Structure for improving vibration performance of contactor

A contactor and performance technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of not meeting the requirements of use, poor reliability of vibration and shock performance, etc., and achieve enhanced shock resistance and improved shock resistance , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

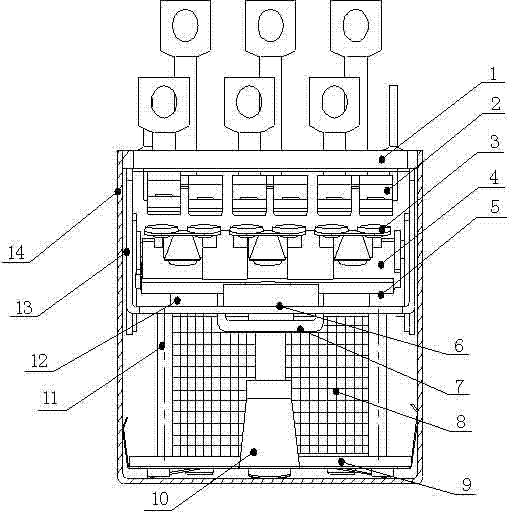

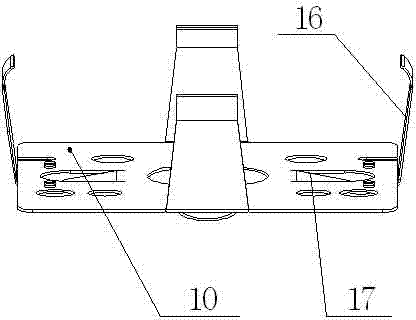

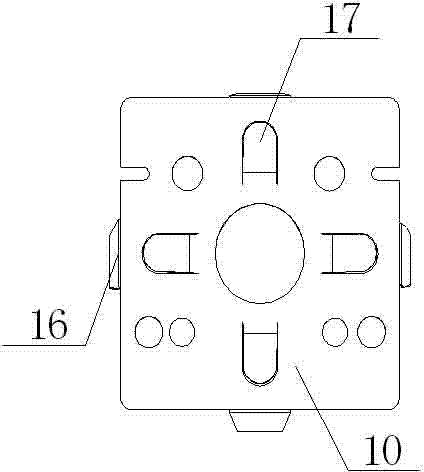

[0029] Embodiment of the present invention: a structure to improve the vibration performance of the contactor, as attached Figure 1-3 As shown, it includes an elastic damping washer 10, which is spot-welded on the yoke 9 on the magnetic circuit part of the contactor, and four pieces of upward protruding The U-shaped elastic piece 16 is also provided with 3 or more downwardly protruding positioning support pieces 17 on the elastic damping gasket 10 .

[0030] When assembling the contactor with the elastic damping gasket 10 added, the static reed 2 is riveted on the base 1 to form the contact part; the magnetic steel 6 and the pole shoe 7 are installed on the bracket 13, and then the yoke 9 and the yoke The coil 8 on 9, the support column 11 installed on the side of the coil 8, and the iron core 12 installed above the coil 8 are riveted to form a magnetic circuit part; then the movable contact 3 is riveted to the push block 4, and loaded The armature 5 forms the armature part;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com