Patents

Literature

86results about How to "Smooth torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

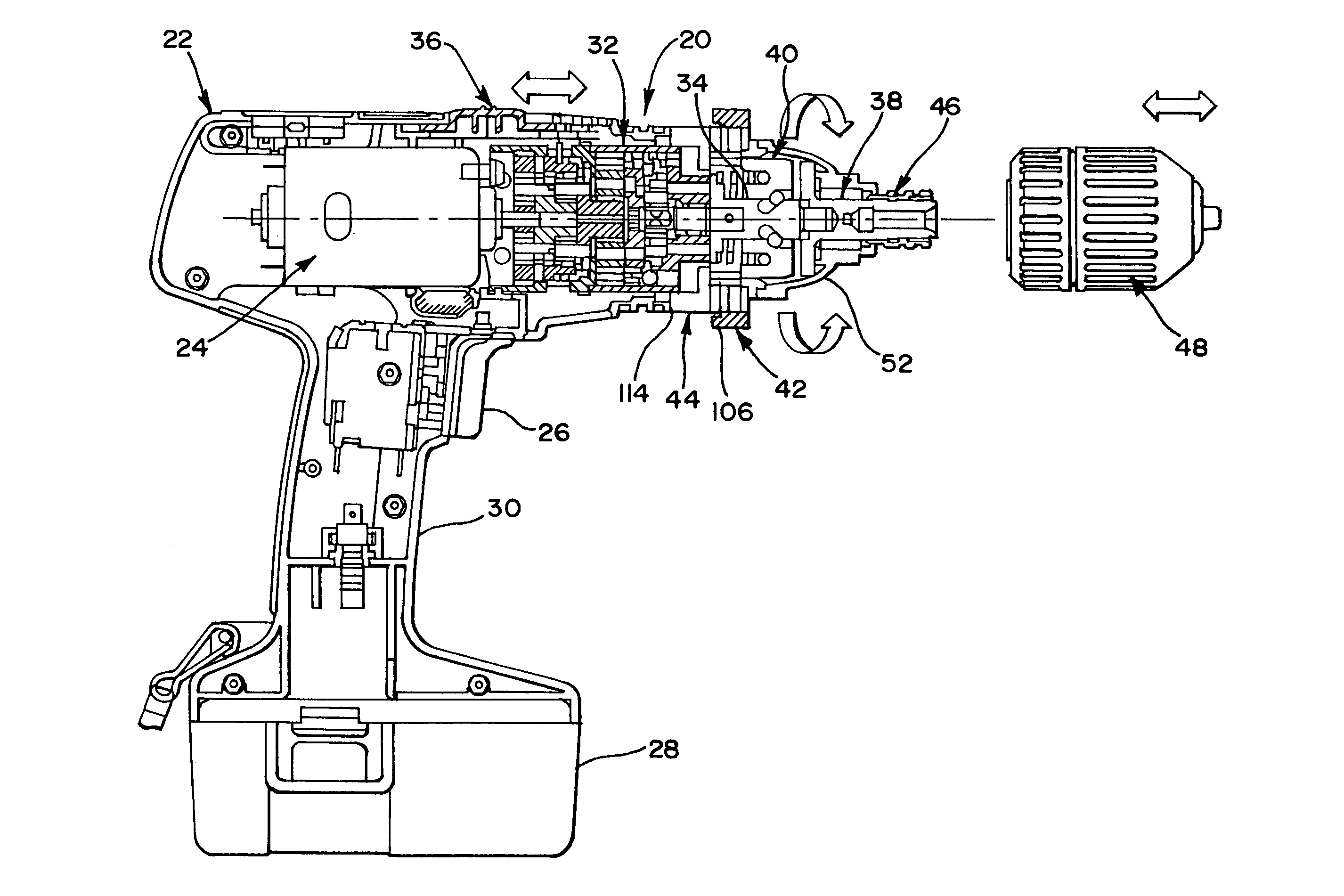

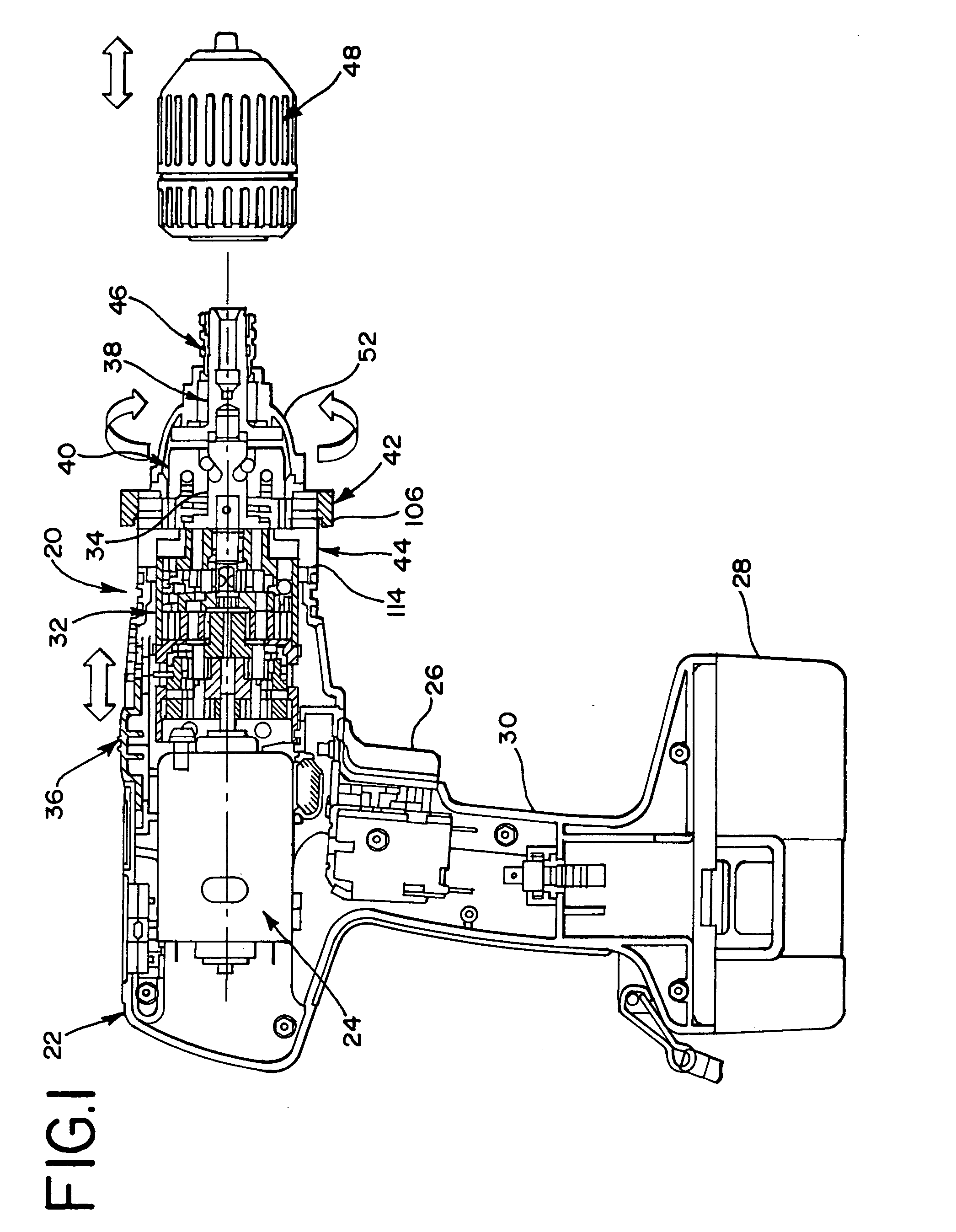

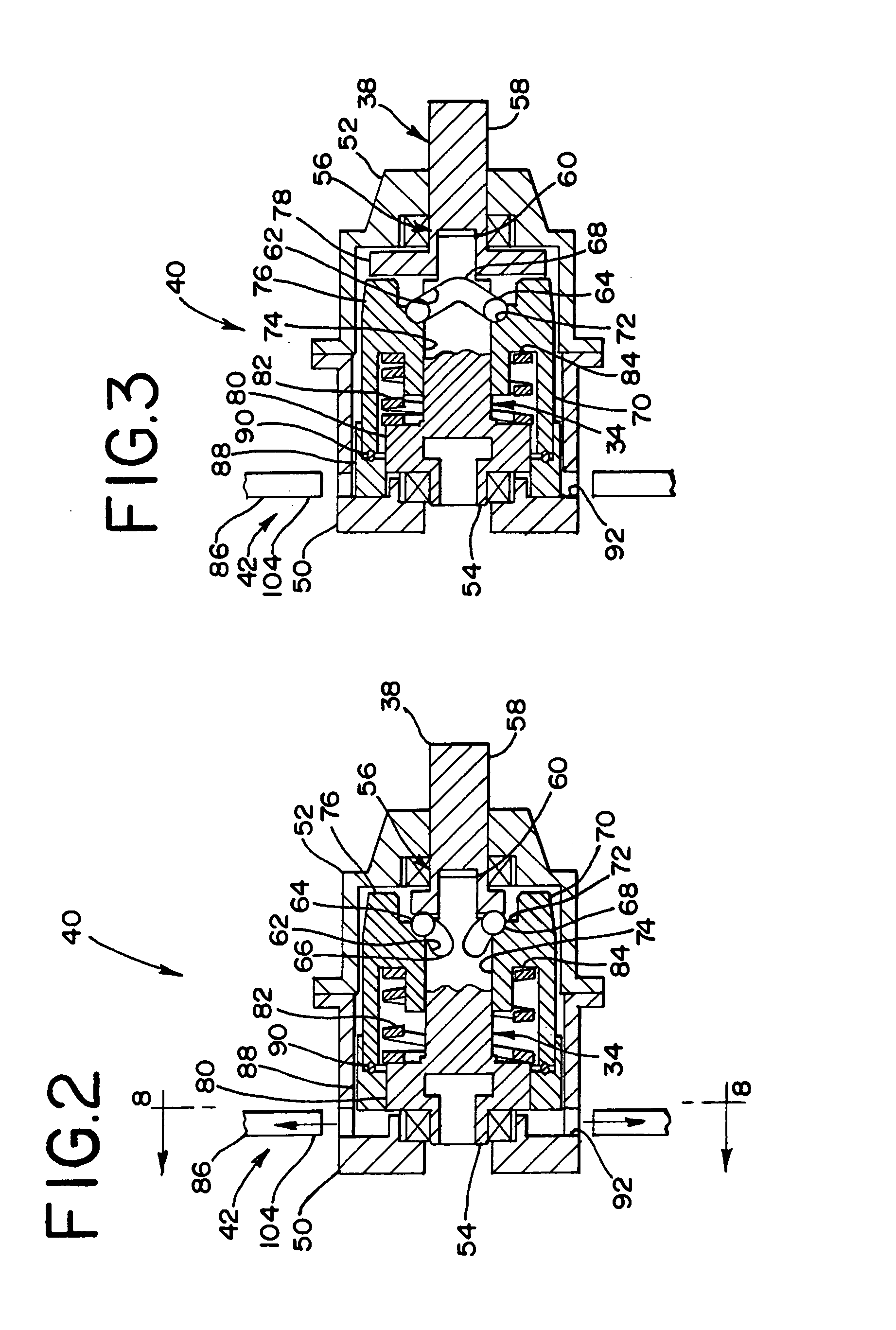

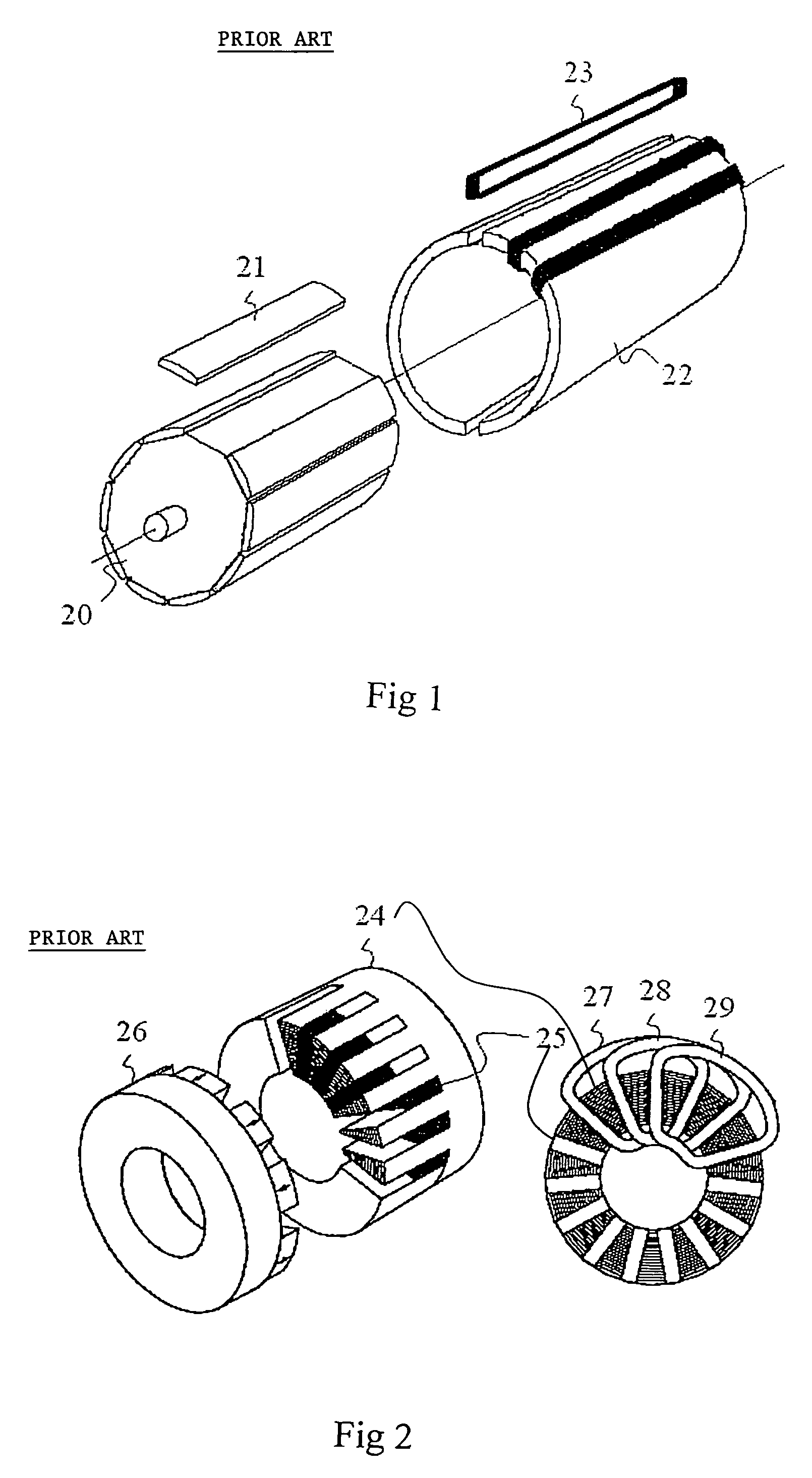

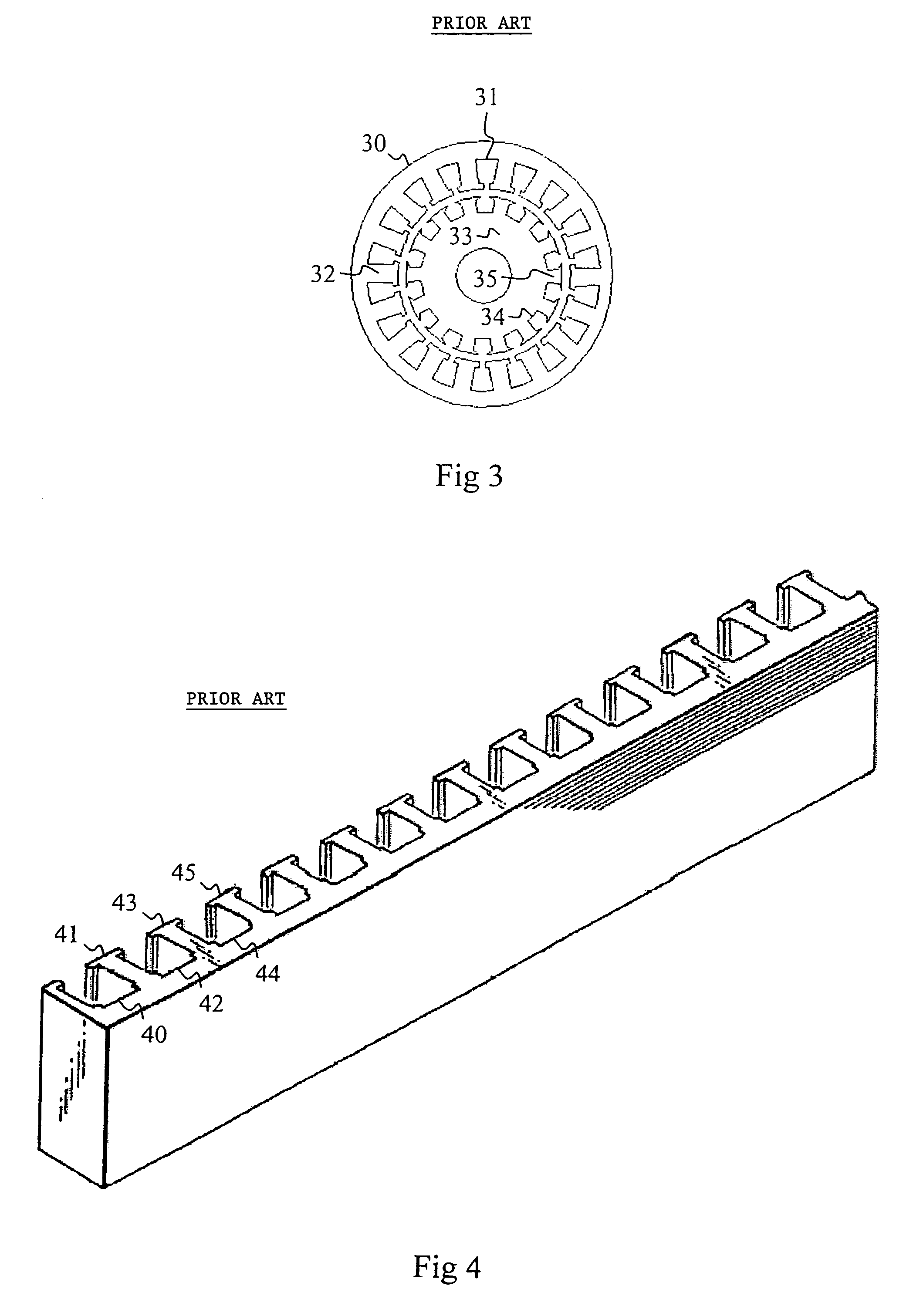

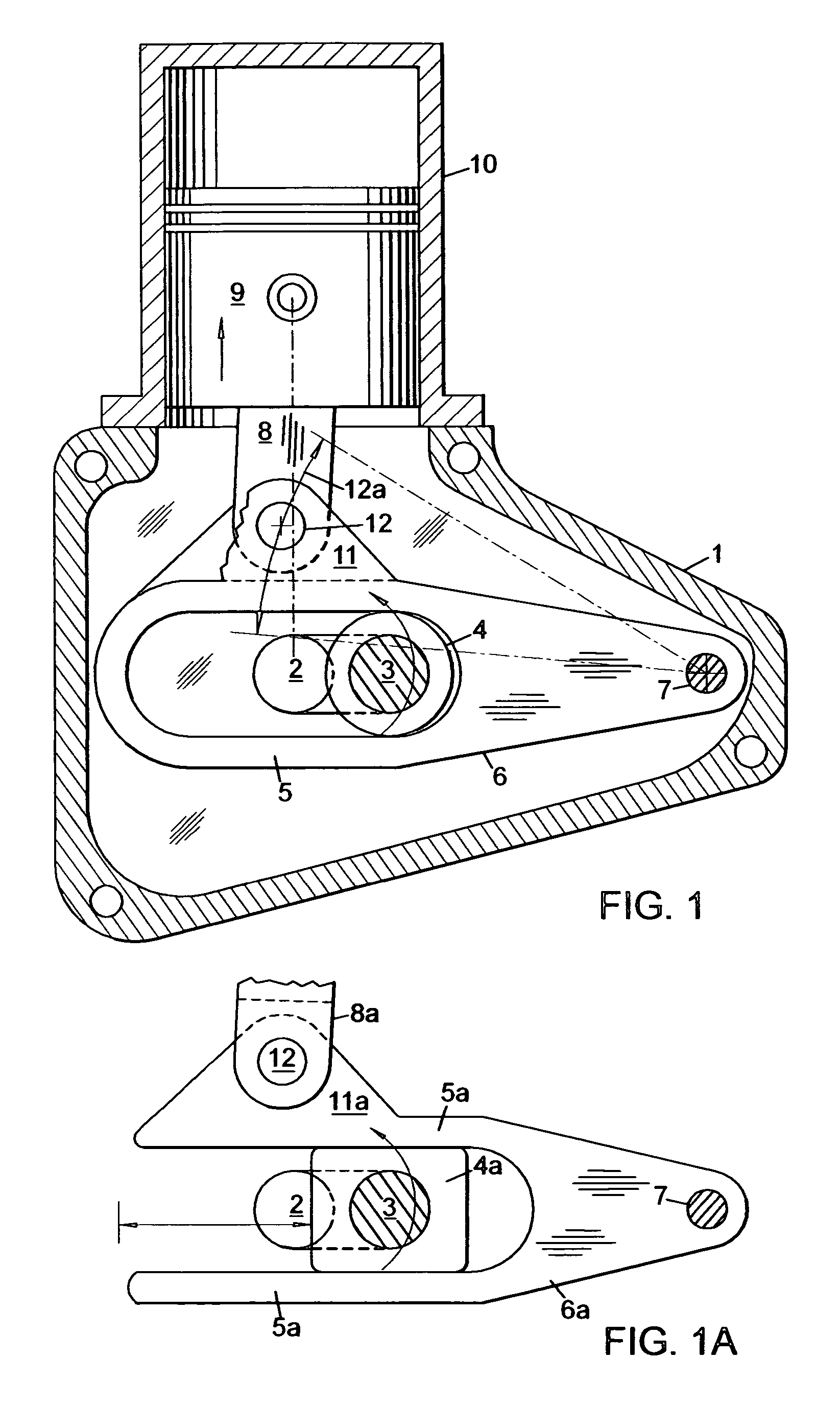

Mode selector mechanism for an impact driver

InactiveUS20060237205A1Improve carrying capacitySmooth torqueDrilling rodsWrenchesPower toolEngineering

A mode selector mechanism is provided for a rotary power tool for selecting between an impact mode and a drill mode. The power tool includes a housing, a motor oriented in the housing, an input shaft and an output shaft both rotationally mounted in the housing. An impact mechanism connects the input shaft to the output shaft for imparting a rotary impact to the output shaft when the torque load exceeds a predetermined torque capacity of the impact mechanism. A stopping member is shiftable by a user between a first orientation that permits the impact mechanism to operate in the impact mode and a second orientation that prevents a coupler of the impact mechanism from retracting, thus maintaining the connection of the input shaft and the output shaft in the drill mode.

Owner:EASTWAY FAIR

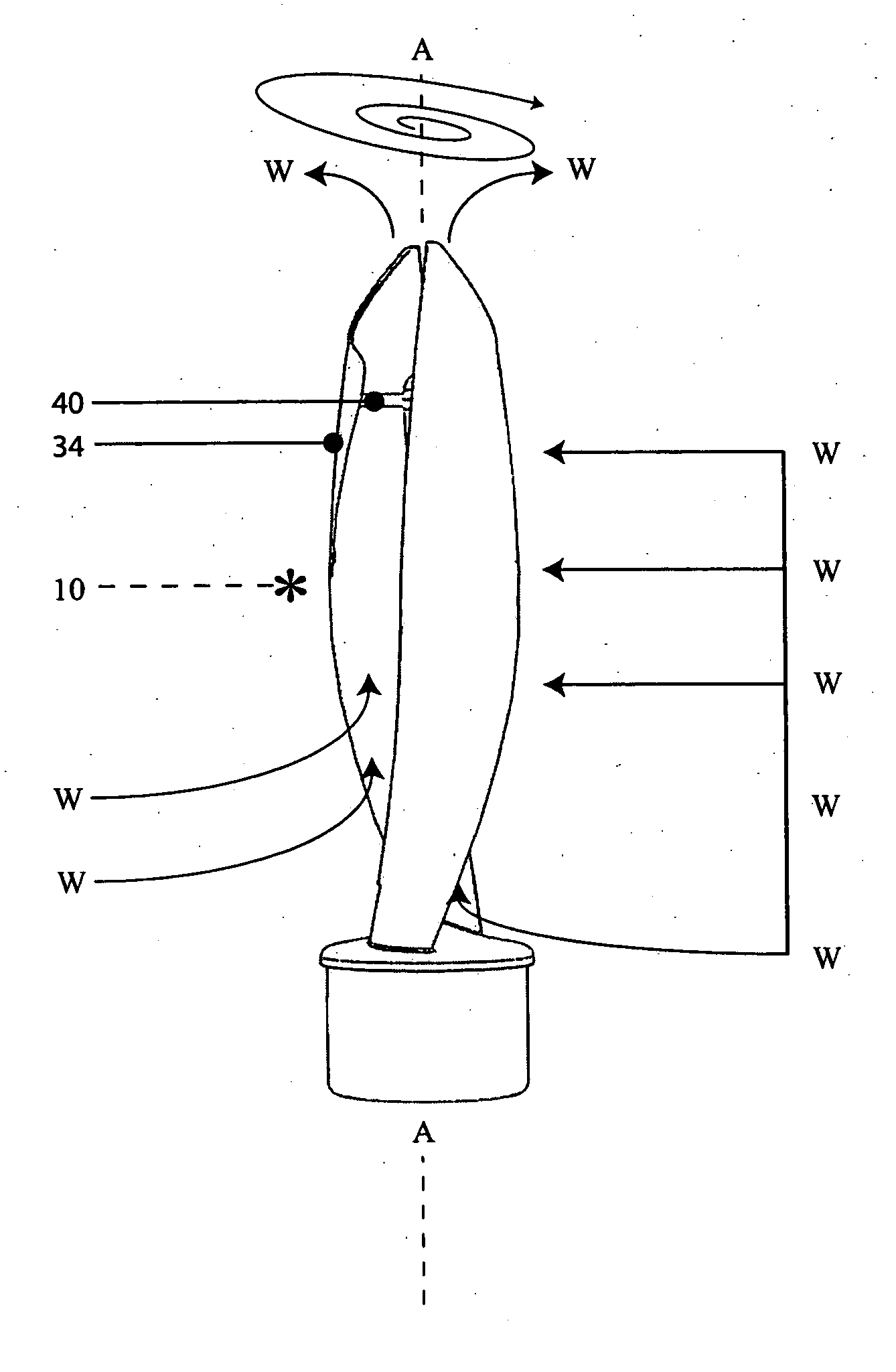

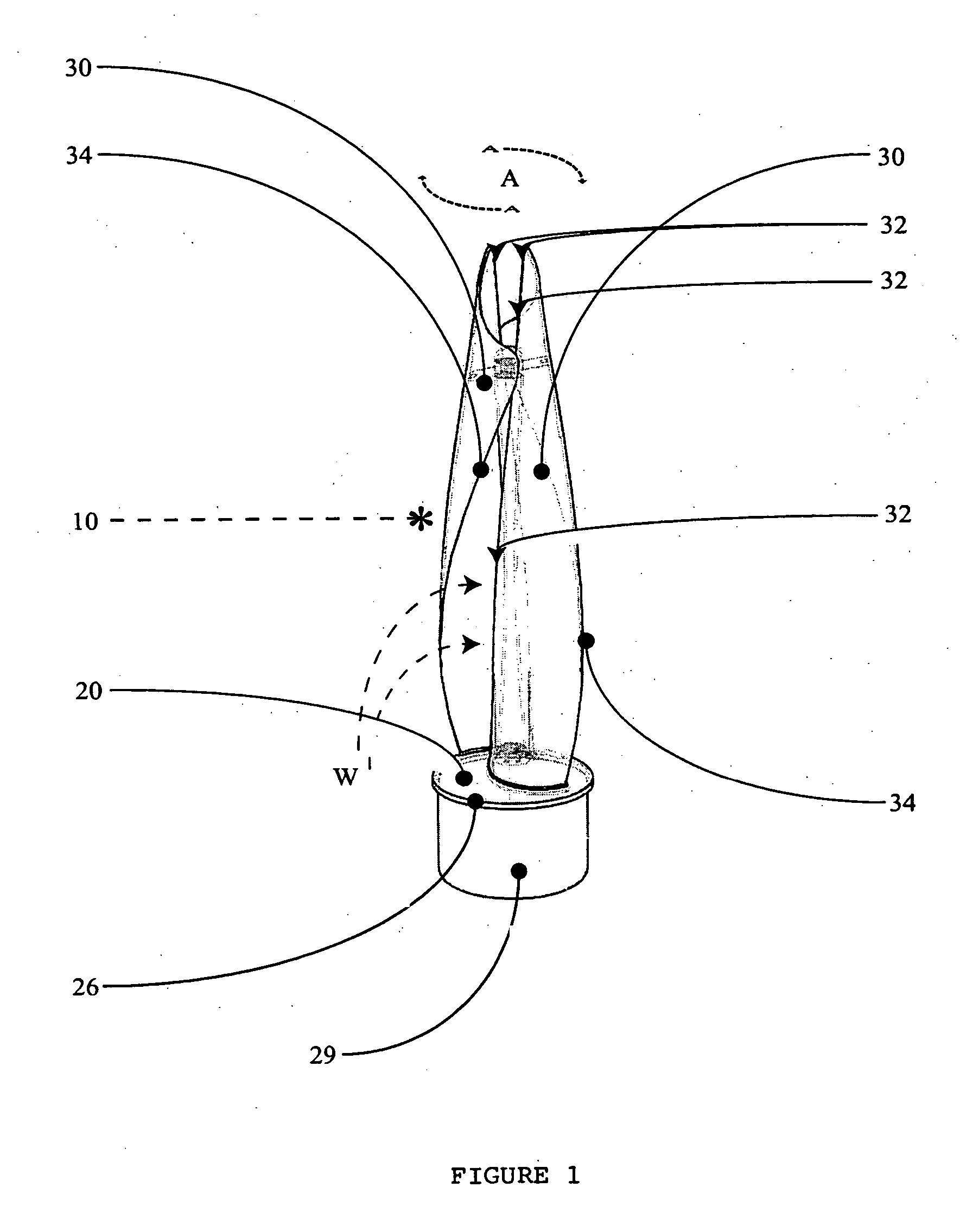

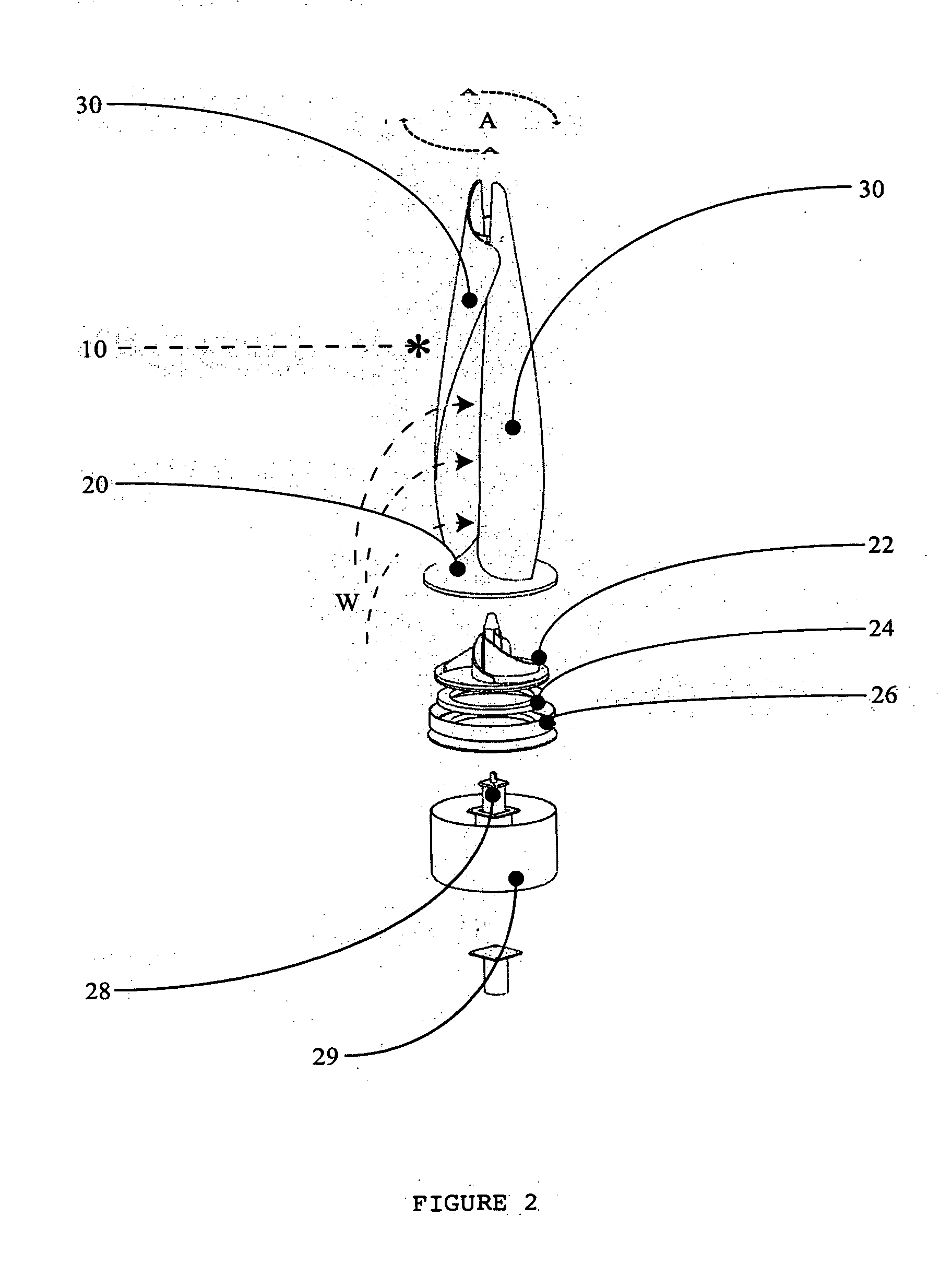

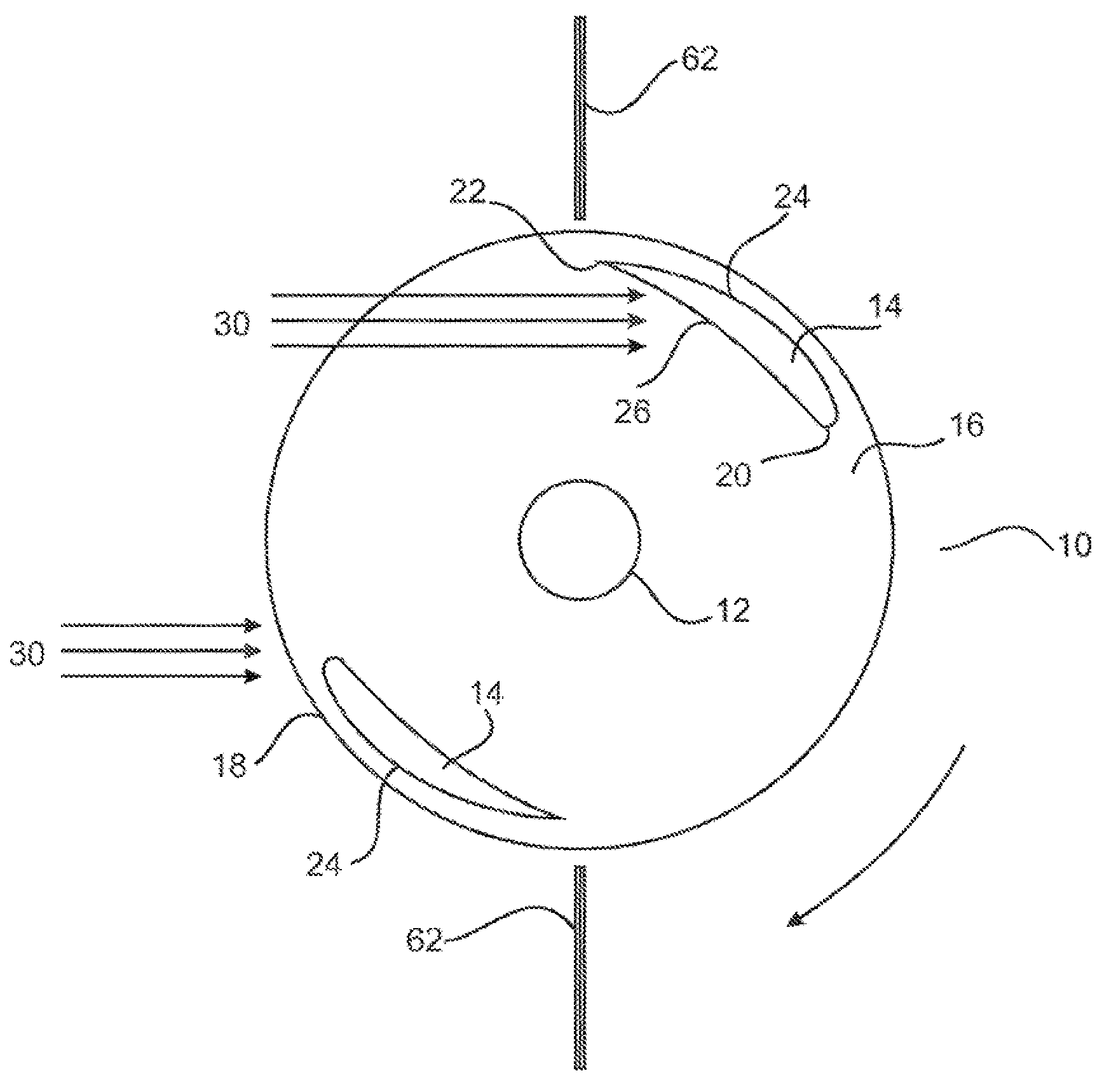

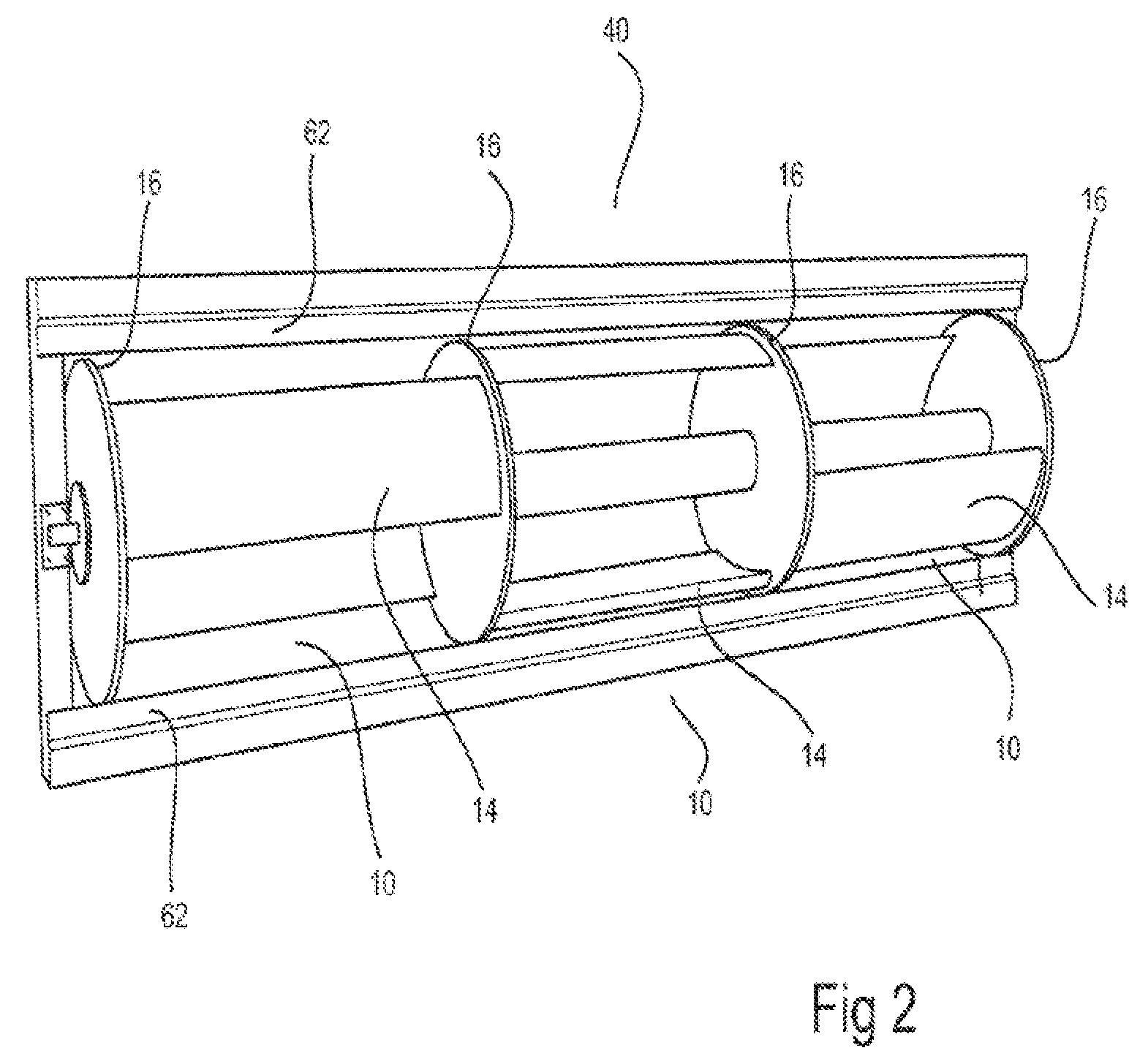

Helical taper induced vortical flow turbine

ActiveUS20070258806A1Harvest energyLow air pressurePump componentsWind motor controlAirflowElectric generator

