Multidirectional vibration damping device for fluid conveying pipeline

A vibration damping device, a technology for conveying fluids, applied in the direction of shock absorbers, friction shock absorbers, shock absorbers, etc., can solve problems such as inability to apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

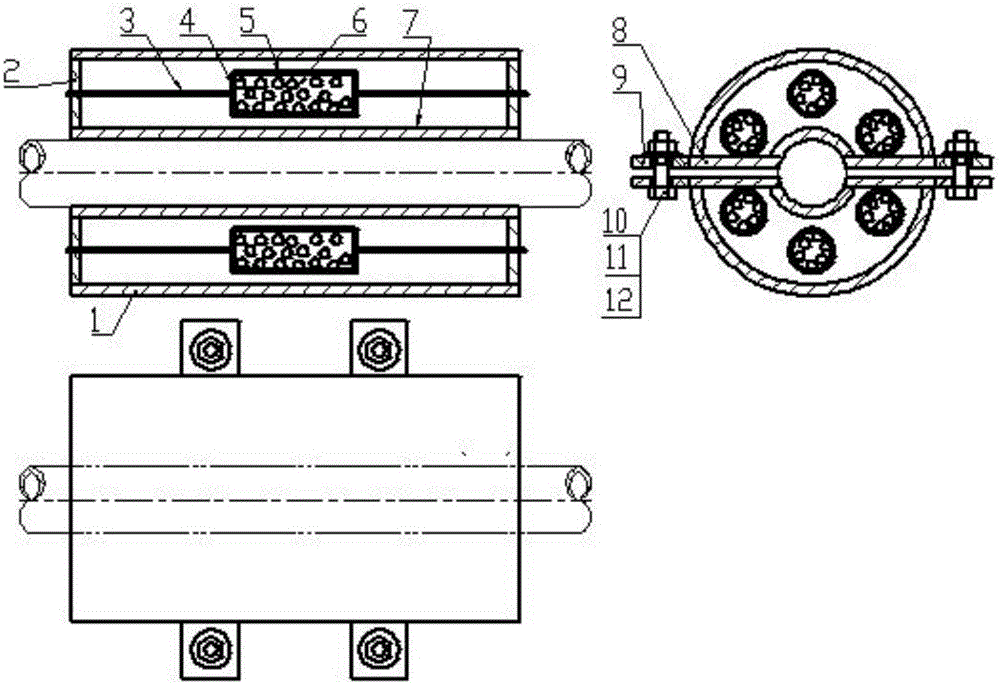

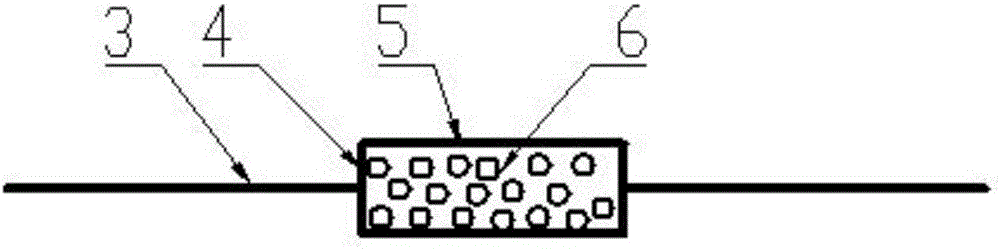

[0016] Such as figure 1 As shown, a multi-directional vibration damping device for conveying fluid pipelines includes: an outer shell 1, an end cover A2, a miniature shock absorber, an inner shell 7, a cover plate 8, a connecting plate 9, bolts 10, nuts 11 and washers 12. The shell 1 described above is in the shape of a half cylinder, made of steel pipes, the diameter of which matches the outer diameter of the pipeline to be damped, and the length is 40-300 mm, and parallel miniature shock absorbers are installed inside.

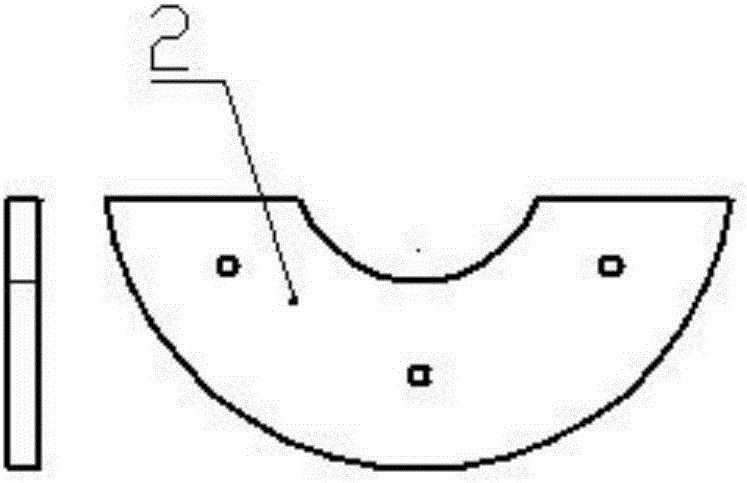

[0017] Such as figure 2 As shown, the shape of the end cap A is half a ring, the outer diameter of the ring is equal to the inner diameter of the outer shell 1, the inner diameter of the ring is equal to the outer diameter of the inner shell 7, and the thickness is 2-10 mm. Between the inner circles, several through holes are evenly distributed along the circumferential direction, the diameter of the through holes is equal to the diameter of the steel wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com