Patents

Literature

207results about How to "Torque stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

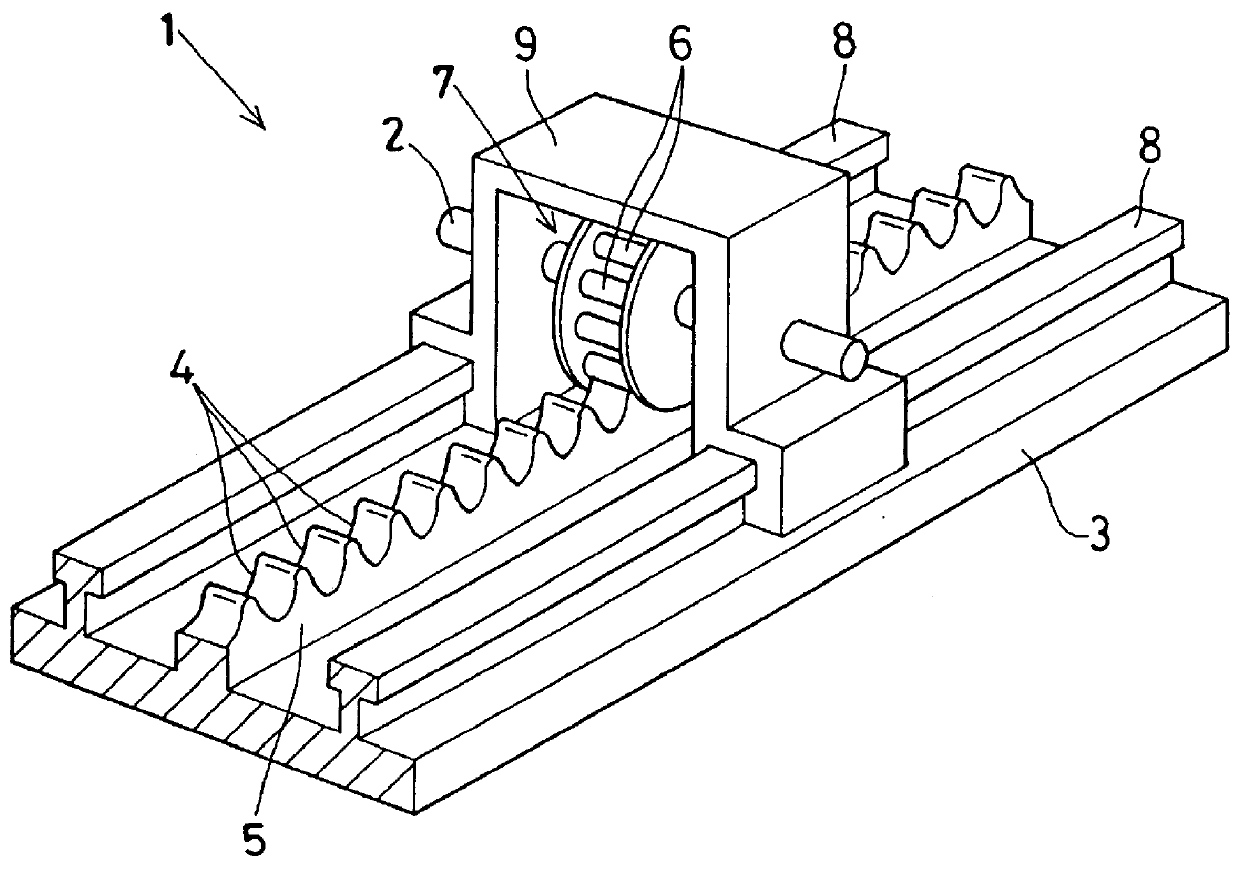

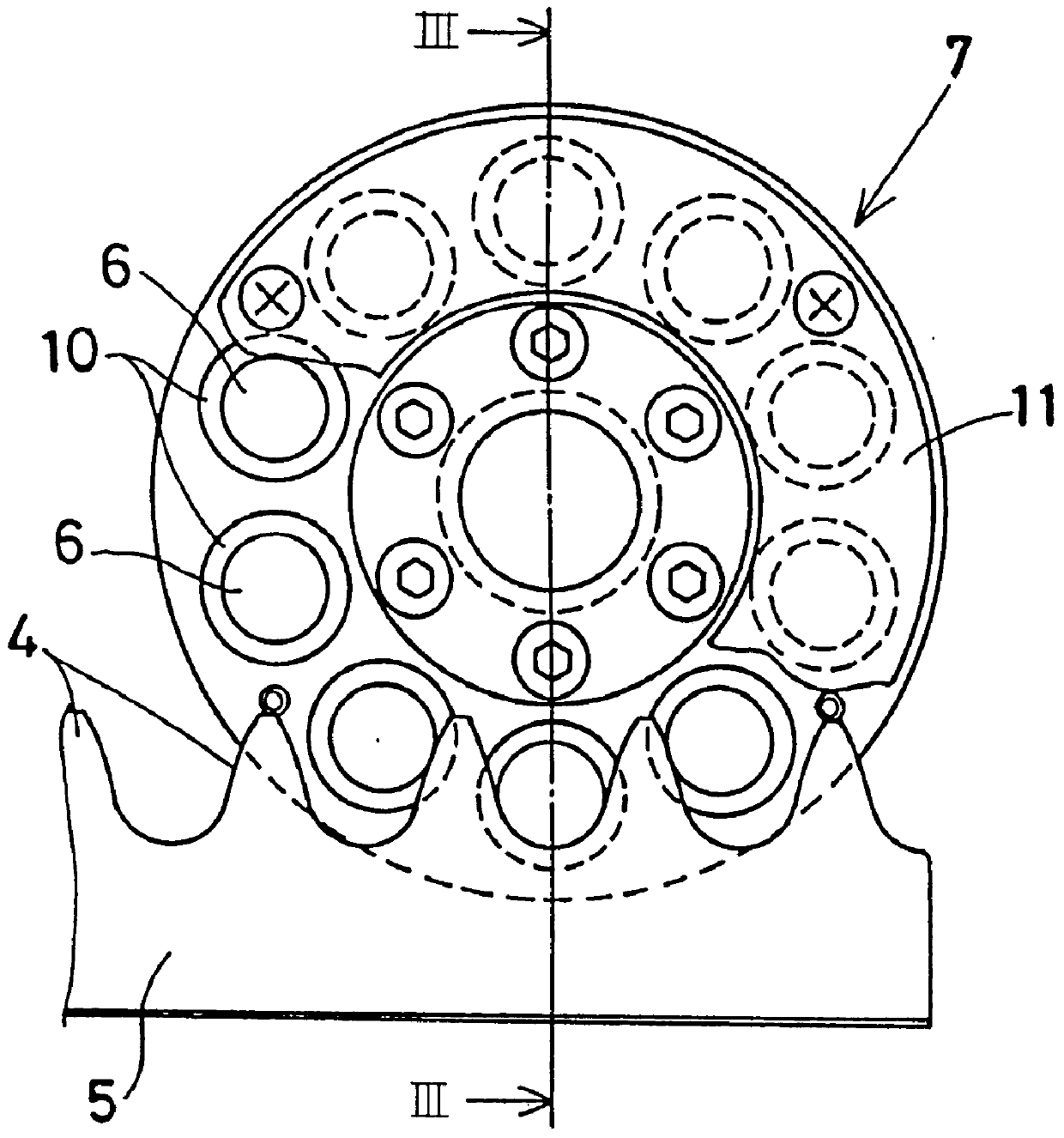

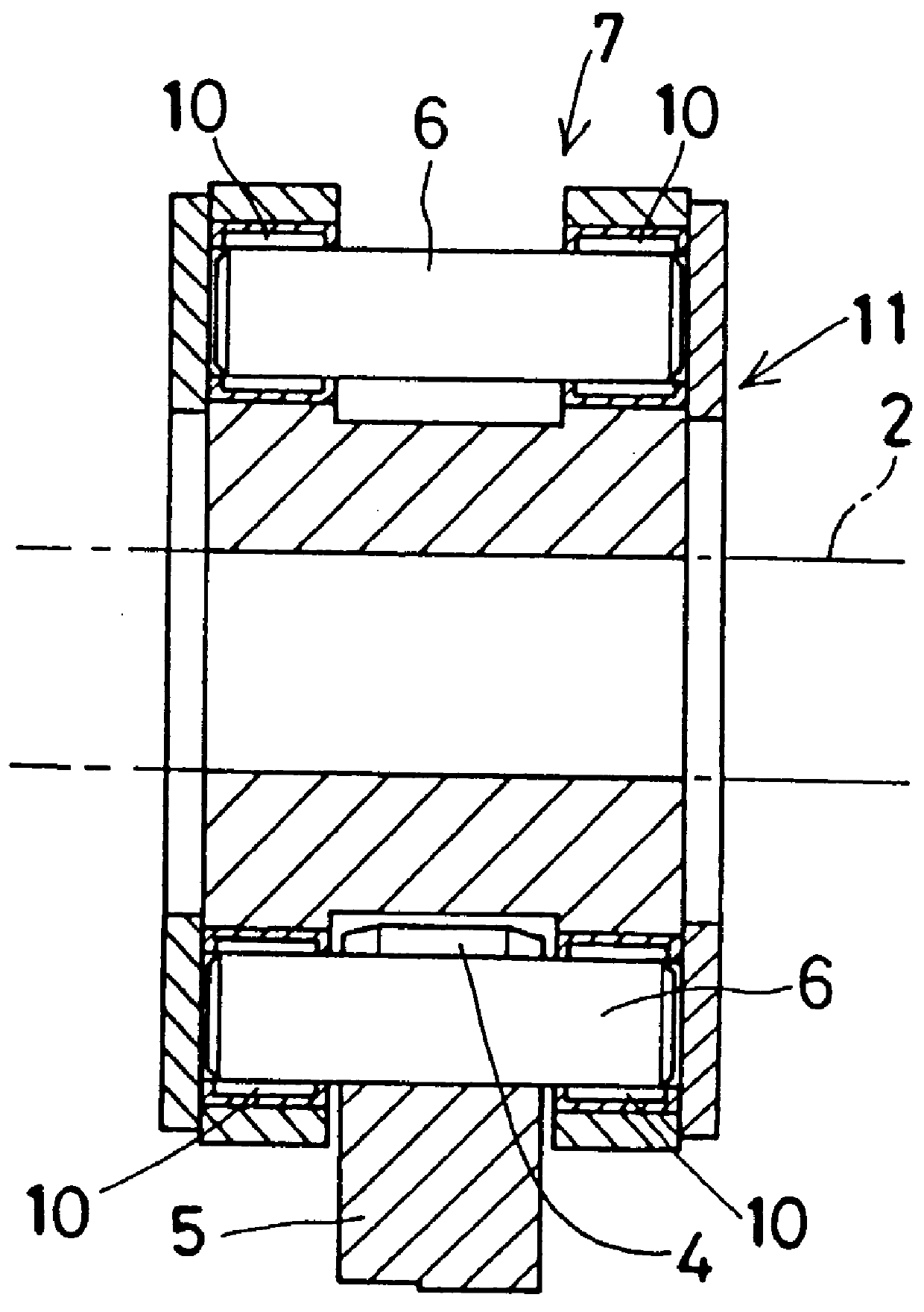

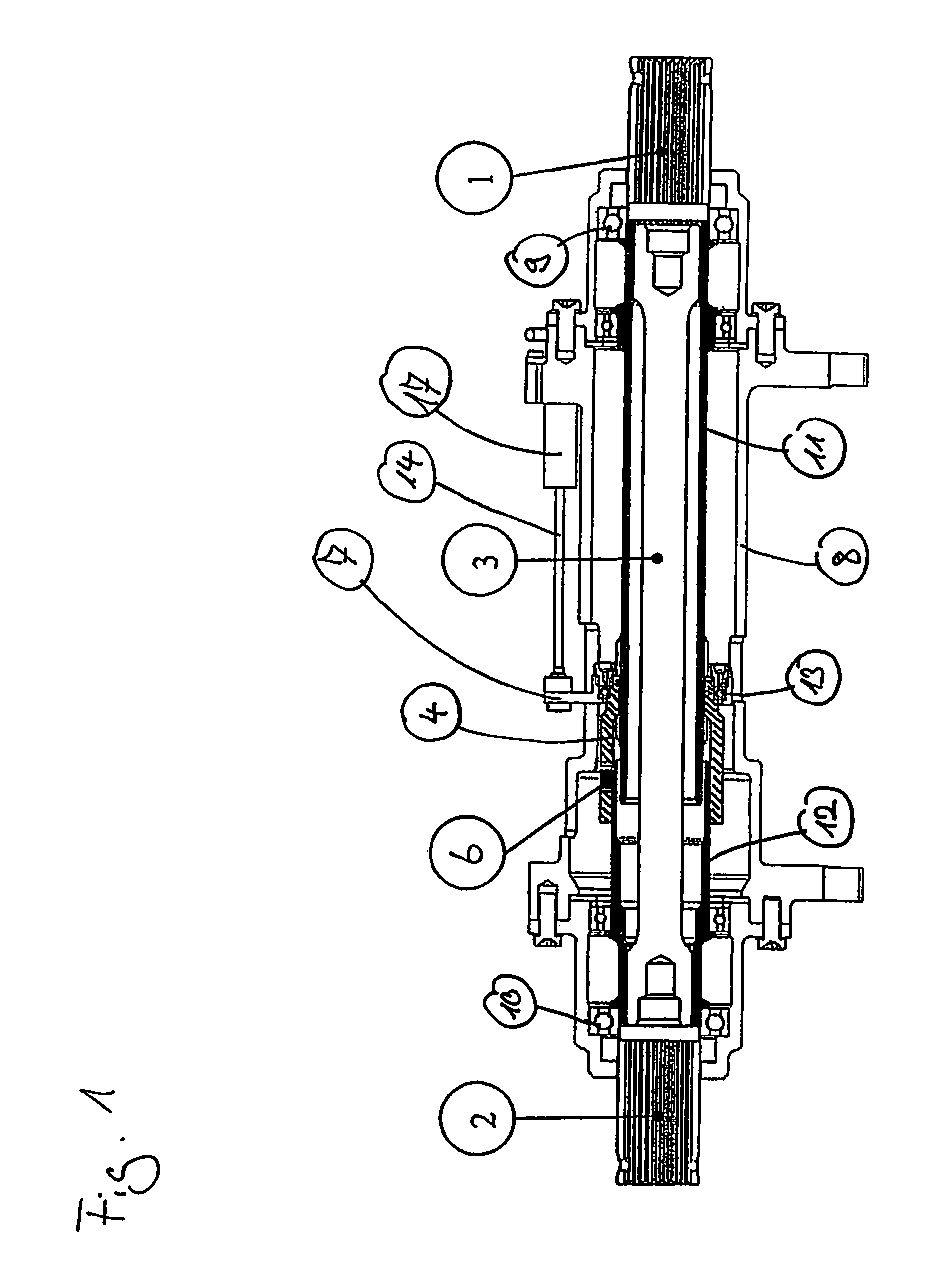

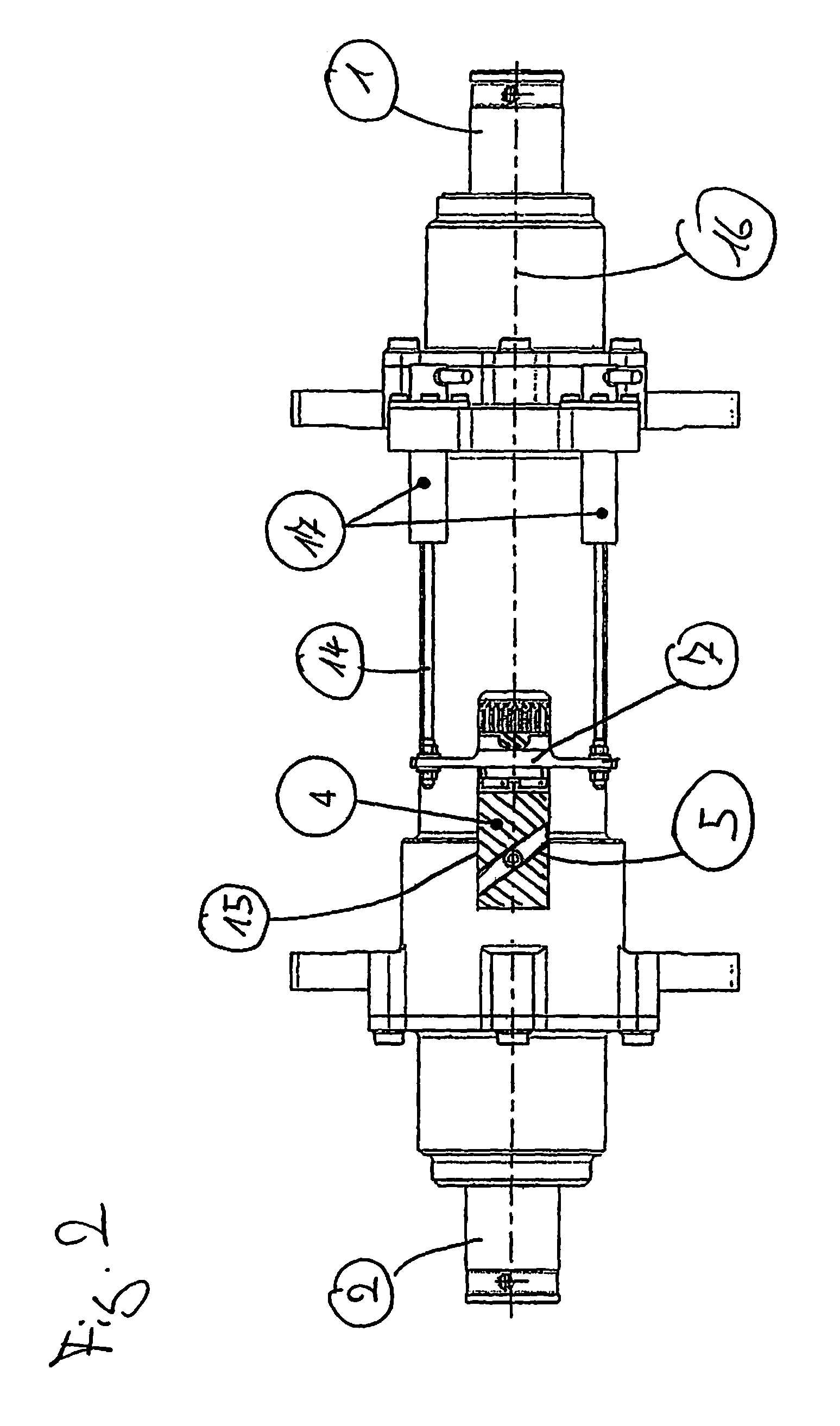

Transmission device for converting a torque between rotary movement and linear movement

InactiveUS6023989ASmooth meshingEliminate fluctuationsToothed gearingsPortable liftingLinear motionGear wheel

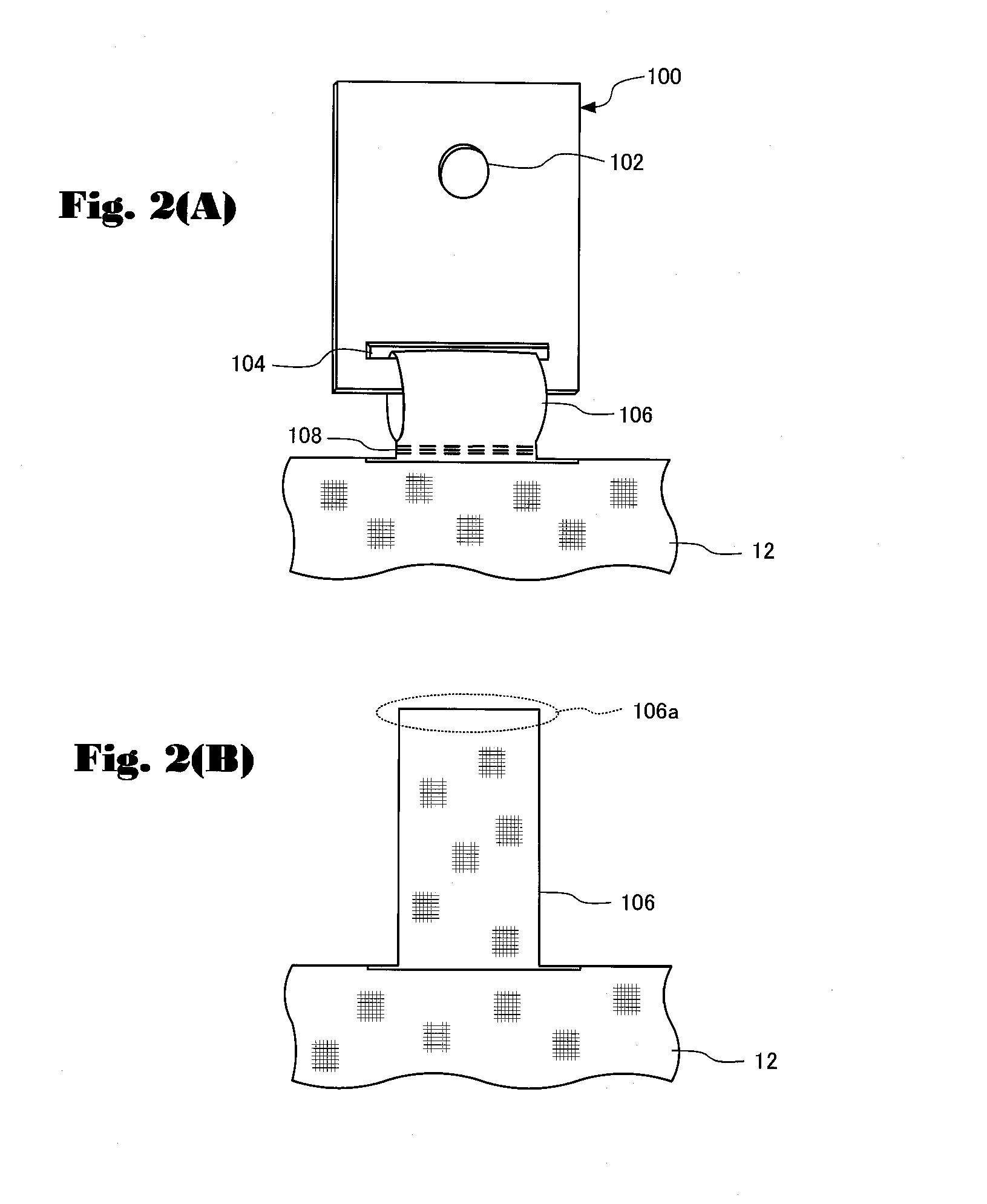

A transmission device for converting a torque from rotary to linear movement includes a rack having a plurality of teeth and a pinion having rollers which mesh with the teeth of the rack, with pressurization provided therebetween. The rack has an arcuate tooth flank diametrically greater than each of the rollers of the pinion. The rack also has a tooth face which has an approach profile progressively moving away from the path of contact of each of the rollers along which each of the rollers would otherwise engage with the tooth face. A plurality of each of the rollers of the pinion concurrently mesh with the corresponding teeth of the rack. Another embodiment converts a torque between rotary and linear movement and comprises a pinion having a plurality of teeth and a rack having a plurality of rollers to mesh with the teeth of the pinion. The device achieves reduced transmission resistance, a silent intermeshing movement with no substantial noise and vibration, as well as reduced wear on the teeth and rollers.