Owner:HART JAMES R

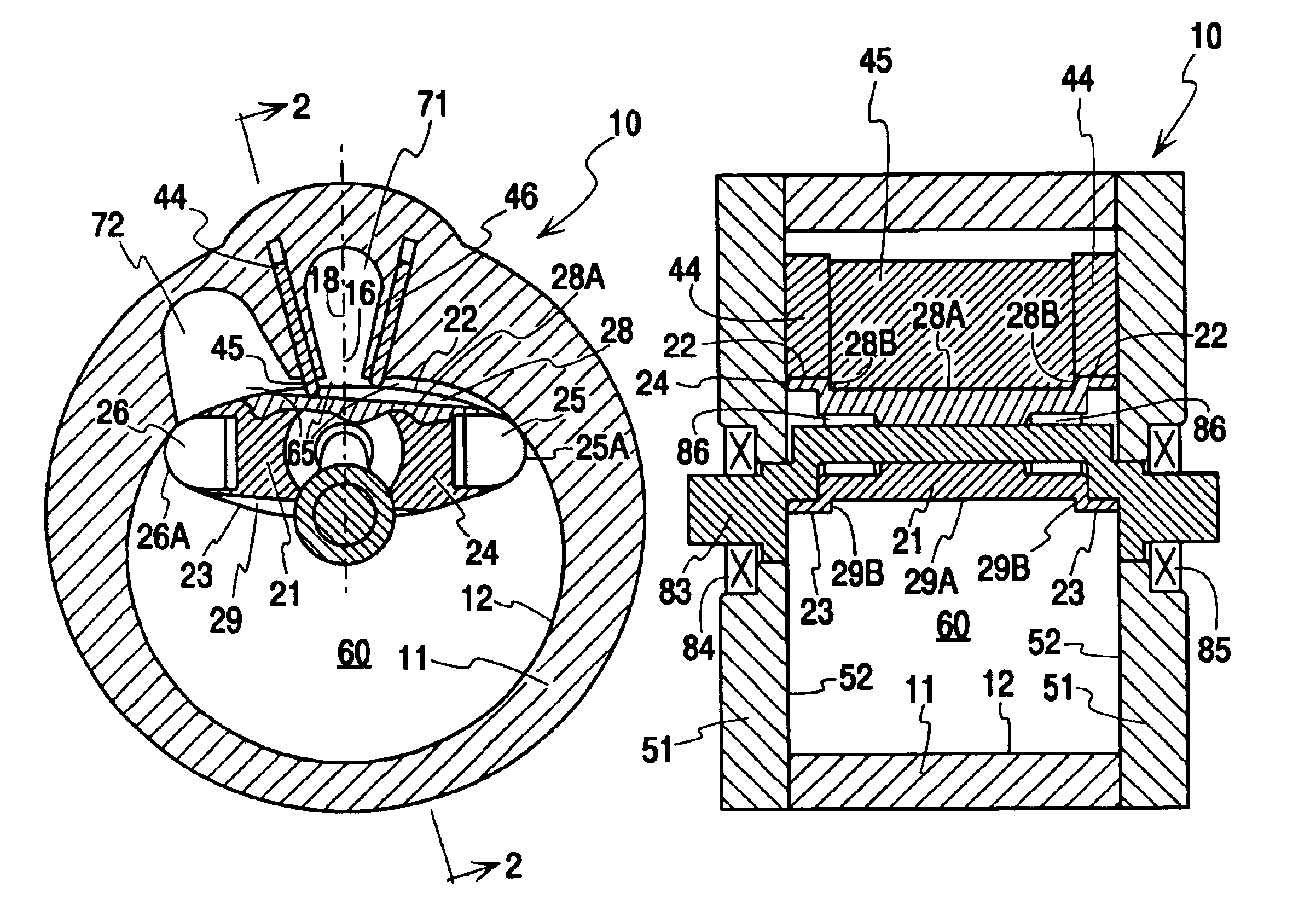

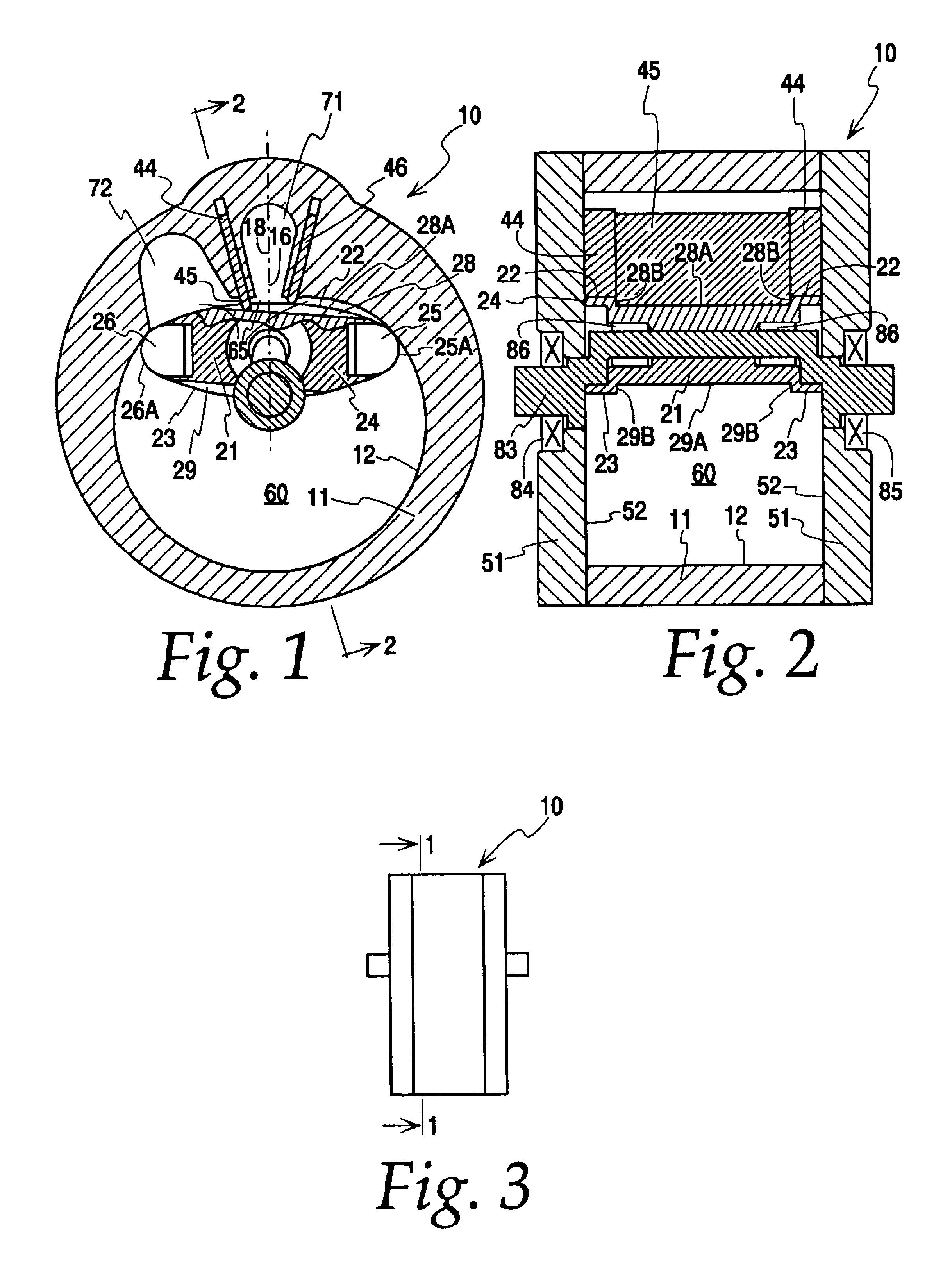

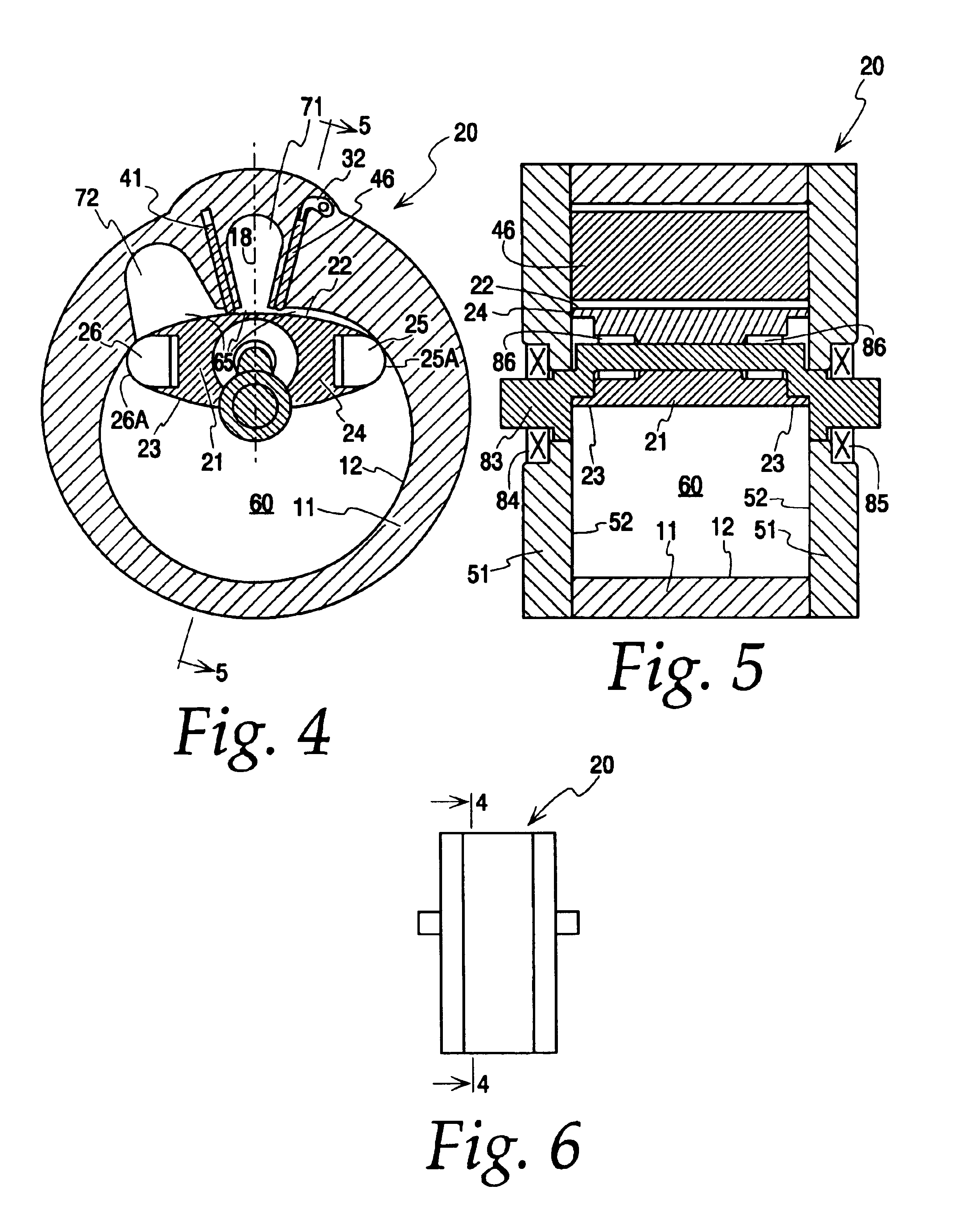

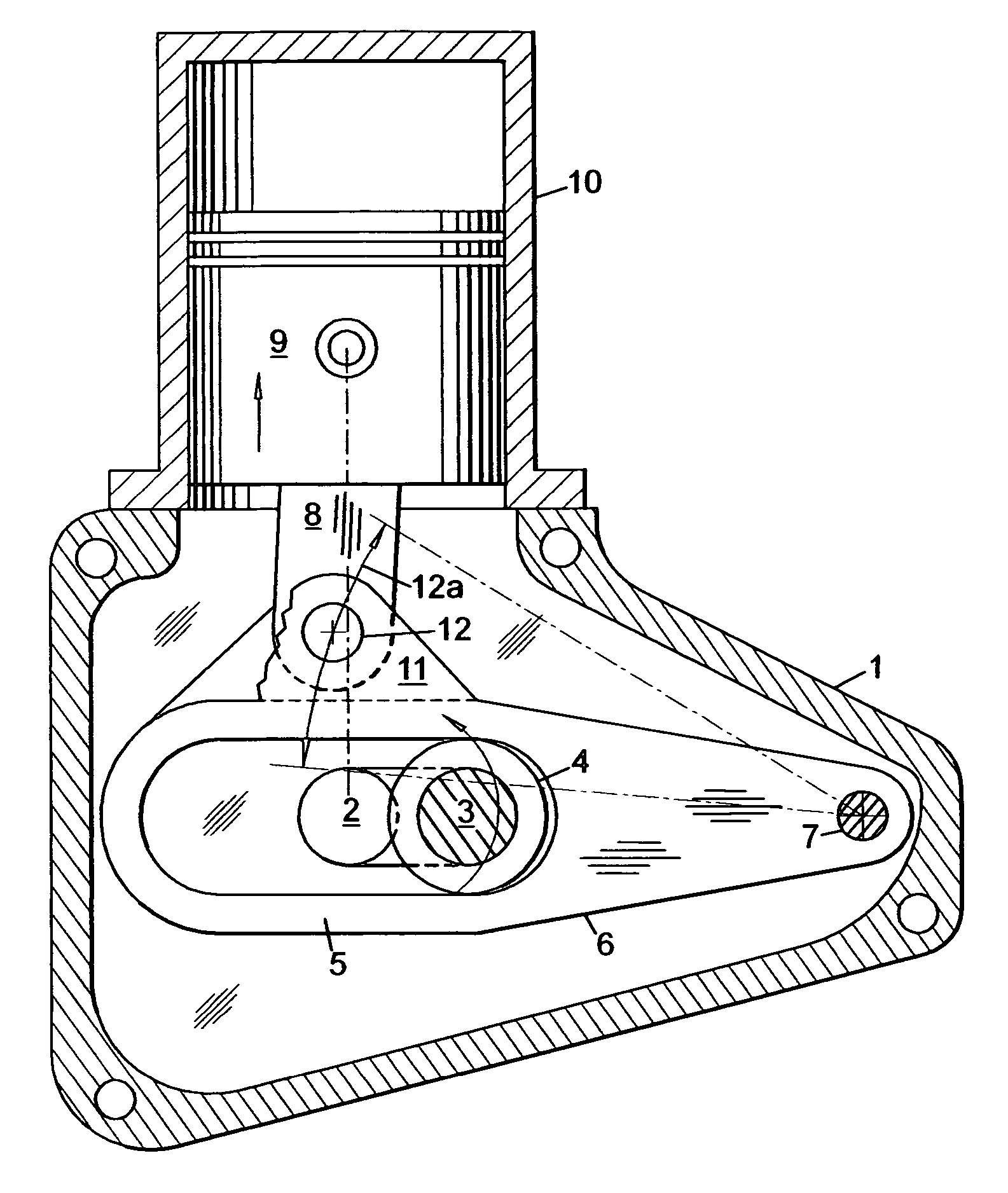

Rotary machine housing with radially mounted sliding vanes

InactiveUS6926505B2InhibitionLower the volumeCooking-vessel materialsEngine of arcuate-engagement typeMechanical engineeringRotary machine

Two or more slidably mounted seals of radially orientation are provided in a rotary machine. One of the slidably mounted seals can be selectably retractable to perform a valving operation with respect to a rotor mounted for eccentric rotary motion within the machine.

Owner:SBAROUNIS JOASEPH A

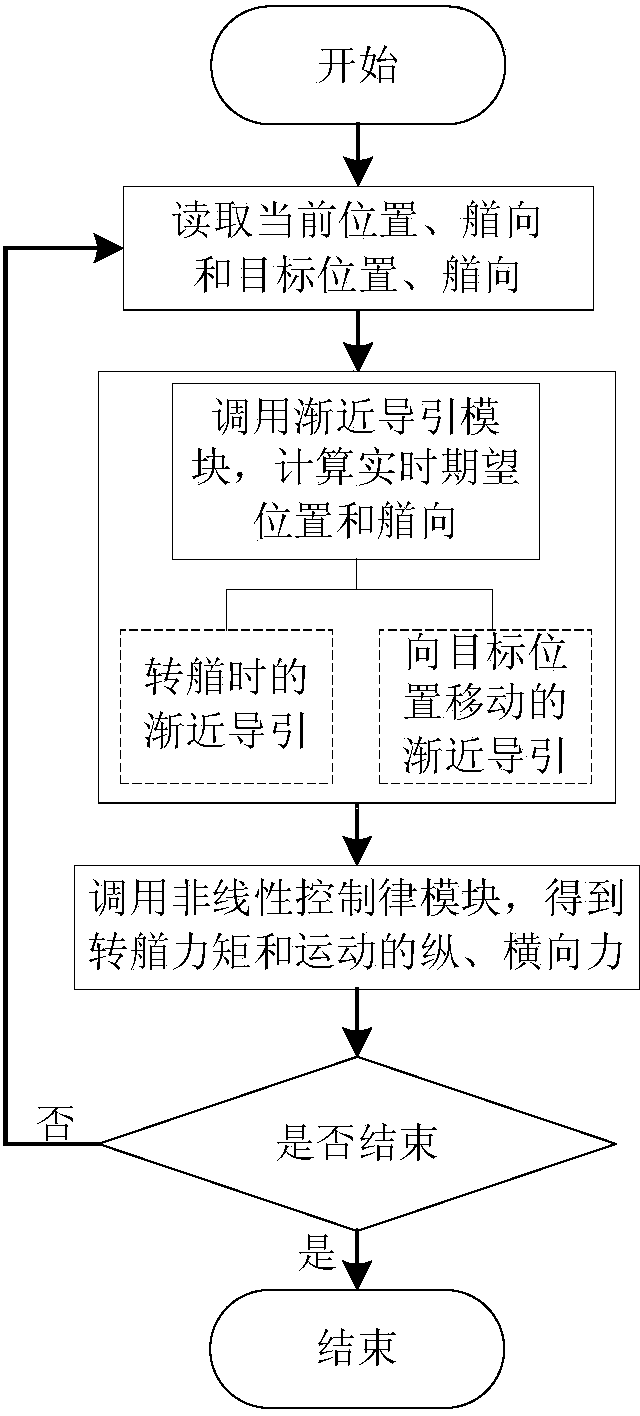

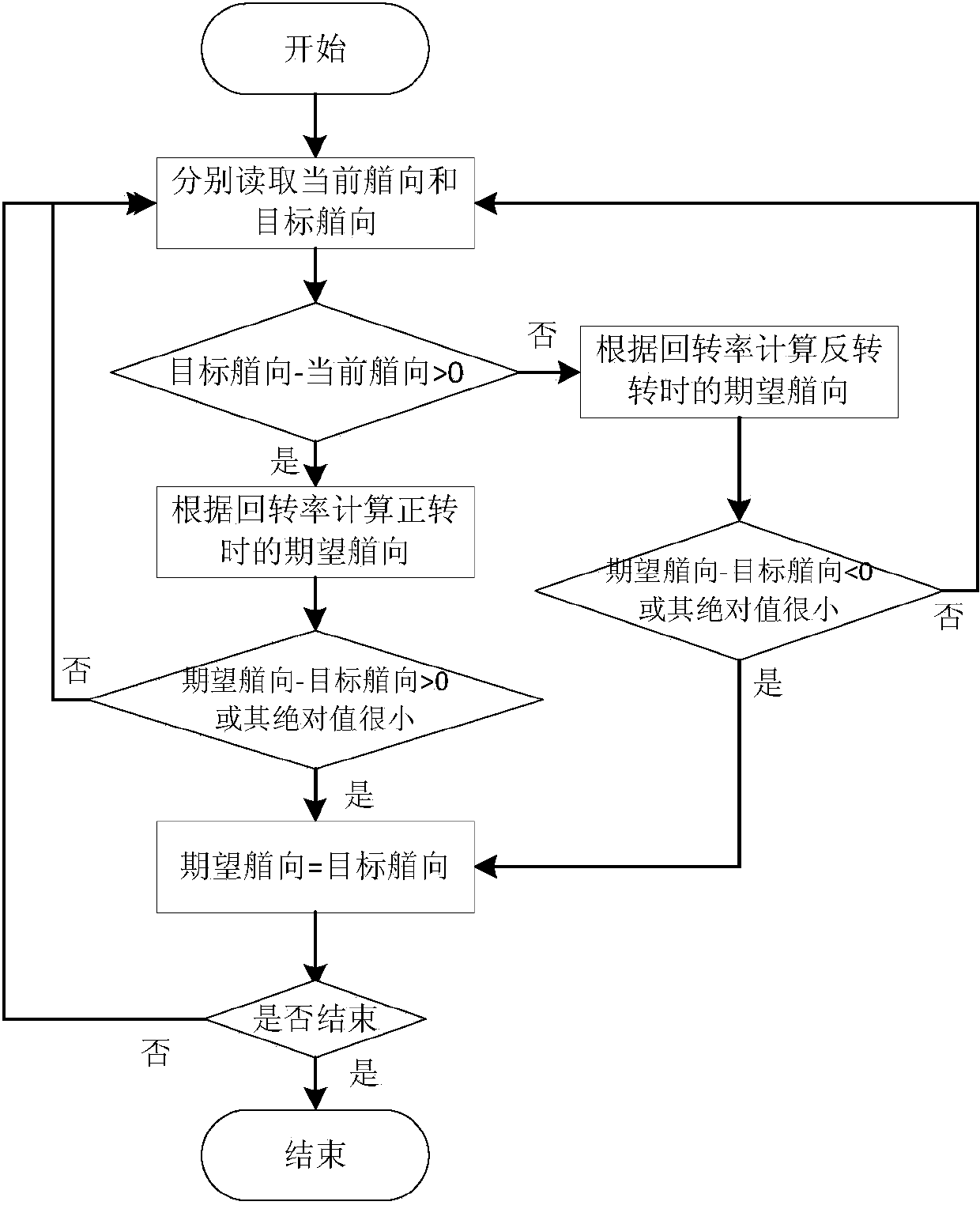

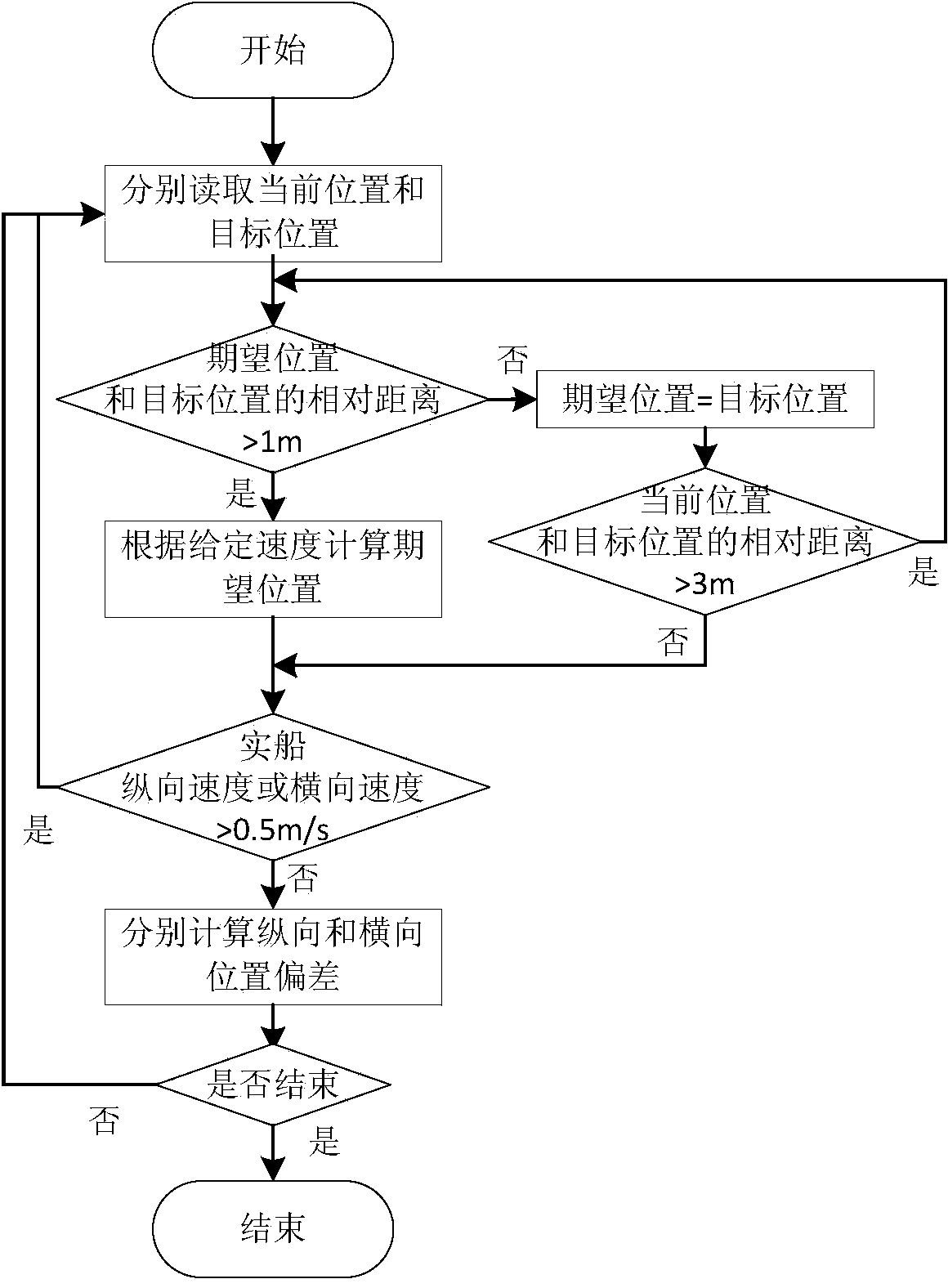

Ship positioning control method based on progressive guidance

ActiveCN103529842ASmooth torqueNo oscillationPosition/course control in two dimensionsPropellerDynamic positioning

The invention belongs to the field of dynamic positioning ship control and particularly relates to a ship positioning control method based on progressive guidance. The ship positioning control method comprises the following steps: (1) determining the target heading and the target position of a ship; (2) calculating real-time expected positions and the heading; (3) calculating required longitudinal force, lateral force, moment required during bow rotating, a north position deflection, an east position deflection and a bow direction deflection according to the current north position, the current east position, the current heading, a target north position, a target east position, a target heading, the longitudinal instantaneous speed of the ship, the lateral instantaneous speed of the ship, clockwise rotating rate, and longitudinal force, lateral force and moment which are generated by ambient disturbance. The positioning control method is designed based on progressive guidance and control. The moment and thrust which are obtained by the method gradually vary and can be ensured within the limit range of a propeller, so that the ship can stably arrive in the target position without oscillation, and the positioning precision is higher.

Owner:HARBIN ENG UNIV

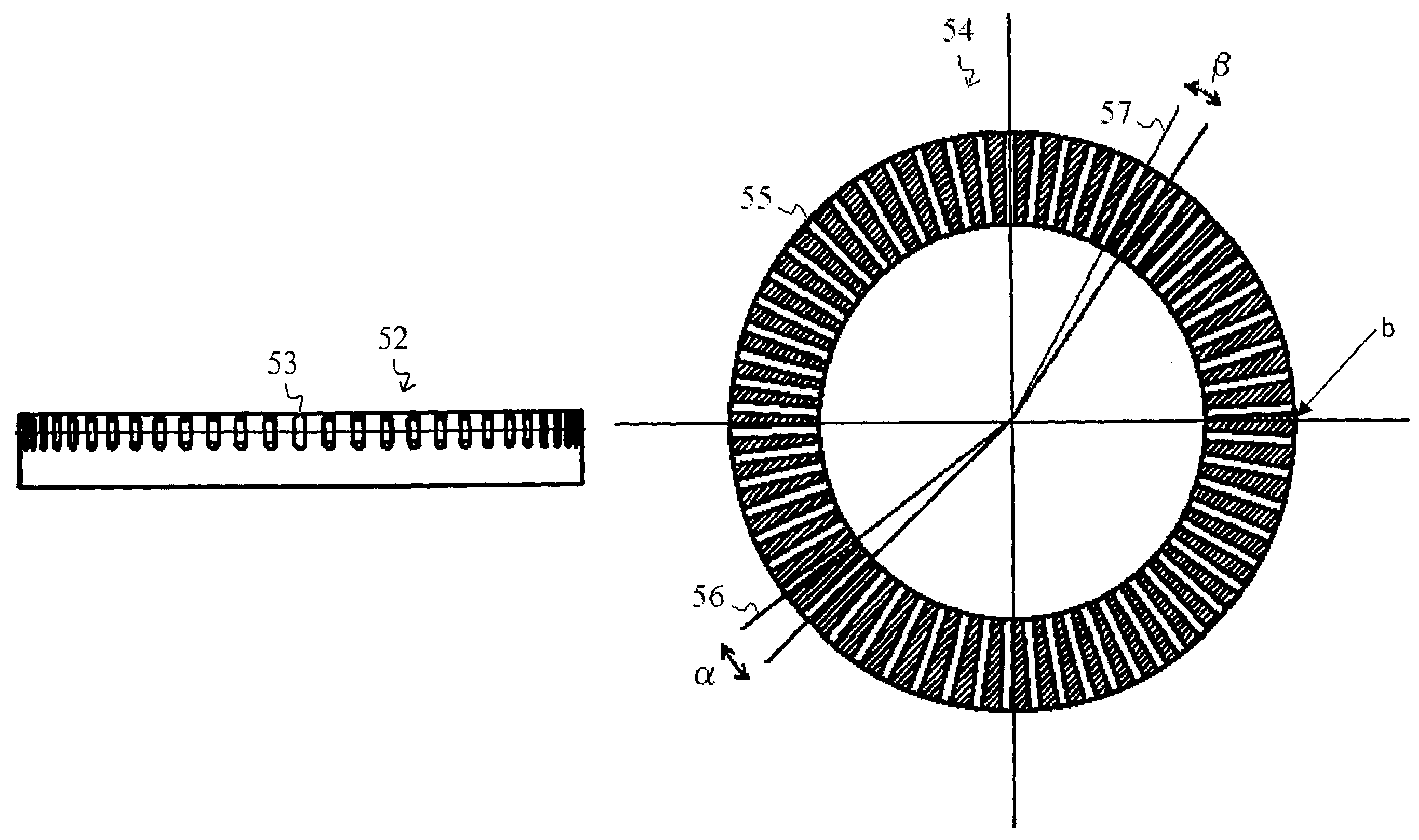

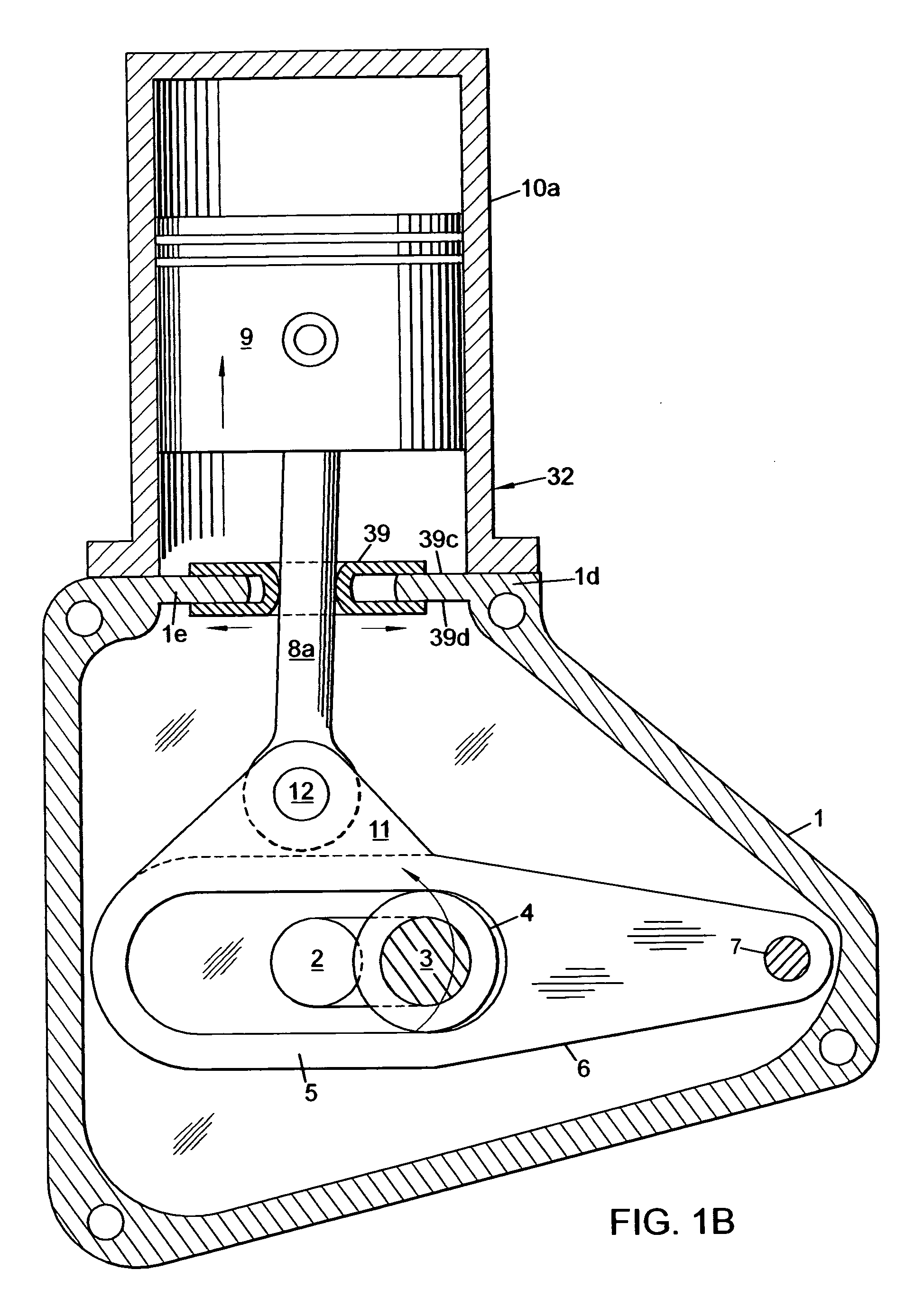

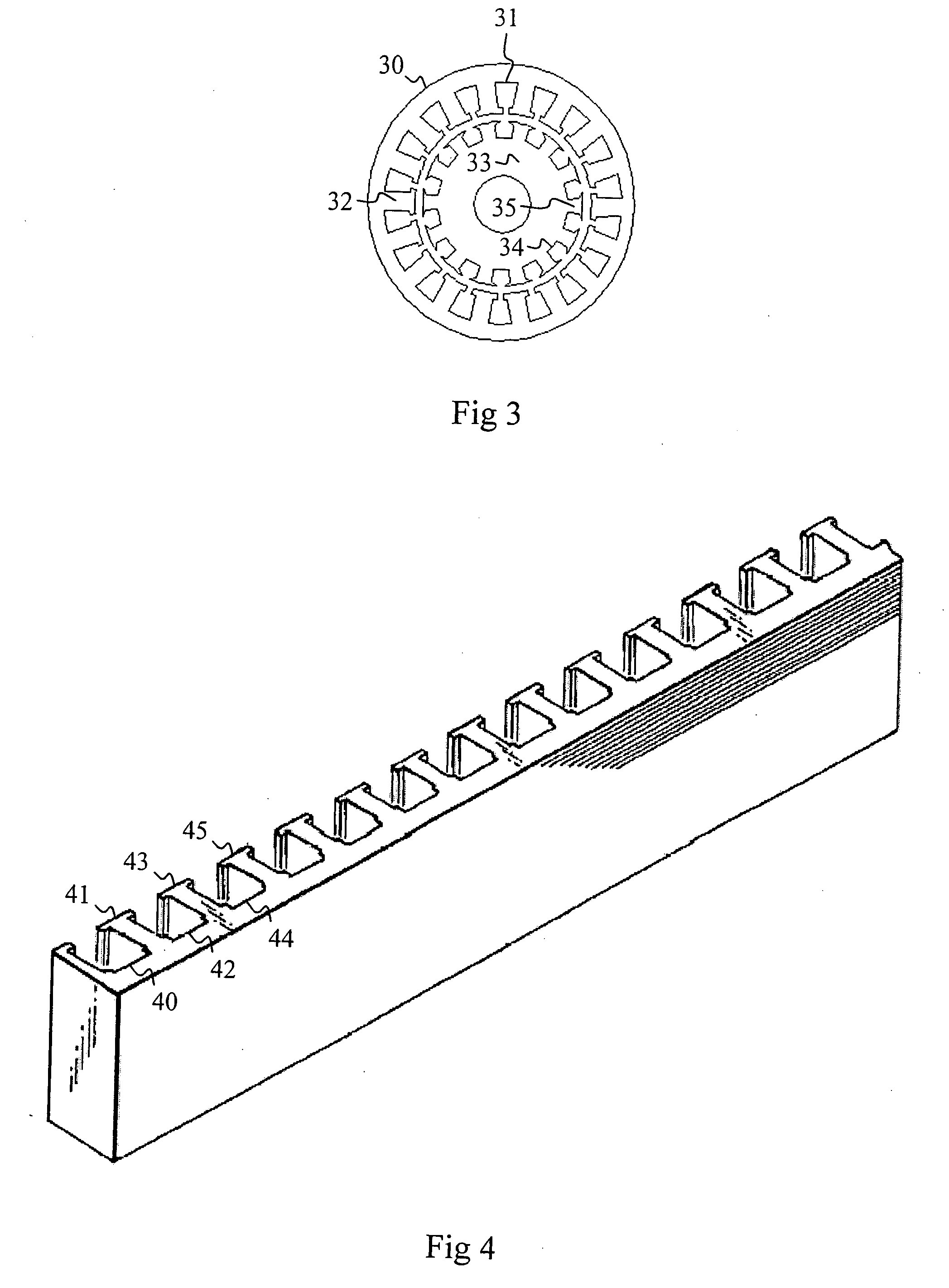

Reduction of harmonics in an electric motor

ActiveUS7675213B2Reduce noiseReduce vibrationMagnetic circuit rotating partsMagnetic circuit stationary partsHarmonicConductor Coil

In the present invention the positions of the slots or poles of the stator of an electric motor are changed in order to reduce the harmonics caused by the stator winding and any vibration caused by these harmonics. In the present invention a shape function is defined according to the new placement positions for the stator slots and / or stator poles. A conversion function sums for the slot placement positions to be given to equidistant stator slotting placement. In one embodiment of the invention the conversion function is the sum of sinusoidal functions and in its amplitude small in relation to the distance between the slots.

