Magnetic-field modulation wave power generator with permanent-magnet concentric structure

A technology of magnetic field modulation and eccentric structure, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electrical components, etc., can solve the problems affecting the performance and accuracy of the control system, reduce the stability of the motor, torque vibration and other problems, and achieve effective The value and fluctuation are small, the accuracy and stability are improved, and the effect of magnetic load is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

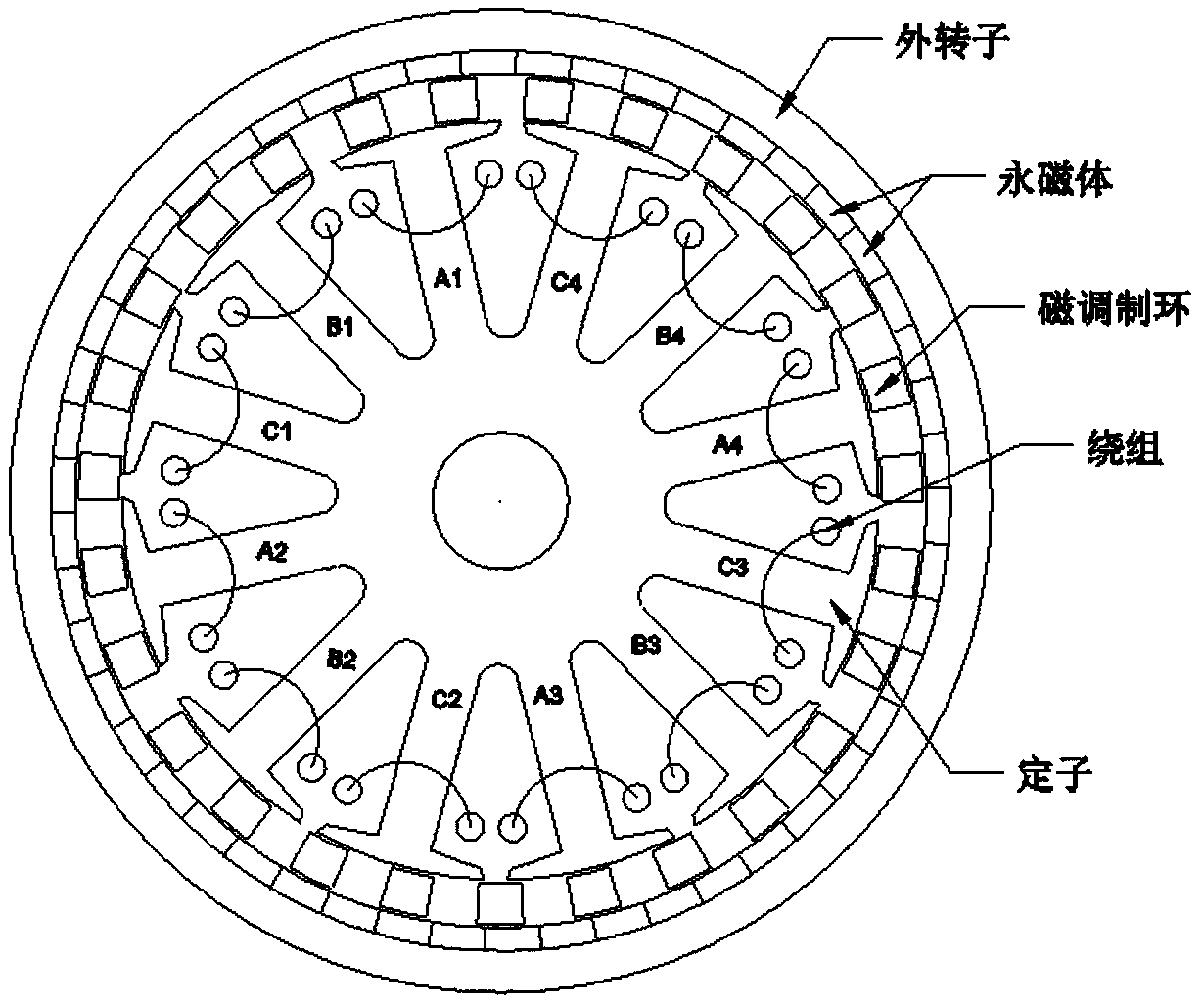

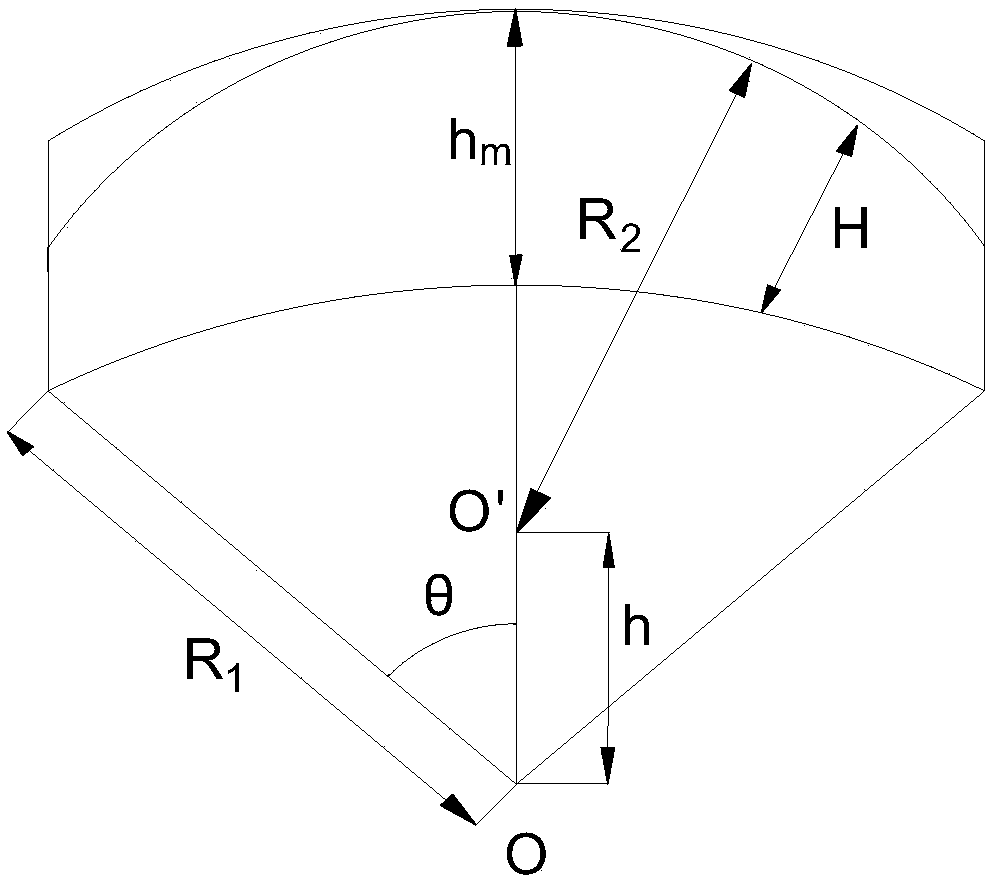

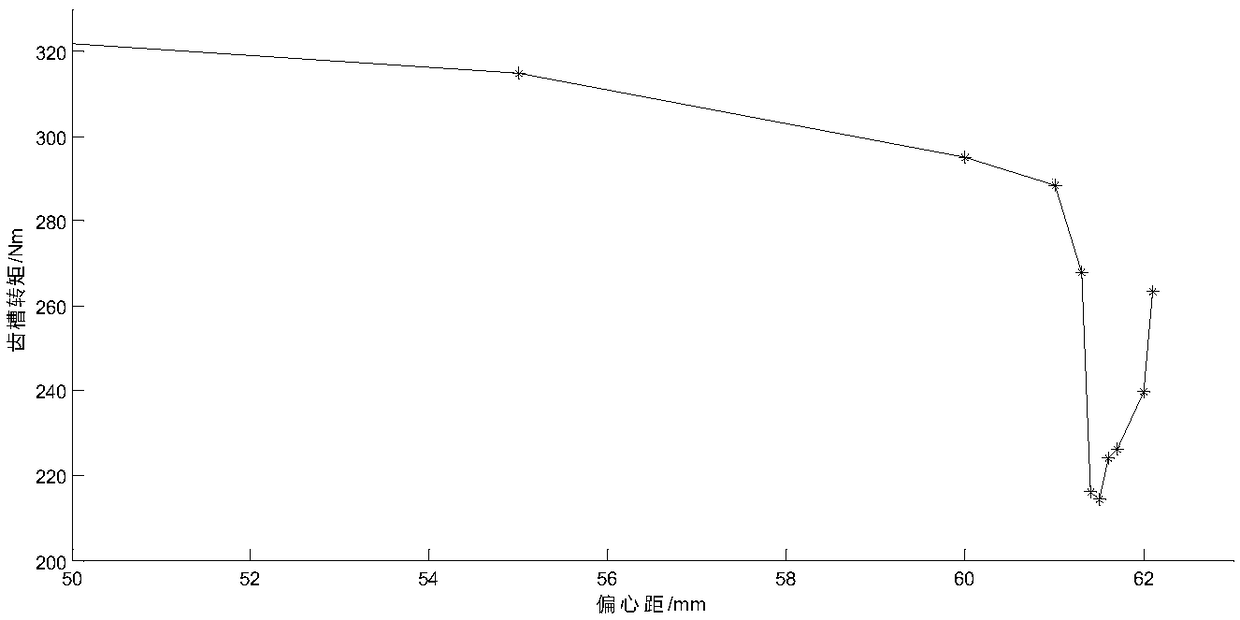

[0023] The invention proposes a permanent magnet eccentric structure, and the motor structure changes the air gap magnetic field distribution by adjusting the permanent magnet structure of the outer rotor. The eccentric structure of the magnetic field modulation wave generator includes a stator, a rotor and a magnetic modulation ring. The stator consists of a 12-slot stator core and distributed stator windings. The magnetic modulation ring is located between the outer rotor and the stator, and 27 magnetic modulation blocks are evenly distributed to play the role of magnetic field modulation. The outer rotor is composed of a rotor core and a surface-mounted permanent magnet. The surface-mounted permanent magnet adopts a magnetic pole shape of unequal thickness, that is, the thickness of the permanent magnet gradually decreases from the middle to both sides. The centers of the circles do not coincide, there is an eccentricity h, and the eccentricity is 61.5mm. It is equivalent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com