Evaporator integrated component

A technology of evaporators and components, applied in evaporators/condensers, refrigeration components, mechanical equipment, etc., can solve problems such as gas-liquid separation, reduce the heat transfer capacity of heat exchangers, reduce the performance of refrigeration and air-conditioning systems, and improve efficiency and energy-saving performance, reduce energy loss, and shorten the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

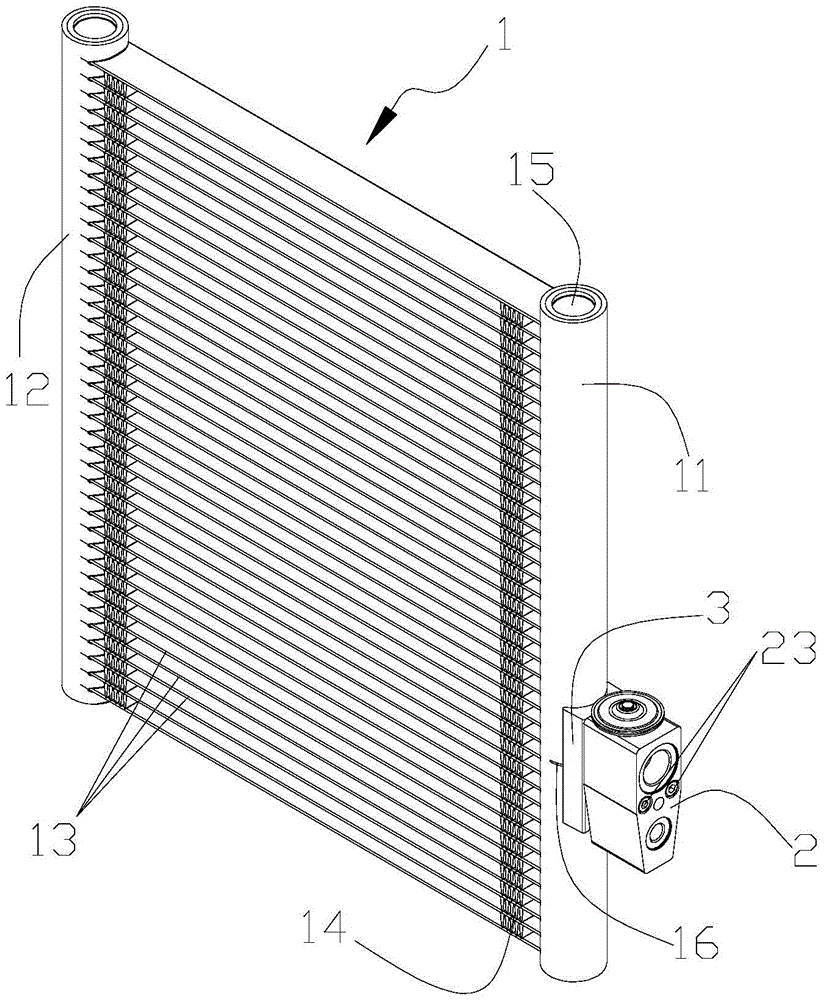

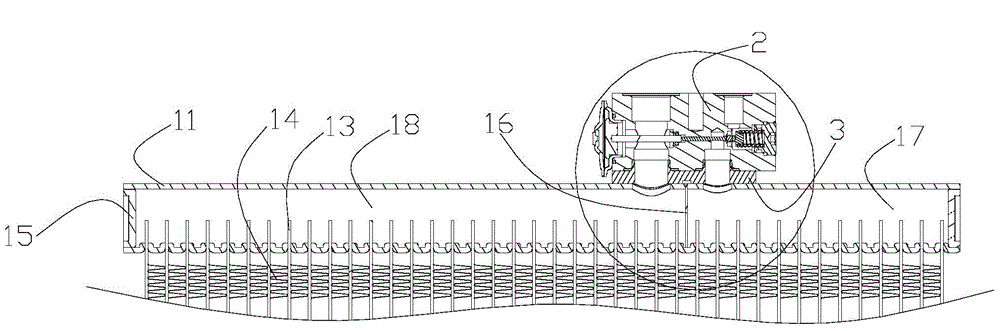

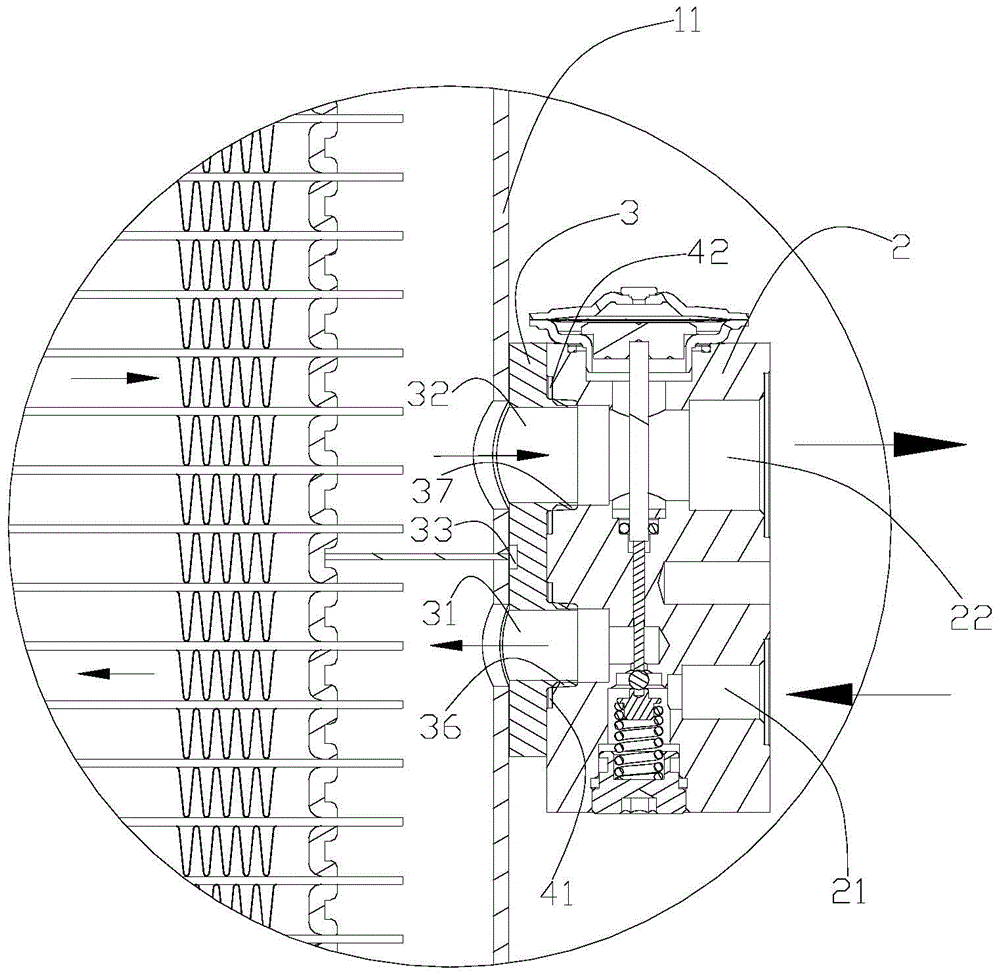

[0032] The present invention provides an evaporator integrated assembly. The evaporator integrated assembly of the present invention includes an expansion valve and a heat exchanger. The expansion valve is fixedly installed on one of the header pipes through a connecting block. In this way, the expansion valve and the heat exchanger can be realized as There is no pipeline connection between the inlet and outlet of the heat exchanger of the evaporator, and the refrigerant throttling through the expansion valve can directly flow into the evaporator, which reduces the journey of the refrigerant from the expansion valve to the evaporator, making the refrigerant It maintains the gas-liquid two-phase state very well, which is conducive to the uniform distribution of refrigerant in the evaporator, and also prevents the energy loss of refrigerant in the connecting pipeline, and has a simple structure, which can effectively improve the efficiency of the air conditioning system and energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com