Owner:KONE CORP

Efficiencies for piston engines or machines

ActiveUS20070056552A1Eliminating shaft counter weightExcessive vibrationConnecting rodsPositive displacement pump componentsCost effectivenessSingle plate

Disclosed are crankshaft, single-plate cam and beam mechanisms that provide significant improvements in performance for 2 & 4-stroke engines, compressors and pumps. These cost effective mechanisms include linkages with the new and improved use of pivoting arms that operate with a variety of cylinder arrangements. One embodiment of the crankshaft mechanism has its crankpin roller positioned within a novel yoke-arm. The cam mechanism uses a pair of centrally positioned parallel links that are connected to roller cam followers and single or diametrically-opposed pistons. A pair of laterally extending follower arms connects to the ends of the links to provide support and alignment for the piston rods. Between the reciprocating links, cam followers and follower arms is a rotating odd-lobe plate cam. A beam mechanism uses opposite-direction extending balancing beams that are connected to links, cam followers and piston rods.

Owner:FISHER PATRICK T

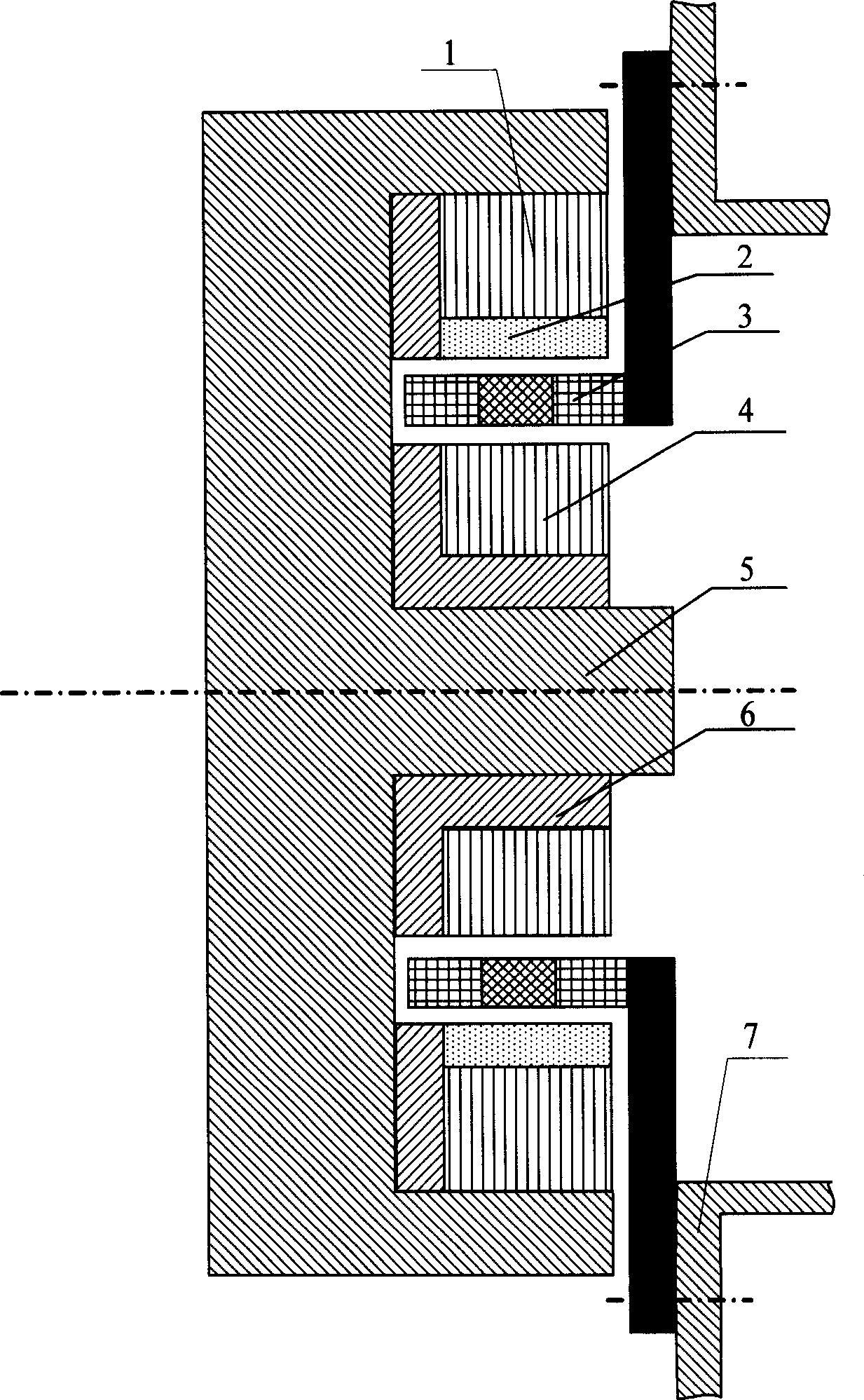

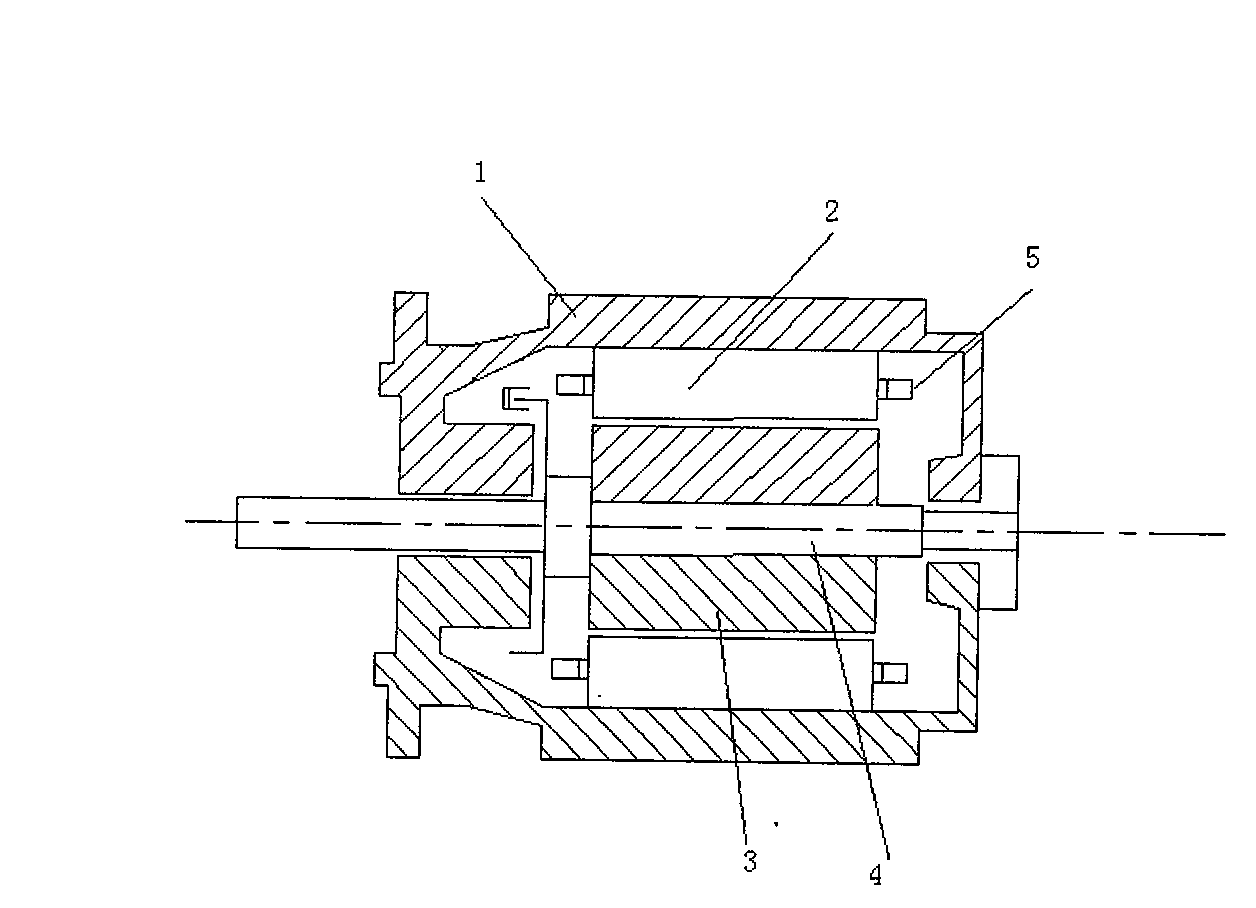

Non-stator iron core brushless DC motor

The brush-less DC motor without stator iron core includes mainly outer rotor iron core, hollow cup stator, permanent magnet, inner rotor iron core and rotor shaft. Both the outer rotor iron core and the inner rotor iron core are connected to the rotor shaft for synchronous rotation; the permanent magnet is installed onto the outer rotor iron core or the inner rotor iron core; and the hollow cup stator is fixed to the casing. The permanent magnetic path is one closed loop comprising the outer rotor iron core, the inner rotor iron core and the air gap in between. Unlike traditional brush-less DC motor, the present invention has no stator iron core and rotor iron core divided into two parts including the outer rotor iron core and the inner rotor iron core, and has no stator iron loss radically and lowered total motor loss.

Owner:BEIHANG UNIV

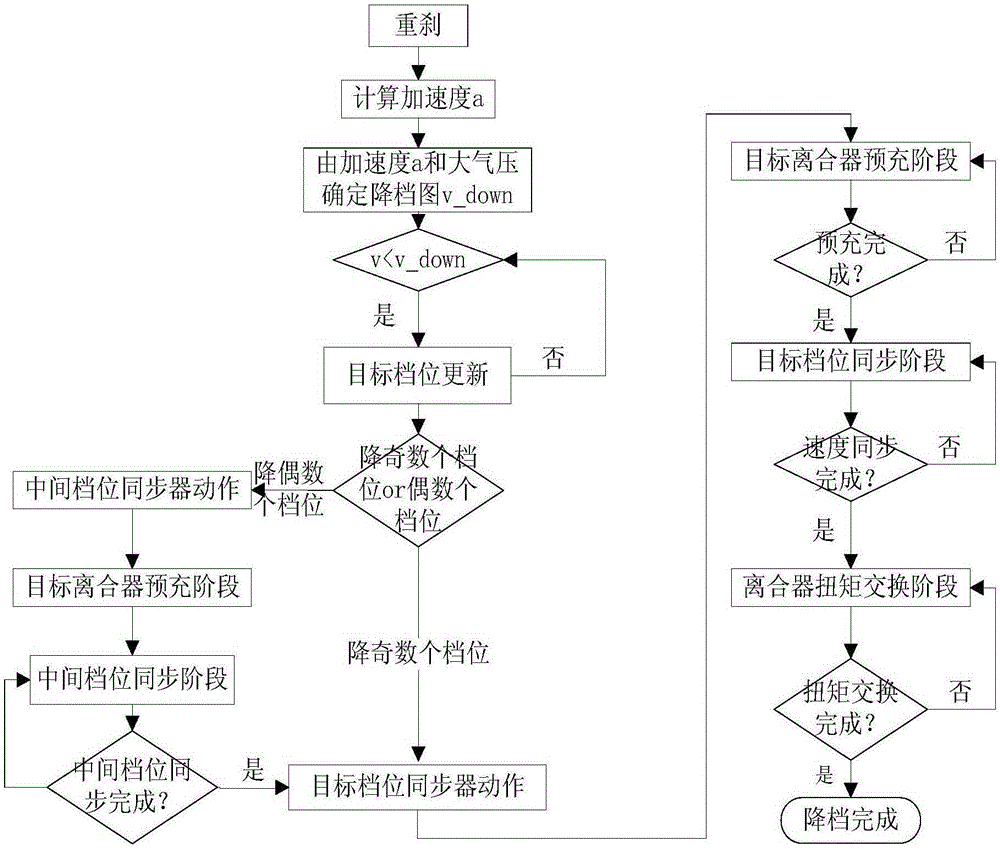

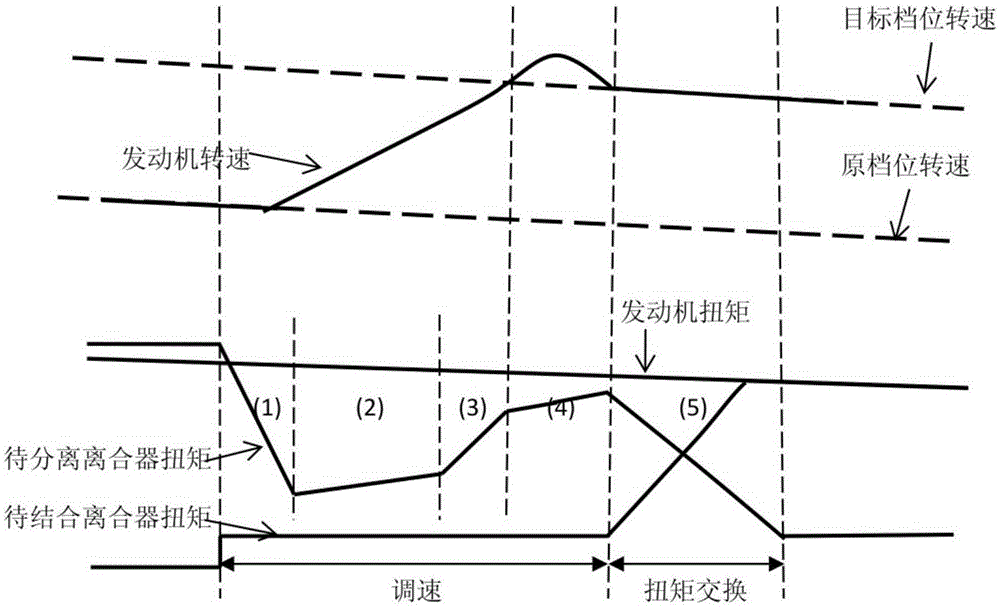

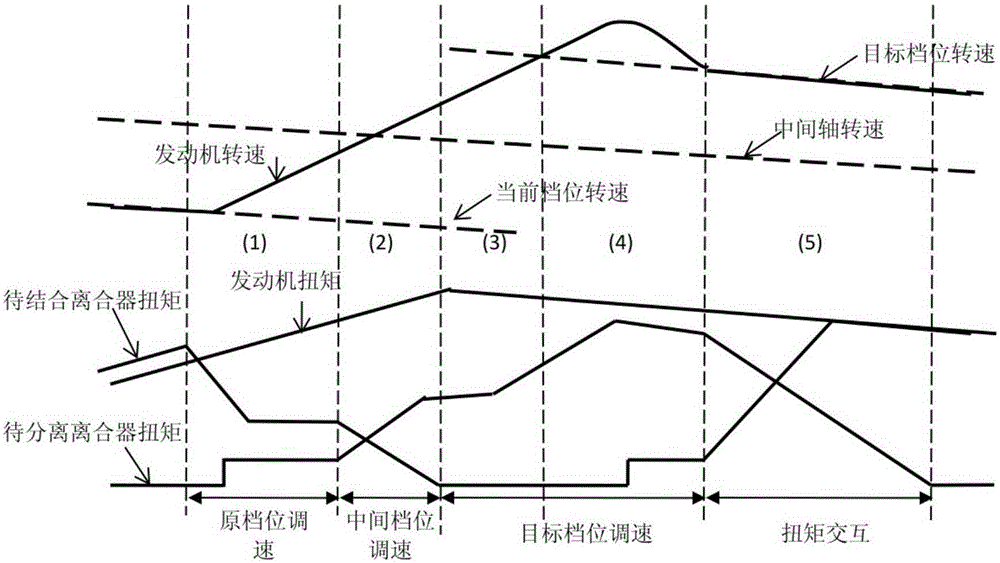

Braking downshifting control method for automatic six-speed wet type double-clutch transmission

ActiveCN105179676AIn line with actual intentSmooth torqueGearing controlAutomatic transmissionEngineering

The invention discloses a braking downshifting control method for an automatic six-speed wet type double-clutch transmission. The braking downshifting control method for the automatic six-speed wet type double-clutch transmission comprises the steps that a driving intention is judged rapidly by monitoring the traveling state in real time, and the target accelerated speed is worked out; and then the target gear is updated in real time by checking a gear graph, whether the downshifting type refers to that an odd number of gears need to be reduced or that an even number of gears need to be reduced is determined according to the target gear, so that corresponding single-gear downshifting or multi-gear downshifting is controlled. According to the braking downshifting control method for the automatic six-speed wet type double-clutch transmission, in order to guarantee smooth downshifting of a vehicle, multi-gear downshifting in a repeated-braking downshifting strategy is developed based on the structural characteristics of a wet clutch and is verified in real vehicles.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

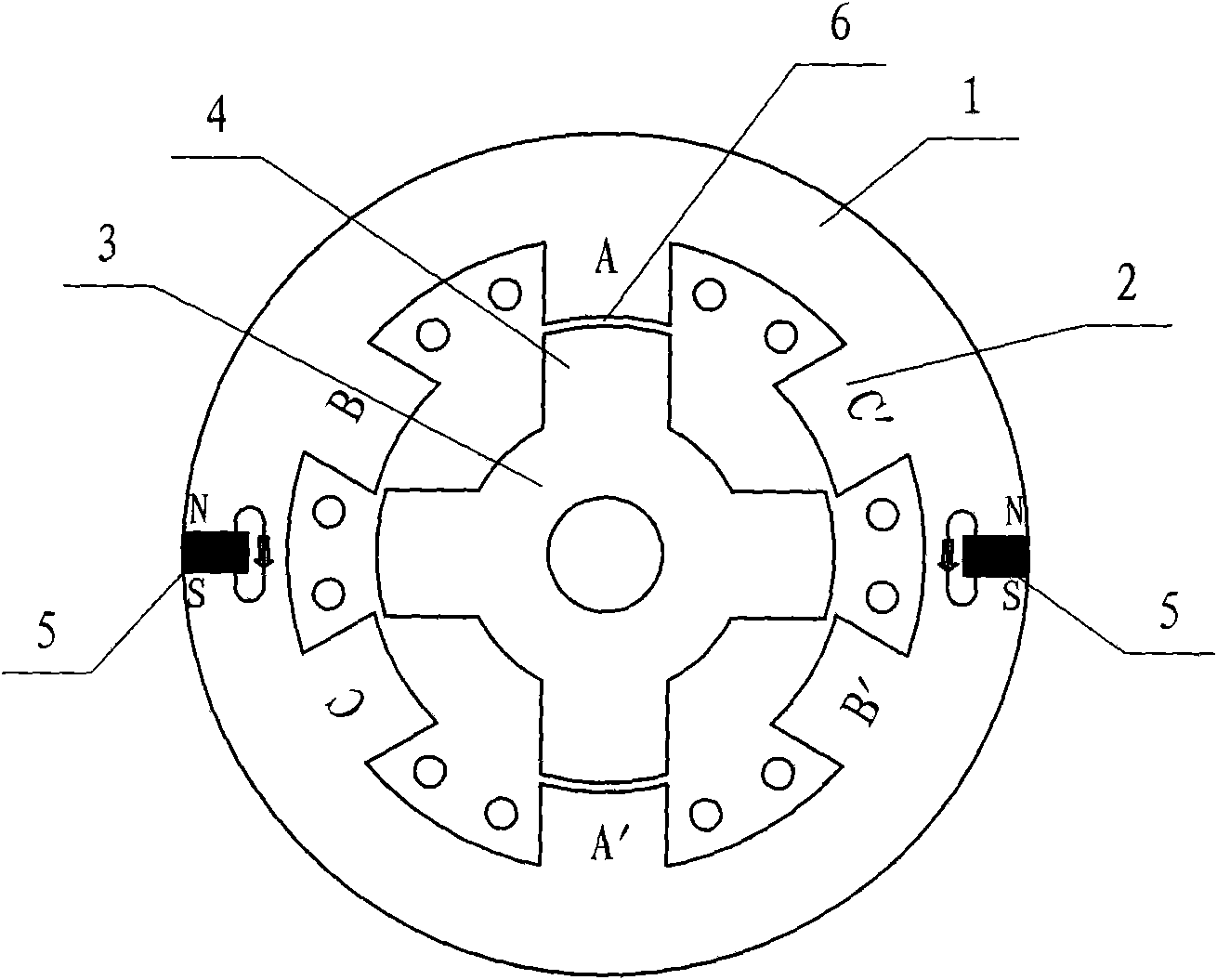

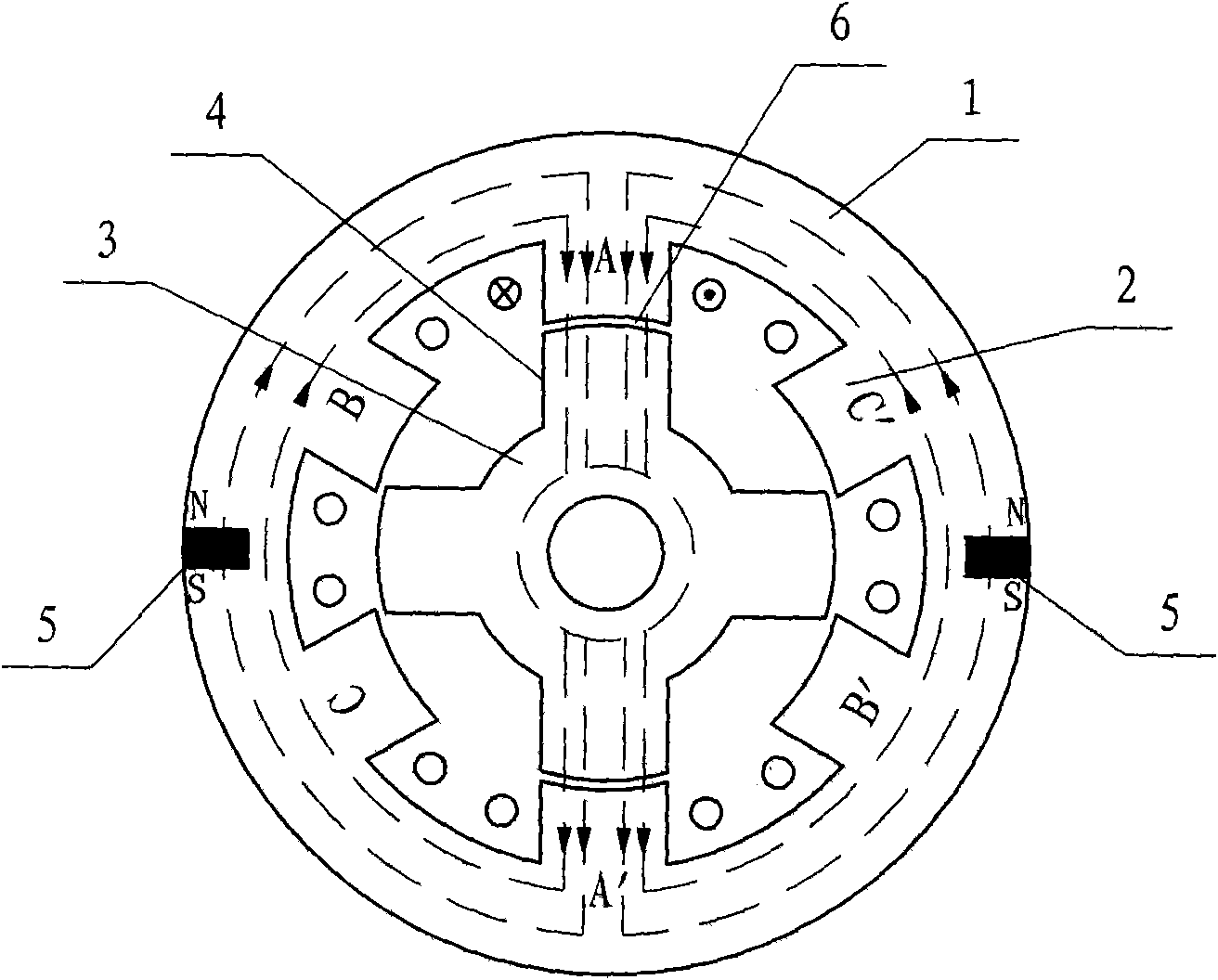

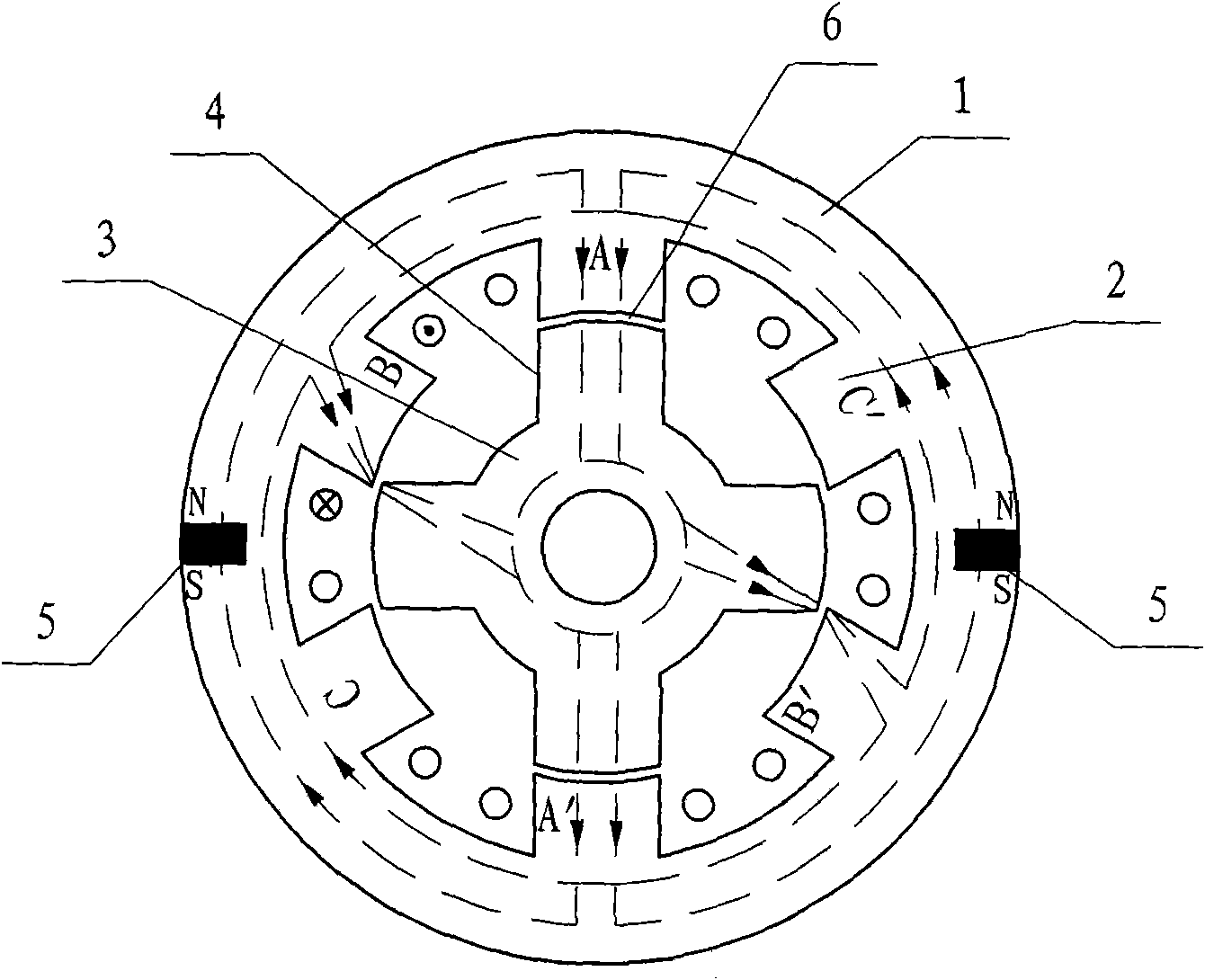

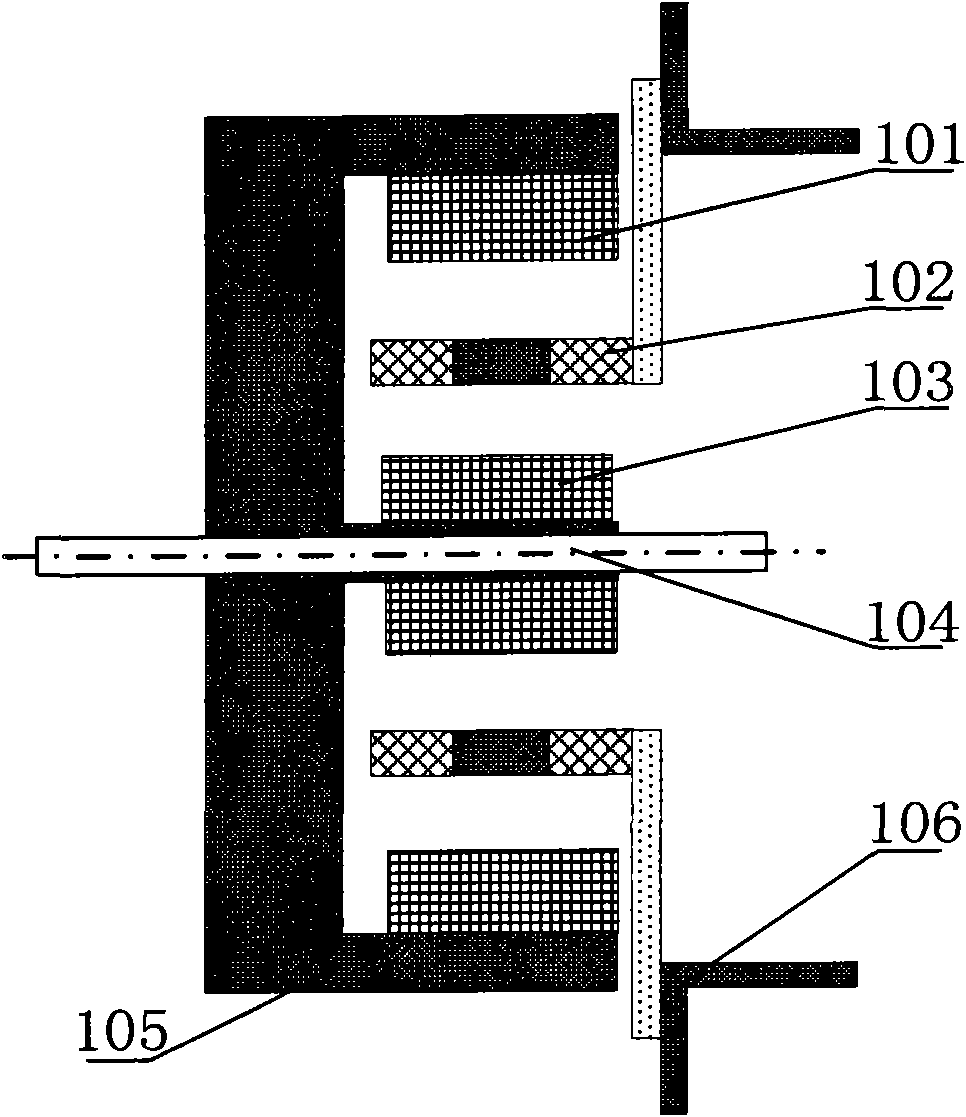

Switched reluctance motor with torque pulsation inhibited by permanent magnetic flux

InactiveCN101562387ASuppression of torque rippleSmooth torqueMagnetic circuit stationary partsElectric machineReluctance motor

The invention provides a switched reluctance motor with torque pulsation inhibited by permanent magnetic flux, belongs to the motor field, and aims to solve the problem of unobvious effect of the prior method for inhibiting the torque pulsation of the switched reluctance motor. In the switched reluctance motor, a stator and a rotor both have a salient-pole structure; two permanent magnets are symmetrically embedded along the radial direction inside the external circle surface of a stator core, and are arranged in stator cores corresponding to stator phase windings in the radial direction; the magnetic flux direction generated by the permanent magnets is in accordance with the magnetic flux direction of excitation generated by a stator winding; and the stator winding generates a magnetic field to cover the permanent magnets. When the stator winding is not electrified, the permanent magnets and the stator core form a loop, and do not generate a torque to the motor rotor. After the stator winding is electrified, the torque generated by the permanent magnets is changed into positive from negative; when the torque generated by the permanent magnets is negative, a torque wave crest is inhibited; and when the torque generated by the permanent magnets is positive, a torque wave trough is compensated, so that the torque pulsation of the switched reluctance motor is effectively inhibited.

