Rotor structure of switched reluctance motor

A technology of switched reluctance motor and rotor structure, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problem of reducing the radial force of the rotor slot, weakening the effect of radial force, increasing motor loss, and large use limitations, etc. problems, to achieve the effect of alleviating large torque fluctuations, reducing noise, and maintaining the output torque capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

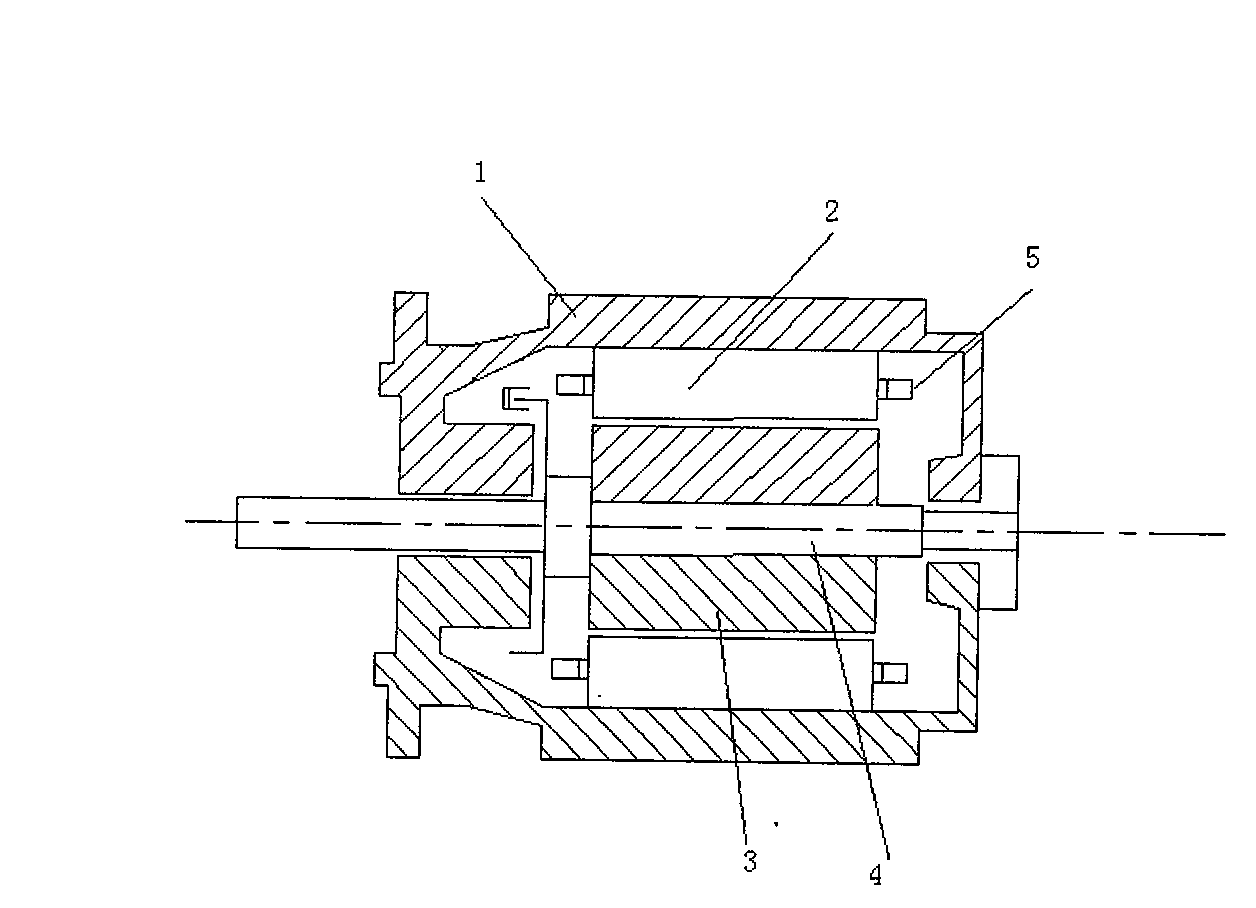