Owner:KAMOSEIKO

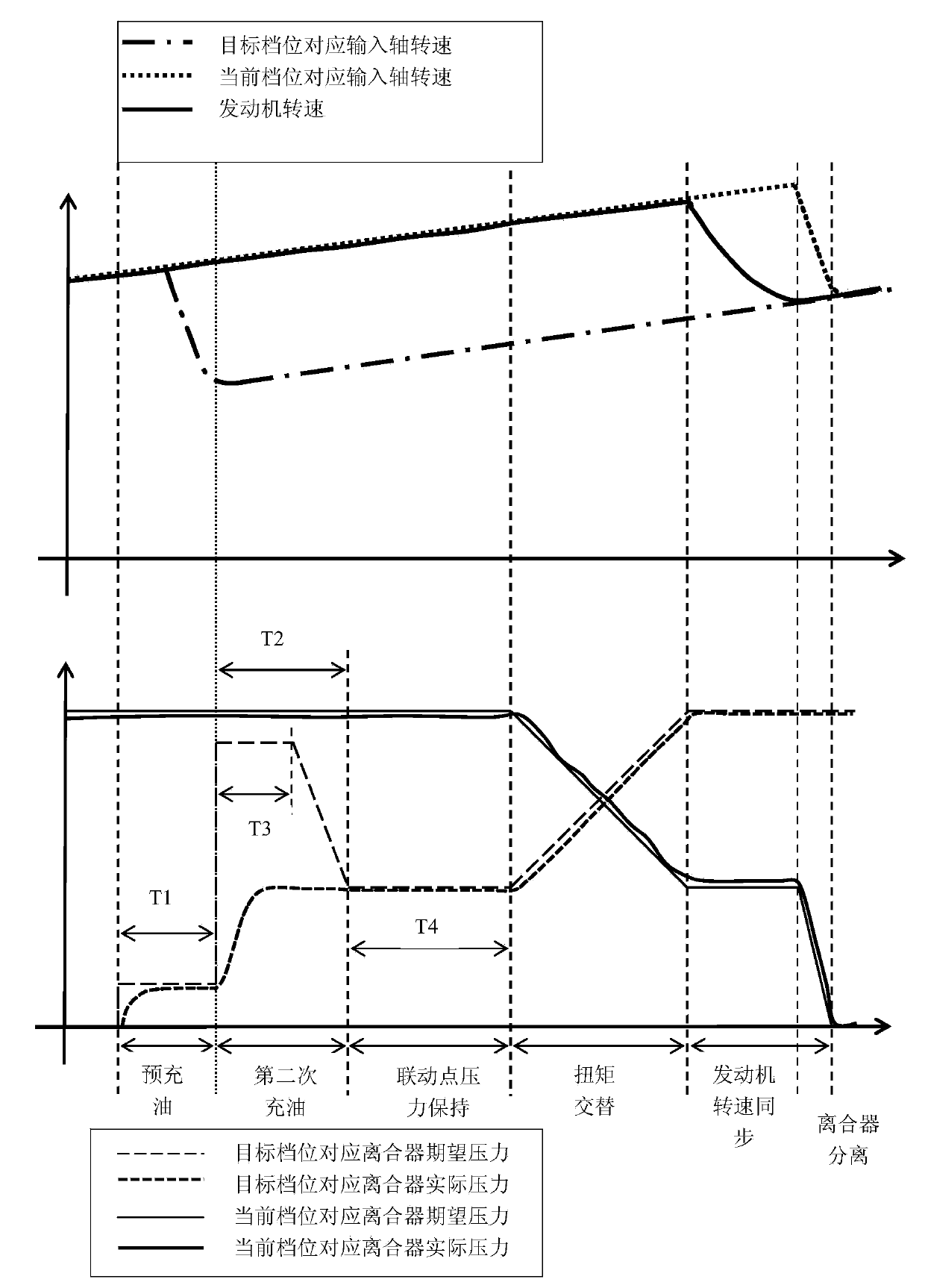

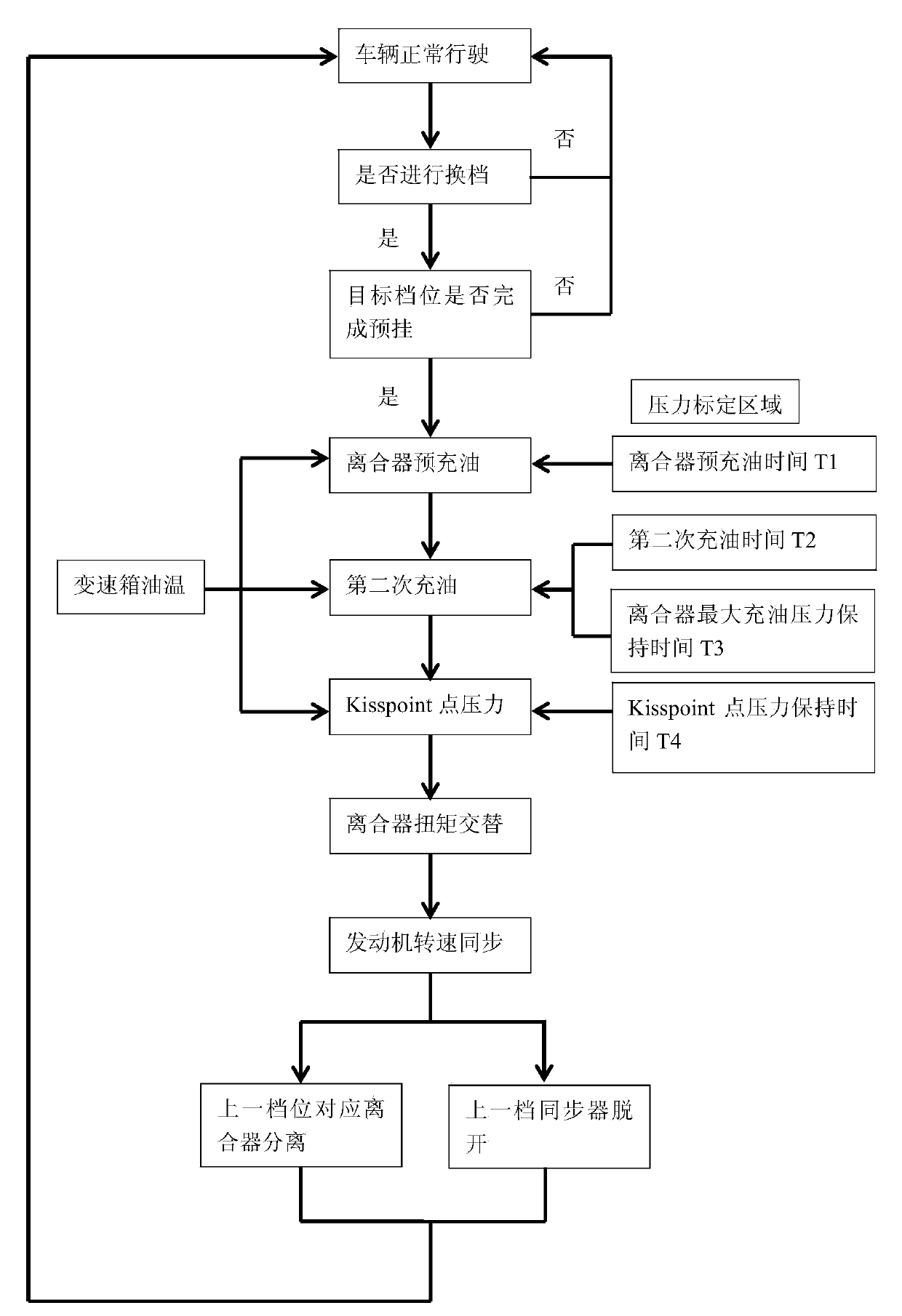

Method for controlling oil filling of clutches of automatic double-clutch gearbox

ActiveCN103438124APlay a preventive effectImprove shiftFluid actuated clutchesOil temperatureFault rate

The invention provides a method for controlling oil filling of clutches of an automatic double-clutch gearbox. The method comprises the step of filling oil in advance, wherein the clutches are filled with the oil in advance after pre-shifting of a target gear is finished, and the preset time is maintained; the step of filling the oil for the second time, wherein the clutches of the target gear are filled with the oil for the second time until linkage point pressure is reached; the step of maintaining the linkage point pressure, wherein the linkage point pressure of the clutches of the target gear is maintained until torque is alternated. In the step of filling the oil in advance, the current oil temperature of the gearbox is measured, and filling the oil in advance is carried out according to the current oil temperature of the gearbox. The temperature change of the oil in the gearbox is utilized for controlling the clutch oil filling process, and therefore timeliness and smoothness of clutch motions in the shifting process can be improved, and the fault rate of the automatic wet type double-clutch gearbox can be lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