Owner:HARBIN INST OF TECH

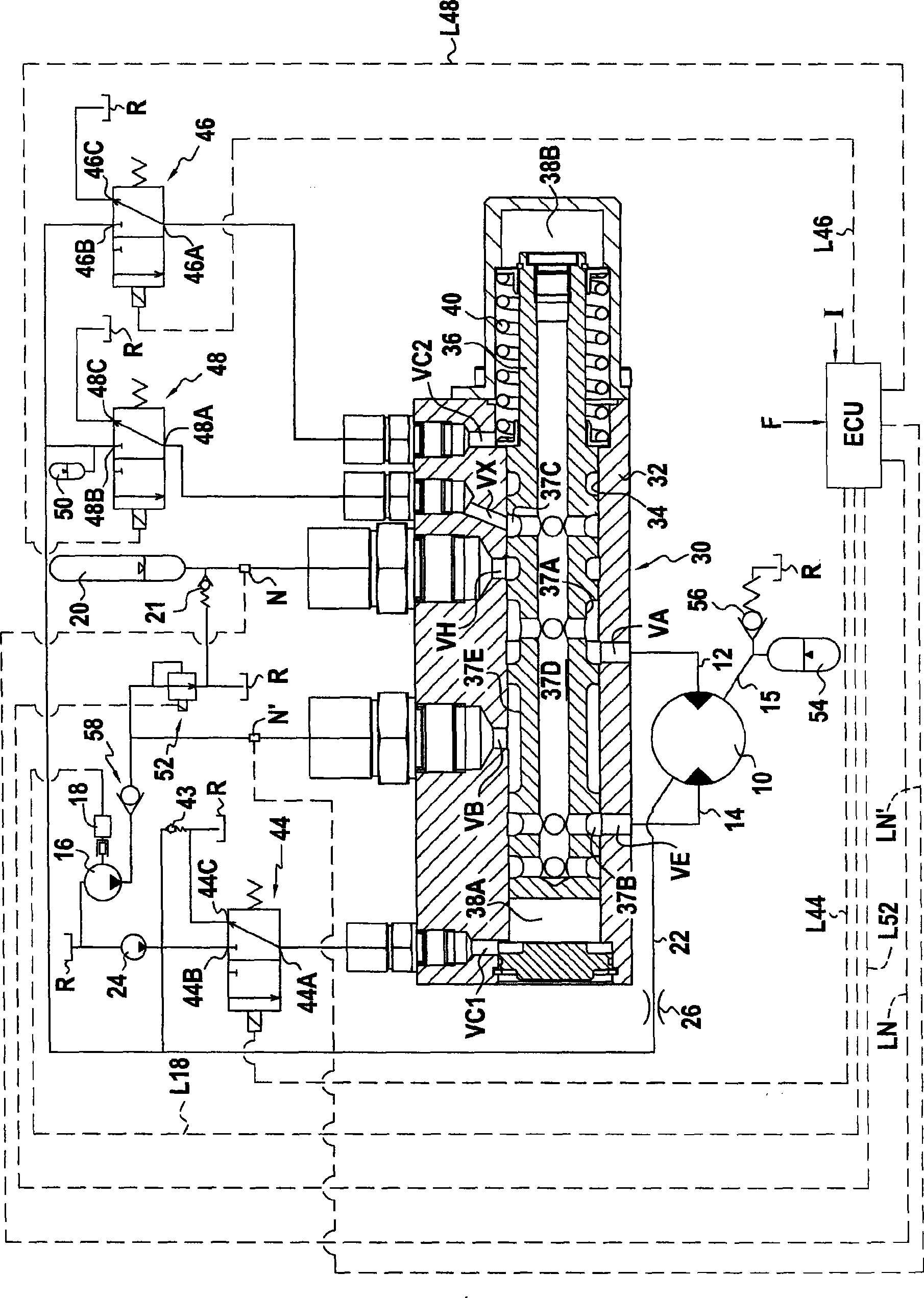

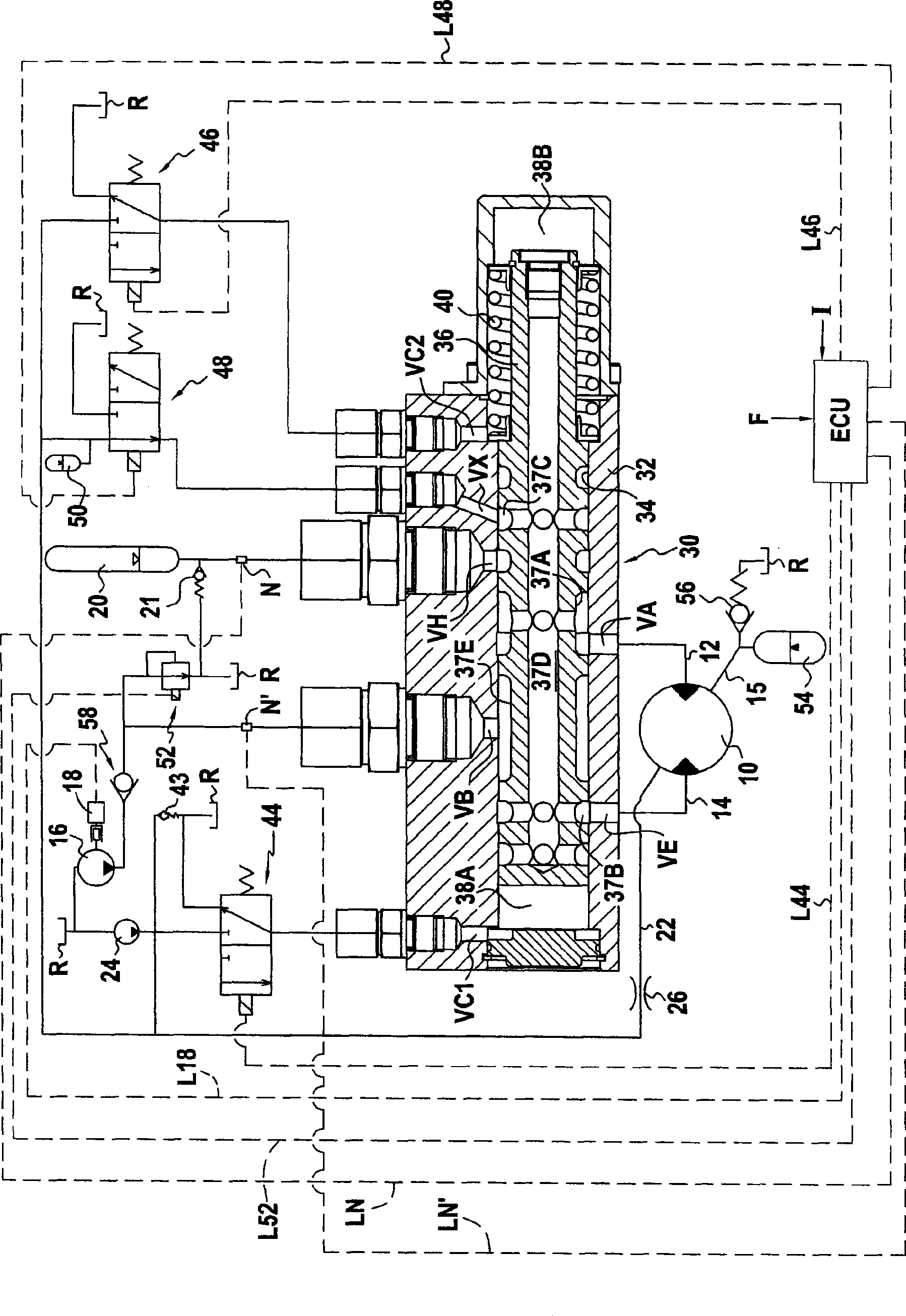

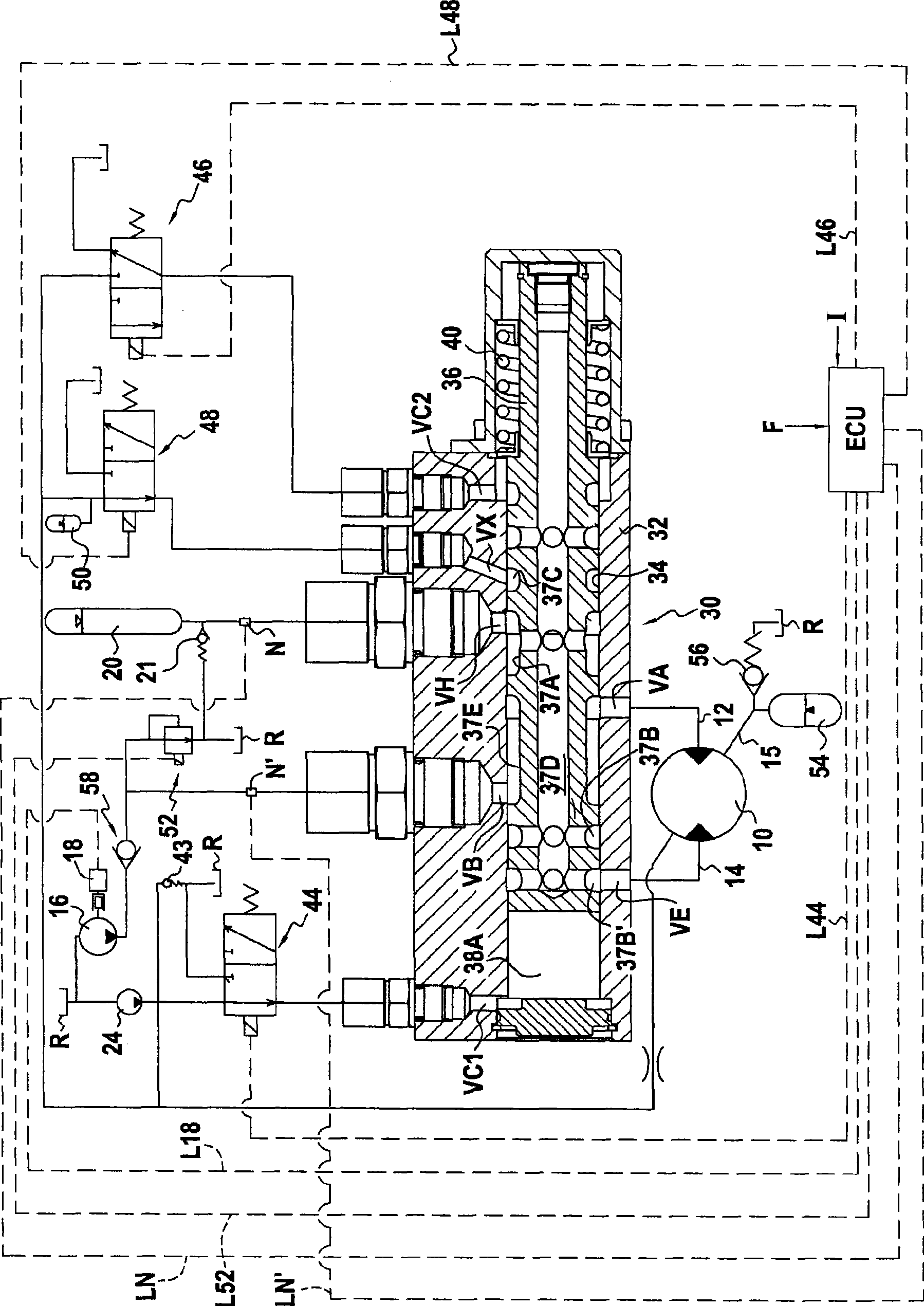

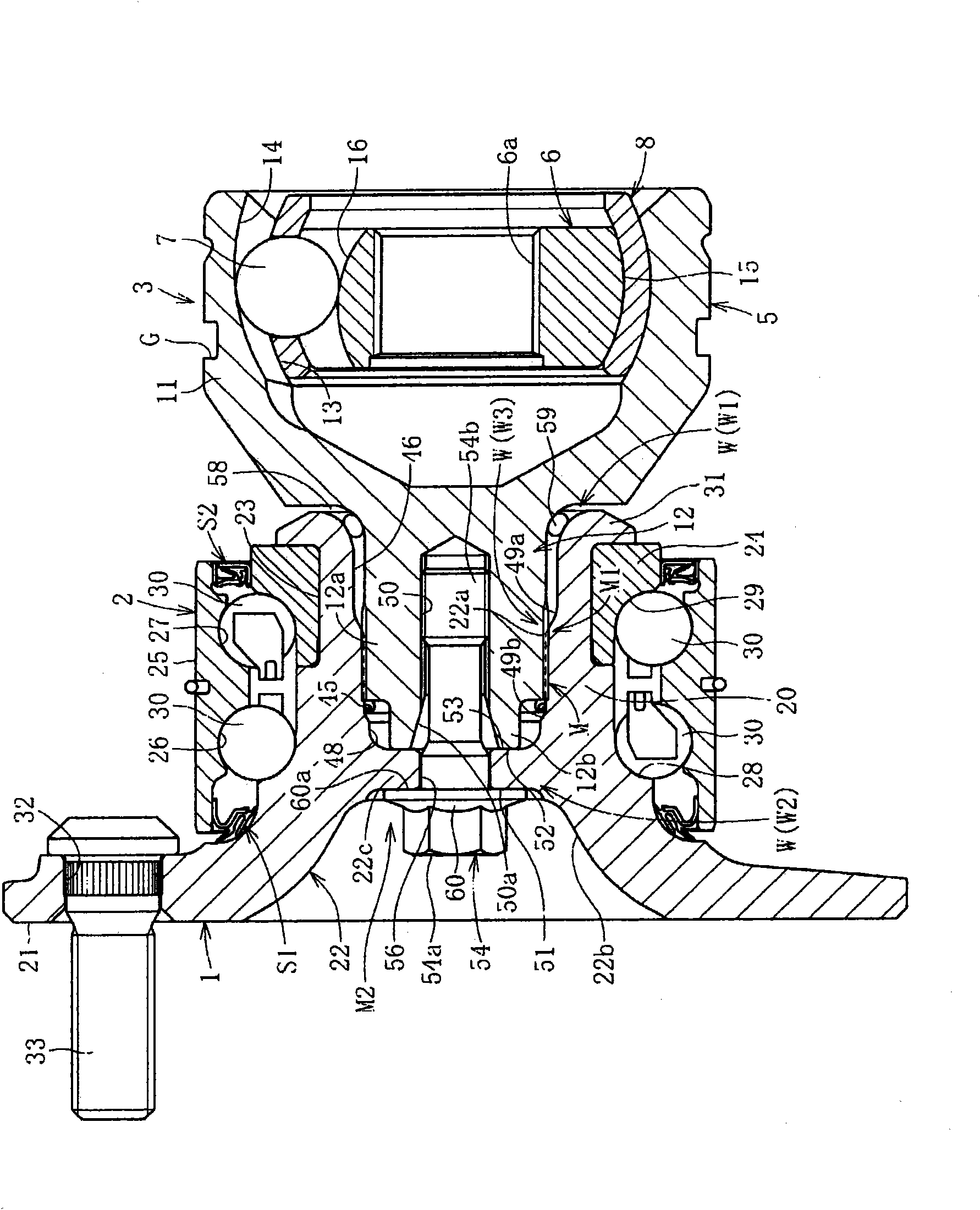

Hydraulic energy recovery system

InactiveCN101484731AEasy to adjustIncrease outlet pressureRoad transportGas pressure propulsion mountingHydraulic motorMain channel

The invention relates to a hydraulic energy recovery system. The system includes at least one hydraulic motor (10), two main channels (12, 14) serving as the feed channel or the exhaust channel of said at least one motor, a low-pressure fluid source (16, 52, R) and a high-pressure accumulator (20) forming a high-pressure fluid source. Said system can operate in an energy recovery mode, in which the main feed channel (12) is connected to the low-pressure fluid source (16, 52) and the main exhaust channel (14) is connected to the high-pressure accumulator (20), and an energy release mode, in which the connections are reversed. The low-pressure fluid source comprises a high-flow booster pump (16) which can deliver a sufficient fluid flow in order to supply the at least one hydraulic motor (10) with fluid while said motor is operating at maximum speed in the energy recovery mode and an adjustable pressure limiter (52) which can be controlled in order to vary the pressure of the fluid at the outlet of the low-pressure fluid source.

Owner:POCLAIN HYDRAULICS IND

Axial magnetic field printed circuit board permanent magnet brushless DC motor

InactiveCN105703510AIncrease powerFlexible designWindings conductor shape/form/constructionElectric machineEngineering

The invention discloses an axial magnetic field printed circuit board permanent magnet brushless DC motor. Including the rotating shaft, a pair of symmetrically arranged turntables installed on the rotating shaft; permanent magnets are fixed on the opposite surfaces of the two turntables; a printed circuit board is arranged in the middle of the two turntables, and there is a gap between the printed circuit board and the permanent magnets on both sides ; On the printed circuit board, there are many radial single wires evenly distributed around the center of the circle; the single wires are evenly divided into multiple groups, and each group of single wires includes a 3-phase coil; the single wire in each phase coil passes through the outer The outer ring connecting wire at the end and the inner ring connecting wire at the inner end are connected to form a winding loop. The invention uses printed circuit boards instead of traditional windings, so that the design of the motor stator is flexible and changeable, and high-precision wiring is realized; the circuit boards are arranged in multiple layers to increase the current carrying capacity, thereby increasing the power of the motor; no iron core is required, and eddy current loss is eliminated. The efficiency is improved, and the overall structure is simplified, which is beneficial to the assembly line and improves the production efficiency.

Owner:江苏河谷矿业科技发展有限公司

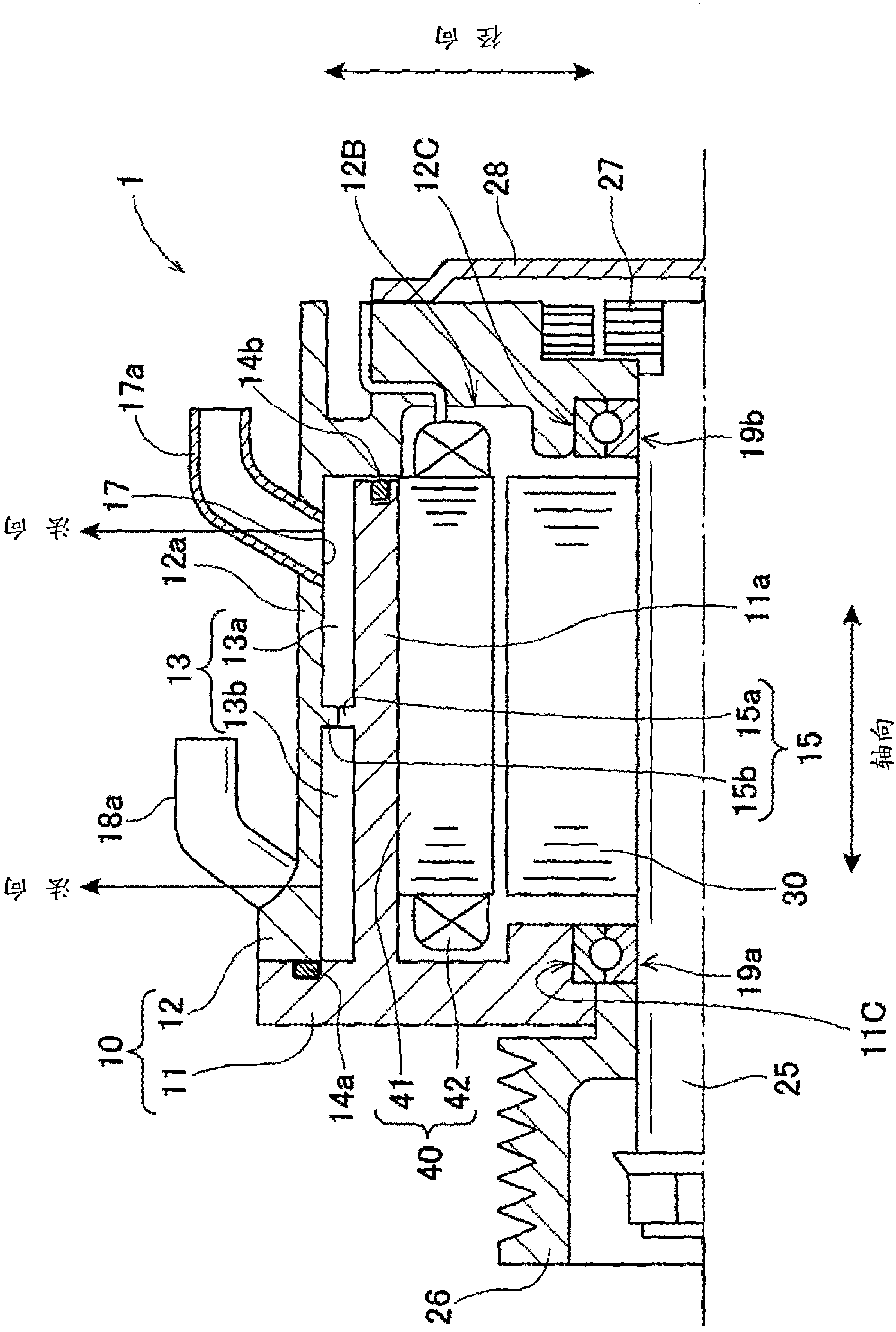

Electric rotary machine

InactiveCN103187831ASmooth output torqueOutput torque stability is limited by the temperature distributionCooling/ventillation arrangementSupports/enclosures/casingsElectric machineCooling fluid

An electric rotary machine has a motor frame having a cooling fluid passage, a rotary shaft rotatably supported by the motor frame, a rotor fixed to the rotary shaft, and a stator. The stator has a core having a ring shape and a stator winding wound around the core. The stator core is arranged to face an outer periphery of the rotor in a radial direction. An inlet section and an outlet section are formed in the motor frame. Cooling fluid is introduced into the cooling fluid passage through the inlet section and discharged from the outlet section. A partition wall section is formed on the motor frame and divides the cooling fluid passage into a cooling fluid inlet passage and a cooling fluid outlet passage. Through an opening formed in the partition wall section, the cooling fluid inlet passage and the cooling fluid outlet passage communicate with each other.

