Patents

Literature

249results about How to "Reduce vibration shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

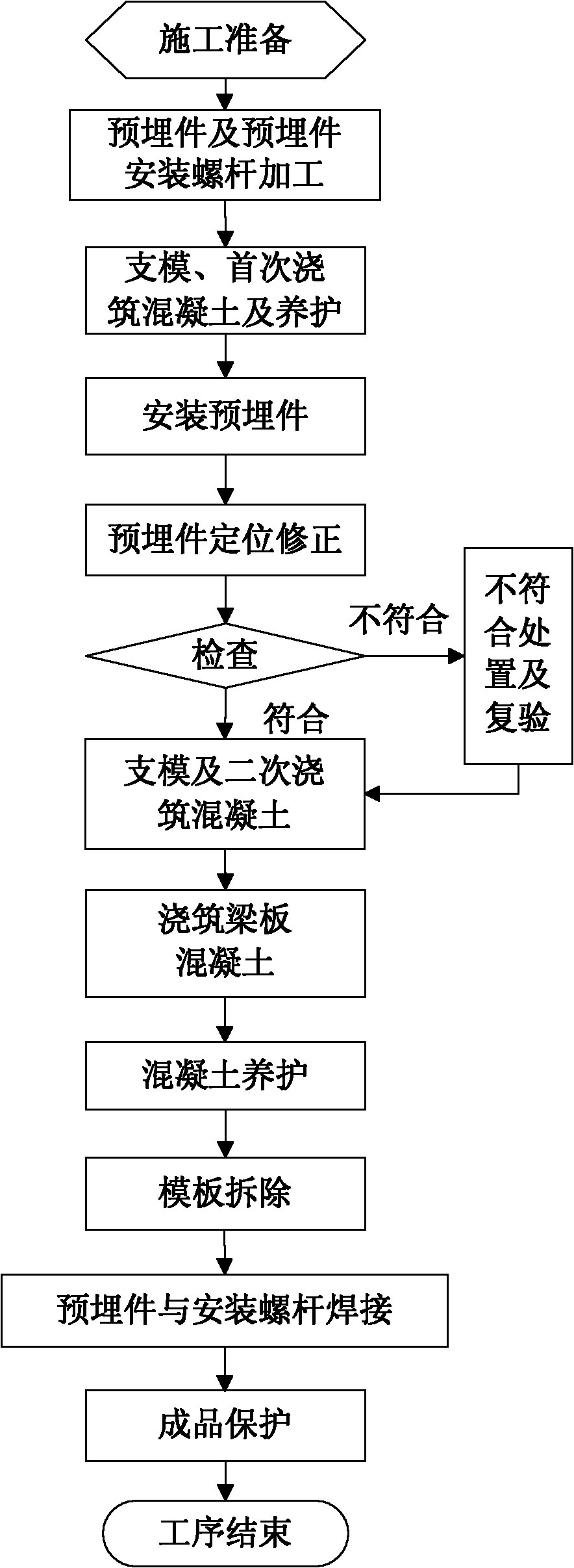

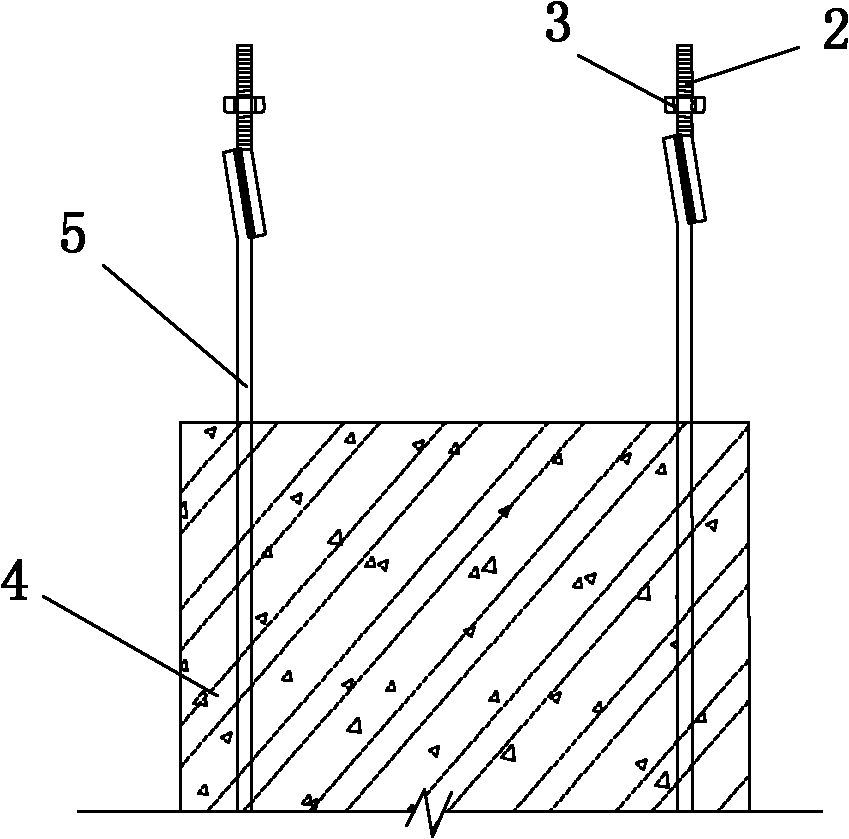

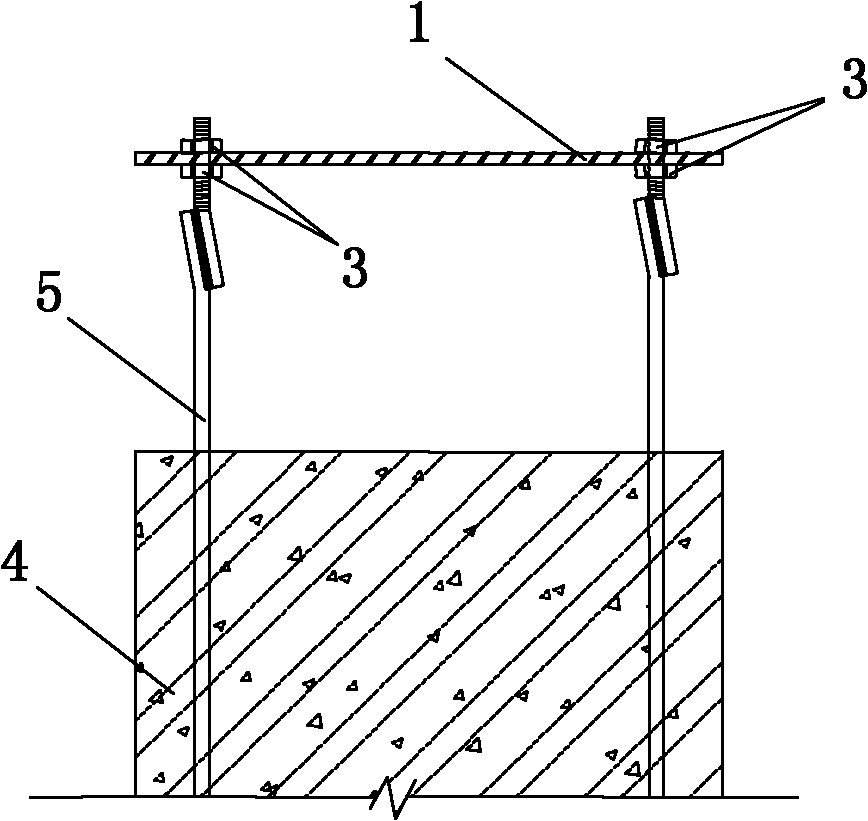

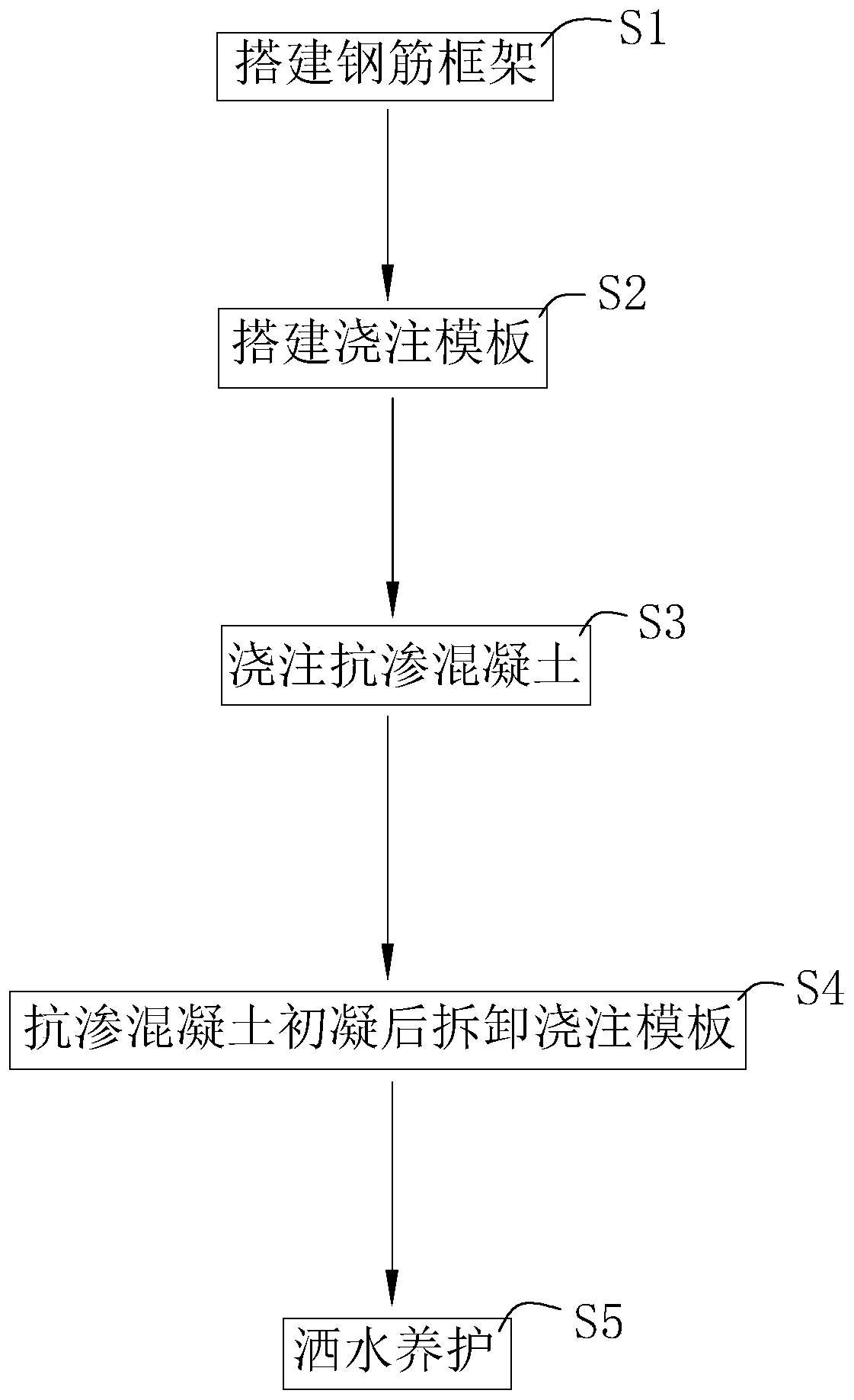

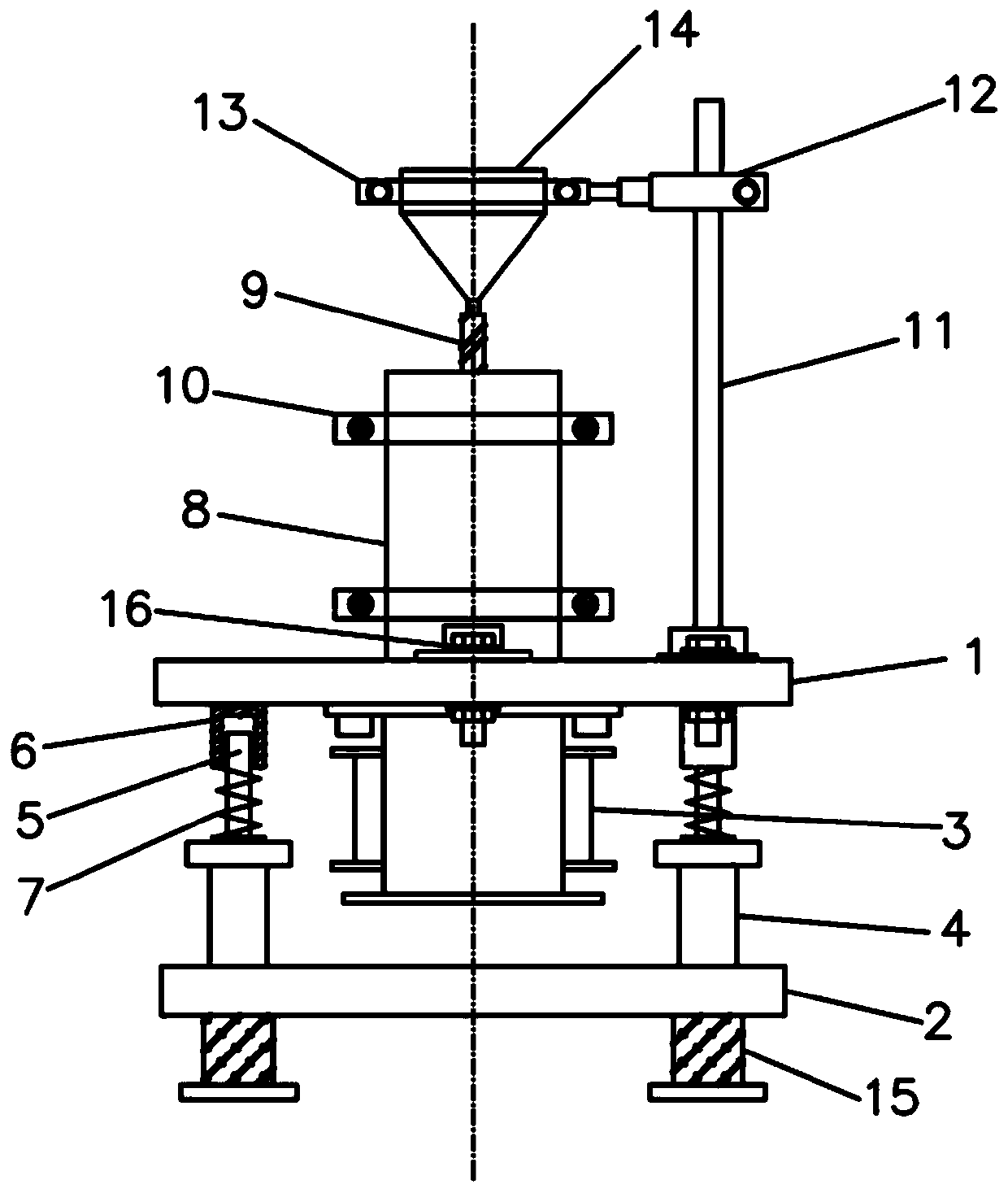

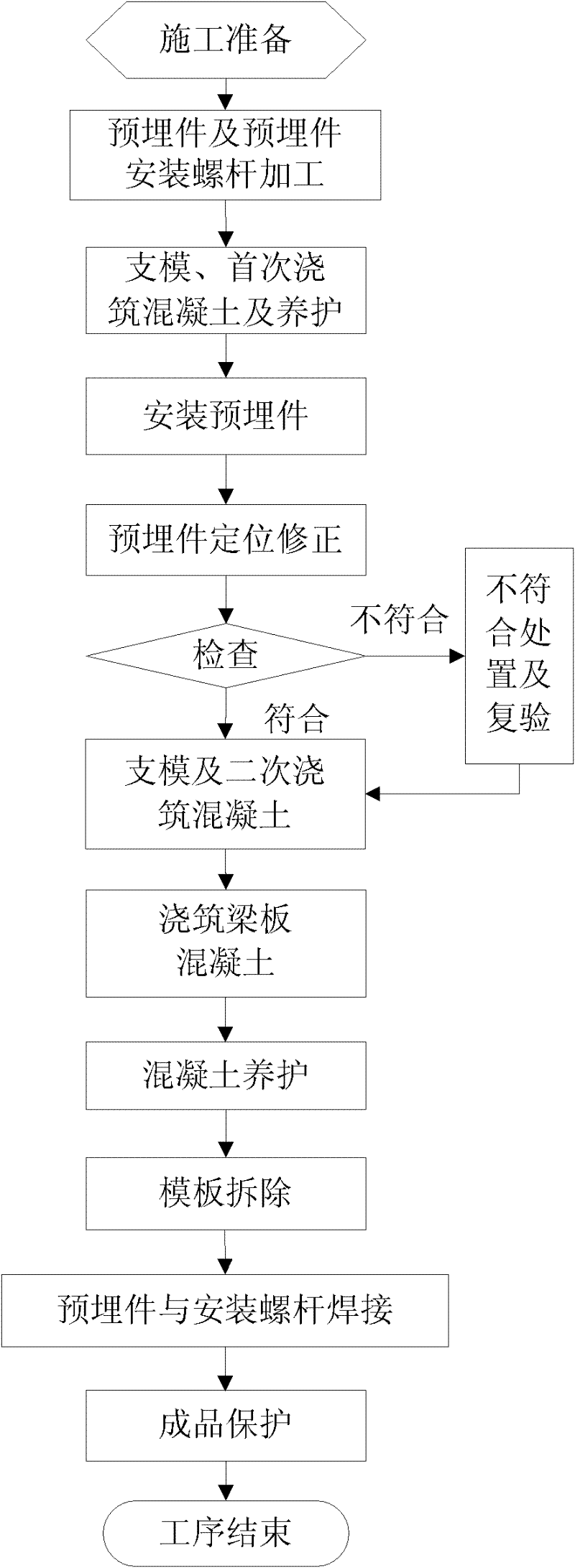

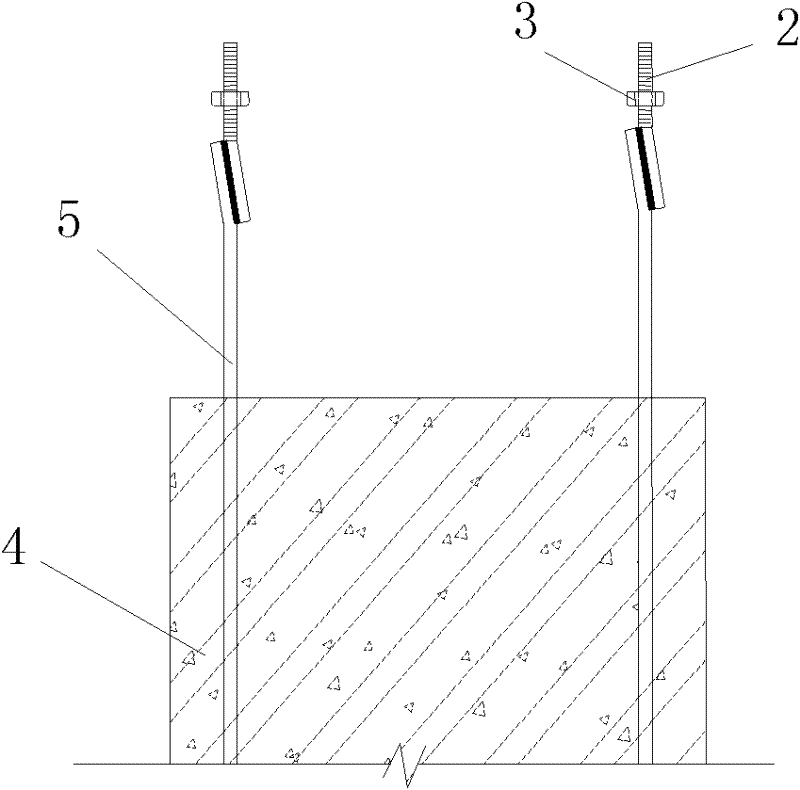

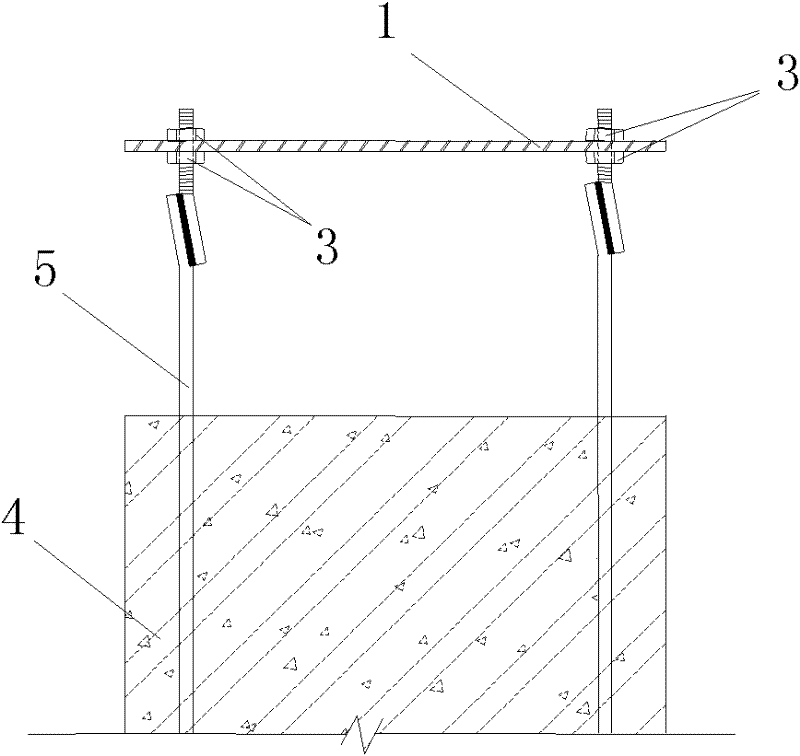

Embedding accuracy control construction method for embedded part of overlong equipment foundation platform

InactiveCN102134879AReasonable designSimple construction stepsFoundation engineeringBuilding constructionsRebarReinforced concrete

The invention discloses an embedding accuracy control construction method for an embedded part of an overlong equipment foundation platform, including the following steps: firstly, processing the embedded part and the installation screw of the embedded part; secondly, molding construction of the lower middle reinforced concrete structure of the foundation platform needing construction: a plurality of vertical reinforcing steel bars extend out from the top of the lower middle reinforced concrete structure under construction of molding and are arranged vertically; thirdly, installing the installation screw of the embedded part; fourthly, installing a nut at the bottom of the threaded section of the installation screw of the embedded part; fifthly, installing and positioning the embedded part; sixthly, installing a nut on top of the threaded section of the installation screw of the embedded par; seventhly, molding construction of the upper reinforced concrete structure of the foundation platform needing construction; and eighthly, subsequent construction treatment. The method has in design, simple construction steps, easy control of construction quality, high construction accuracy and good in use effect, and can solve the problems of the existing embedding construction method of embedding parts that the embedding accuracy is inconvenient to control, the embedding accuracy is low, the construction quality is poor, the investment cost is high, the construction period is long, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

