Low-torque diamond drill bit

A diamond bit, low torque technology, applied in drilling tools, drilling equipment, earthwork drilling and mining, etc., can solve the problems of bit chipping, drilling tool breakage, affecting drilling efficiency, etc., to reduce vibration impact and reduce amplitude Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

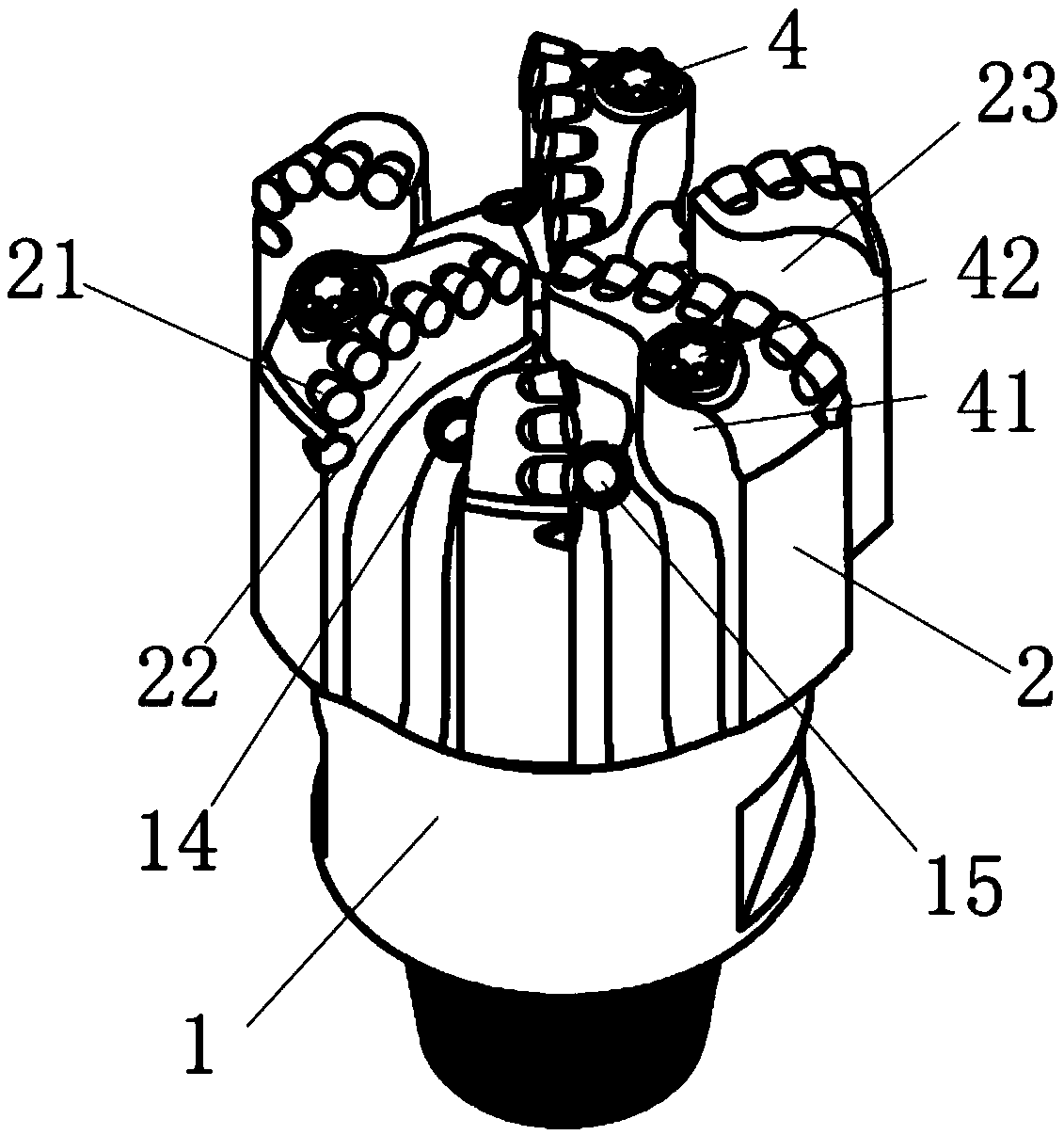

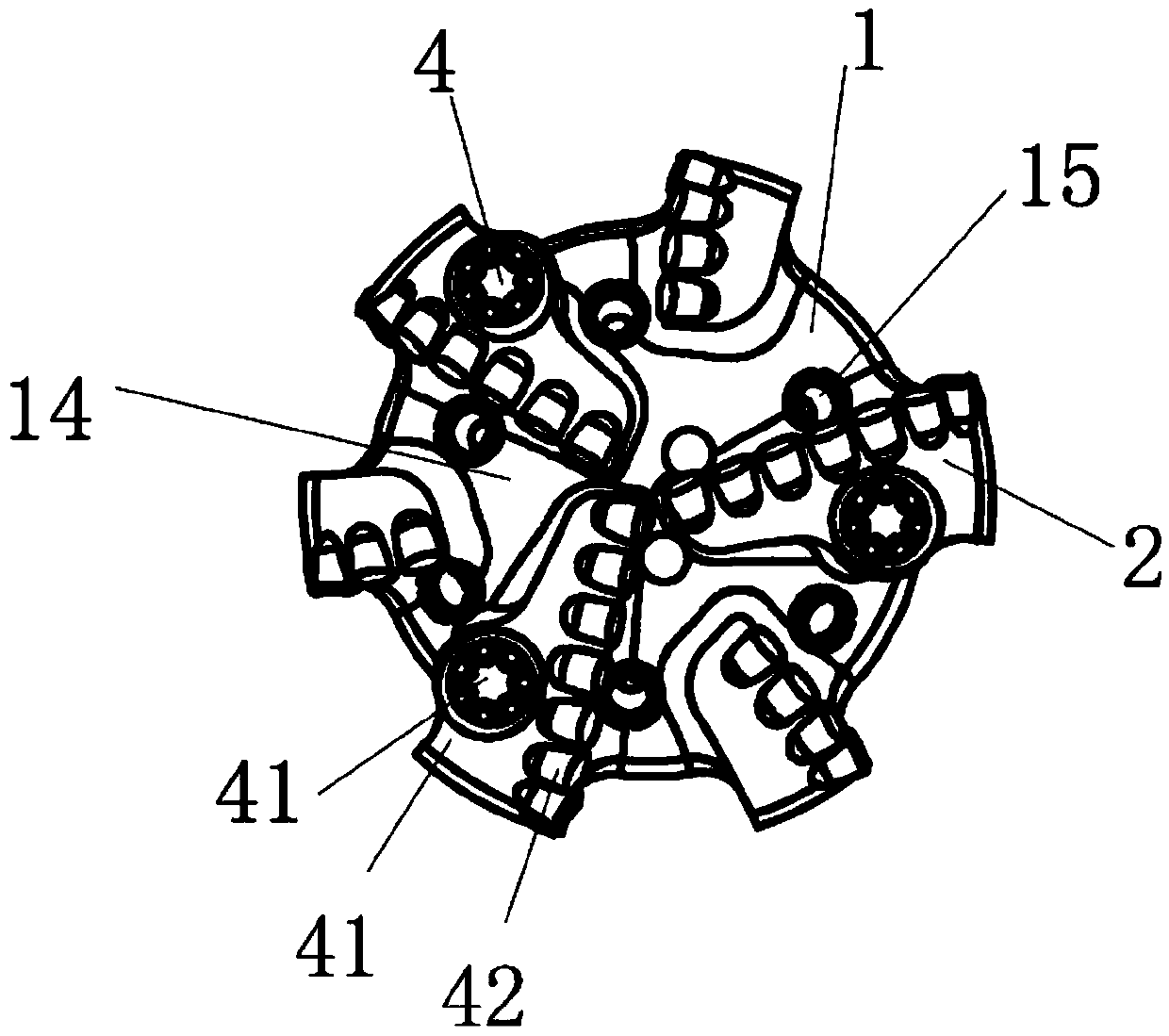

[0088] A low-torque diamond drill bit, comprising a drill body 1, a plurality of blades 2 extending from the drill body or fixed on the drill body, water holes or nozzles 15, and flow channels 14, at least one blade 2 is provided with scraping teeth 21 , the rear end 23 of at least one blade 2 is extended with a base 41, and the base 41 is provided with a normal wheel unit 42, and the normal wheel unit 42 is made up of a normal wheel 421, a normal wheel shaft 422, and a shaft sleeve 423. The wheel 421 can rotate relative to its own axis, such as figure 1 , 2 , 4, 6 shown.

