Reel holder for high speed elastic wire winder

An elastic wire and coiler technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of short life of O-rings, weak gripping force, and weak rotation characteristics of spool clamps. , to achieve the effect of prolonging the service life and increasing the gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

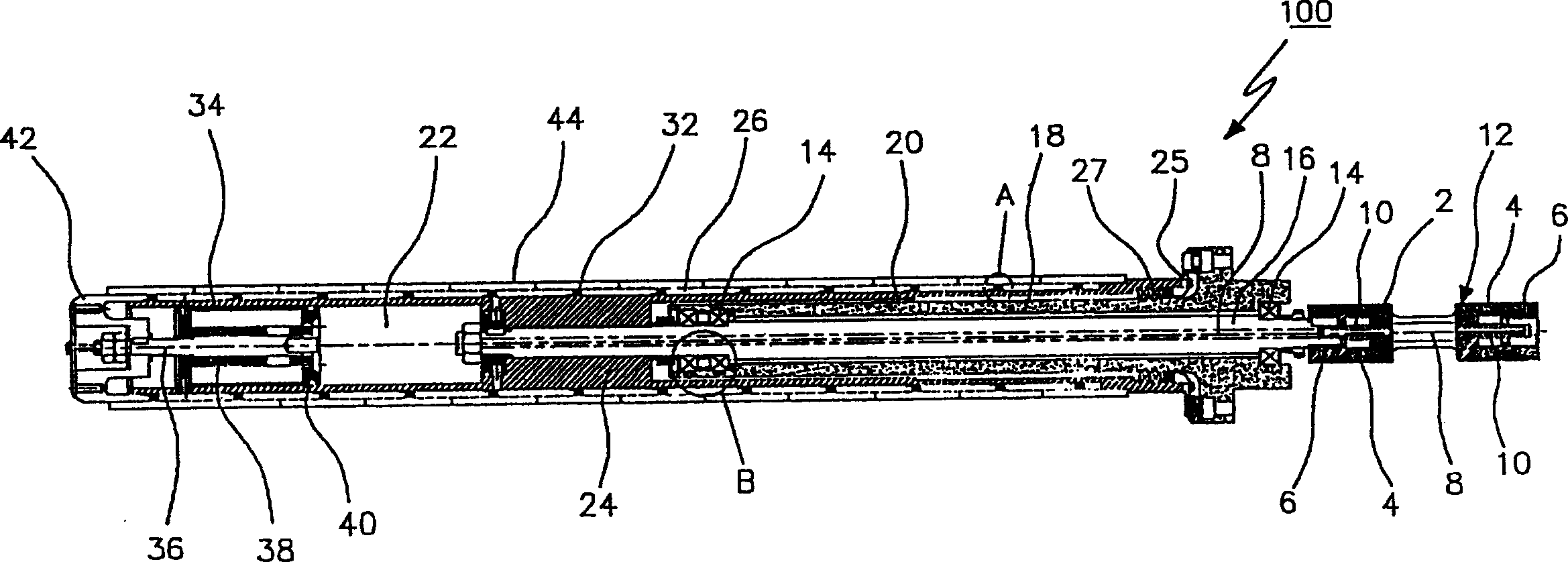

[0038] Hereinafter, the present invention will be described in detail with reference to the drawings.

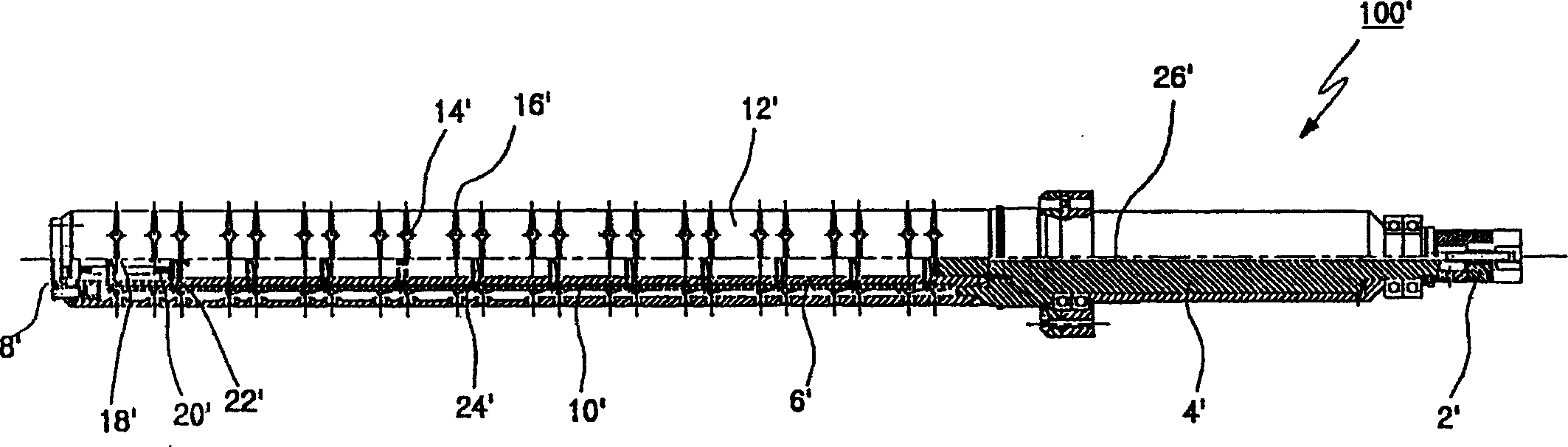

[0039] figure 2 A sectional view showing a bobbin gripper 100 of a coiler for high-speed elastic yarn coiling.