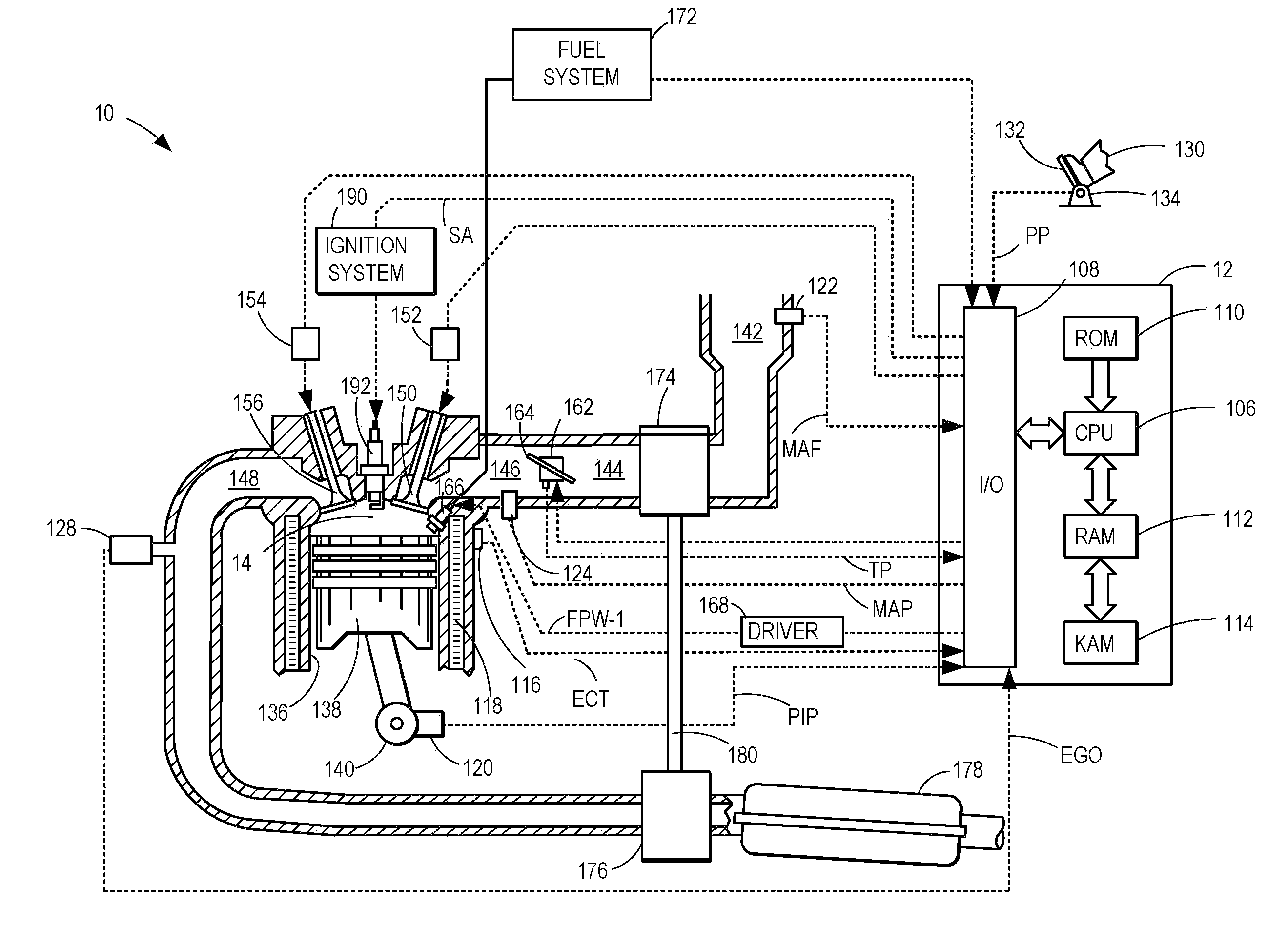

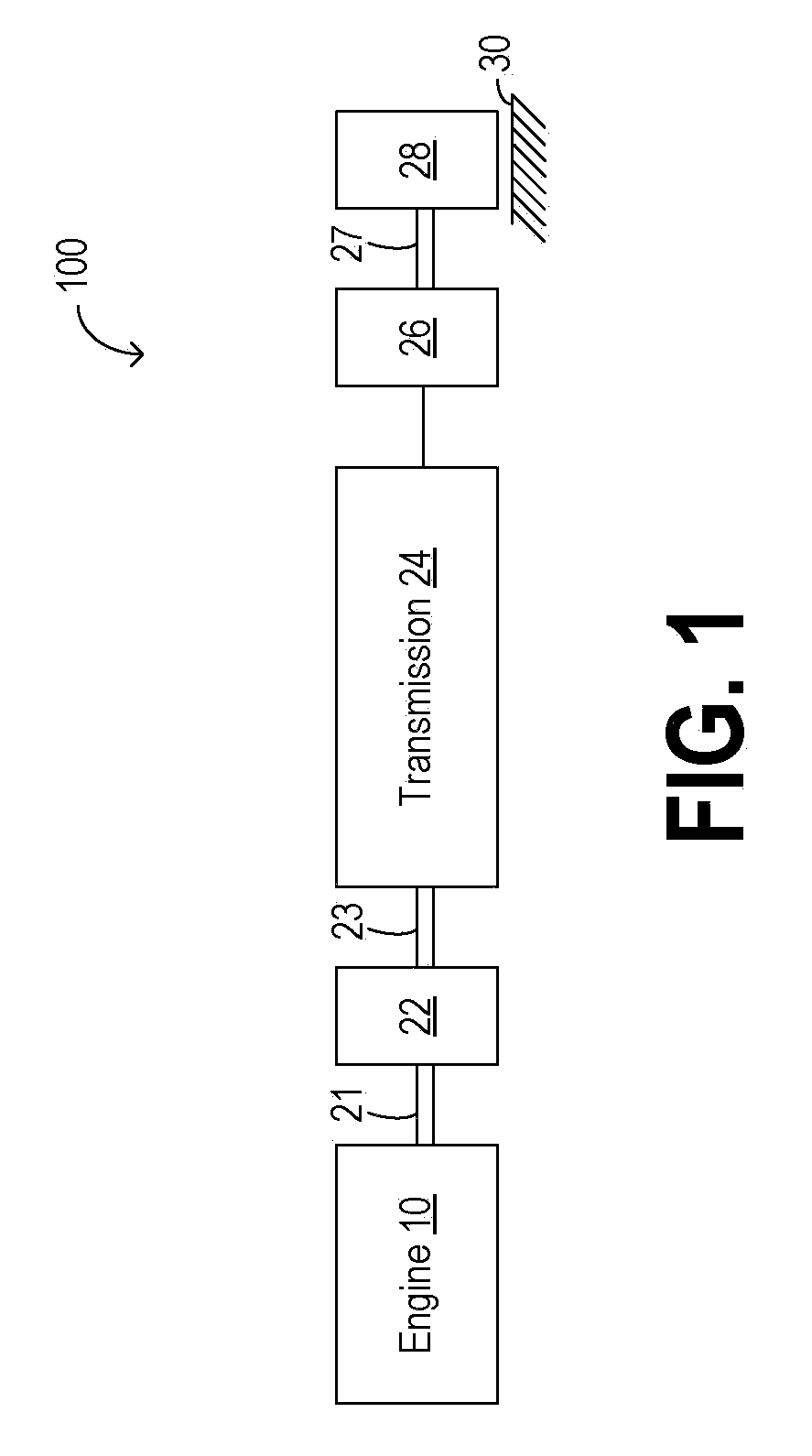

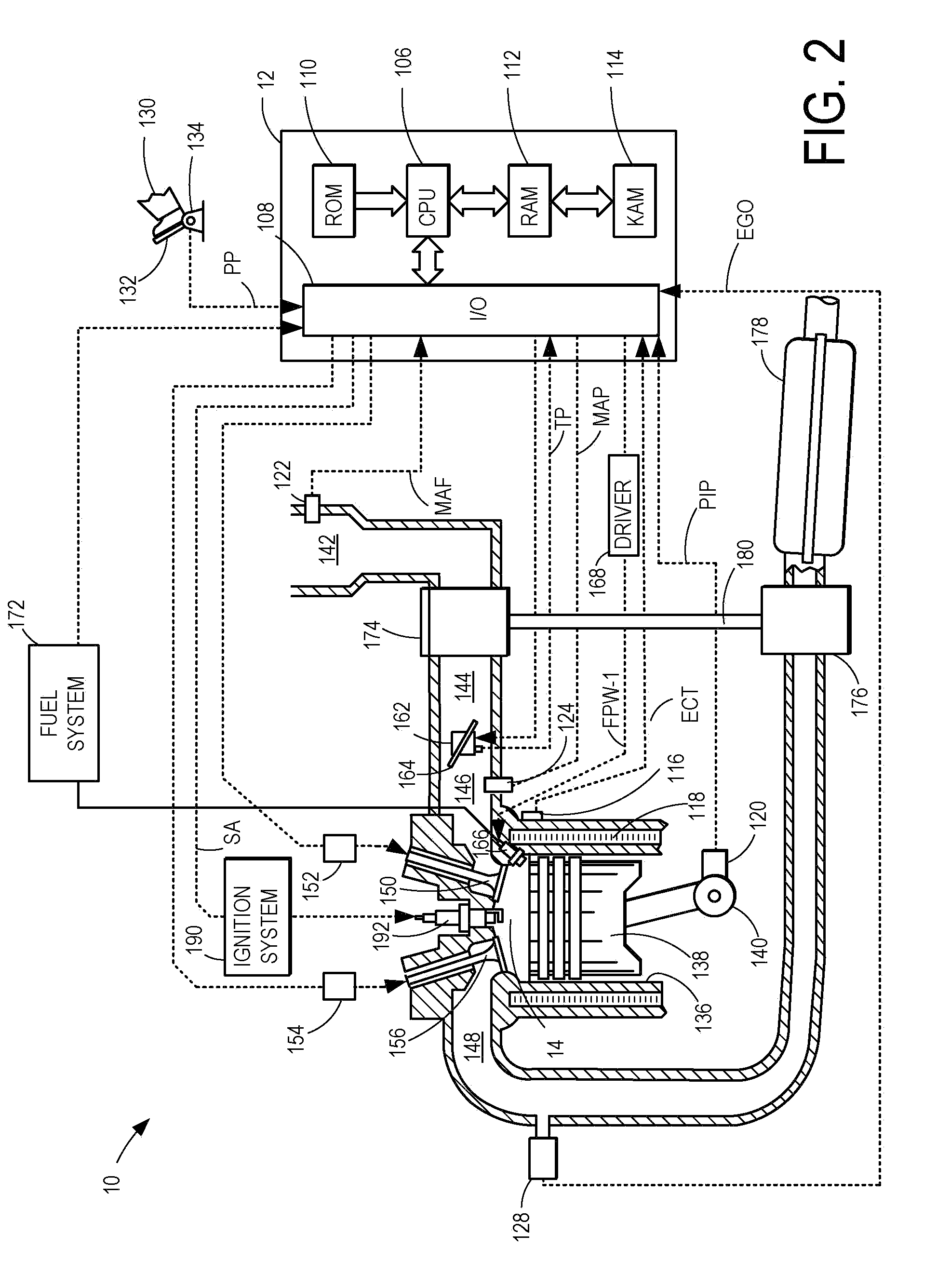

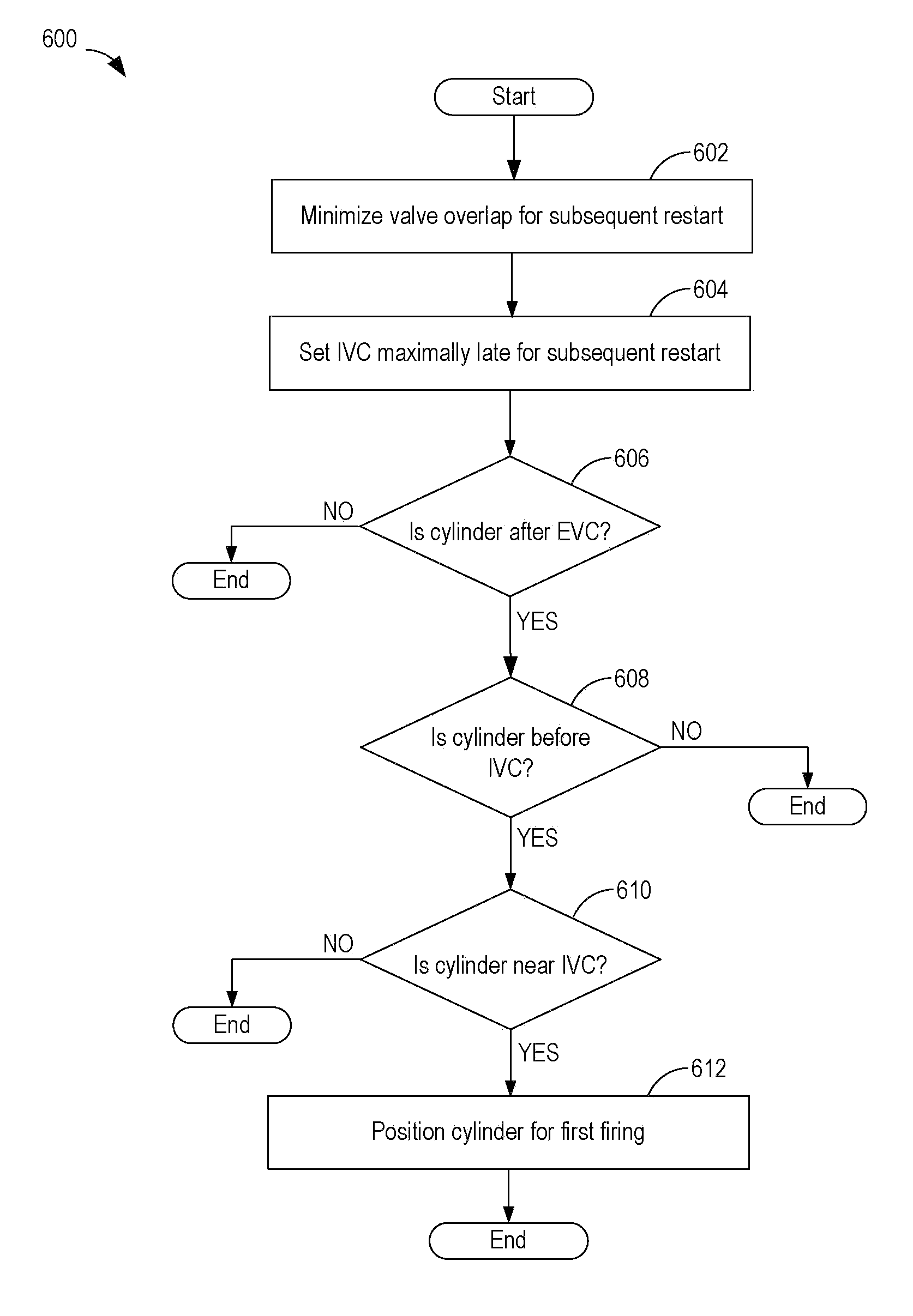

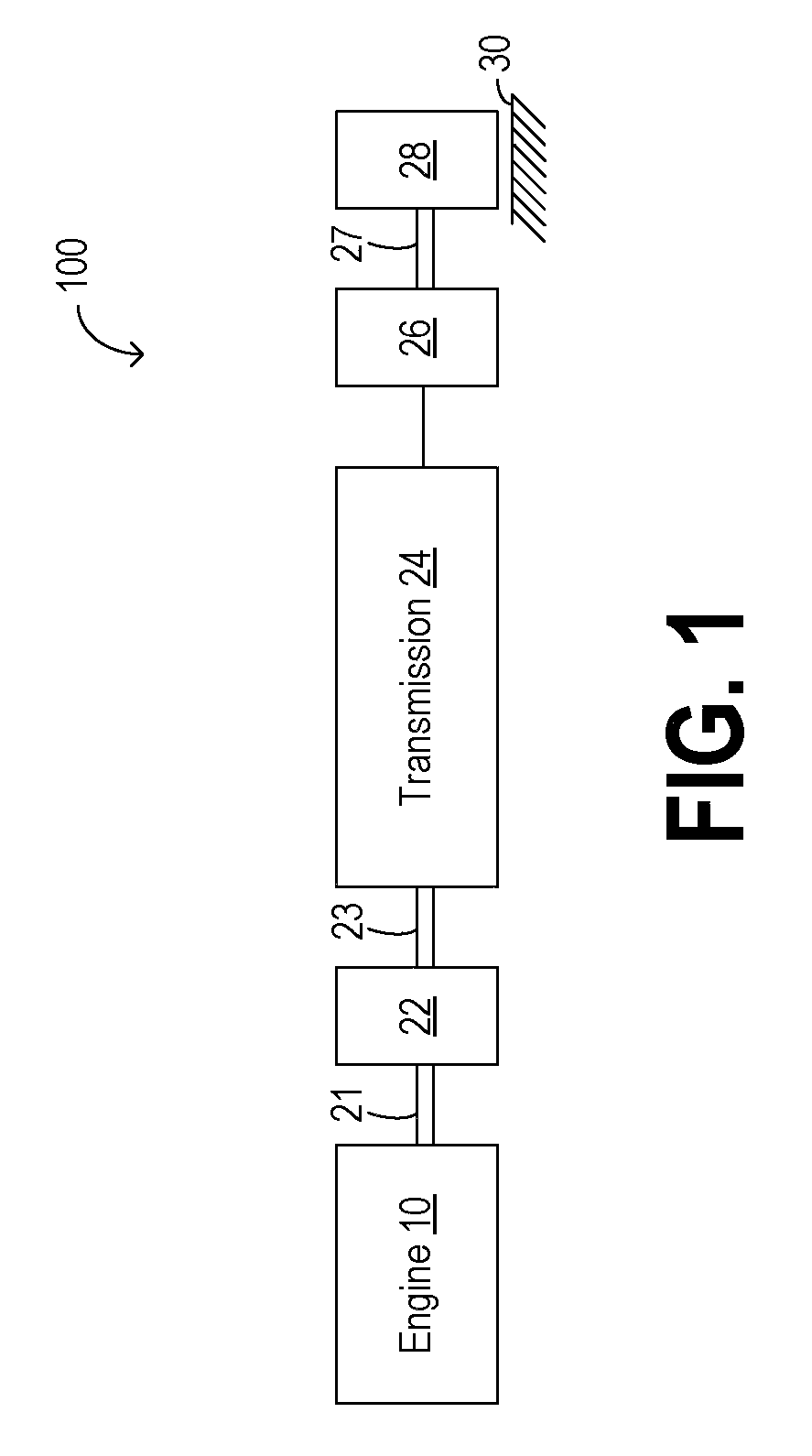

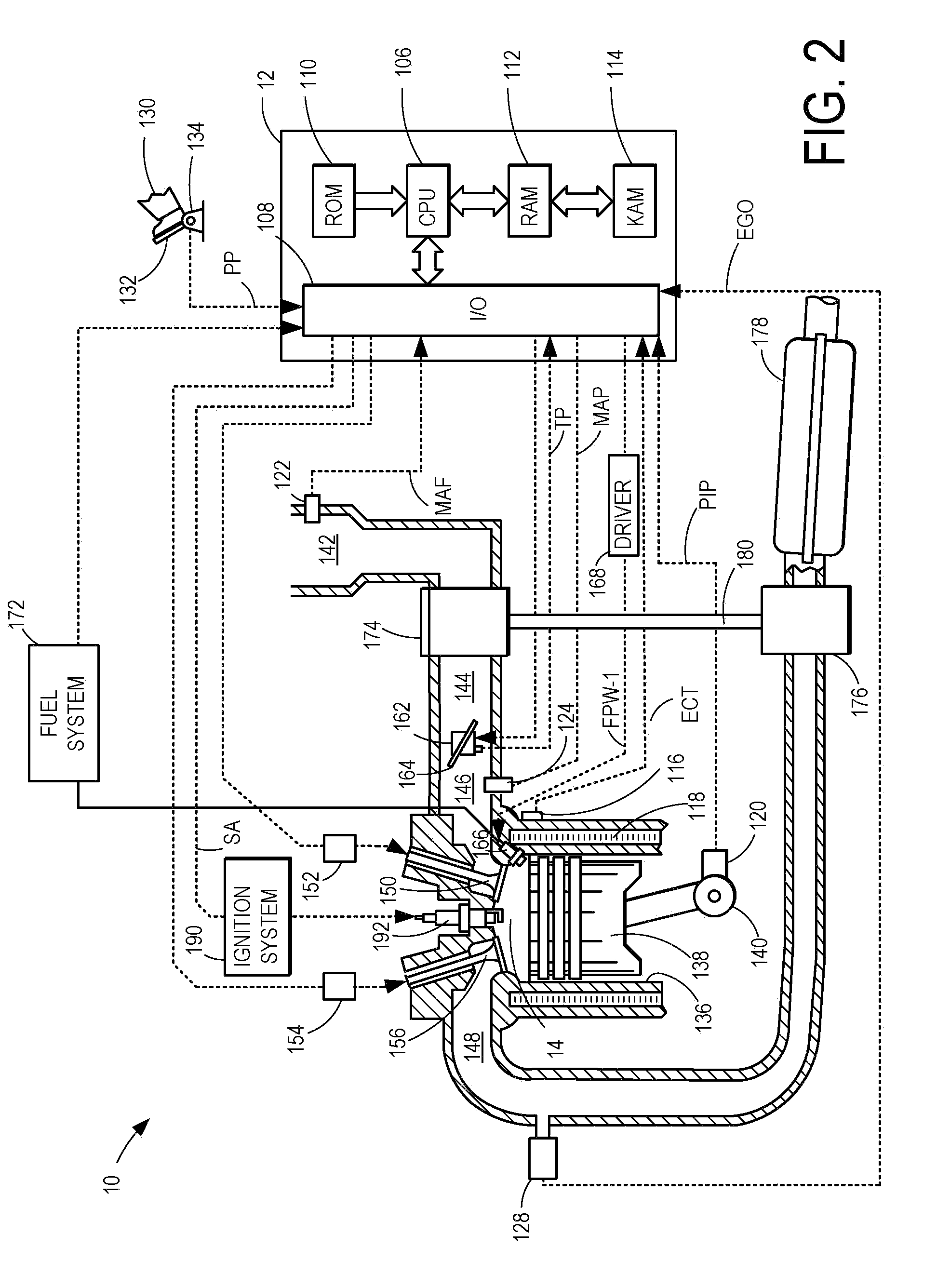

Methods and systems for engine starting

ActiveUS20100211288A1Reduce exhaust emissionsSave fuelAnalogue computers for vehiclesElectrical controlPistonCombustion

Methods and systems are provided for controlling a vehicle system including an engine that is selectively deactivated during engine idle-stop conditions and selectively reactivated during engine restart conditions. One example method comprises, during an engine restart from an idle stop, performing a first combustion event in a cylinder with a piston at an engine crankshaft position that is after a crankshaft position at which said cylinder's exhaust valve opens, and before a crankshaft position at which the cylinder's intake valve closes, during a cycle of said cylinder.

