Side double-chain scraper blade for mining scraper conveyer

A technology of scraper conveyor and chain scraper, which is applied in the field of mining equipment, can solve the problems of large transportation vibration shock, damage, long transportation distance, etc., and achieve the effect of reducing vibration shock, scientific and reasonable structure, and balancing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

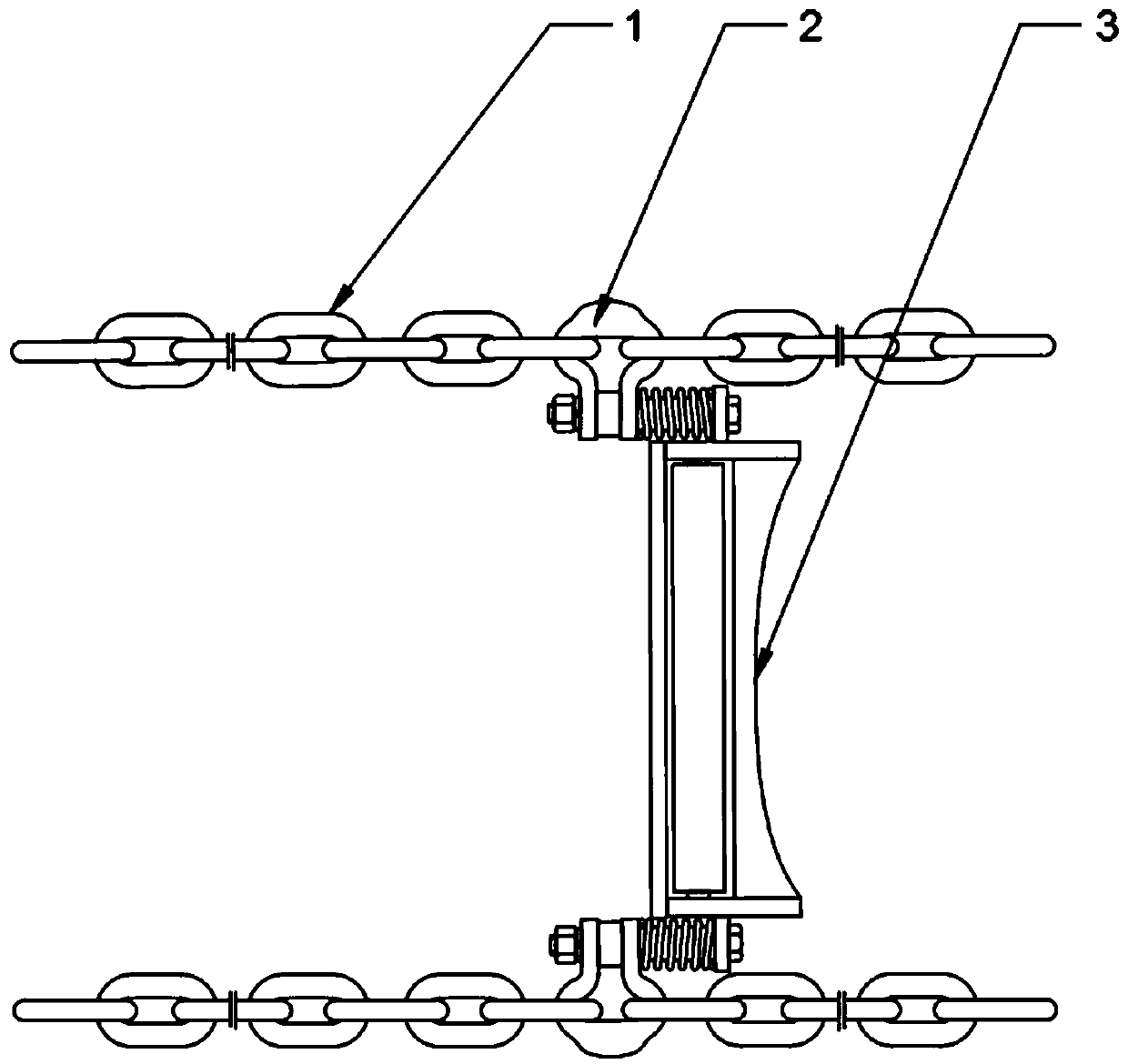

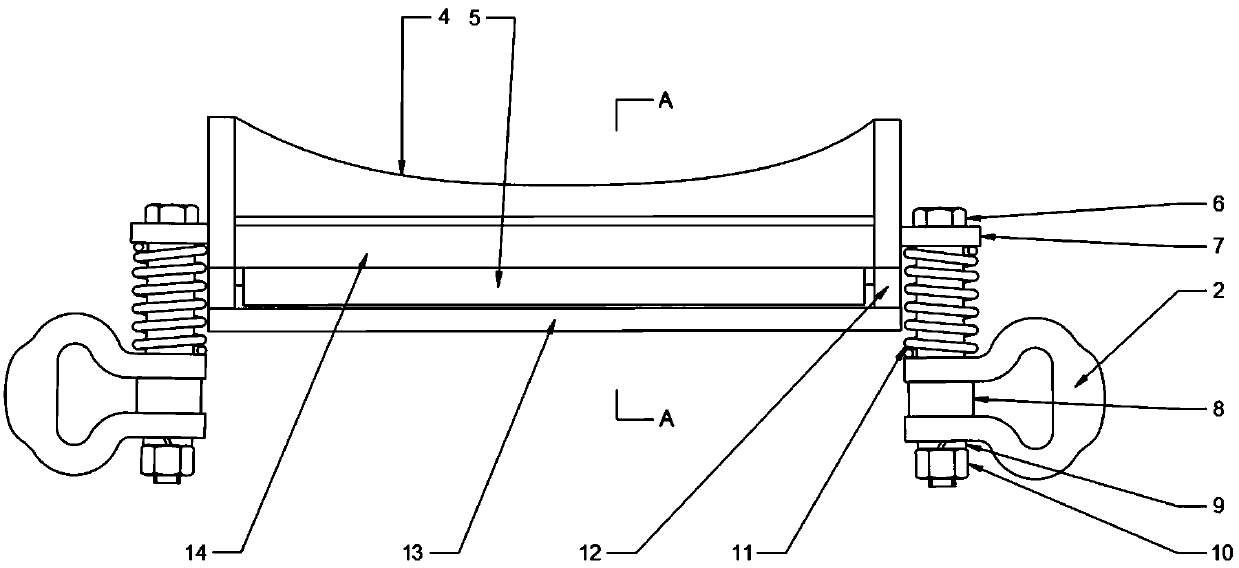

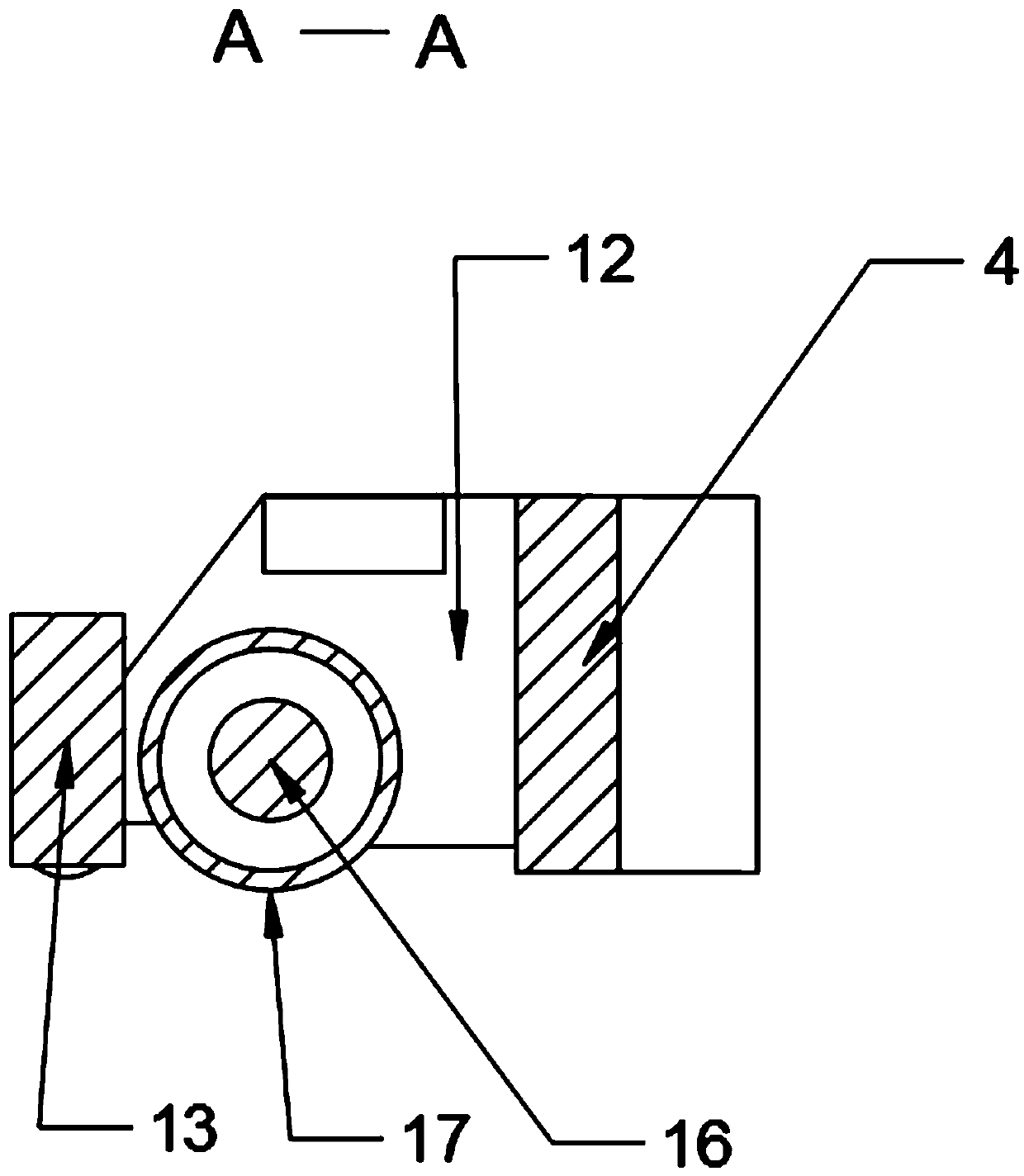

[0024] see Figure 1 to Figure 5 , the present invention provides a technical solution: a side double-chain scraper for a mining scraper conveyor, including a connecting ring 2 and a scraper device 3, chains 1 are connected to both sides of the connecting ring 2, and the connecting ring 2 A limit sleeve 8 is