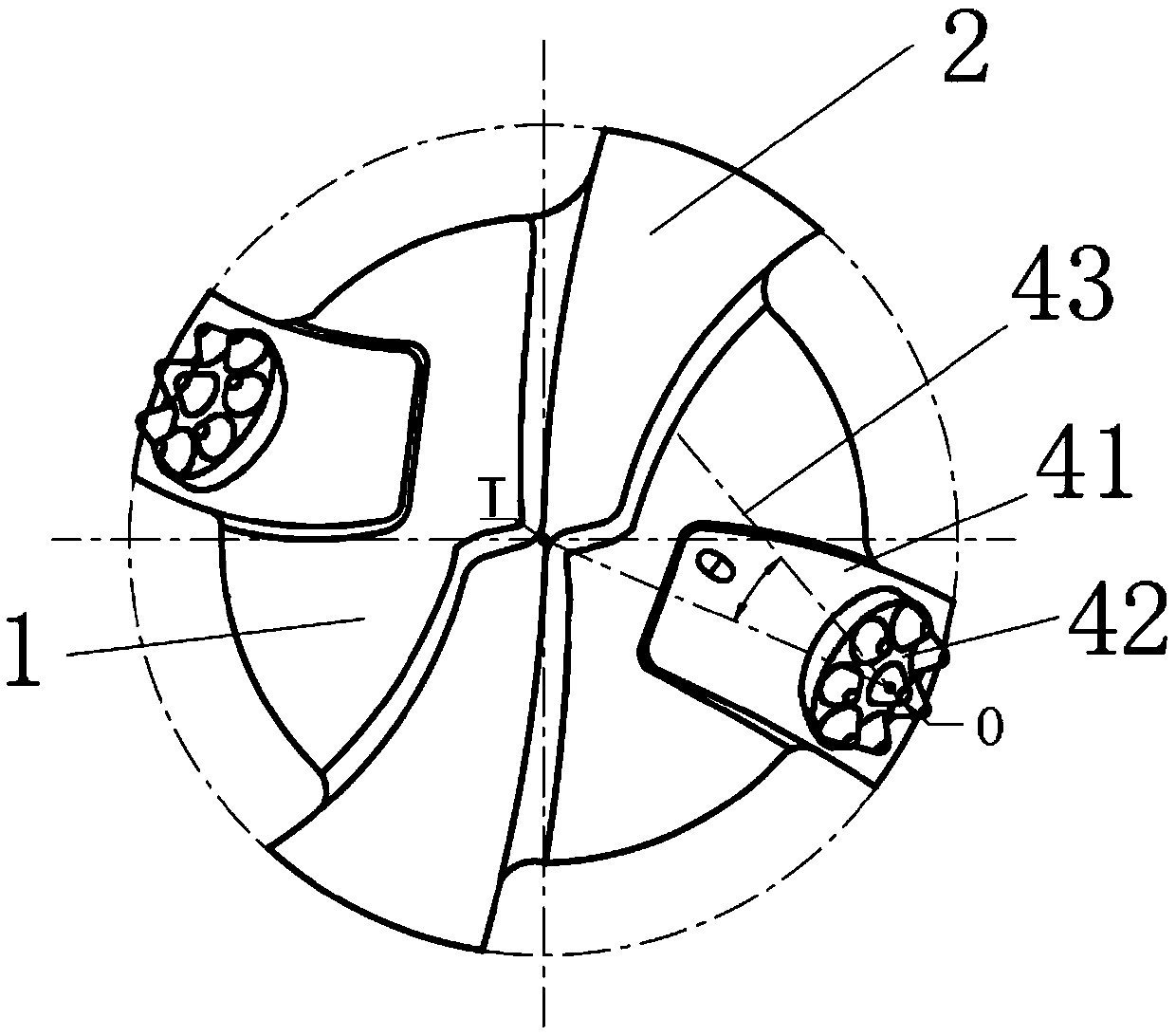

[0089] Alternatively, see Figure 8 , 37 , 38, and 39, the range of the normal distance between the working contour line 44 of the normal wheel unit 42 and the cutting contour line 13 of the drill bit |H|≤5mm. For further options, see Figure 8 , in the bottom hole coverage diagram, the working contour 44 of the normal wheel unit 42 is enveloped by the cutting contour 13 of the drill bit, and the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com