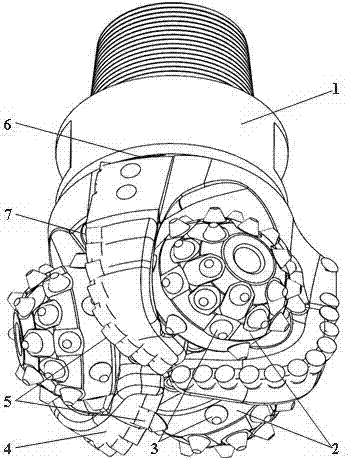

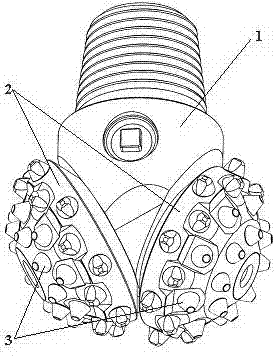

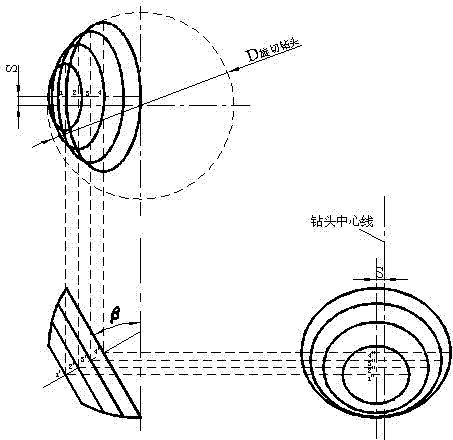

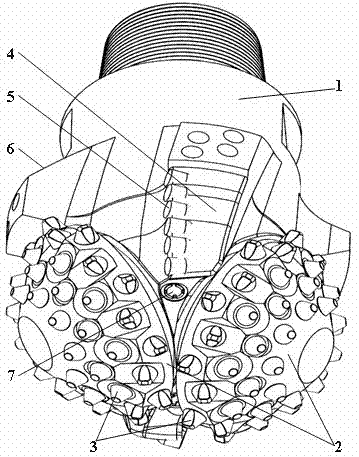

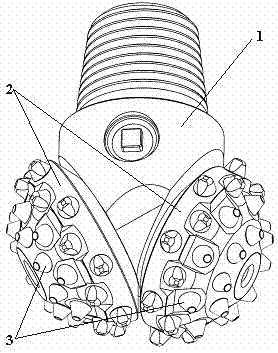

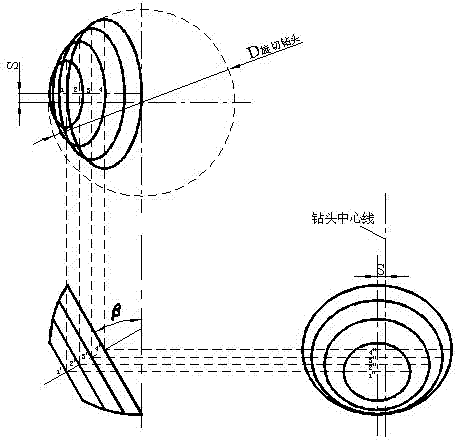

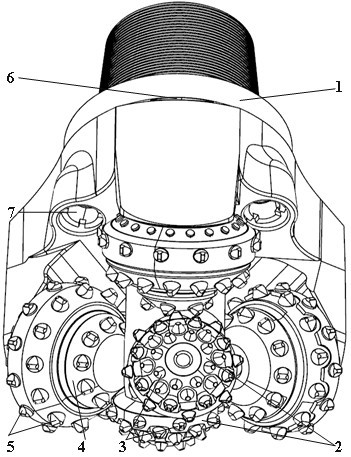

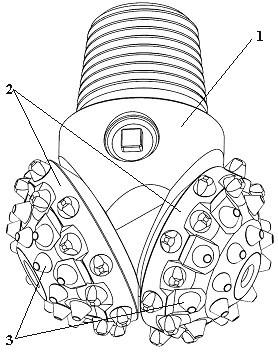

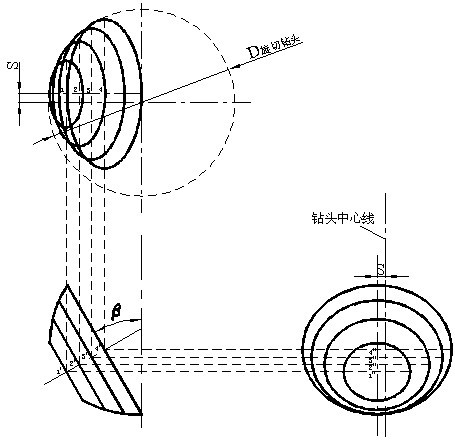

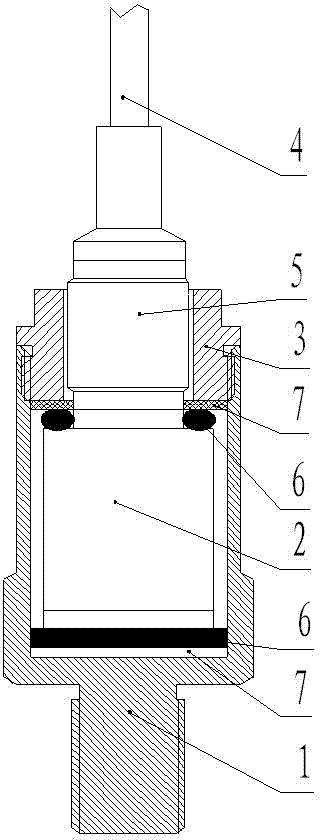

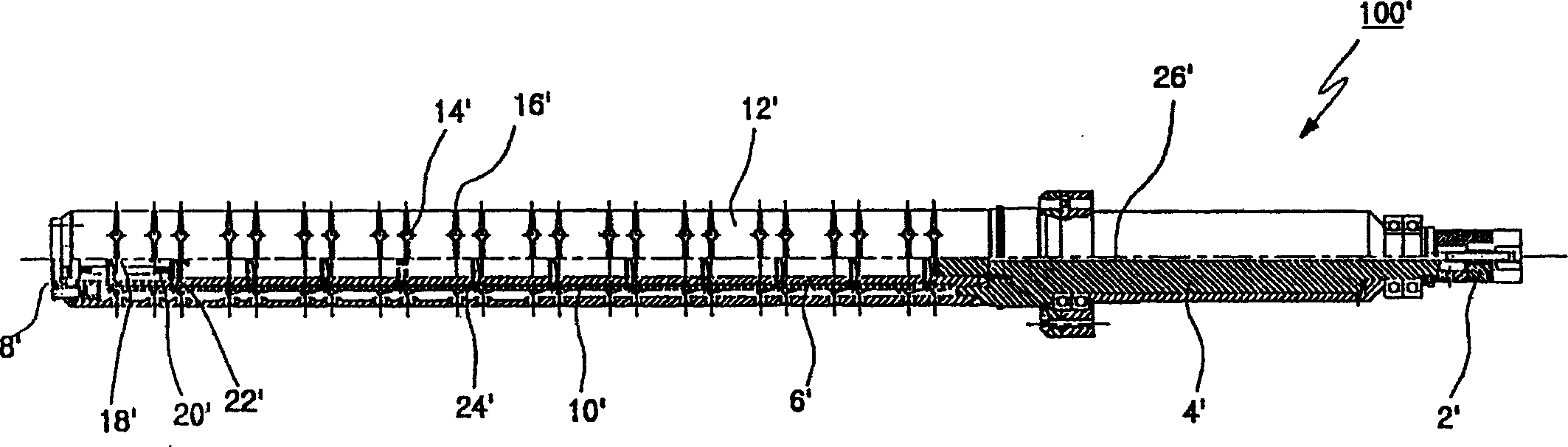

Compound bit formed by PDC (polycrystalline diamond compact) bits and rotary cutting bit

InactiveCN102392605AExtended service lifeIncrease cutting forceConstructionsHigh ratePolycrystalline diamond

The invention discloses a compound bit formed by PDC (polycrystalline diamond compact) bits and a rotary cutting bit. The compound bit comprises a main body (1), rotary cutting bit cones (2), rotary cutting bit cutting teeth (3), PDC blades (4), PDC cutting teeth (5), oil storage sacs (6) and nozzles (7), wherein the main body (1) comprises a cone journal, centralizing blocks, high-pressure slurry channels and a connection screw thread. The compound bit is characterized in that a compound bit cutting unit comprises the rotary cutting bit and a PDC bit cutting unit. The compound bit has the following beneficial effects: the PDC bits complete drilling the central part of the borehole in the drilling process; the linear velocity of the periphery of the borehole is high in the drilling process and the rotary cutting bit and the PDC bit cutting unit complete drilling the periphery of the borehole; and the rotary cutting bit in the compound bit shocks, crushes and cuts the rocks by way of rotary cutting, has high central rock breaking efficiency, high rate of penetration and better dynamic performance, is uniform in wear, simultaneously improves the bit bearing structure, ensures to prolong the service life of the bit while improving the rock breaking efficiency, improves the cutting capability of the compound bit and ensures good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

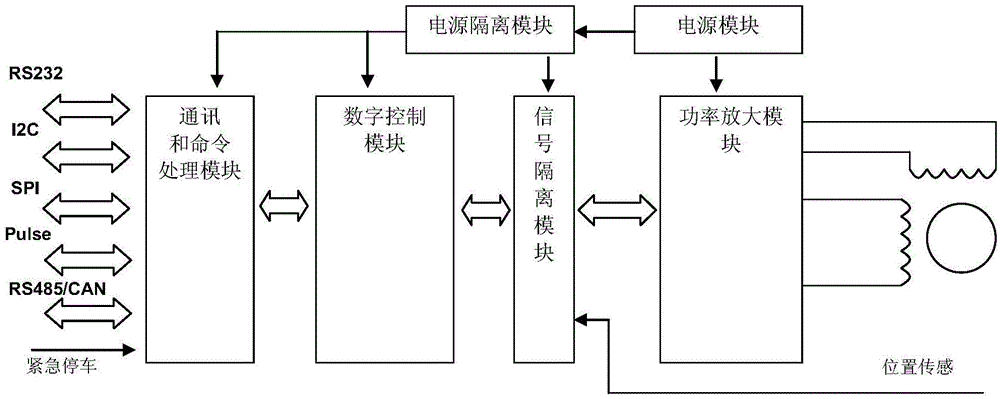

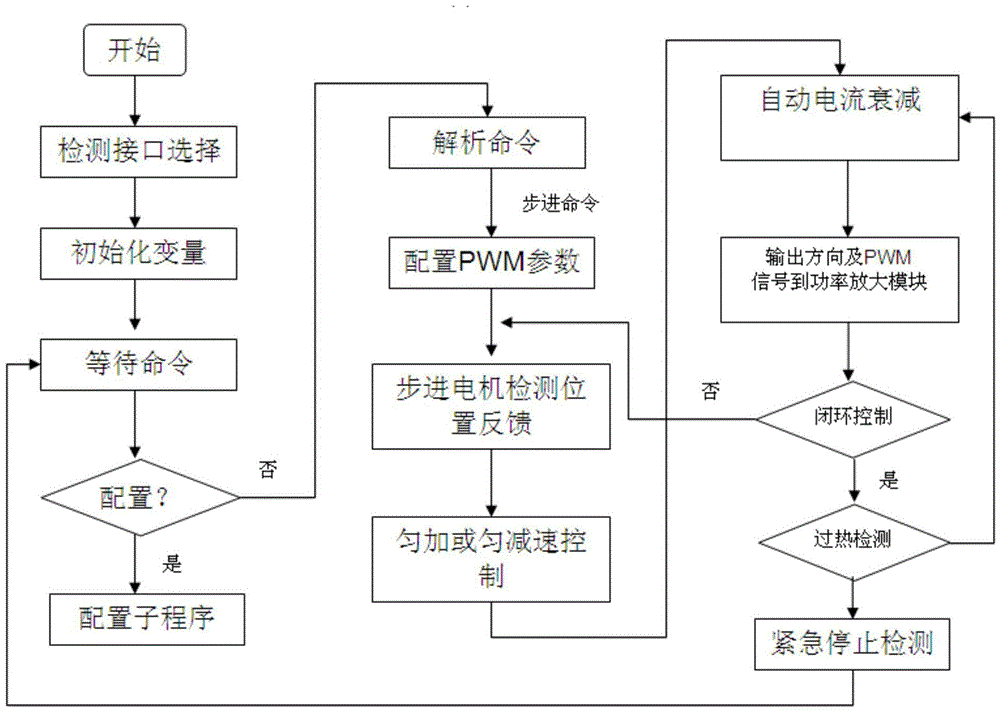

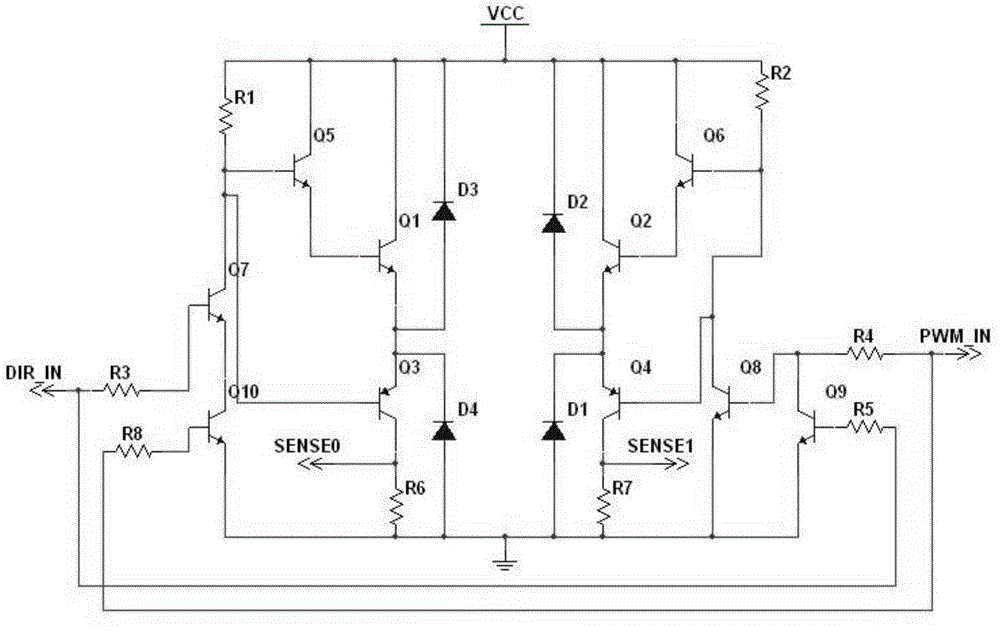

Stepping motor controller and control method thereof

ActiveCN104660127AIncrease flexibilityWide voltage rangeDynamo-electric converter controlAutomatic controlDigital control

The invention discloses a stepping motor controller and a control method thereof, and relates to the technical field of stepping motor control. The stepping motor controller comprises a power supply isolating module, a communication and command processing module, a digital control module for processing a command of an upper computer and then controlling the stepping motor to operate, a signal isolating module and a power amplification module. The stepping motor controller has the benefits that a plenty of communication interfaces are provided, and control interfaces such as RS232, RS485 / CAN, I2C, SPI and PULSE are supported; the upper computer can randomly select any interface for connection control; remote multi-motor control is realized; one upper computer can be connected in series with a plurality of stepping motor controllers through an RS485 / CAN bus and carries out real-time control on any one of the stepping motor controllers. The digital control module can be used for automatically controlling the motor to perform constant acceleration / constant deceleration motion, so that a mechanical system connected with the stepping motor is smoother, and the vibration impact is reduced.

Owner:CHONGQING PUSI ROBOT CONTROL SYST

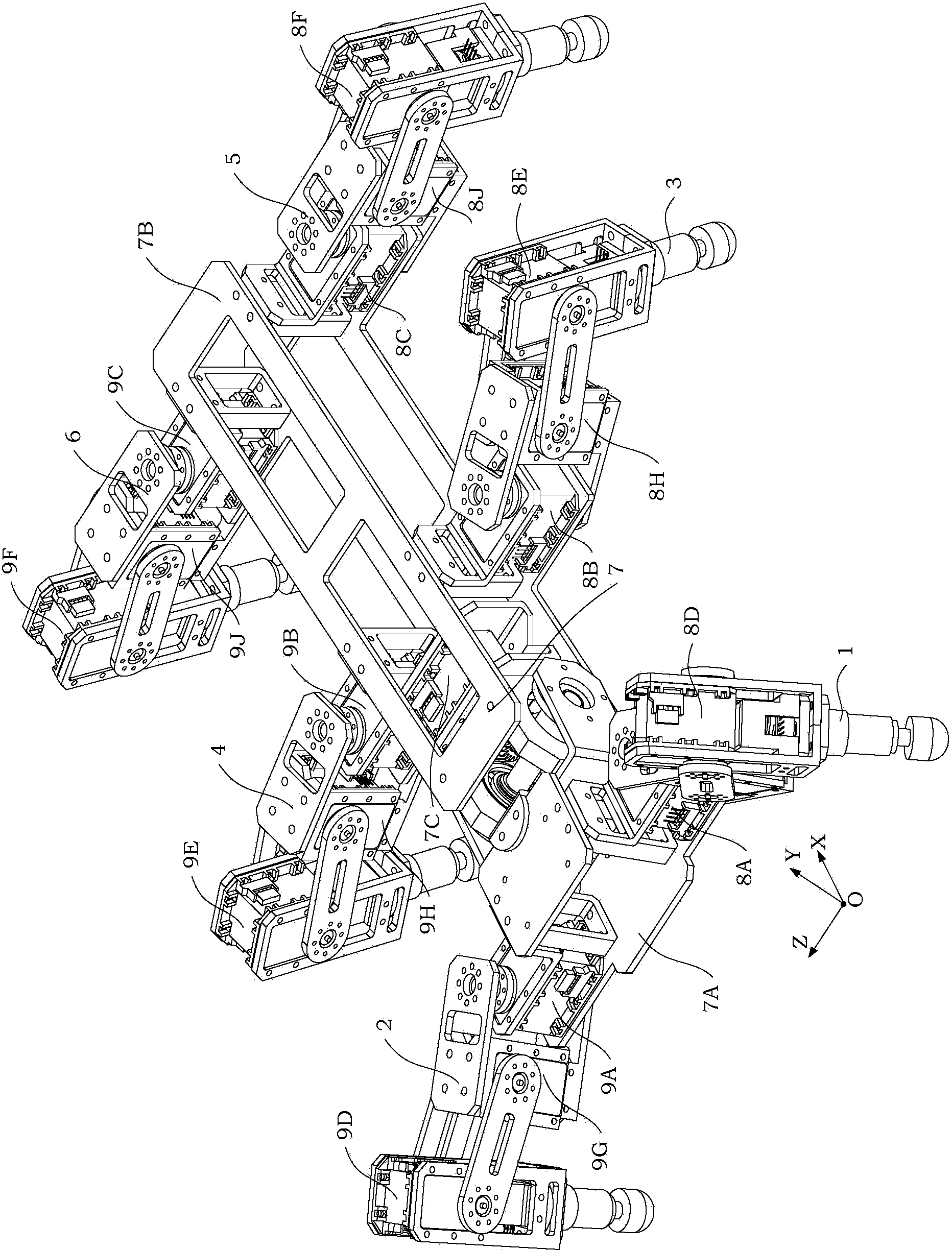

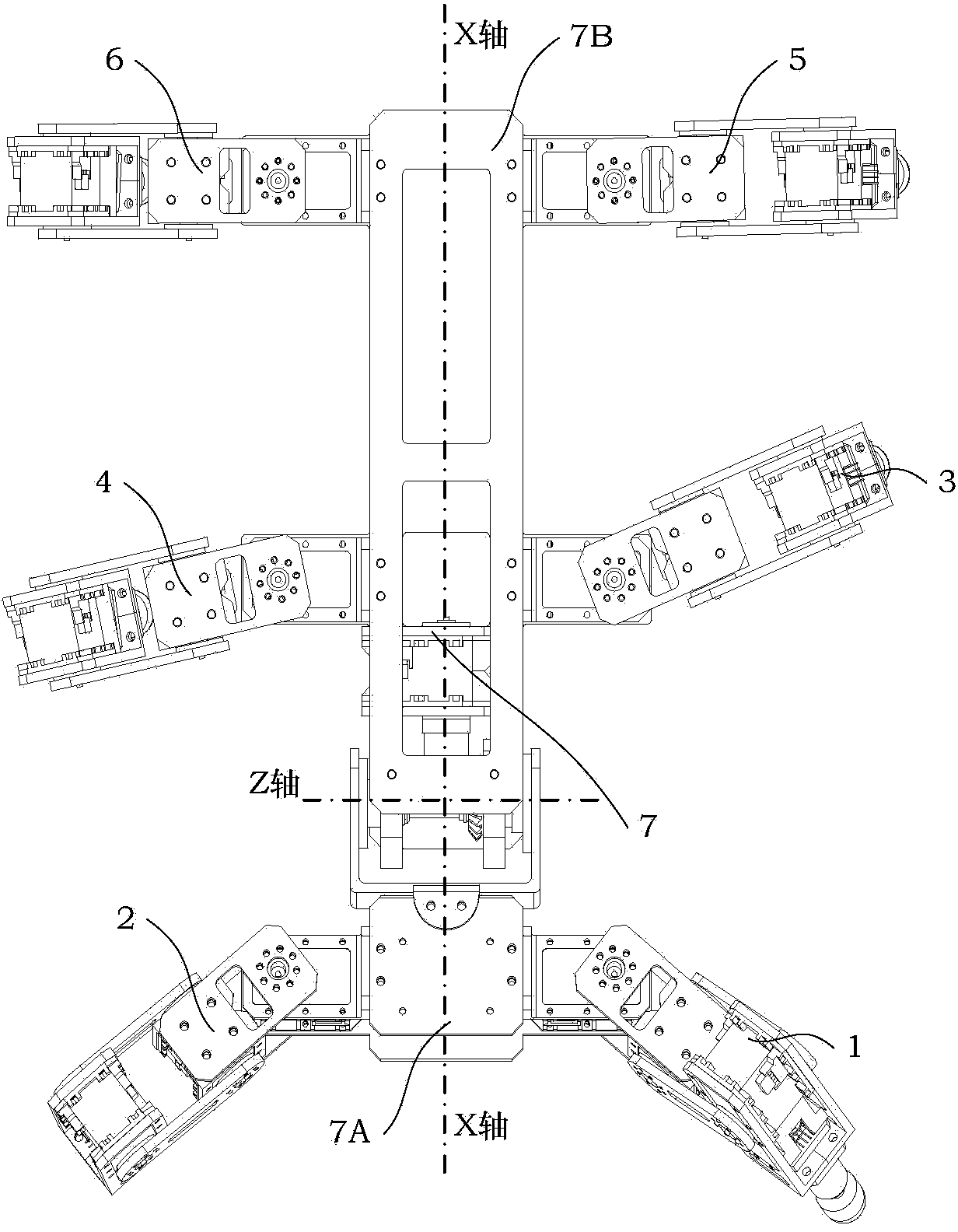

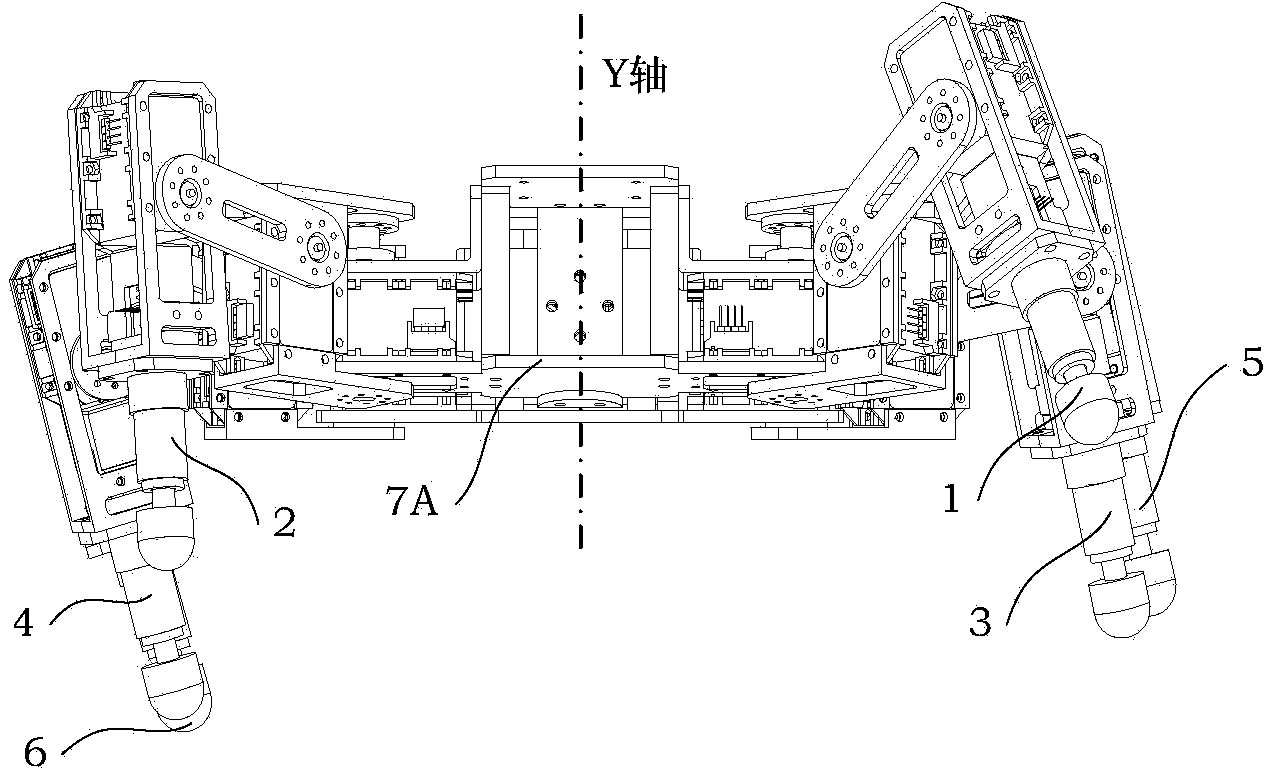

Two-stage buffer foot device applicable to obstacle crossing robot

The invention discloses a two-stage buffer foot device applicable to an obstacle crossing robot. The foot device comprises an AD steering gear bracket (1A), an AG steering gear bracket (1B), an AA transfer plate (1C), an AB transfer plate (1D), an AA connecting plate (1E), an AB connecting plate (1F), an AA swivel bearing (1G), an AA linear bearing (1P), an AA pressure sensor (1M), an AA spring (11), an AB spring (1H), an AA sliding rod (1J), an AA rubber foot pad (1k), an AA gasket (1L), an AA external unit (1N) and an AA sleeve (1Q). Each foot achieves passive compliance through a spring damping system and a rubber sole; the pressure sensors are integrated in the two-stage spring buffer device to realize active compliance, and accordingly foot end pressure information can be effectively acquired; meanwhile, external environment disturbance is avoided, and consumption and wear are reduced. In addition, positioning is performed through the linear bearings and flanges to realize linear displacement of the foot end sliding rods.

