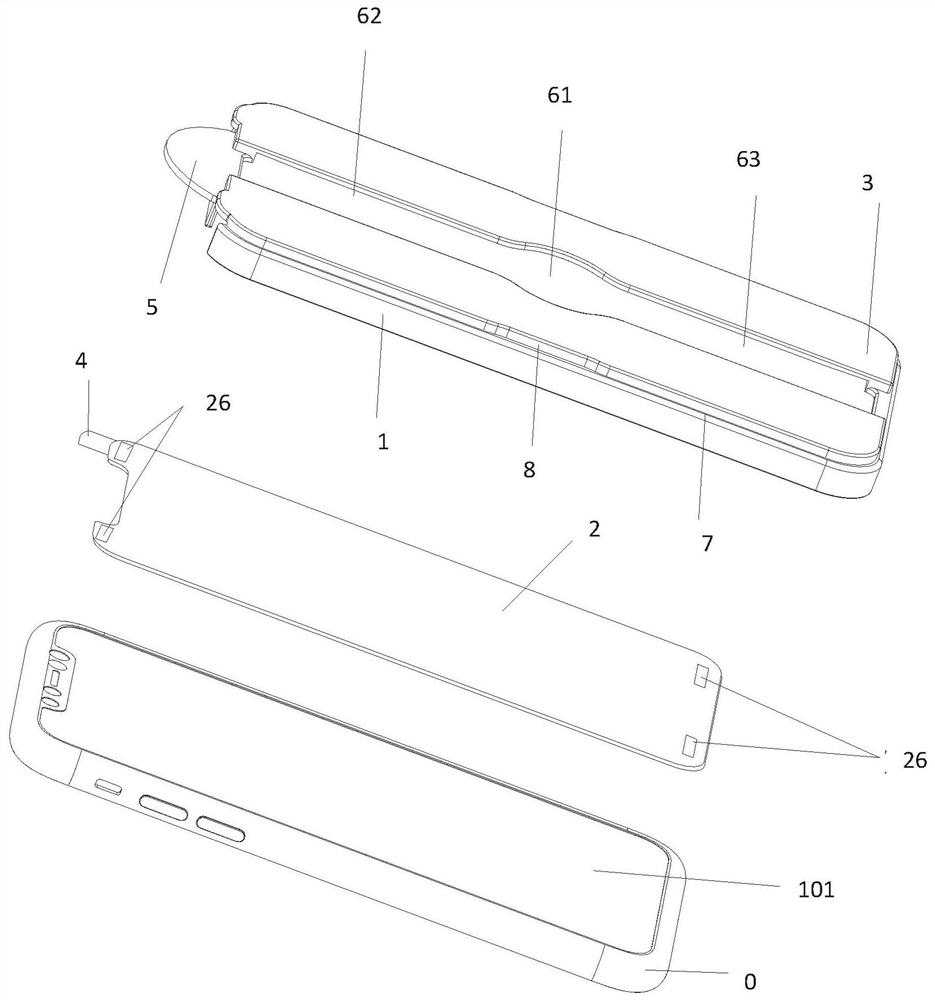

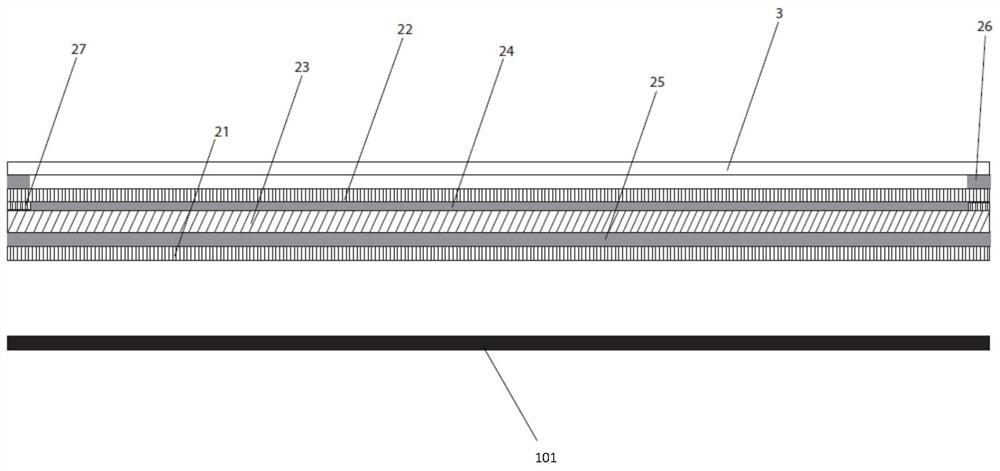

[0051] The applicator of the screen protective film according to the first embodiment of the present invention is as Figures 1 to 7D shown. The screen protective film applicator includes a film applicator tray 1 and a screen protective film assembly 2 . The film applicator tray 1 has a base 3 with an equipment side and an opposite side, walls 11 at the four edges of the base 3 and positioning ridges 12 on the equipment side of the base 1 and along the inside of the walls 11. The height of the wall 11 is higher than that of the positioning ridge 12 . In this embodiment, the base 3 has a shape similar to that of the mobile phone 0 . That is, if figure 1 As shown, it has two longer edges and two shorter edges. The positioning ridges 12 are provided along the entire inside of the two walls corresponding to the longer edge and one wall corresponding to the shorter edge. Alternatively, positioning ridges 12 may be provided along all or part of the inside of one or more of the ...

no. 2 example

[0069] The film applicator of the screen protective film according to the second embodiment of the present invention is as shown in Fig. 8 to Figure 12 shown. The screen protective film applicator includes a film applicator tray 1 and a screen protective film assembly 2 . Since the screen protective film assembly 2 of this embodiment is substantially the same as that of the aforementioned first embodiment, a detailed description thereof will be omitted in this embodiment.

[0070] The applicator tray 1 has a base 3 with an equipment side and an opposite side, walls 11 at the four edges of the base 3 , and positioning ridges 12 on the equipment side of the base 1 and along the inside of the walls 11 . The height of the wall 11 is higher than that of the positioning ridge 12 . Substrate 3 has a shape similar to cell phone 0, i.e. it has two longer edges and two shorter edges, as figure 1 shown. Locating ridges 12 are provided along the entire inside of the four walls. Alte...

no. 3 example

[0085] Except that the film applicator tray 1 with the stop protrusions 28a and 28b on the equipment side in the second embodiment is replaced by the film applicator tray with inclined equipment sides, the film applicator for the screen protective film according to the embodiment of the present invention is the same as that of the aforementioned first embodiment. The screen protection film assembly 2 of the two embodiments is basically the same. When a cell phone positioned horizontally as in the second embodiment is housed in a film applicator tray with sloped device sides, the screen protector assembly is also sloped relative to the screen of the cell phone. Since other structures and effects of the screen protective film applicator of this embodiment are basically the same as those of the second embodiment, a detailed description thereof will be omitted here.

[0086] The advantages of the present invention are as follows:

[0087] Compared with the prior art, the screen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com