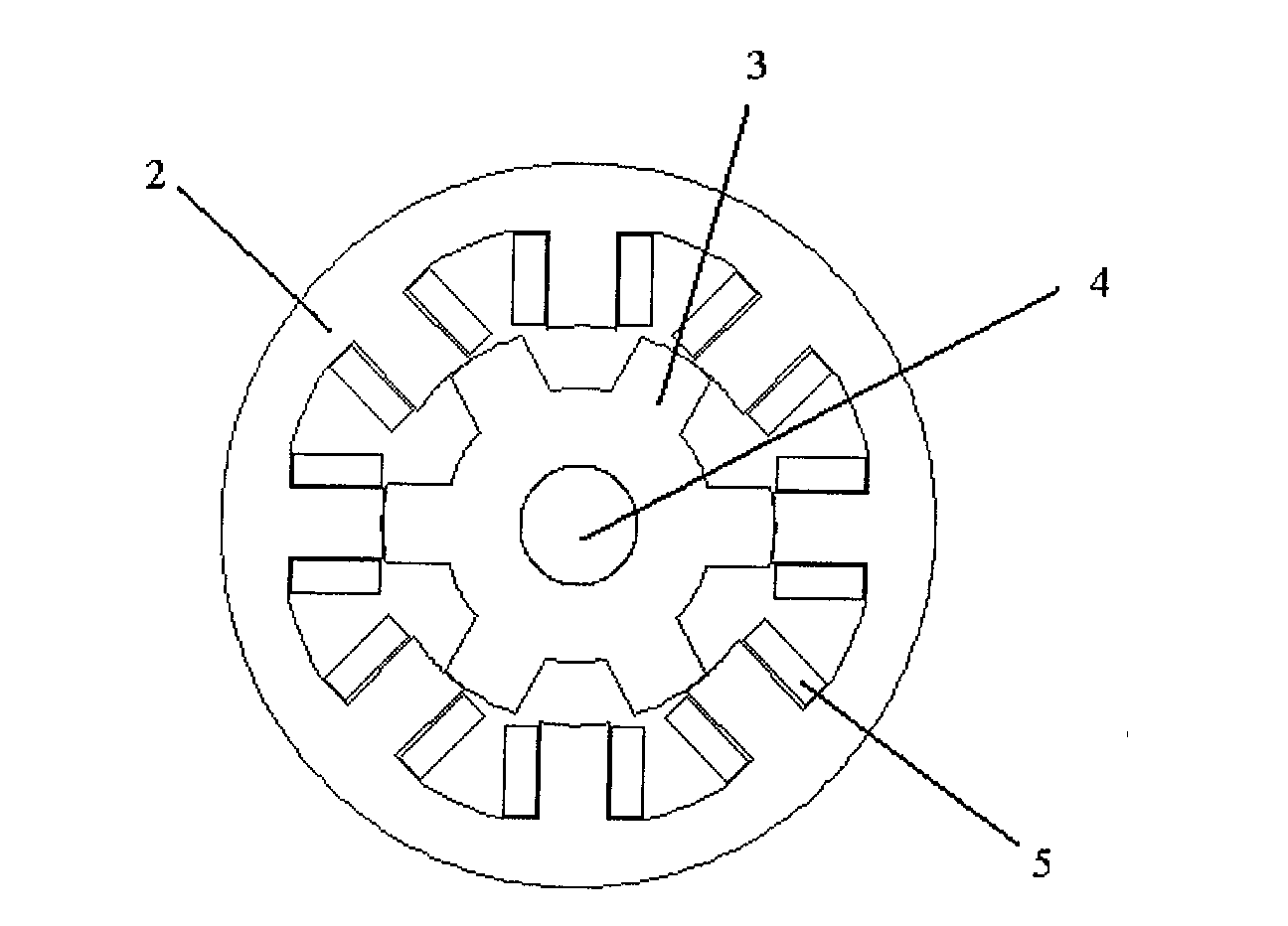

[0022] The present invention is specifically described as follows in conjunction with the accompanying drawings:

[0023] The rotor of the switched reluctance motor provided by the invention has no windings and no permanent magnets, and is formed by laminating silicon steel sheets, and the rotor pole type is a multi-air gap salient pole structure that reduces vibration and noise. The rotor structure is as follows: the protrusion at the end of the rotor is a multi-air-gap stepped type.

