Air source heat pump water heater unit with phase change heat accumulation

An air source heat pump and phase change heat storage technology, which is applied to heat storage equipment, refrigerators, refrigeration components, etc., can solve problems such as poor defrosting reliability, insufficient heating capacity, and large energy loss, and improve operating conditions. , the effect of increasing the heating capacity and optimizing the operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing

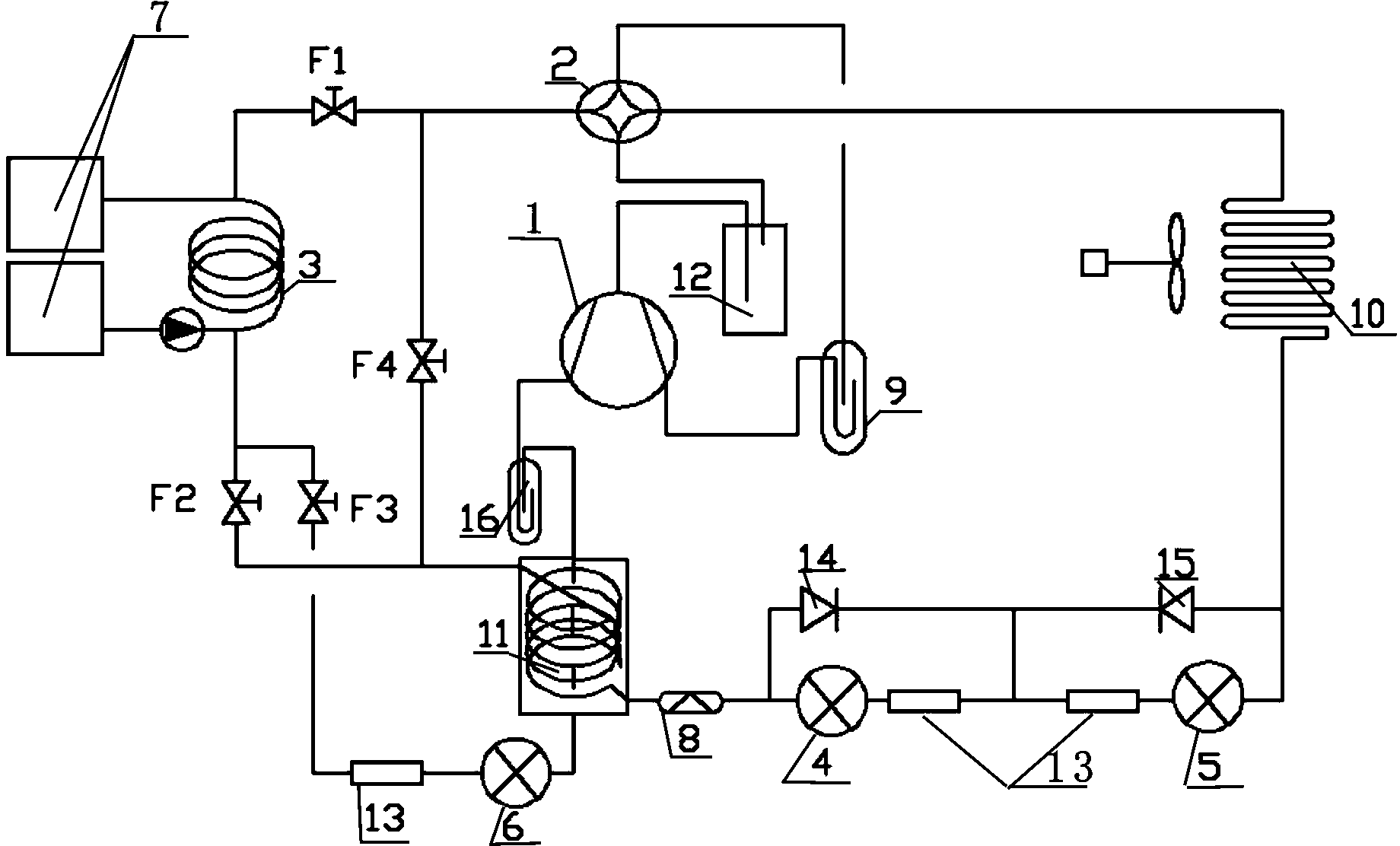

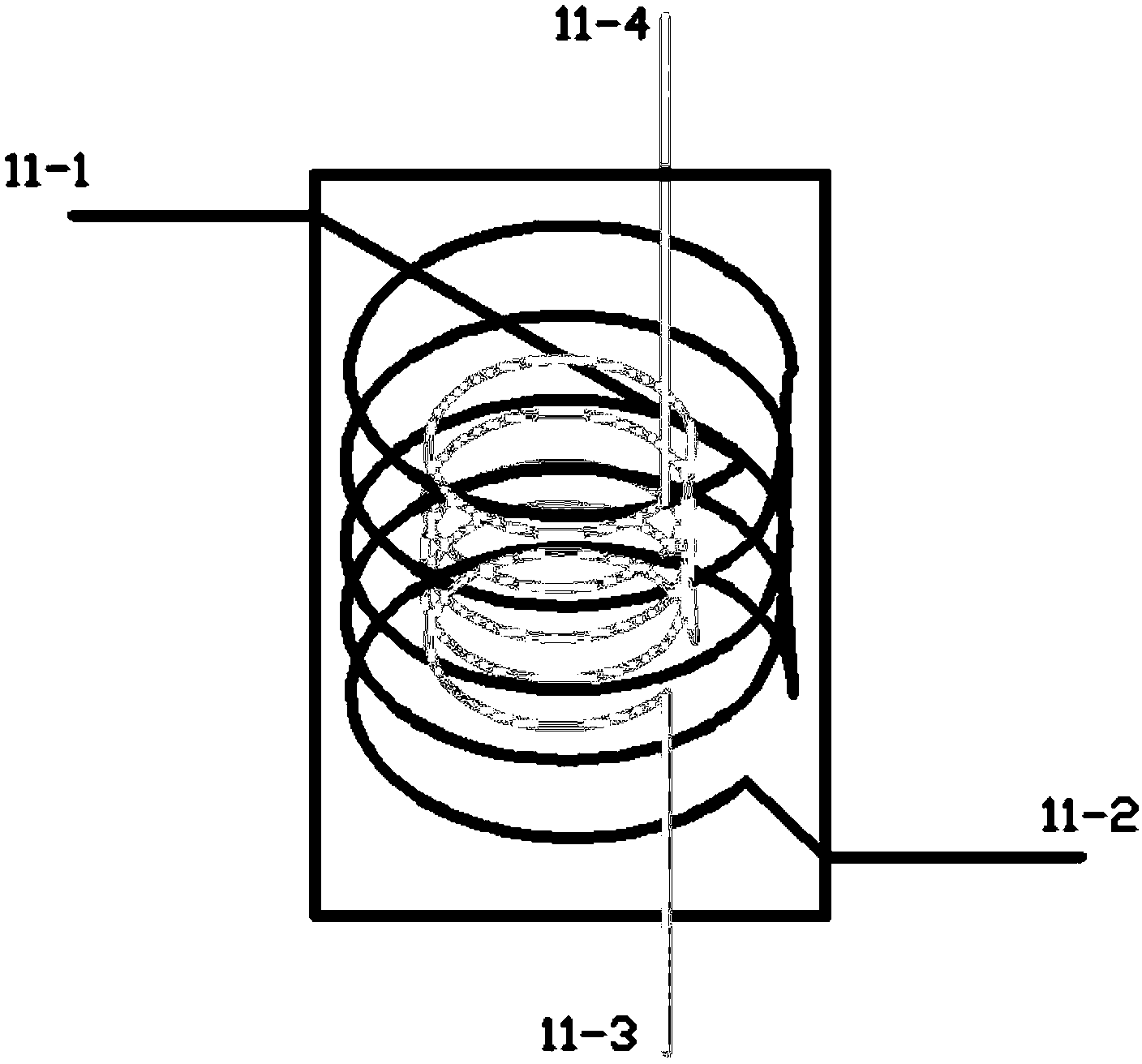

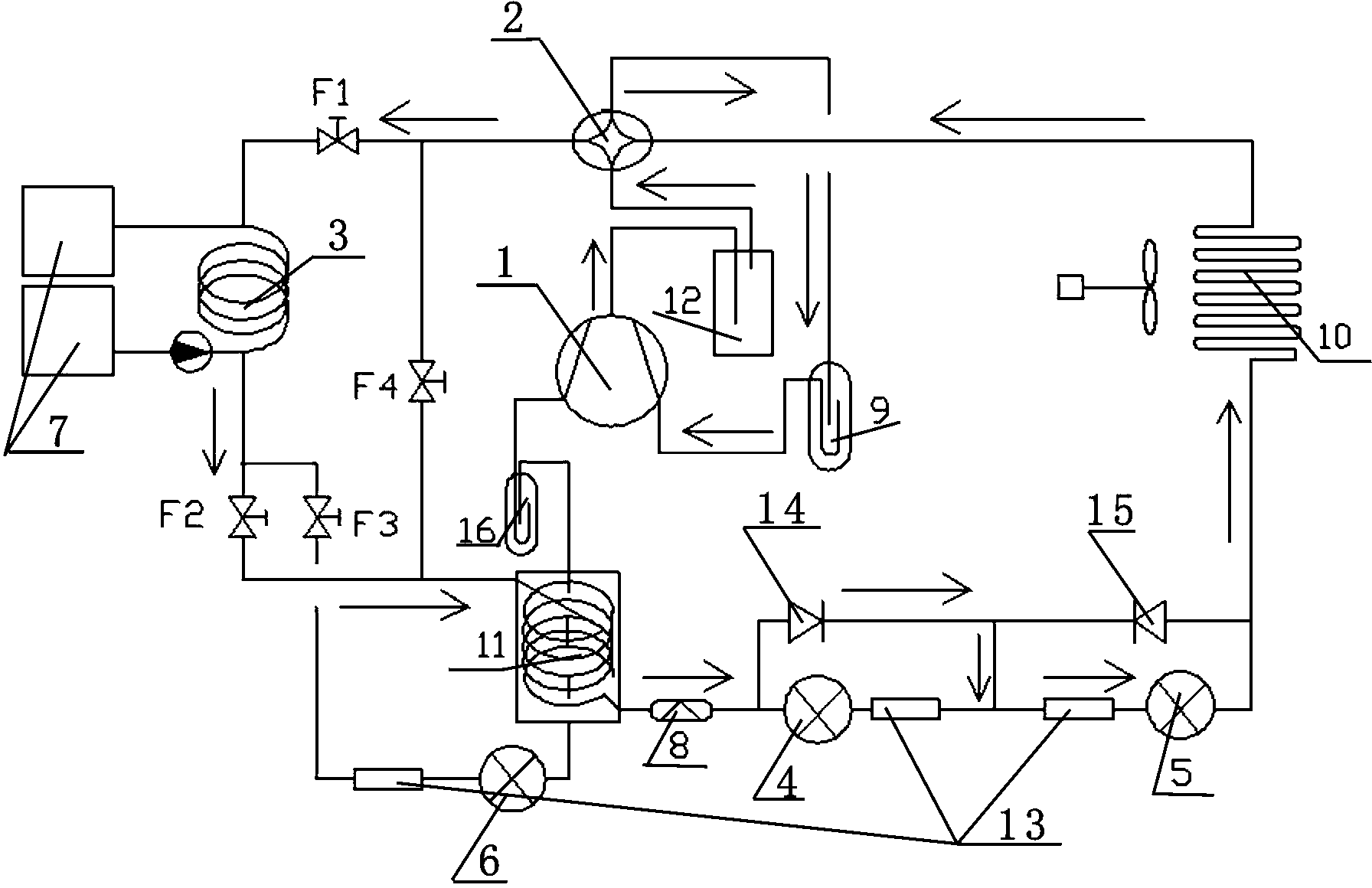

[0029] Such as figure 1 , figure 2Shown: the present invention includes a scroll compressor 1, a four-way reversing valve 2, a condenser 3, thermal expansion valves 4, 5 and 6, a water tank 7, a sight glass 8, gas-liquid separators 9 and 16, and an outdoor Evaporator 10, phase change heat accumulator 11, oil separator 12, dry filter 13, check valves 14 and 15, solenoid valves F1, F2, F3 and F4. The exhaust output pipe of the scroll compressor 1 is connected to the input pipe of the oil separator 12, the output port of the oil separator 12 is connected to the third input and output port of the four-way reversing valve 2, and the intake port of the scroll compressor 1 The input pipe is connected to the output pipe of the gas-liquid separator 9, the input pipe of the gas-liquid separator 9 is connected to the output pipe of the outdoor evaporator 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com