Turnning optical fibre method Fabry-perot filter

A technology of Perot filter and fiber waveguide, which is applied in the field of tunable fiber Fabry-Perot filter, can solve the problems of high equipment and process requirements, complex fiber waveguide method, etc., and achieve low cost and convenient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

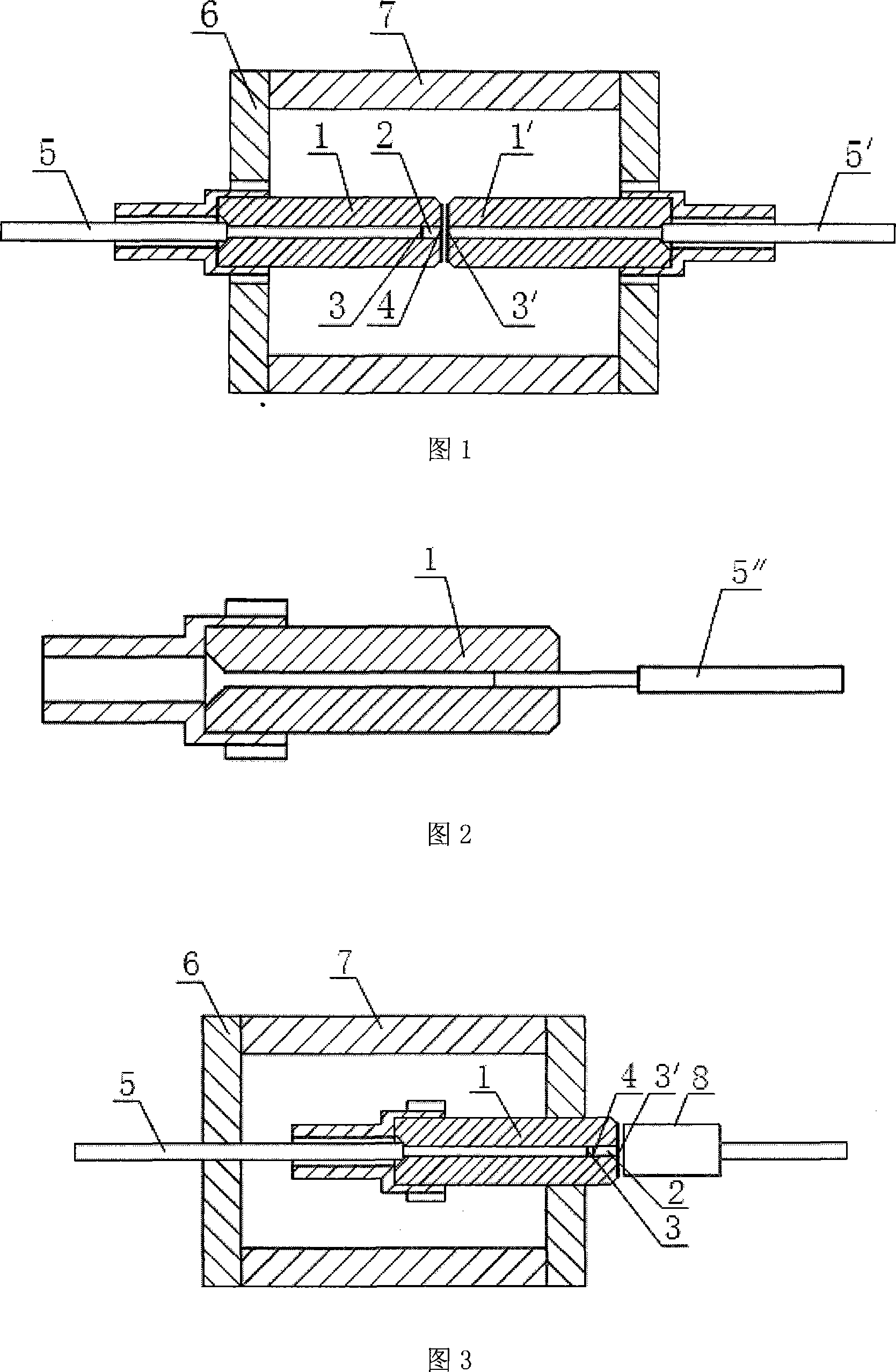

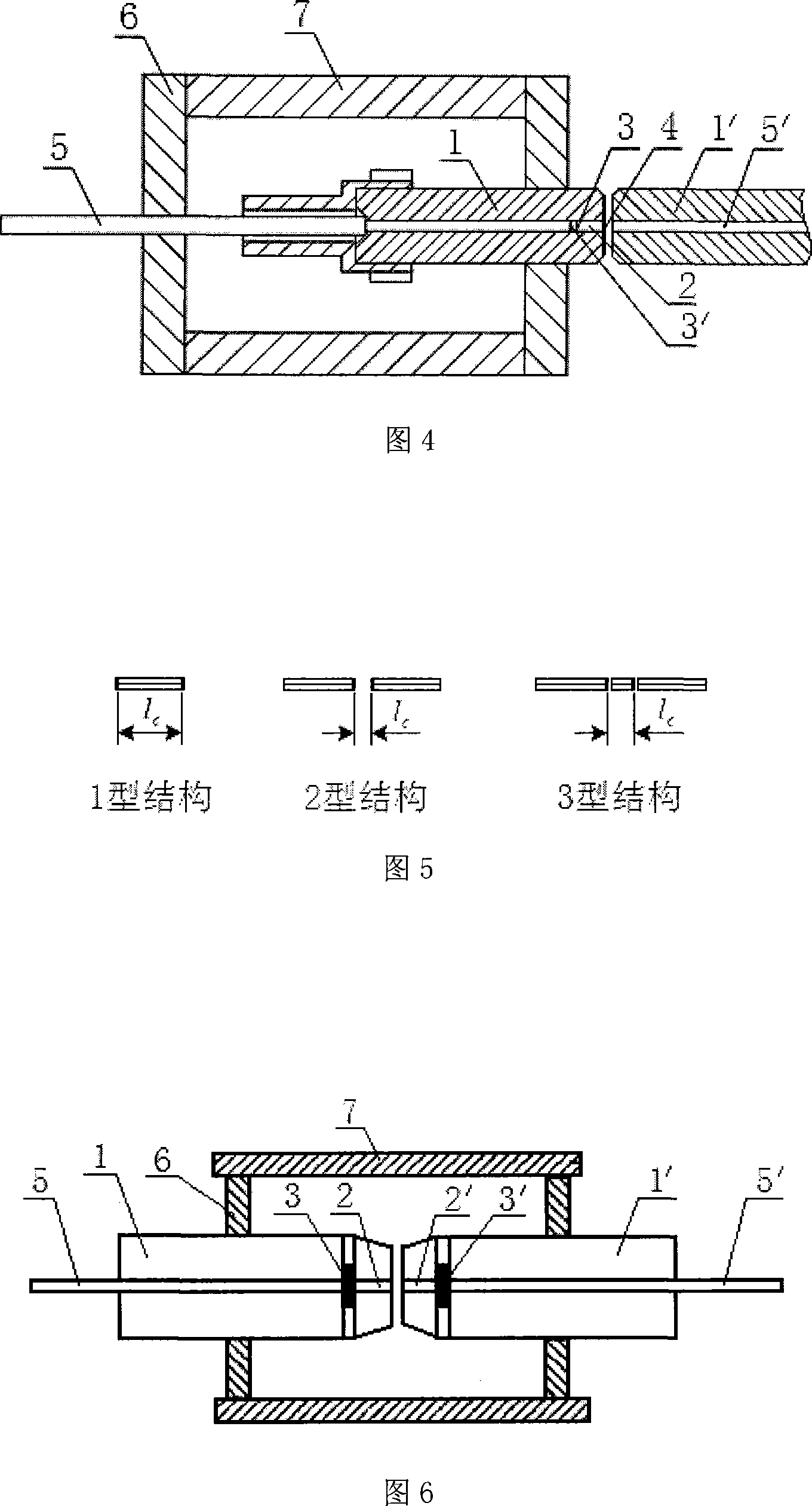

[0026] The first structure of the tunable optical fiber FAB filter of the present invention is shown in FIG. 1 . The tunable optical fiber FAP filter includes two ferrules 1 and 1', a support 6 for fixing the ferrule, and a piezoelectric ceramic 7 for tuning the length of the FAP cavity; the inner hole of the ferrule 1 is fixed with an optical fiber 5 and the optical fiber waveguide 2, between the optical fiber 5 and the optical fiber waveguide 2 is a high reflection film 3, the optical fiber waveguide 2 is located between the high reflection film 3 and the end face of the ferrule 1, and the end face of the ferrule 1 is coated with an anti-reflection film 4; The optical fiber 5' is fixed by glue in the inner hole of the core 1', and the end face of the ferrule 1' is coated with a high reflection film 3'. The ferrules 1 and 1' are fixed on the support 6 after precise adjustment and alignment to form an optical fiber F-P filter, and the transmission wavelength can be tuned by ch...

Embodiment 2

[0029] The second structure of the tunable optical fiber FAB filter of the present invention is shown in FIG. 3 . The tunable optical fiber FAP filter includes a ferrule 1, a support 6 for fixing the FAP filter, a piezoelectric ceramic 7 for tuning the FAP cavity length, and an optical fiber collimator 8 for receiving the transmitted light of the FAP filter; The fiber waveguide 2 is fixed by glue in the inner hole of the ferrule 1. One end face of the fiber waveguide 2 is located in the inner hole of the ferrule and is coated with an anti-reflection film 4 at the same time. The other end face is the end face formed by grinding the ferrule 1 and coated with High reflection film 3'; the optical fiber 5 is inserted into the inner hole of the ferrule 1 from the tail of the ferrule 1, and the end surface is coated with a high reflection film 3. The optical fiber 5 can move along the axis of the inner hole of the ferrule 1, and changing the position of the optical fiber 5 in the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com