Owner:BEIHANG UNIV

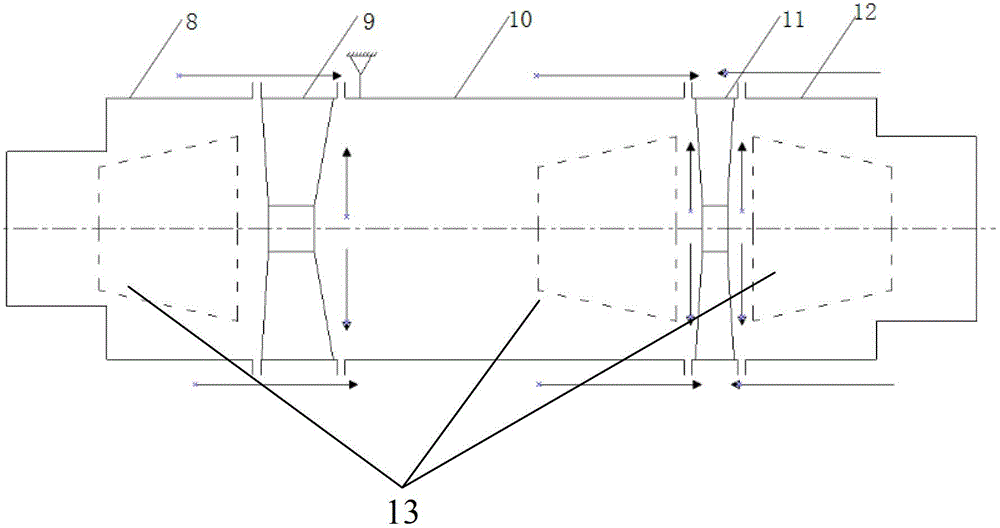

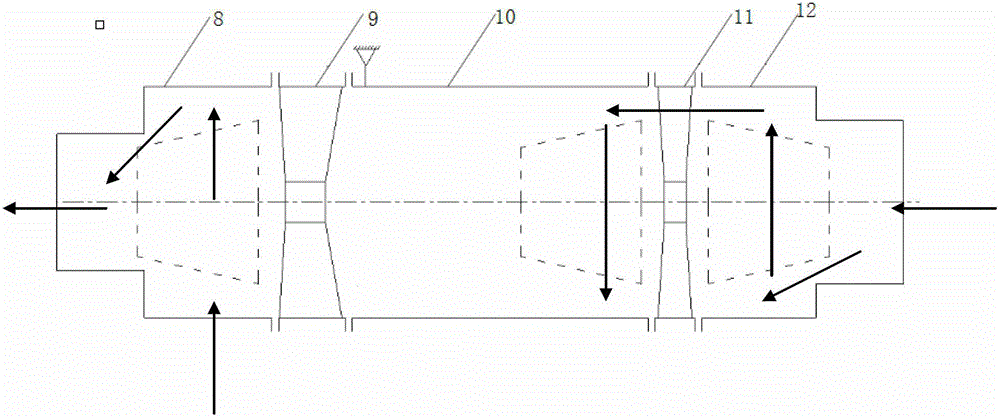

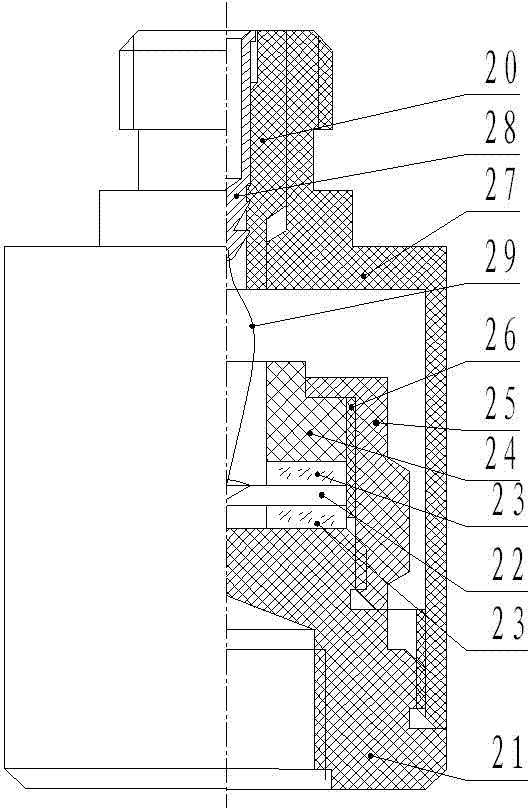

Two-stage turbocharger for aviation piston engine

InactiveCN102748121ASimple structureReduce weightInternal combustion piston enginesEngine componentsAviationTurbocharger

The invention discloses a two-stage turbocharger for an aviation piston engine. The two-stage turbocharger comprises a rotor assembly, a front support assembly, a rear support assembly, a turbine volute, a high-pressure compressor casing, a low-pressure compressor casing and the like, wherein each part in the rotor assembly is locked through a compression nut, and respectively connected with the turbine volute and the compressor casings through bolts; the rear support assembly is of a thin-walled stainless steel soldering structure, and bearings are distributed in a back to back mode; and the compressor casings are of a combined mode, the low-pressure compressor casing is connected with the high-pressure compressor casing through a bolt, and is connected with a regulator assembly through a bolt. The two-stage turbocharger has the advantages that: the turbocharger has simple structure and light weight, and a structure that one turbine drives two compressors is adopted, so that the requirement of an aircraft for high-altitude flight is fulfilled, and the weight of the engine is effectively reduced. The two-stage turbocharger has the characteristics of high reliability and good sealing property, and fulfills the requirement of high-altitude sealing.

Owner:BEIHANG UNIV

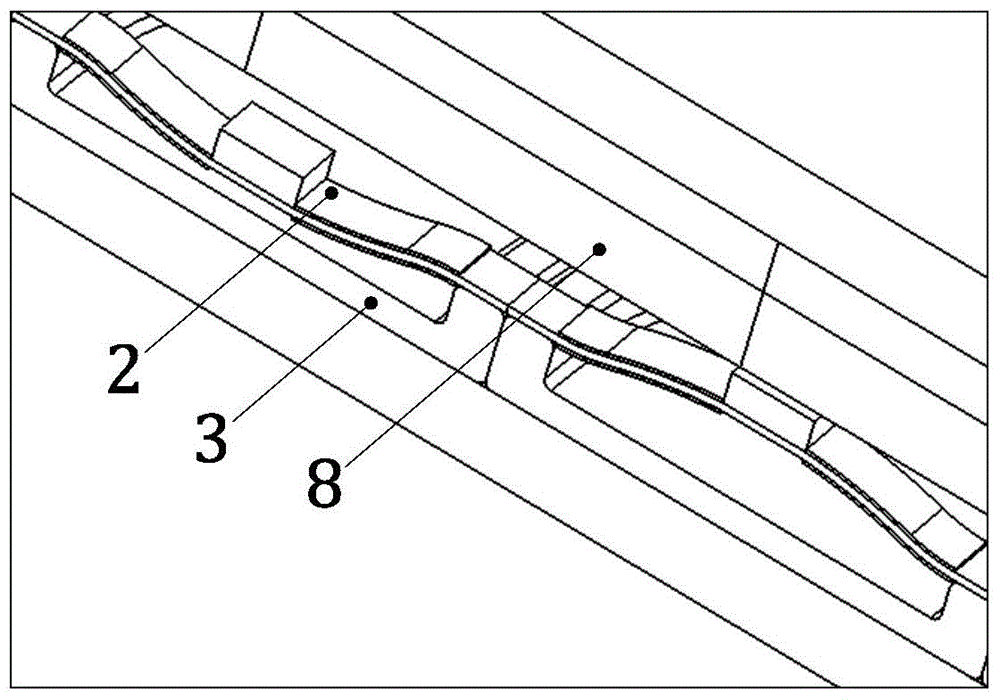

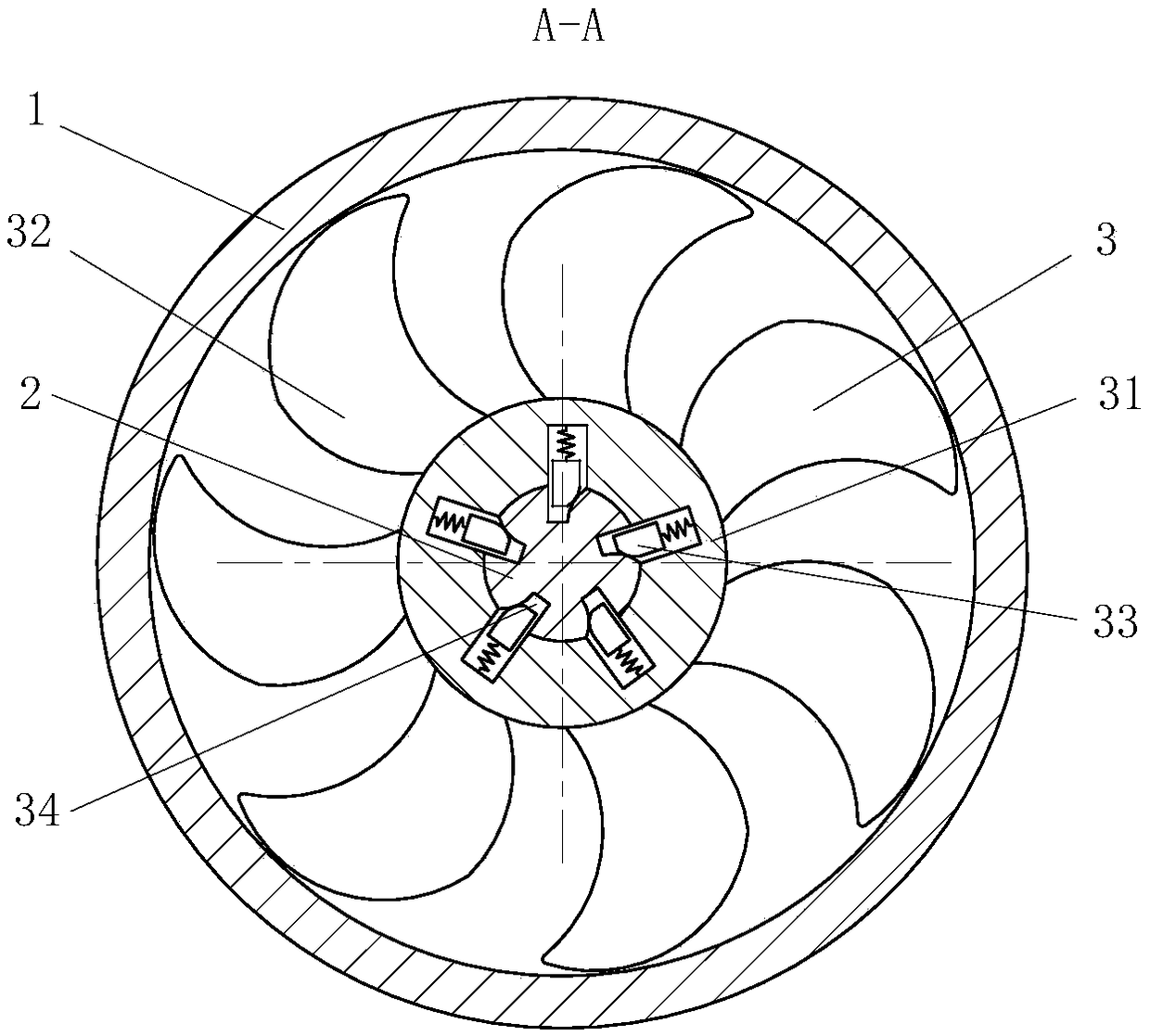

Compound bit formed by rotary cutting bit and PDC (polycrystalline diamond compact) blades

ActiveCN102392603AImprove rock breaking efficiencyHigh rock breaking performance at the centerDrill bitsConstructionsHigh ratePolycrystalline diamond

The invention discloses a compound bit formed by a rotary cutting bit and PDC (polycrystalline diamond compact) blades. The compound bit comprises a main body (1), rotary cutting bit cones (2), rotary cutting bit cutting teeth (3), PDC blades (4), PDC cutting teeth (5), oil storage sacs (6) and nozzles (7), wherein the main body (1) comprises a cone journal, centralizing blocks, high-pressure slurry channels and a connection screw thread. The compound bit is characterized in that a compound bit cutting unit comprises the rotary cutting bit and a PDC bit cutting unit. The compound bit has the following beneficial effects: the rotary cutting bit completes drilling the central part of the borehole in the drilling process; the rotary cutting bit in the compound bit shocks, crushes and cuts the rocks by way of rotary cutting, has high central rock breaking efficiency, high rate of penetration and better dynamic performance, is uniform in wear, simultaneously improves the bit bearing structure and ensures to prolong the service life of the bit while improving the rock breaking efficiency; and the linear velocity of the periphery of the borehole is high in the drilling process and the rotary cutting bit and the PDC bit cutting unit complete drilling the periphery of the borehole, thus improving the cutting capability of the compound bit and ensuring good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

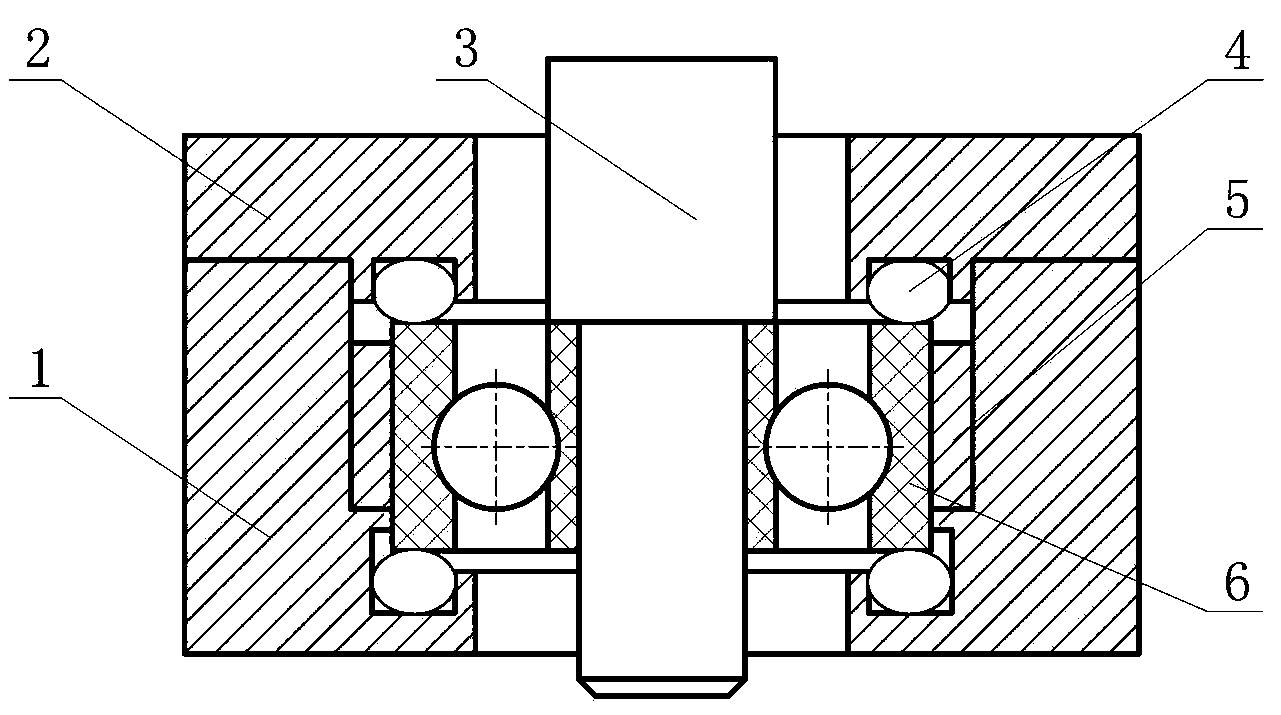

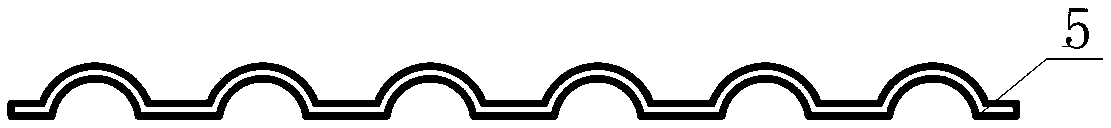

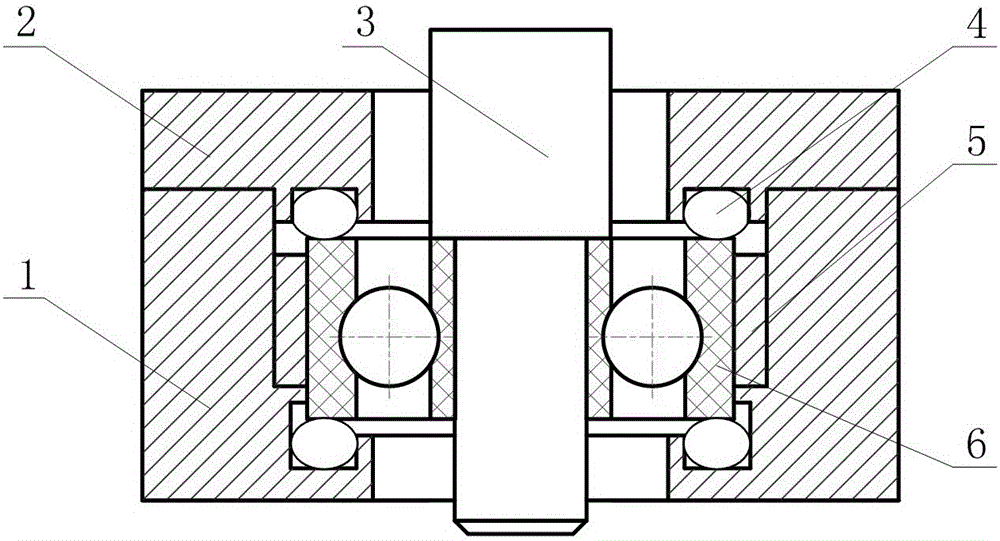

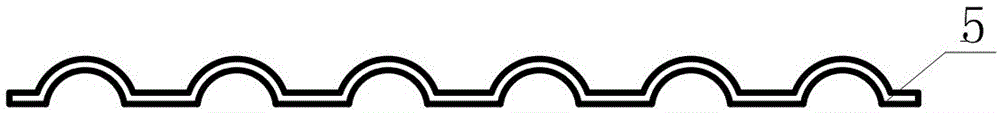

Damping and heat-dissipating device for rolling bearing

ActiveCN103470539AExtended service lifeImprove heat transfer efficiencyPump componentsShaftsRubber ringRolling-element bearing

The invention provides a damping and heat-dissipating device for a rolling bearing. The damping and heat-dissipating device comprises a bearing base, a bearing gland, a revolving shaft, a damping rubber ring, a wave spring and the rolling bearing, wherein the wave spring is arranged in a gap between the side face of the rolling bearing and the bearing base. The wave spring is made of beryllium bronze, so that the wave spring has higher heat conductivity and can be used for effectively transferring heat generated by high-speed rotation of the rolling bearing. According to the damping and heat-dissipating device, the wave spring has a semi-circular arch-shaped structure, so that the elasticity is improved, the radial contact rigidity of the rolling bearing is reduced, and the vibration impact of the rolling bearing is reduced. The service life of the rolling bearing is prolonged, so that the service life of a turbo molecular pump is prolonged.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

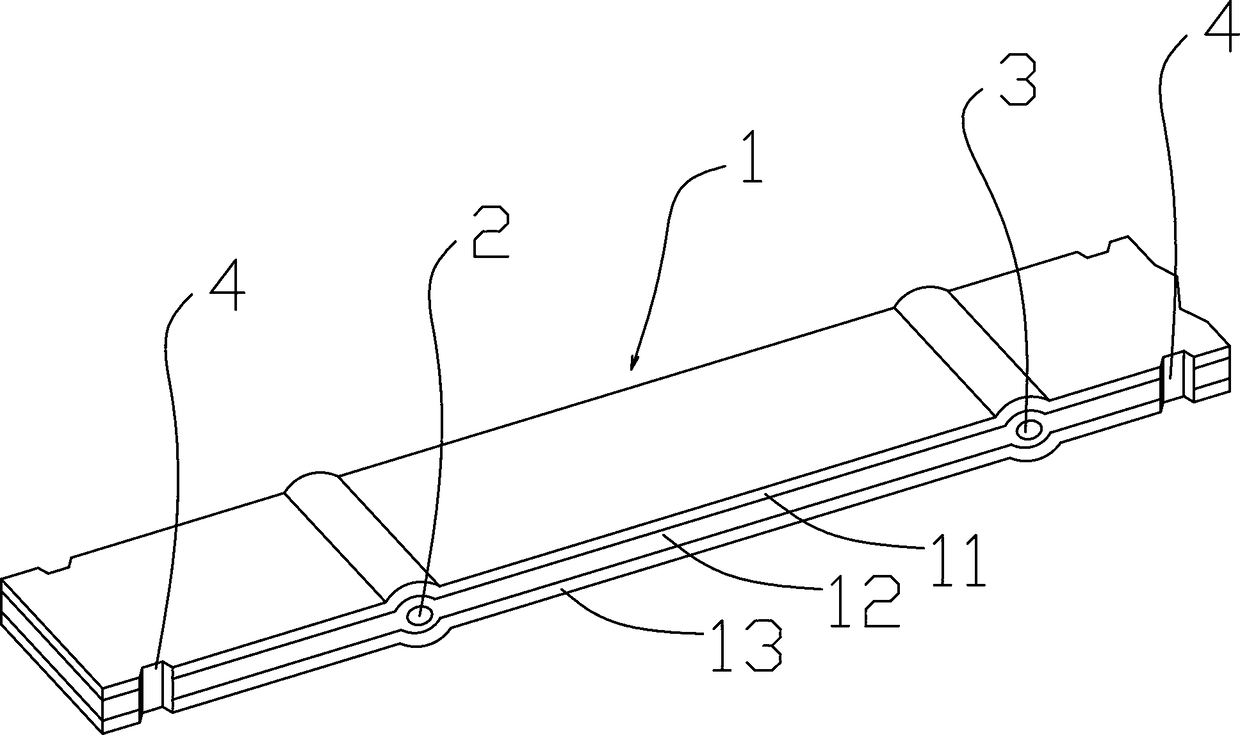

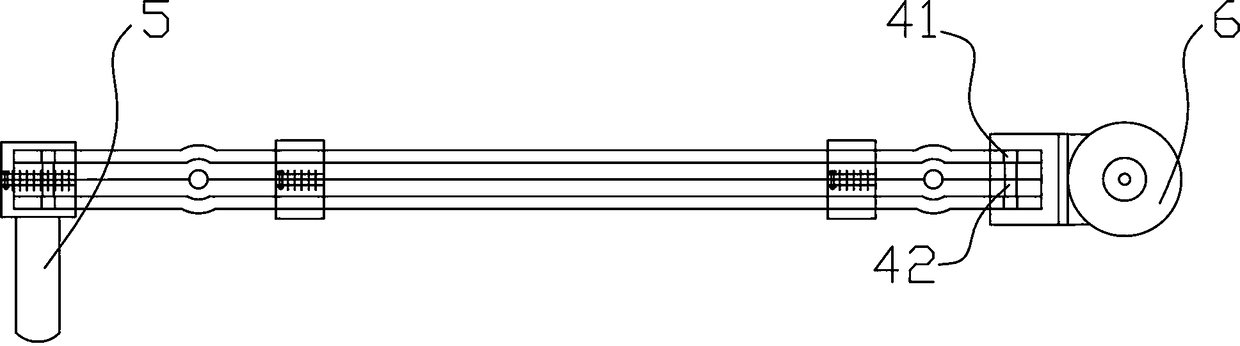

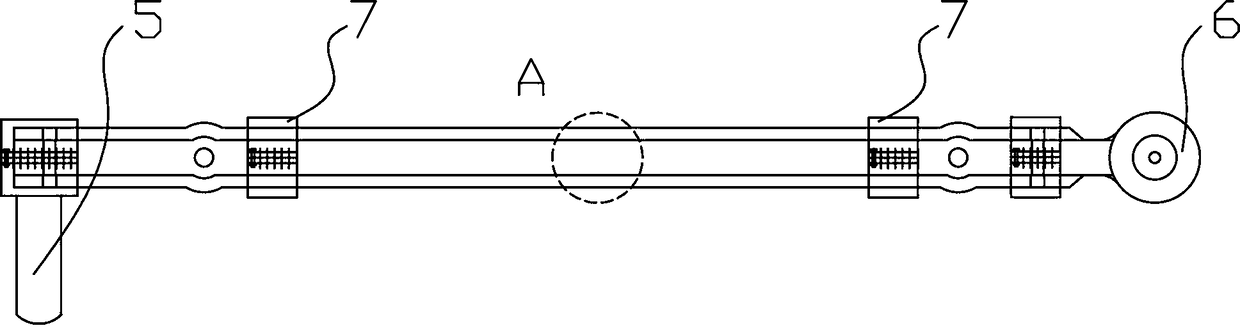

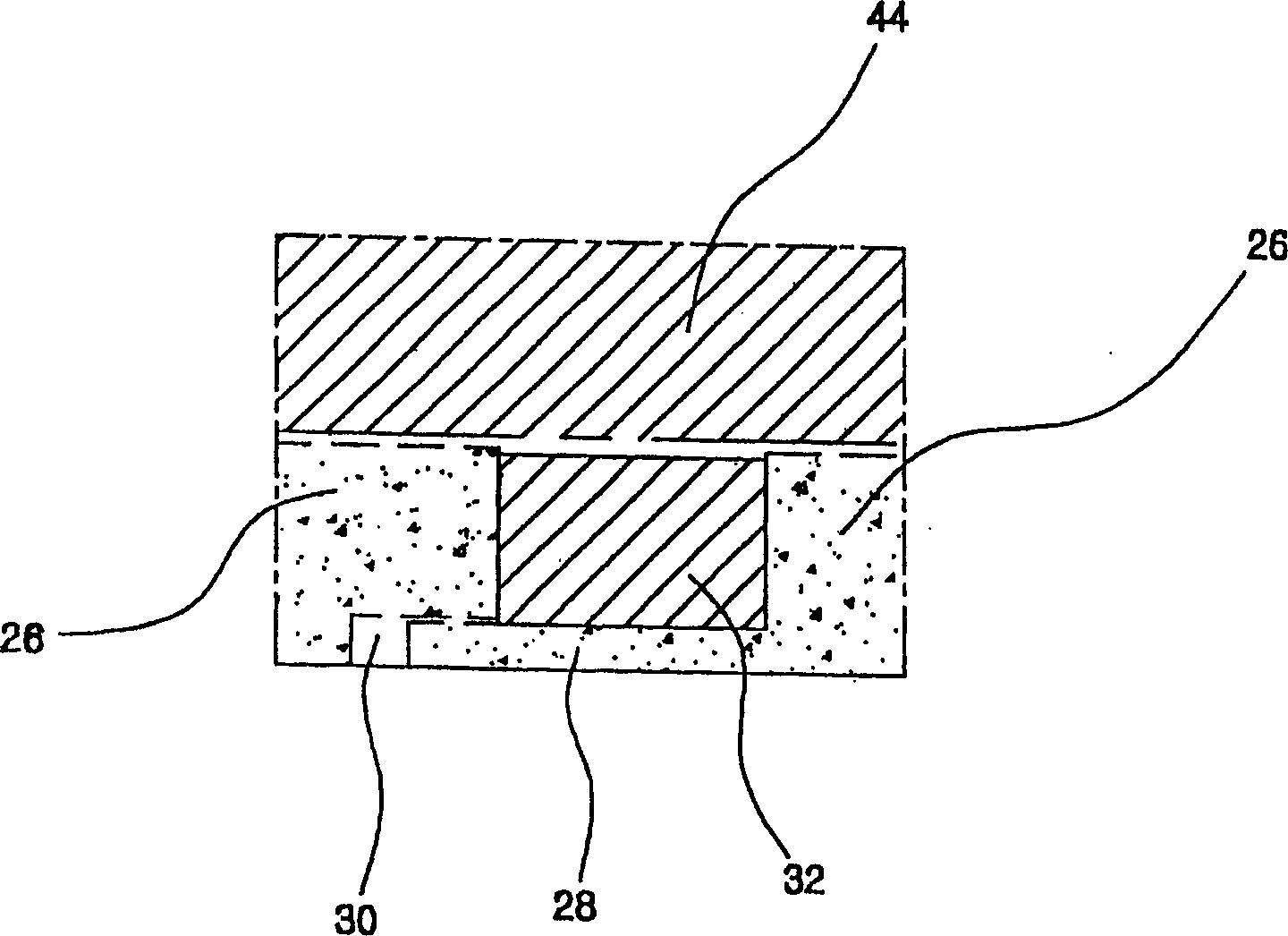

Exciting beam for pavement breaking vehicle

PendingCN109371794AReduce MicrowarpingReduce micro deformationRoads maintainenceRoad surfaceEngineering