[0024] The left and right steps of the multi-air gap stepped type are symmetrical. The widths of the left and right edges of the multi-air-gap stepped shape each account for 1 / 6 of the rotor pole width. The protruding height of the end of the multi-air gap stepped rotor is 1 / 6 of the overall height of the rotor pole. The multi-air-gap stepped type has two layers of steps, and the height and width of each layer of steps are equal.

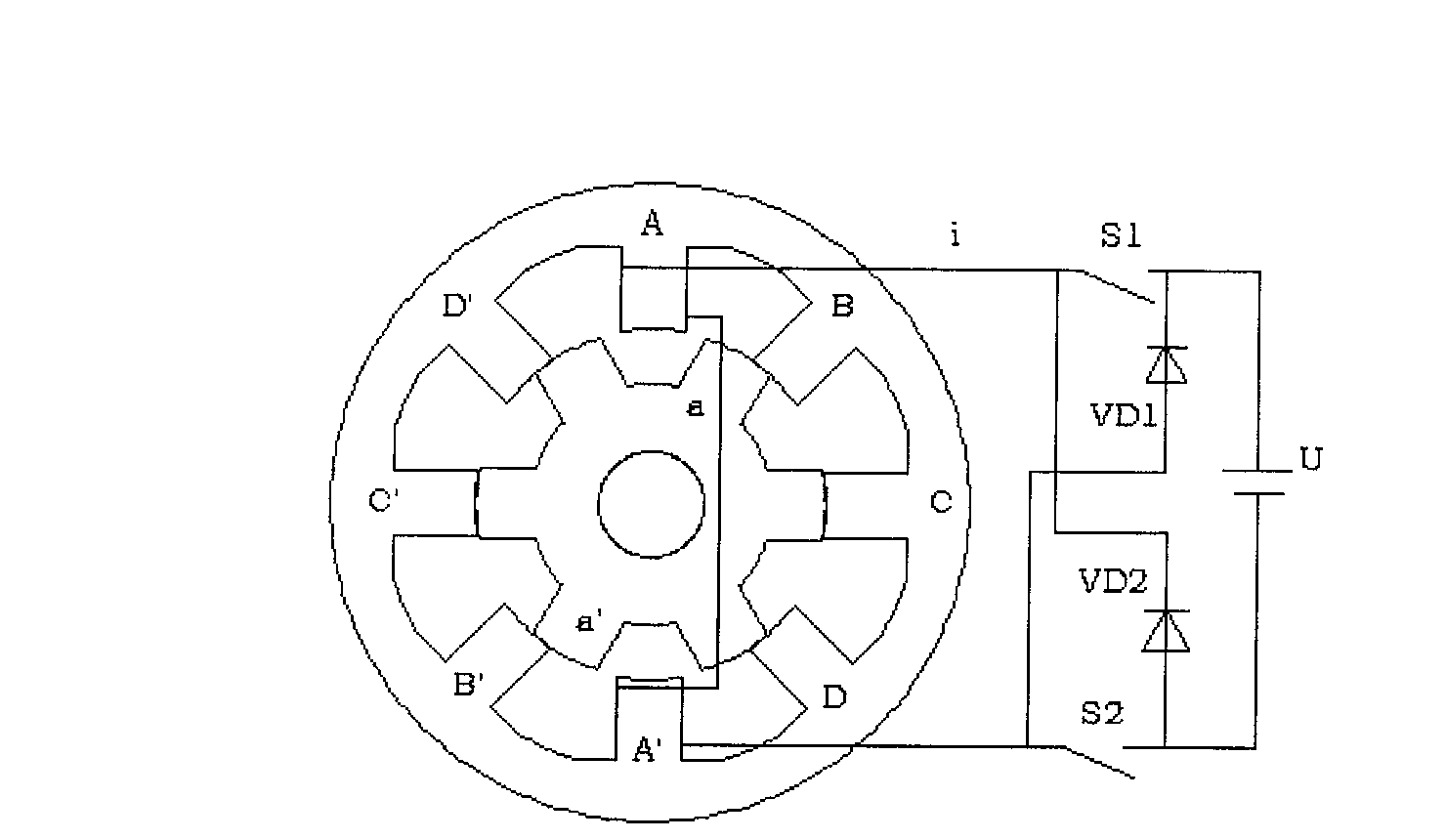

[0025] Taking a four-phase 8 / 6-pole switched reluctance moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com