Owner:FORD GLOBAL TECH LLC

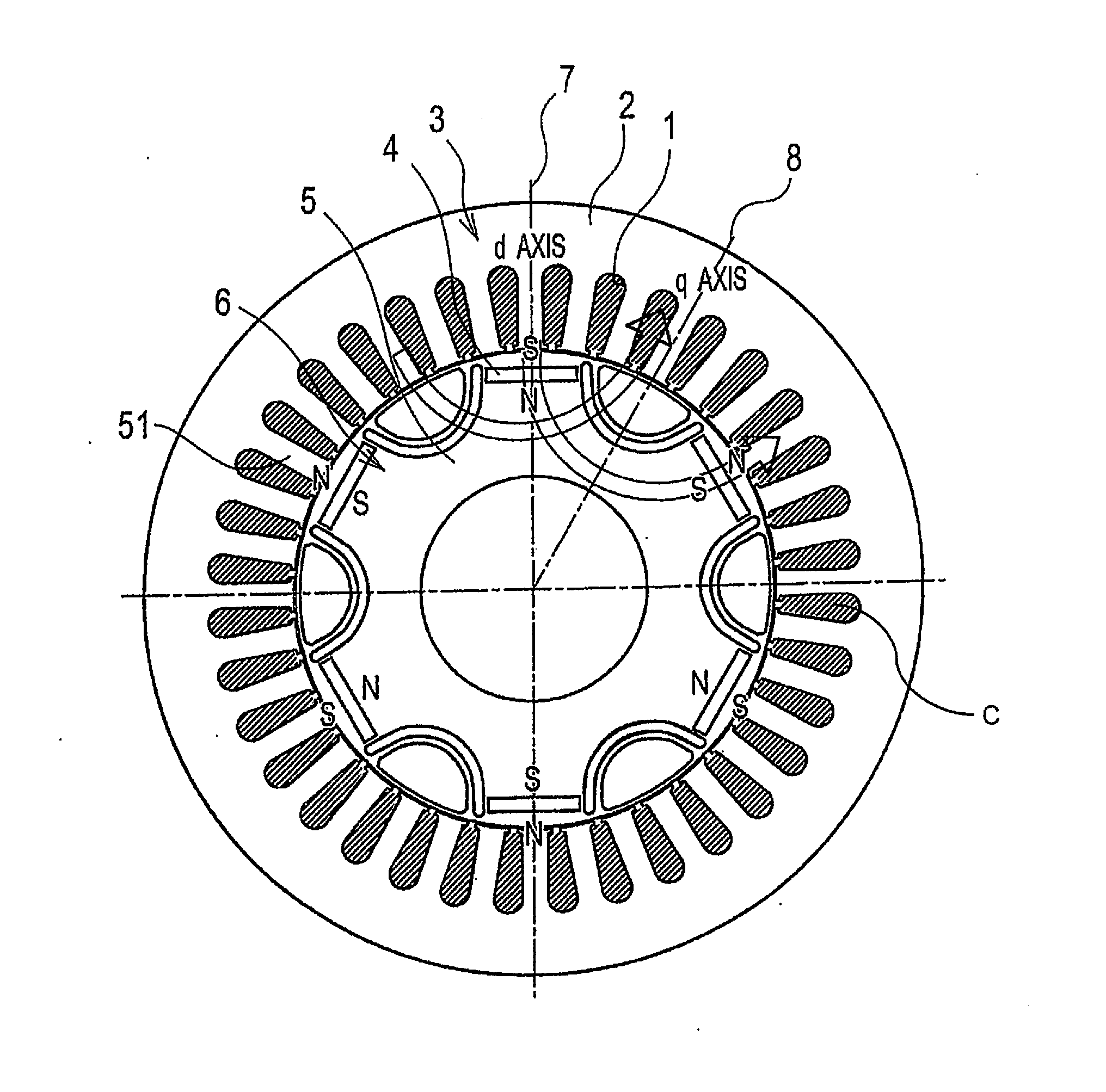

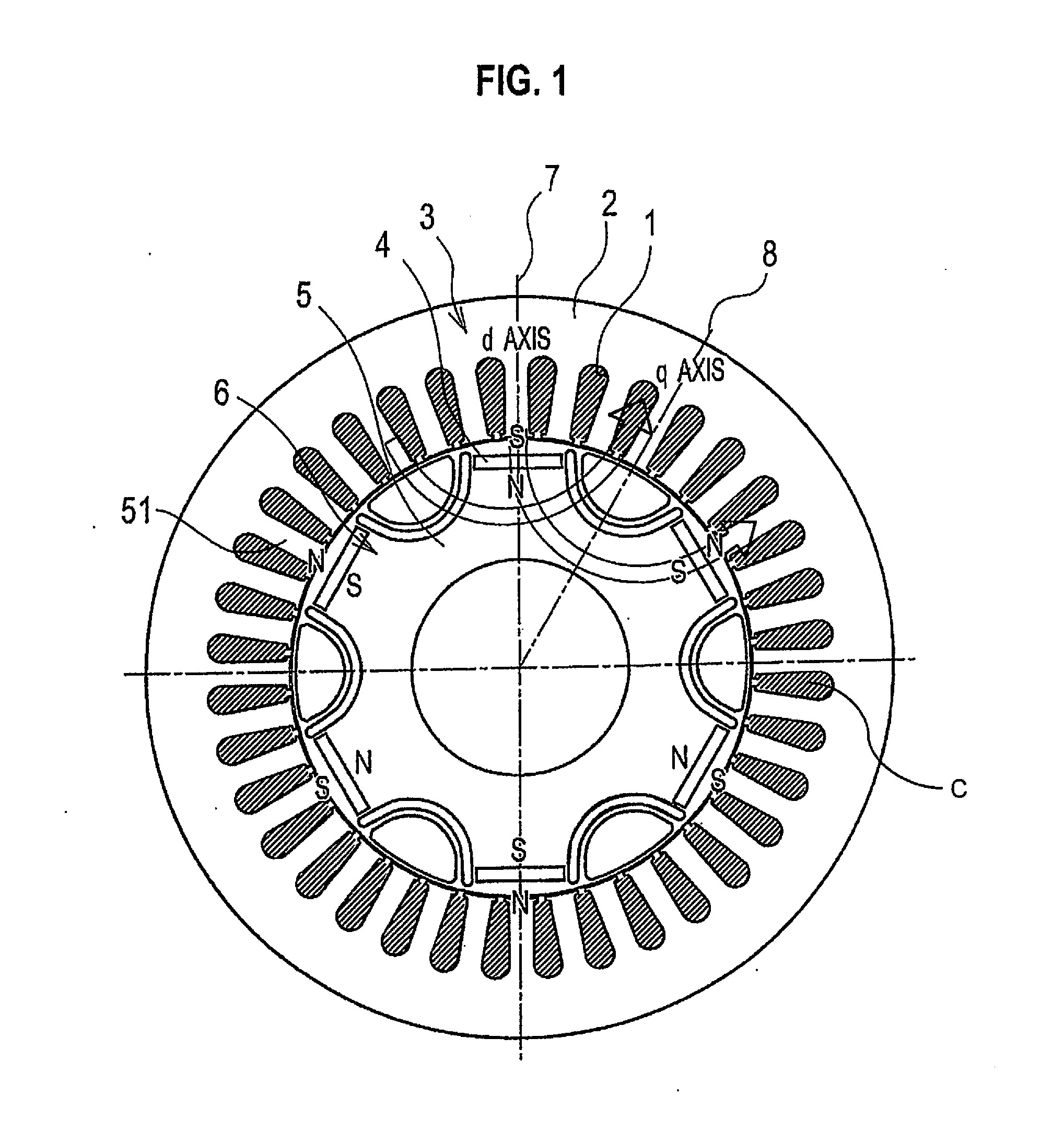

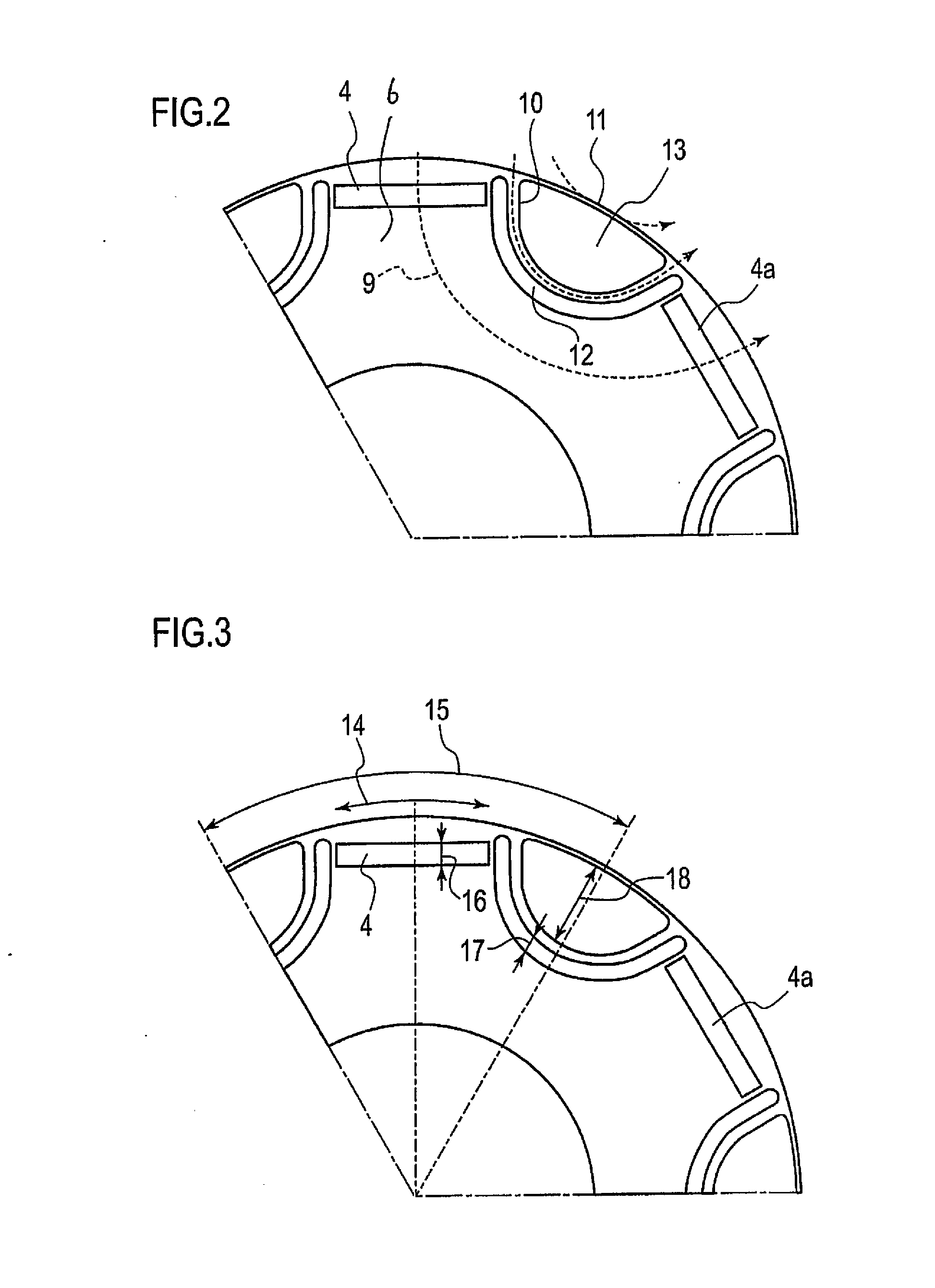

Variable magnetomotive force rotary electric machine and control device for variable magnetmotive force rotary electric machine

ActiveUS20150137648A1High coercivityCost reductionElectronic commutation motor controlMotor/generator/converter stoppersPhysicsMagnetic flux

A rotary electric machine includes a stator and a rotor. The rotor has at least one permanent magnet arranged in a d-axis magnetic path. The rotor includes a magnetic gap part located between the permanent magnet arranged in the d-axis magnetic path of one pole and an adjacent magnet with a different polarity, such that a d-axis magnetic flux forms a d-axis bypass passing through an area other than the permanent magnet. The d-axis bypass provides a magnetic resistance in a d-axis direction that is set below a magnetic resistance in a q-axis direction that is orthogonal to the d-axis resistance.