Owner:DENSO CORP

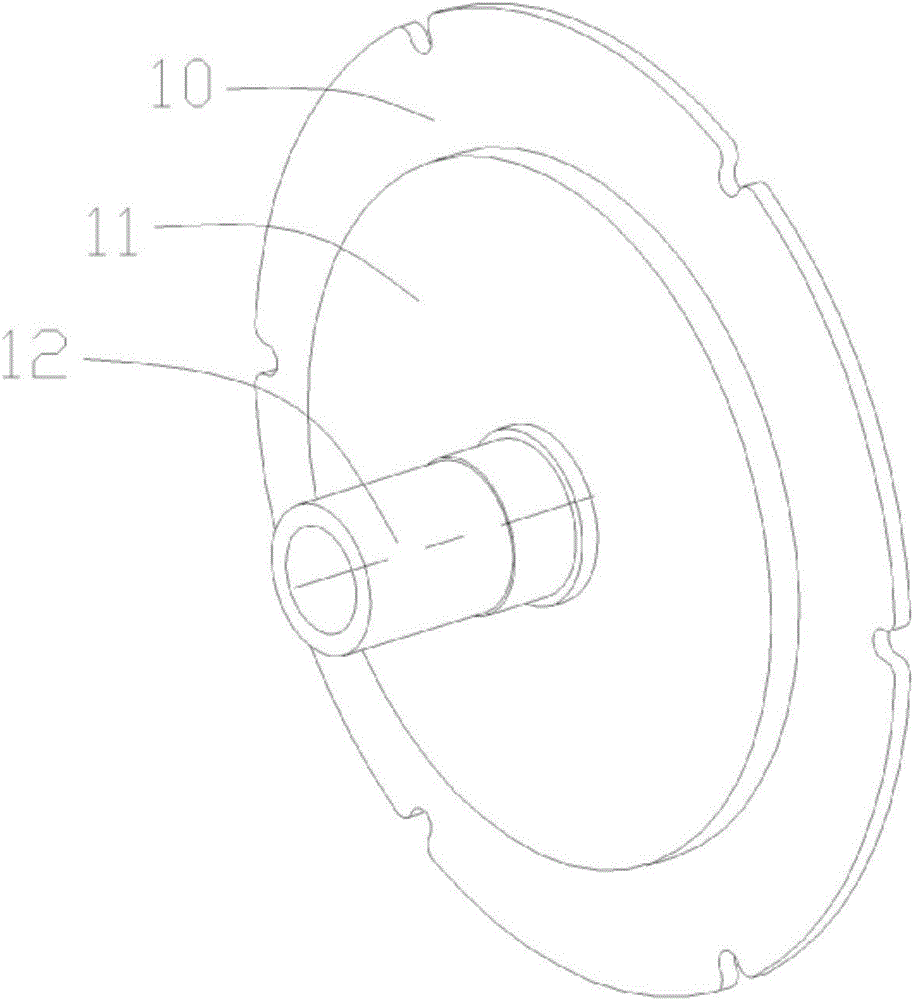

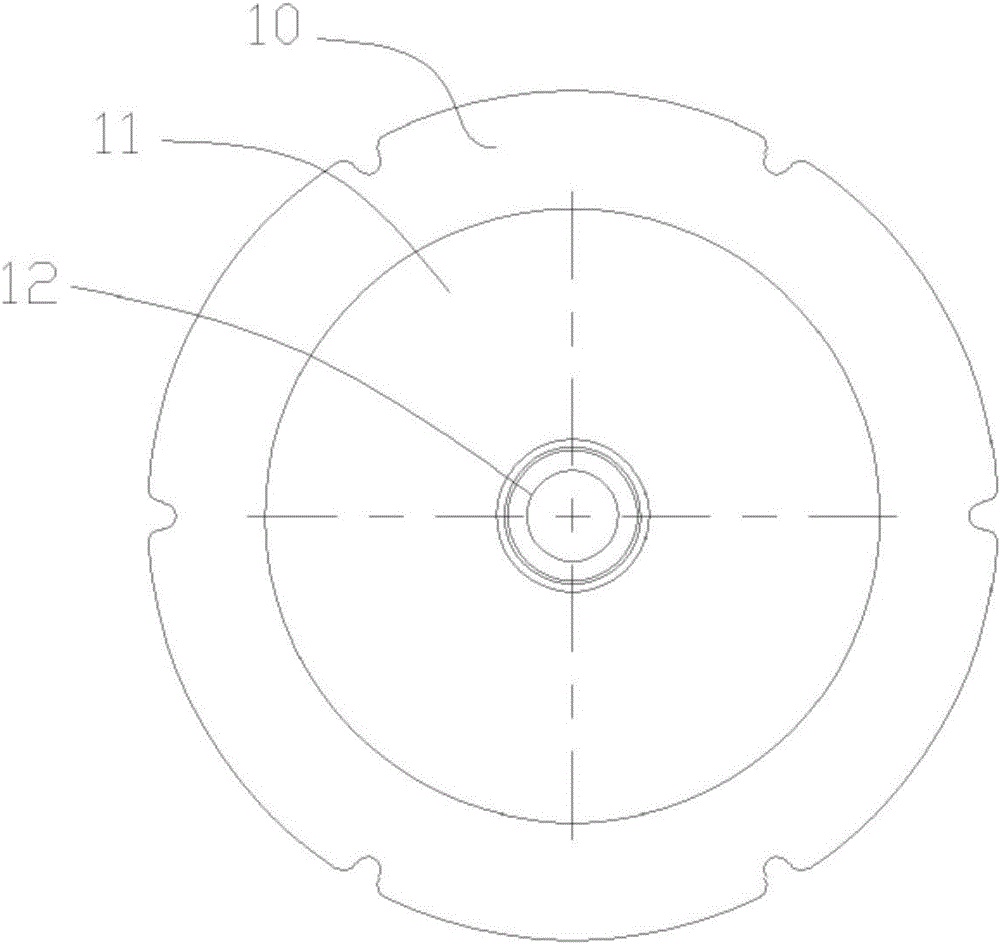

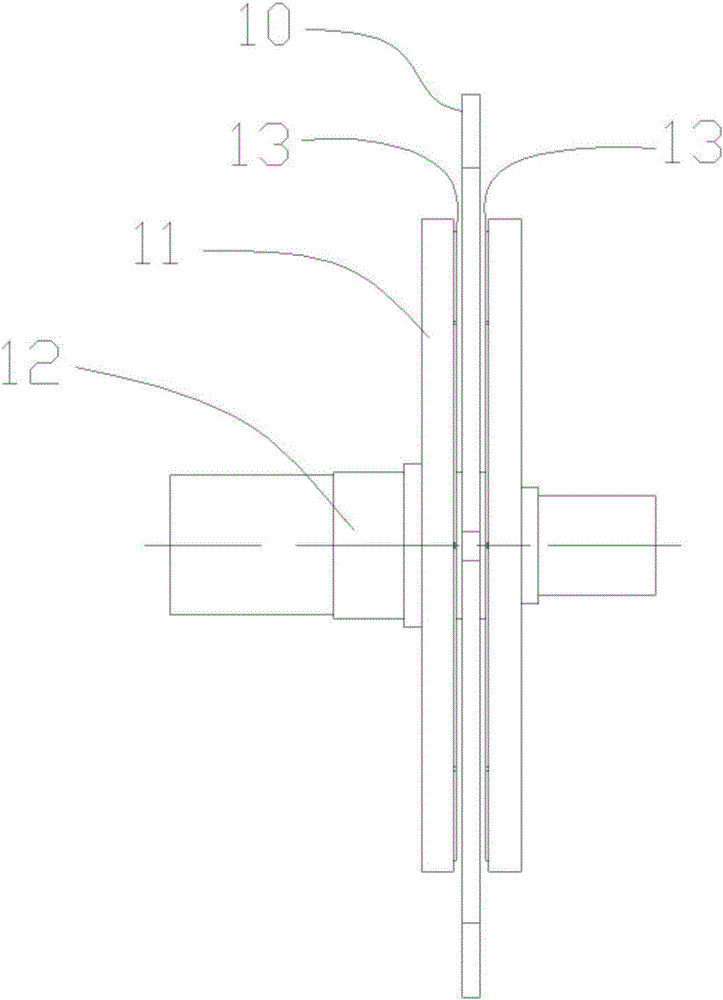

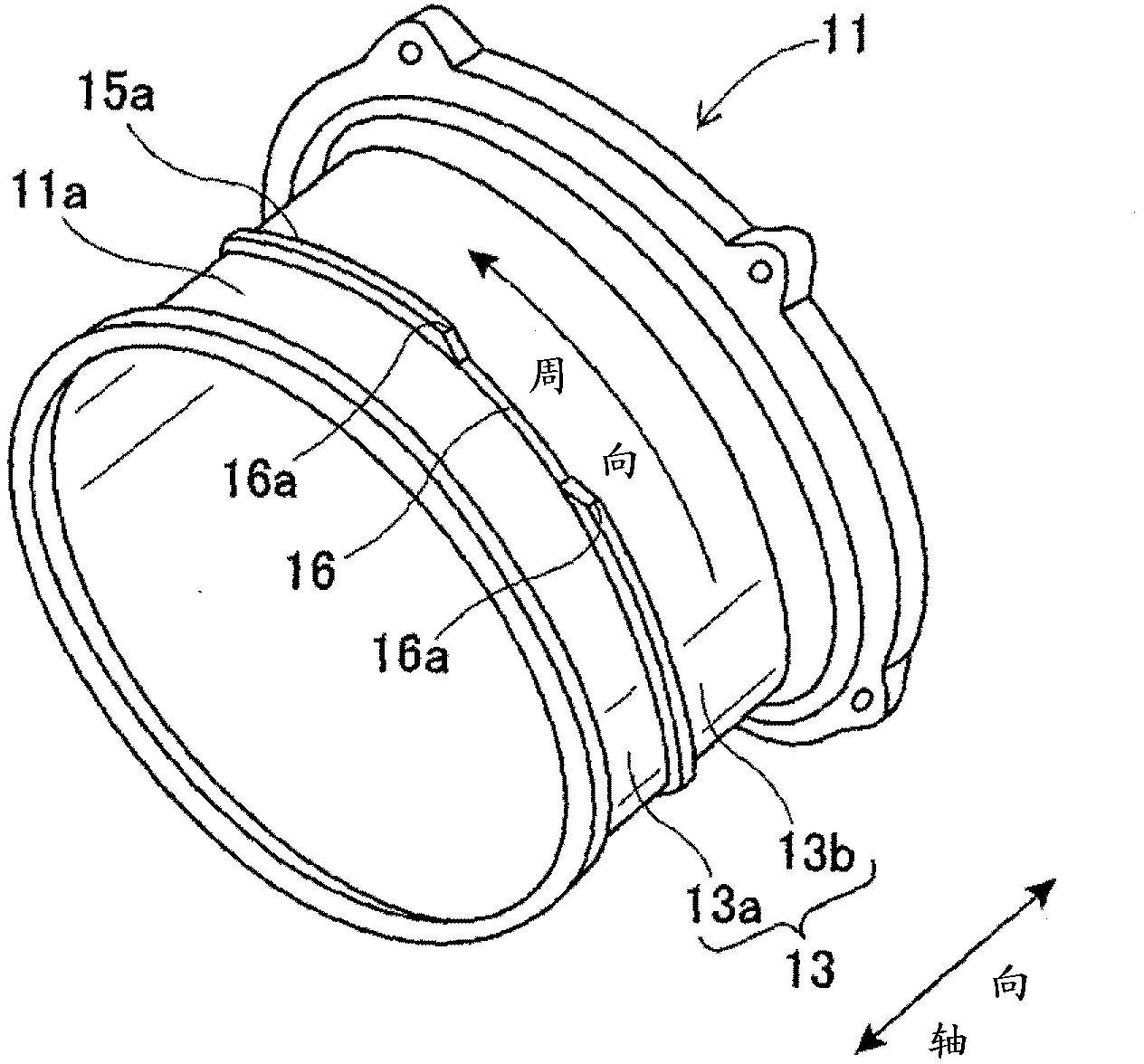

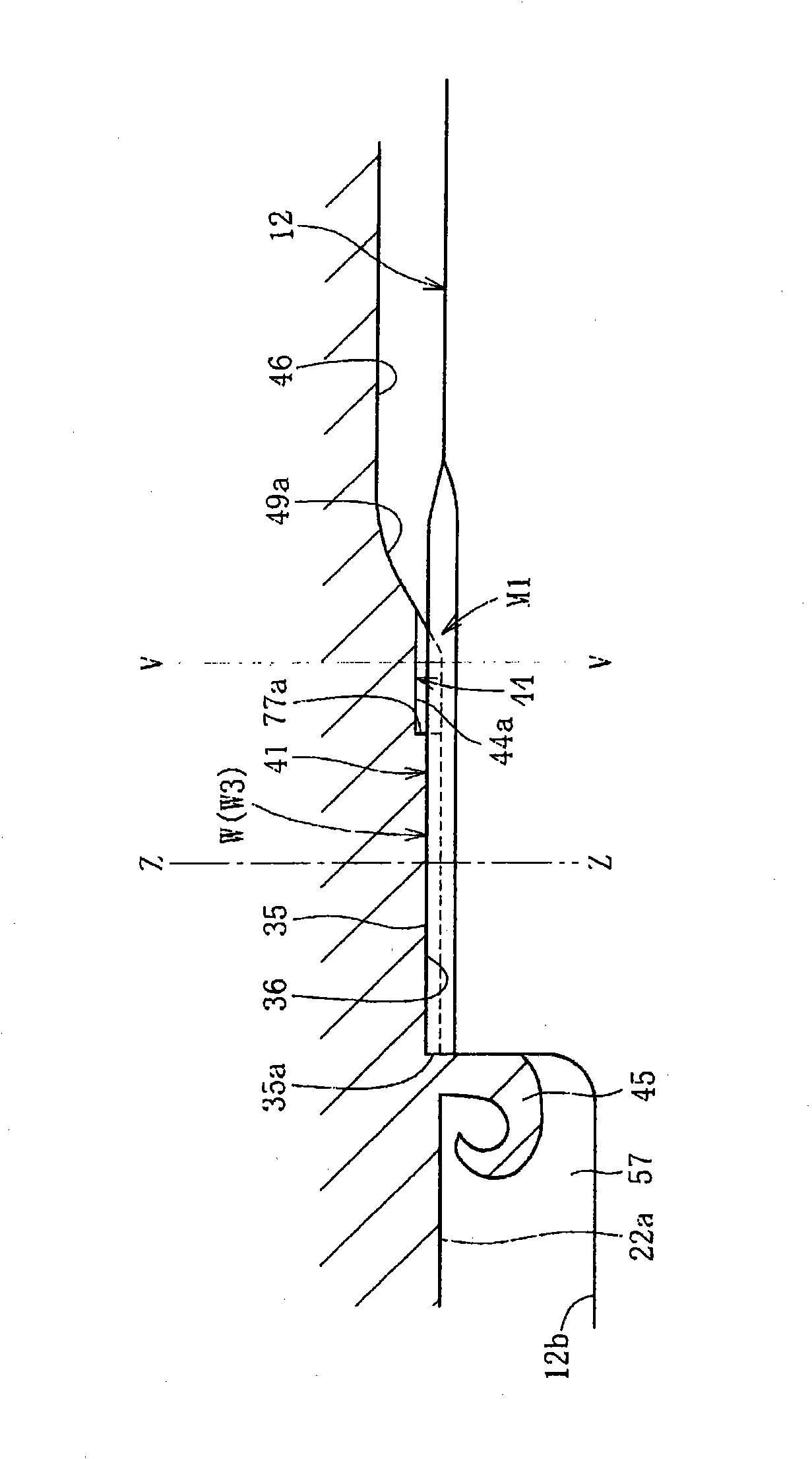

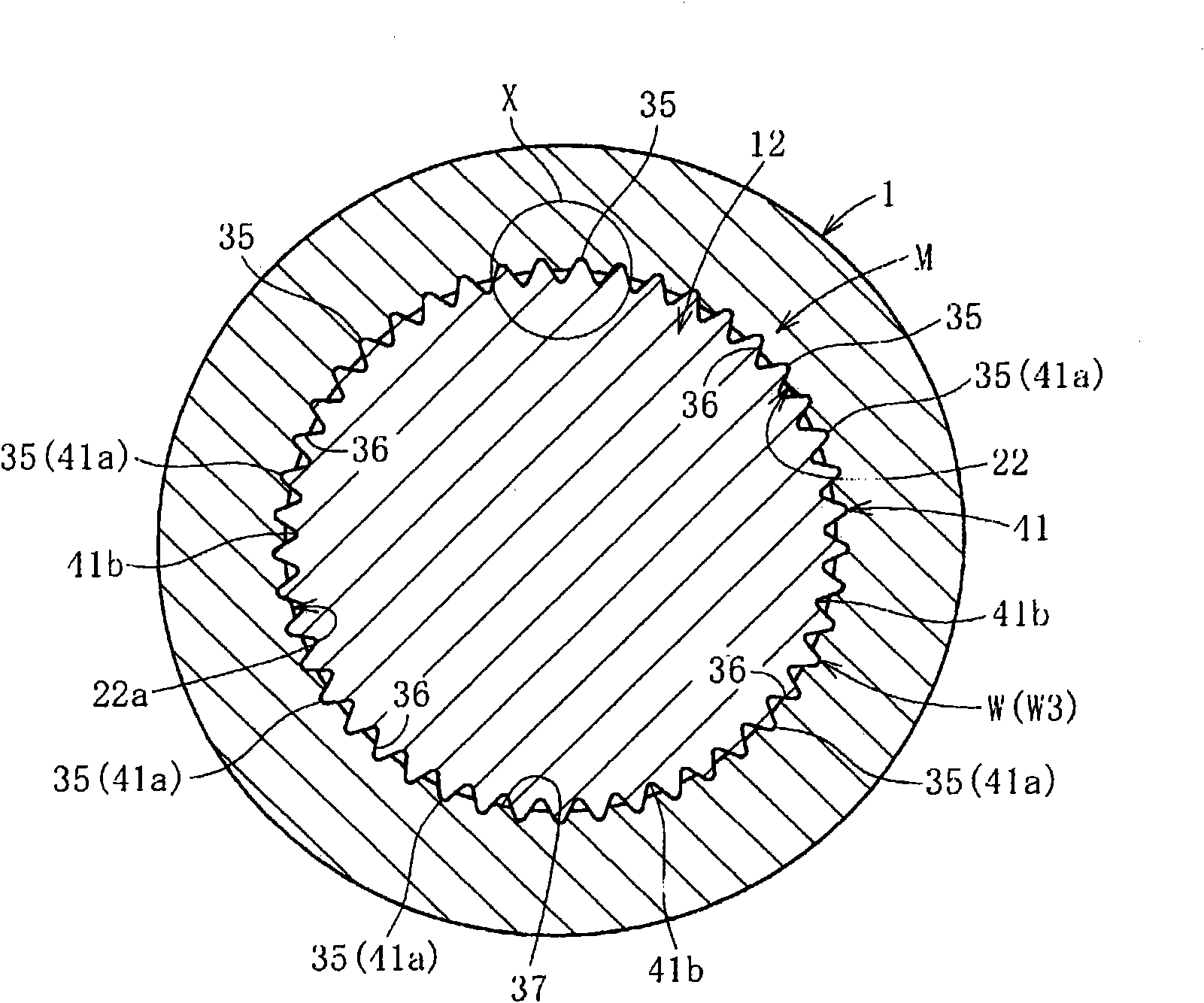

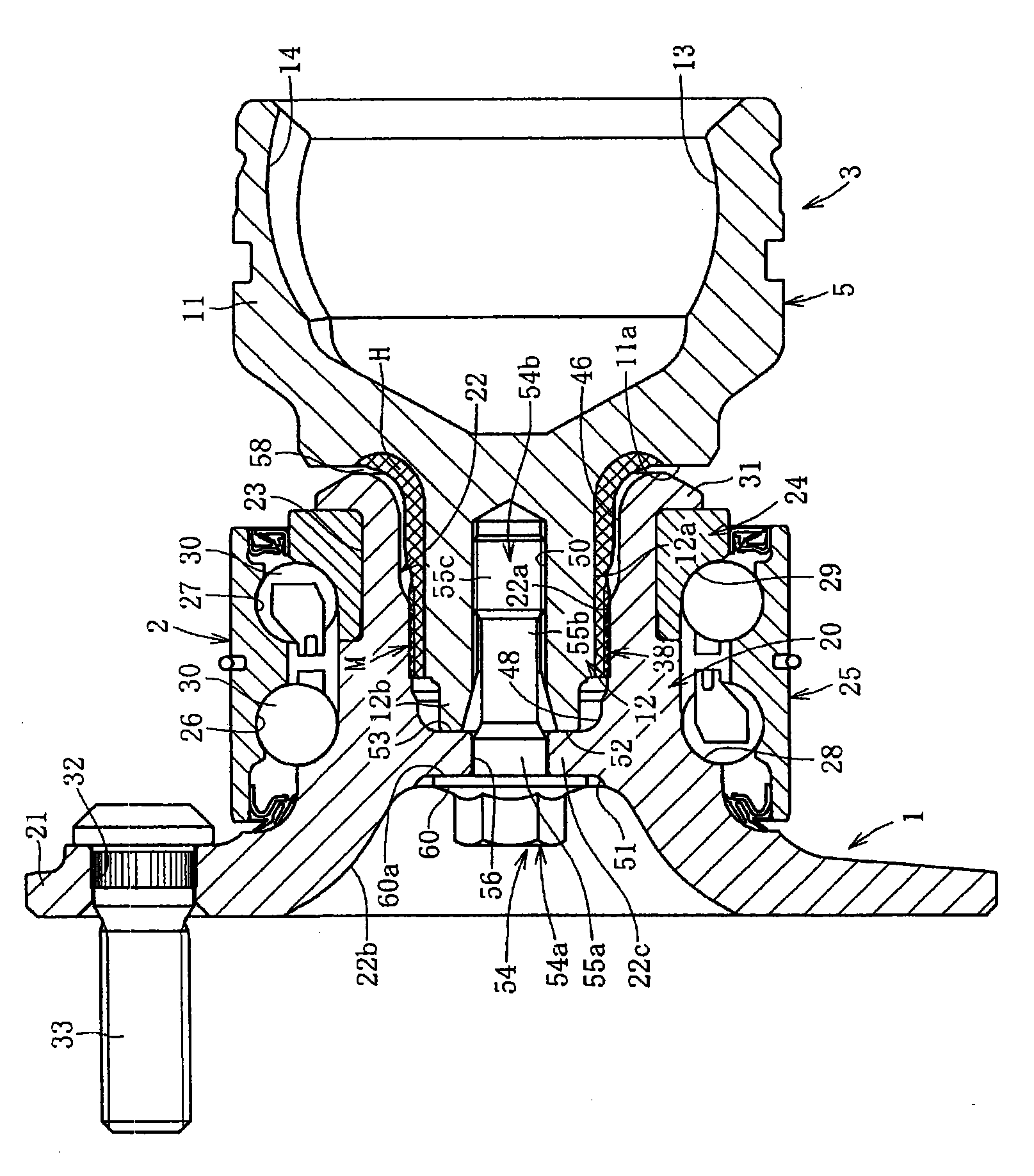

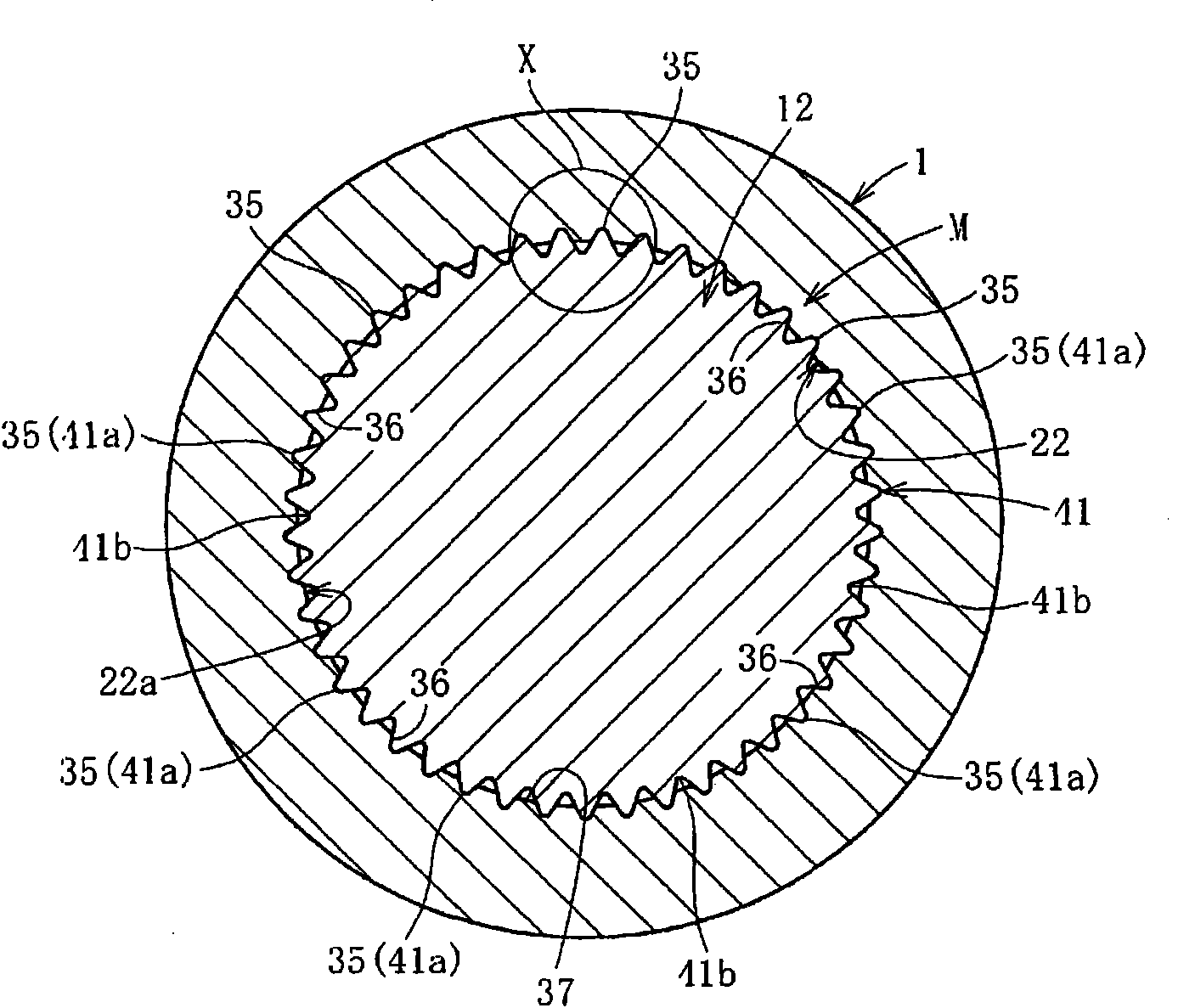

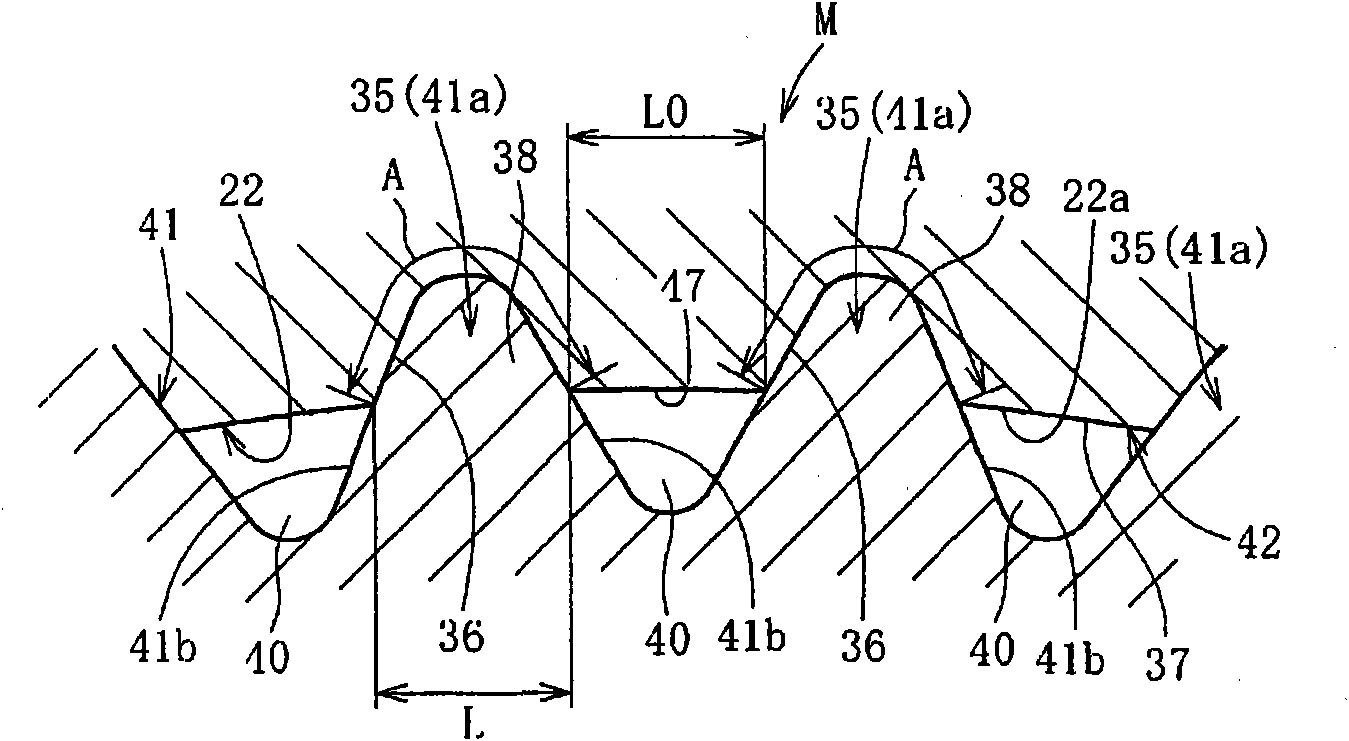

Bearing device for wheel

ActiveCN101827715AStable deliveryHigh strengthYielding couplingRolling contact bearingsJoint componentPull force

A bearing device for a wheel, in which circumferential play is minimized, a hub ring and an outer joint member of a constant velocity universal joint can be connected to each other with good workability, and the hub ring and the outer joint member are adapted to be separable from each other to provide the device with good maintainability. In the bearing device, the outer joint member of the constant velocity universal joint (3) has a shaft section (12) fitted into a hole (22) of the hub ring (1), and the hub ring (1) and the shaft section (12) are separably joined to each other by a ridge-groove fit structure (M). Axially extending ridges are formed on either of the outer diameter surface of the shaft section of the outer joint member and the inner diameter surface of the hole of the hub ring. The ridges are axially press-fitted into the other. As a result, grooves fitting on the ridges are formed in the other to form the ridge-groove fit structure in which the entire areas of fit and contact portions of the ridges and grooves are in intimate contact with each other. The ridge-groove fit structure (M) allows separation between the hub and the outer joint member by axially applied pulling force.

Owner:NTN CORP

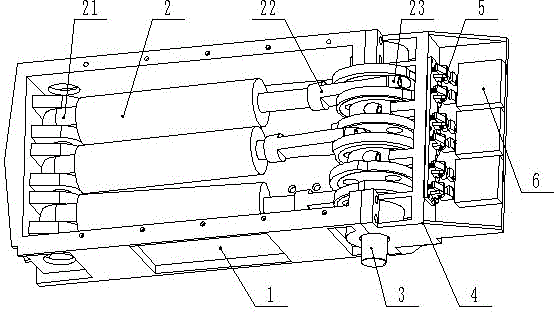

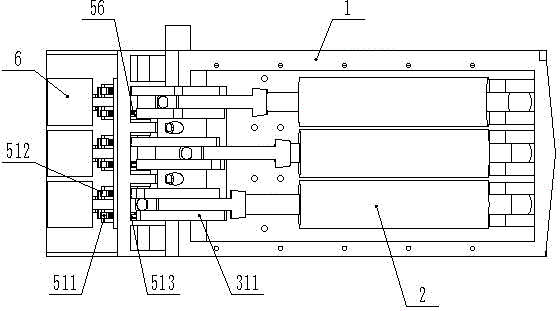

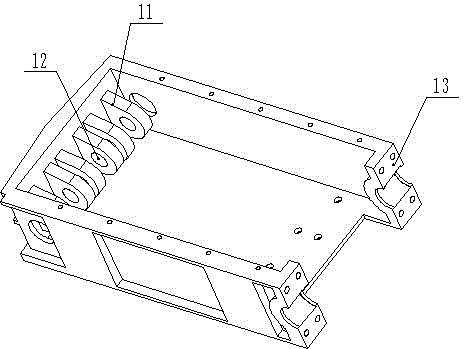

Same-distribution-angle hydraulic cylinder motor

ActiveCN104131945AReduce speedReduce output torque rippleCrankshaftsReciprocating piston enginesHydraulic cylinderHydraulic motor

The invention belongs to the field of mining hydraulic motors, and especially discloses a same-distribution-angle hydraulic cylinder motor. A technical problem to be solved is providing a same-distribution-angle hydraulic cylinder motor with the advantages of simple structure, operation convenience, high safety coefficient, long service life and effective reduction of the coal mine underground accident rate. The motor comprises a case body, three hydraulic cylinders, a crankshaft, a case body front end assembly and a control system, the whole case body is a shell structure, the three hydraulic cylinders are arranged in the case body side by side, the front end of the case body is provided with a case body semicircle seat for installing the crankshaft, the case body front end assembly is fixedly connected with the case body to fix the crankshaft, the piston terminals of the hydraulic cylinders are connected with the crankshaft through piston terminal covers, the hydraulic cylinders move back and forth to drive the crankshaft to rotate, the crankshaft drives the control system to move, and the control system controls the reciprocating motion of the three hydraulic cylinders in order to drive the crankshaft to continuously revolve. The motor adopting the hydraulic cylinders to drive the crankshaft to rotate has the advantages of low rotating speed, large torque, and suitableness for the use requirements of coal mine underground equipment.

Owner:NANTONG JIEFU ELECTRICAL CO LTD

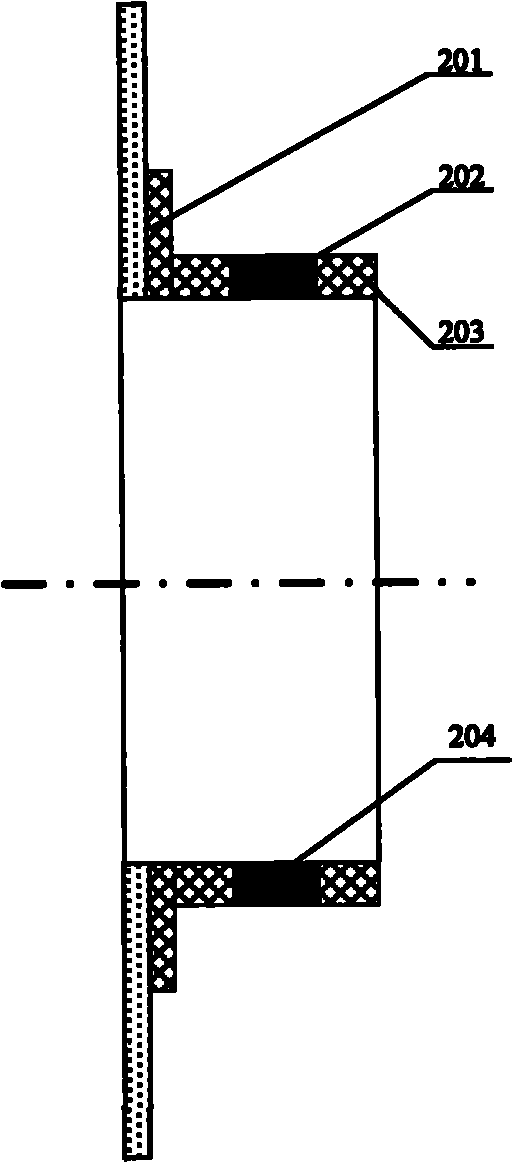

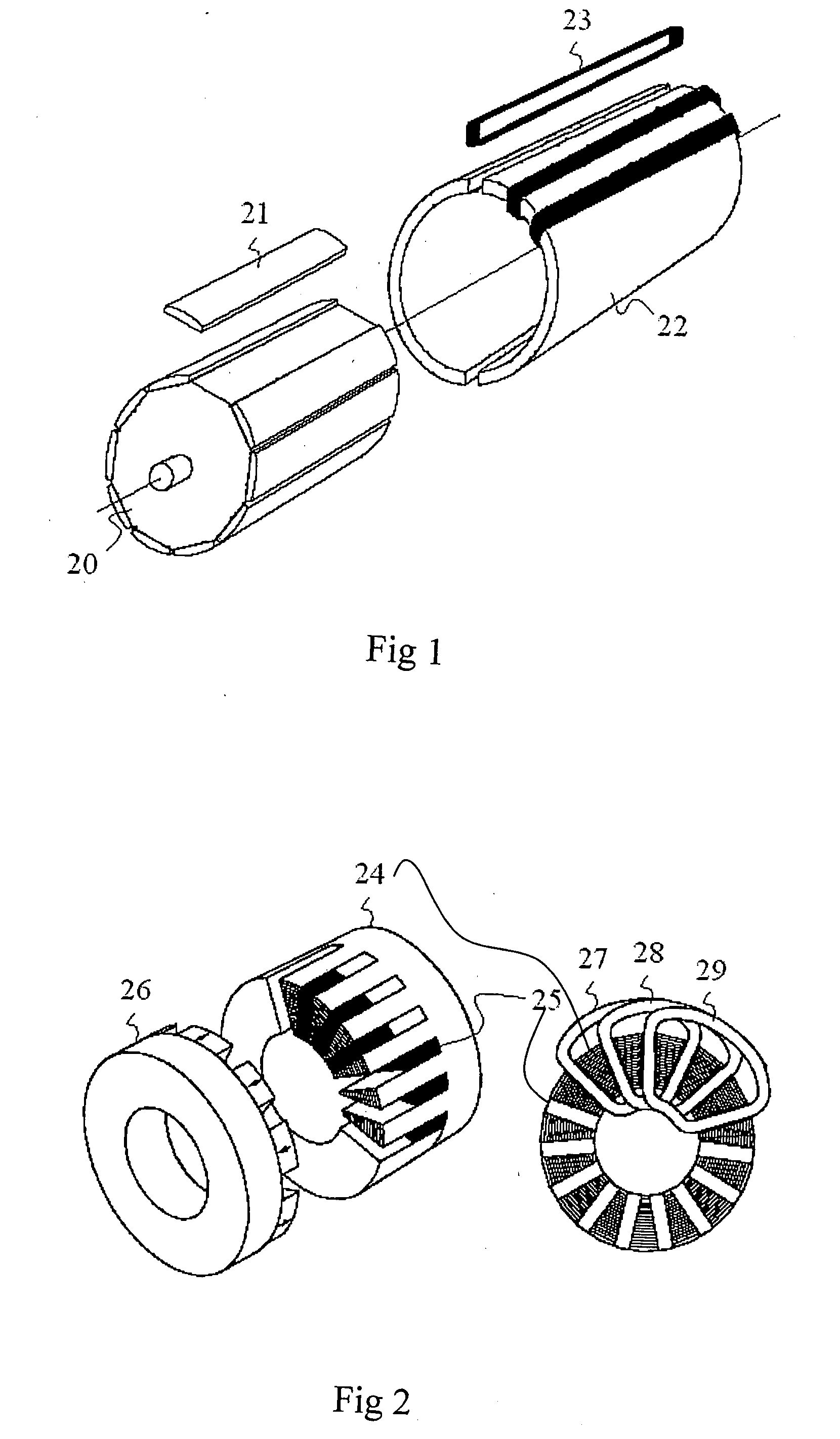

Brushless direct current motor with internal and external rotors and without core losses

InactiveCN102013781AEliminate core lossEliminate coggingMagnetic circuit rotating partsMagnetic circuit stationary partsStatorEngineering

The invention provides a brushless direct current motor without core losses, comprising outer Halbach magnets, inner Halbach magnets, a rotor shaft and coreless stators formed by windings and frameworks, wherein the outer Halbach magnets and the inner Halbach magnets are connected on the rotor shaft by magnet isolating sleeves so that the outer Halbach magnets and the inner Halbach magnets rotate synchronously with the rotor shaft; the coreless stators are installed and fixed on casings; the outer Halbach magnets, the coreless stators, the inner Halbach magnets and the air gaps among the magnets and the coreless stators form closed magnetic circuits; and sinusoidal magnetic fields with high density are formed between the outer Halbach magnets and the inner Halbach magnets. The motor provided by the invention removes the stator cores and the rotor cores so that the rotors do not have core losses at any working speed, thus radically solving the problem of core losses, and the motor simultaneously has the advantages of light weight, low power consumption, reliable structure and the like.

Owner:北京奇峰聚能科技有限公司

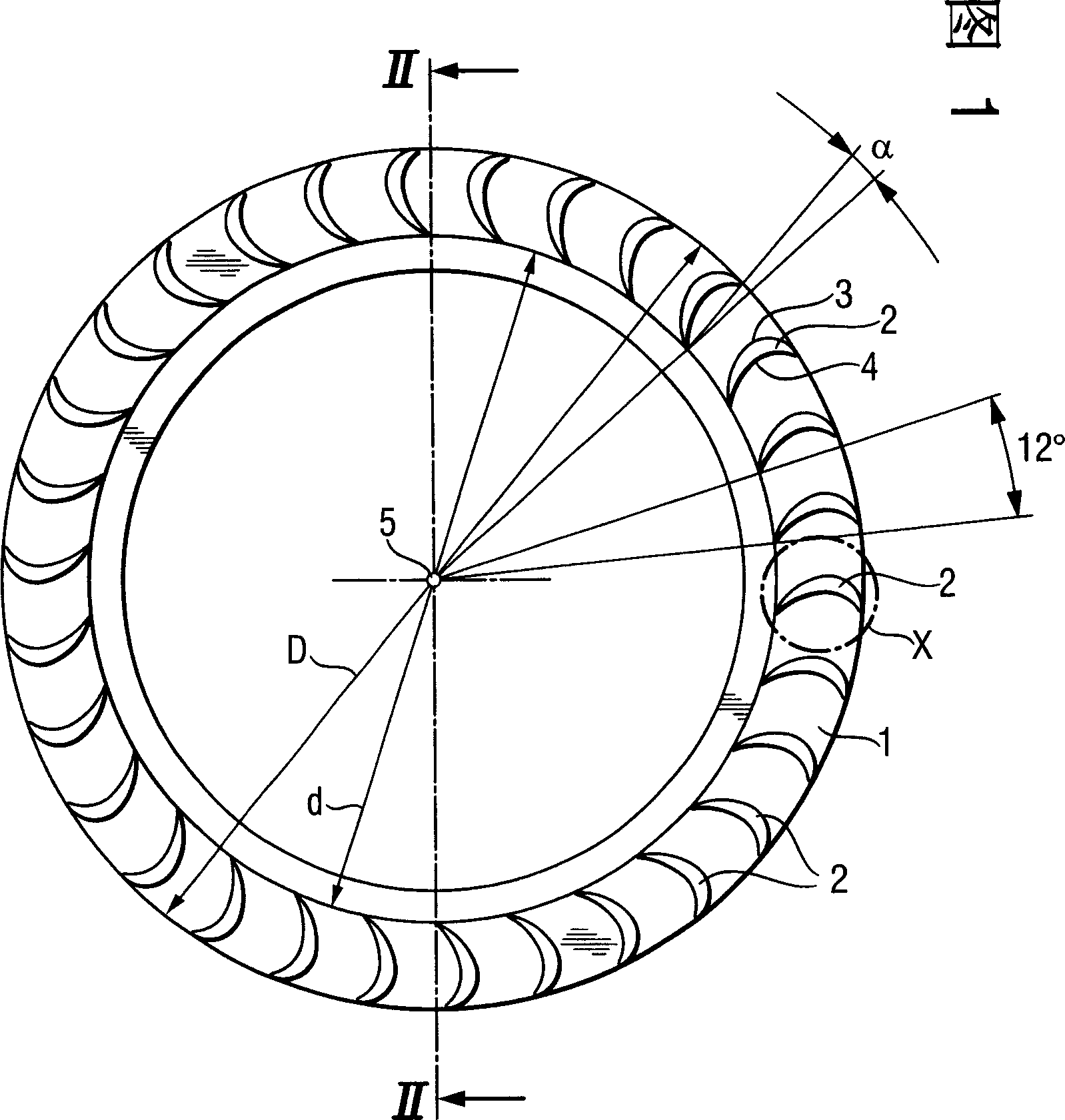

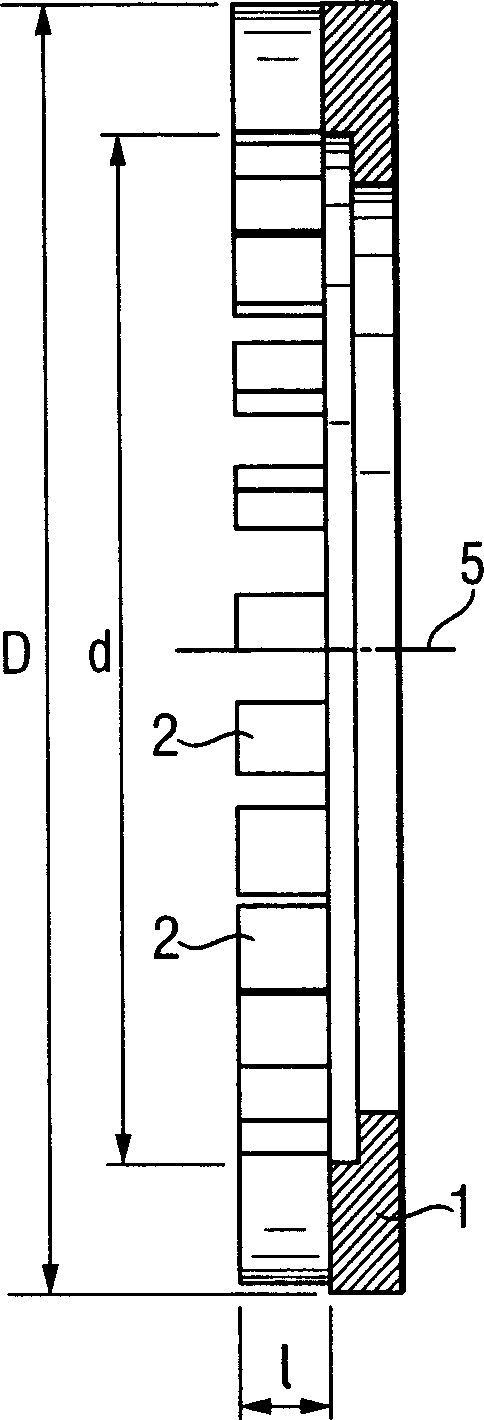

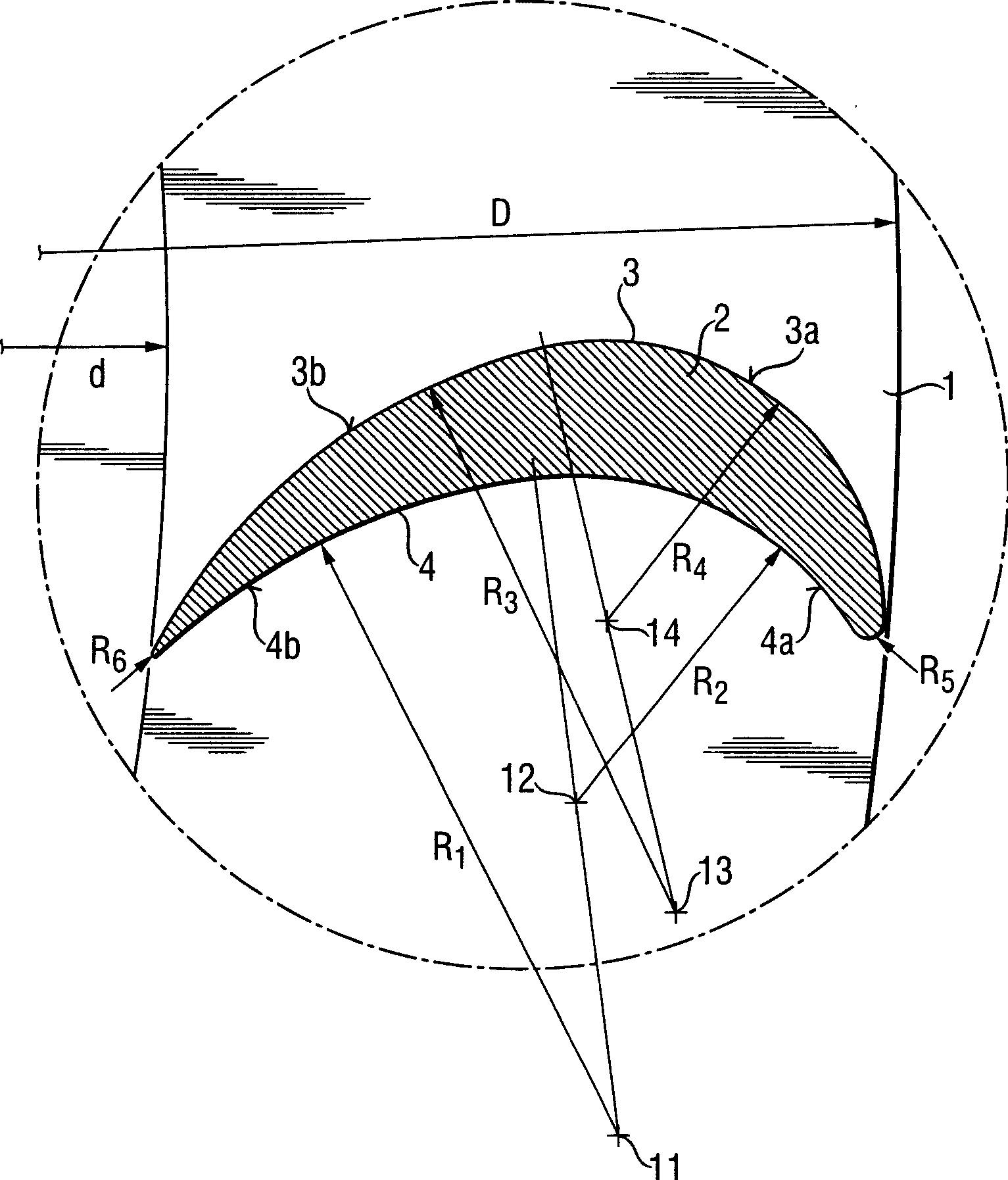

Turbine for driving fast rotary tool

InactiveCN1519055AEfficient productionSmooth torqueEngine manufactureOther chemical processesTurbine wheelTurbine blade

The turbine wheel has blades (2) with axially parallel front and rear surfaces (3, 4) and are radially curved. The radially outer sectors of the front surface (3a, 4a) are of smaller curve radius (R2, R4) than the inner sectors (3b, 4b). The front surface, at least in sectors, has a smaller curve radius than the rear surface.