The invention provides an exciting beam for a pavement breaking vehicle, and relates to the field of cement pavement breaking equipment. The exciting beam consists of eight exciting layers which are stacked from top to bottom, wherein the exciting layers are fixedly connected through hoops; the positions, close to the two ends, of the exciting beam are separately equipped with a first supporting hole and a second supporting hole; the first supporting hole and the second supporting hole are positioned between the two exciting layers; and each exciting layer is equipped with an arc-shaped structure which corresponds to the supporting holes. Or the first supporting hole and the second supporting hole are positioned on the exciting layer on the middle layer, and each exciting layer is equippedwith the arc-shaped structure which corresponds to the supporting holes. A multi-layer structure design is adopted, so that micro deformation amplitude of each exciting layer can be reduced, and therefore, strength influences caused by alternating stress are reduced.

Owner:YICHANG JIANGXIA MARINE MACHINERY

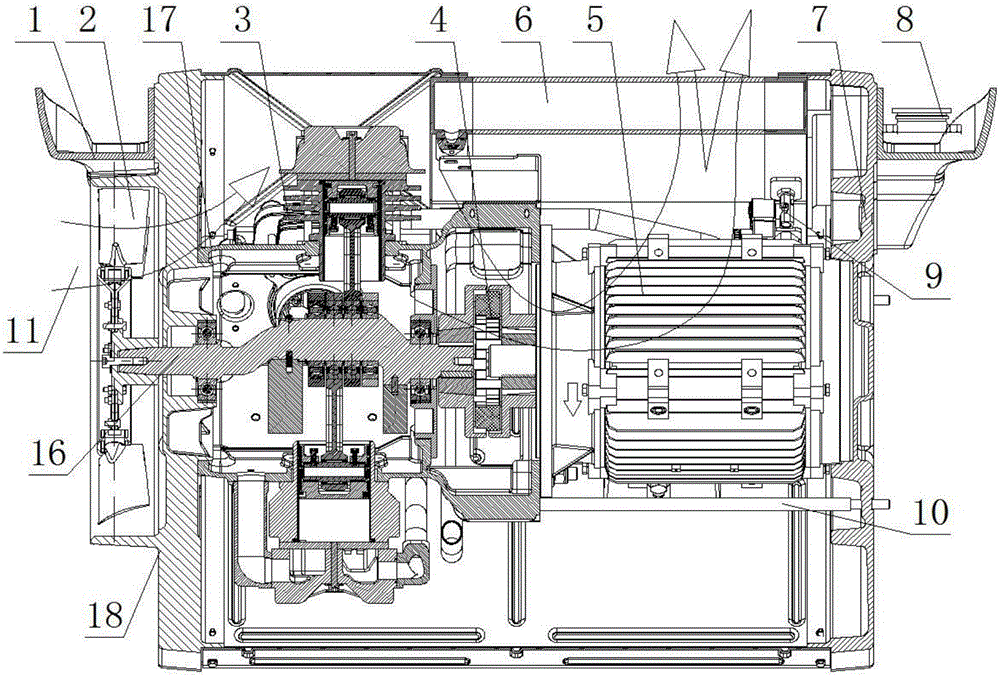

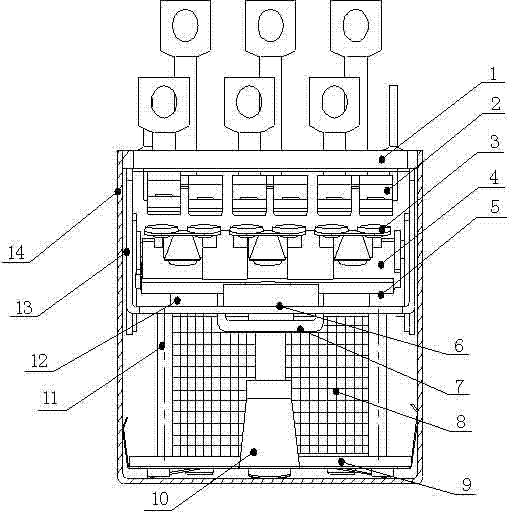

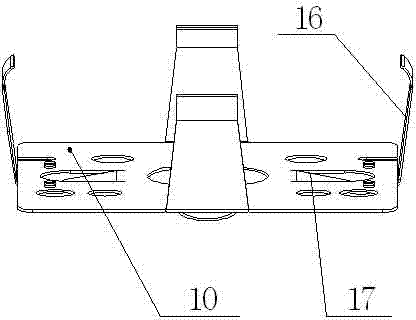

Electric oil-free main air compressor

ActiveCN106194651AReduce vibration shockReduce vibrationPositive displacement pump componentsPump controlAxial compressorOil free

The invention discloses an electric oil-free main air compressor, and belongs to the technical field of air compressors. The electric oil-free main air compressor comprises a fan, an air compressor body, a motor, a cooler, dampers, water drainage electromagnetic valves, a pull rod and a housing. The cooler comprise a middle cooler body and a rear cooler body. At least four dampers are mounted on a fan support and a motor support correspondingly, and are connected with an automobile body. The water drainage electromagnetic valves are mounted at the lower end of the middle cooler body and the lower end of the rear cooler body. The pull rod enables the motor support and the air compressor body to be connected and locked. A damping material layer is arranged in the housing, and the air compressor body is composed of a main shell and a compression cylinder assembly. A bent axle is arranged in the main shell, and the compression cylinder assembly is in an X shape and is composed of at least one high-pressure cylinder assembly and at least two low-pressure cylinder assemblies. According to the electric oil-free main air compressor, the potential hazards of oil leaking and mixing of the air compressor are avoided through air cooling, and the maintaining cost is lowered; the compression cylinder assembly forms reasonable air flow direction, and the maximum cooling efficiency is achieved; damping materials are coated on the housing, and noise is lowered.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

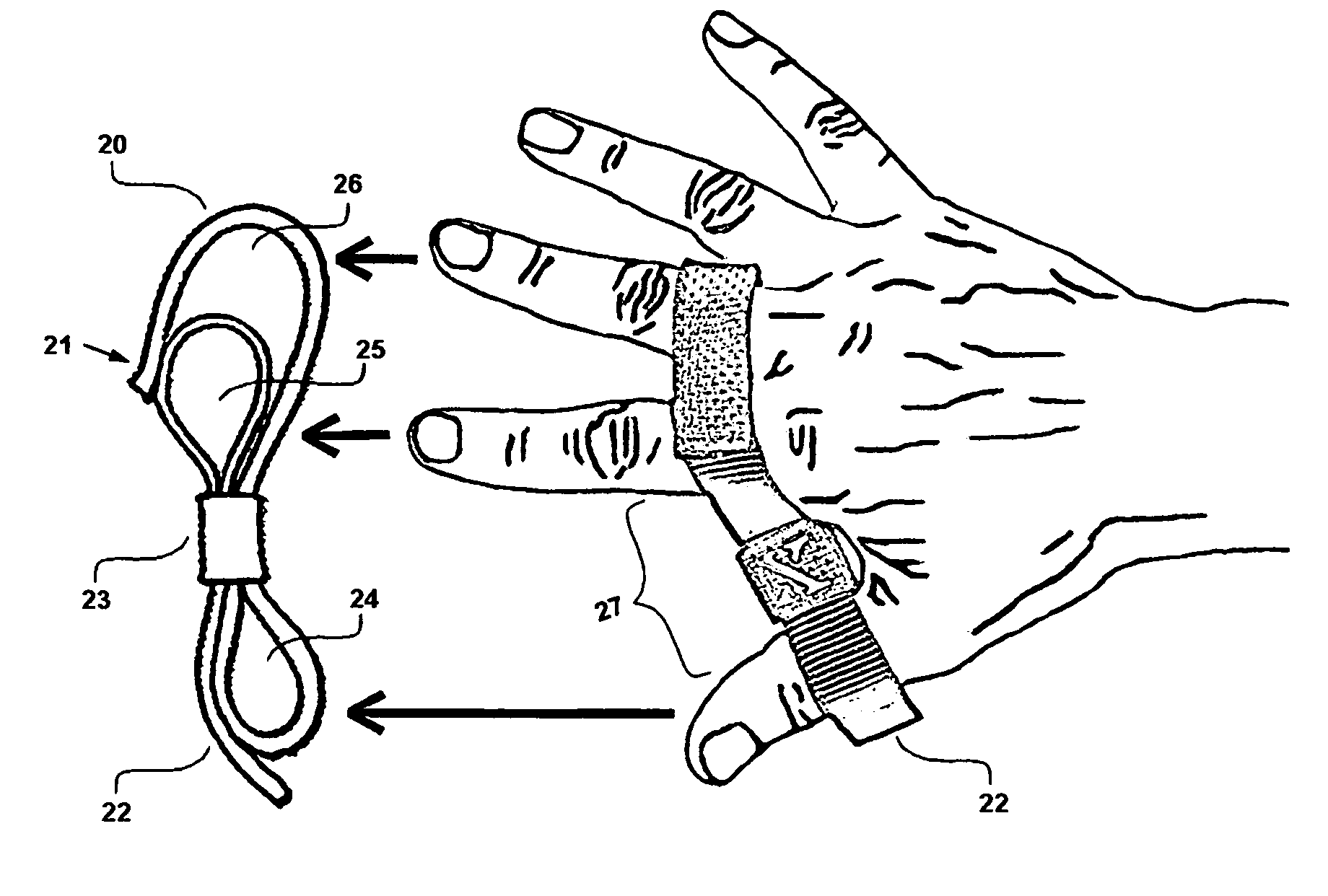

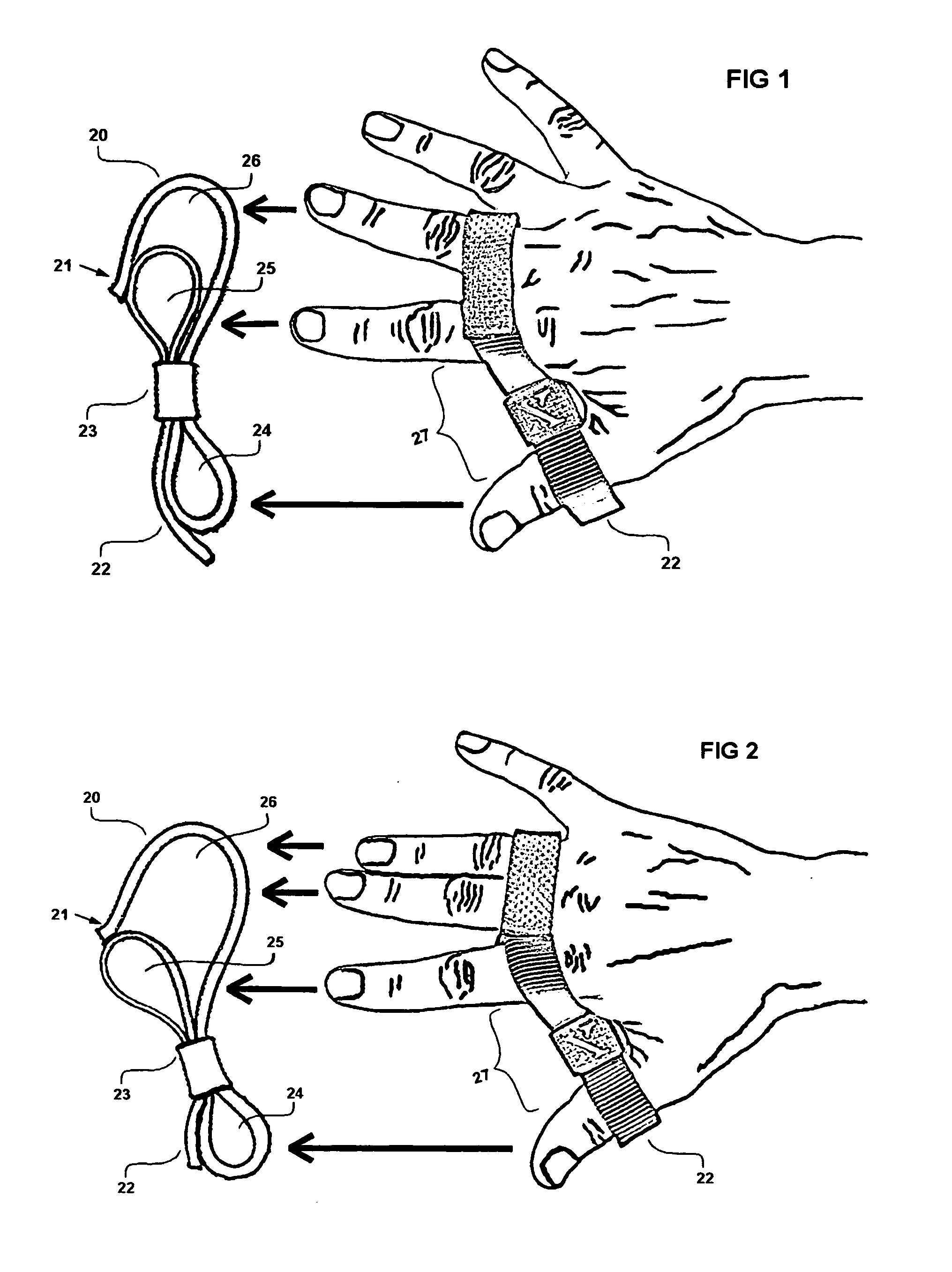

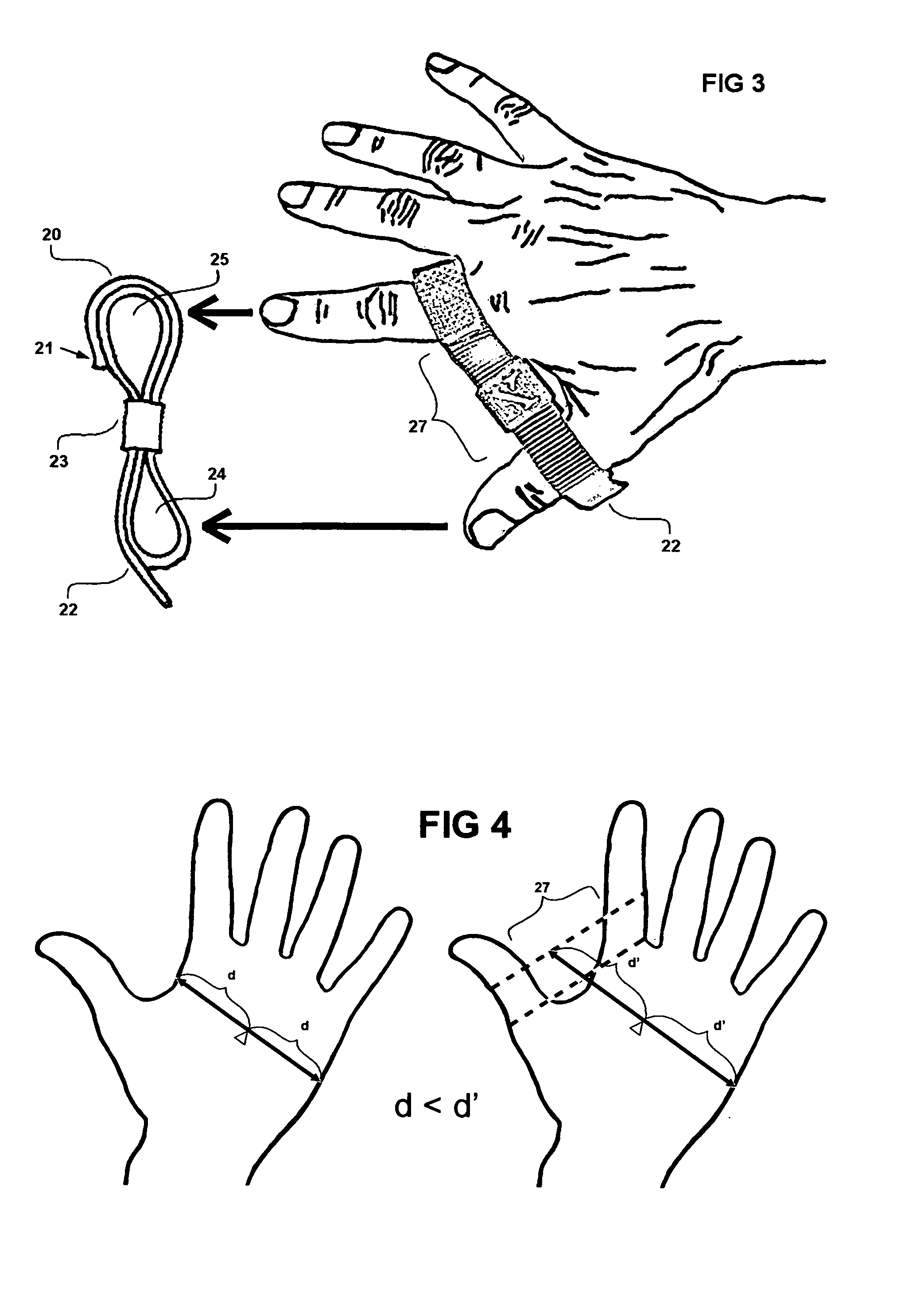

Strape glove

ActiveUS20080276341A1Easy to controlIncrease forceGlovesEye treatmentEnergy transferContact friction

A glove made from narrow strap material. Glove advantages when used with a striking tool: improved control, improved striking force, improved tool head acceleration, improved energy transfer, reduced hand fatigue, improved grip, and reduced vibration shock. It can be configured for 1, 2, 3 or 4 fingers plus the thumb. The glove forms a web between the thumb and fingers. The width of the web and the tightness of fit on the thumb and fingers is controlled by a single pull-tab type of adjustment. The adjustment is secured by a contact friction loop which increases in friction during impact force use. The glove can be worn on a bare hand or over the top of a more conventional type of glove while still providing the same advantages.

Owner:DUBY DANTE

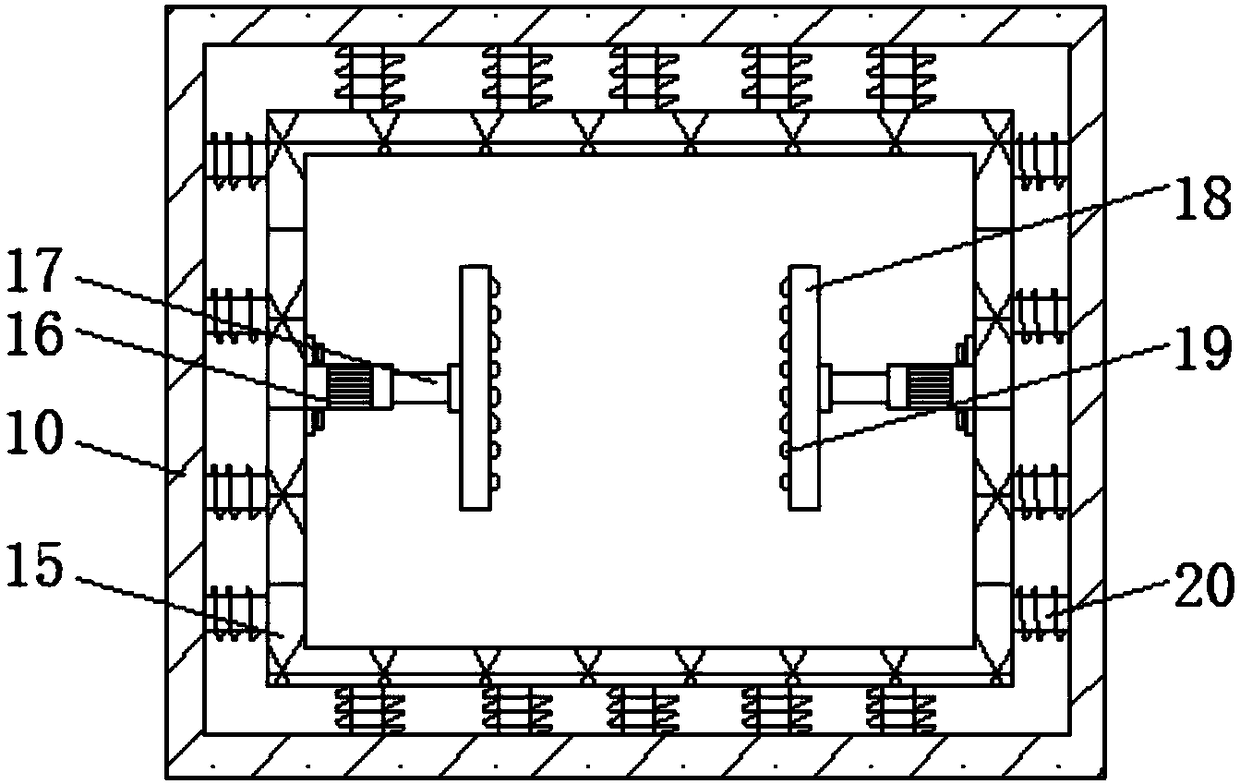

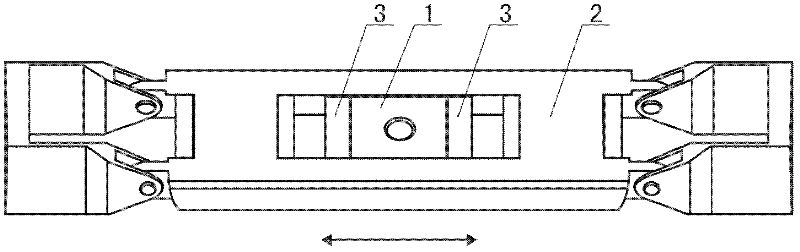

Fixing device for installing battery of new energy automobile

InactiveCN111129389AEasy to installAvoid damageCell component detailsBatteriesEngineeringStructural engineering

The invention discloses a fixing device for installing a battery of a new energy automobile, and the device comprises a base, wherein a cavity is fixedly connected to the upper end face of the base, abattery pack is placed in the cavity, and clamping structures are distributed on the left side and the right side of the inner wall of the cavity. The device is convenient to mount, and only a battery pack needs to be placed in the cavity with the proper size; limiting blocks and limiting plates are arranged on the periphery of the battery pack and connected with clamping springs and limiting springs correspondingly, so an impact force on the periphery of the cavity can be absorbed while the battery pack is fixed. A damping mechanism, vertical springs and transverse springs are arranged belowthe battery pack, so the vibration impact of the battery pack in the vertical direction can be reduced, and the battery pack is protected in all directions; besides, threaded holes are formed in thefour corner areas of the base, so the installation is convenient, the position of the base can be adjusted through the lifting air cylinder, and the battery pack can be installed and maintained conveniently.

