Cooling intake system for steam turbine condensation and pumping back heat supply and intelligent control method

A steam turbine, cooling steam technology, applied in engine control, steam engine installations, mechanical equipment, etc., can solve the problems of low-pressure cylinder operation safety hazards, high humidity of cooling steam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0086] Example.

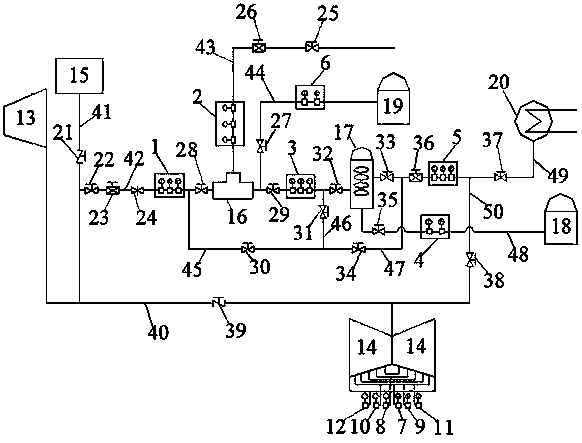

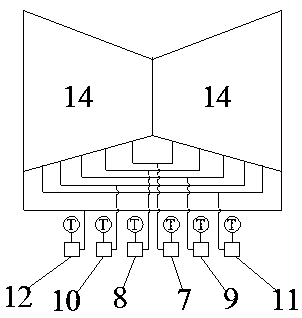

[0087] see Figure 1 to Figure 2 .

[0088] This embodiment is a cooling steam intake system for steam turbine condensing and pumping back heat supply, including steam turbine medium pressure cylinder 13, steam turbine low pressure cylinder 14, heat network heater 15, desuperheater 16, steam-water separator 17, separated water Storage tank 18, drain tank 19 and condenser 20.

[0089] A communication pipe 40 is connected between the medium-pressure cylinder 13 of the steam turbine and the low-pressure cylinder 14 of the steam turbine, and a first LCV valve 39 is arranged on the communication pipe 40 .

[0090]A heating extraction pipe 41 is connected between the communication pipe 40 and the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com