[0040] As shown in the figure, the spool gripper 100 of the present invention has a shaft coupling 12, the first body 2, the star wheel rubber 4 and the second body 6 are connected in a linear arrangement with each other; 2. The body 6 is coupled to the rotation shaft of a motor (not shown).

[0041] The second body 6 on the other side of the coupling 12 is combined with a shaft 16 having a certain length, and a plurality of bearings 14 are combined near both ends of the outer diameter surface of the shaft 16 . Here, a compressed air supply passage 8 communicating with the coupling 12 and the shaft 16 is formed.

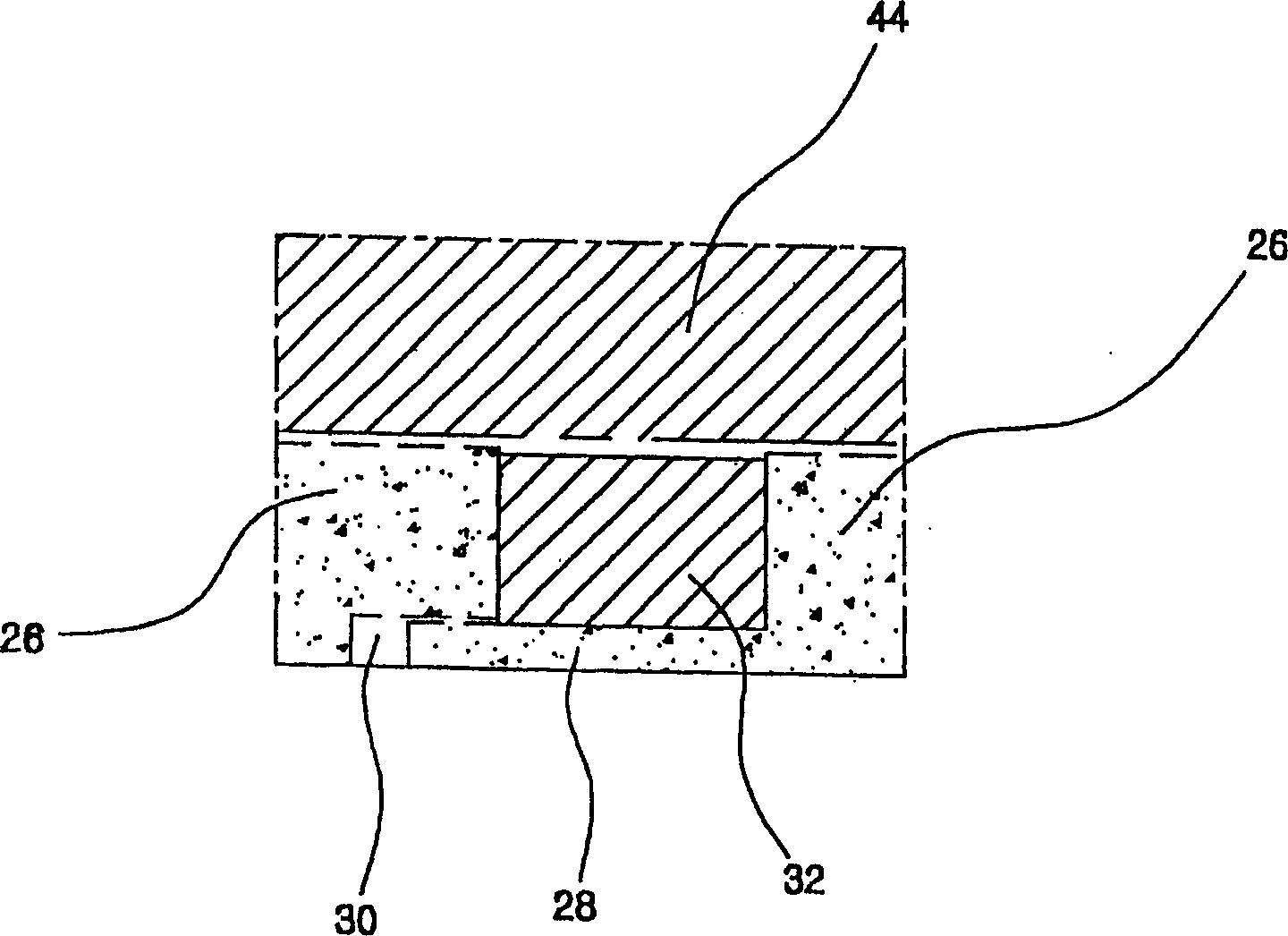

[0042] The outer diameter surface of the aforementioned shaft 16 is combined with a supporter 18 completely fixed on the coiler, and the bearing 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com