Owner:NISSAN MOTOR CO LTD +1

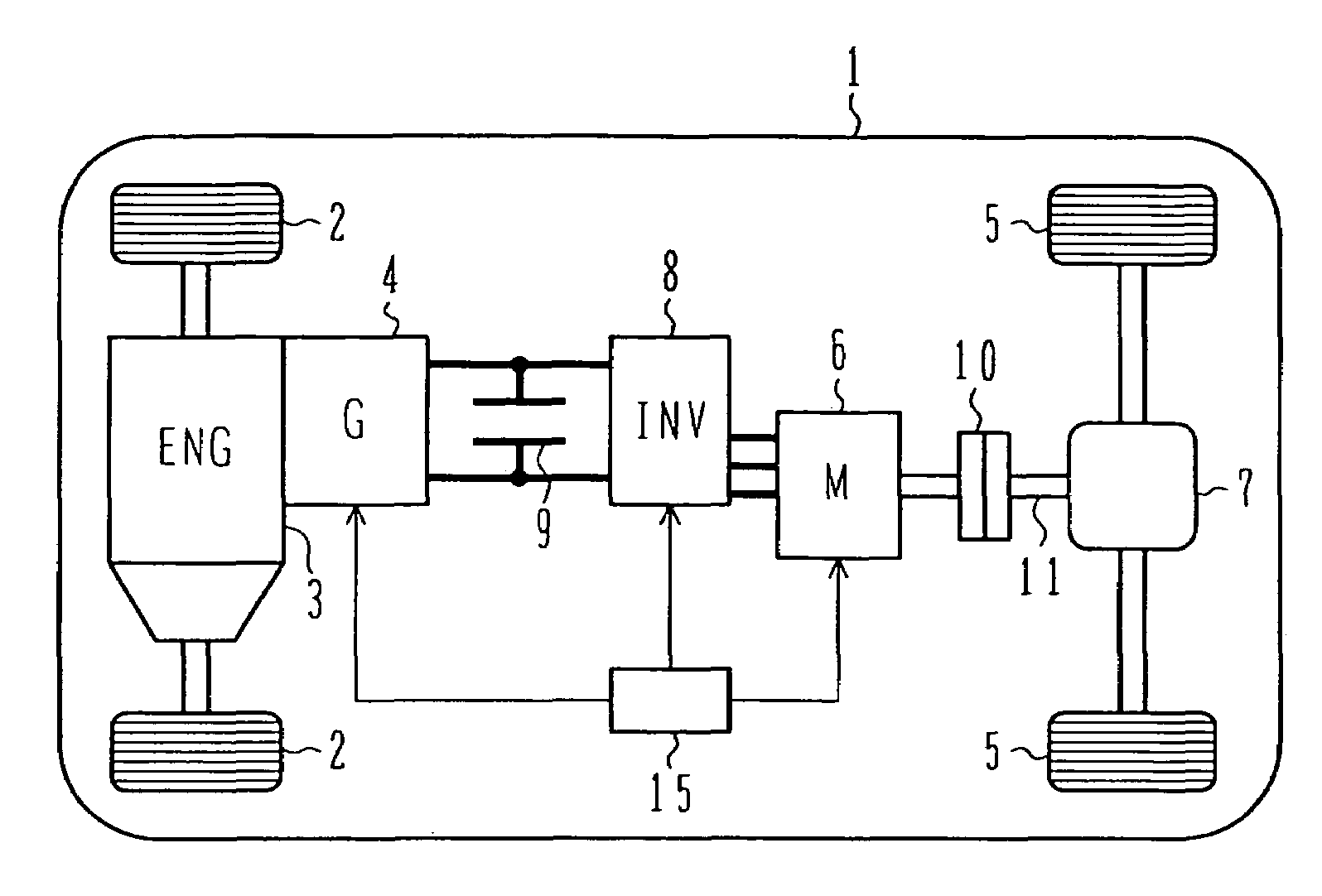

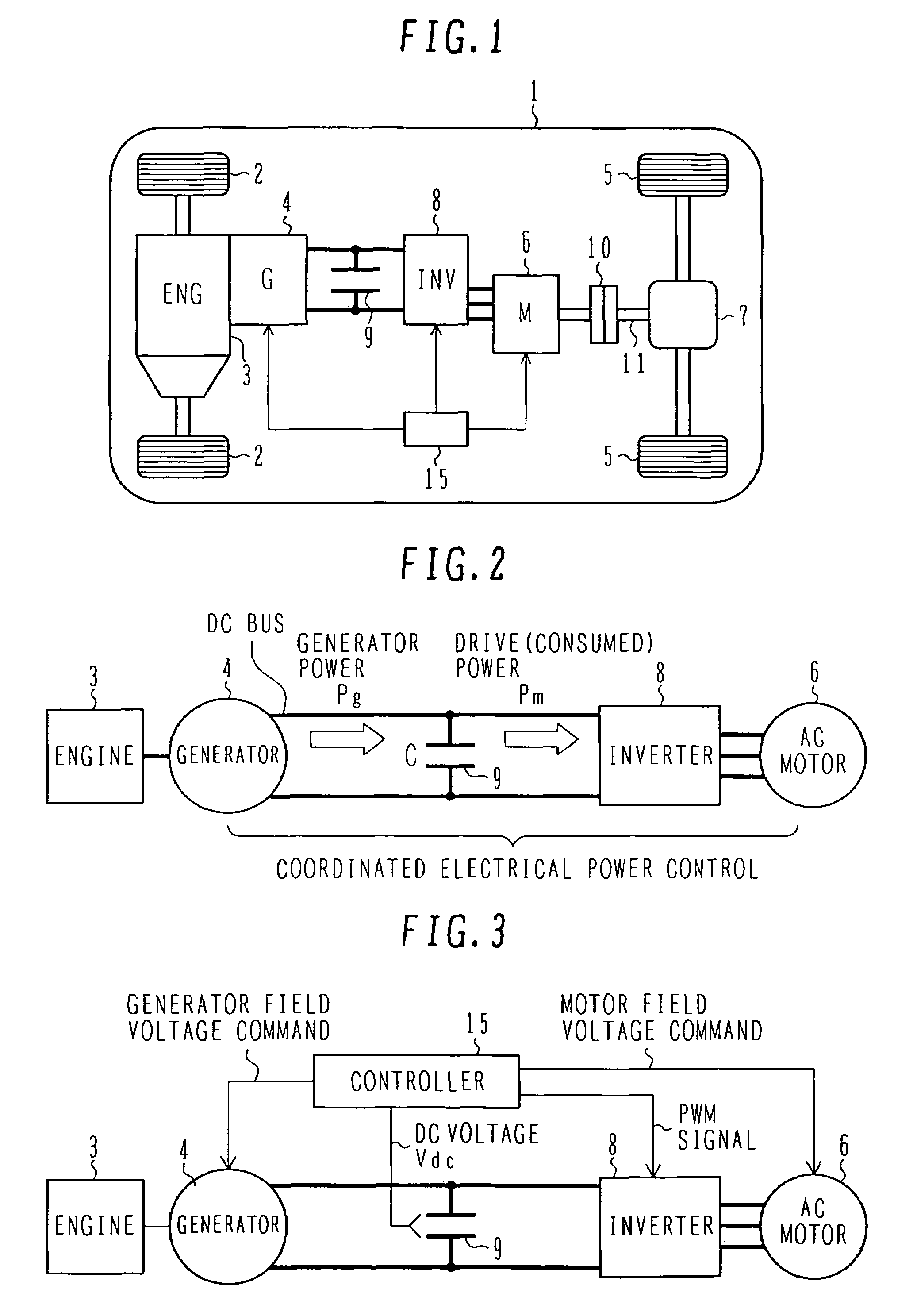

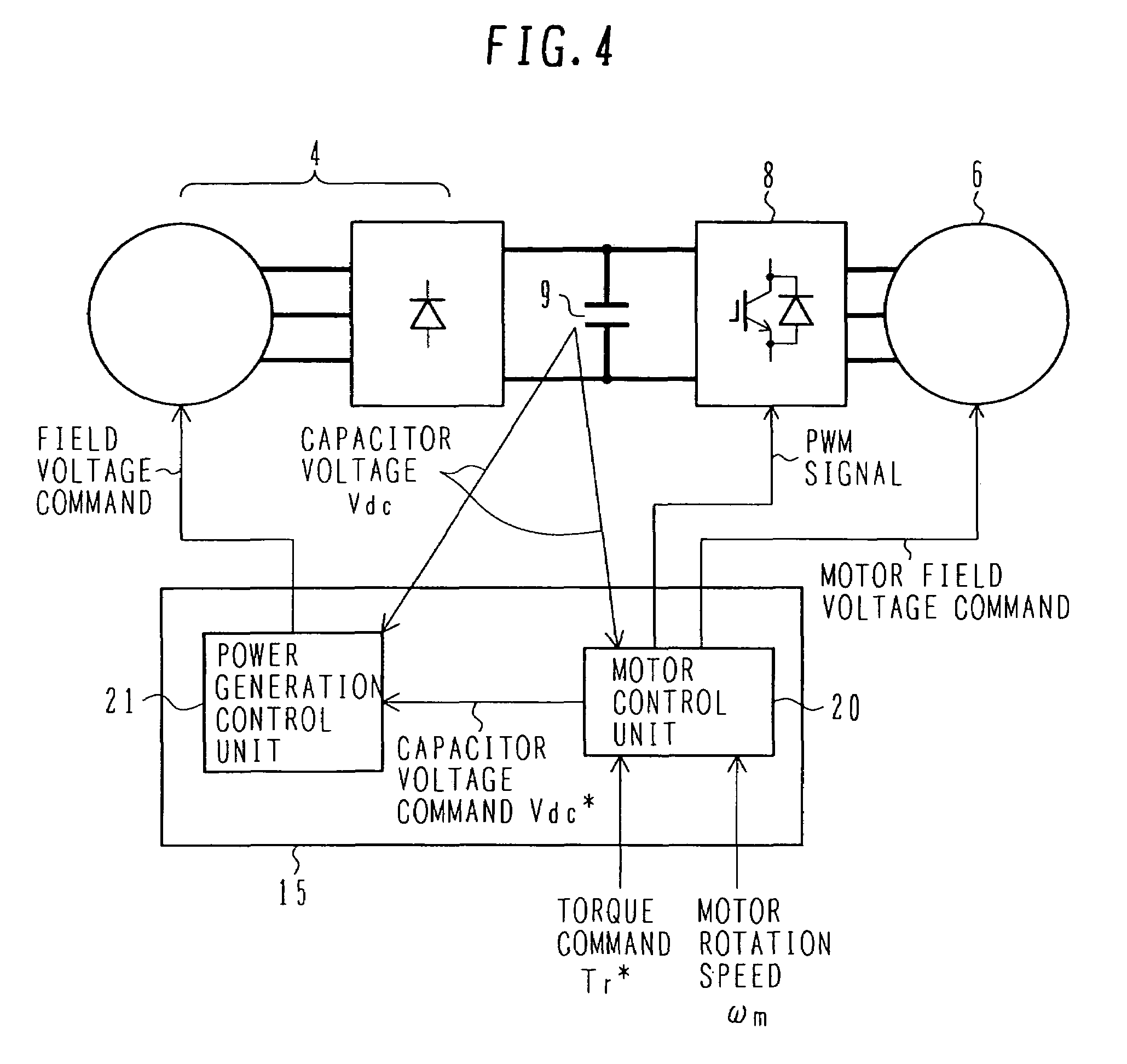

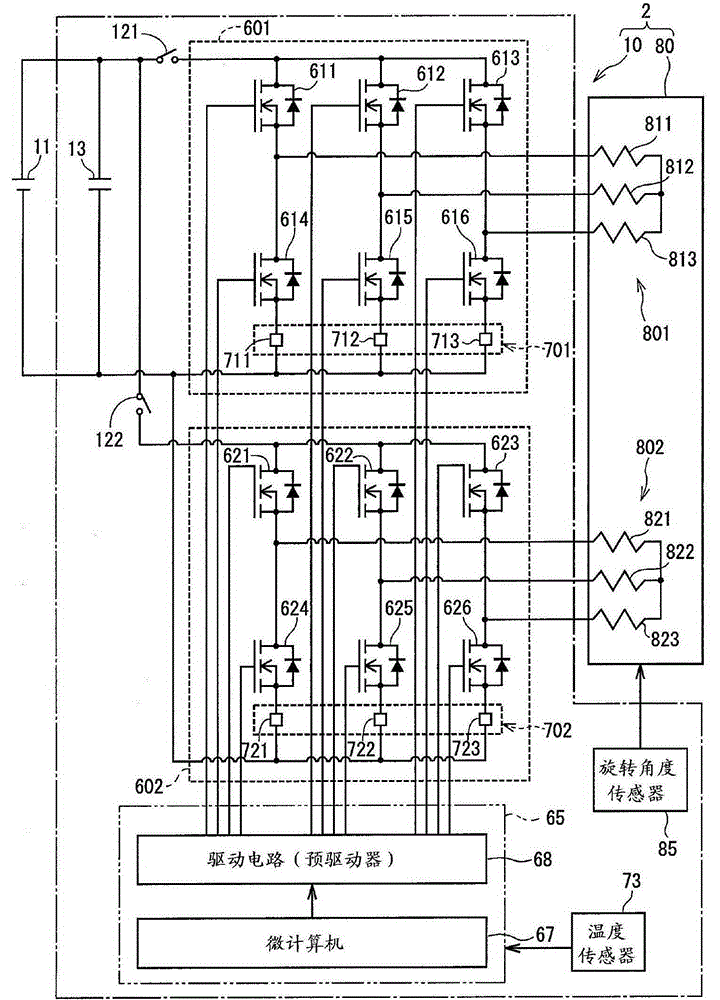

Controller for an electric vehicle and driving apparatus for the electric vehicle

InactiveUS7427849B2Torque stabilizationSmooth output torqueAnalogue computers for vehiclesDC motor speed/torque controlOperating pointMotor control

The present invention provides a controller and driving apparatus for an electric vehicle, which enables a motor to steadily output torque even when there is an increase in the rotation speed of an internal combustion engine that drives a generator. A motor control unit includes a voltage / current command generator F10. The voltage / current command generator F10 includes a base command determination unit, which determines a base command value for the output voltage of the generator and base command values for d- and q-axis currents that drive an AC motor, and power generation operating point change means, which changes the command values that are output from the base command determination unit. When an operating point of the generator approaches an unstable region where the generator unsteadily operates, the power generation operating point change means changes the generator's operating point to position it within a stable region.

