Magnetic circuit structure of washer variable frequency DC motor

A frequency conversion DC and washing machine technology, applied in the field of washing machines, can solve the problems of soft mechanical properties of DDM DC motors, small impact force of clothes and water flow, and inability to rub and squeeze clothes, so as to speed up system response speed and increase mechanical hardness , The effect of cogging torque weakening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

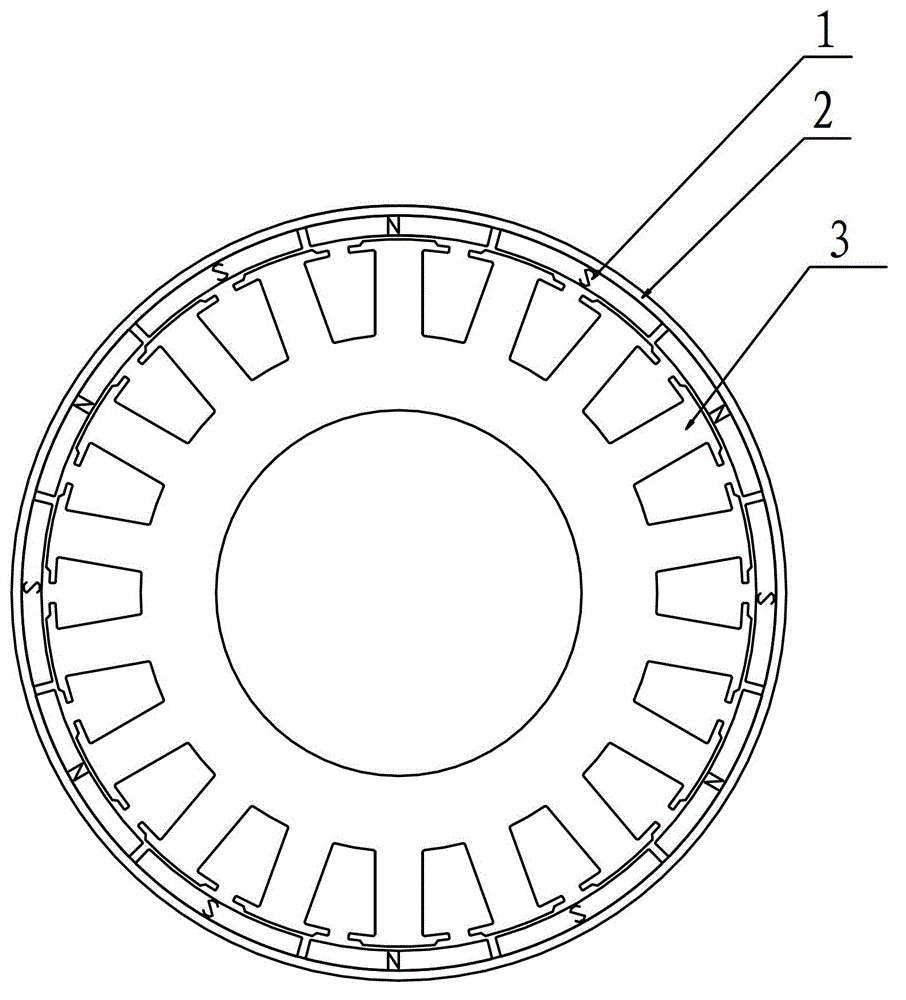

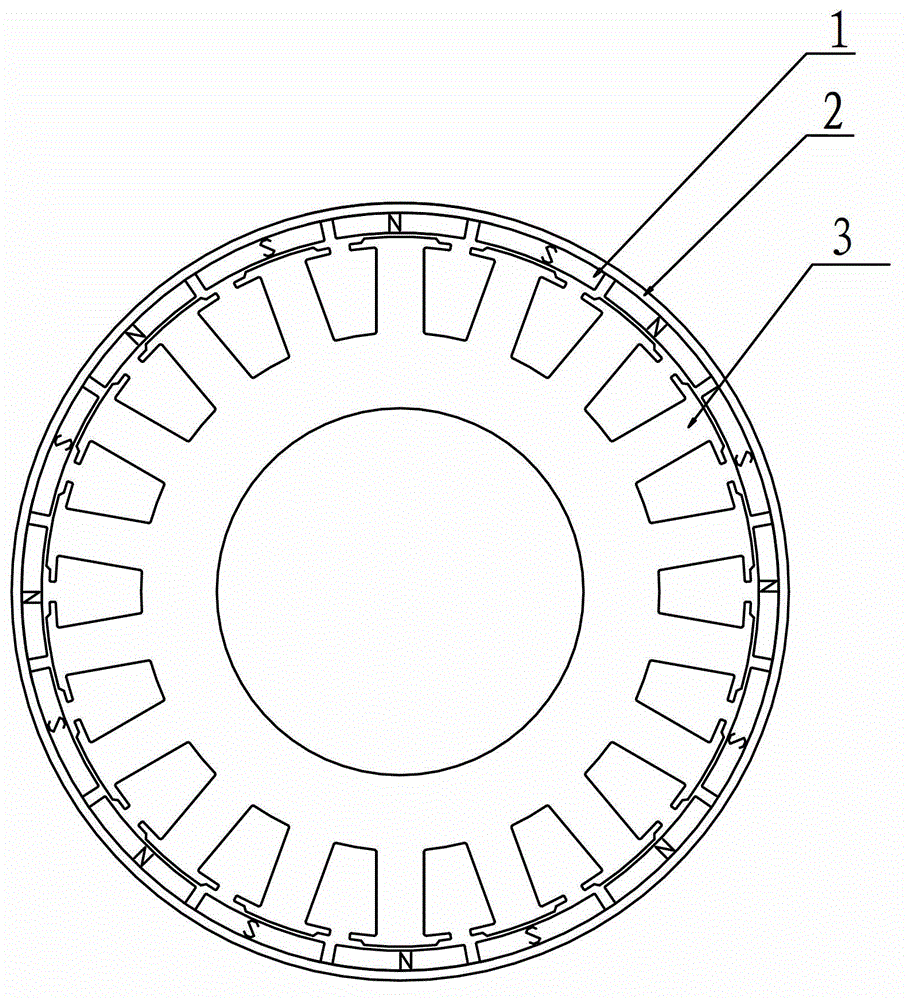

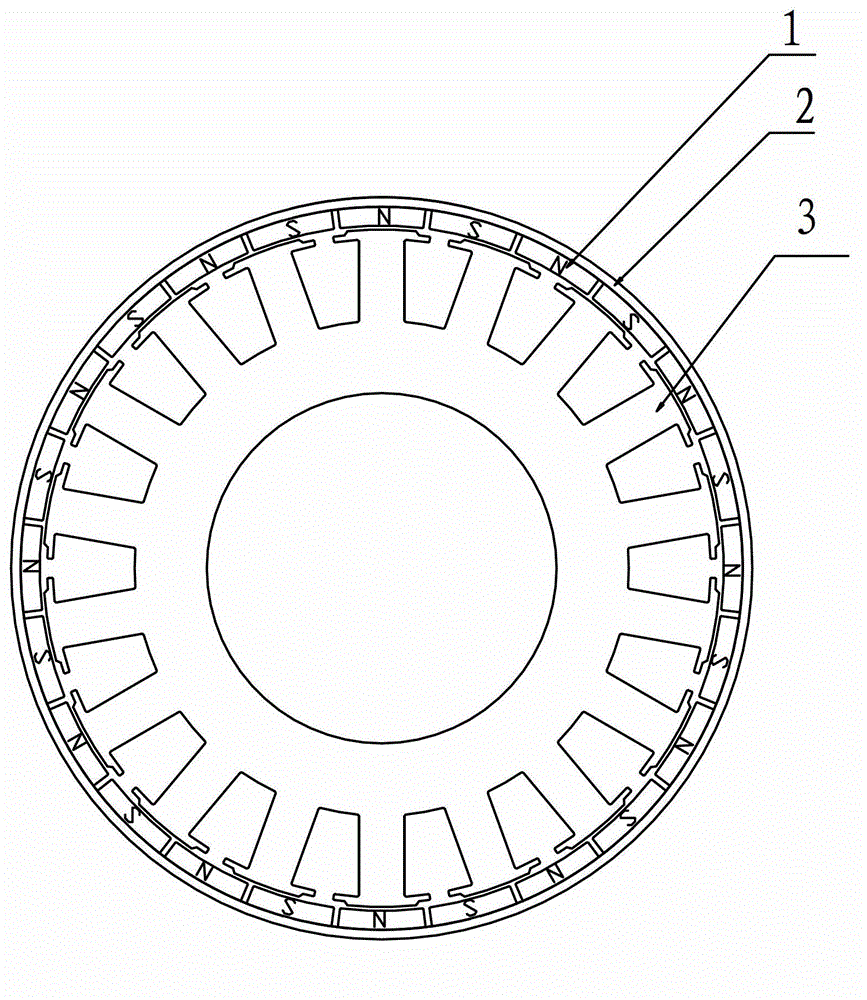

[0022] combine Figure 4 , which is a structural schematic diagram of an embodiment of the stator core of the frequency conversion DC motor of the washing machine of the present invention, which includes a stator core 3, a rotor yoke 2 is arranged on the outside of the stator core 3, and a magnetic tile is arranged inside the yoke 2 1. The magnetic tile 1 forms the N and S poles of the same magnetic tile through magnetization; the magnetic tile 1 is evenly distributed on the circumference, and each pair of N and S magnetic poles formed is offset relative to the center of the circle; the magnetic tile has 12 pieces, the magnetic tiles 1 are fixed on the rotor yoke 2 by uniform paste or other methods; outer diameter and thickness; the magnetic circuit of the stator core 3 adopts an 18-slot structure, and the magnetic tile 1 adopts 12 pieces of magnetic steel, and a motor with 12 pairs of poles of N and S poles is formed on the same magnetic tile by punching .

[0023] Most of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com