arranged in the middle, a gasket 9 is arranged below the connecting ring 2, a nut 10 is arranged below the gasket 9, a side plate 12 is arranged on the left side of the fixing plate 7, and a side plate 12 is arranged on the left side of the side plate 12. An arc-shaped scraper 4 is arranged above, and a baffle 14 is arranged below the arc-shaped scraper 4, and an idler 5 is installed below the baffle 14, and the idler 5 includes a roller 17 and a connecting shaft 16. The roller 5 can reduce the influence of the weight of the scraper device 3 itself on the scraper transportation. A rear baffle 13 is arranged below the idler roller 5. The present invention is compatible with...

Embodiment 2

[0027] see figure 1 , Figure 4 , Figure 5 and Figure 6 , the present invention provides a technical solution: a side double-chain scraper for mine scraper conveyor, including a connecting ring 2 and a scraper device 3, chains 1 are connected to both sides of the connecting ring 2, and the scraper device 3 The right side is provided with a fixed plate 7, the upper part of the fixed plate 7 is provided with a bolt 6, the lower part of the fixed plate 7 is provided with a spring 11, the lower part of the spring 11 is provided with a connecting ring 2, and the middle part of the connecting ring 2 is provided with a limited A bit sleeve 8, a gasket 9 is provided below the connecting ring 2, a nut 10 is provided below the gasket 9, a side plate 12 is provided on the left side of the fixing plate 7, and a side plate 12 is provided on the left side of the side plate 12 The arc-shaped scraper 4 is compatible with the existing design of the side double-chain scraper conveyor, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com