Yttrium aluminium garnet and yttria double crystal transparent ceramic and method for making same

A technology of yttrium aluminum garnet and transparent ceramics, which is applied in the field of yttrium aluminum garnet and yttrium oxide double crystal phase transparent ceramics and their preparation, can solve the problems of limited application scope, low thermal conductivity and the like, and achieves the effect of widening the application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

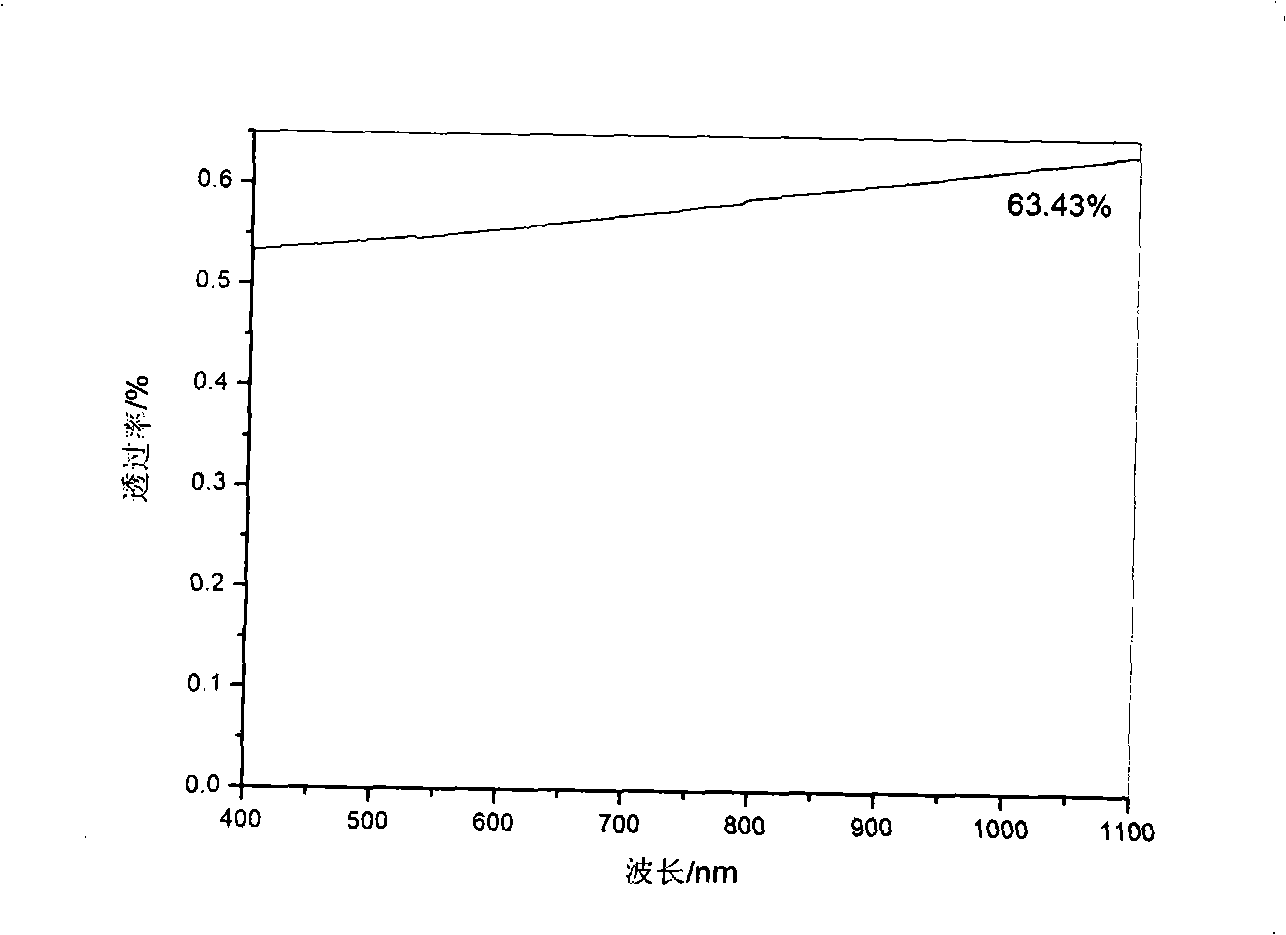

[0028] take Y 2 o 3 and Al 2 o 3 Powder, the molar ratio is 0.6005, alumina balls are used as grinding balls, anhydrous ethanol is used as solvent, orthosilicate ethyl ester is used as sintering aid, and they are put into an alumina pot for ball milling for 6 hours, and then the slurry Separate from the grinding balls, put the slurry into a drying oven and dry at 80°C, sieve the dried slurry, and press the powder into a 20±5mm round block by axial one-way pressure, pre-pressed The wafer is then cold isostatically pressed, kept in a vacuum sintering furnace at 1700±50°C for 50 hours, and the sintered YAG ceramics are surface ground and polished, and the light transmittance is 63.43%.

