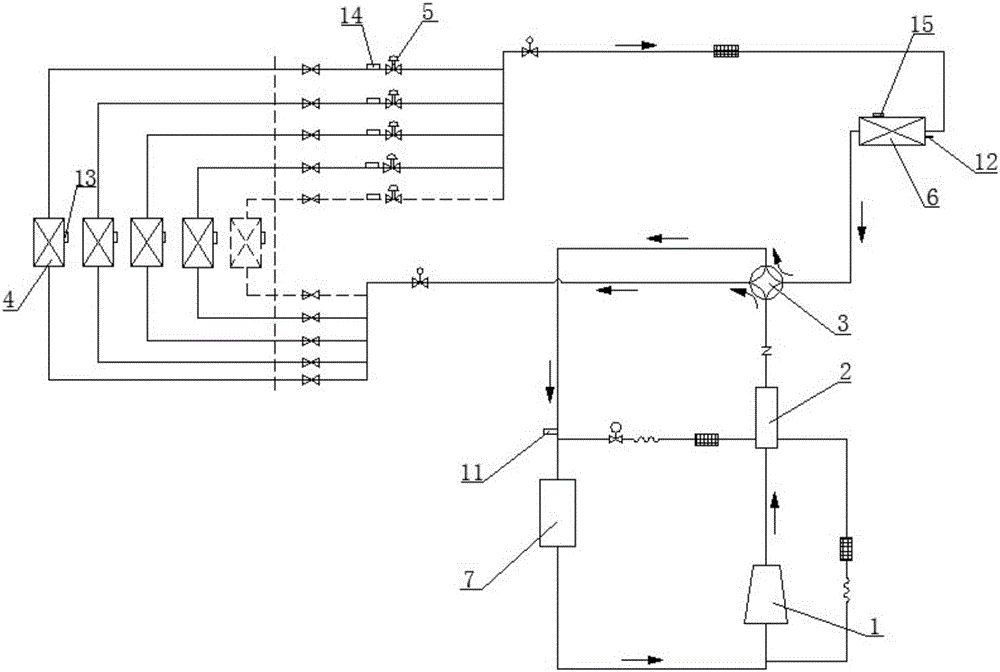

Method for controlling electronic expansion valves during multi-connected air conditioning unit heating

An electronic expansion valve and control method technology, applied in the direction of control input related to air characteristics, space heating and ventilation control input, heating mode, etc., can solve the problem of unbalanced heating effect, unreasonable refrigerant distribution, and refrigerant distribution Unevenness and other problems can be achieved to achieve reasonable distribution and balanced heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

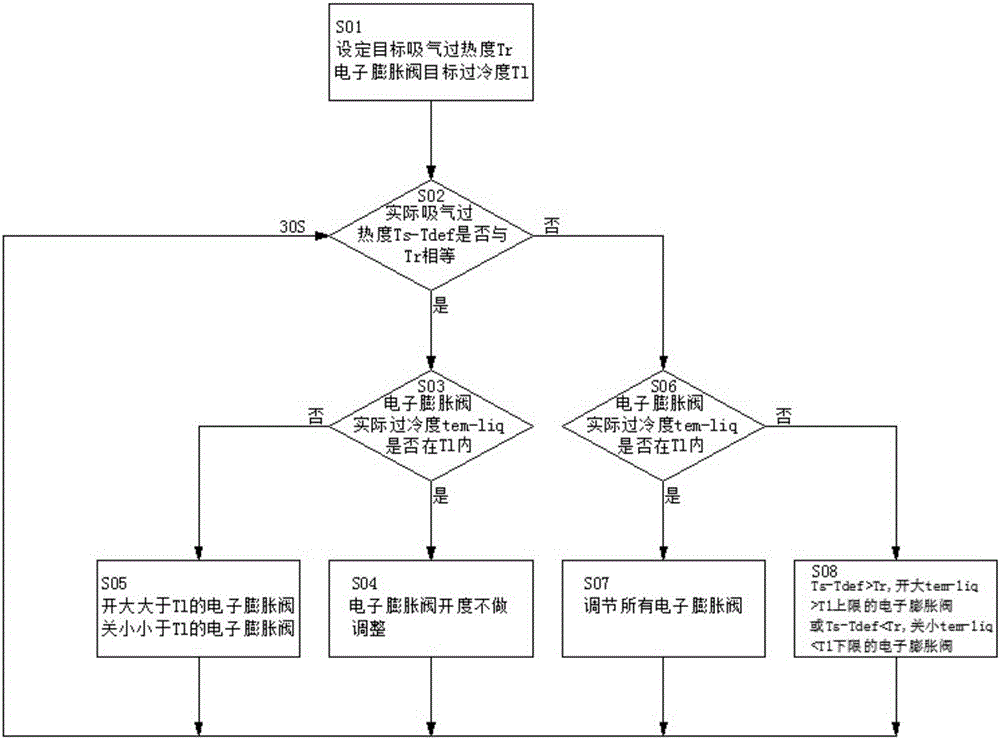

[0043] System setting: when Tao6°C, Tr=2°C; 6°C≤Tl≤10°C.

[0044] For example, if the temperature measured by the ambient temperature sensor of the outdoor unit is 1°C, Tr is 4°C.

[0045] If the actual suction superheat Ts-Tdef=6°C, it is judged that the obtained Ts-Tdef is not equal to Tr.

[0046] Determine whether the actual subcooling degrees of all electronic expansion valves are within the range of 6°C to 10°C, and open all electronic expansion valves (Ts-Tdef)-Tr=6-4=2 steps.

Embodiment 2

[0048] System setting: when Tao6°C, Tr=2°C; 6°C≤Tl≤10°C.

[0049] For example, if the temperature measured by the ambient temperature sensor of the outdoor unit is 1°C, Tr is 4°C.

[0050] If the actual suction superheat Ts-Tdef=3°C, it is judged that the obtained Ts-Tdef is not equal to Tr.

[0051] Determine whether the actual subcooling degree of all electronic expansion valves is between 6°C and 10°C. If two electronic expansion valves are not within this range, the actual subcooling degree of one electronic expansion valve is 4°C, and the other The actual subcooling degree of the valve is 12°C; when closing down the electronic expansion valve whose actual subcooling degree is 4°C, the number of steps for closing down is: Tr-(Ts-Tdef)=4-3=1 step.

Embodiment 3

[0053] System setting: when Tao6°C, Tr=2°C; 6°C≤Tl≤10°C.

[0054] For example, if the temperature measured by the ambient temperature sensor of the outdoor unit is 1°C, Tr is 4°C.

[0055] If the actual suction superheat Ts-Tdef=4°C, it is judged that the obtained Ts-Tdef is equal to Tr.

[0056] Determine whether the actual subcooling degree of all electronic expansion valves is between 6°C and 10°C. If two electronic expansion valves are not within this range, the actual subcooling degree of one electronic expansion valve is 4°C, and the other The actual subcooling degree of the valve is 12°C; when closing down the electronic expansion valve whose actual subcooling degree is 4°C, the number of steps to close is: Tl lower limit - the actual subcooling degree of the electronic expansion valve = 6-4 = 2 steps ; Open the electronic expansion valve whose actual subcooling degree is 12°C, the number of steps to open is: the actual subcooling degree of the electronic expansion val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com