Vibration feeding device

A charging device and vibration platform technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as hindering the transmission of superconducting current, uneven charging density, and affecting the performance of superconducting wire strips, and achieve saving Labor cost, improved production efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

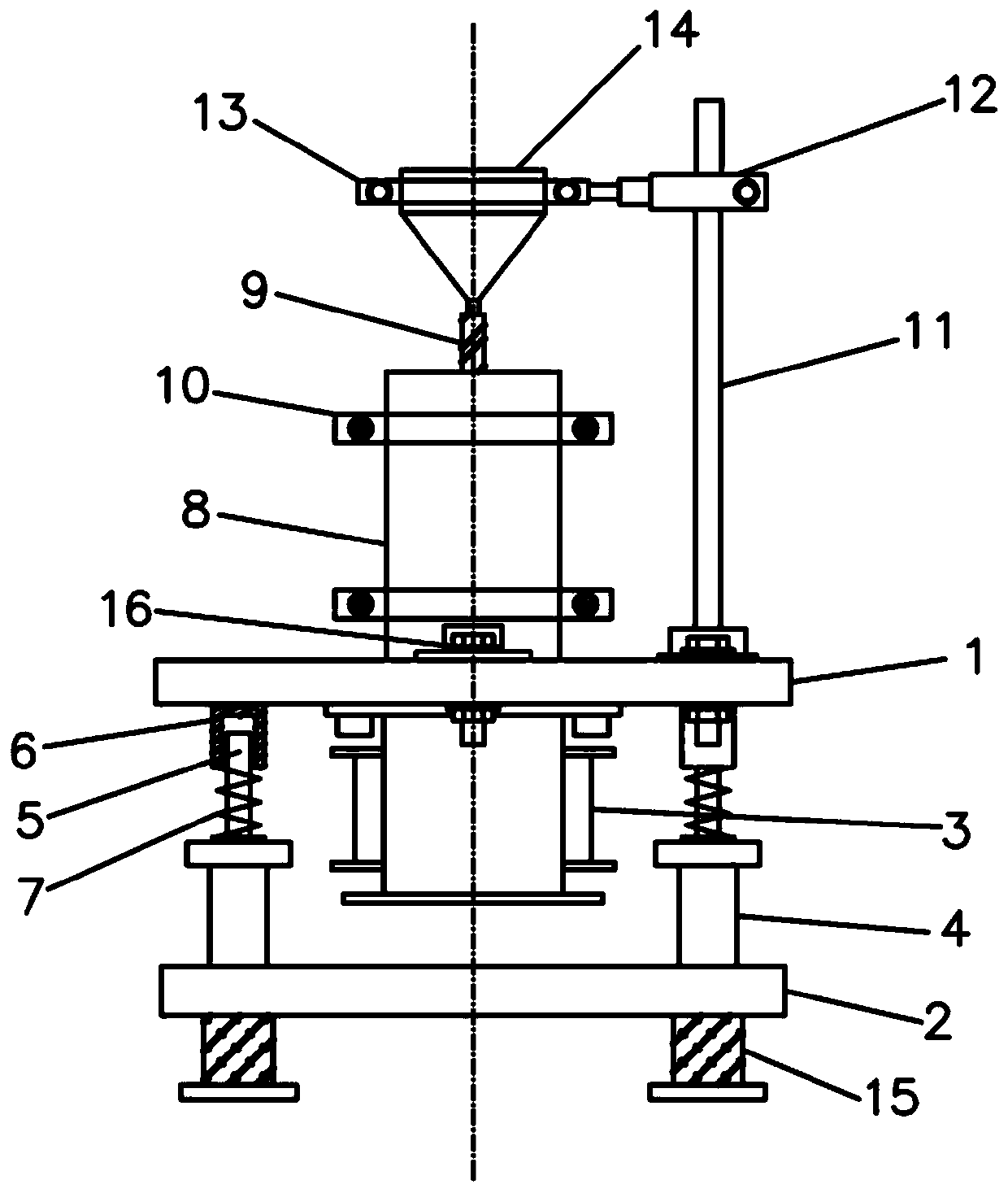

[0034] Embodiment 1 vibration charging device

[0035] Such as figure 1 A kind of specific embodiment of the shown vibrating charging device comprises: charging structure, comprises the pipe loading mold 8 of fixed charging pipe 9; The tube loading mold 8 is arranged on the vibrating platform 1 .

[0036] In the present invention, through the above arrangement, the vibration of the vibration motor 3 drives the vibration platform 1 to vibrate, and the vibration of the vibration platform 1 drives the vibration of the charging pipe 9. The cooperation of the components of the above-mentioned device can effectively eliminate the internal friction between the powder particles force, increase the fluidity of the powder, remove the gas existing between the powders, realize powder compaction, and increase the packing density, thereby effectively reducing the holes and bulges inside the sintered iron-based superconducting wire strip and improving the performance of the iron-based super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com