Steam supplementing valve for turbine

A steam turbine and supplementary steam technology, applied in the field of supplementary gas valve, can solve the problems of unstable vibration, uncontrollable steam flow, large noise, etc., and achieve the effect of satisfying primary frequency modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

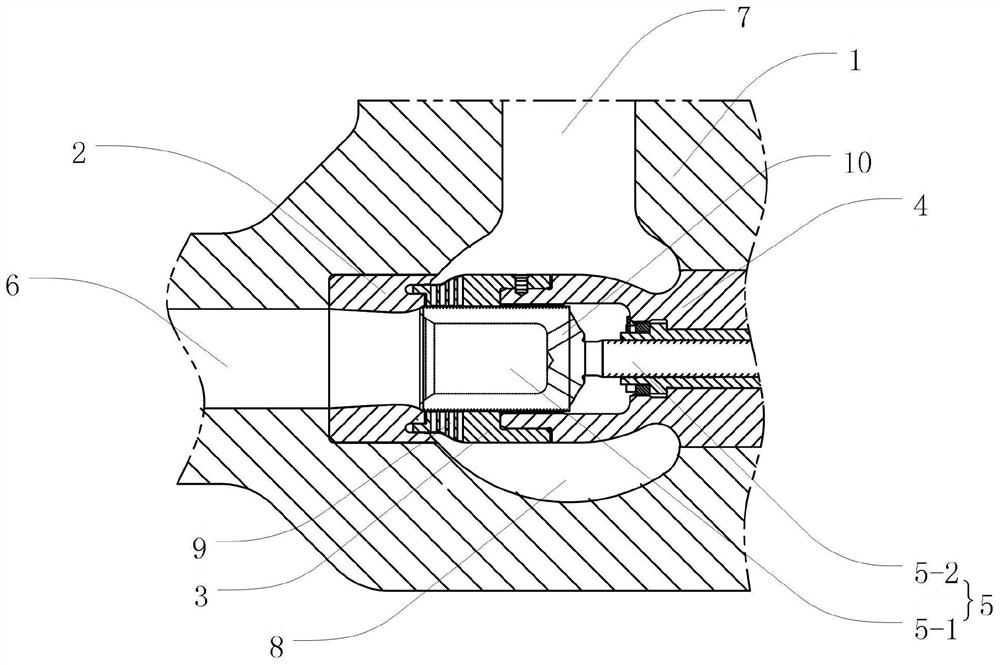

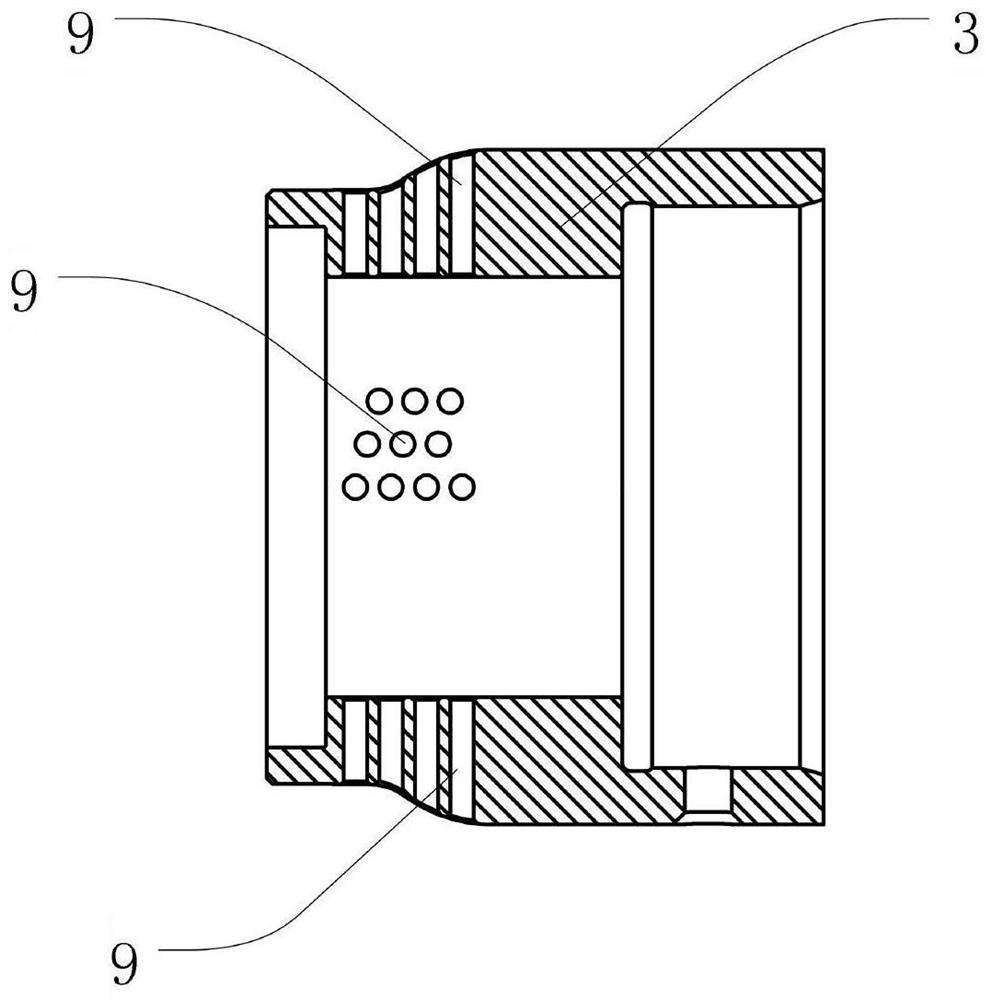

[0018] Embodiment 1. A steam supplement valve for a steam turbine in this embodiment includes a valve housing 1, a valve seat 2 located in the valve housing 1, a hole valve butterfly 3, a valve cover 4 and a steam supplement regulating valve butterfly 5;

[0019] The valve casing 1 is provided with an air inlet passage 6, an air outlet passage 7 and a valve cavity 8, and one end of the air inlet passage 6 and one end of the air outlet passage 7 communicate with the outside respectively; One end communicates with the valve cavity 8 respectively;

[0020] The valve seat 2, the orifice valve butterfly 3 and the bonnet 4 are all tubular, and one end of the valve seat 2, one end of the orifice valve butterfly 3 and the bonnet 4 are connected coaxially in sequence;

[0021] The outer wall of the valve seat 2 is fixed and sealed with the inner wall of the valve housing 1, and the other end of the valve seat 2 communicates with the other end of the intake passage 6;

[0022] The side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com