Owner:HITACHI LTD

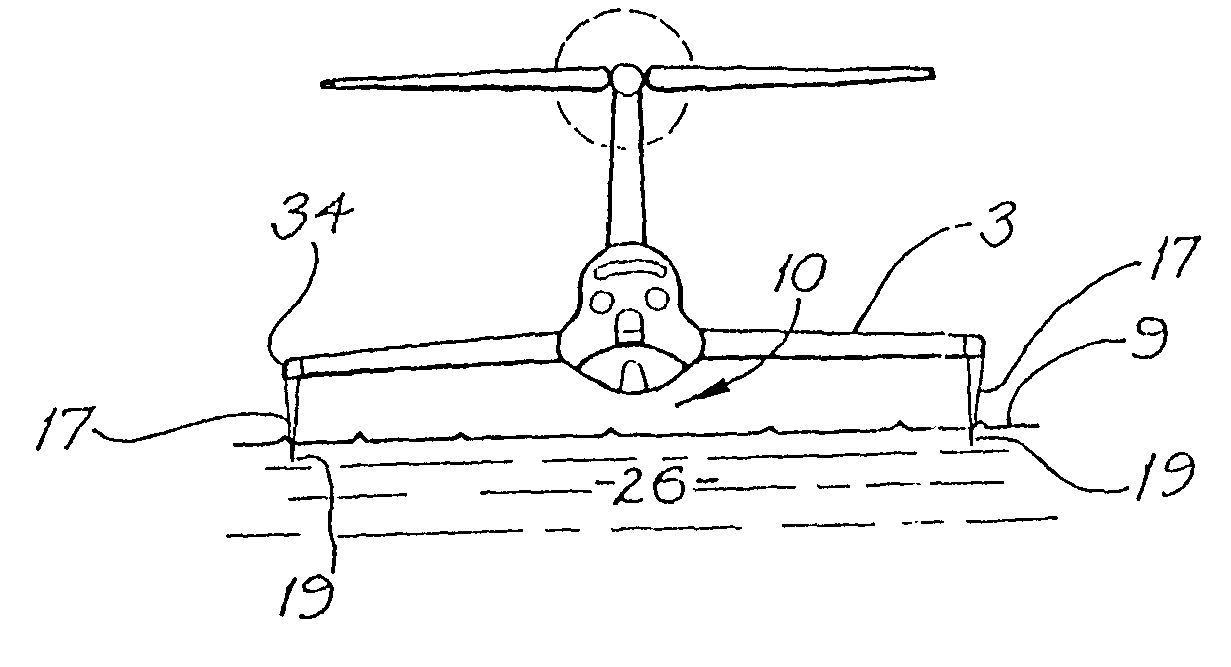

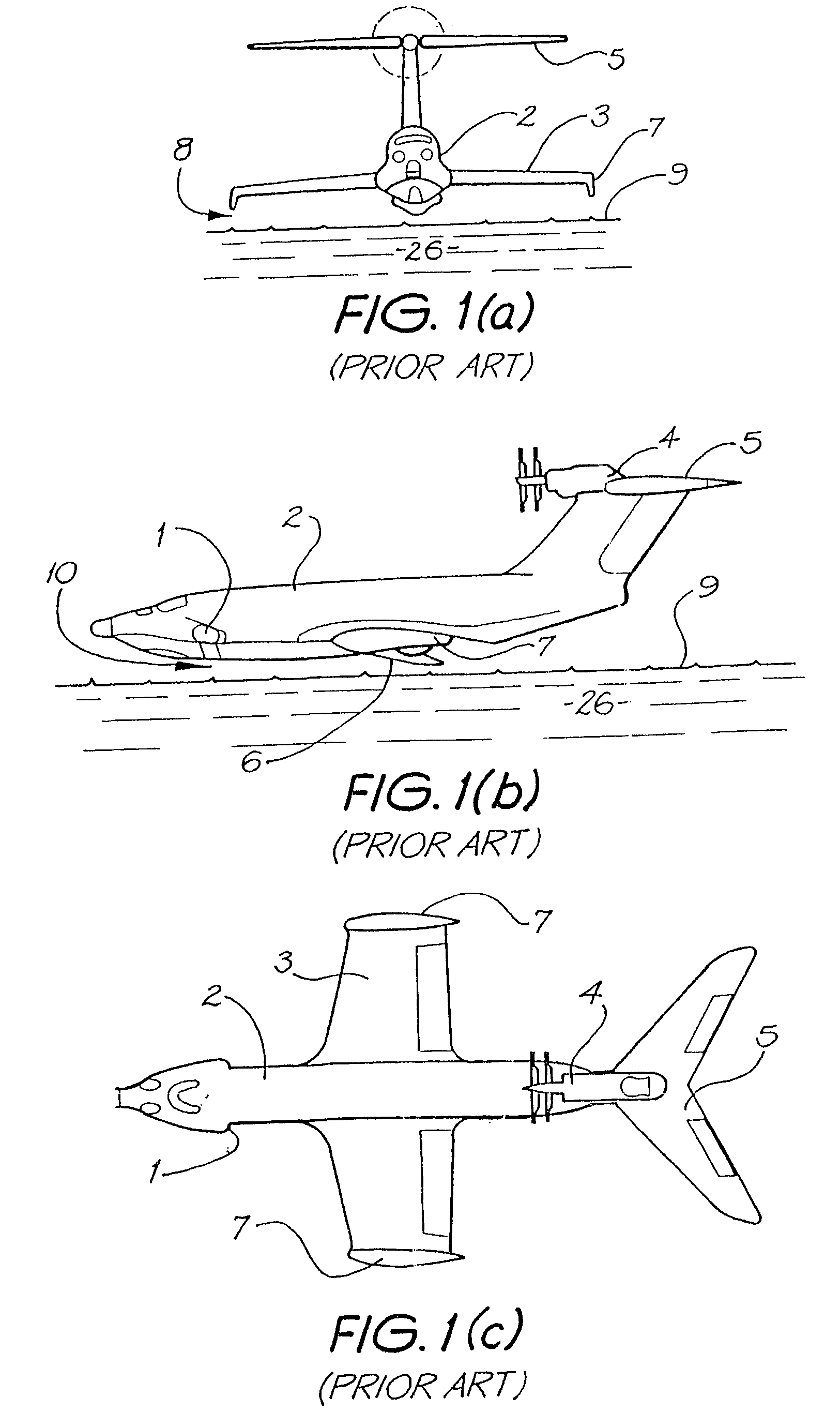

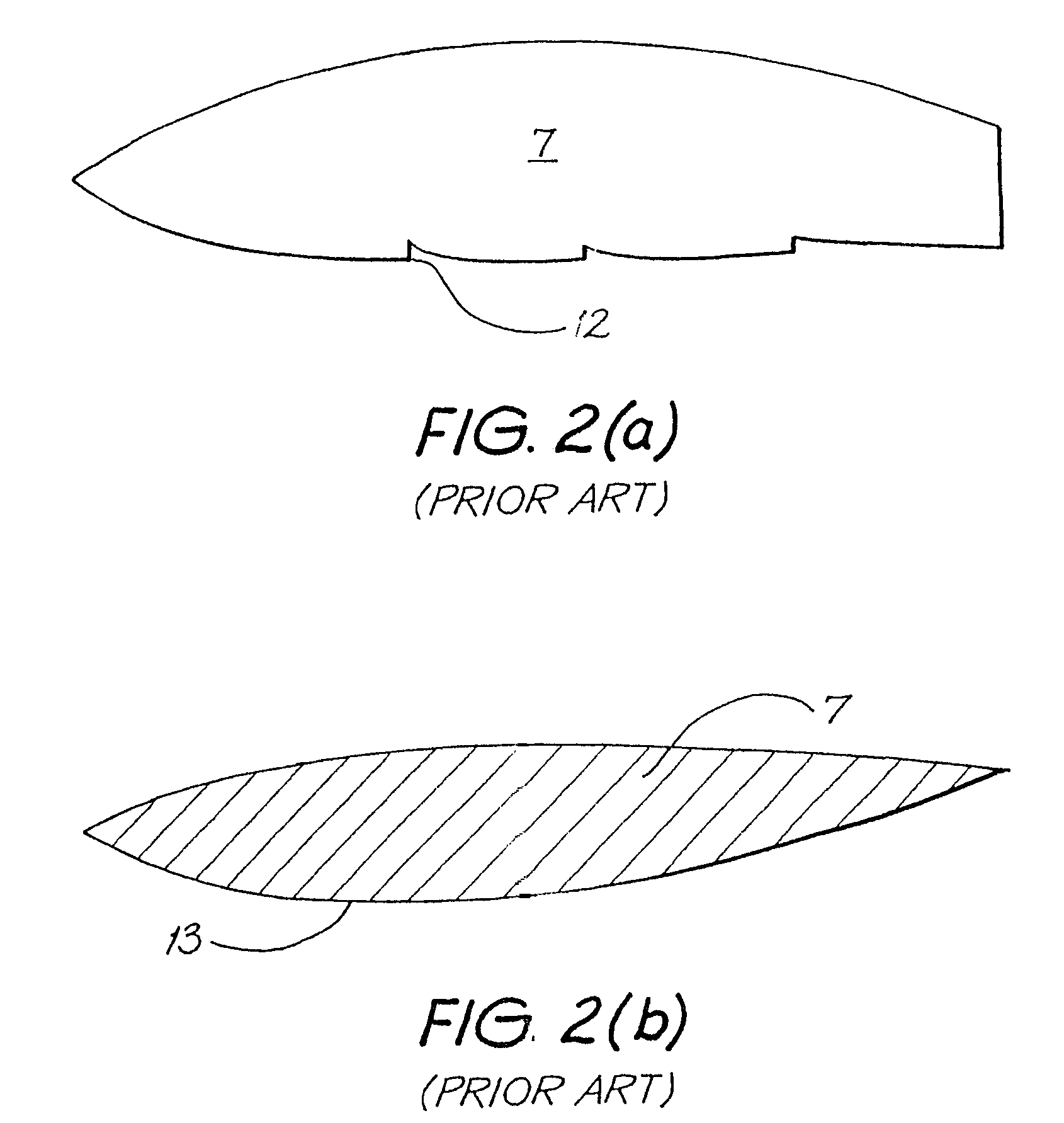

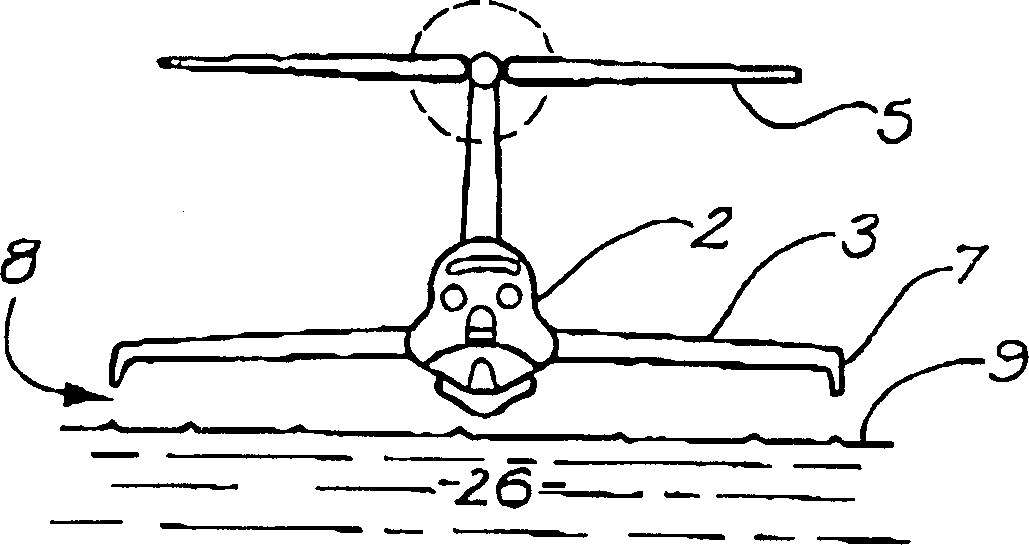

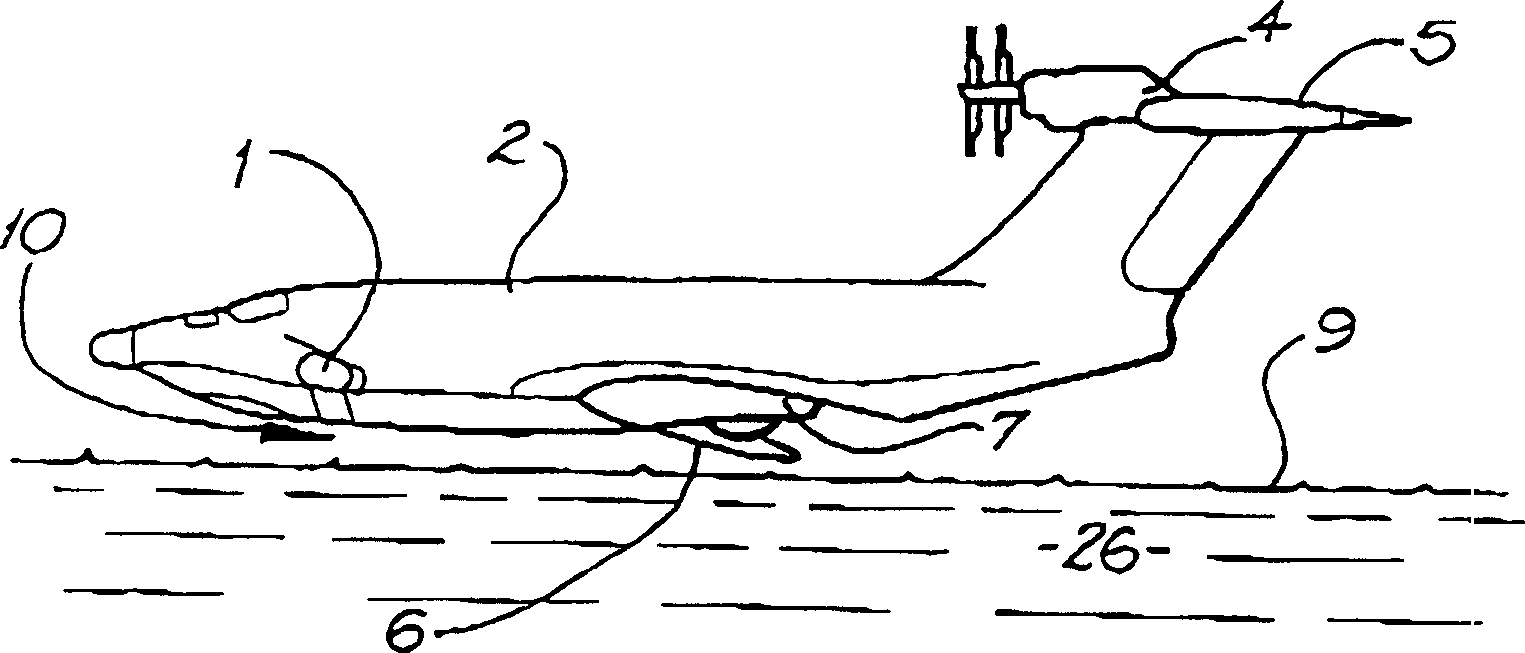

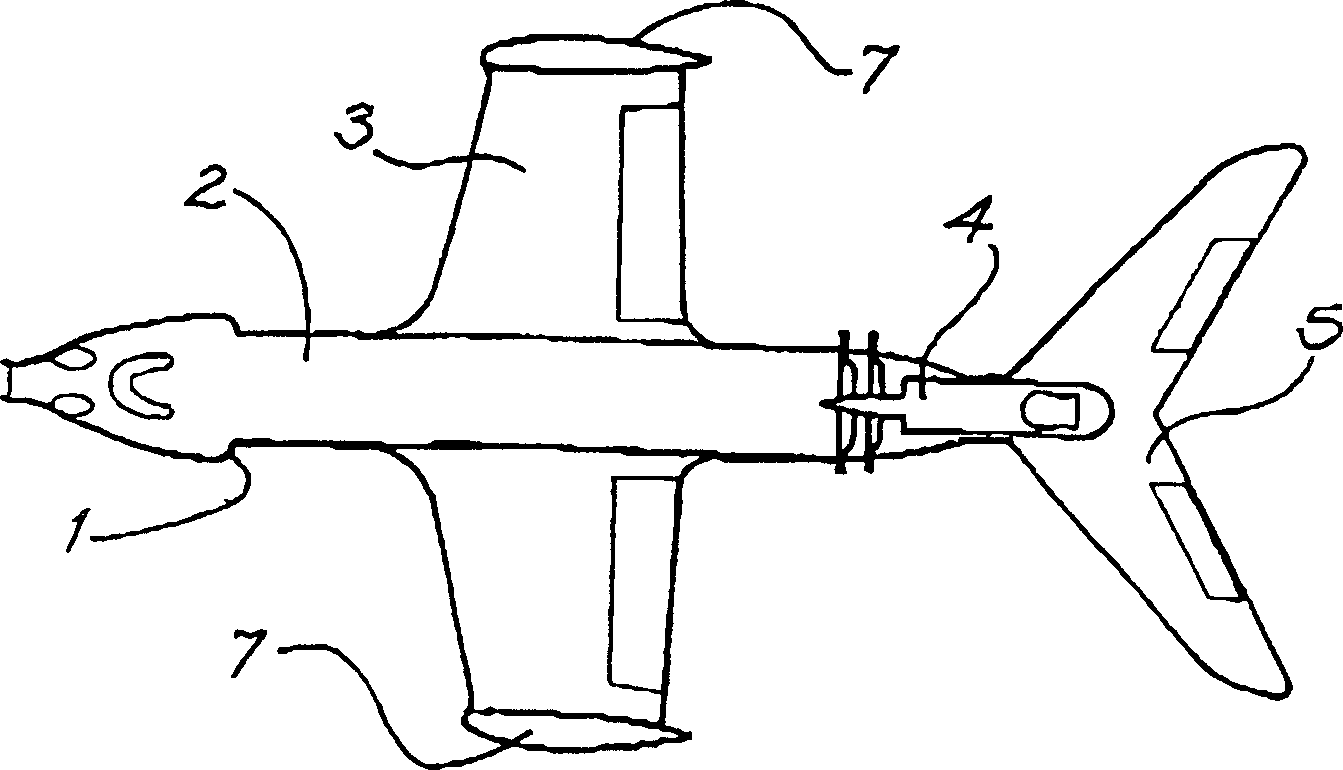

Wing in ground effect vehicle with endplates

A Wing In Ground Effect Vehicle has a pair of supercavitating endplates (17) which extend below the fuselage (2) such that they can be immersed in water during flight thereover. The endplates have a nose (28) defining a leading edge (20) and adapted to generate a supercavity. The endplates (17) typically pivot about a pivot axis P to provide a stabilising weathercock-type effect.

Owner:COSMOS HLDG LTD

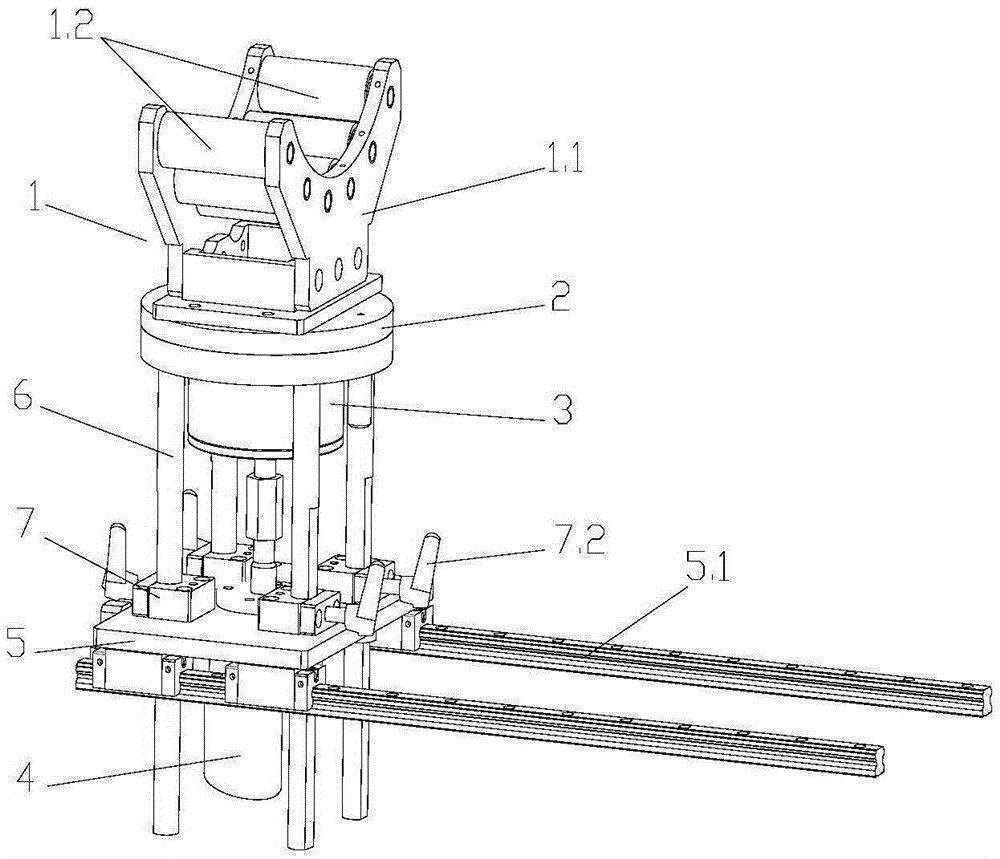

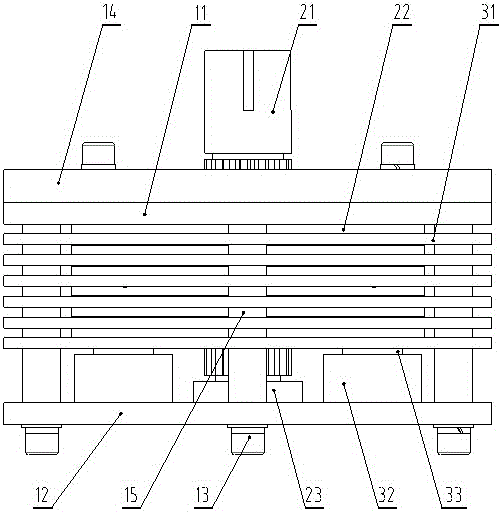

Motor stator fixture

InactiveCN105356692AAvoid damage and deformationEasy to adjustWork holdersEmbedding prefabricated windingsSlide plateEngineering

The present invention belongs to the technical field of tool fixtures and particularly relates to a motor stator fixture which comprises a stator bracket, a rotation seat at the bottom of the stator bracket. The bottom of the rotation seat is provided with a bracket seat which is rotatingly connected to the rotation seat. The bottom of the bracket seat is provided with a driving device which controls the lifting of the bracket seat. The driving device is fixed to the sliding plate of the bottom of the bracket seat. The bottom of the sliding plate is provided with a sliding rail which is matched with the sliding plate. Multiple uniformly distributed lifting support shafts are vertically arranged between the bracket seat and the sliding plate. The sliding plate is provided with locking position machanisms which lock the lifting