Method and control circuit for realizing multistep speed regulation of single-phase alternating current motors

A single-phase AC motor and speed regulation technology, which is applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of polluting the power grid, high motor noise, and high cost, and achieve low cost, stable operation, and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

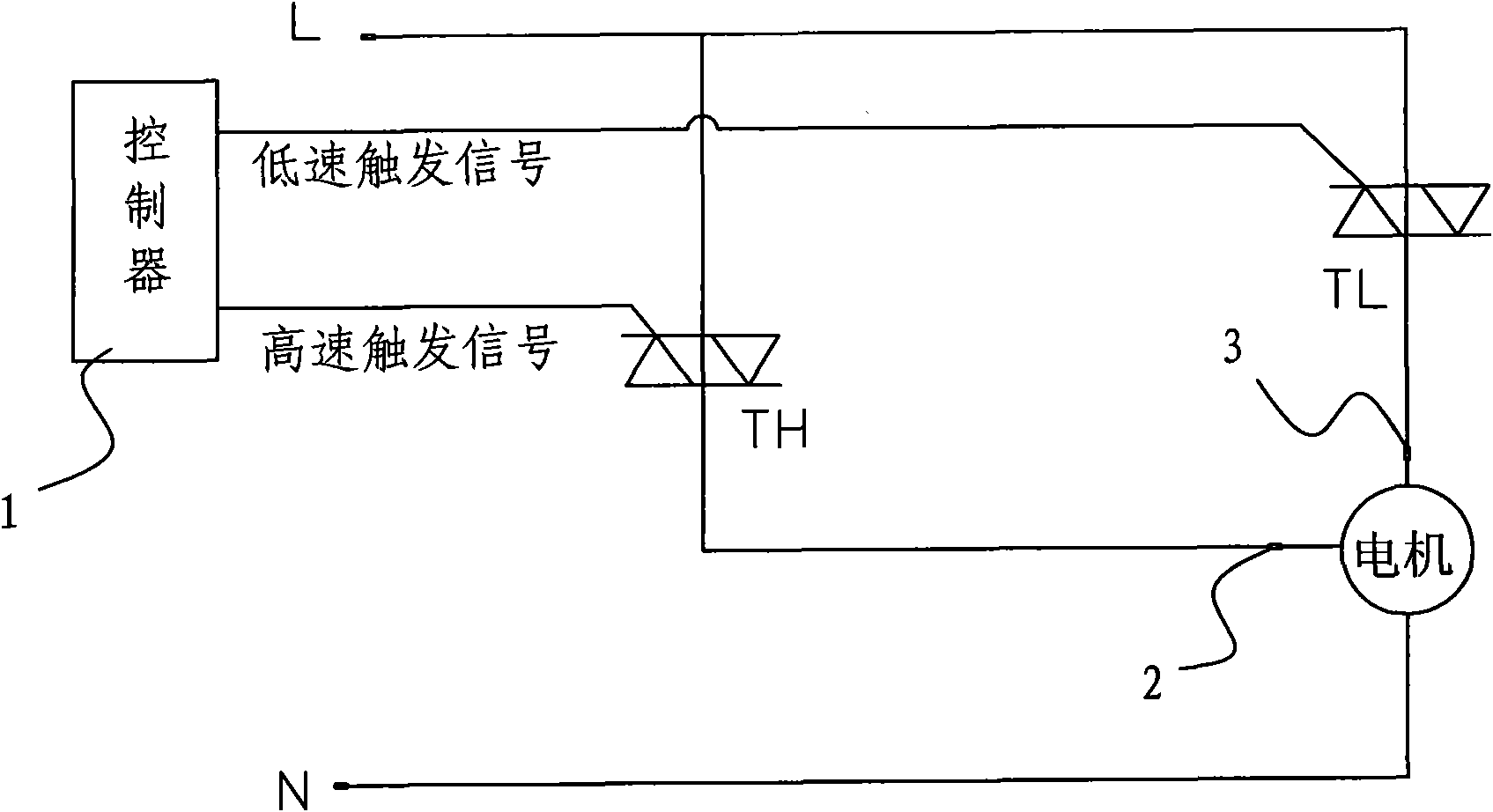

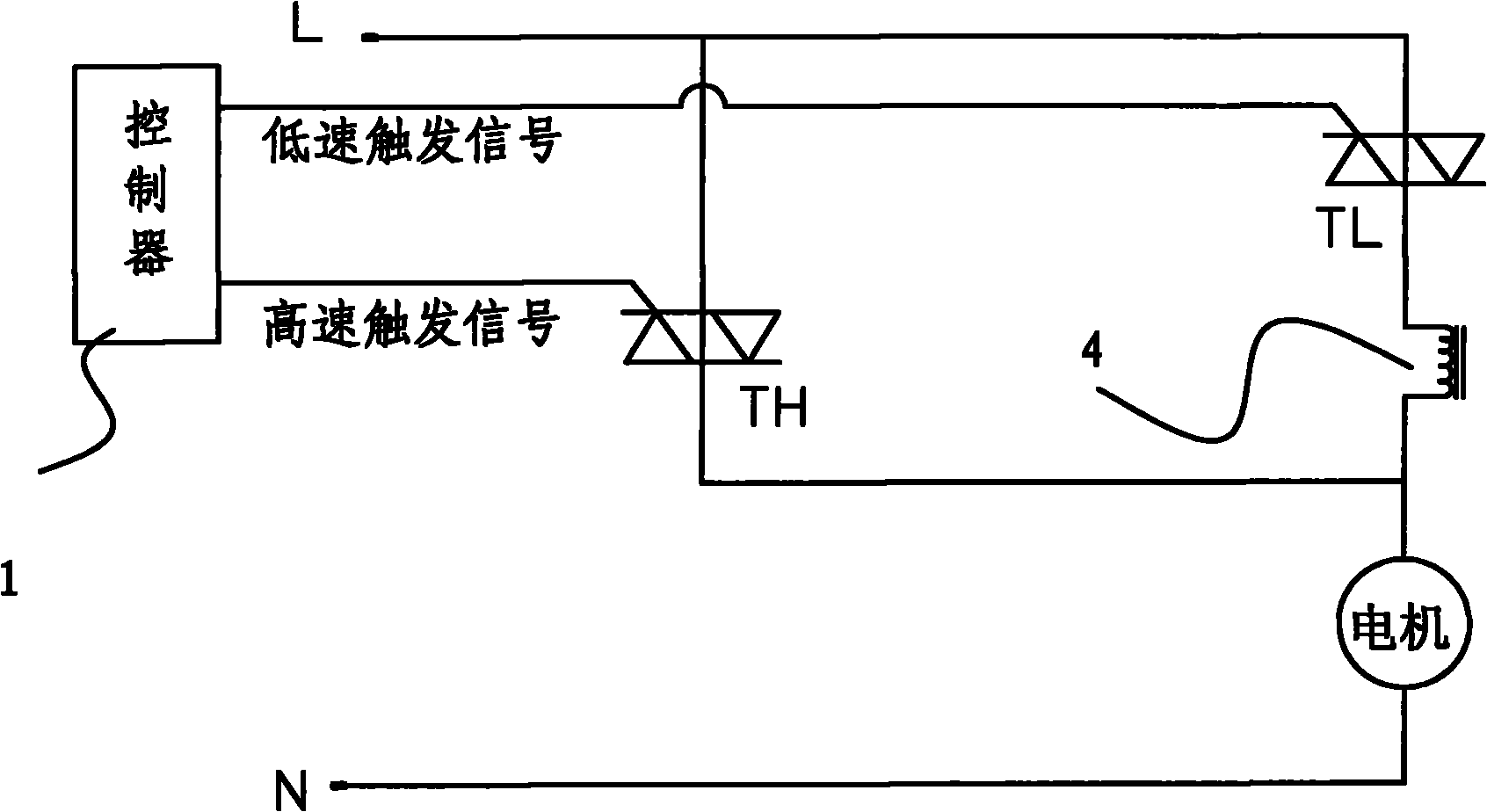

[0024] like figure 1 As shown, a single-phase AC motor input current control circuit is composed of a controller 1 (STM8S103K2), a bidirectional thyristor TL connected to the controller 1, and a bidirectional thyristor TH. The bidirectional thyristor TH and the bidirectional thyristor TH The SCR TL is respectively connected to the high-speed tap 2 and the low-speed tap 3 of the single-phase AC motor.

[0025] The input current of the single-phase AC motor is divided into several continuous input cycles, and the number of input cycles is determined according to the input time, and the longer the time, the more input cycles. Each input cycle contains 8 cycles, of course, the number of cycles can be adjusted, at least two, the more the number of cycles, the more the motor speed series. But it is not that the more the better, although the more the number of stages that can be adjusted, the more. But on the one hand, it doesn't need so many series when working, on the other hand,...

