Constant-pressure and constant-torque tool for well drilling

A technology for drilling and tools, which is applied in the field of downhole tools in oil and gas drilling engineering. It can solve problems such as drill bit chipping, downhole drilling tool assembly damage, damage, etc., and achieve the effect of reducing torsional vibration and axial vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

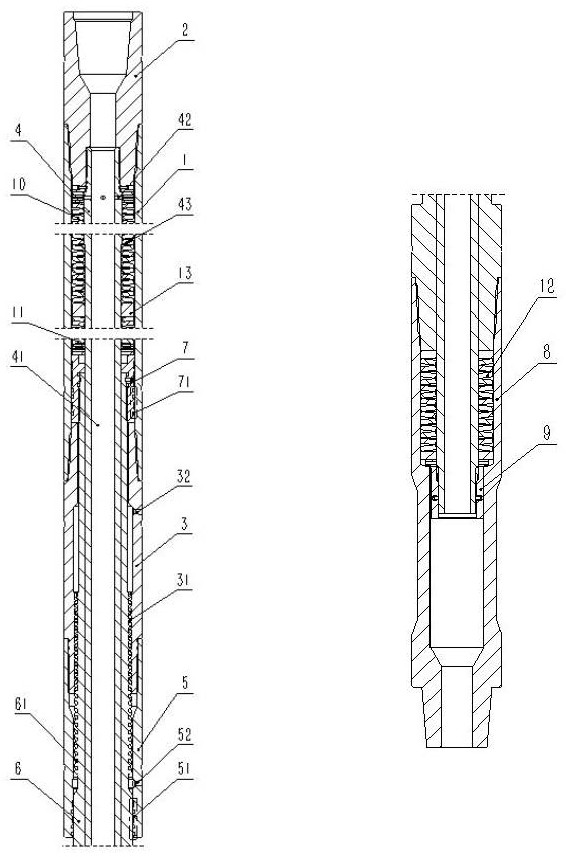

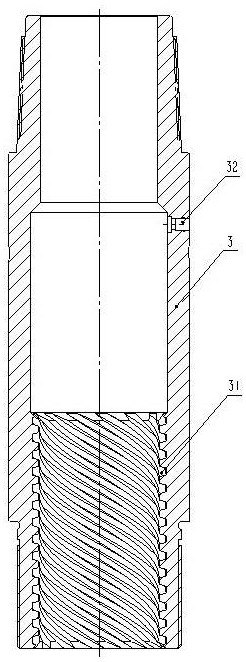

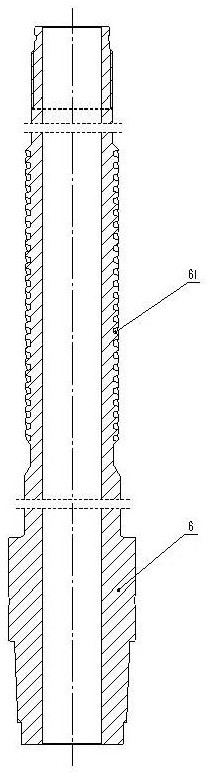

[0027] like Figure 1 to Figure 3 As shown, a constant pressure and constant torque tool for drilling includes an upper casing (1), an upper joint (2) connected to the upper casing (1) through threads, and a middle joint (2) connected to the upper casing (1) through threads. The shell (3), the mandrel (4) connected with the upper joint (2) by thread, the lower shell (5) connected with the middle shell (3) by thread, the one connected with the lower joint (6) by thread Piston (7), compensation joint (8) connected to lower joint by thread, nut (9) connected to mandrel by thread, disc spring group I is installed between upper shell (1) and mandrel (4) (10) and disc spring group II (11), disc spring group III (12) is housed between the lower joint (6) and the mandrel (4), installed in disc spring group I (10) and disc spring group II ( 11) between the limit retaining ring (13), the mandrel (4) is provided with an inner through hole (41), a mandrel bypass hole (42) and a limit ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com