Large crankshaft follow-up grinding machine

A crankshaft and large-scale technology, which is applied in the field of grinding machines for large-scale crankshaft grinding, can solve the problems of not being able to meet the requirements of large-scale crankshaft grinding and overall rigidity requirements, and achieve the guarantee of grinding precision, self-precision, and strong bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

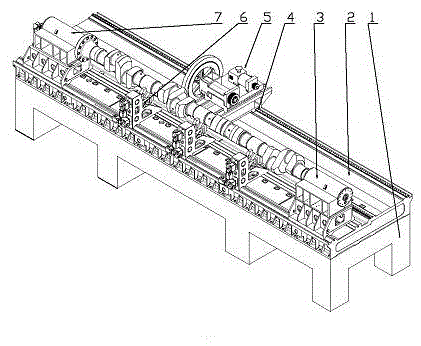

[0029] exist figure 1 In the shown large crankshaft follow-up grinding machine, the bed 2 is supported on the bed base 1, and the bed 2 supports a headstock 7 and a tailstock 3 for clamping a large crankshaft to be ground and a support for a large crankshaft. Three groups of center frames 6, three groups of center frames 6 are located between the head frame 7 and the tail frame 3, and the bed frame 2 is also supported with a grinding wheel frame 5 by two linear guide rail pairs 4.

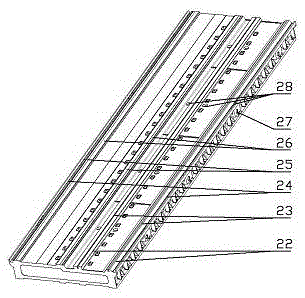

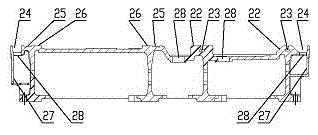

[0030] Such as figure 2 and image 3 As shown, the shape of the bed 2 is cuboid, and its cross-section is frame-shaped. Two reinforcing ribs are arranged in the frame-shaped middle part of the cross-section of the bed 2, and the two reinforcing ribs run through and are arranged in the length direction of the bed 2. 2 Both sides are respectively provided with a number of bolt holes for installation and fixing, which are used for fixed connection with the bed base 1, and head and tail frame suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com