Owner:GAT GES FUR ANTRIEBSTECHN

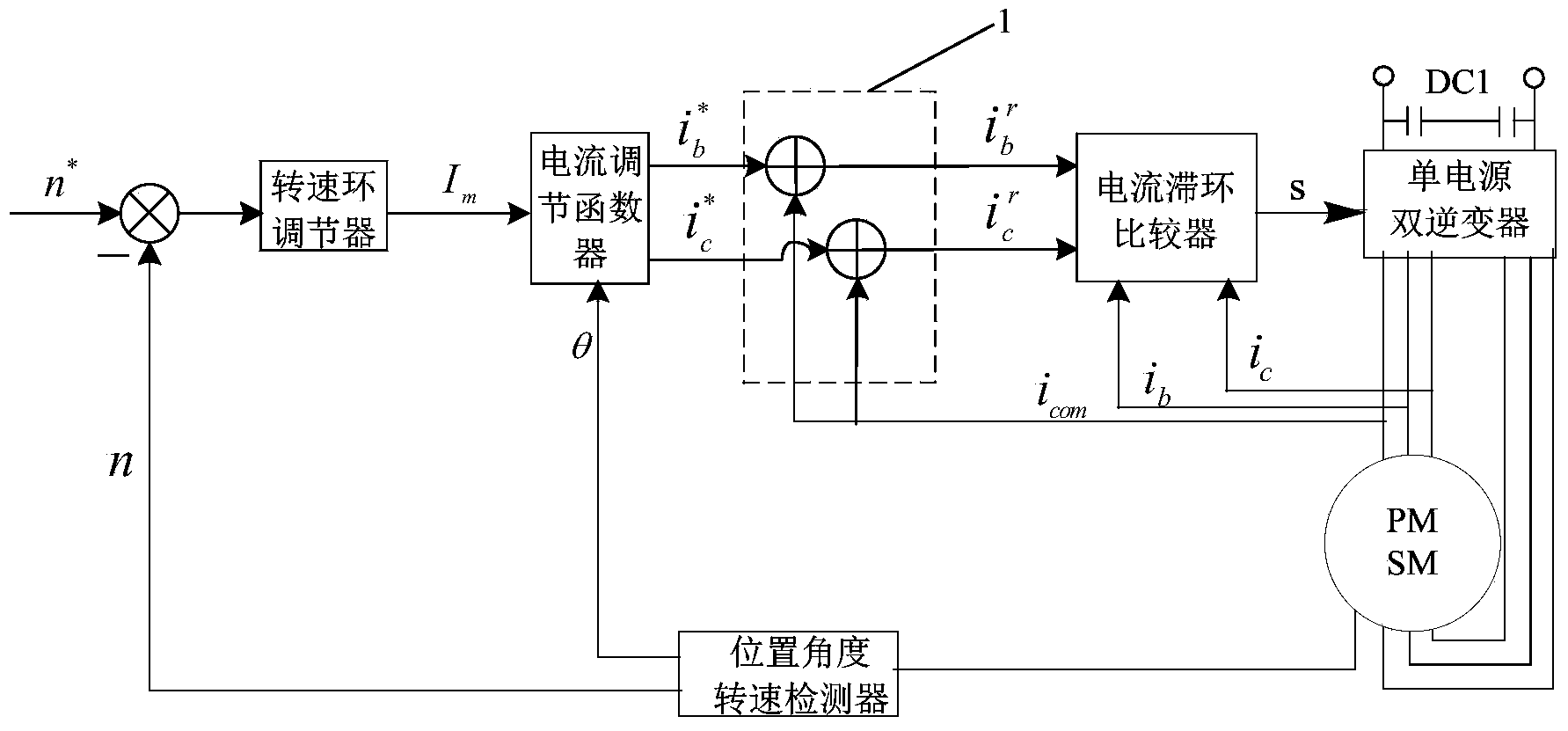

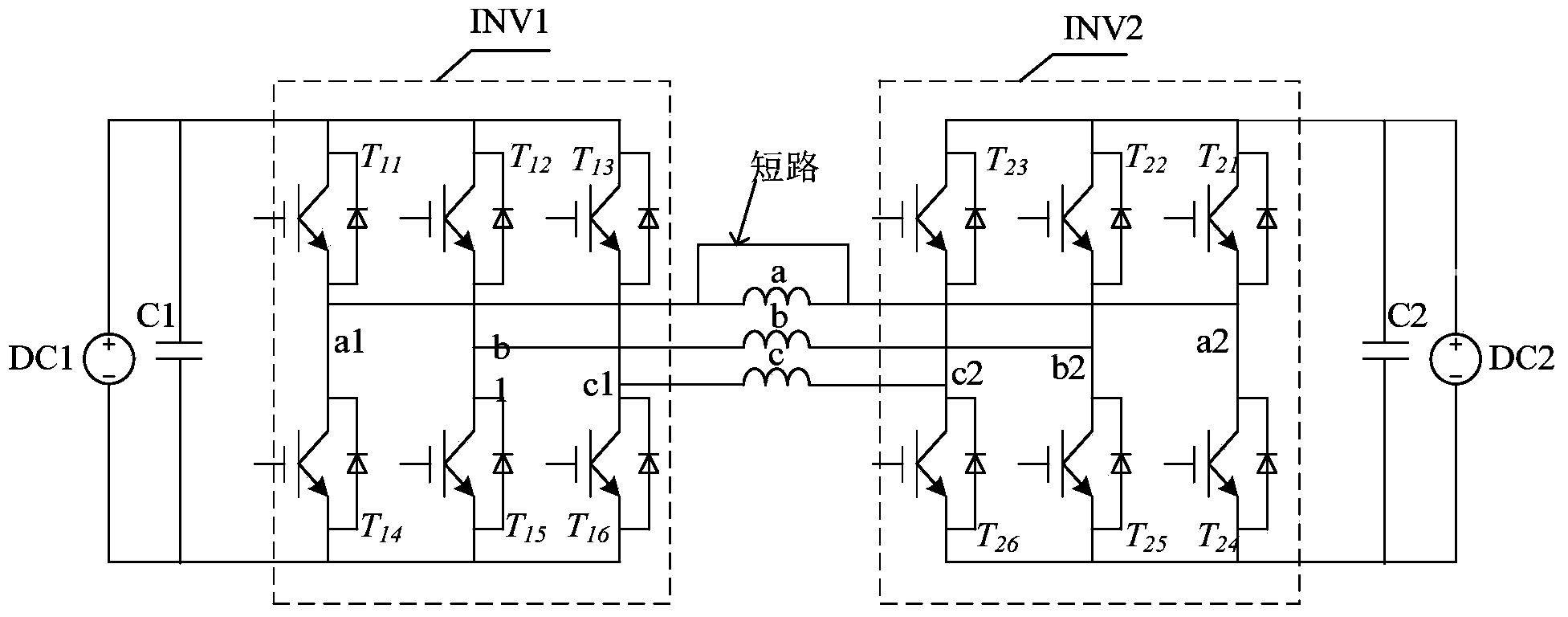

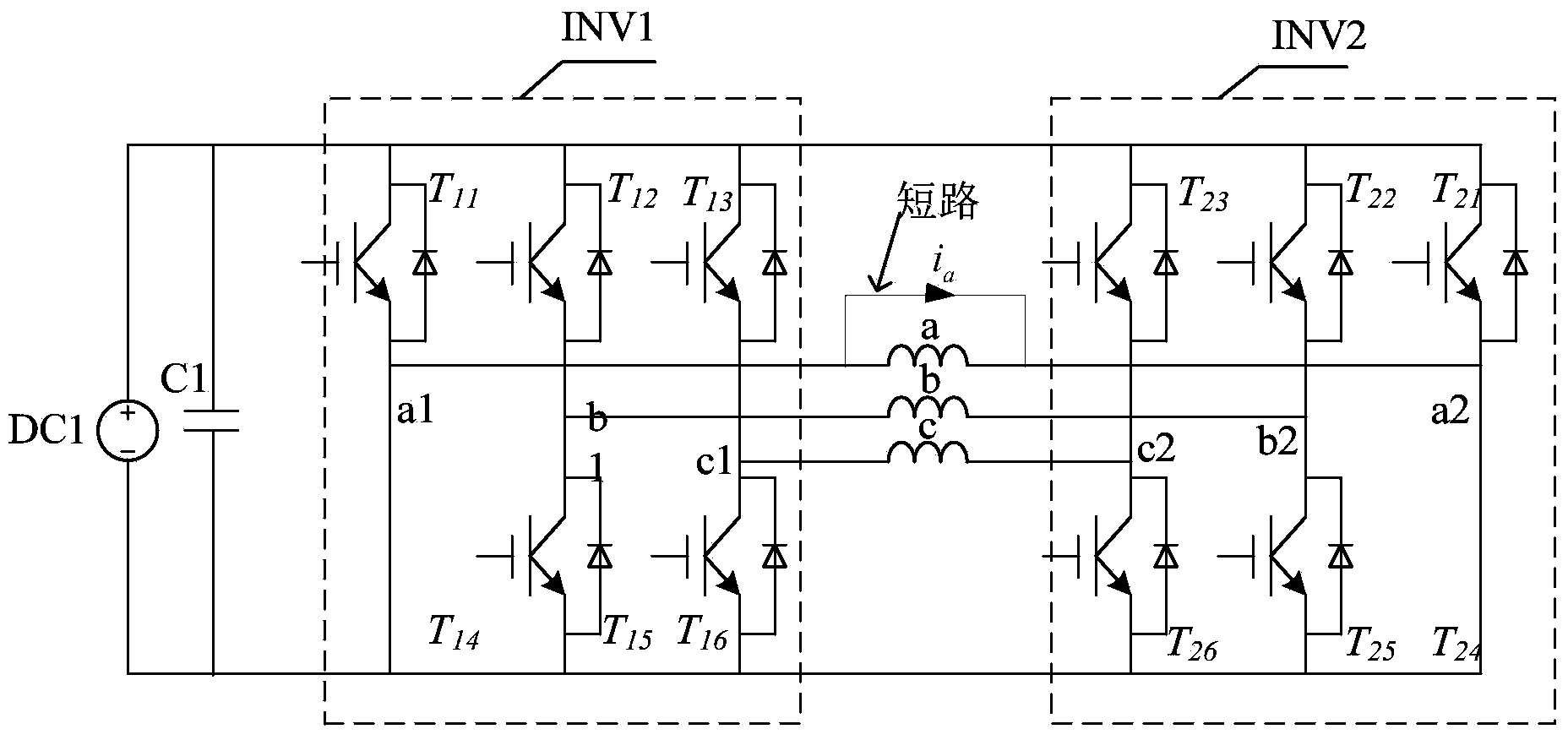

Fault tolerant system and method of single-phase winding short circuit of three-phase permanent magnet synchronous motor of open winding

InactiveCN104333272AOffset the impactSmooth torqueTorque ripple controlSingle motor speed/torque controlPhase currentsReference current

The invention discloses a fault tolerant system and method of a single-phase winding short circuit of a three-phase permanent magnet synchronous motor of an open winding. A current regulation function machine generates normal phase initial reference currents, short circuit phase currents compensate the normal phase initial reference currents, final reference currents are formed, and finally the final reference currents and double inverter normal phase currents are compared through a current hysteresis comparator to generate double inverter normal phase switching signals to double inverters. Compensation of the short circuit phase currents for the normal phase currents eliminates the influence of fault phase currents on motor torque, the purpose of tolerance of single-phase winding short circuit faults is achieved, the current use ratio of the motor winding is improved, and stable torque can be output.

Owner:SOUTHEAST UNIV

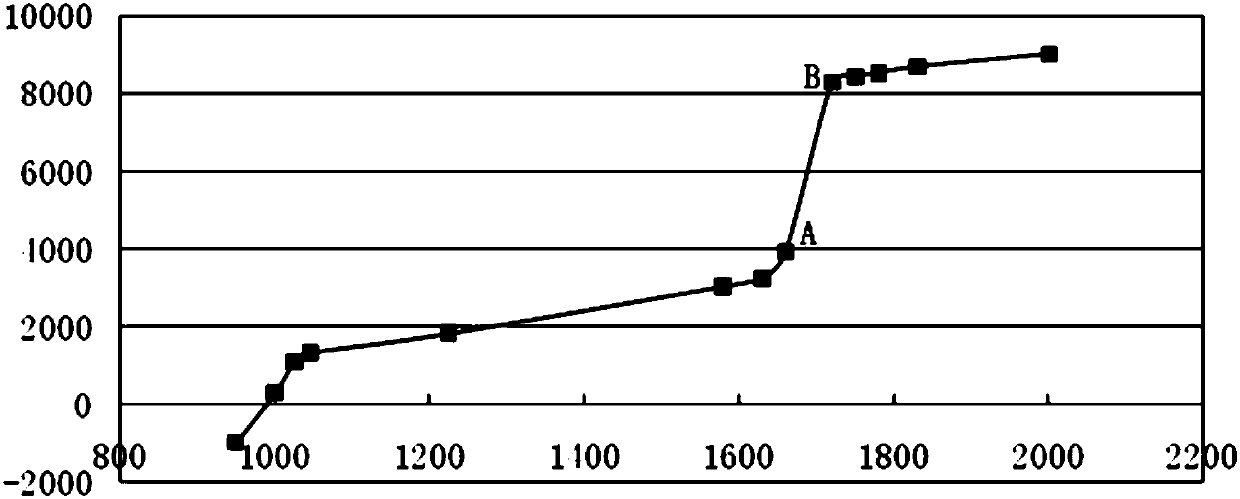

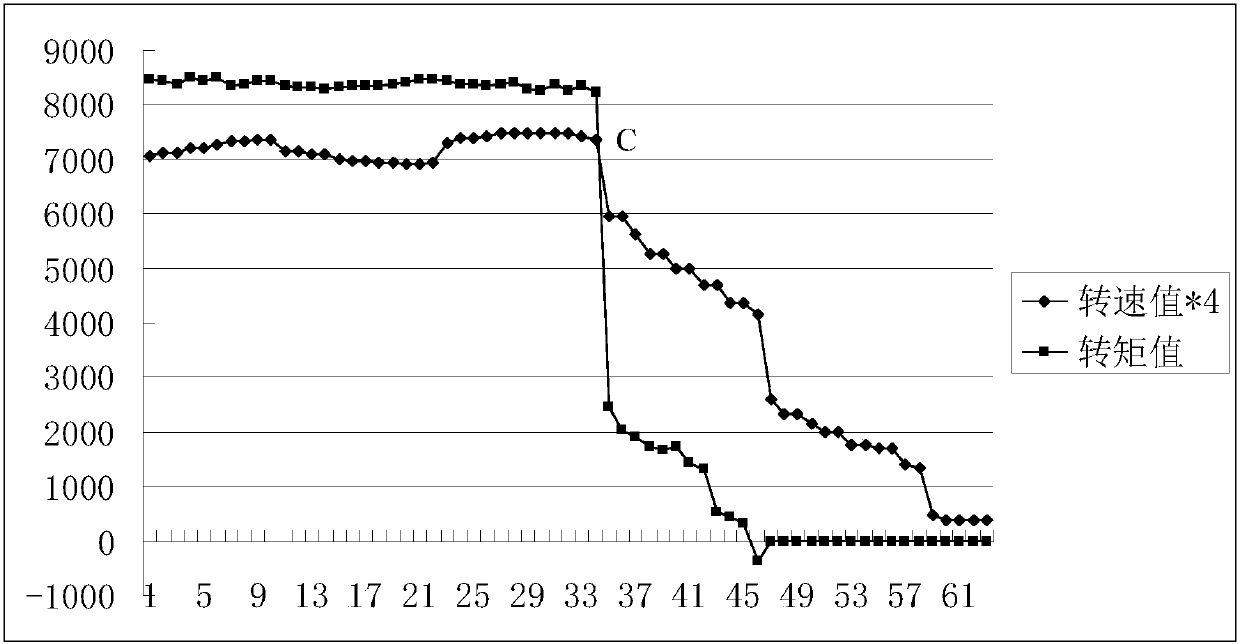

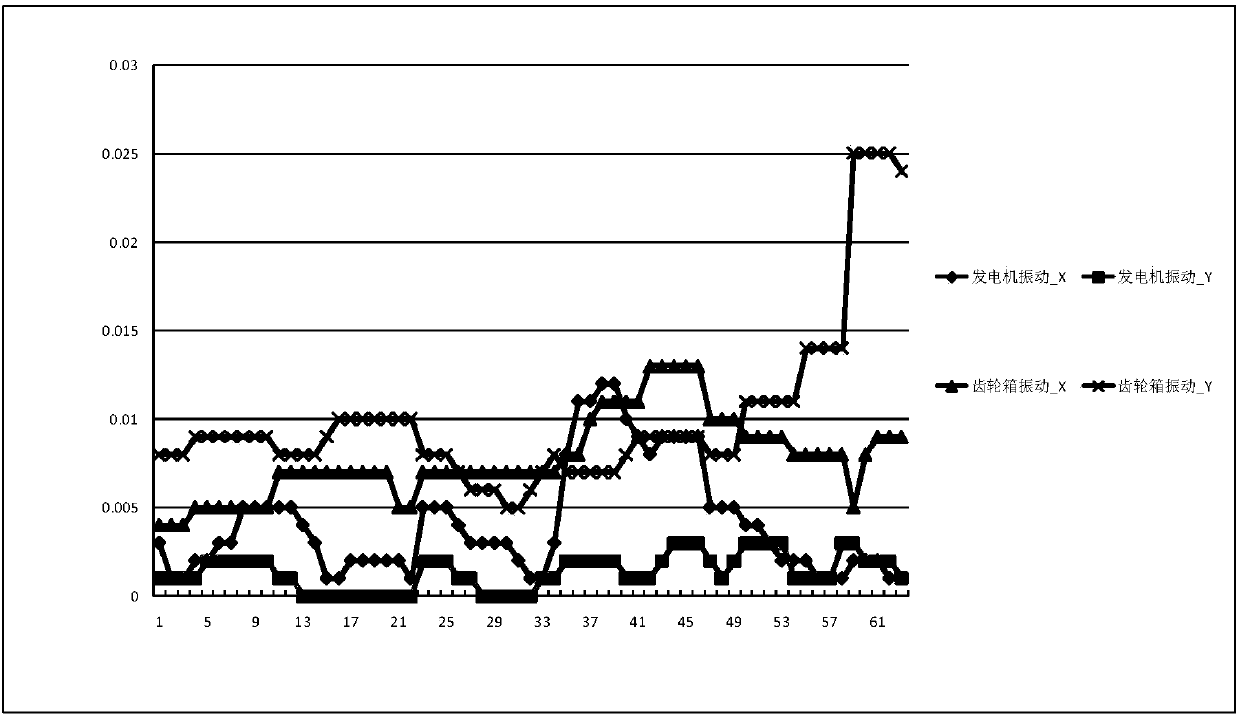

Shutdown control method and device for wind power generator set

ActiveCN108119301AReduce vibration shockSmooth torqueWind motor controlMachines/enginesDynamoWind force

The invention provides a shutdown control method and device for a wind power generator set. The method comprises the steps that an interval with a larger decrease rate of the rotating torque in a curve of the corresponding relation between the rotating speed and the rotating torque in the operating process of a preset wind power generator set is determined, an inflection point corresponding to a smaller rotating speed value in the inflection points of two ends of the interval is used as a critical point, and one or more reference points are selected according to the critical point; the rotating speed when a wind power generator is shut down is collected, when the rotating speed is higher than the rotating speed corresponding to the critical point, and a monotonous shutdown control functionwith an upward opening is constructed according to the rotating torque and rotating speed data corresponding to the reference point and the rotating torque and rotating speed data of the actual initial shutdown time of the wind power generator set; and a rotating torque value corresponding to the rotating speed is obtained according to the shutdown control function, and shutdown control is carried out on the wind power generator by utilizing the rotating torque value. According to the method, the rotating torque of the generator can be declined in a more stable manner, so that the vibration impact on the wind power generator set caused by sudden change of the rotating torque in the shutdown process is reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Wind turbine

Owner:DESIGN LICENSING INT PTY LTD

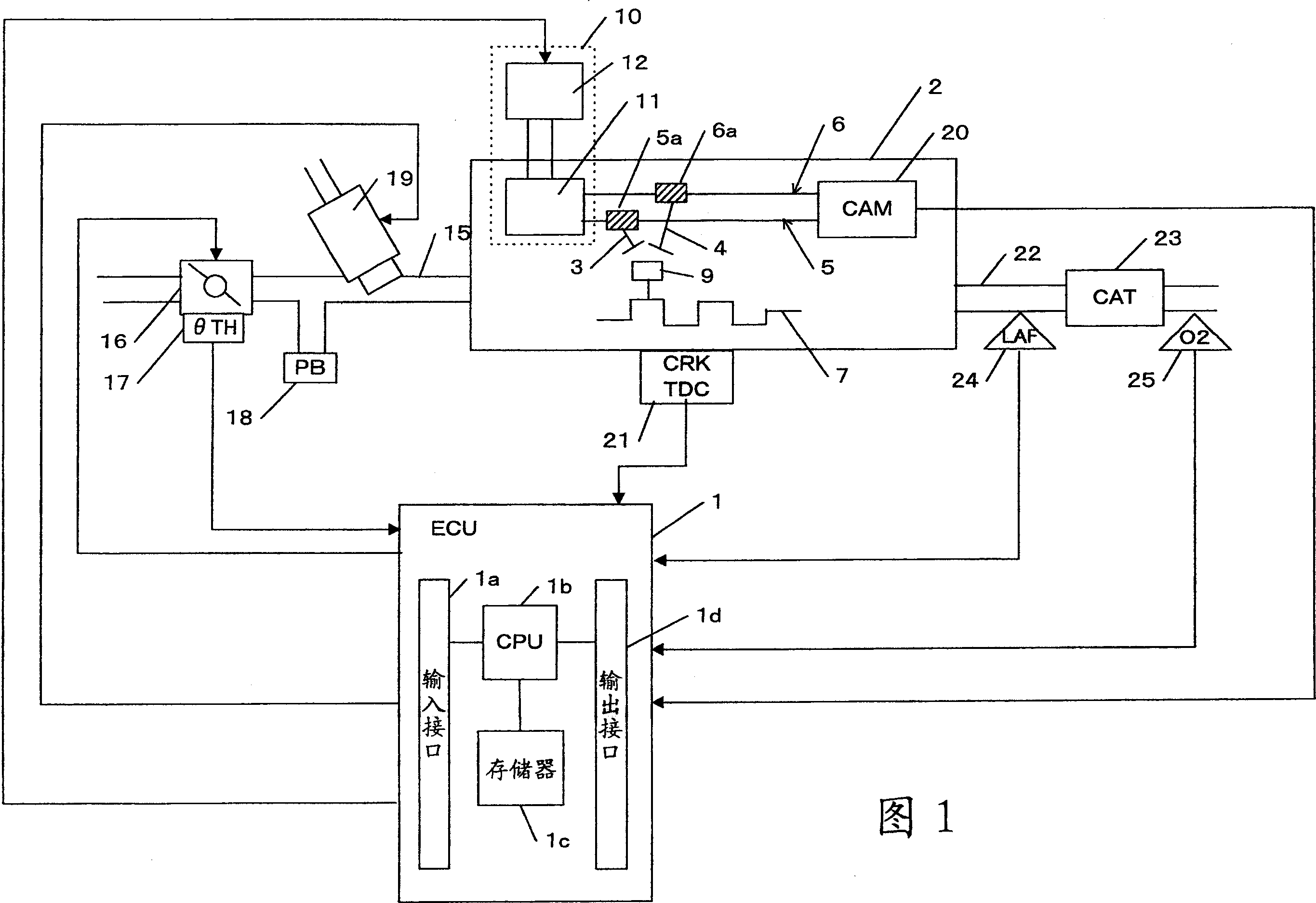

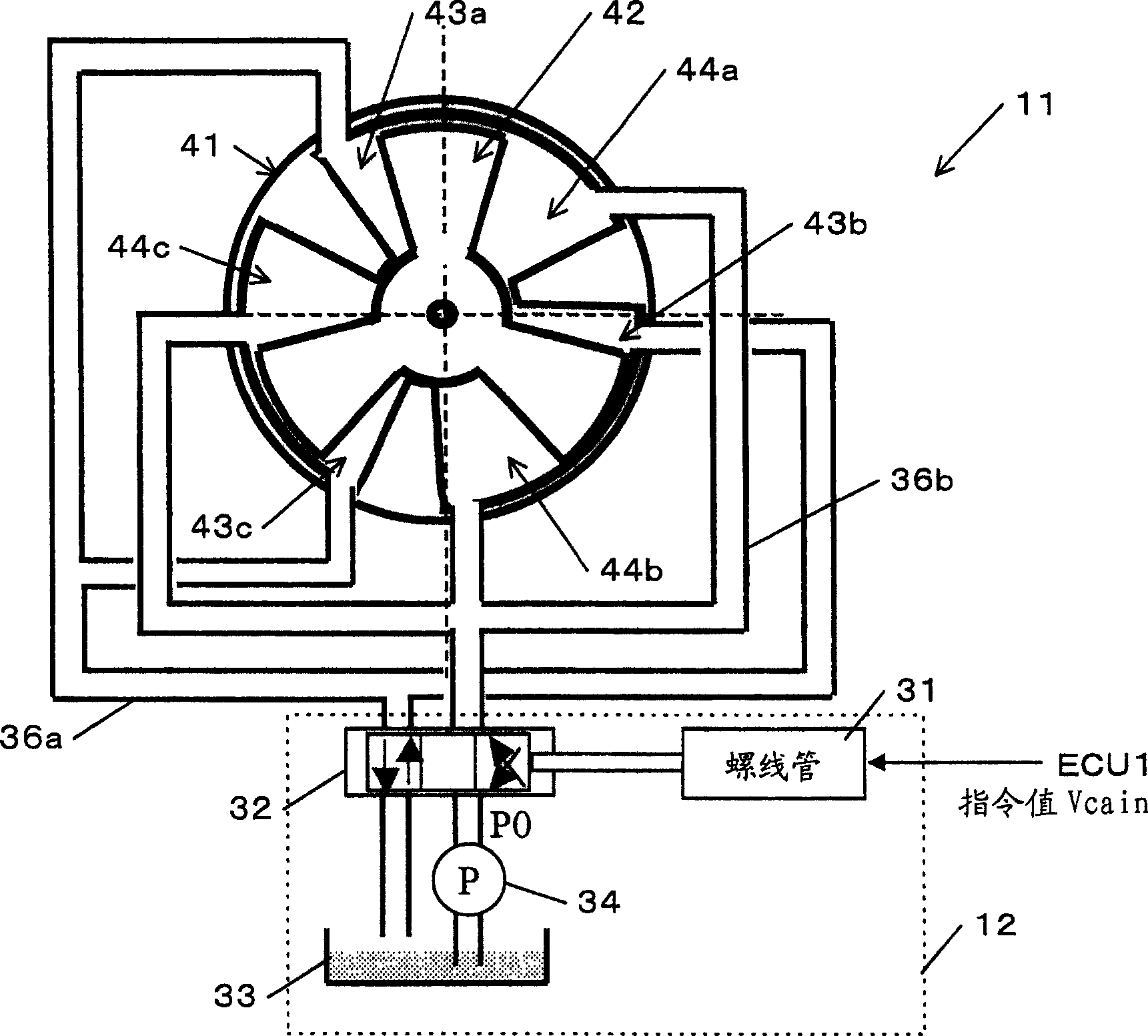

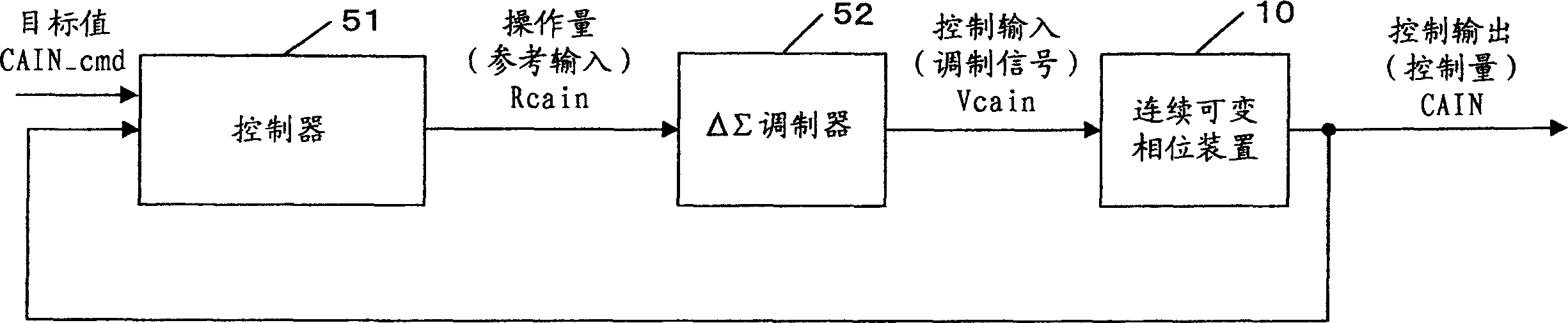

A control apparatus for controlling a plant by using a delta-sigma modulation algorithm

InactiveCN1667530AReduce surgeGood air-fuel ratioValve arrangementsElectrical controlControl theorySigma delta modulation

The invention provides a control apparatus comprising a controller for determining a manipulated variable for manipulating a controlled object so that an output of the controlled object converges to a desired value and a modulator for modulating the manipulated variable by using one of a delta-sigma modulation algorithm, a sigma-delta modulation algorithm and a delta modulation algorithm to generate a modulated signal to be applied to the controlled object. The modulator generates the modulated signal so that a center value of an amplitude of the modulated signal follows a change of the manipulated variable. Thus, the modulated signal in which the manipulated variable is reflected without any loss can be generated even when the manipulated variable changes.

Owner:HONDA MOTOR CO LTD

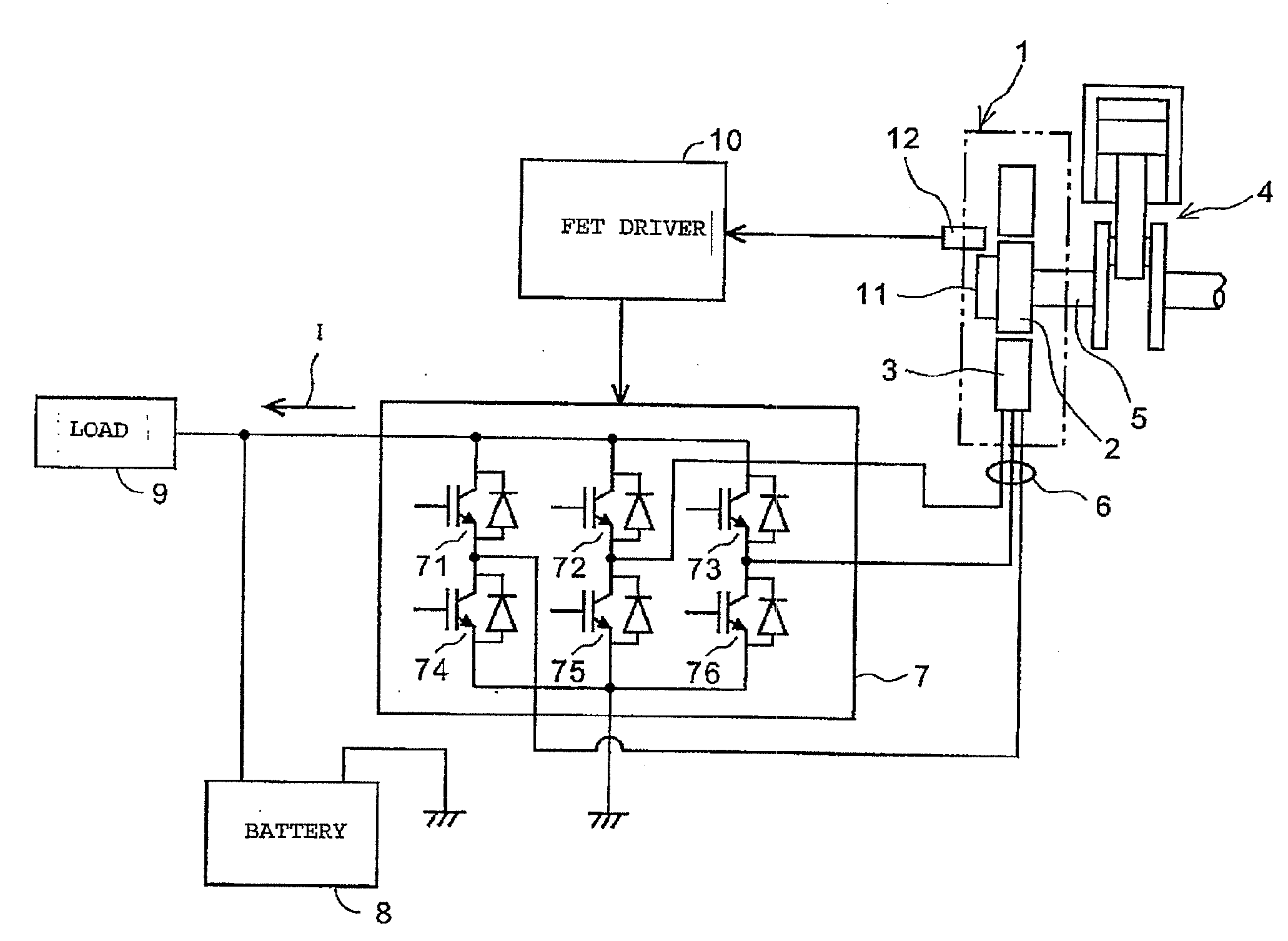

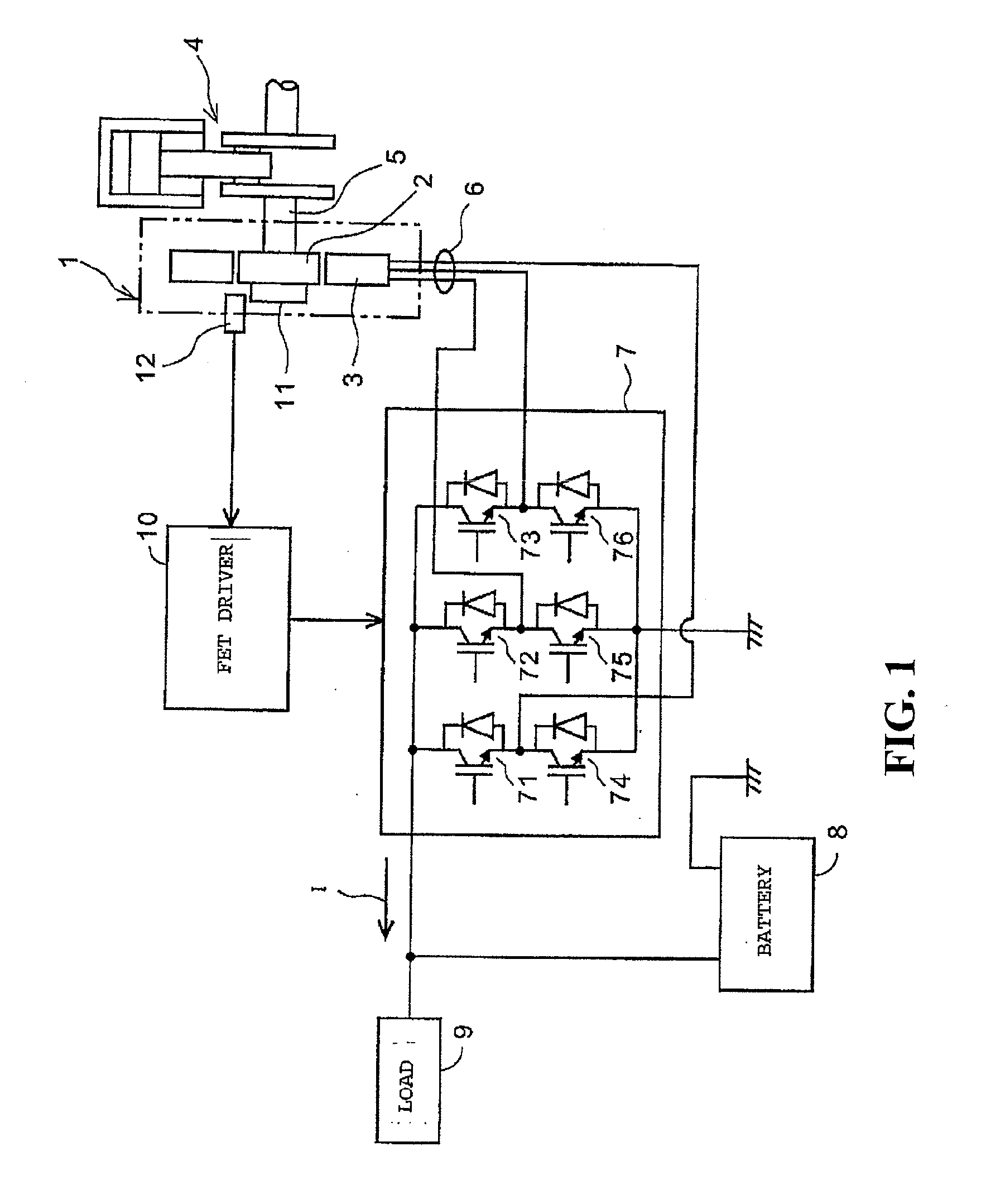

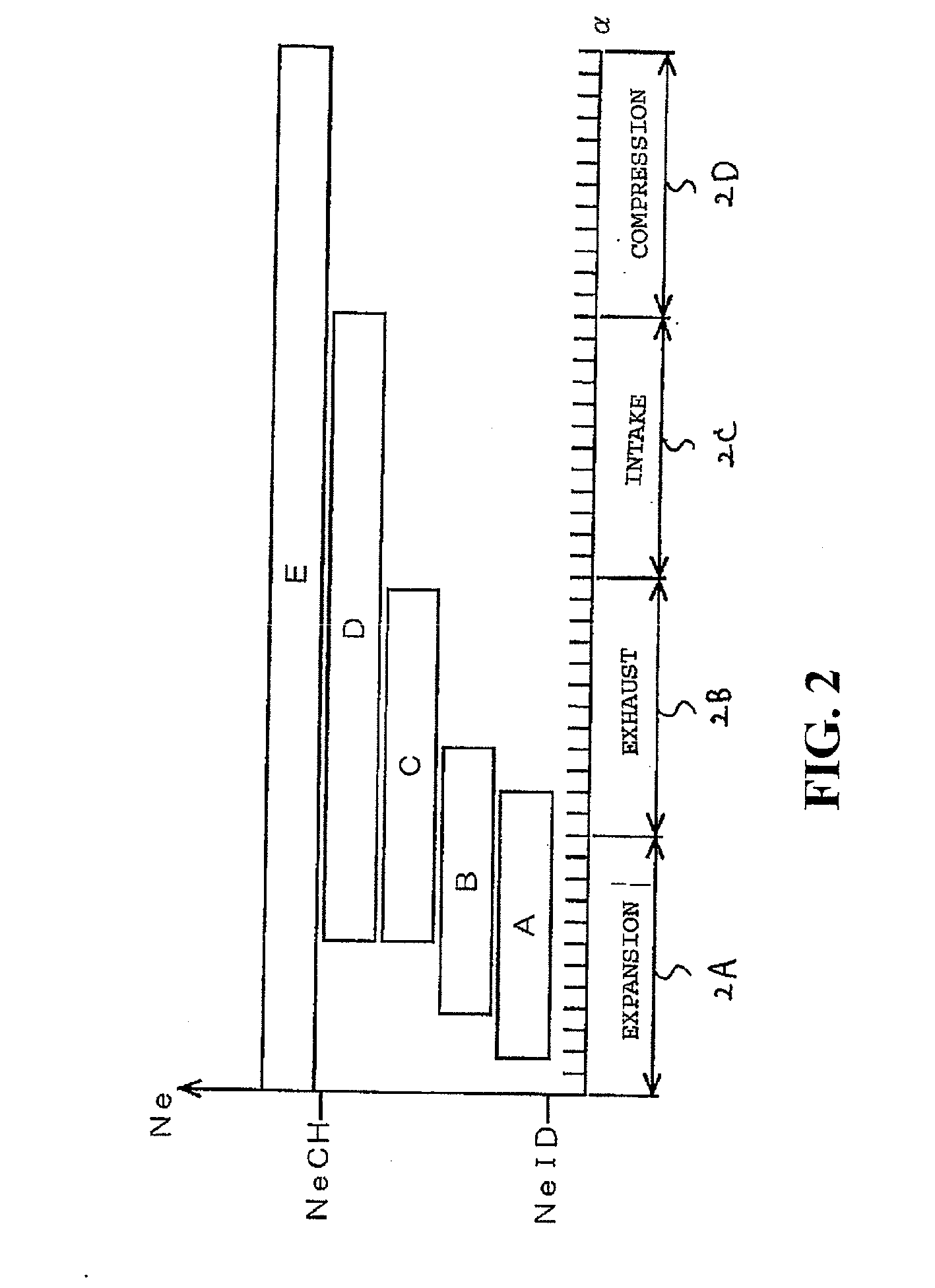

Power generation control device

InactiveUS20090079190A1Smooth torqueReduce distanceEngine controllersMachines/enginesFour-stroke engineEngineering

A power generation control device for a generator driven by a four-stroke cycle engine is provided. The power generation control device includes a switching circuit for controlling an output current from the generator; and a power generation period control device configured to operate the switching circuit to output the output current from the generator in only a predetermined power generation period of the four strokes of the engine, wherein the power generation period ranges from an expansion stroke to an intake stroke of the four strokes.

