Sandy soil curing agent used for water conservancy project soft sinking mattress bottom protection, shore protection, and beach protection

A technology of curing agent and sand, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem of the integrity of the bottom protection structure and the high requirements for adapting to changes in beach scouring, and the discharge of ballast materials. It should not be too thick, and the firewood riprap bottom protection is unrealistic, so as to achieve the effect of good water flow scouring and soil protection, high anti-lifting and anti-slip stability, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

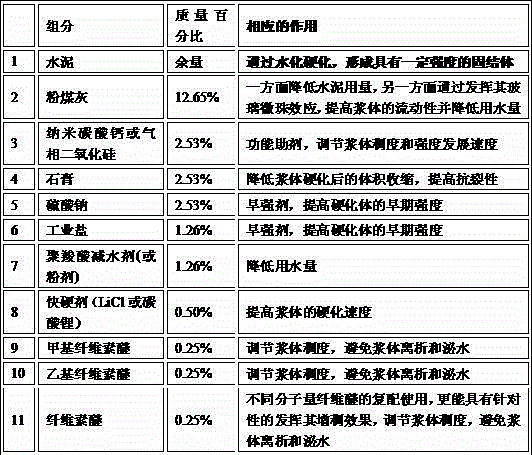

[0030] The sand solidifying agent of the present embodiment (comprising composition and its), as table 1:

[0031]

[0032]

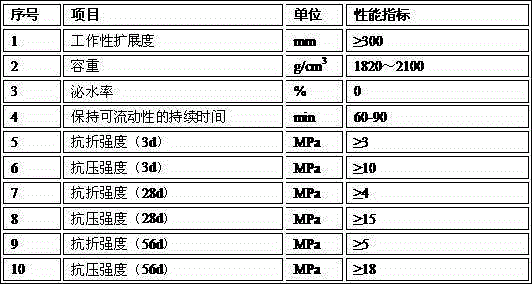

[0033] The main performance indicators of the above-mentioned sand curing agent are shown in Table 2:

Embodiment 2

[0035] The sand solidifying agent of the present embodiment (comprising composition and its), as follows:

[0036] components mass percentage 1 cement margin 2 fly ash 8.11% 3 Nano calcium carbonate 4.53% 4 plaster 1.13% 5 sodium sulfate 1.23% 6 industrial salt 2.26% 7 Polycarboxylate superplasticizer (or powder) 2.86% 8 LiCl or lithium carbonate 0.95% 9 methyl cellulose ether 0.11% 10 Ethyl cellulose ether 0.11% 11 Cellulose ether 0.55%

[0037] The main performance indicators of the above-mentioned sand solidifying agent are shown in Table 2.

Embodiment 3

[0039] The sand solidifying agent of the present embodiment (comprising composition and its), as follows:

[0040] components mass percentage 1 cement margin 2 fly ash 15.81% 3 Nano calcium carbonate 1.13% 4 plaster 4.53% 5 sodium sulfate 1.13% 6 industrial salt 0.96% 7 Polycarboxylate superplasticizer (or powder) 0.86% 8 LiCl or lithium carbonate 0.55% 9 methyl cellulose ether 0.51% 10 Ethyl cellulose ether 0.51% 11 Cellulose ether 0.15%

[0041] The main performance indicators of the above-mentioned sand solidifying agent are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com