All-solid-waste cementing material containing refining slag and preparation method of all-solid-waste cementing material

A technology for cementitious material and refining slag, which is applied to the field of all-solid waste cementitious material containing refining slag and its preparation, can solve the problems of poor working performance, small application range, low strength, etc., to protect the environment and broaden the scope of application , The effect of increasing the content of converter steel slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides an all-solid waste gelling material containing refining slag and a preparation method thereof.

[0028] In terms of mass percentage, the cementitious material includes 1% to 20% of refining slag, 10% to 20% of industrial by-product gypsum, and the balance is converter steel slag and slag, wherein the mass ratio of converter steel slag to slag is 3 / 4~4 / 3, the specific surface area of refining slag and industrial by-product gypsum is 300m 2 / kg~600m 2 / kg, the specific surface area of slag and converter steel slag is 400m 2 / kg~650m 2 / kg.

[0029] The preparation method of the cementitious material is roughly as follows: firstly, the refining slag, industrial by-product gypsum, converter steel slag and slag are mixed according to the mass ratio; 400~650m 2 / kg, refining slag and industrial by-product gypsum are ground separately or mixed to a specific surface area of 300-600m2 / kg; finally, mix the ground slag, refining slag, converter ...

Embodiment 1

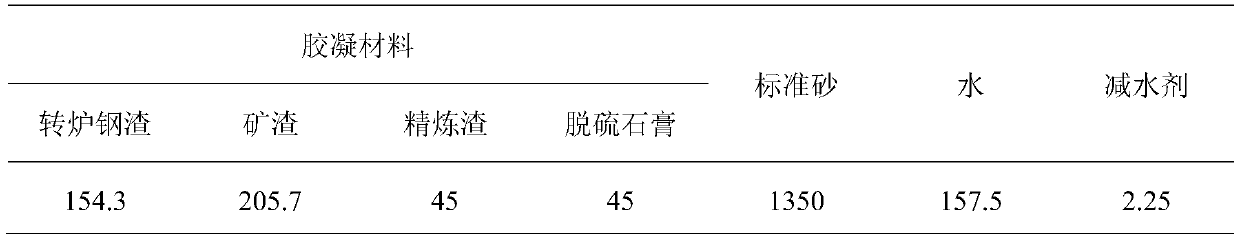

[0032] Preparation of cementitious material: It is prepared by mixing raw materials according to the following mass percentages, wherein the mass ratio of converter steel slag to slag is 3 / 4, refining slag is 10%, and desulfurization gypsum is 10%, and the slag is ground to a ratio of 560m 2 / kg, the converter steel slag is ground to a ratio of 450m 2 / kg, refining slag grinding to 350m 2 / kg, desulfurized gypsum is ground to a ratio of 400m 2 / kg, the stability test of cementitious materials is carried out in accordance with the provisions of GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods". Prepare consistent all-solid waste gelling materials according to the above-mentioned "gelling material" ratio. After testing by the test cake method and Rayleigh clip method, the stability is qualified. After the initial setting time and final setting time are tested, the initial setting time is determined to be 154min, the final ...

Embodiment 2

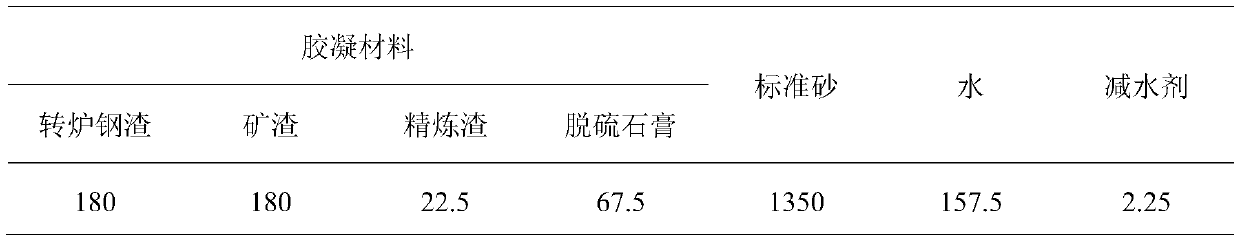

[0038] Preparation of cementitious material: The raw materials are mixed according to the following mass percentages, wherein the ratio of converter steel slag to slag is 1 / 1, refining slag is 5%, and desulfurization gypsum is 15%, and the slag is ground to a ratio of 560m 2 / kg, the converter steel slag is ground to a ratio of 450m 2 / kg, refining slag grinding to 350m 2 / kg, desulfurized gypsum is ground to a ratio of 400m 2 / kg, the stability test of cementitious materials is carried out in accordance with the provisions of GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Methods". Prepare consistent all-solid waste gelling materials according to the above-mentioned "gelling material" ratio. After testing by the test cake method and Rayleigh clip method, the stability is qualified. After the initial setting time and final setting time are tested, the initial setting time is determined to be 186min, the final setting time is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com