Owner:HONDA MOTOR CO LTD

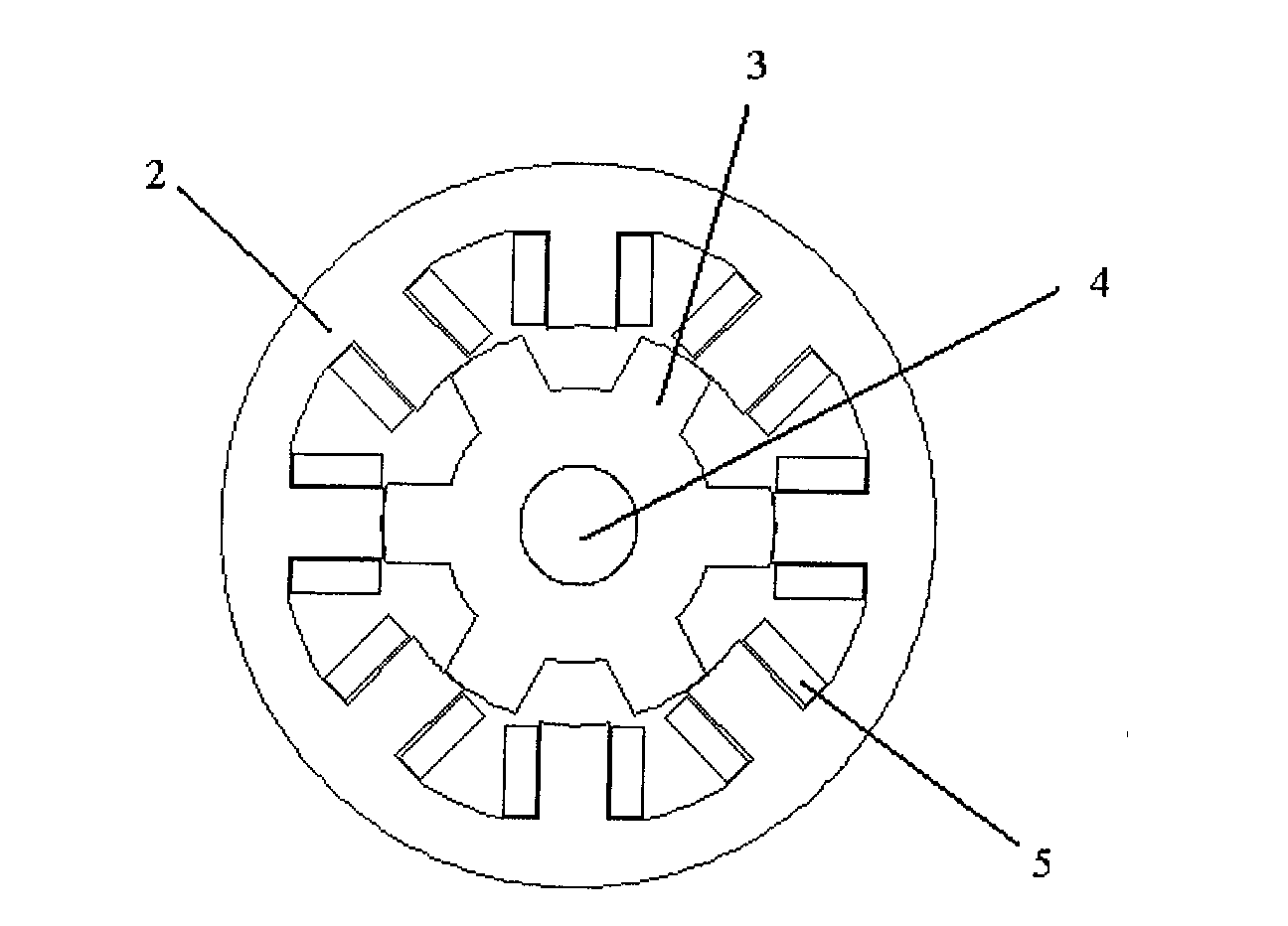

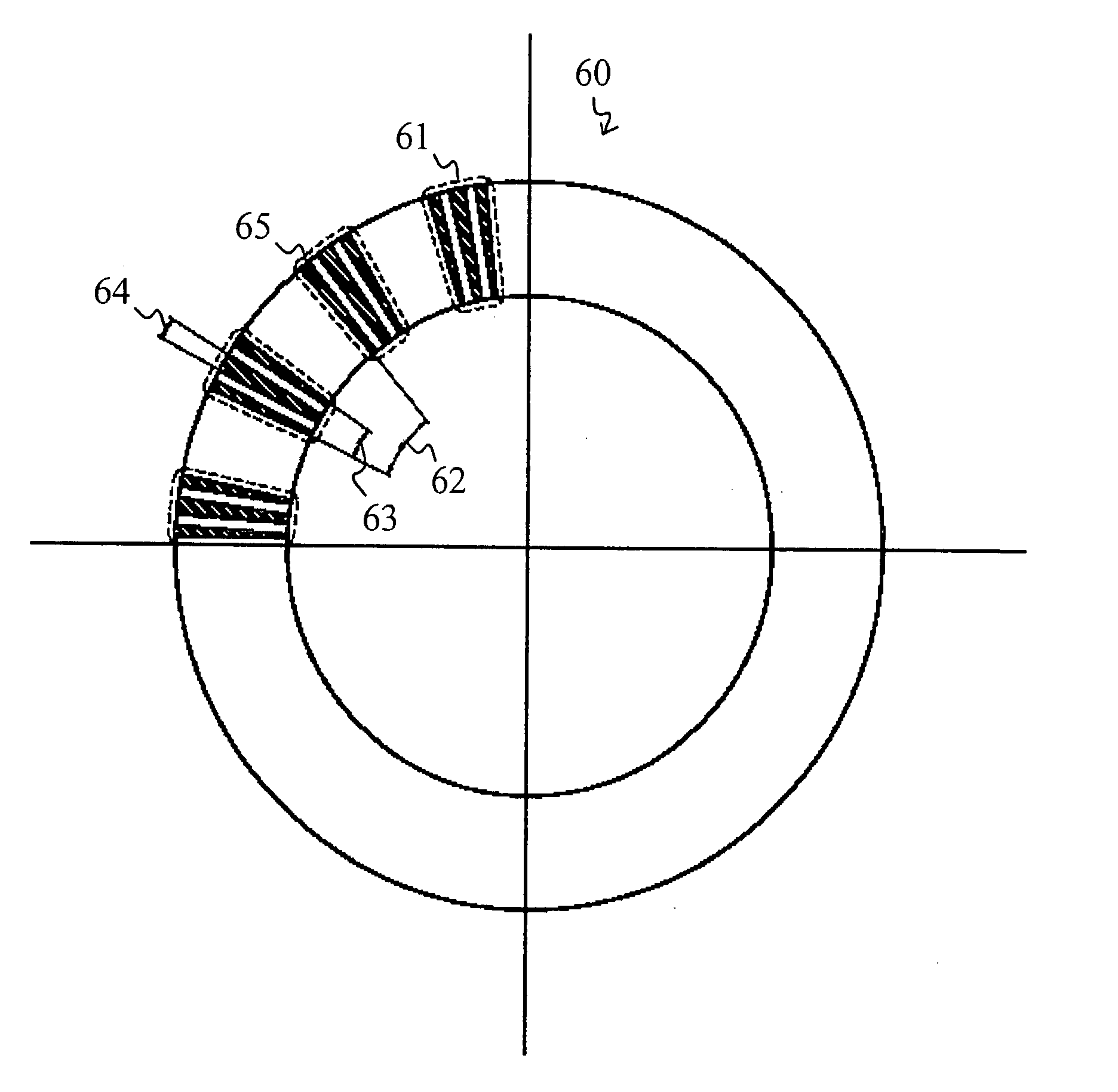

Rotor structure of switched reluctance motor

InactiveCN101667758ASmooth torqueAchieve the effect of reducing vibration and noiseMagnetic circuit rotating partsReluctance motorConductor Coil

The invention relates to a rotor structure of a switched reluctance motor, which is formed by stacking silicon steel sheets and has no windings or permanent magnets. The polar form of the rotor is a multi-air-gap salient pole structure for reducing vibration and noise, and the salient pole at the tail end of the rotor is of a multi-air-gap step type. The invention can realize steady conversion oftorques during the operation of motors, effectively reduces the great fluctuation of the torque caused by sudden change of the torque in the operation process of motors and reduces compression and expansion vibration of a motor housing structure caused by rapid alternation of the radial magnetic attraction of the motor so as to achieve the effect of reducing the vibration noise of the motor. The invention can maintain a certain output capacity of the motor and is suitable for all occasions where the switched reluctance motor is applied.

Owner:HEBEI UNIV OF TECH

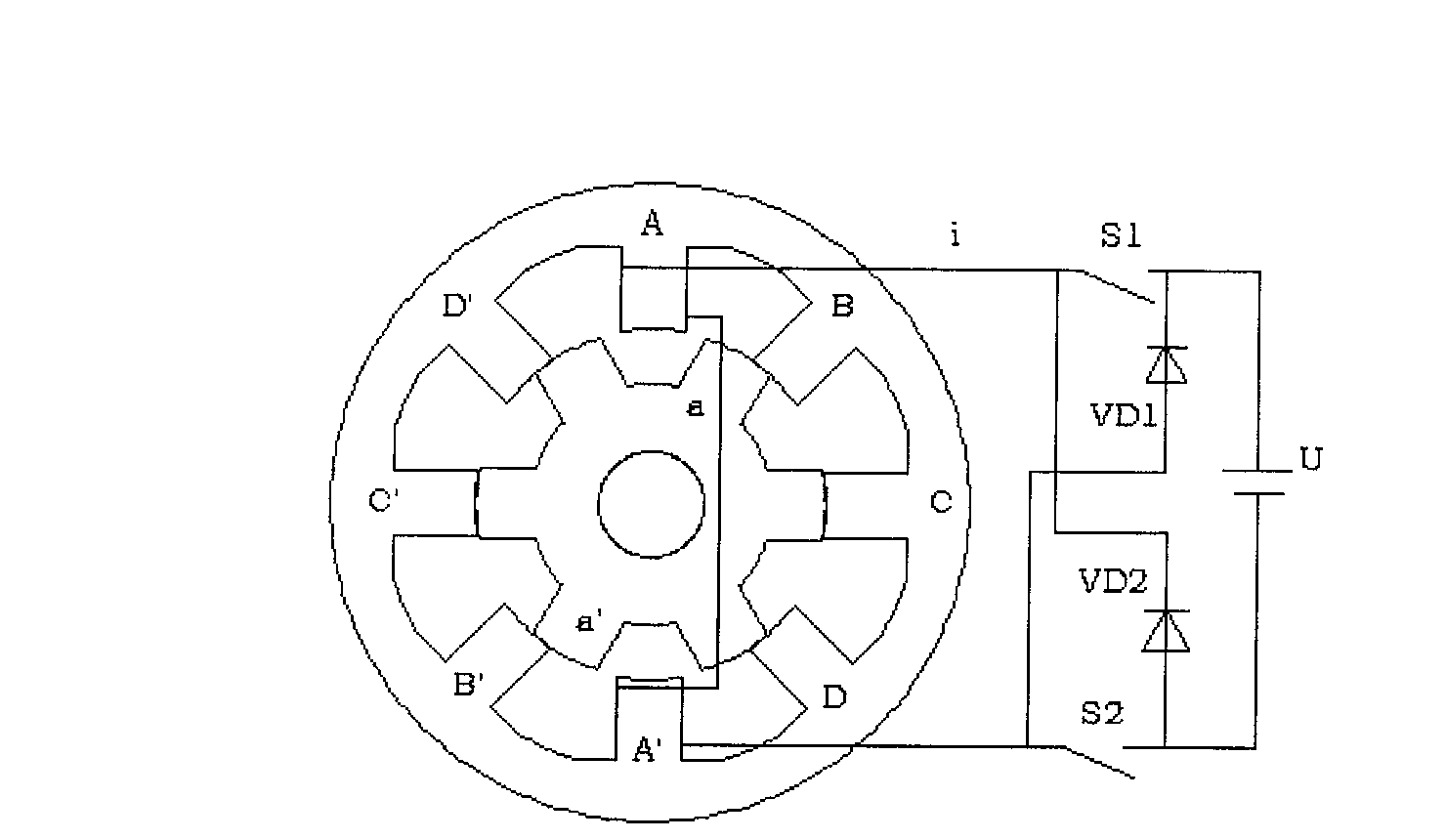

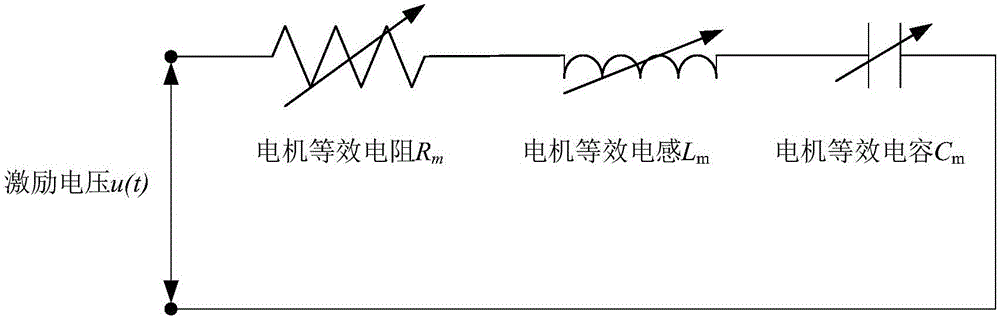

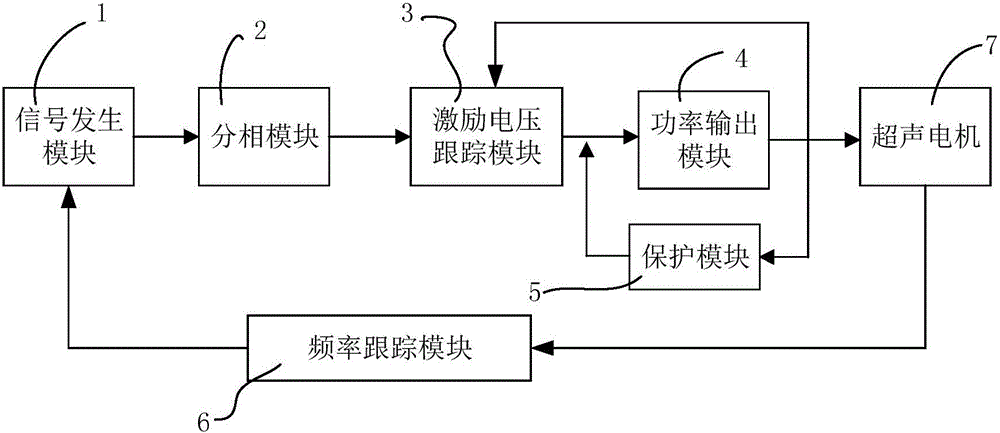

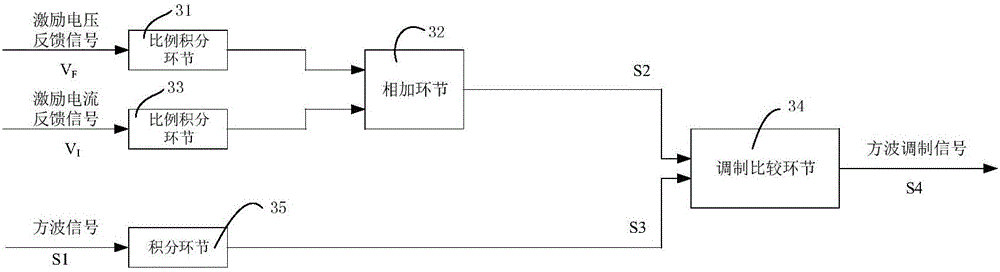

Ultrasonic motor driving control device and control method

ActiveCN104993736AStable speedSmooth torquePiezoelectric/electrostriction/magnetostriction machinesExcitation currentMotor control

The embodiment of the invention discloses an ultrasonic motor driving control device and control method and belongs to the motor control technical field. With the ultrasonic motor driving control device and control method of the invention adopted, the rotation speed and torque of the operation of an ultrasonic motor can be effectively adjusted and stabilized. The method of the invention includes the following steps that: feedback signals of excitation voltage and excitation current of the ultrasonic motor are received; square wave signals are converted to triangular wave signals through an integral link; modulation is performed according to the triangular wave signals and the feedback signals of the excitation voltage and the excitation current, so that modulated square wave signals can be obtained; and power amplification is performed on the modulated square wave signals, and the square wave signals which have been subjected to power amplification are inputted into the ultrasonic motor. The ultrasonic motor driving control device and control method of the invention are applicable to the driving control of ultrasonic motors.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

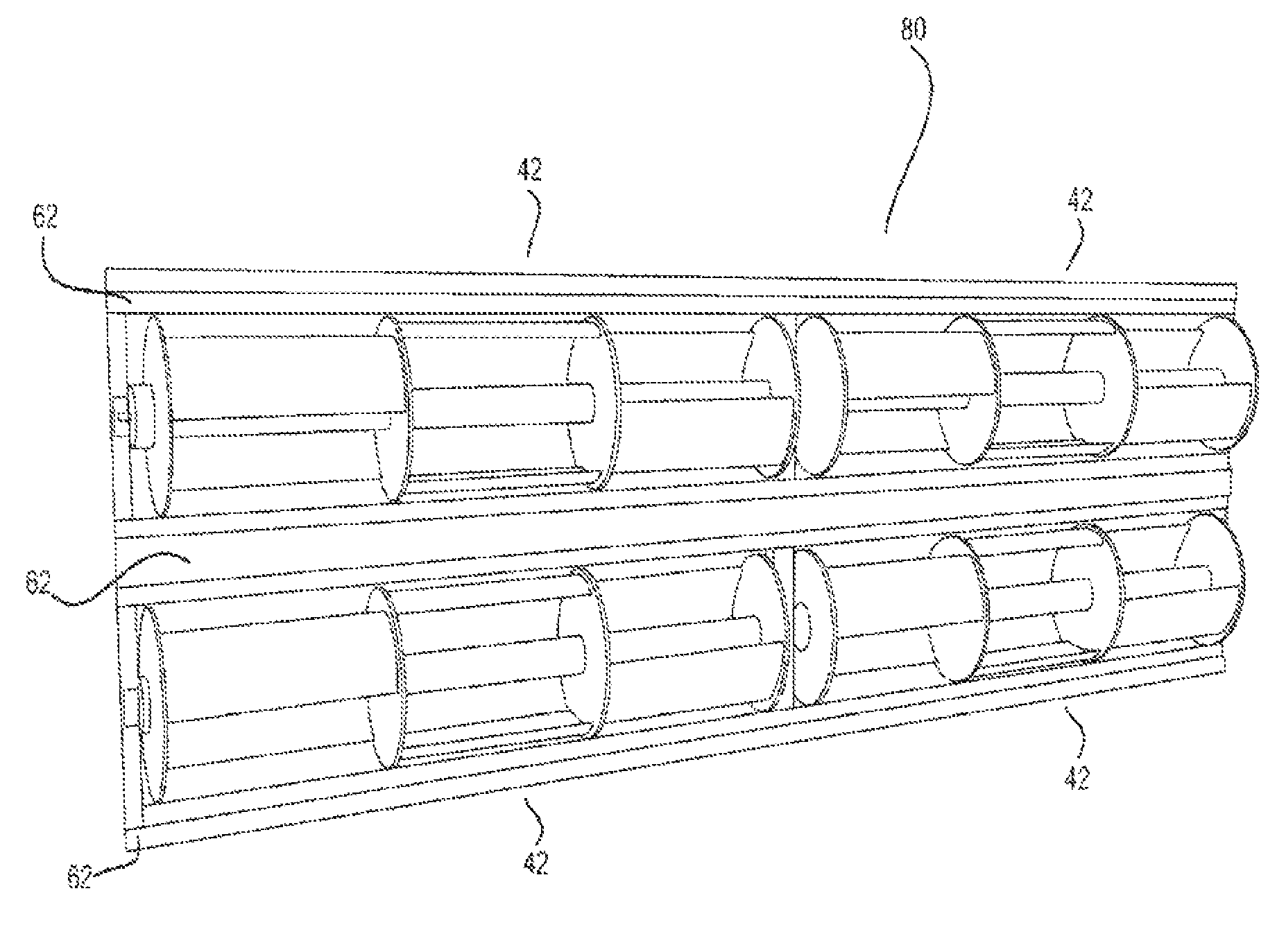

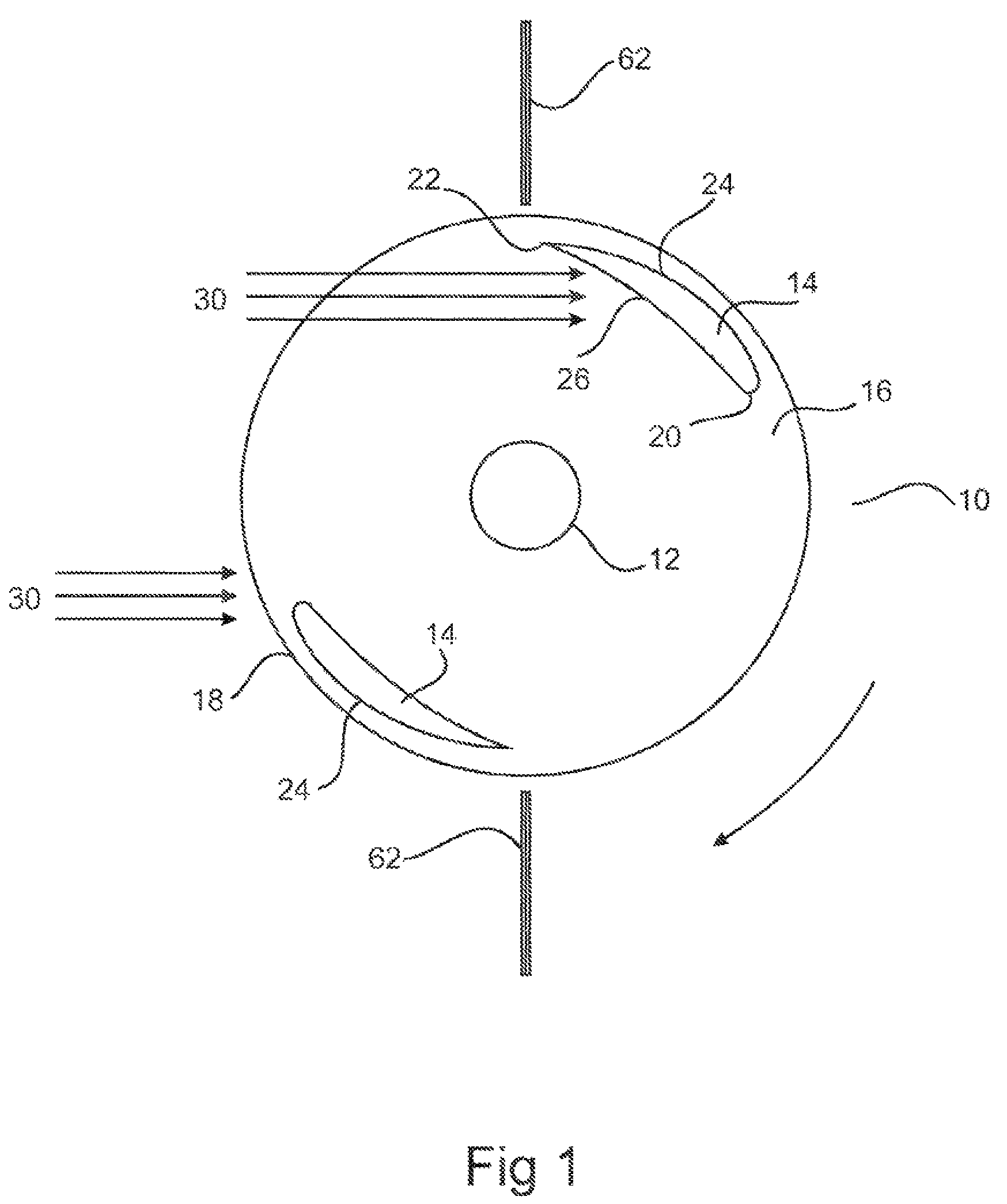

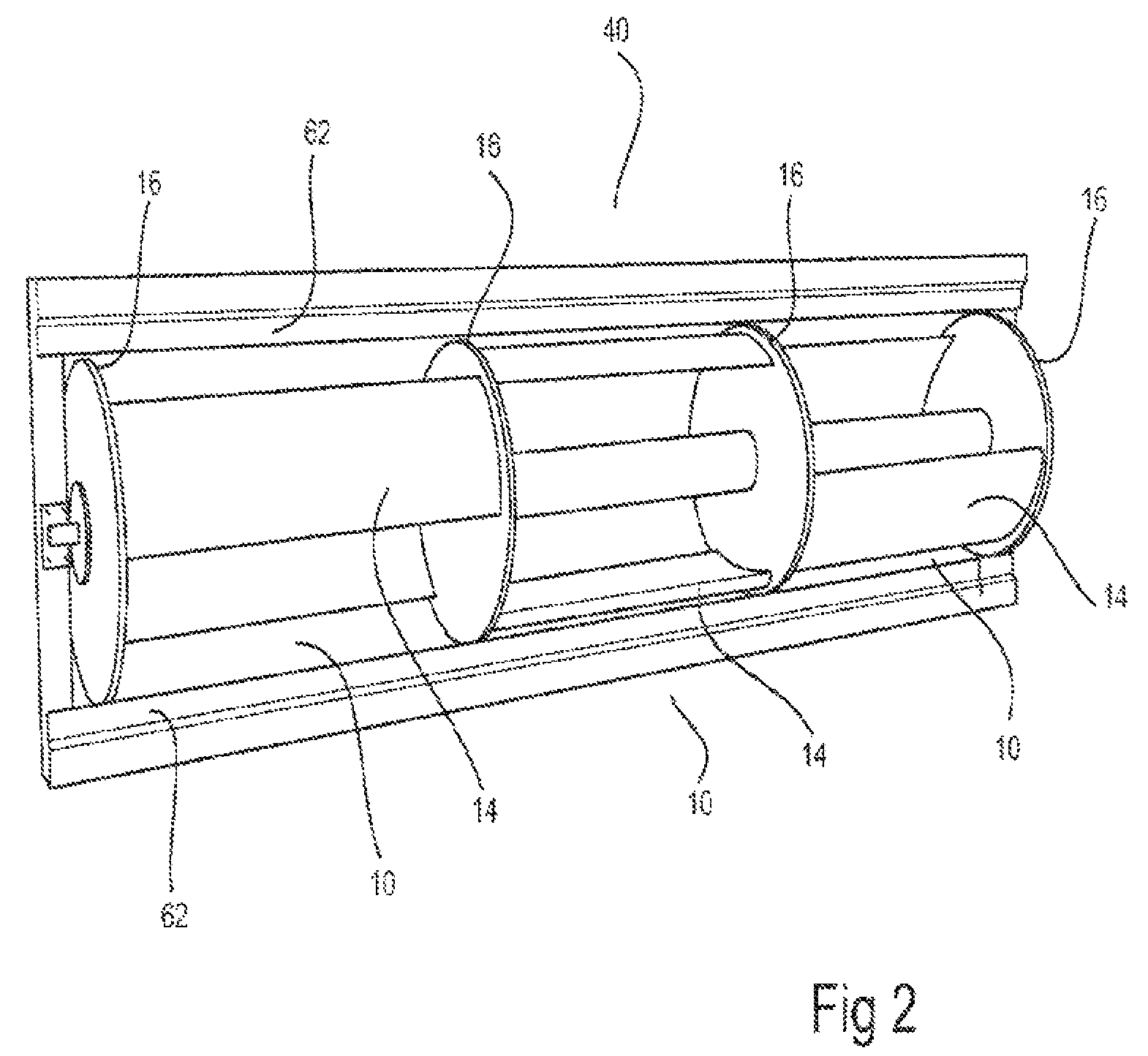

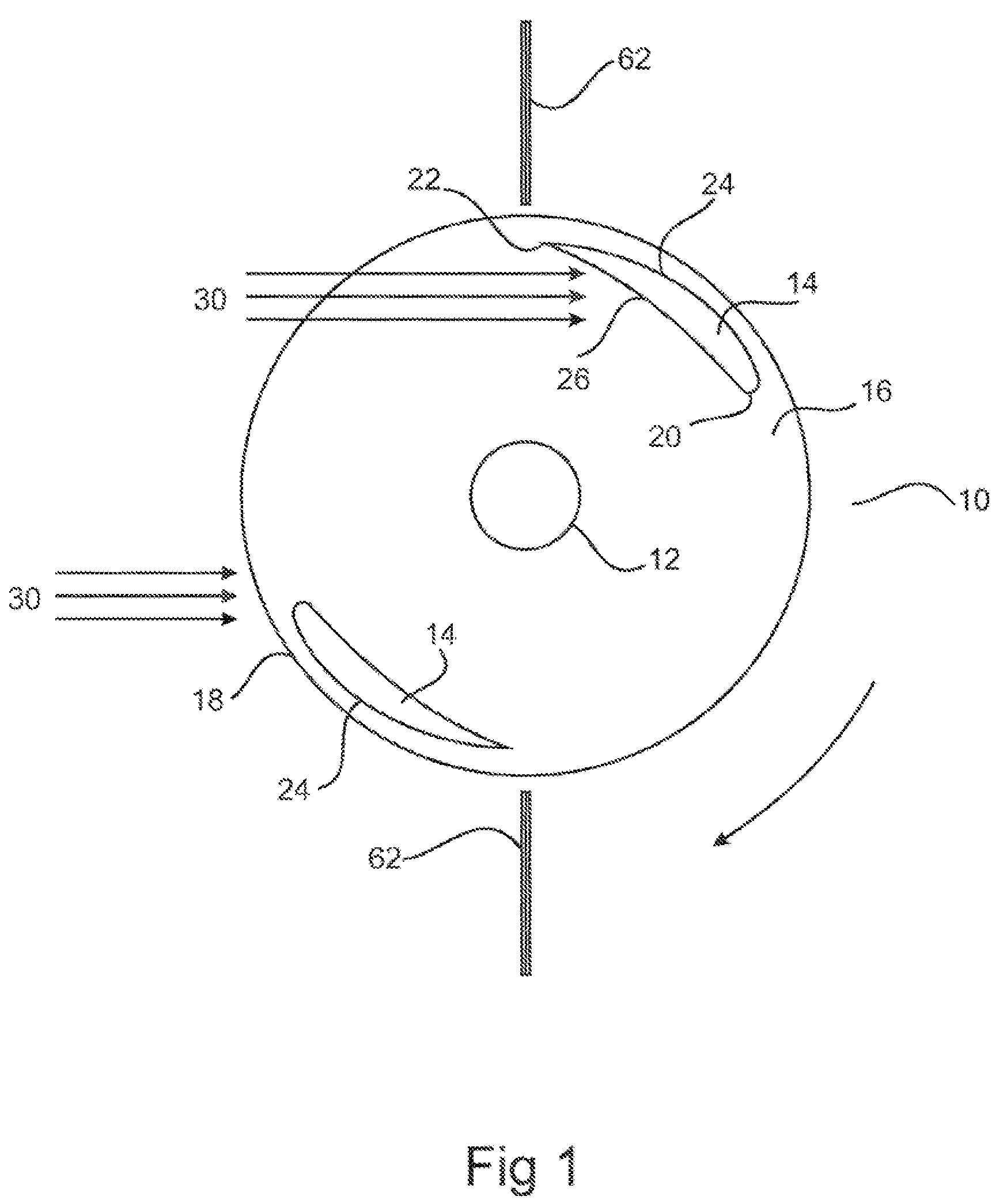

Wind turbine

InactiveUS20110070087A1Even airflowEasy to operatePropellersWind motor controlTurbine bladeWind force

A wind turbine arranged to operate in confined area is disclosed. The wind turbine is constrained within two axially displaced end plates and diametrically opposed wind barriers. The wind barriers are parallel to the axis and extend between end plates. The wind barriers each having an axially extending inner edge radially spaced from an outer swept surface of the turbine blades by less than 20% of the turbine radius. In another embodiment, there is disclosed a 2-dimensional array of wind turbines, with wind barriers being arranged between parallel axes.

Owner:DESIGN LICENSING INT PTY LTD

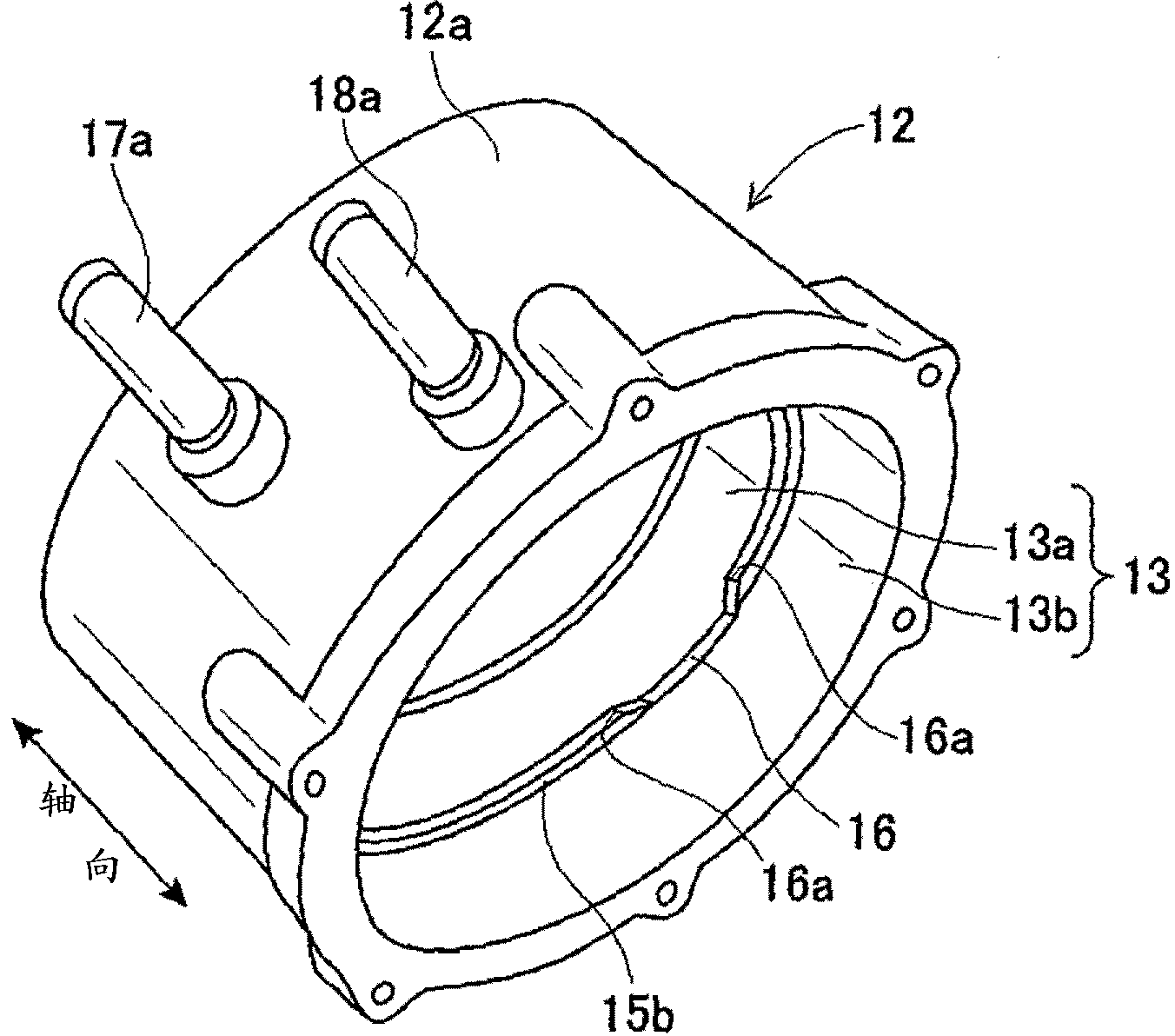

Bearing device for wheel

ActiveCN101784398AHigh strengthExcellent productivityYielding couplingRolling contact bearingsDouble rowPull force

A bearing device for a wheel, in which circumferential play is suppressed, in which a hub ring and an outer joint member of a constant velocity universal joint can be connected to each other with good workability, and in which the hub ring and the outer joint member are adapted to be separable for excellent maintainability. In the bearing device, the hub ring (1), a double-row roller bearing (2), and the constant universal joint (3) are unitized, and the hub ring (1) and a shaft (12) of the outer joint member of the constant universal joint (3), which is fitted in a hole (22) of the hub ring (1), are separably joined to each other by a groove-ridge fit structure (M). Ridges (35) extending in the axial direction are provided either the outer diameter surface of the shaft (12) of the outer joint member or the inner diameter surface (37) of the hole (22) of the hub ring (1). The ridges (35) are press-fitted into the other in the axial direction to form grooves (36) in the other such that the grooves (36) are in intimate contact with the ridges (35). Thus, the groove-ridge fit structure (M) is formed, in which the ridges (35) and the grooves (36) are in close contact with each other in the entire area of the fit-contact portion (38) between the ridges (35) and the grooves (36). The groove-ridge fit structure (M) allows separation between the hub ring and the outer joint member performed by pulling force applied in the axial direction.