Embodiment 2

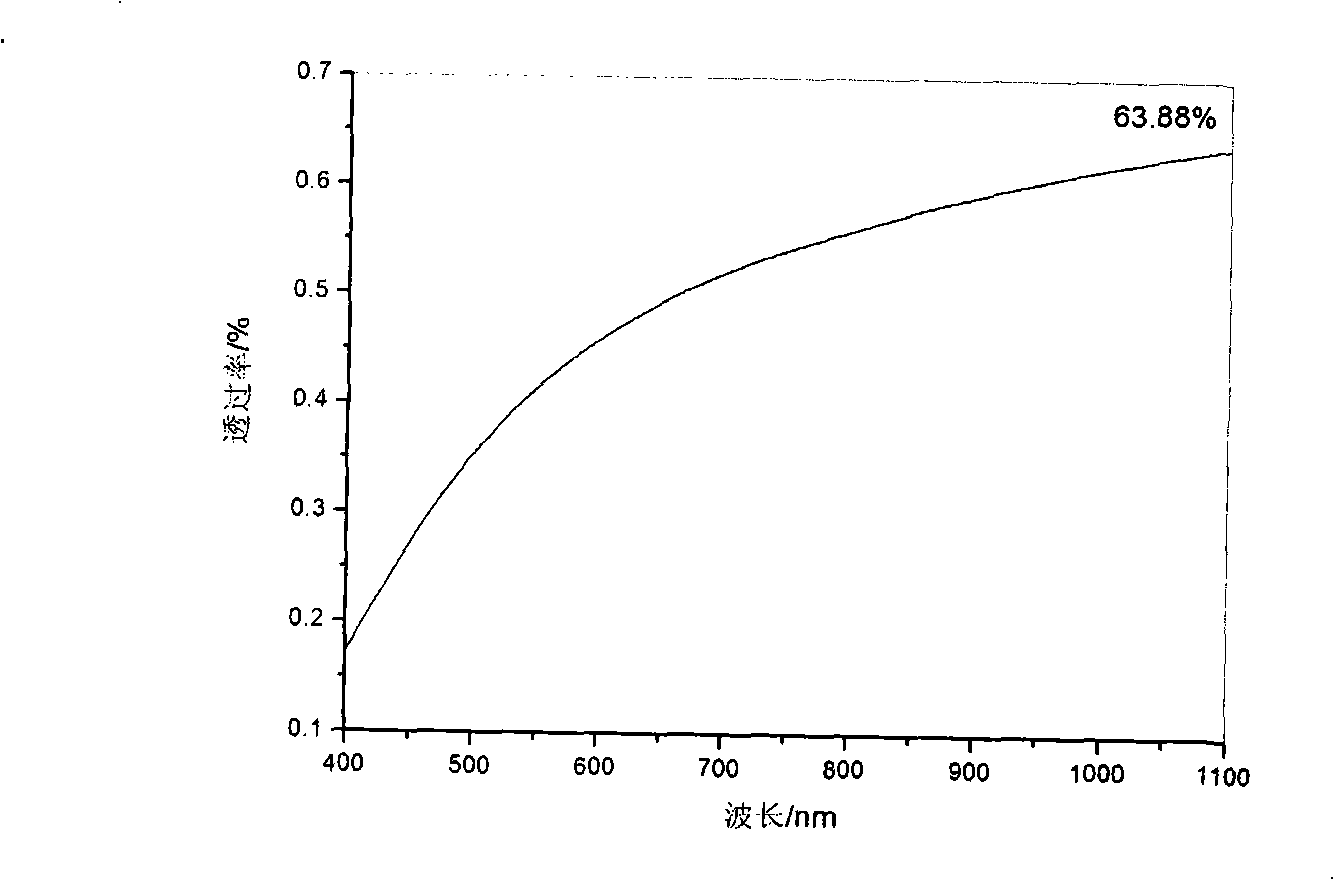

[0030] take Y 2 o 3 and Al 2 o 3 Powder, the molar ratio is 0.6270, alumina balls are used as grinding balls, anhydrous ethanol is used as solvent, orthosilicate ethyl ester is used as sintering aid, and they are put into an alumina pot for ball milling for 12 hours, and then the slurry Separate from the grinding balls, put the slurry into a drying oven and dry at 80°C, sieve the dried slurry, and press the powder into a 20±5mm round block by axial one-way pressure, pre-pressed The wafer is then cold isostatically pressed, kept in a vacuum sintering furnace at 1710±50°C for 15 hours, and the sintered YAG ceramics are surface ground and polished, and the light transmittance is 63.88%.

