A vibration damping and heat dissipation device for a rolling bearing

A technology of rolling bearings and heat sinks, applied in rolling contact bearings, ball bearings, bearing cooling and other directions, can solve the problems of vibration reduction and heat dissipation of rolling bearings, and achieve the effects of reducing vibration impact, prolonging service life and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

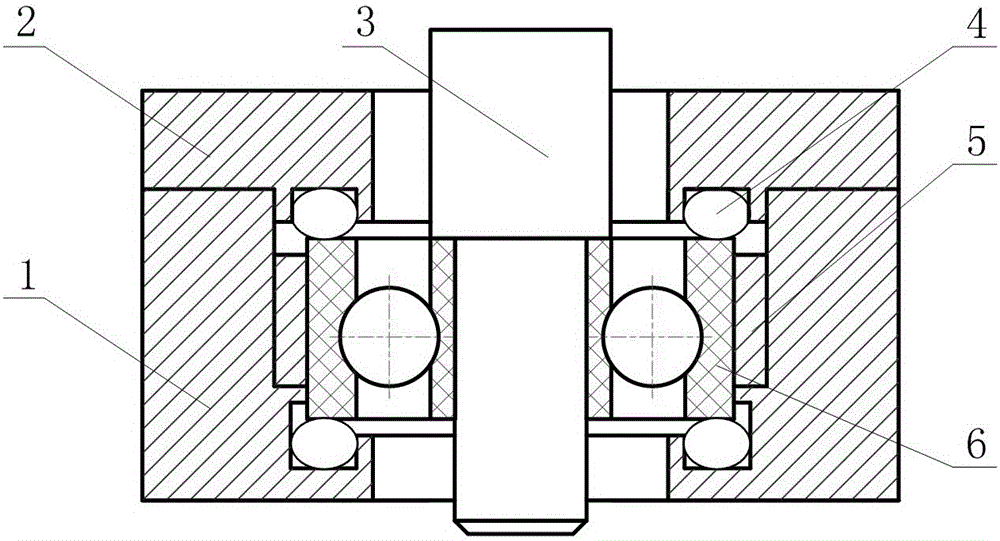

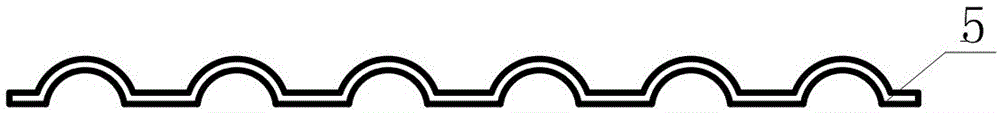

[0017] figure 1 It is a schematic diagram of the damping and heat dissipation device of the support bearing in the turbomolecular pump of the present invention, figure 2 for figure 1 Schematic diagram of the wave spring in .

[0018] exist figure 1 , 2 Among them, the heat dissipation and damping structure of the rolling bearing in the turbomolecular pump of the present invention includes a bearing housing 1, a bearing gland 2, a rotating shaft 3, a damping rubber ring 4, a wave spring 5, and a rolling bearing 6; its connection relationship is, A damping rubber ring 4 is embedded in the bearing housing 1 and the bearing gland 2; the rolling bearing 6 is installed on the rotating shaft 3, and the rotating shaft 3 is supported in the bearing housing 1 through the rolling bearing 6; There is a wave spring 5, and the upper and lower end surfaces of the rolling bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com