Owner:张和平

Multifunctional plant protection unmanned aerial vehicle

InactiveCN108477116AQuick fixReduce shakingBatteries circuit arrangementsElectric powerHydraulic cylinderUncrewed vehicle

The invention discloses a multifunctional plant protection unmanned aerial vehicle which comprises an unmanned aerial vehicle body and a pesticide application box. Arms are mounted on two sides of theunmanned aerial vehicle body, spraying rods are connected at the bottoms of the arms through telescopic hanging rods, a pesticide box mounting frame is fixed at the bottom of the unmanned aerial vehicle body, an anti-vibration inner frame is connected on the inner side of the pesticide box mounting frame through a buffer spring, the pesticide application box is arranged in the anti-vibration inner frame, and a hydraulic cylinder is mounted on the inner side wall of the anti-vibration inner frame and connected with a clamping plate through a hydraulic telescopic rod. The unmanned aerial vehicle is simple in structure, multifunctional and high in practicability, the hydraulic telescopic rod is matched with the clamping plate, the pesticide application box can be rapidly fixed into the anti-vibration inner frame and is conveniently assembled and disassembled, time and labor are saved, the anti-vibration inner frame is connected with the pesticide box mounting frame through the buffer spring, shaking generated by the pesticide application box in pesticide application process can be effectively buffered and reduced, unstable flight of the unmanned aerial vehicle caused by shaking of the pesticide application box is avoided, and stable flight of the unmanned aerial vehicle is ensured.

Owner:湖州归谷信息科技有限公司

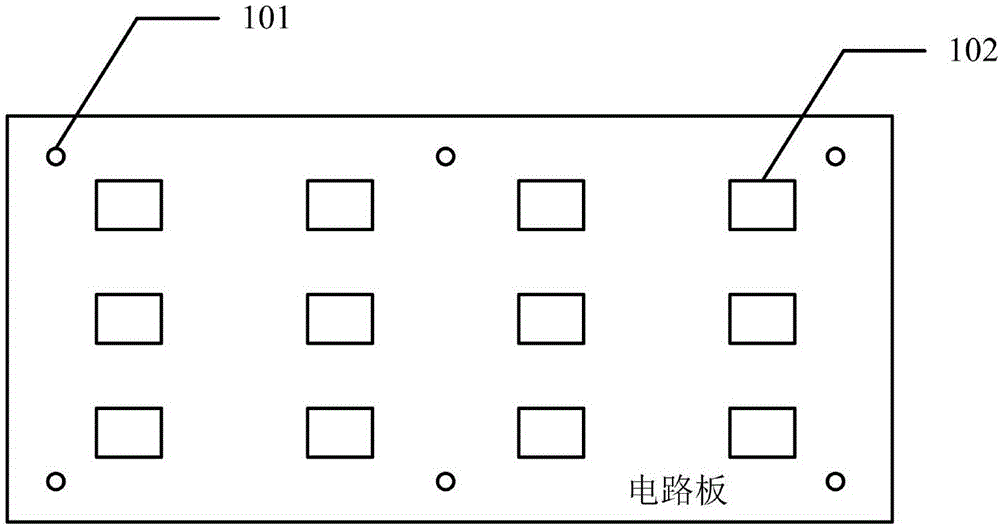

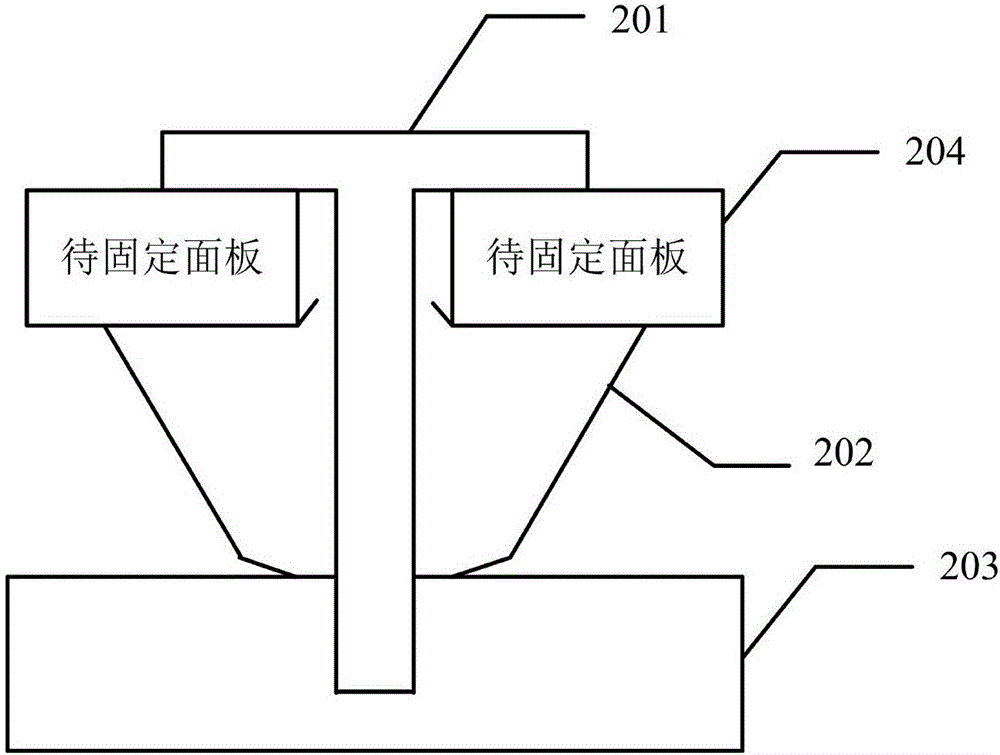

Shock absorption apparatus and circuit board assembly

InactiveCN106455400AReduce vibration shockReduce vibration amplitudeResilient/clamping meansVertical vibrationEngineering

The invention relates to the electronic technical field, and discloses a shock absorption apparatus and a circuit board assembly. According to the embodiments of the invention, the first surface of the shock absorption apparatus with a hollow interior is in contact with a to-be-fixed panel equipped with at least one fixing hole while the second surface of the shock absorption apparatus is in contact with a fixed plane, so that the shock absorption apparatus is positioned between the to-be-fixed panel and the fixed plane; and the to-be-fixed panel passes through the fixing hole and the shock absorption apparatus through a fixing part to be fixed on the fixed plane, so that the shock absorption apparatus is positioned between the fixing hole of the to-be-fixed panel and the fixed plane. According to the embodiments of the invention, by additionally arranging the shock absorption apparatus between the fixing hole of the to-be-fixed panel and the fixed plane, vibration buffering between the to-be-fixed panel and the fixed plane is formed, so that the vertical vibration amplitude transferred to the to-be-fixed panel through the fixing part is lowered, and the vibration impact on the overall to-be-fixed panel is weakened.

Owner:FUDAN UNIV

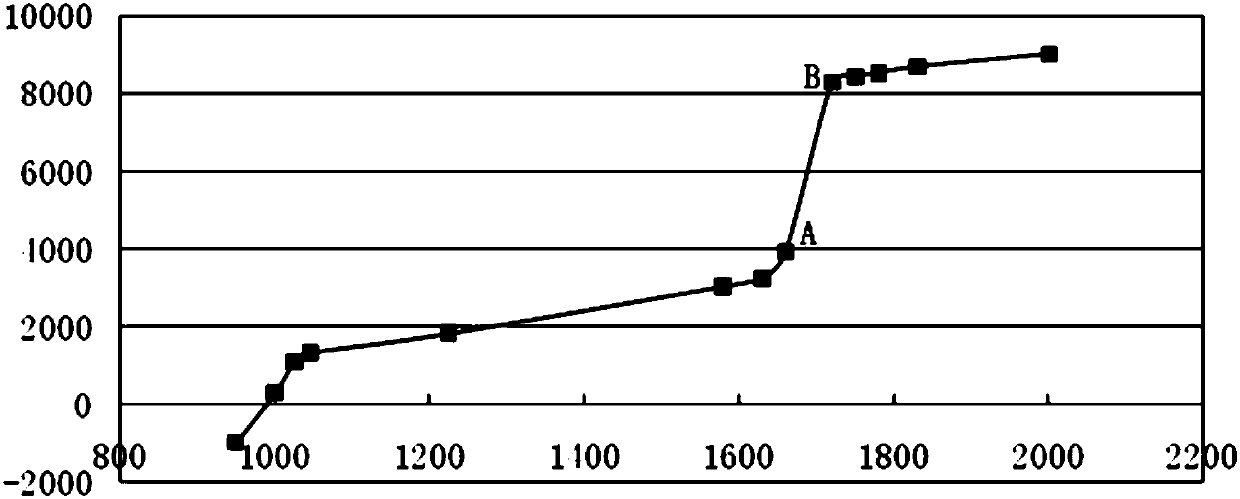

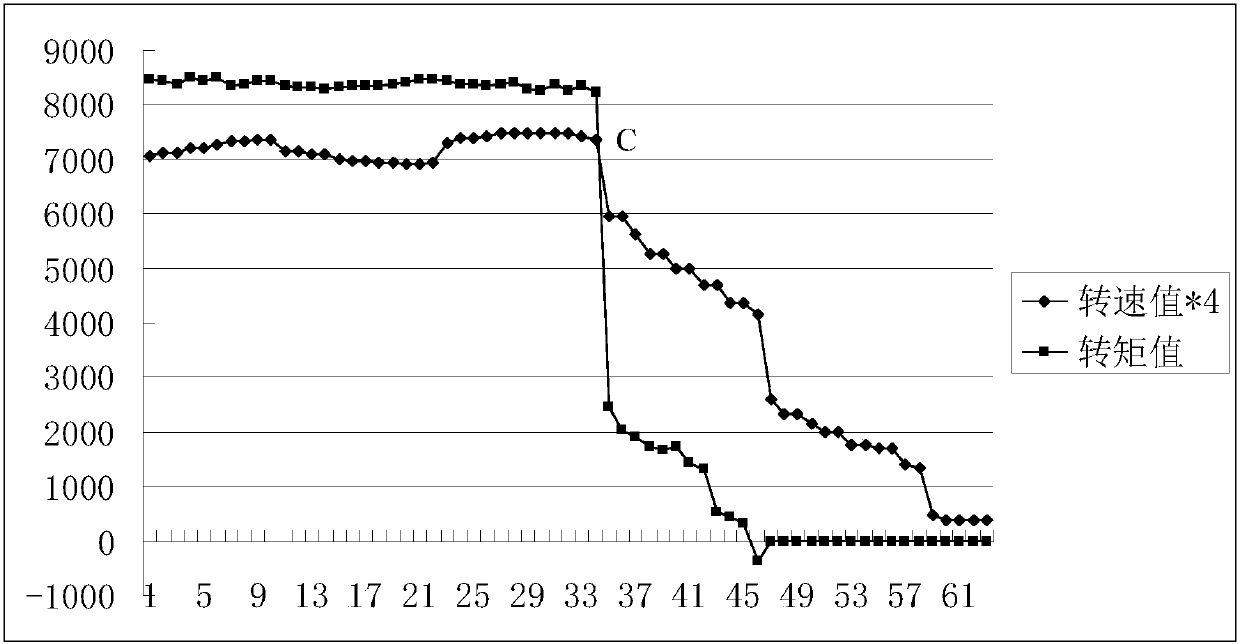

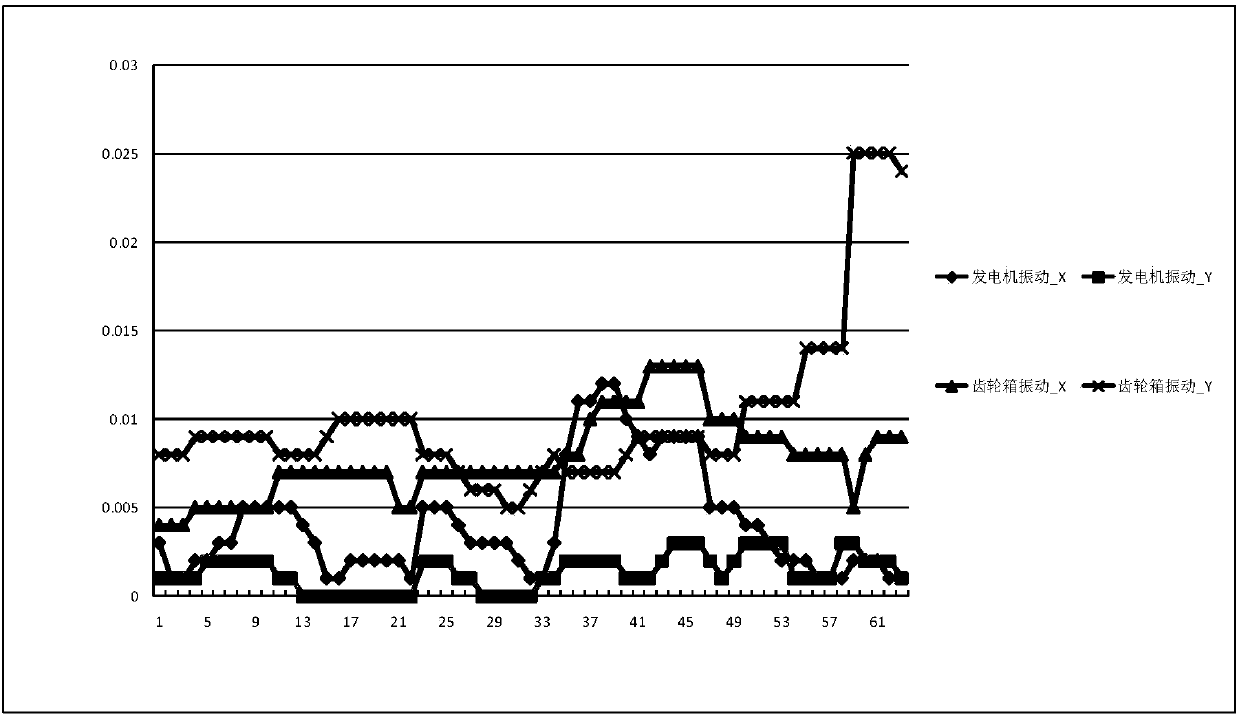

Shutdown control method and device for wind power generator set

ActiveCN108119301AReduce vibration shockSmooth torqueWind motor controlMachines/enginesDynamoWind force

The invention provides a shutdown control method and device for a wind power generator set. The method comprises the steps that an interval with a larger decrease rate of the rotating torque in a curve of the corresponding relation between the rotating speed and the rotating torque in the operating process of a preset wind power generator set is determined, an inflection point corresponding to a smaller rotating speed value in the inflection points of two ends of the interval is used as a critical point, and one or more reference points are selected according to the critical point; the rotating speed when a wind power generator is shut down is collected, when the rotating speed is higher than the rotating speed corresponding to the critical point, and a monotonous shutdown control functionwith an upward opening is constructed according to the rotating torque and rotating speed data corresponding to the reference point and the rotating torque and rotating speed data of the actual initial shutdown time of the wind power generator set; and a rotating torque value corresponding to the rotating speed is obtained according to the shutdown control function, and shutdown control is carried out on the wind power generator by utilizing the rotating torque value. According to the method, the rotating torque of the generator can be declined in a more stable manner, so that the vibration impact on the wind power generator set caused by sudden change of the rotating torque in the shutdown process is reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

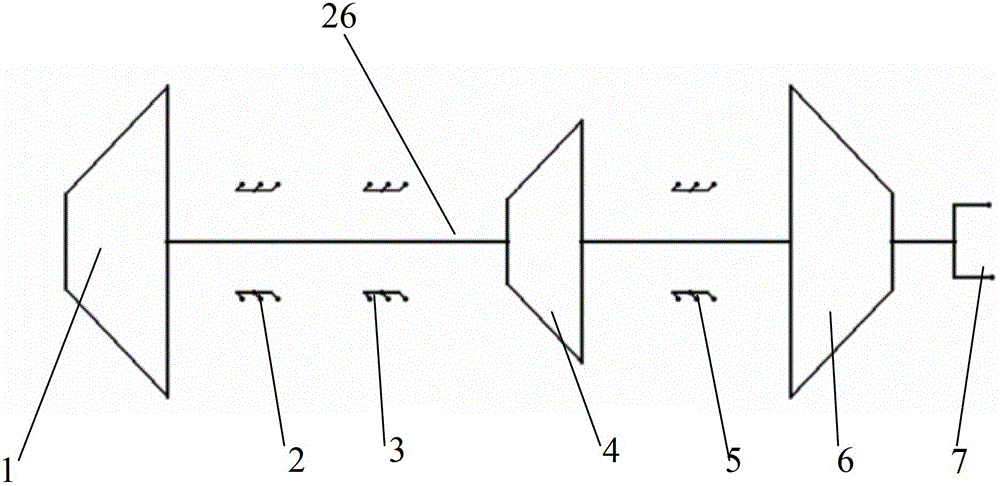

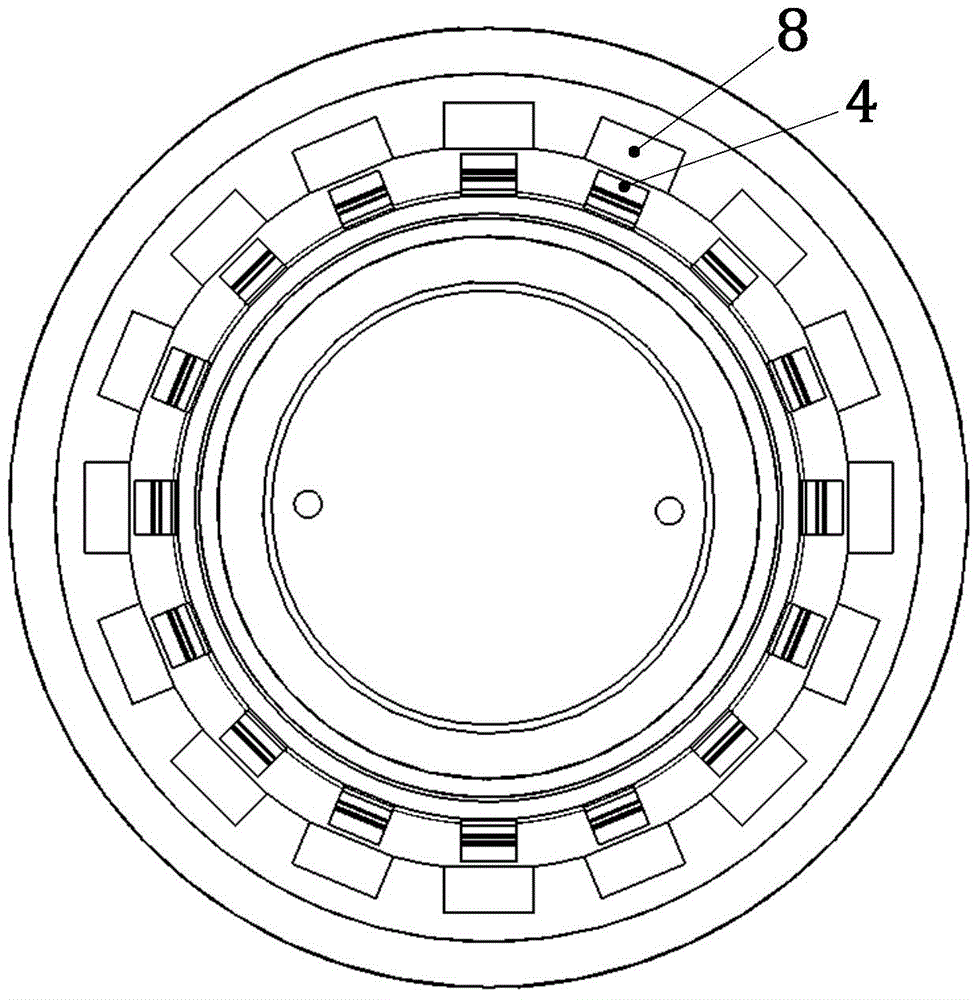

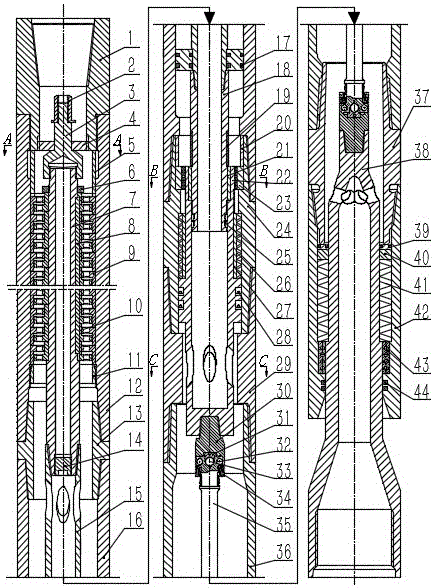

Composite bit formed by rotary cut bit and roller bit

ActiveCN102400646AExtended service lifeIncrease cutting forceDrill bitsConstructionsSpray nozzleEngineering

The invention discloses a composite bit formed by a rotary cut bit and a roller bit, comprising a main body (1), a rotary cut bit roller (2), a rotary cut bit cutting tooth (3), a roller bit roller (4), a roller bit cutting tooth (5), an oil storage bag (6) and a spray nozzle (7). The main body (1) of the bit comprises a roller axle journal, a straightening block, a high-pressure slurry channel and a connection thread. The composite bit formed by rotary cut bit and roller bit has the characteristics that: a composite bit cutting unit comprises the rotary cut bit and a roller bit cutting unit. When in a drilling process, the drilling of the central part of a borehole is completed by the rotary cut bit, and the drilling of the periphery of the borehole is completed by the roller bit. The rotary cut bit in the composite bit impacts, presses and cuts the rock in a rotary cutting way, has high central rock breaking efficiency and mechanical drilling speed, has better mechanical properties, wears uniformly, simultaneously improves a bearing structure of the bit, ensures to improve the rock breaking efficiency and prolong the service life of the bit, and has good diameter keeping effect. Different composite structures in the composite bit can achieve the effects of high rock breaking performance and high mechanical drilling speed.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