Embodiment 2

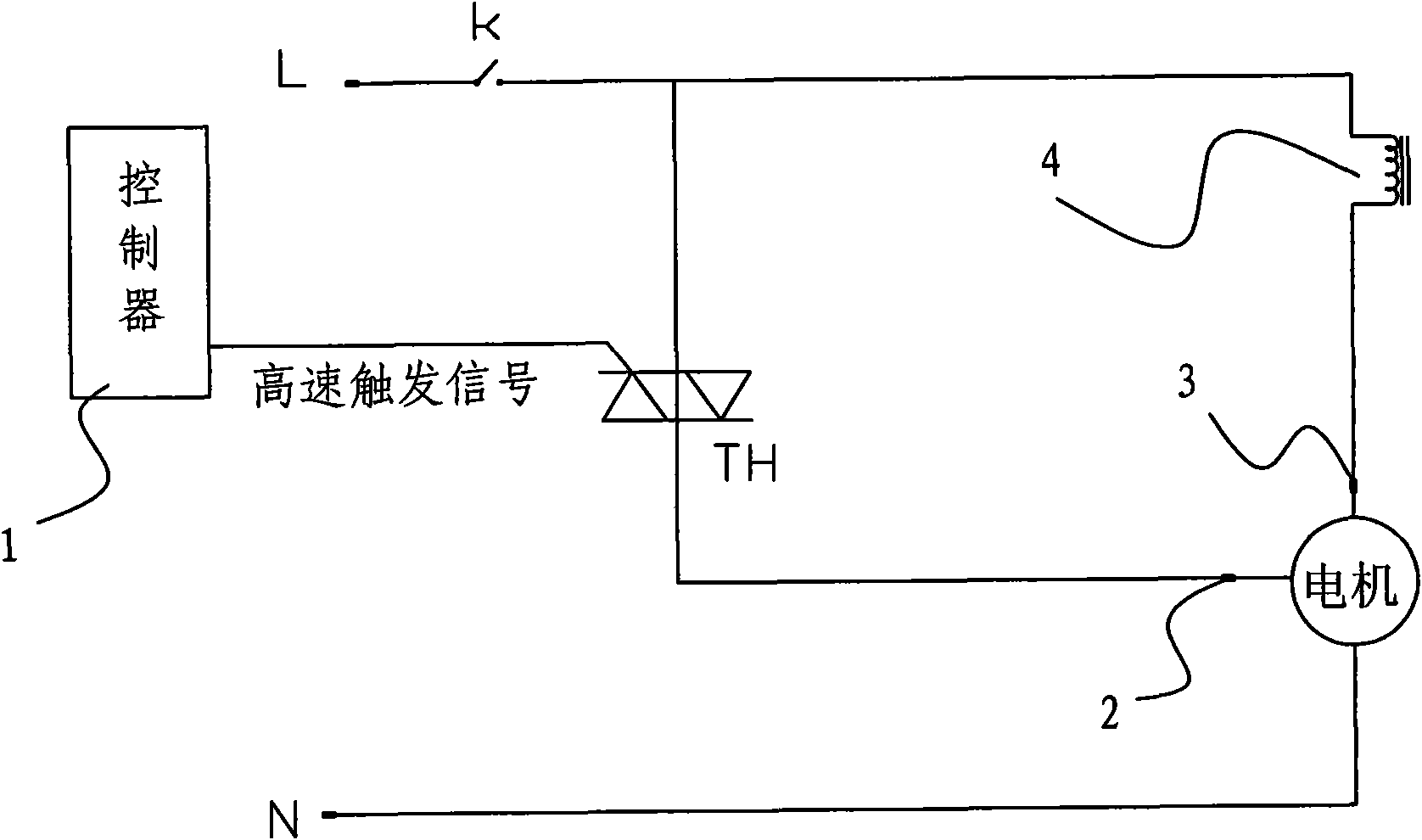

[0031] like figure 2 As shown, another control circuit for the input current of a single-phase AC motor is composed of a controller 1, a triac TH connected to the controller 1, and a speed regulating reactor 4 connected in parallel with the triac TH. The output ends of the bidirectional thyristor TH and the speed regulating reactor 4 are connected to the motor, and the input ends are connected to the power supply through the switch k, so that single-phase current can be introduced.

[0032] Similarly, the input current of the single-phase AC motor is divided into several continuous input cycles, and each input cycle contains 8 cycles. After the switch k is closed, the controller 1 sends a signal to make the bidirectional thyristor TH conduct. In each input cycle of the input current, q cycles are directly input to the single-phase AC motor. At this time, the motor speed is theoretically the highest. After the input is completed, the controller 1 controls the bidirectional thy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com