Exciting beam for pavement breaking vehicle

A vibration excitation beam and vibration excitation technology, applied in roads, roads, road repair and other directions, can solve the problems of difficulty in reaching the crushing depth and crushing quality, high energy consumption, low efficiency, etc., to reduce vibration impact, reduce micro-deformation, The effect of reducing the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

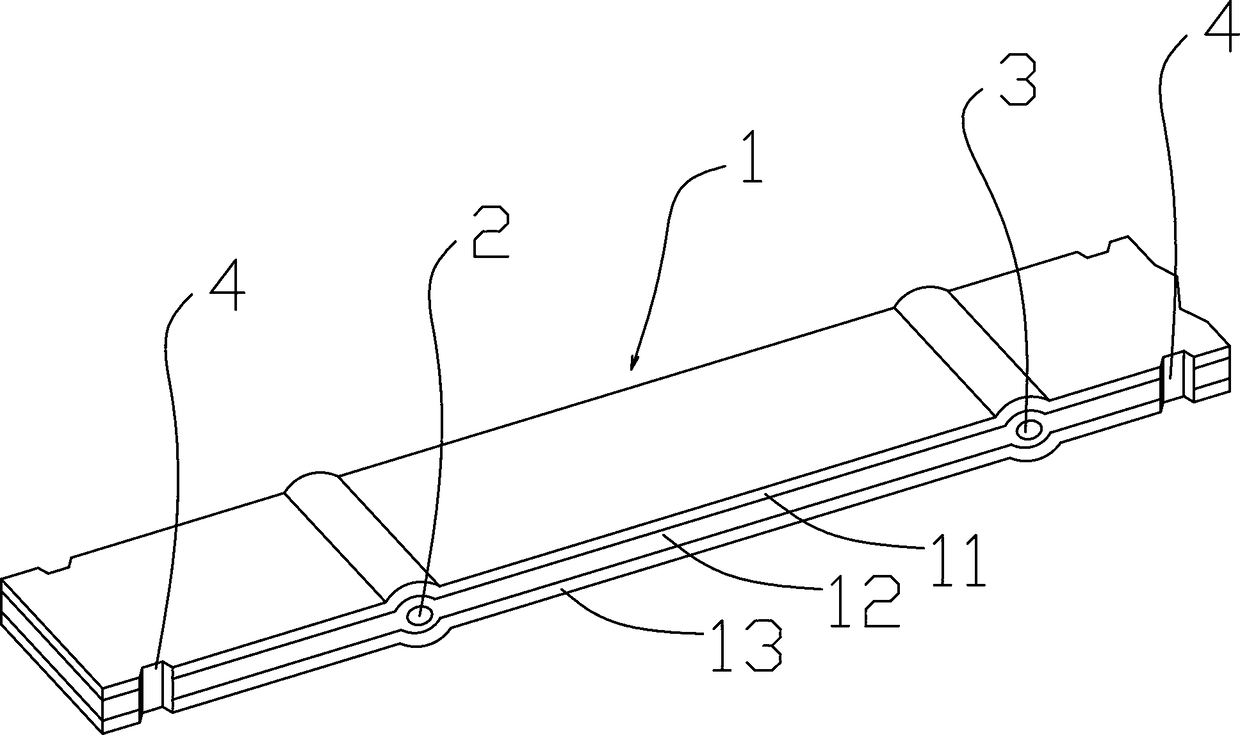

[0034] Such as figure 1 Among them, an excitation beam for a road crushing vehicle, the excitation beam 1 is composed of a plurality of excitation layers stacked from top to bottom, and each excitation layer is fixedly connected by a hoop 7 . With this structure, it is possible to reduce the amount of deformation of the upper surface and the lower surface of each excitation layer, reduce the heat generated by the alternating stress, and reduce the influence on the strength.