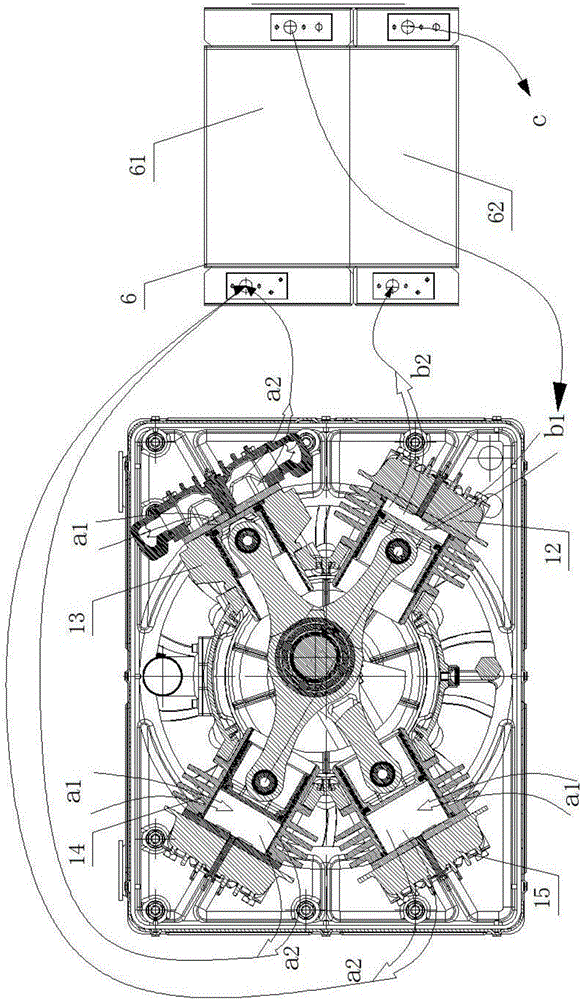

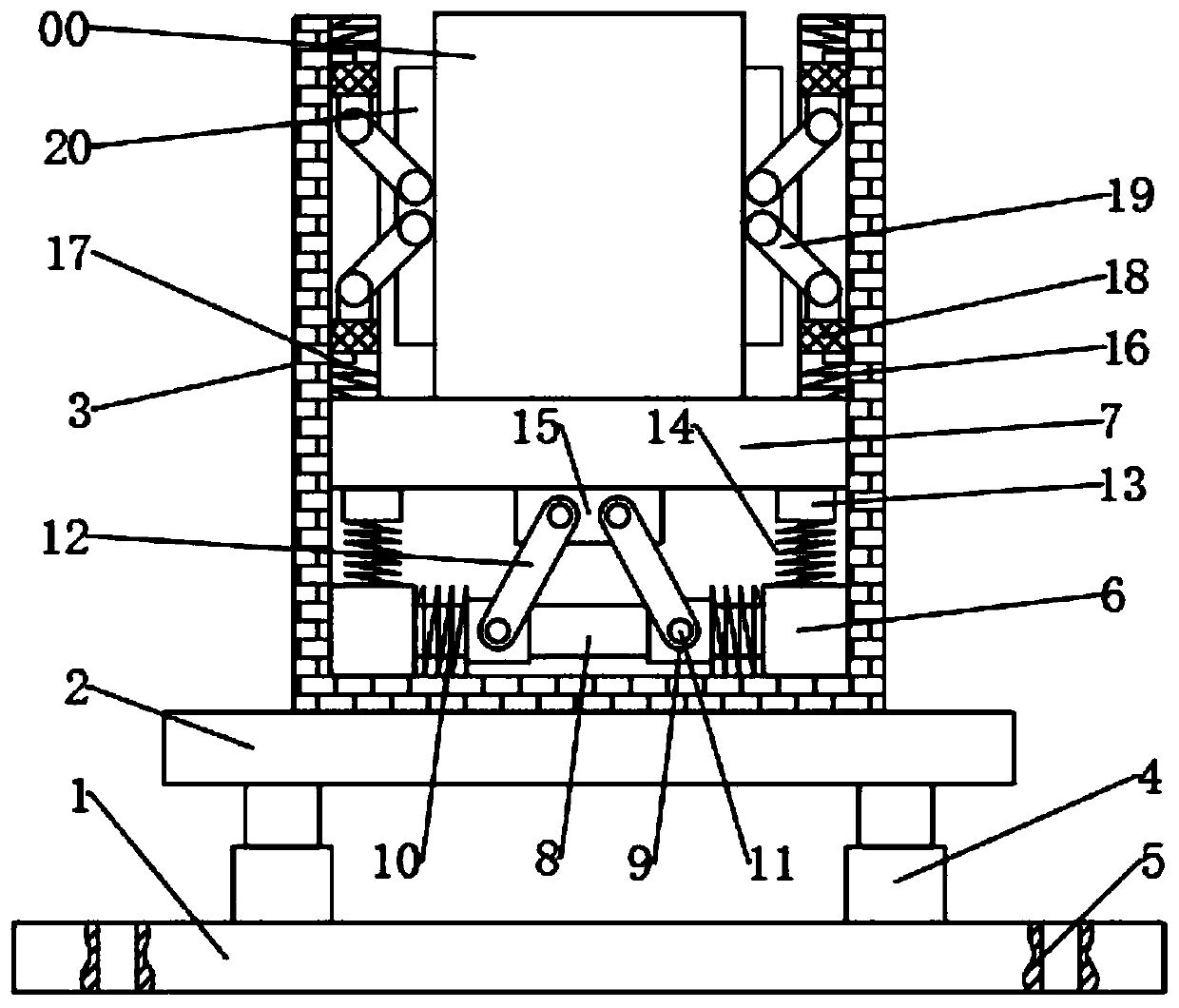

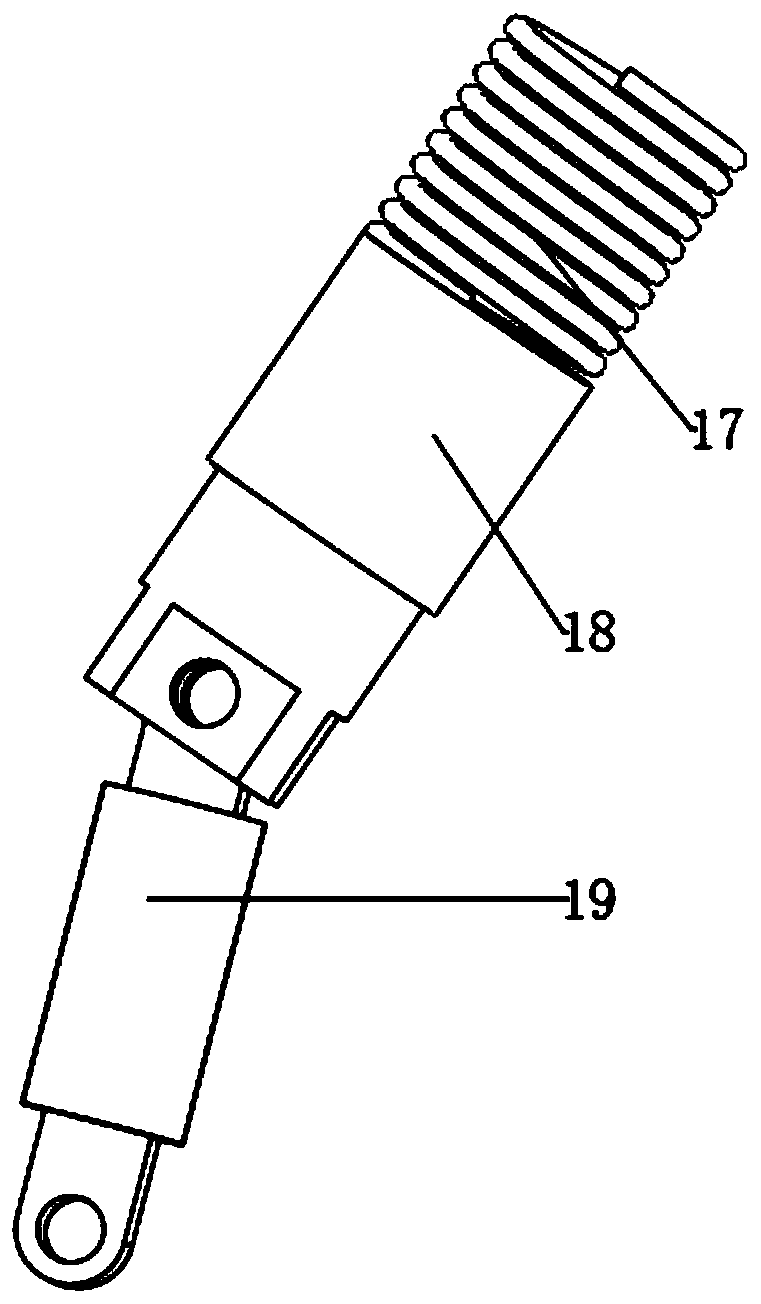

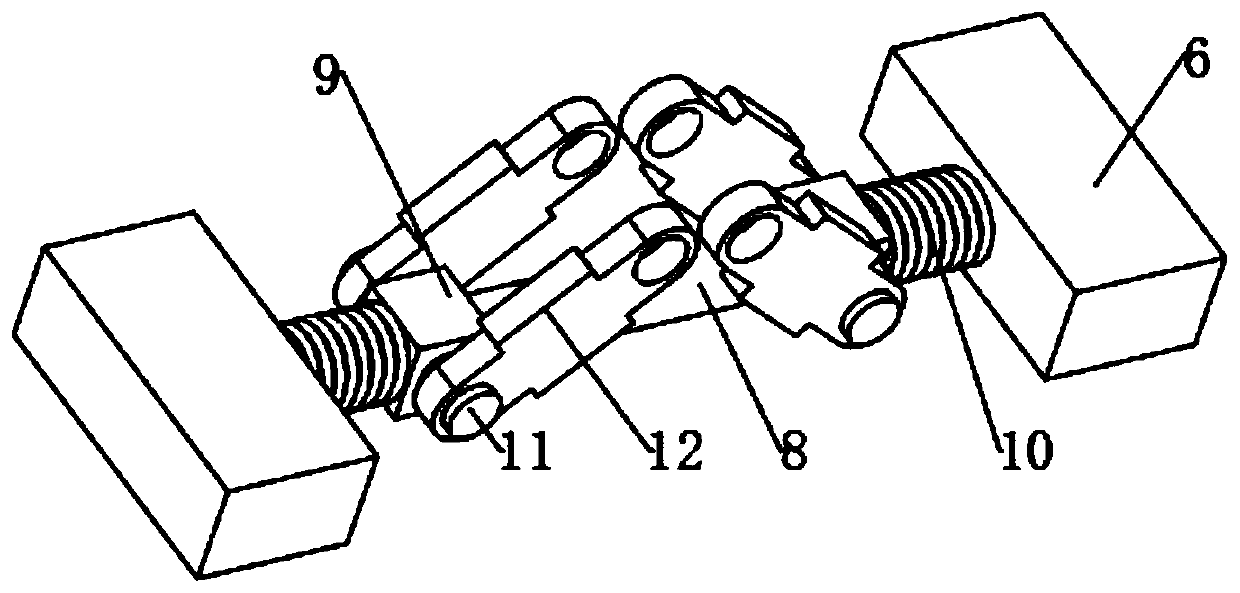

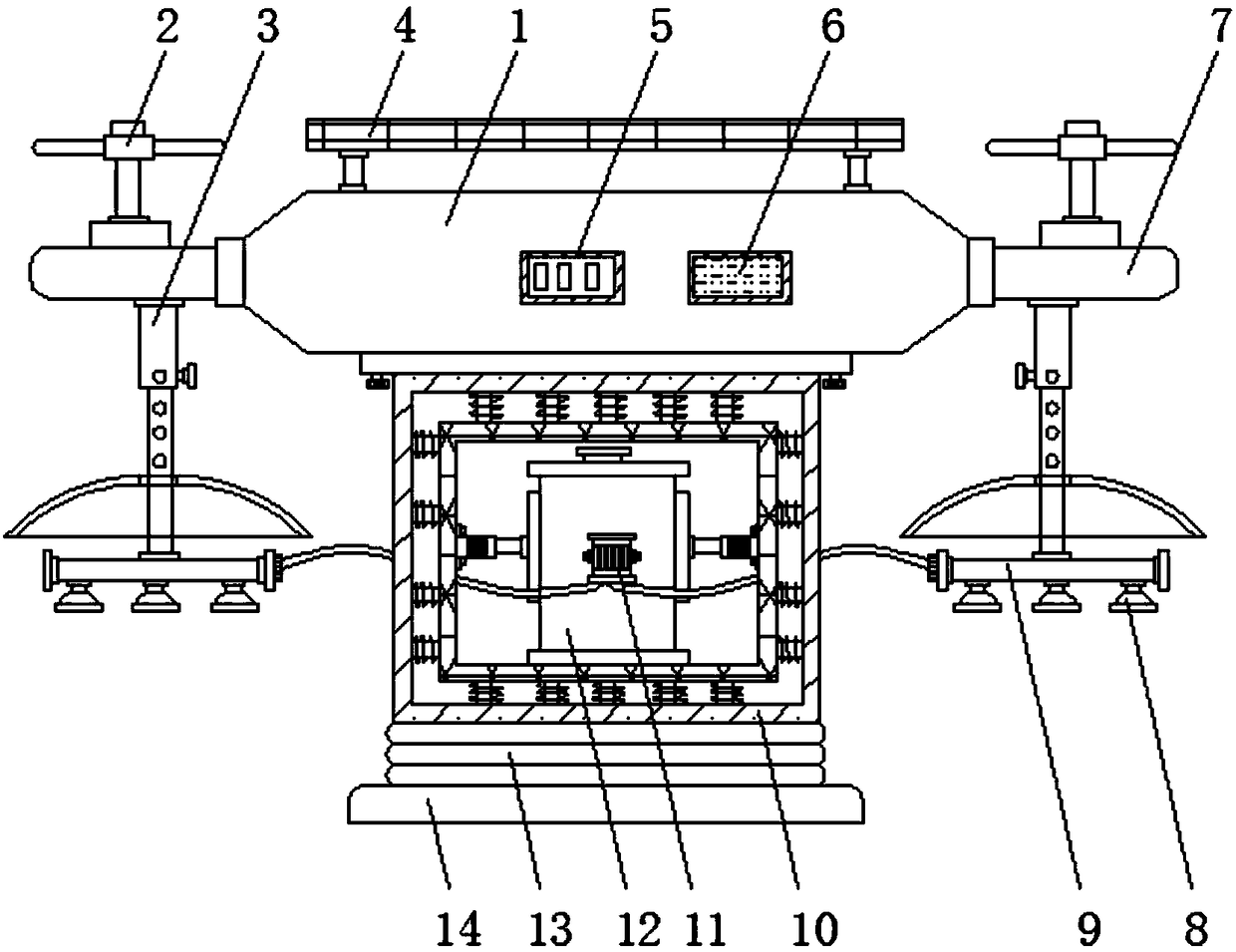

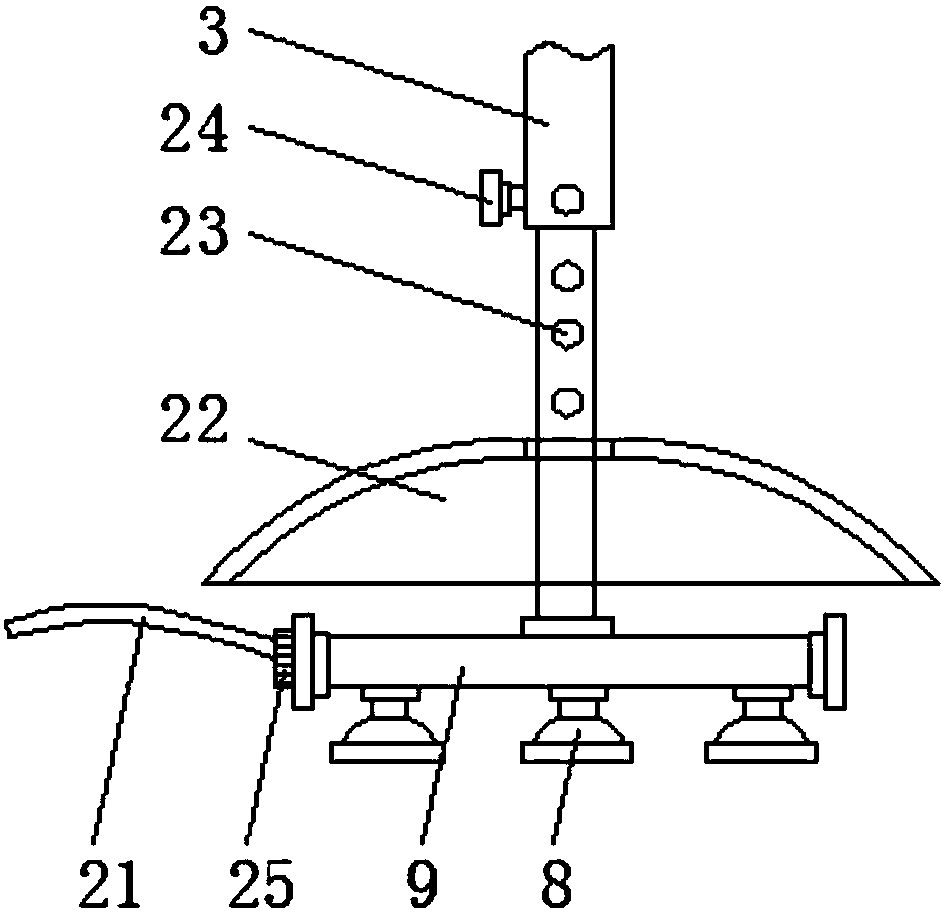

Vibration isolation system of vibrating centrifuge

InactiveCN102652930ASmall dynamic stiffness and natural frequencyImprove static stiffnessCentrifugesAir springEngineering

The invention discloses a vibration isolation system of a vibrating centrifuge. The vibration isolation system comprises a vibration isolation device, wherein the vibration isolation device comprises a guide rod, the axial direction of the guide rod is taken as the up-and-down direction, the upper end of the guide rod is connected with a rotating arm support of the vibrating centrifuge, the lower end of the guide rod sequentially penetrates through an upper-layer rigid plate, a middle-layer rigid plate and a lower-layer rigid plate, a linear bearing is connected with a regulating block, the regulating block is mounted on the lower-layer rigid plate, the lower end of the guide rod penetrates through the linear bearing, the two ends of the lower-layer rigid plate are respectively connected with the inner side of a support of a rotating arm system of the vibrating centrifuge, a force sensor is positioned between the rotating arm support and the upper-layer rigid plate, and an air spring is positioned between the upper-layer rigid plate and the middle-layer rigid plate. By adopting the structure that the air spring cooperates with the rigid plates, the imbalance force of the support of the rotating arm system relative to the rotating arm support is buffered and the vibration isolation purpose can be achieved. The vibration isolation system disclosed by the invention has the advantages of small dynamic rigidity, small inherent frequency, great static rigidity, good vibration isolation performance and capabilities of isolating vibration waves with higher frequency and bearing greater imbalance force.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

High-impact piezoelectric accelerometer

ActiveCN103792389AReduce strainReduce lateral accelerationAcceleration measurement using interia forcesAccelerometerEffective strain

The invention discloses a high-impact piezoelectric accelerometer. The high-impact piezoelectric accelerometer comprises a hollow installing seat, a core is arranged in the hollow installing seat through a compressing ring in a press fit mode and is connected with a cable through a plug, one shock insulation cushion and one insulating cushion are arranged between one end of the core and the compressing ring, and another shock insulation cushion and another insulating cushion are arranged between the other end of the core and the installing seat. Because the shock insulation cushions large in damping are installed at the two ends of the core of the piezoelectric accelerometer, high-frequency large-amplitude acceleration generated by strong-impact waves on a structure can be filtered out, and transverse acceleration transmitted to an acceleration sensor can be reduced so as to achieve the purpose of reducing zero drift. Due to the adoption of a base strain isolation type structure, strain of sensitive elements can be effectively reduced; because the insulating cushions are arranged at the two ends of the core and serve as isolators, the accelerometer can be isolated from an installing face mechanically so that effective strain transmitted to the accelerometer can be reduced and the purpose of reducing zero drift can be achieved.

Owner:YMC PIEZOTRONICS

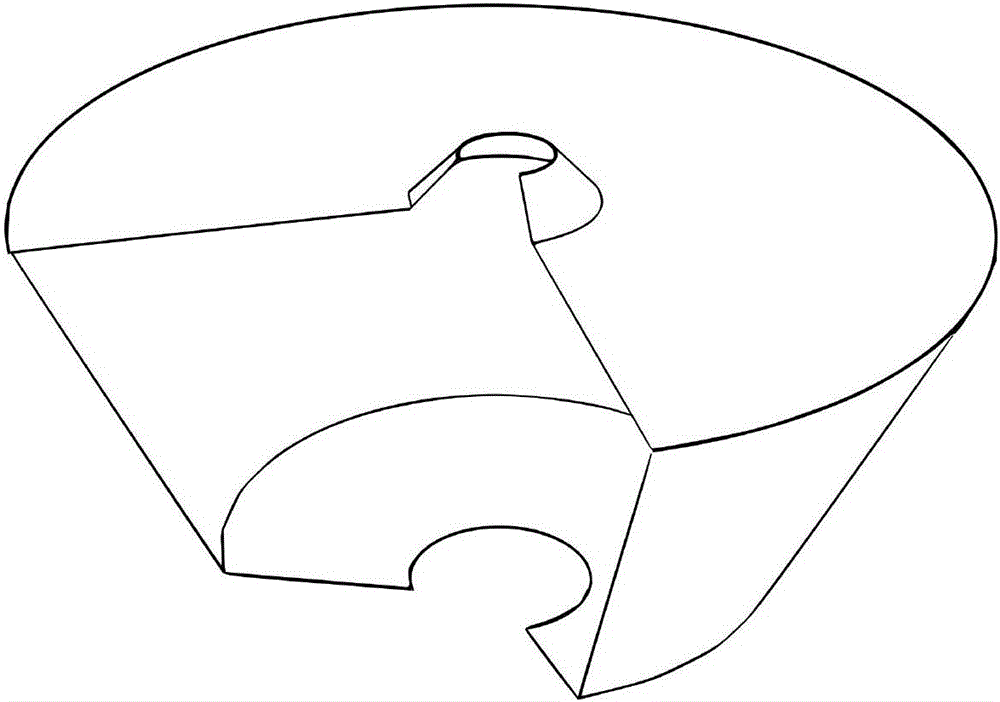

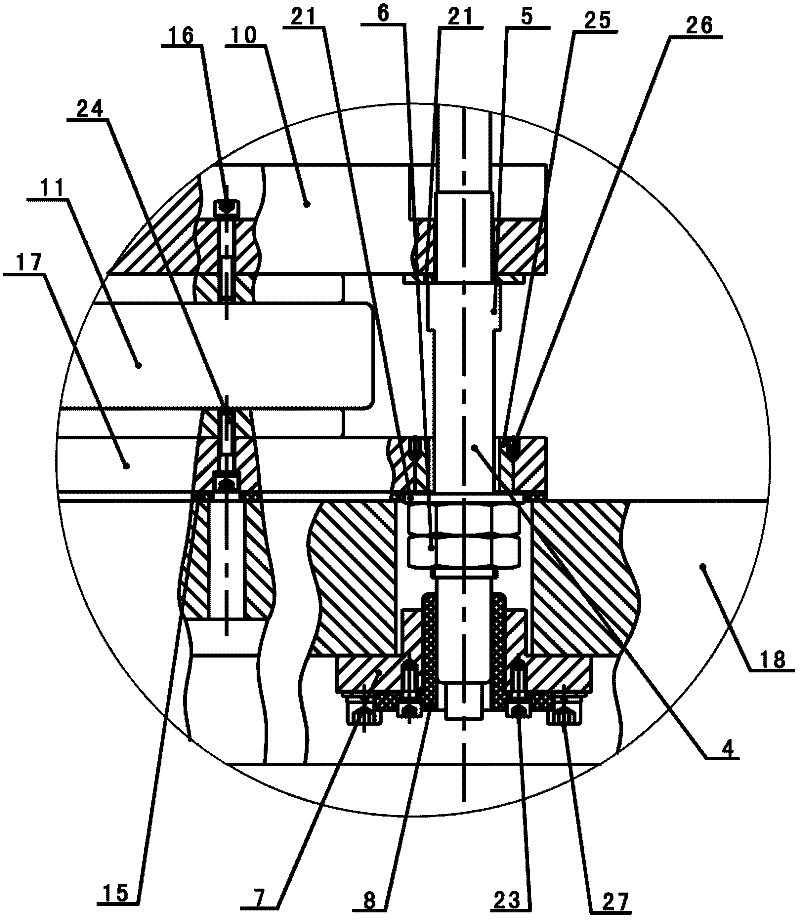

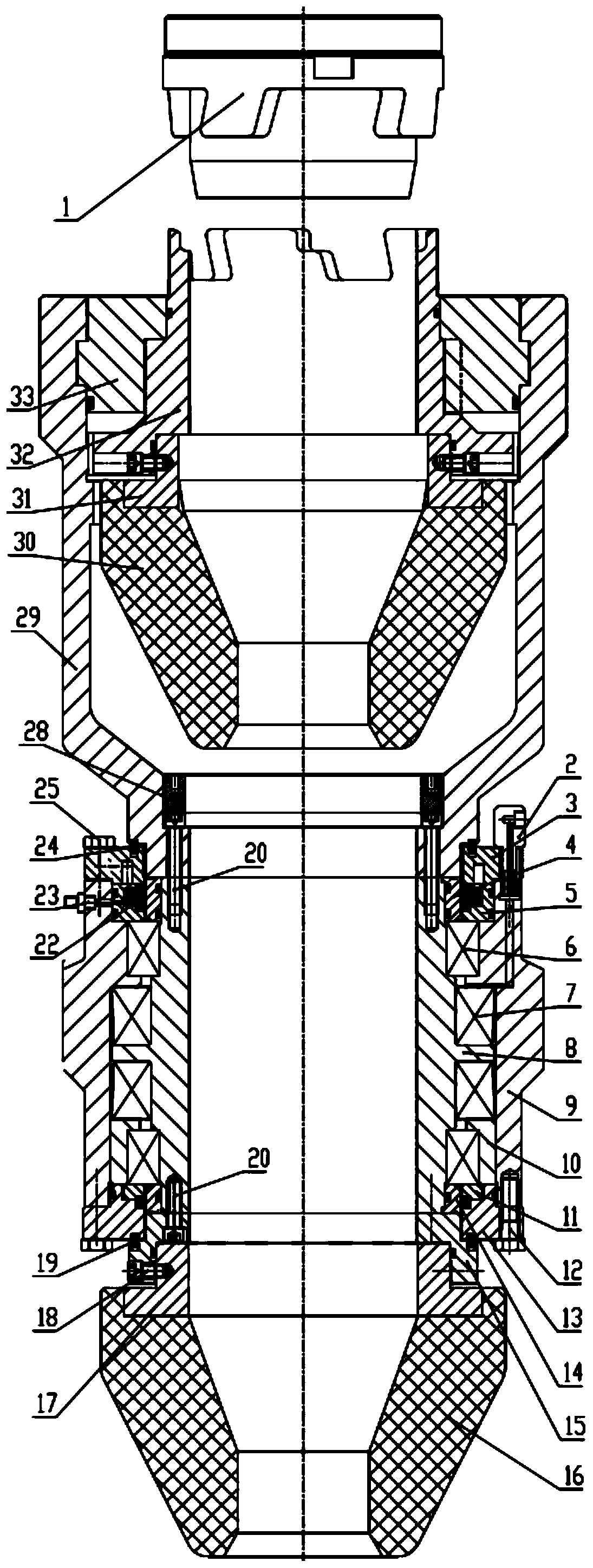

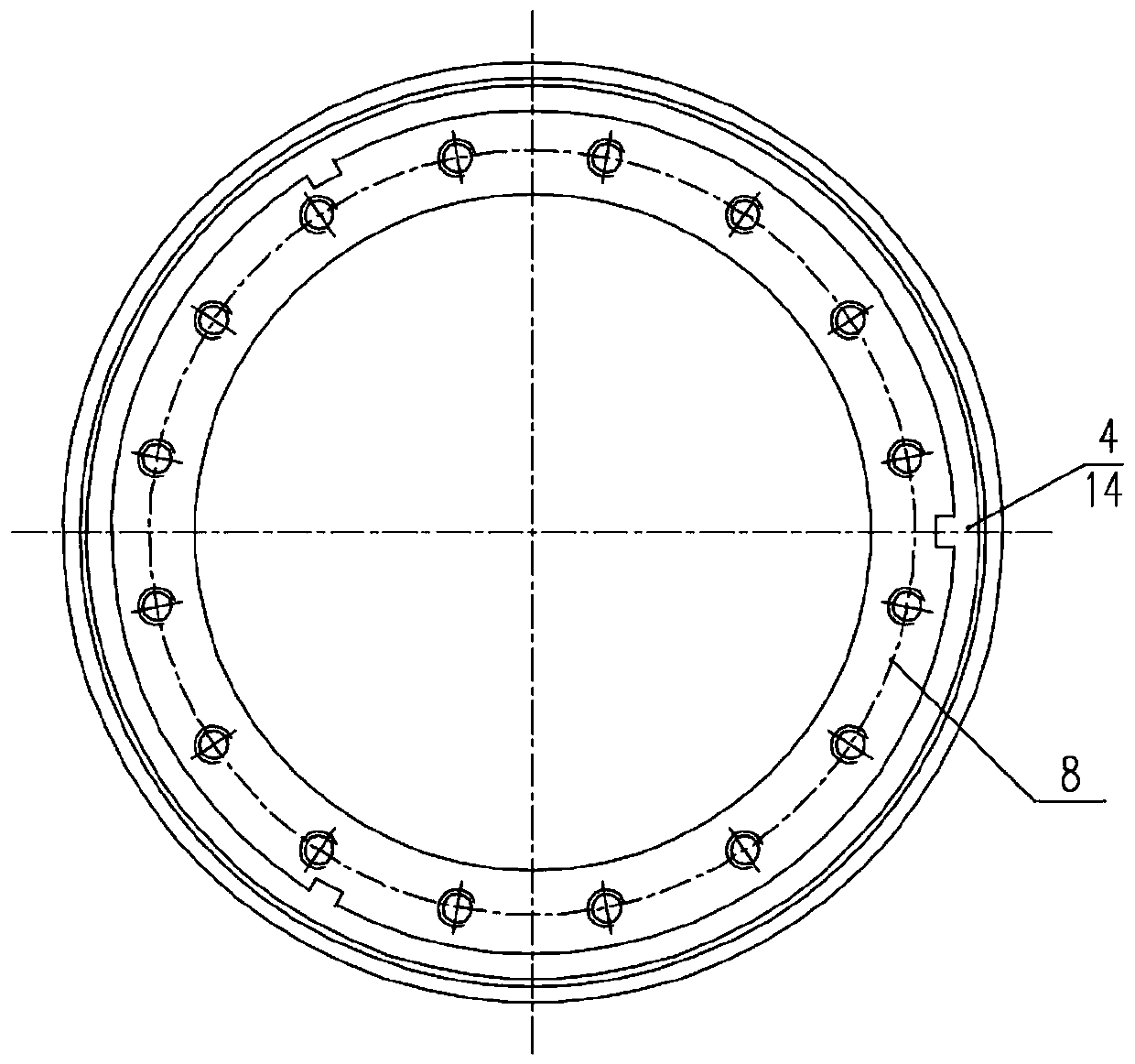

Large-diameter single-double quick-change rotary blowout preventer assembly

PendingCN111425162AReduce usageReduce use costSealing/packingStructural engineeringBlowout preventer

