A non-pneumatic tire with bionic vibration-damping webs

A technology of non-pneumatic tires and webs, applied in non-pneumatic tires, tire parts, road transportation and emission reduction, etc., can solve problems such as hindering the development of non-pneumatic tires, non-uniform stiffness, ground pressure and ground contact area fluctuations, etc. Achieve the effect of avoiding design and manufacturing difficulties and costs, reducing fluctuations, and reducing radial vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

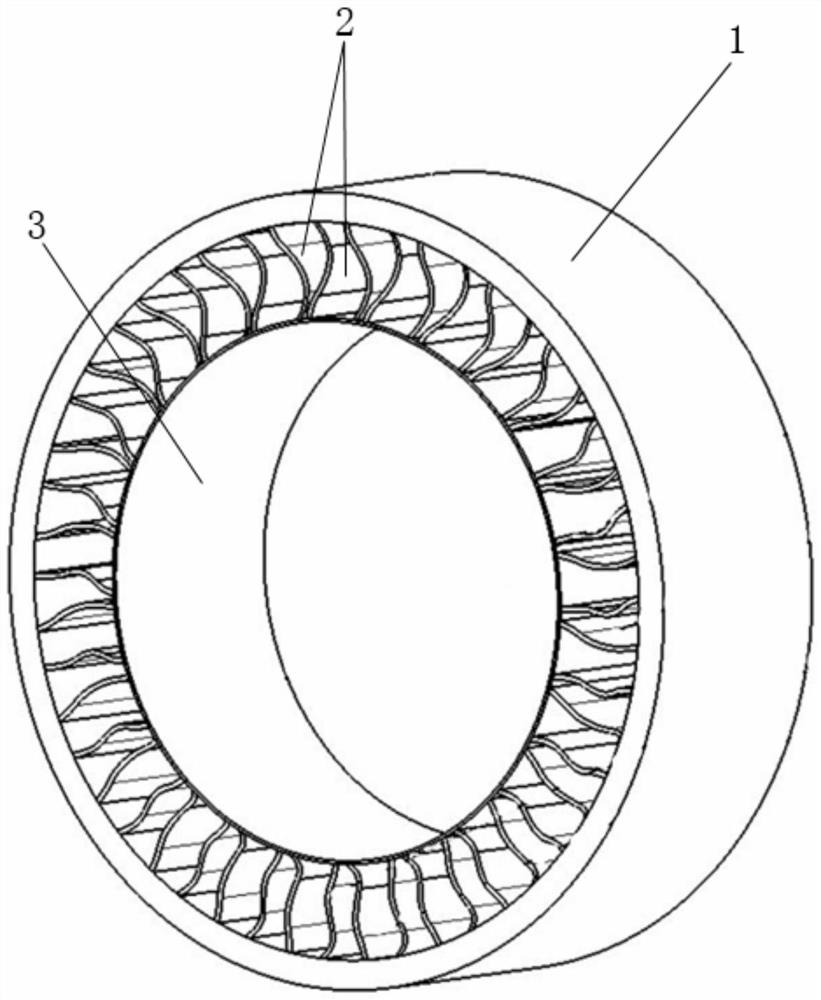

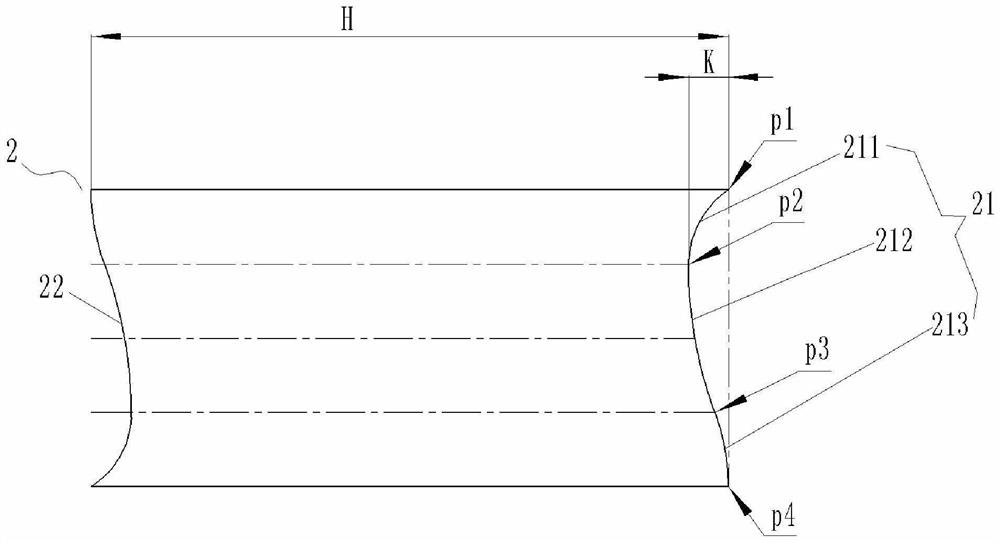

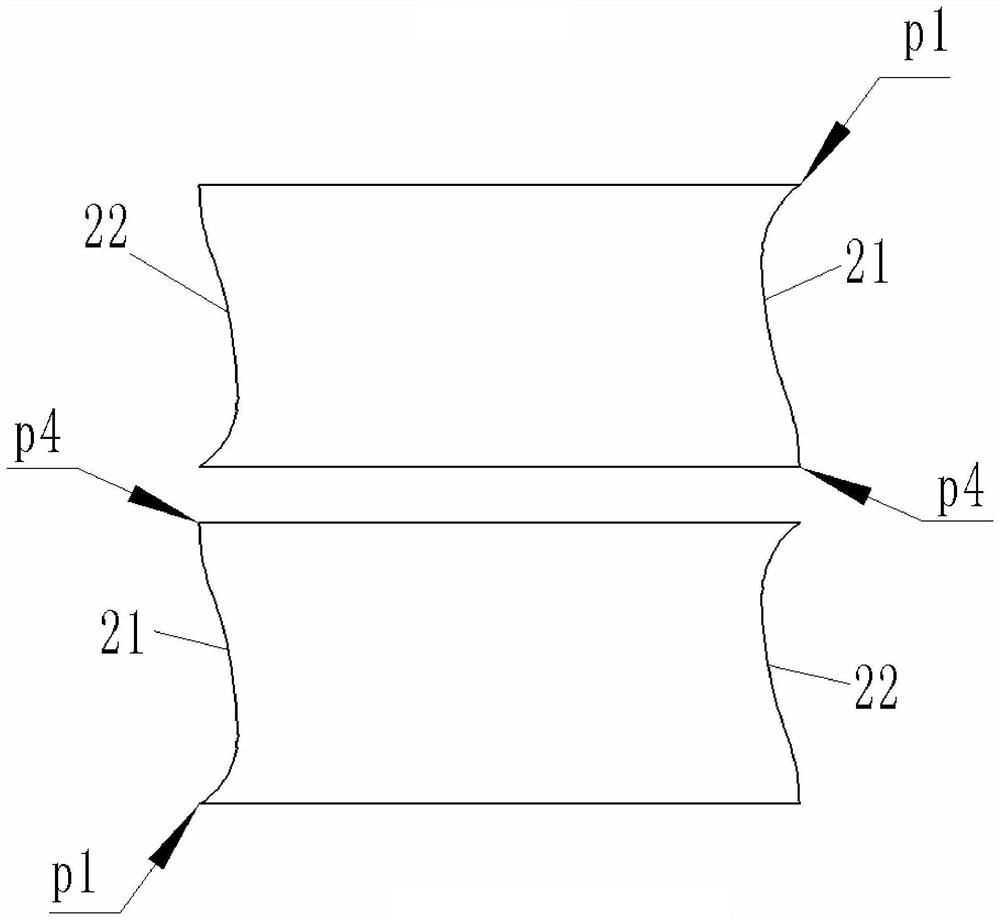

[0028] see Figure 1 to Figure 3 , The present invention provides a non-pneumatic tire with bionic vibration damping webs, including: a tire crown 1 and a rim joint ring 3 connected by the wheel spokes; the wheel spokes are composed of several evenly distributed bionic vibration damping webs 2; The two sides of the vibration plate 2 along the axial direction are smooth curved surfaces A21 and B22; the contours of the curved surfaces A21 and B22 are both asymmetrical arcs, and the asymmetrical arcs are used to reduce the radial excitation force when the non-pneumatic tire rolls And reduce the fluctuation of the excitation force, thereby reducing the radial vibration.

[0029] As an embodiment of the present invention, the above-mentioned curved surfaces A21 and B22 are center-symmetrical with respect to the geometric center of the bionic vibration-damping web 2 .

[0030] Preferably, the two sides of the wheel spoke are respectively a curved surface A21 and a curved surface B2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com