Electric rotary machine

A technology for rotating electrical machines and rotors, applied in electrical components, electromechanical devices, electrical components, etc., to solve complex problems, reduce cooling fluid flow pressure, and increase manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, various embodiments of the present invention will be described with reference to the accompanying drawings. In the following description of various embodiments, the same drawing text or numerals indicate the same or equivalent components throughout the several drawings.

[0028] first exemplary embodiment

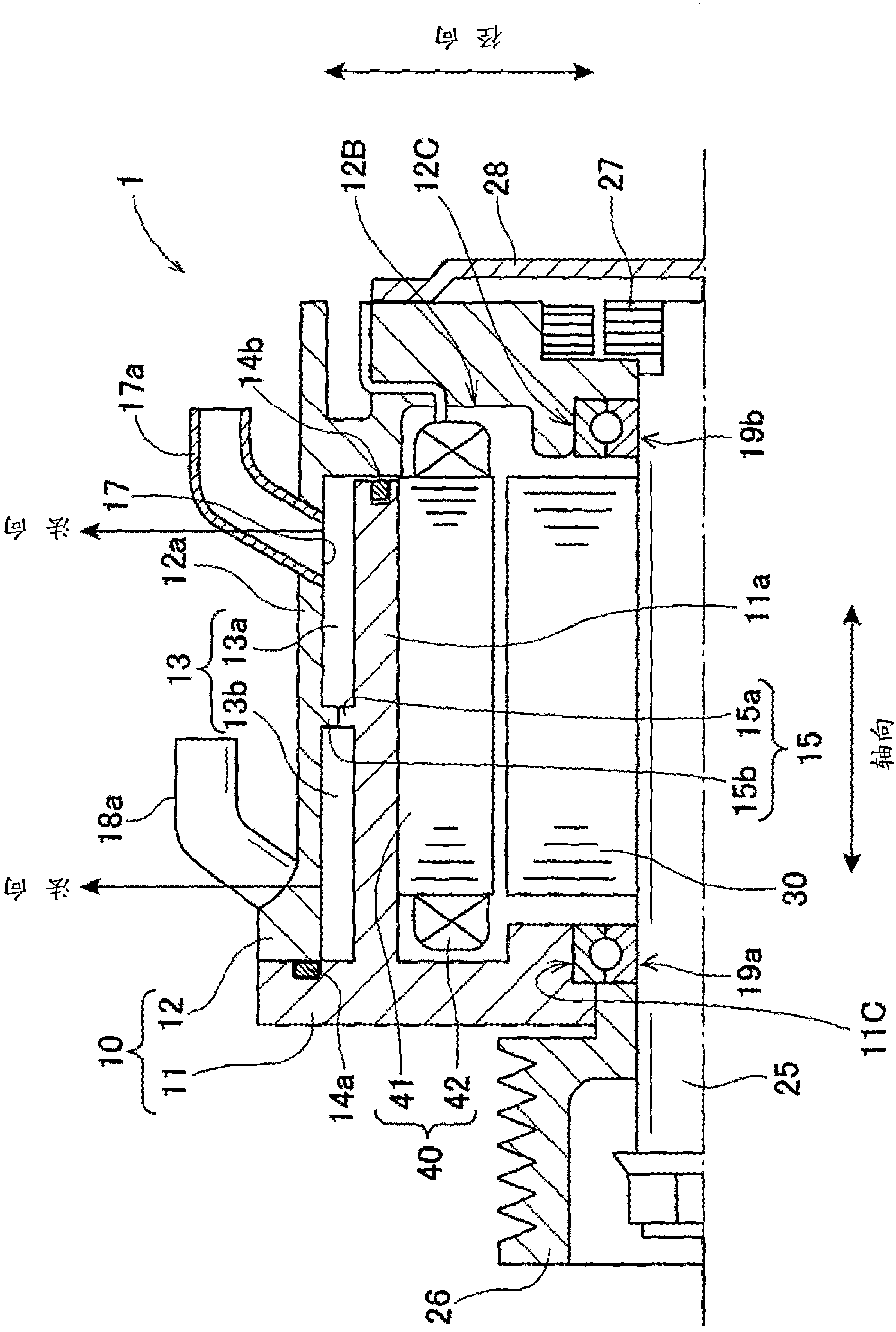

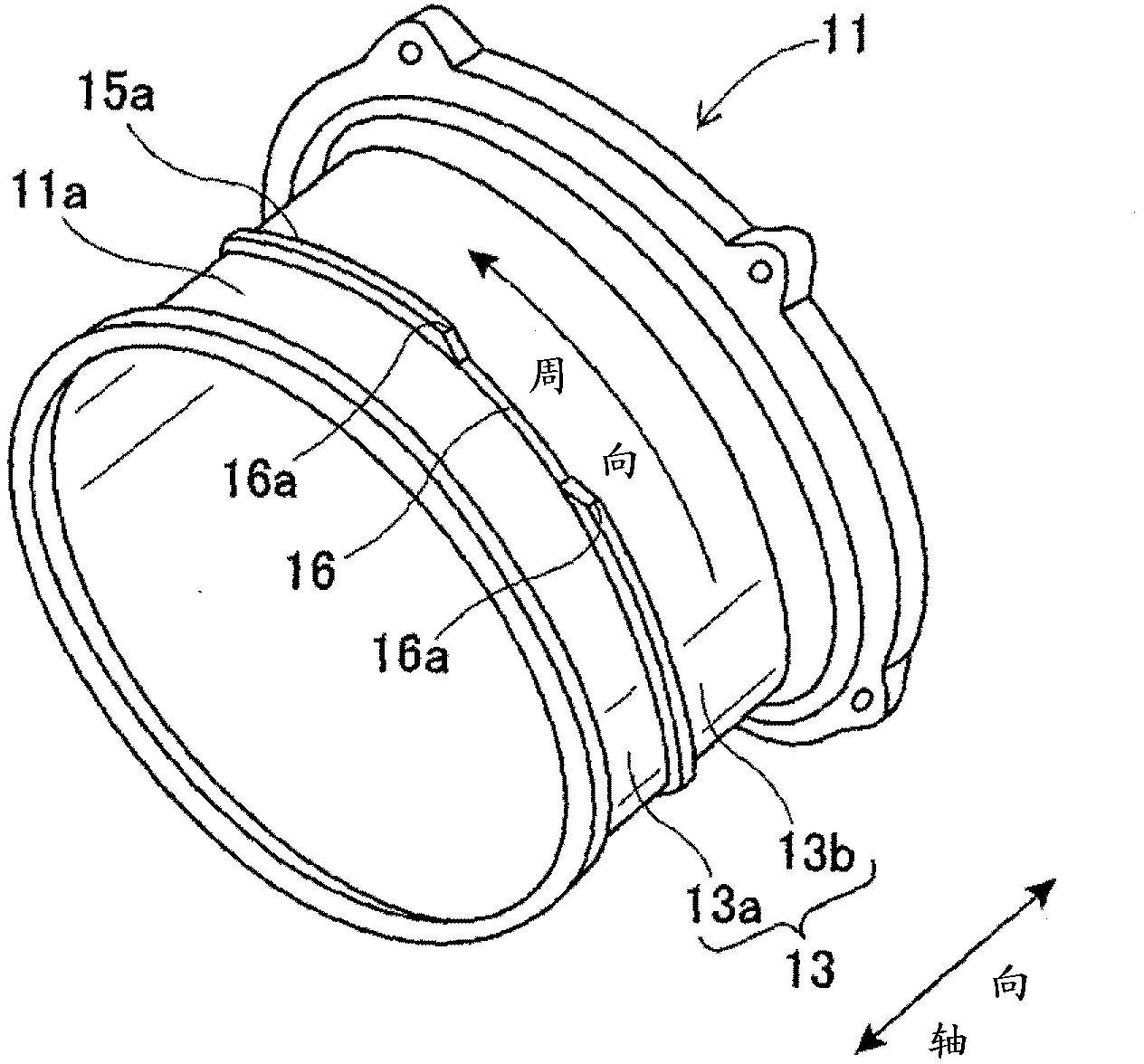

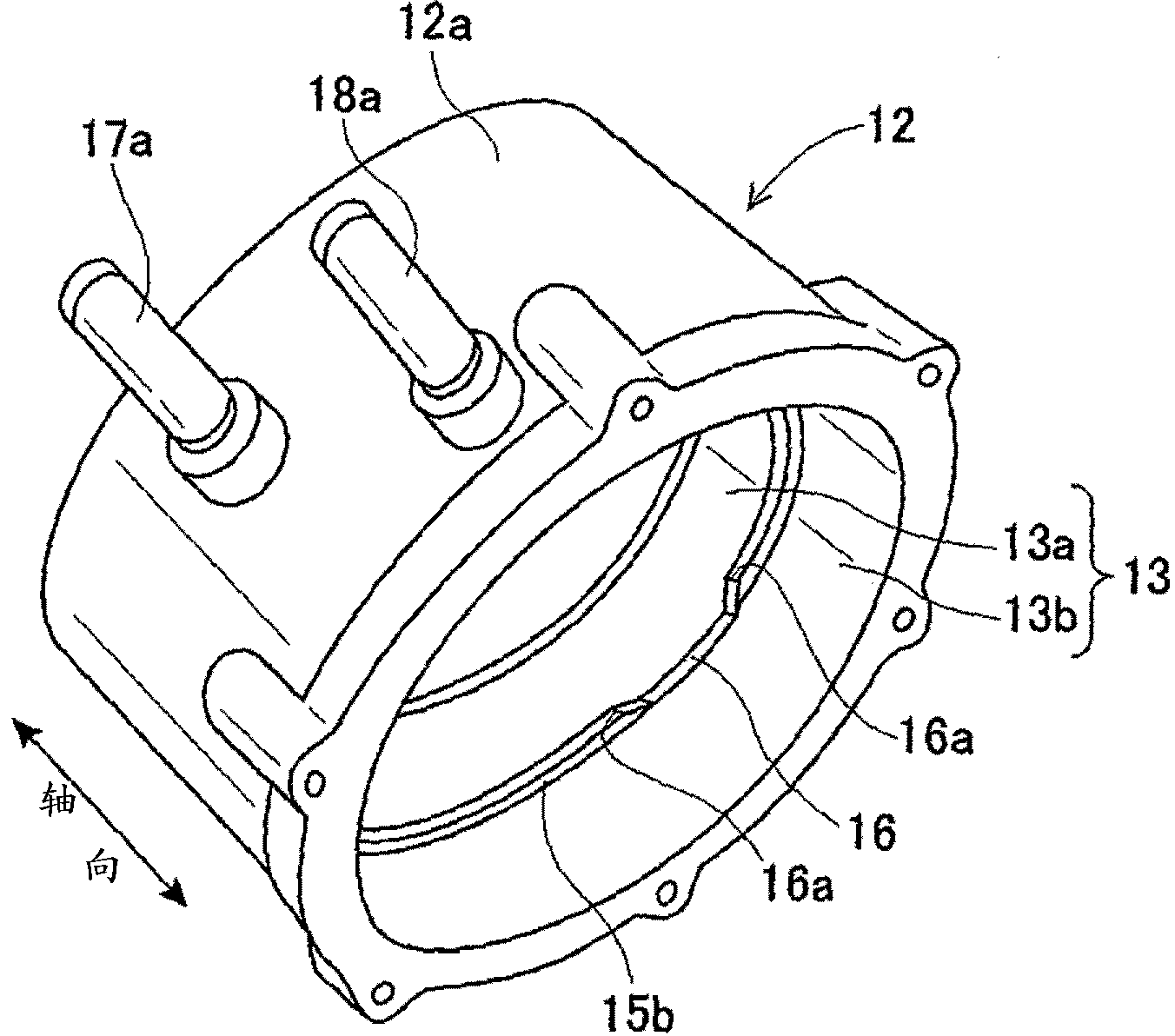

[0029] will now refer to Figure 1 to Figure 8A , Figure 8B and Figure 8C A description is given of the rotating electric machine 1 according to the first exemplary embodiment of the present invention.

[0030] figure 1 is a view showing a partial section of the upper half in the axial direction of the rotary electric machine 1 according to the first exemplary embodiment of the present invention. figure 2 is based on figure 1 A perspective view of the first motor frame 11 among the motor frames 10 of the rotating electric machine 1 of the first exemplary embodiment shown in . image 3 is based on figure 1 A perspective view of the second motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com