The invention discloses a large-diameter single-double quick-change rotary blowout preventer assembly. The assembly comprises a driving assembly, an upper rubber core rotating assembly and a lower rubber core rotating assembly detachably connected with the bottom of the upper rubber core rotating assembly, wherein the upper rubber core rotating assembly comprises an upper central shaft protectivesleeve, an upper rubber core outer shell, an upper rubber core, an upper rubber core framework, an upper rubber core driving hanger and an upper rubber core sealing gland. The large-diameter single-double quick-change rotary blowout preventer assembly gives consideration to the large-diameter central shaft size and the high-dynamic sealing pressure, on the premise of ensuring that a central shaftdiameter is unchanged, quick change of a high-pressure double-rubber-core assembly and a low-pressure single-rubber-core assembly can be realized, meanwhile, a connection mode of the rubber core hanger and a sealing rubber core, a connection mode of the upper rubber core sealing gland and the upper rubber core outer shell as well as a fixing mode of a rotary sealing bushing are improved, the situation that equipment sealing failure caused by screw thread loosening and sealing bushing abrasion due to vibration can be effectively prevented, and the assembly is compact and simple in structure, convenient in on-site disassembly and assembly, and high in practicability.

Owner:四川国励石油工程有限公司

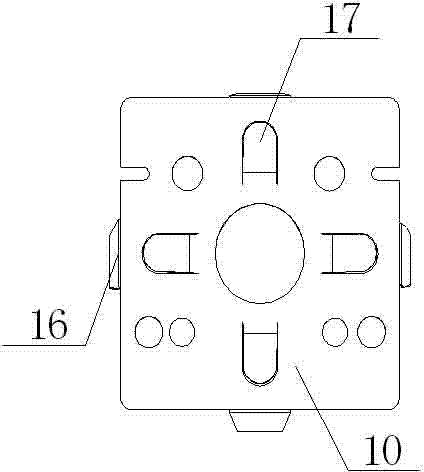

Structure for improving vibration performance of contactor

InactiveCN103578867AImprove stabilityImprove impact resistanceElectromagnetic relay detailsElement analysisGravity center

The invention discloses a structure for improving vibration performance of a contactor. The structure comprises an elastic damping spacer arranged on a yoke on the part of a magnetic circuit in a point welding mode. A U-type elastic piece stretching upwards is arranged outside the elastic damping spacer and makes contact with the inner lateral wall of a cover. The elastic damping spacer is further provided with a positioning supporting piece, and the positioning supporting piece stretches downwards to make contact with the inner bottom surface of the cover. Finite element analysis is adopted in the structure, through changes of positioning and installing modes of contact of inner final assembly parts in the contactor and the cover part and the additional arrangement of the elastic damping spacer, the problems that because coils are too heavy, the centers of the coils deviate from the axes, the overall gravity center of the coils and the overall centroid of the coils are not symmetric, the cover is not tightly connected with a machine core, restraints on the heavy coils are not enough, and accordingly in the vibration compact process of the contactor, the resonance point descends, and the contactor is subject to vibration and impact when used under poor environment and loses efficiency are solved.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

A vibration damping and heat dissipation device for a rolling bearing

ActiveCN103470539BIncrease elasticityReduce radial contact stiffnessPump componentsShaftsRubber ringRolling-element bearing

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Bistable contactless magnetic vibration energy capture device

InactiveCN104578911AEasy to resonateNovel structurePiezoelectric/electrostriction/magnetostriction machinesStable stateMagnetic tension force

The invention relates to a bistable contactless magnetic vibration energy capture device comprising a plurality of bistable piezoelectric sleeves (1). Each bistable piezoelectric sleeve (1) has two stable states including a raised state and a recessed state; first permanent magnets (4) are arrange on the outer walls of the bistable piezoelectric sleeves (1), and the bistable piezoelectric sleeves (1) are mounted on the outer wall of an inner cylinder (5) in a sleeving manner; a plurality of magnetic sleeves (6) sleeve the bistable piezoelectric sleeves (1), are coaxial with the bistable piezoelectric sleeves (1) and are mounted on the inner wall of an outer cylinder (7); second permanent magnets (8) are embedded in the magnetic sleeves (6), and the pole directions of the second permanent magnets (8) embedded in adjacent magnetic sleeves (6) are opposite. The bistable contactless magnetic vibration energy capture device has the advantages that vibration energy is captured through switching between the recessed stable state and the raised stable state of poles due to vibration of the bistable piezoelectric sleeves, collision and friction energy losses can be eliminated in a contactless mode under the action of magnetic force, and accordingly, energy capture is improved.

Owner:张文明 +1

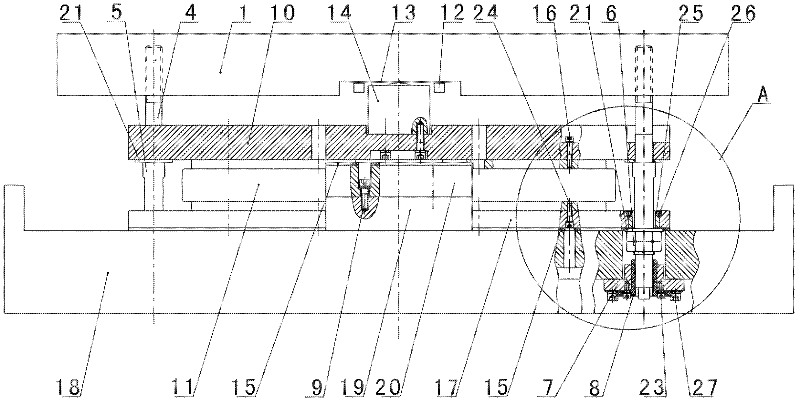

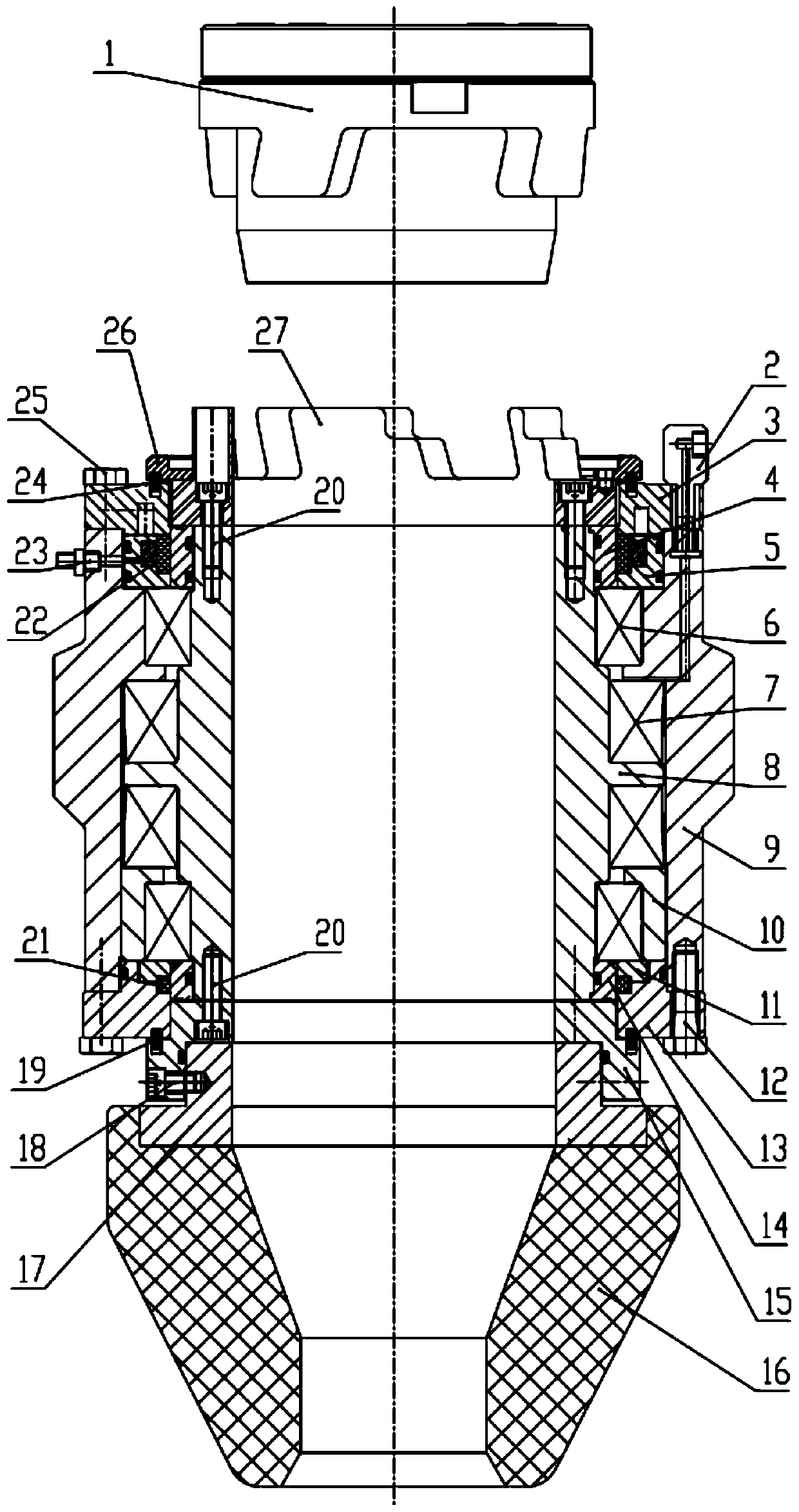

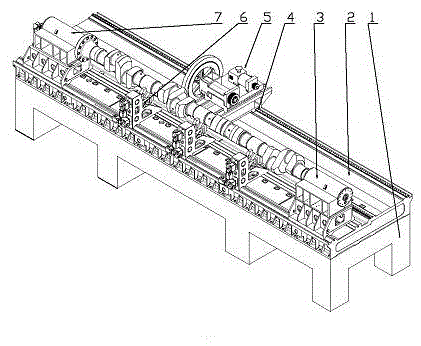

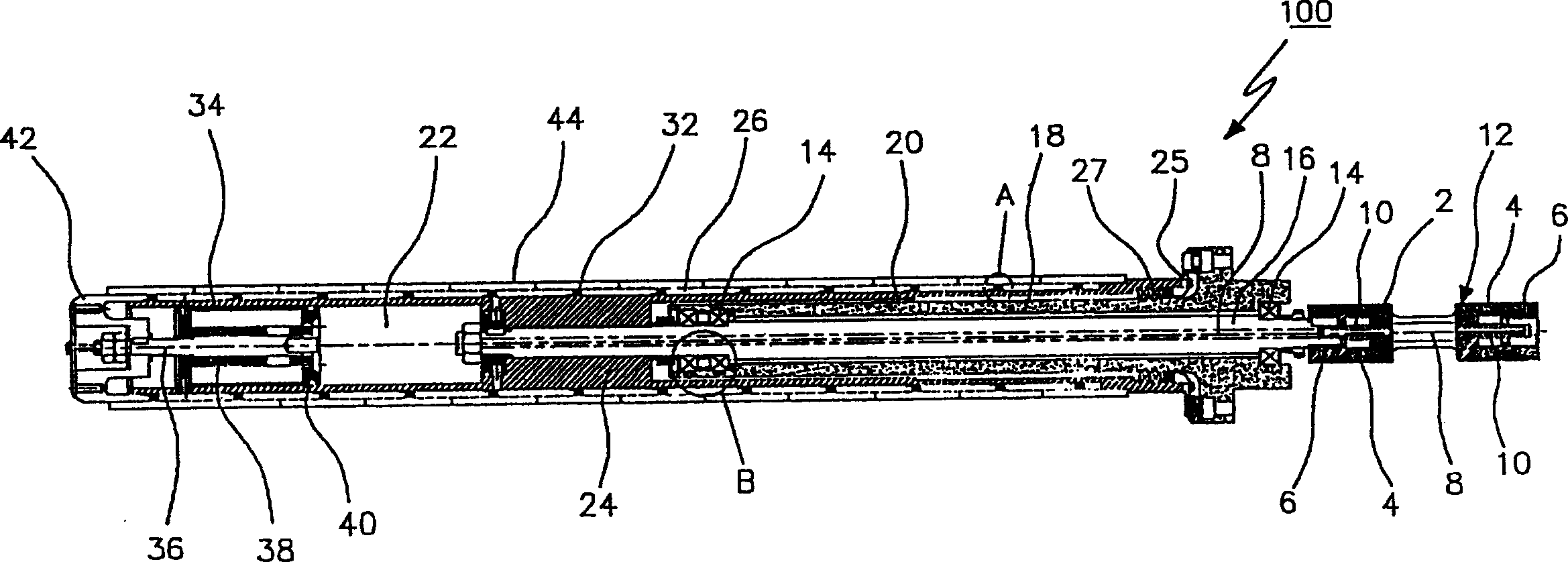

Large crankshaft follow-up grinding machine

InactiveCN105598757AHigh rotation accuracyImprove carrying capacityGrinding carriagesRevolution surface grinding machinesEngineeringLinear motor

The invention discloses a large crankshaft follow-up grinding machine which comprises a machine body, a headstock, a tailstock, a grinding carriage and at least one central frame. The headstock, the tailstock, the grinding carriage and at least one central frame are supported on the machine body. Headstock and tailstock supporting guide rails and grinding carriage supporting guide rails are arranged on the bed body and are mutually and parallelly arranged, and grinding fluid backflow channels are formed among the guide rails. A grinding wheel on the grinding carriage is fixedly connected to one end of a spindle, the spindle is rotatably supported on a grinding wheel support through a hydrostatic bearing, the other end of the spindle is fixedly connected with a drive belt wheel, and the drive belt wheel is further rotatably supported on the grinding wheel support through a bearing and is in driven connection with a grinding wheel driving motor. The grinding wheel support is movably supported on a carriage through a feed hydrostatic guide rail and is in driven connection with the carriage through a linear motor. The large crankshaft follow-up grinding machine has higher structure rigidity and can meet the movement flexibility, precision and rigidity requirements for the grinding carriage and other parts of large crankshaft machining performed by adopting a follow-up grinding technology.

