Nuclear class-1 equipment performance test system and method

A technology of equipment performance and test system, applied in the field of nuclear power, can solve the problems of environmental performance test of containment accident, can not ensure uniform temperature distribution, can not meet the environmental test of three generations of units, etc., achieves high temperature and pressure control accuracy, reliable and accurate experiments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention aims at the deficiencies of the above-mentioned prior art, and provides a nuclear first-level equipment performance testing system and method. The technical solution provided by the embodiment of the present invention can simultaneously realize the temperature and pressure control in the LOCA furnace, and increase the steam flow and regulation The ability makes the first-level equipment performance test system of this nuclear unit meet the thermal shock requirements of the second-generation and third-generation unit tests, and the temperature and pressure control accuracy in other stages and thermal stability stages is high. Moreover, the temperature and pressure in the LOCA furnace are uniformly distributed, ensuring that the tested nuclear first-level equipment can withstand the specified temperature and pressure, and ensuring that the experiment is reliable and accurate.

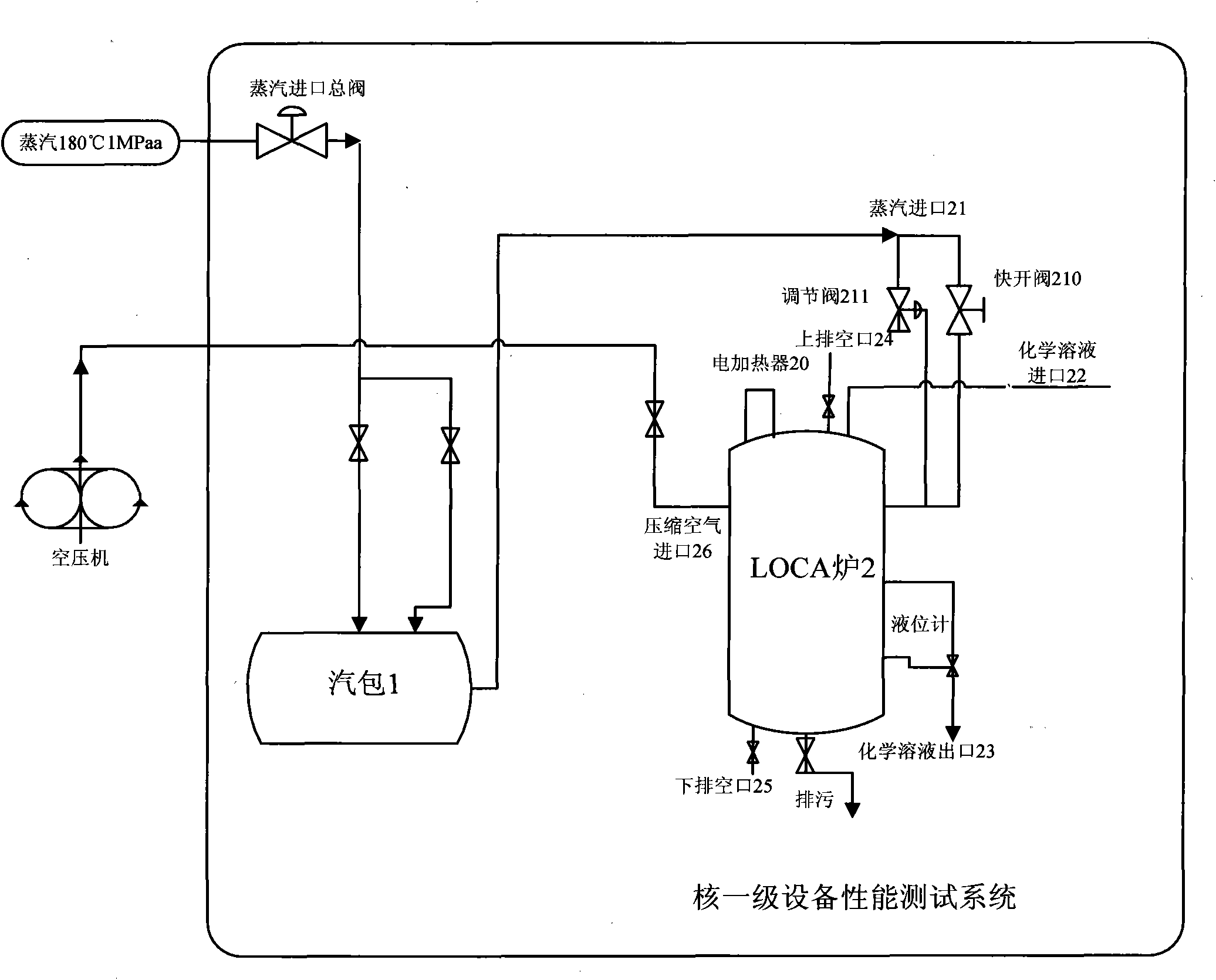

[0042] seefigure 1 , which is a structural schematic diagram of Embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com