Thermal expansion assembly for water mist fire suppression system

A fire-extinguishing system and thermal expansion technology, applied in the field of fire-extinguishing systems, can solve problems such as time-consuming and inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

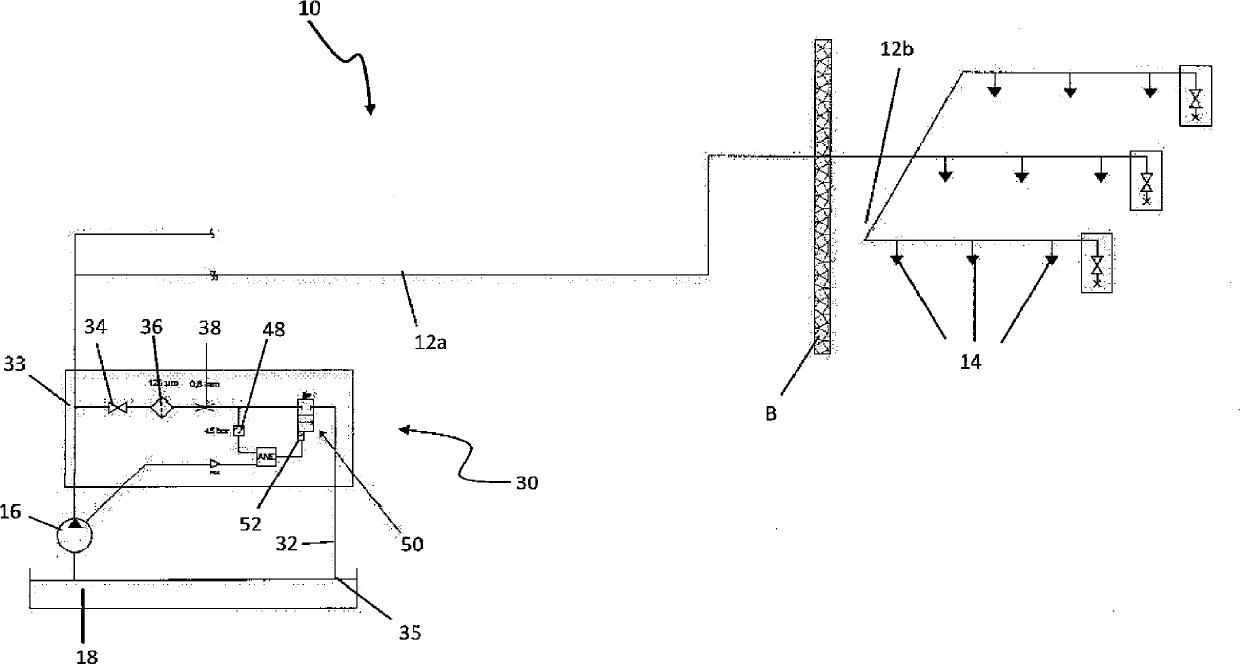

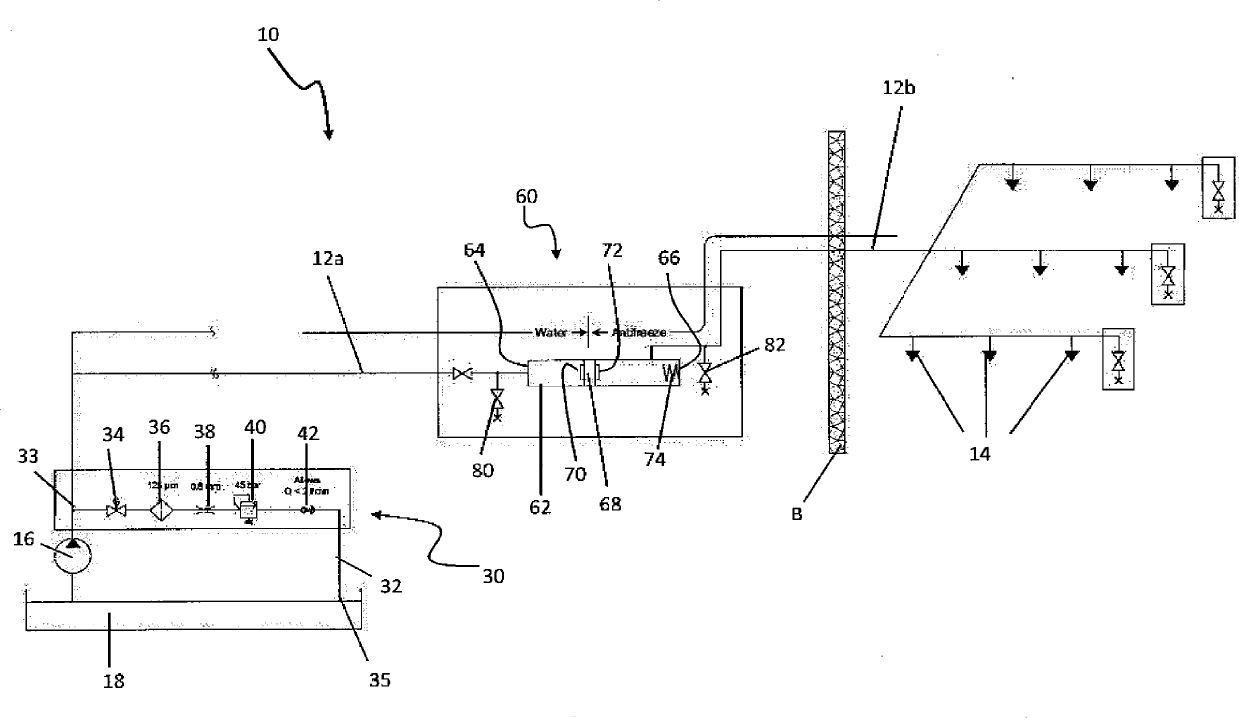

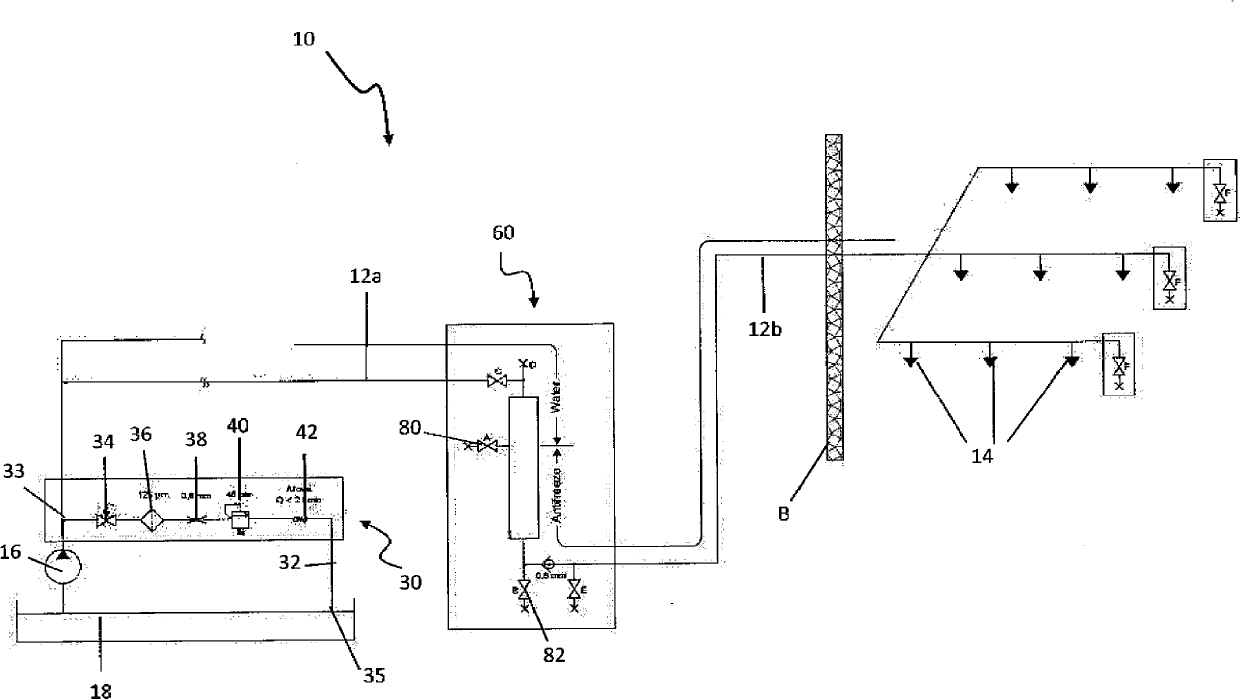

[0017] see now figure 1 , shows a known fire suppression system 10 comprising a drive source 16 . A supply line 12 extends from a drive source 16 to a plurality of spray heads 14 to supply the extinguishing medium thereto. In one embodiment, the spray head 14 includes a nozzle having small holes configured to spray a liquid mist of water. The drive unit 16 is also connected to a source 18 of an extinguishing medium, such as a pipe network or a tank. The spray heads 14 of each fire suppression system 10 may be located in the same general area as the drive source 16, or alternatively may also be separated from the drive source 16 by a barrier B such as a wall, for example. Depending on the location of sprinkler heads 14 and the type of fire suppression system 10, any part of the system, especially sprinkler heads 14, may be subject to extreme temperatures, such as, for example, -40°C or 60°C, or extreme temperature fluctuations (see figure 1 and figure 2 ).

[0018] In one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com