Owner:GUNAI HEAVY IND SUZHOU

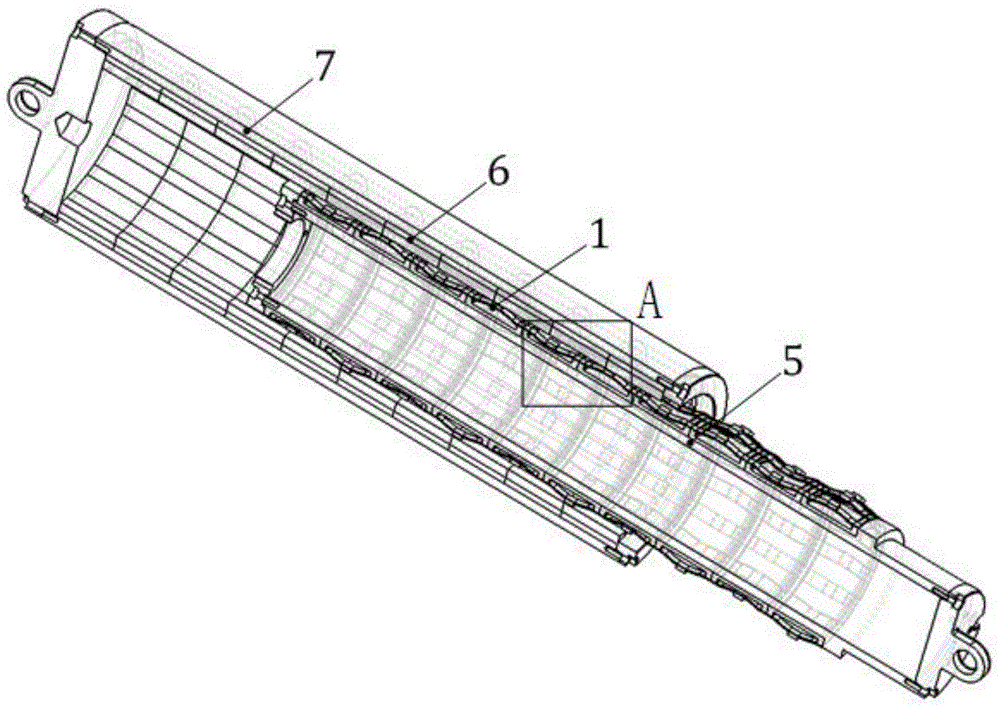

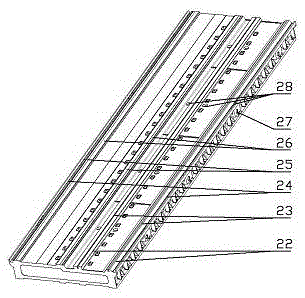

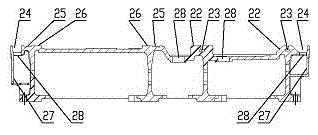

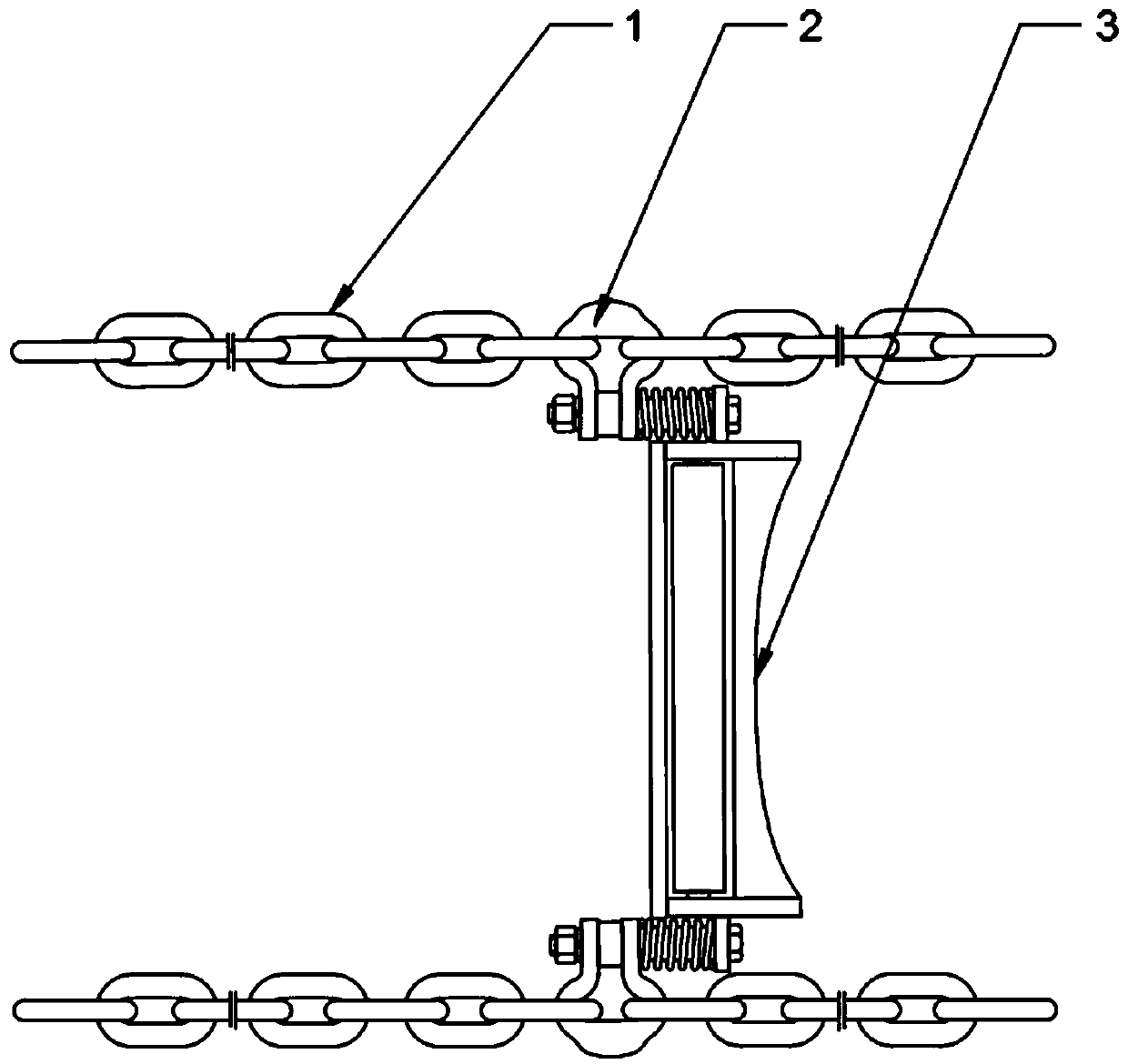

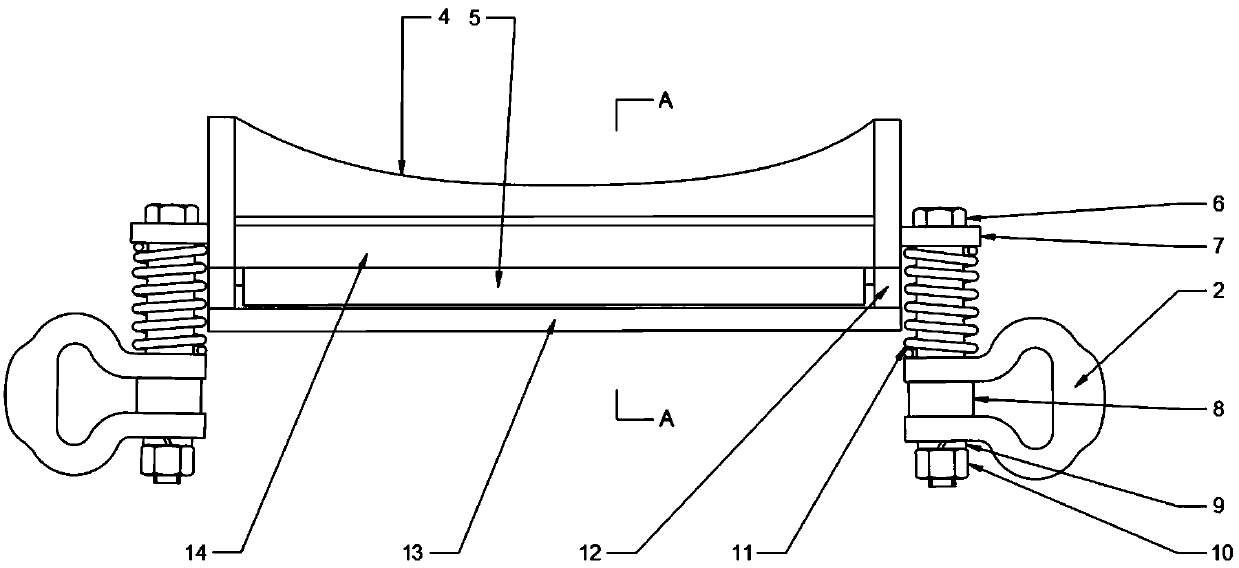

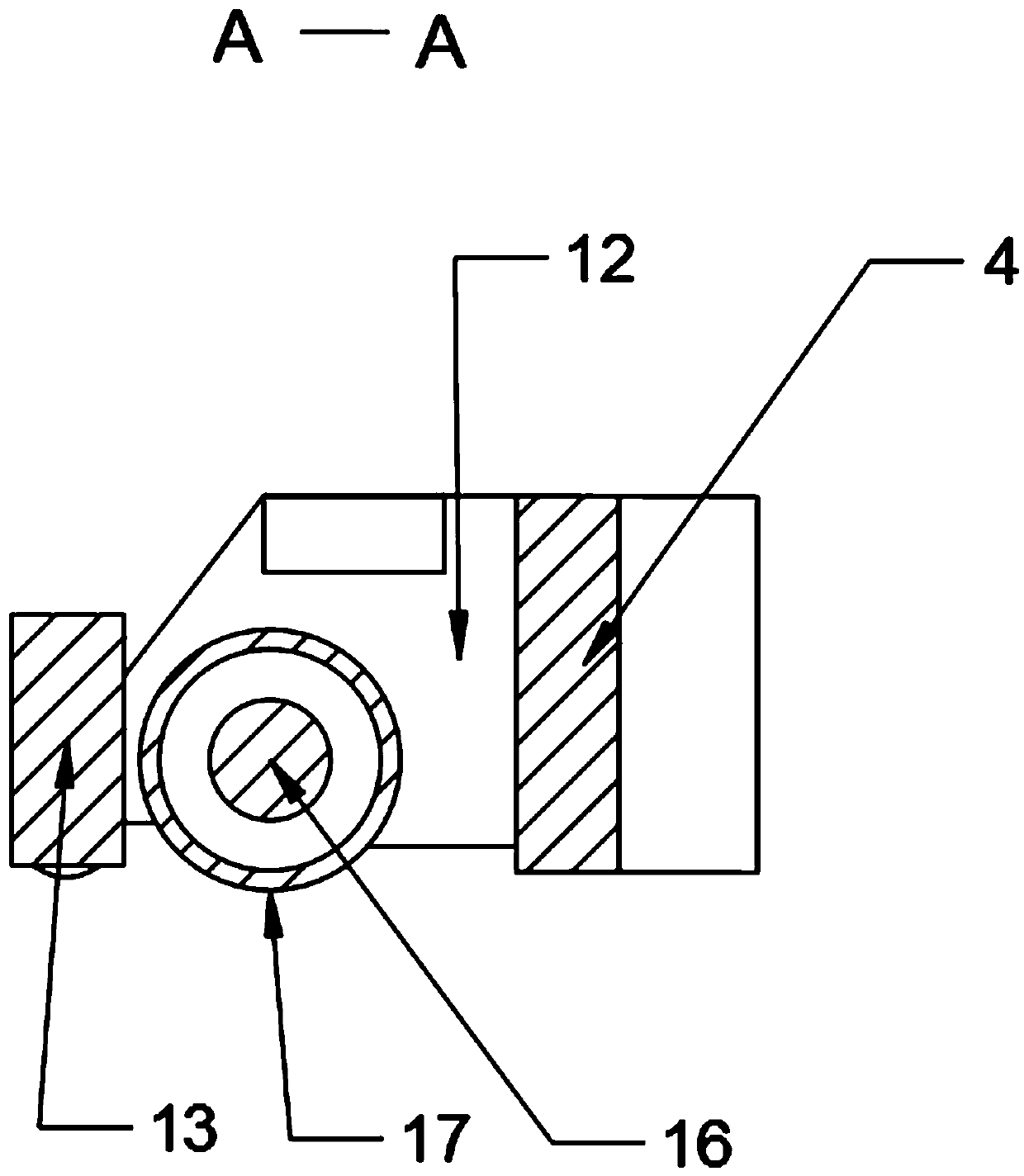

Side double-chain scraper blade for mining scraper conveyer

Owner:安徽宇艳智能机械科技有限公司

Vibration feeding device

PendingCN110189864AGood choiceReduce volumeCable/conductor manufactureEngineeringMechanical engineering

The invention relates to the preparation field of a superconducting material and particularly relates to a vibration feeding device. The vibration feeding device includes a feeding structure includinga pipe feeding mold for fixing a feeding pipe, and a vibration structure including a vibration motor and a vibration platform arranged on the vibration motor, wherein the vibration platform is provided with the pipe feeding mold. The vibration feeding device is advantaged in that powder vibration compaction can be realized, pipe feeding density is enhanced, holes and bulges inside sintered iron-based superconducting tapes can be effectively reduced, and transmission performance of the iron-based superconducting tapes is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Embedding accuracy control construction method for embedded part of overlong equipment foundation platform

InactiveCN102134879BReasonable designSimplify construction stepsFoundation engineeringBuilding constructionsReinforced concreteRebar

The invention discloses an embedding accuracy control construction method for an embedded part of an overlong equipment foundation platform, including the following steps: firstly, processing the embedded part and the installation screw of the embedded part; secondly, molding construction of the lower middle reinforced concrete structure of the foundation platform needing construction: a plurality of vertical reinforcing steel bars extend out from the top of the lower middle reinforced concrete structure under construction of molding and are arranged vertically; thirdly, installing the installation screw of the embedded part; fourthly, installing a nut at the bottom of the threaded section of the installation screw of the embedded part; fifthly, installing and positioning the embedded part; sixthly, installing a nut on top of the threaded section of the installation screw of the embedded par; seventhly, molding construction of the upper reinforced concrete structure of the foundation platform needing construction; and eighthly, subsequent construction treatment. The method has in design, simple construction steps, easy control of construction quality, high construction accuracy and good in use effect, and can solve the problems of the existing embedding construction method of embedding parts that the embedding accuracy is inconvenient to control, the embedding accuracy is low,the construction quality is poor, the investment cost is high, the construction period is long, and the like.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

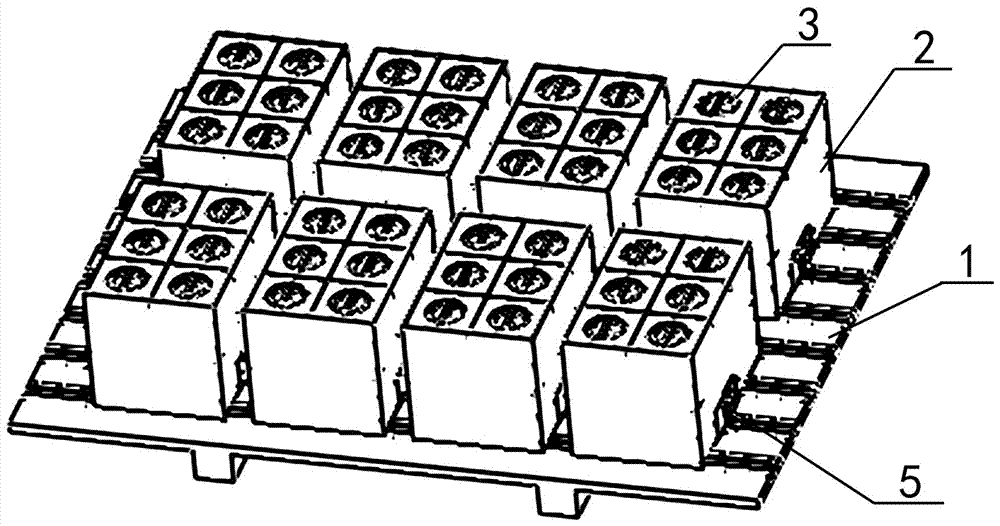

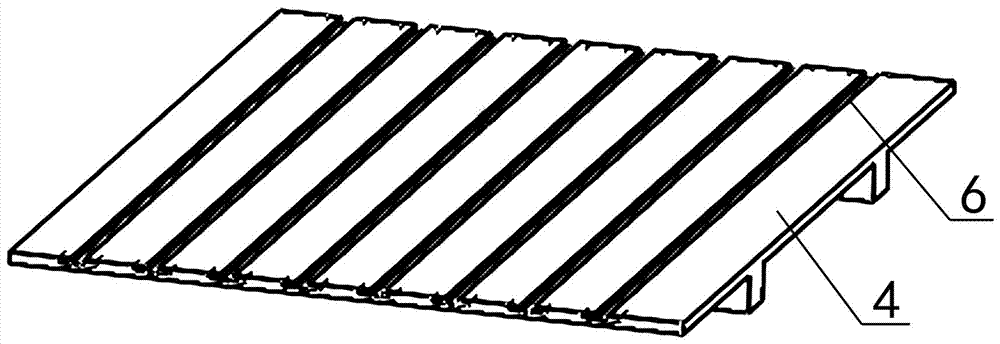

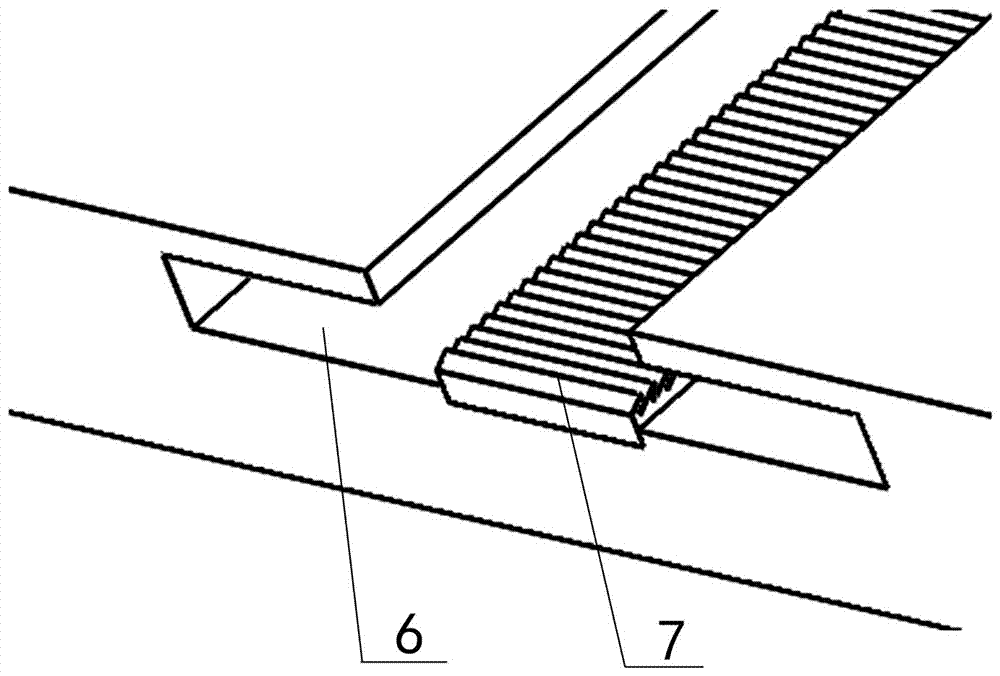

High-grade fragile product packaging and transporting integrated device

InactiveCN107226261ASuit one's needsAchieve reuseContainers to prevent mechanical damageRigid containersSelf lockingEngineering

The invention belongs to the technical field of packaging devices and provides a high-grade fragile product packaging and transporting integrated device in order to solve the technical problem that high-grade fragile products are likely to get broken in the transportation process. The high-grade fragile product packaging and transporting integrated device comprises a transport pallet, a plurality of inner packaging boxes placed on the transport pallet and a plurality of packaging boxes arranged in the inner packaging boxes. The transport pallet comprises a pallet body and a plurality of clamping devices arranged on the pallet body and used for clamping the inner packaging boxes. The pallet body is of a cuboid structure. A plurality of parallel slideways are arranged on the upper surface of the pallet body at intervals. Slide rails are arranged in the slideways and sleeved with the clamping devices. The upper surfaces of the slide rails are provided with racks. Each clamping device comprises a self-locking control plate and a clamping plate mounted on the upper portion of the self-locking control plate. The clamping devices are arranged on the slide rails through bases of the self-locking control plates in a sleeving mode and mounted on the pallet body. The packaging device can meet the requirements of different sizes of fragile products in regular shapes and irregular shapes, can be utilized repeatedly and is easy and convenient to operate and high in safety performance.

Owner:ZHONGBEI UNIV

Reel holder for high speed elastic wire winder

This invention provides a bobbin holder of winder for winding elastic thread at high speed, which steadily holds bobbins for winding elastic thread to increase holding tension, rotating speed and production rate. The bobbin holder of winder in accordance with the present invention includes: a coupler, a plurality of bodies and rubber being connected in linear arrangement, one side of the bodies being connected to a motor spindle; a shaft connected to the bodies at another end of the coupler, two ends of its diametrical surface being connected to a plurality of bearings and having a fixed length; a support having an inner diametrical surface joining to the bearings and an outer diametrical surface being secured to the winder; a housing joined to an end of the shaft, and formed with a first space subjecting the support and the shaft to be located at an inside, between the inner diametrical surface of the first space and the outer diametrical surface of the support being connected with bearings, a second space being formed on an opposing direction of the first space; a plurality of rollers, surroudingly connected to the entire diametrical surface of the housing; a plurality of rubbers, surroudingly connected between the rollers; and a cover joined to the housing and an end of the second space for pressing the rollers towards the coupler, or recovering the rollers to their original locations, so as to vary the expanding volume of the rubbers. As such, the diametrical surface of the rollers is able to retain or release the bobbin of the elastic thread.

Owner:ILJIN A TECH

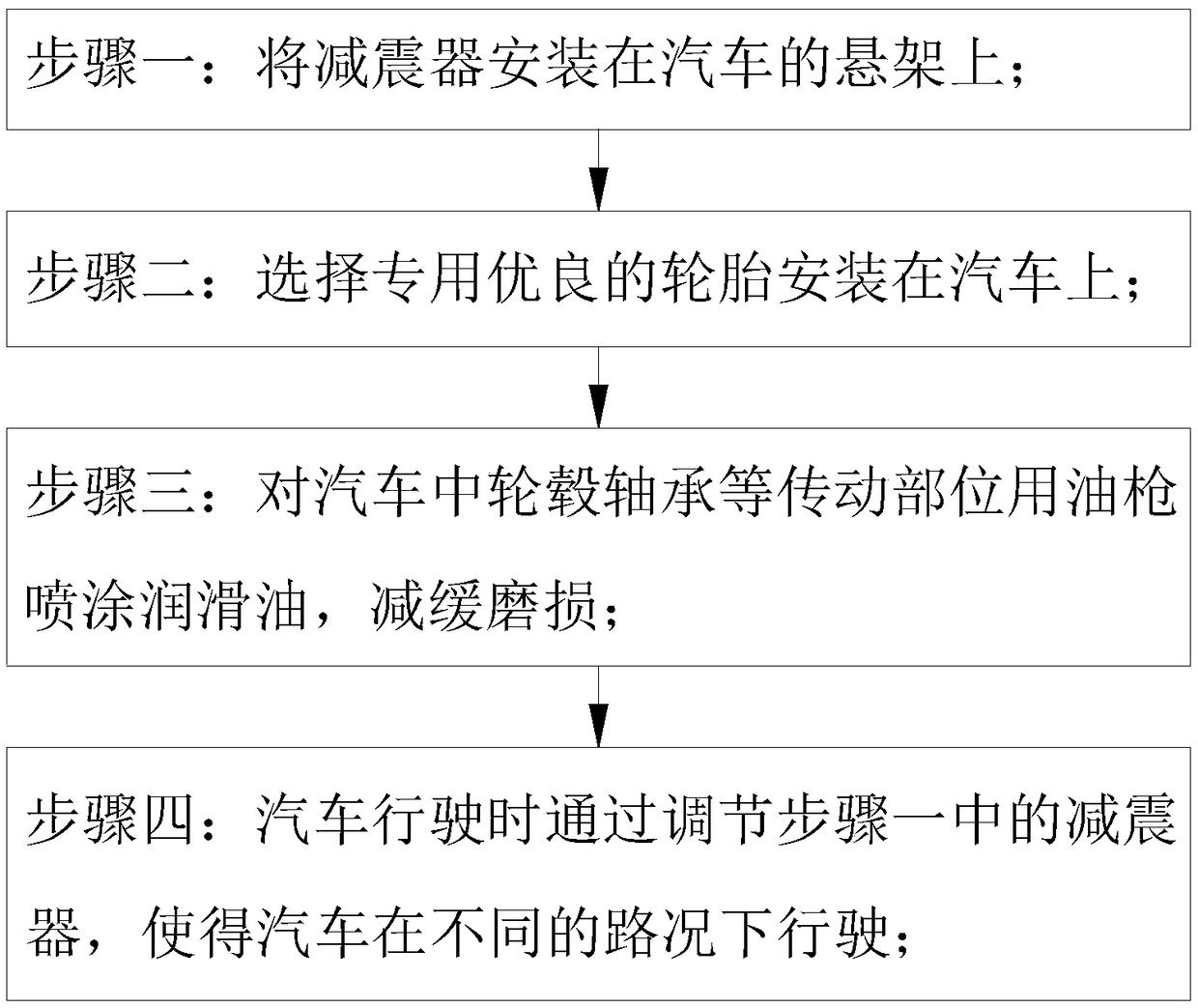

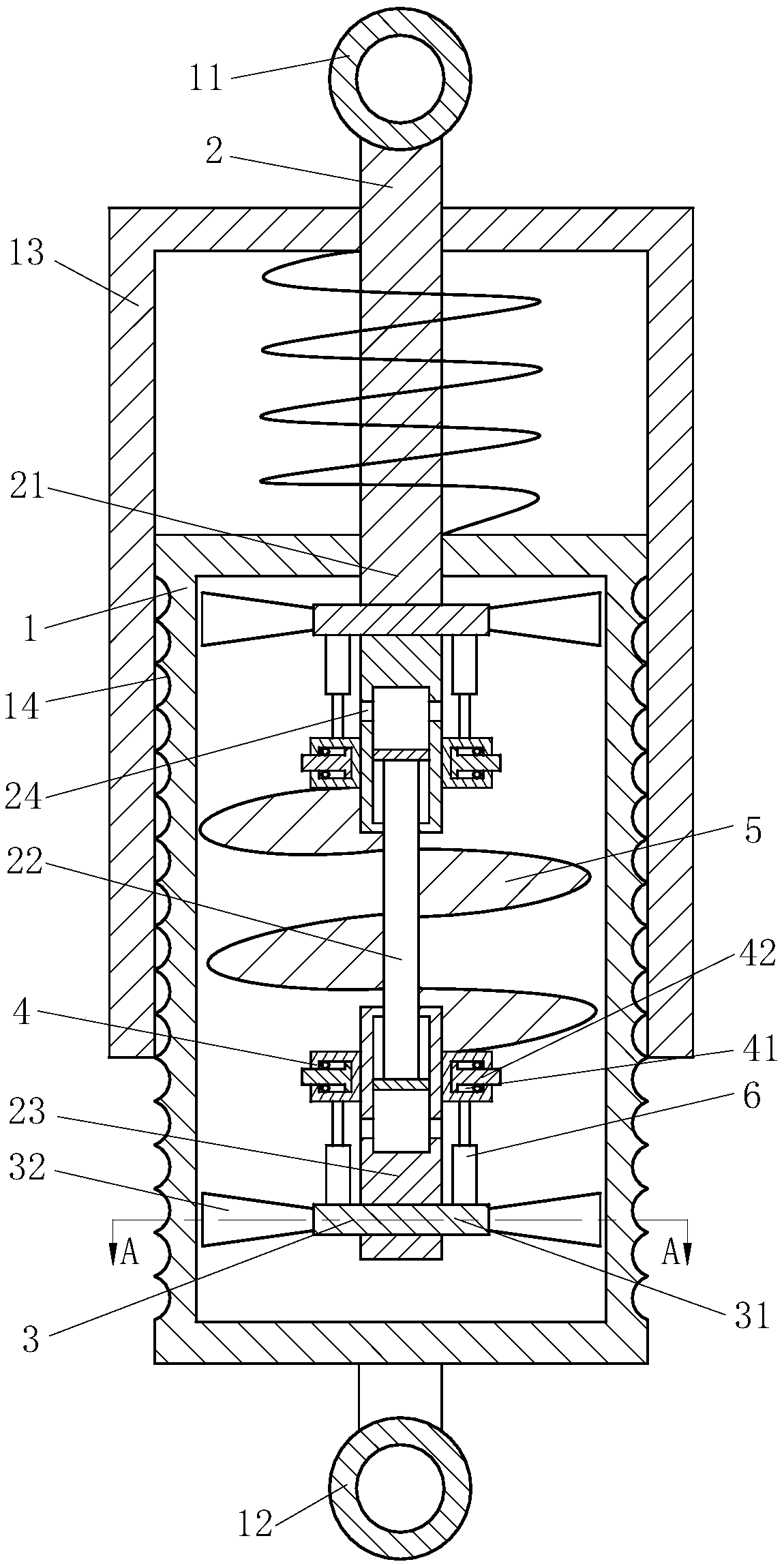

Method for improving automobile driving stability

ActiveCN108869608AImprove riding performanceReduce spacingSpringsLiquid based dampersControl theoryPiston

The invention belongs to the technical field of automobiles, and particularly relates to a method for improving automobile driving stability. The method adopts a damper, the damper comprises a workingcylinder barrel, a piston shaft, an upper lifting lug, a lower lifting lug and a dustproof cover, and further comprises a rotating device and a first rotating disc, the outer wall of the working cylinder barrel is sleeved with the dustproof cover, the piston shaft is arranged inside the working cylinder barrel, hydraulic oil is contained at the bottom of the working cylinder barrel, and the periphery of the piston shaft is sleeved with the rotating device. Hydraulic oil is squeezed through the rotating device and flows in the working cylinder barrel, one part of hydraulic oil acts to enable the rotating device to rotate, the other part of hydraulic oil makes friction with a rotating plate to produce damping force, and automobile vibration is buffered; and in the flowing process of hydraulic oil, the flowing speed of hydraulic oil is gradually reduced, therefore, the effects of rapid vibration and slow damping for automobiles are achieved, self vibration of the damper is reduced, and automobile driving stability is improved.

Owner:WM MOTOR TECH GRP CO LTD

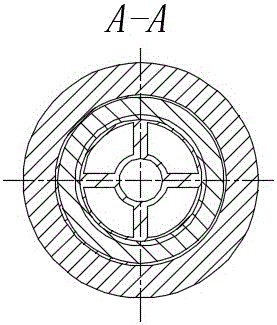

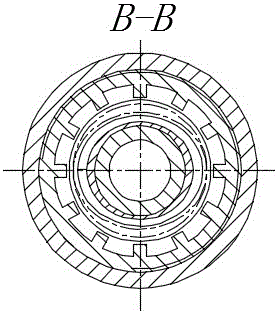

Speed reduction tool for achieving large transmission ratio through harmonic gear

ActiveCN106594226AReduce speedLower requirementFluid gearingsGearing detailsInterference fitHarmonic

The invention relates to a speed reduction tool for achieving the large transmission ratio through a harmonic gear, and belongs to the field of petroleum drilling. The speed reduction tool is installed to the upper portion of a drill bit through threaded connection and comprises a turbine assembly, a harmonic gear assembly, a universal shaft assembly and a damping assembly. The harmonic gear assembly is composed of an oval harmonic producer used as power input, a flexible gear used as power output and a rigid gear fixed to a shell. An input shaft is in interference fit with the harmonic producer, and the flexible gear is subjected to controllable elastic deformation through the harmonic producer to be in an oval shape also. According to the speed reduction tool for achieving the large transmission ratio through the harmonic gear, the tooth number of the rigid gear is slightly larger than that of the flexible gear in harmonic gear transmission, the formula of the transmission ratio is shown in the description, ZR is the tooth number of the flexible gear, ZG is the tooth number of the rigid gear, meanwhile, the engaged tooth number is large, the characteristics of the large transmission ratio can be achieved, the rotating speed of a turbine drill is effectively reduced, the torque is greatly increased, and the drilling efficiency of the turbine drill is improved.

Owner:重庆桐雨石科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com