Owner:NTN CORP

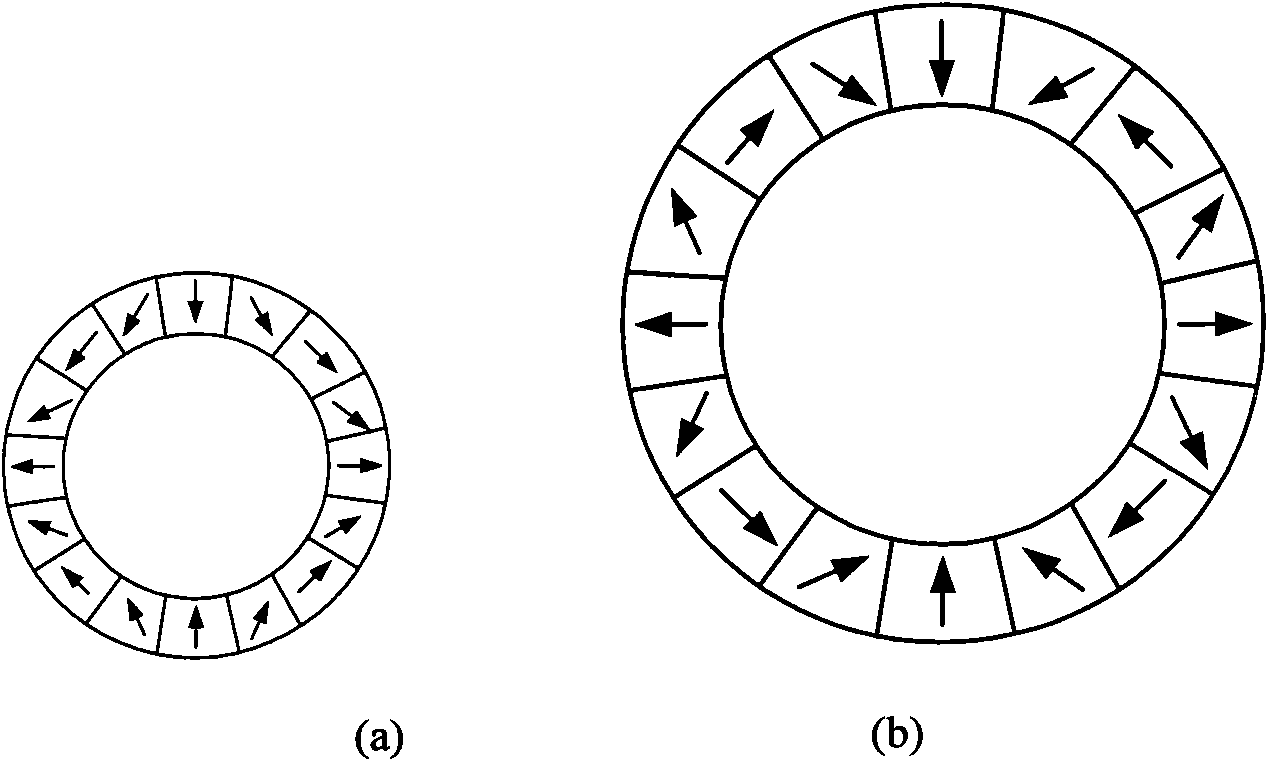

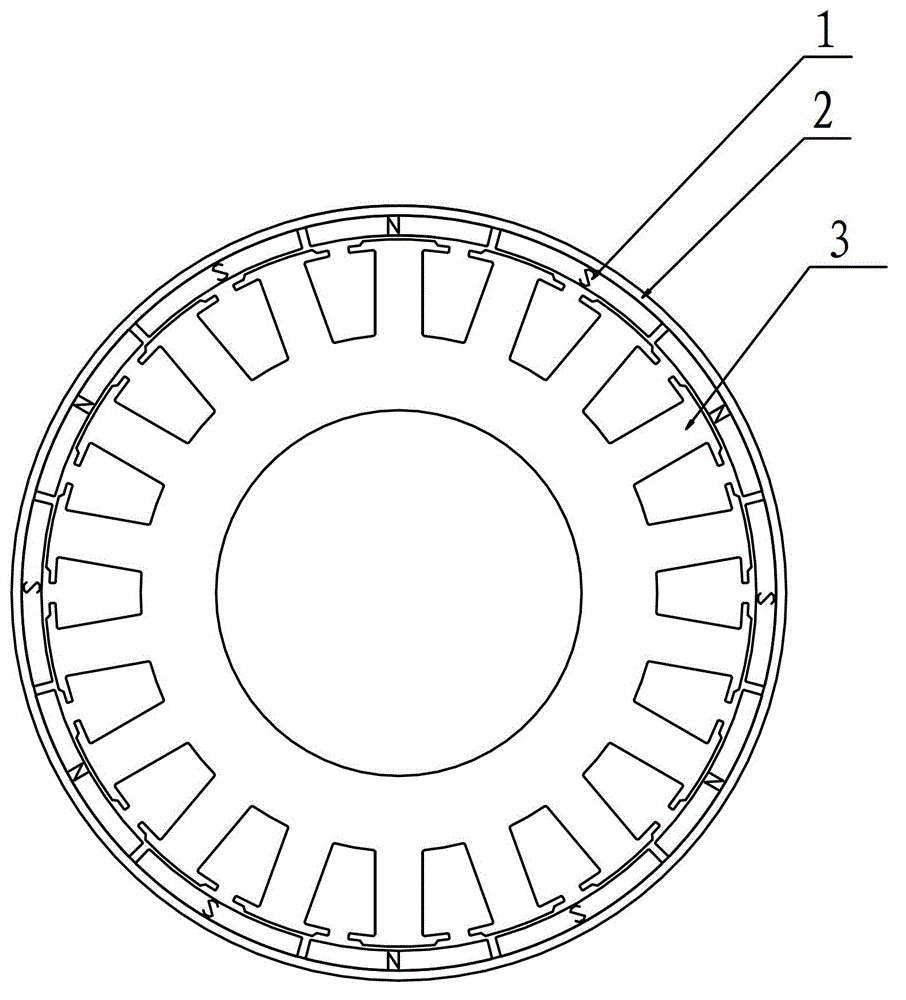

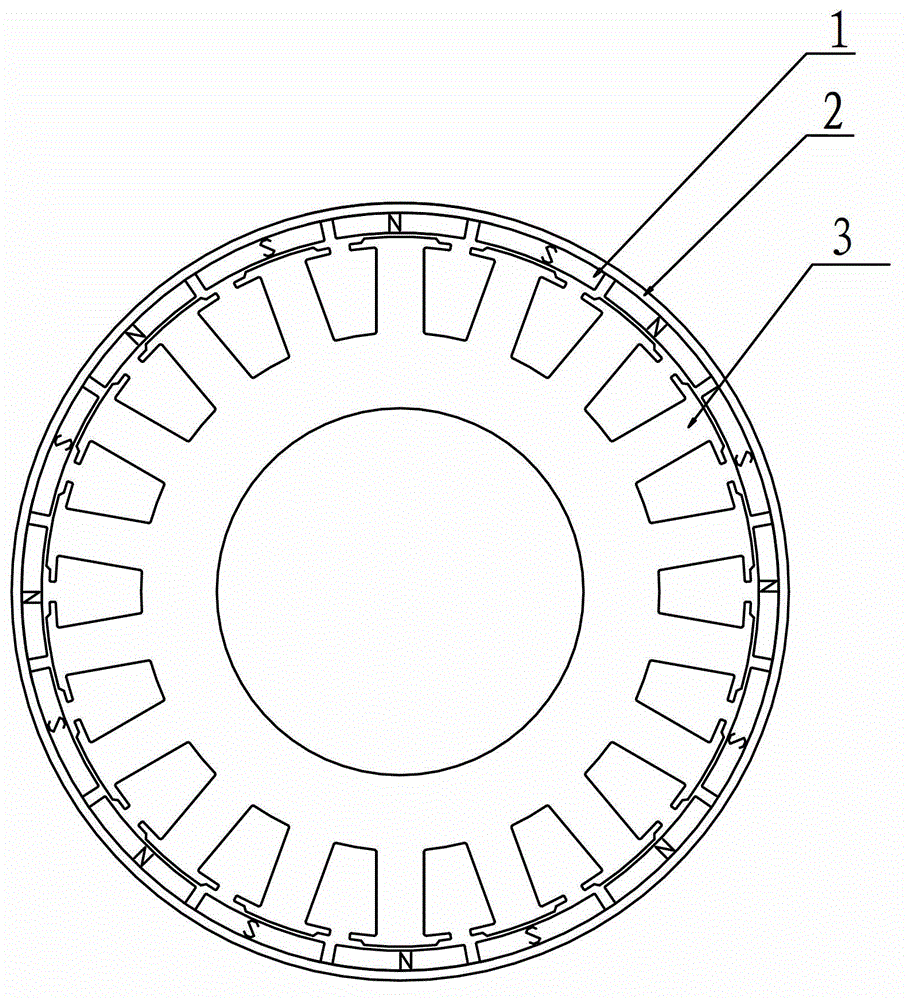

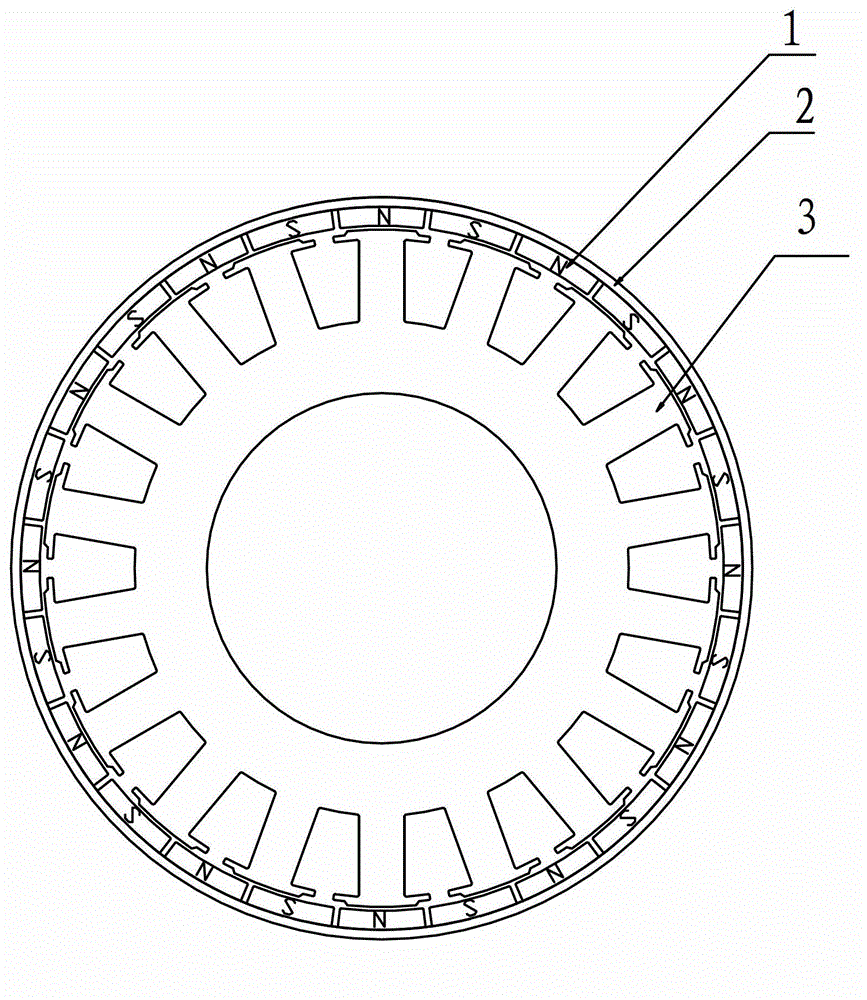

Magnetic circuit structure of washer variable frequency DC motor

InactiveCN104377853AImprove efficiencySmooth torqueMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineHarmonic

The invention provides a magnetic circuit structure of a washer variable frequency DC motor, and relates to the technical field of washers. The magnetic circuit structure of the washer variable frequency DC motor comprises a stator iron core, magnetic shoes are arranged on the outer circumference of the stator iron core, and a magnetic yoke is arranged outside the magnetic shoes. The magnetic circuit structure of the washer variable frequency DC motor is characterized in that an N pole and an S pole are formed in the same magnetic shoe through magnetic steel magnetizing, the magnetic shoes are circumferentially and evenly distributed on the magnetic yoke so that each pair of N pole and S pole can deflect relative to the angle of the circle center, harmonic waves of 2p and the multiple of 2p are weakened, the efficiency of the motor is improved, and meanwhile the processing technology is simplified. Twelve magnetic shoes are evenly distributed on the magnetic yoke to form a motor with 12 pairs of poles, and cogging torque can also be weakened. The entire machine working noise caused by torque fluctuation is reduced, meanwhile, the motor can achieve higher torque density, the mechanical hardness of the motor is improved, and revolution drop caused by incremental loading of the motor is reduced. Meanwhile, the system response speed is increased under the condition of the same loads, the acceleration time can be shortened, and the unit eddy-current loss of the stator iron core of the motor can further be reduced.

Owner:ANHUI JULONG TRANSMISSION TECH

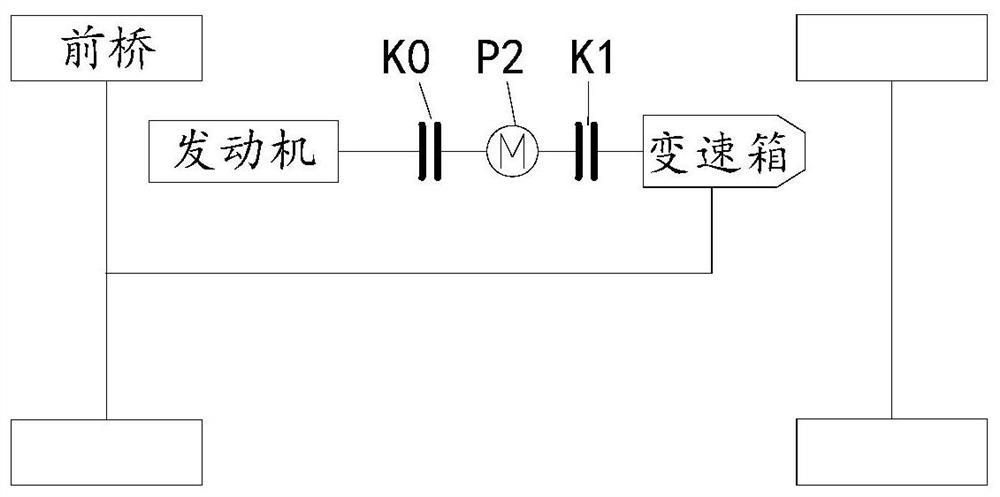

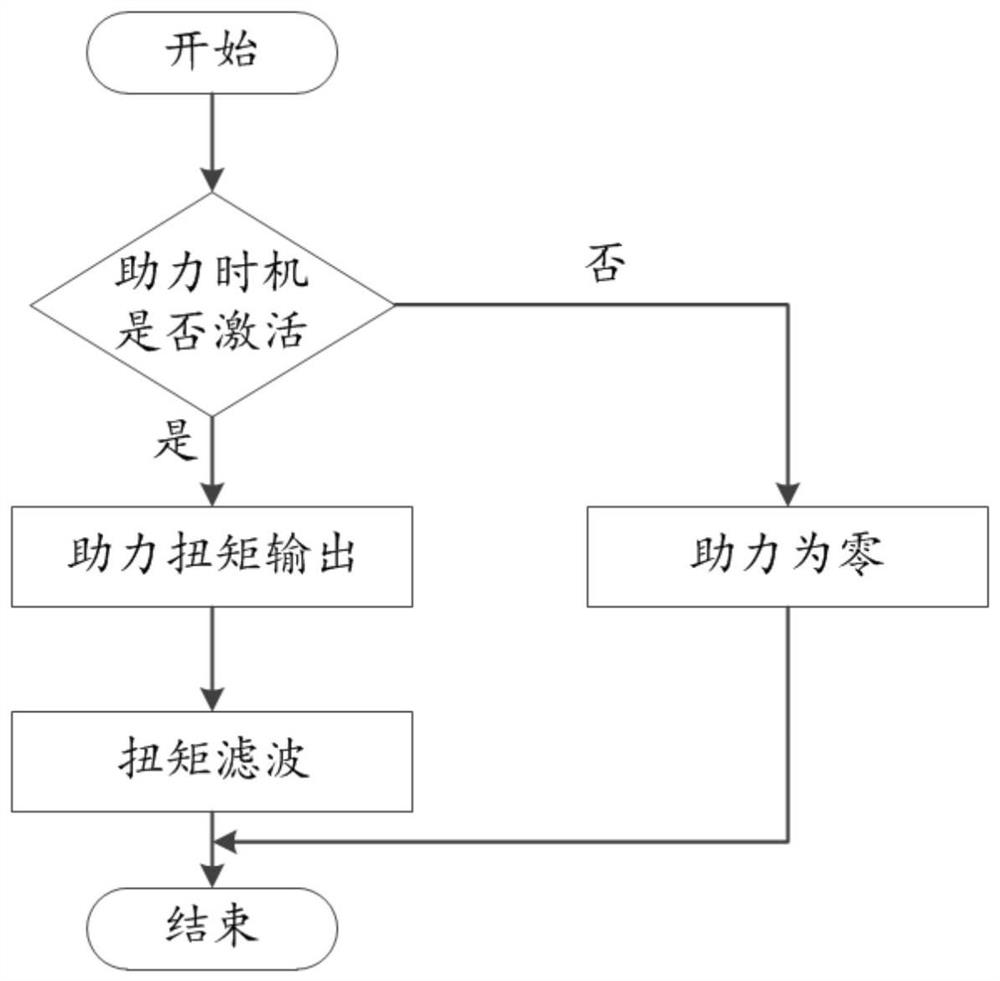

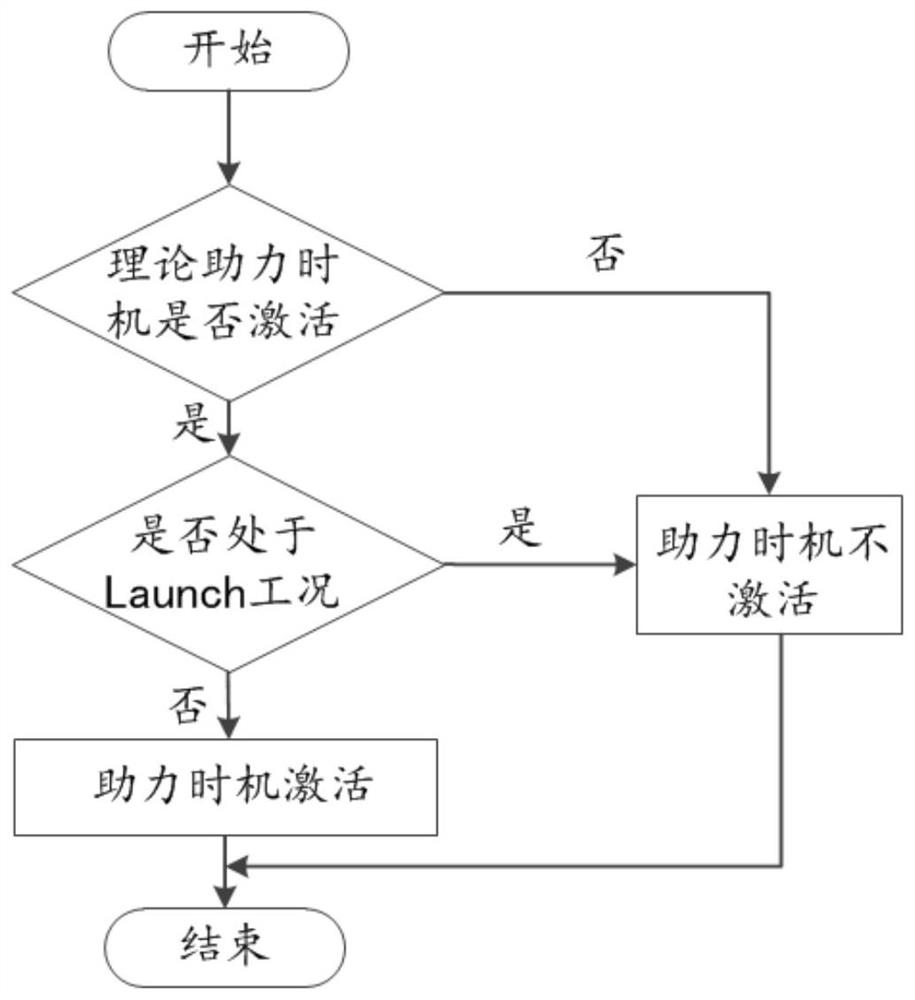

Turbine hysteresis power-assisting compensation method, device and equipment as well as hybrid vehicle

ActiveCN112253308ASmooth torqueAccurateHybrid vehiclesElectrical controlElectric machineryControl theory

The invention relates to a turbine hysteresis power-assisting compensation method, device and equipment as well as a hybrid vehicle. The method comprises the following steps: calculating a theoreticalrequired power-assisting torque initial value Ts; comparing the theoretical required power-assisting torque Ts with the maximum output torque Tpmax of a P2 motor, wherein when Ts is larger than or equal to Tpmax, the required output power-assisting torque Ts' is equal to Tpmax; and when Ts is smaller than Tpmax, the required output power-assisting torque Ts' is equal to Ts; judging whether the turbine hysteresis power-assisting opportunity is activated or not; if so, outputting the required output power-assisting torque Ts'; and if not, making the power assisting be zero. The device and the equipment execute the method. The device or the equipment of the hybrid vehicle executes the method. Through the application of the scheme of each embodiment of the invention, the adverse effects of slow torque response, sudden torque change and the like on the whole vehicle caused by turbine hysteresis can be effectively avoided, and the drivability and dynamic property of the whole vehicle are improved.

Owner:GREAT WALL MOTOR CO LTD

Reduction of harmonics in an electric motor

ActiveUS20070241634A1Reduce noise levelReduce vibrationMagnetic circuit rotating partsMagnetic circuit stationary partsHarmonicConductor Coil

In the present invention the positions of the slots or poles of the stator of an electric motor are changed in order to reduce the harmonics caused by the stator winding and any vibration caused by these harmonics. In the present invention a shape function is defined according to the new placement positions for the stator slots and / or stator poles. A conversion function sums for the slot placement positions to be given to equidistant stator slotting placement. In one embodiment of the invention the conversion function is the sum of sinusoidal functions and in its amplitude small in relation to the distance between the slots.

Owner:KONE CORP

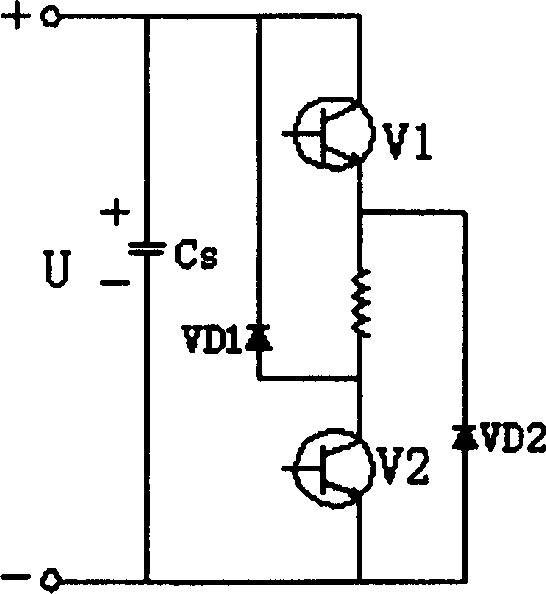

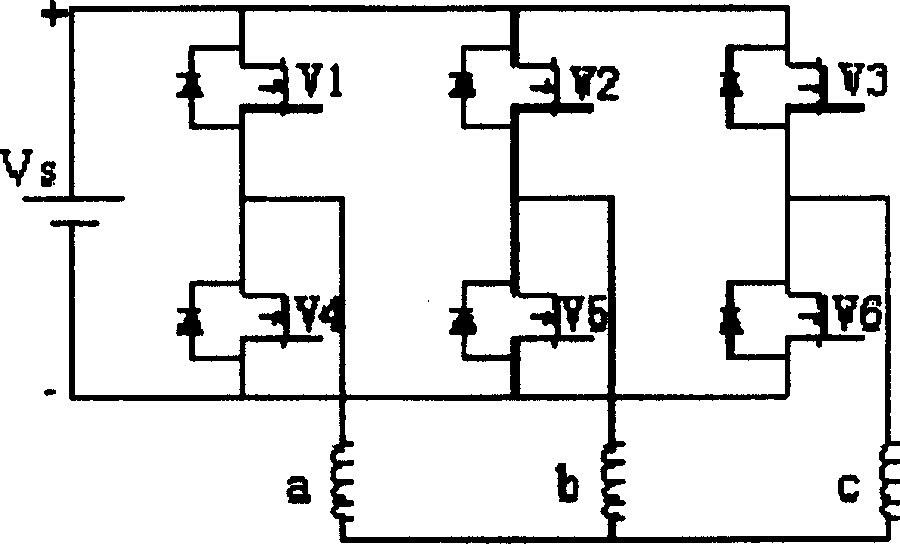

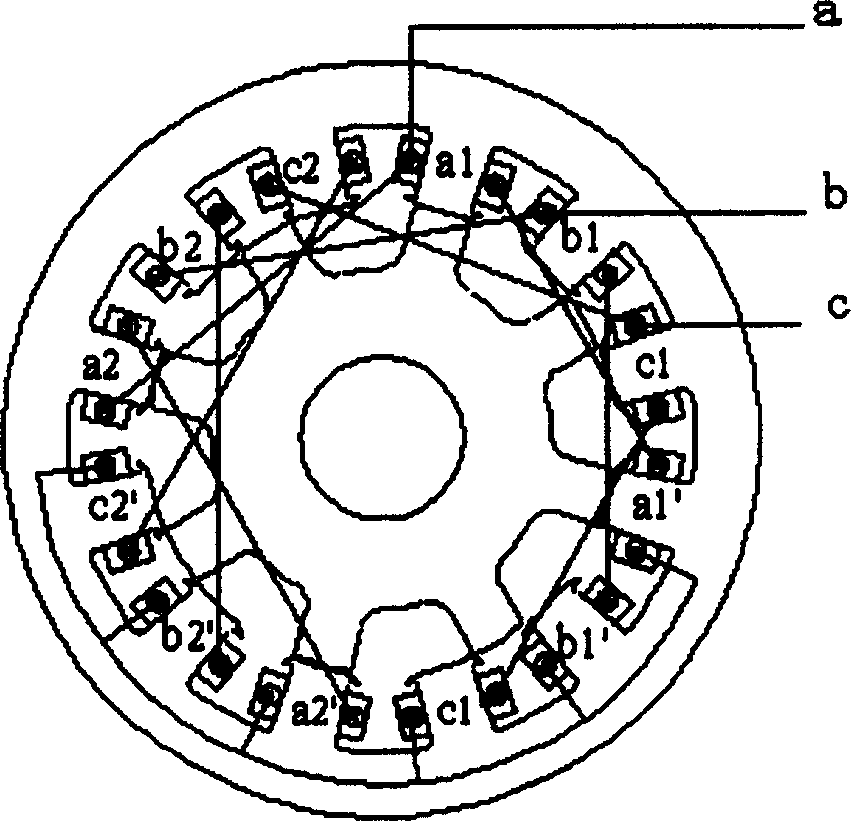

Control method of power converter in speed regulating system for three phase switched magnetic resistant motor

InactiveCN1266823CIncrease the output per unit volumeReduce the number of turnsAC motor controlSingle motor speed/torque controlElectricityThree-phase

Owner:HEFEI UNIV OF TECH

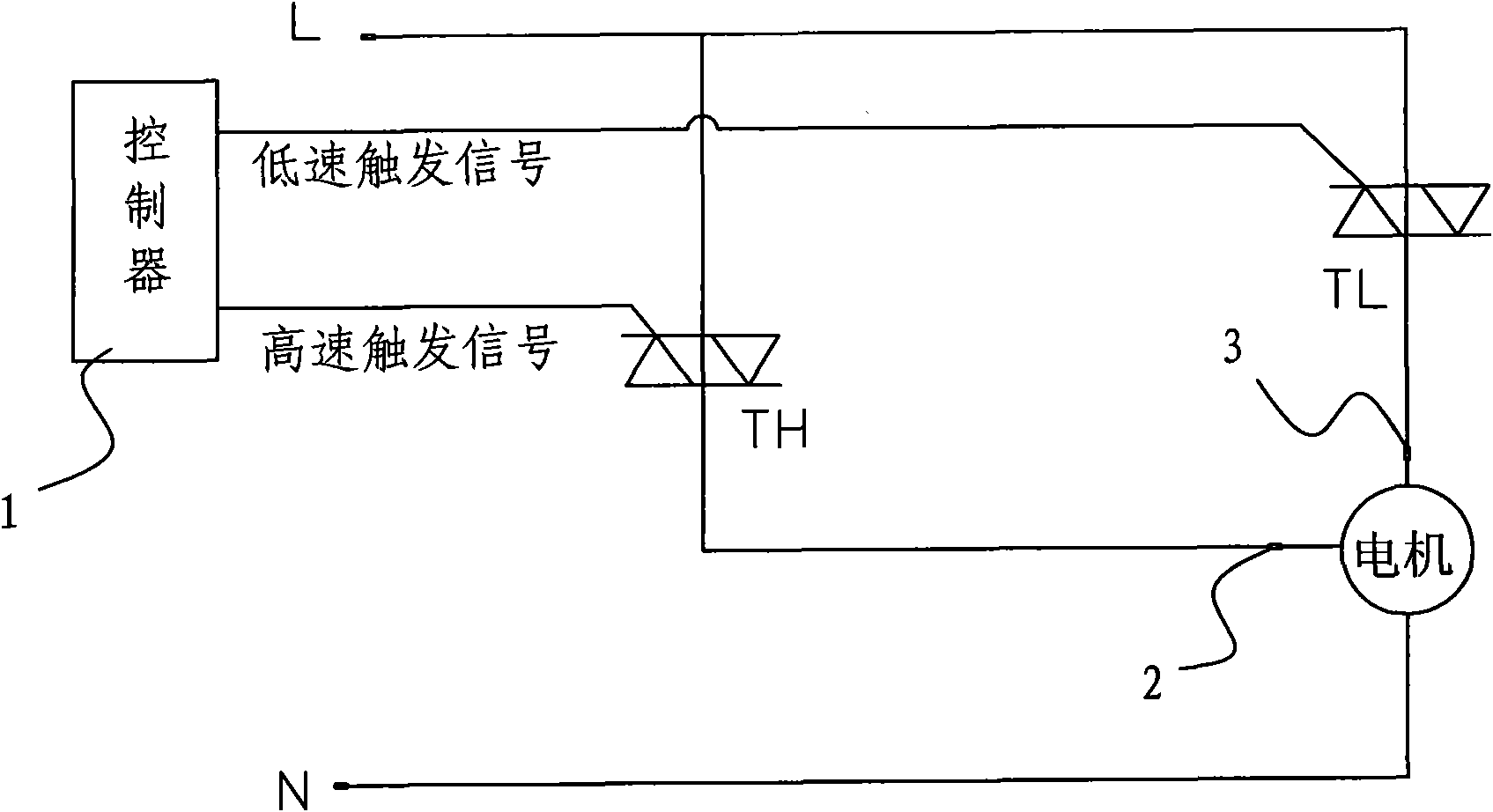

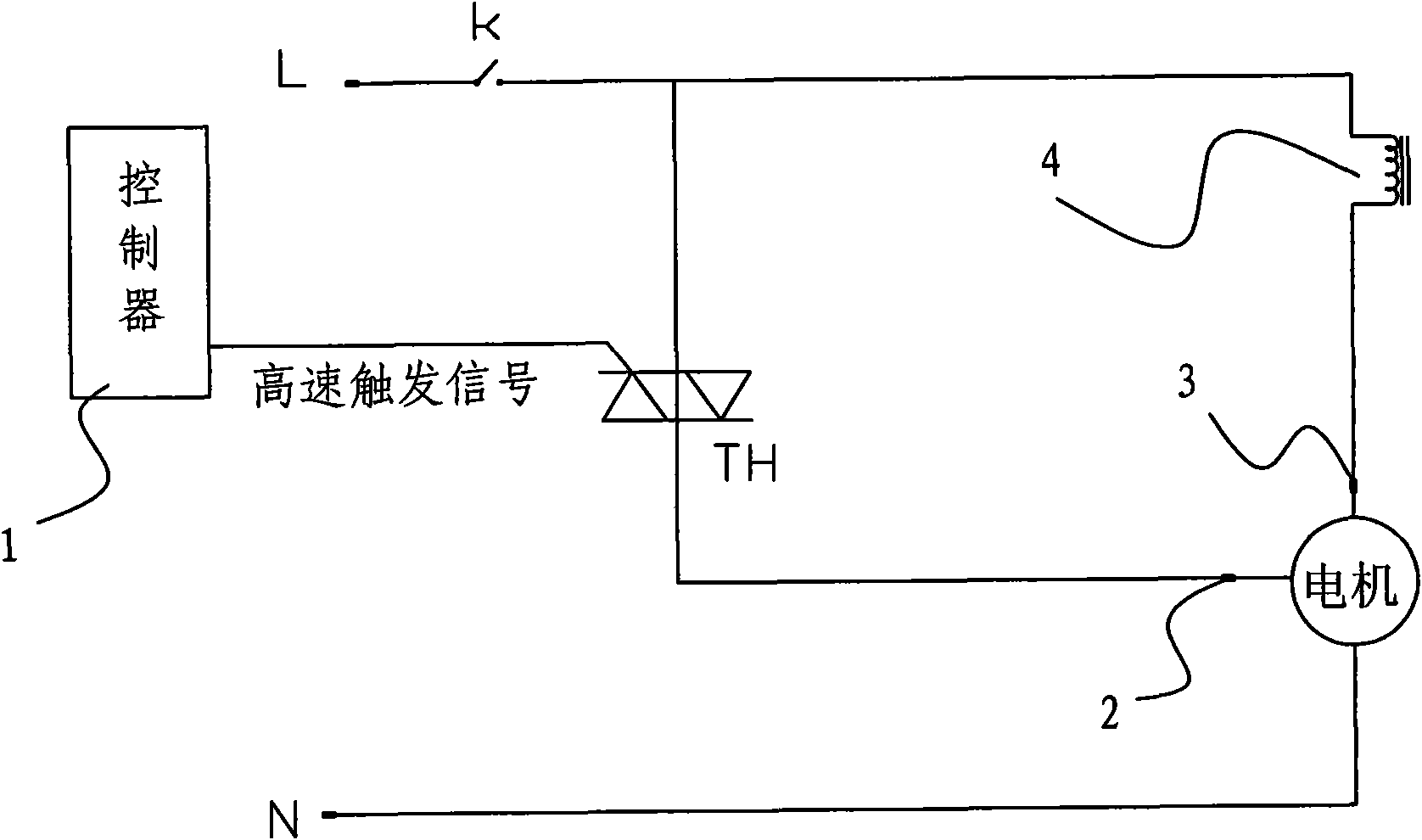

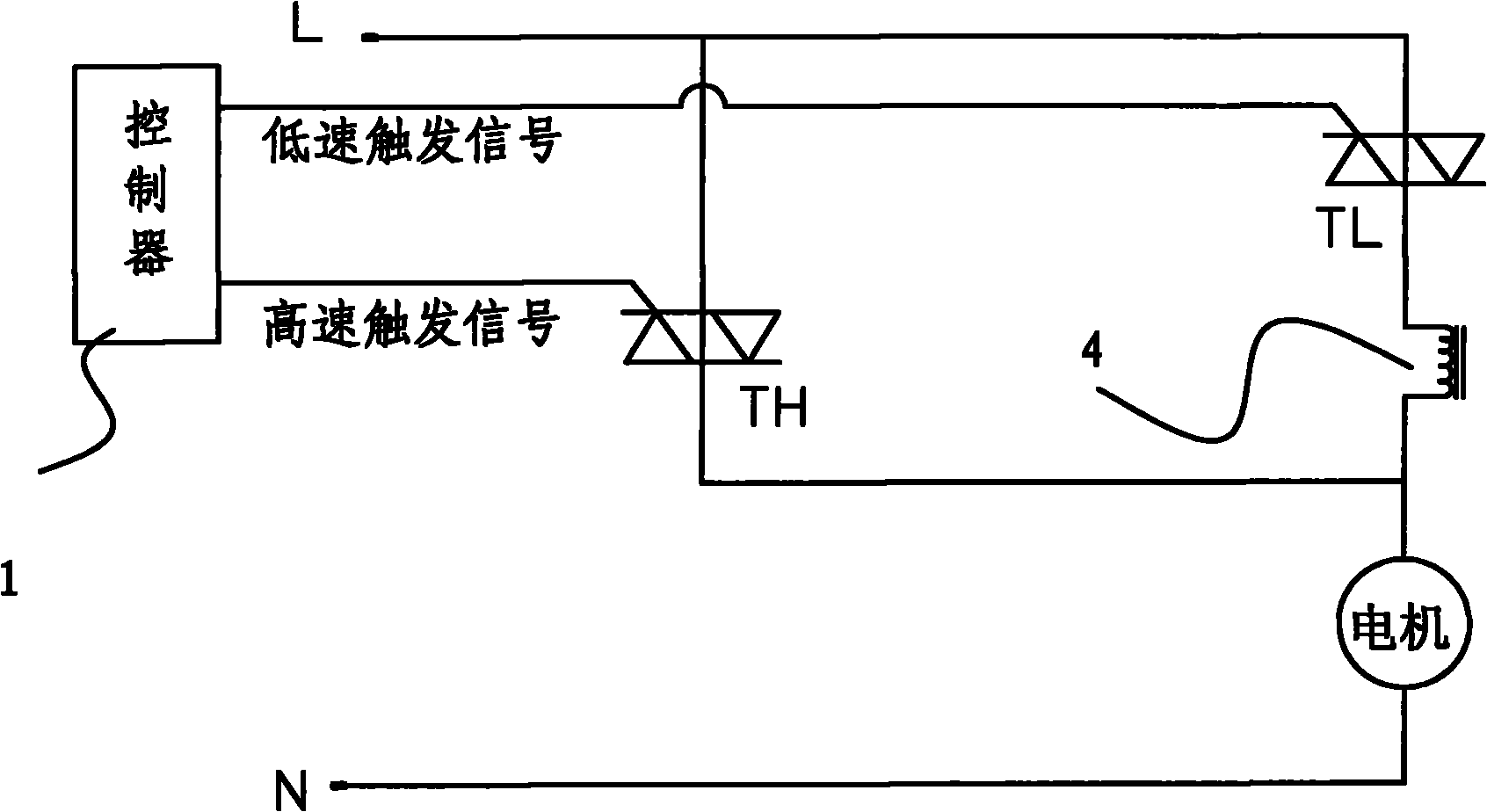

Method and control circuit for realizing multistep speed regulation of single-phase alternating current motors

InactiveCN101873099ASmooth torqueTorque, so that the speed is stable at the highest speedAC motor controlMotor speedElectric machine

The invention discloses a method for realizing multistep speed regulation of single-phase alternating current motors. The single-phase alternating current motor comprises a low-speed tap and a high-speed tap; the single-phase alternating current motor realizes two different rotating speeds after the input current is led into the low-speed tap and the high-speed tap respectively; the input current of the single-phase alternating current motor is divided into a plurality of continuous input cycles; each input cycle contains n cyclic waves; n cyclic waves in each cycle are divided into two continuous parts and are input into the low-speed tap and the high-speed tap; and the single-phase alternating current motor adjusts the rotating speed through adjusting the wave number proportion of the two parts. The method of the invention divides the input current into a plurality of input cycles containing integral numbers of cyclic waves; each input cycle is divided into two parts to be input to the high-speed tap and the low-speed tap of the motor; the method realizes the adjustment to the rotation speed of the motor through changing proportion of the two parts, can not generate pollution to power grids, has low cost, stable motor operation and smaller noise.

Owner:HANGZHOU ALLYTECH TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com