Embodiment 2

[0036] On the basis of Example 1, the preferred scheme is as figure 2 Among them, a first support hole 2 and a second support hole 3 are respectively provided at positions close to both ends of the exciting beam 1;

[0037] The first support hole 2 and the second support hole 3 are located between two excitation layers, and each excitation layer is provided with an arc structure corresponding to the support holes. With this structure, it is possible to reduce the difficulty of post-processing and facilitate the adoption of cold forging technology, especially the influence of the processing of the first support hole 2 and the second support hole 3 on the material. For example, due to the reduction of machining, steel materials with high elasticity can be selected for each excitation layer, such as silicon-manganese spring steel doped with one or more of boron, niobium or molybdenum.

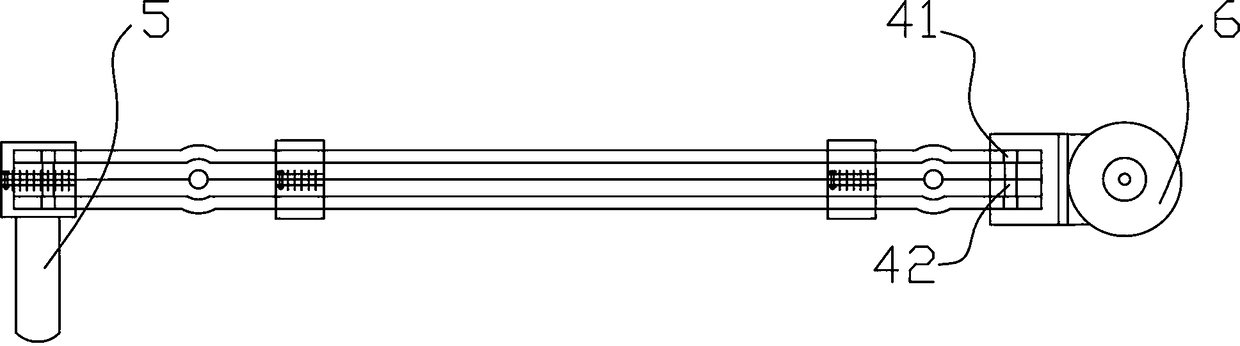

[0038] The preferred solution is as figure 2 Among them, an excitation hammer 5 is provide...

Embodiment 3

[0042] On the basis of Example 1, the preferred scheme is as figure 2 Among them, a first support hole 2 and a second support hole 3 are respectively provided at positions close to both ends of the exciting beam 1;

[0043] The first support hole 2 and the second support hole 3 are located in the excitation layer of the middle layer, and each excitation layer is provided with an arc structure corresponding to the support hole.

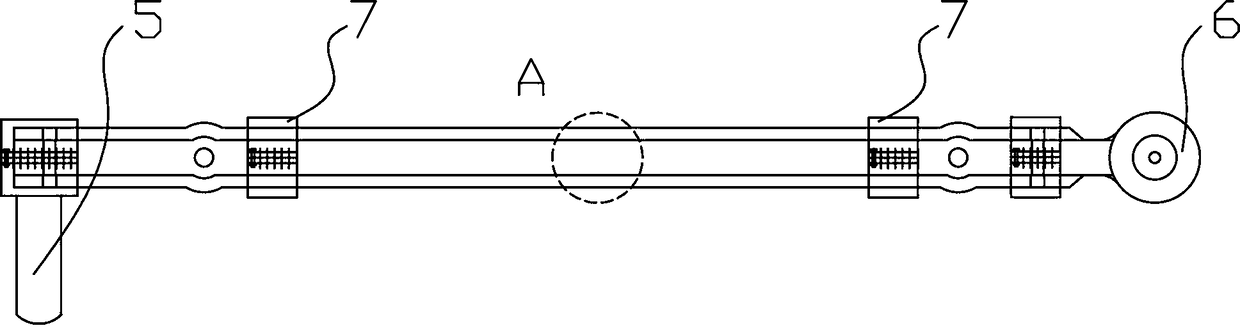

[0044] In a preferred solution, an exciting hammer 5 is provided at one end of the exciting beam 1, and a mounting seat for installing the exciting motor 6 is provided at the other end, and the exciting hammer 5 is connected with the exciting beam 1 through a hoop structure, and the The two sides of the hoop structure are connected by multiple bolts;

[0045] The mounting base is fixedly connected to the excitation layer on the middle layer;

[0046] The positions of the hoop 7 on both sides are connected by a plurality of bolts. With this structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com