Embodiment 3

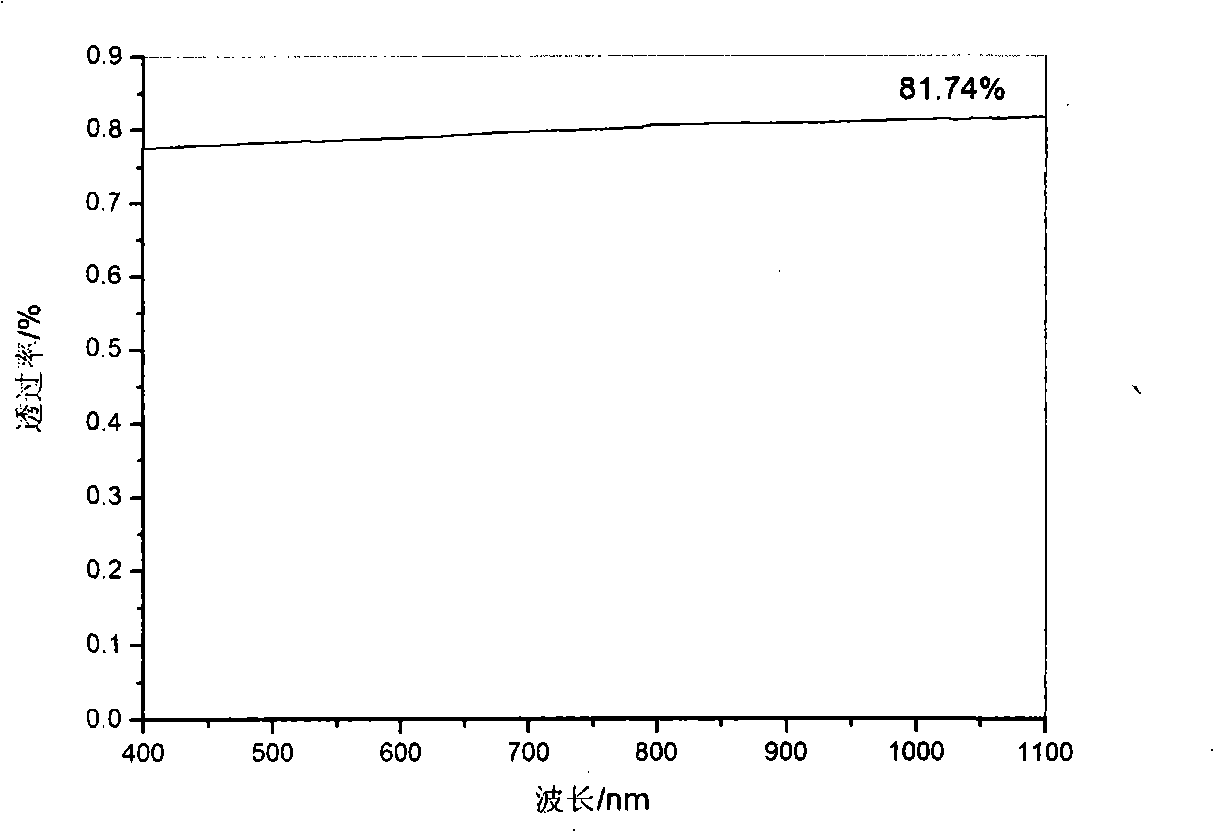

[0032] Take YAG and Y 2 o 3 , the mass ratio is 95:5, alumina balls are used as grinding balls, anhydrous ethanol is used as solvent, orthosilicate ethyl ester is used as sintering aid, and they are put into an alumina pot for ball milling for 20 hours, and then the slurry is The material and the grinding ball are separated, the slurry is put into a drying oven and dried at 80°C, the dried slurry is sieved, and the powder is pressed into a 20±5mm round block by axial one-way pressure, and pre-pressed The wafers were then cold isostatically pressed, kept in a vacuum sintering furnace at 1700±40°C for 15 hours, and the sintered YAG ceramics were surface ground and polished, and the light transmittance was 81.74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com