support shafts corresponding to the lifting support shafts. The stator bracket comprises two opposite support plates, and multiple magnetic rollers are arranged in a curved way between the support plates. The magnetic rollers are provided with wrenches for controlling magnetic force. The structure is simple, the operation difficulty of clamping a motor stator is reduced, the efficiency is improved greatly, the adjustment performance is good, and the adjustment is flexible.

Owner:CHANGZHOU XIXIASHU ENTERPRISE INNOVATION DEV CENT

Cage twisting machine wire barrow paying out tension controlling method and apparatus

InactiveCN1933038ASmall initial pay-off tensionGood radial positioningFilament handlingCable/conductor manufactureInstabilityMagnetic poles

Strain of payoff control method and device uses for cage stranger payoff tray of electrical wire and cable equipment. Existing technology adopts strap friction to control the strain of payoff, while the strain of payoff is instability and is disaccord of some cradle payoff tray. It adopts permanent damp technology to adjust magnetic pole air-gap of damp tray and to control strain of payoff. It relates to passive damp tray, active damp tray, accommodate handle, active tray slide cover, transmission shaft, graduation direction mark, fix seat of passive damp tray, bearing, bearing cover and cradle body. Turn accommodate handle to adjust strain of payoff. Accommodate moment is extended constant and dose not change with temperature, time and opposite slide difference speed for non-friction. The whole operation keeps steady strain of payoff and realizes the coherence of strain of payoff to all cradle payoff trays by clearance graduation direction mark.

Owner:百通赫思曼工业(苏州)有限公司

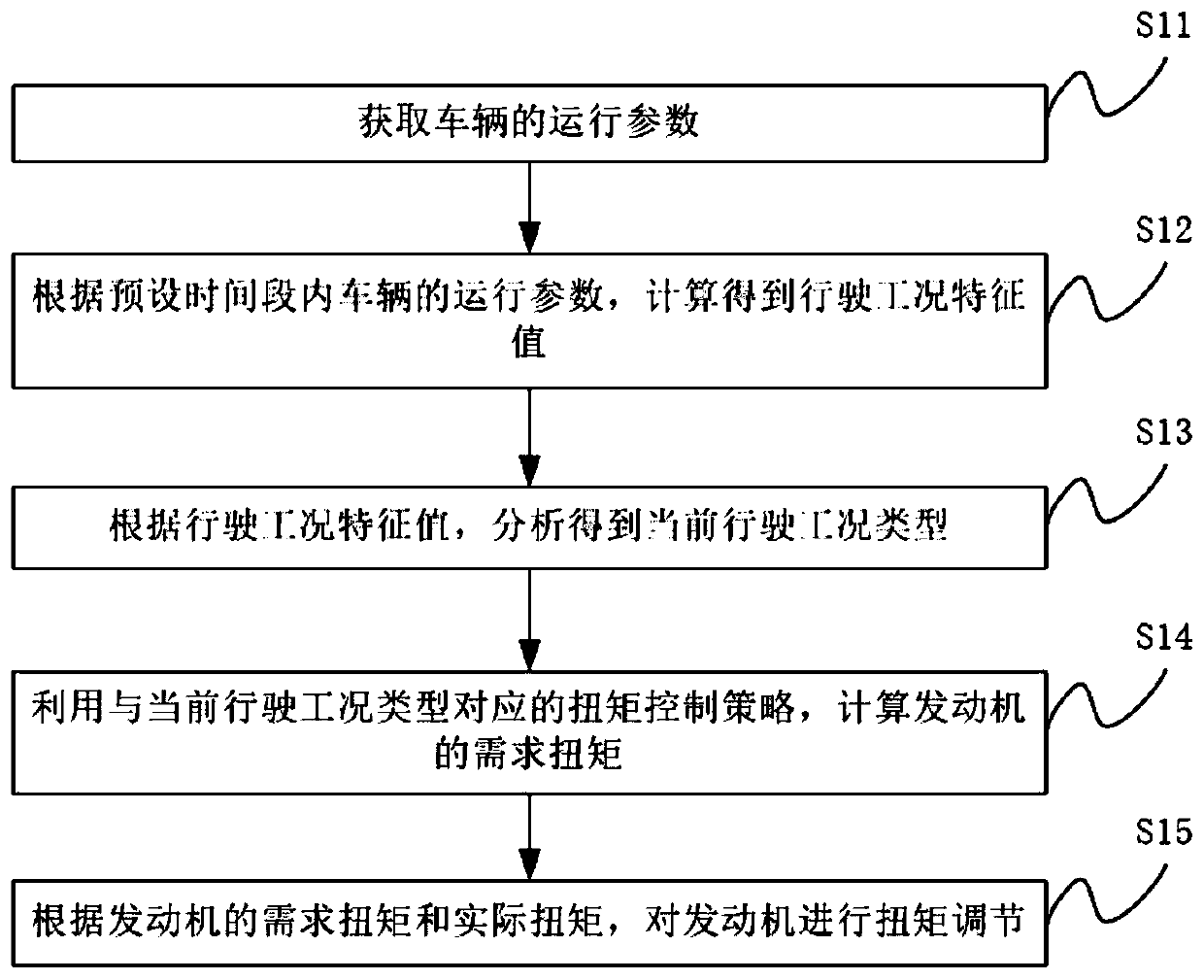

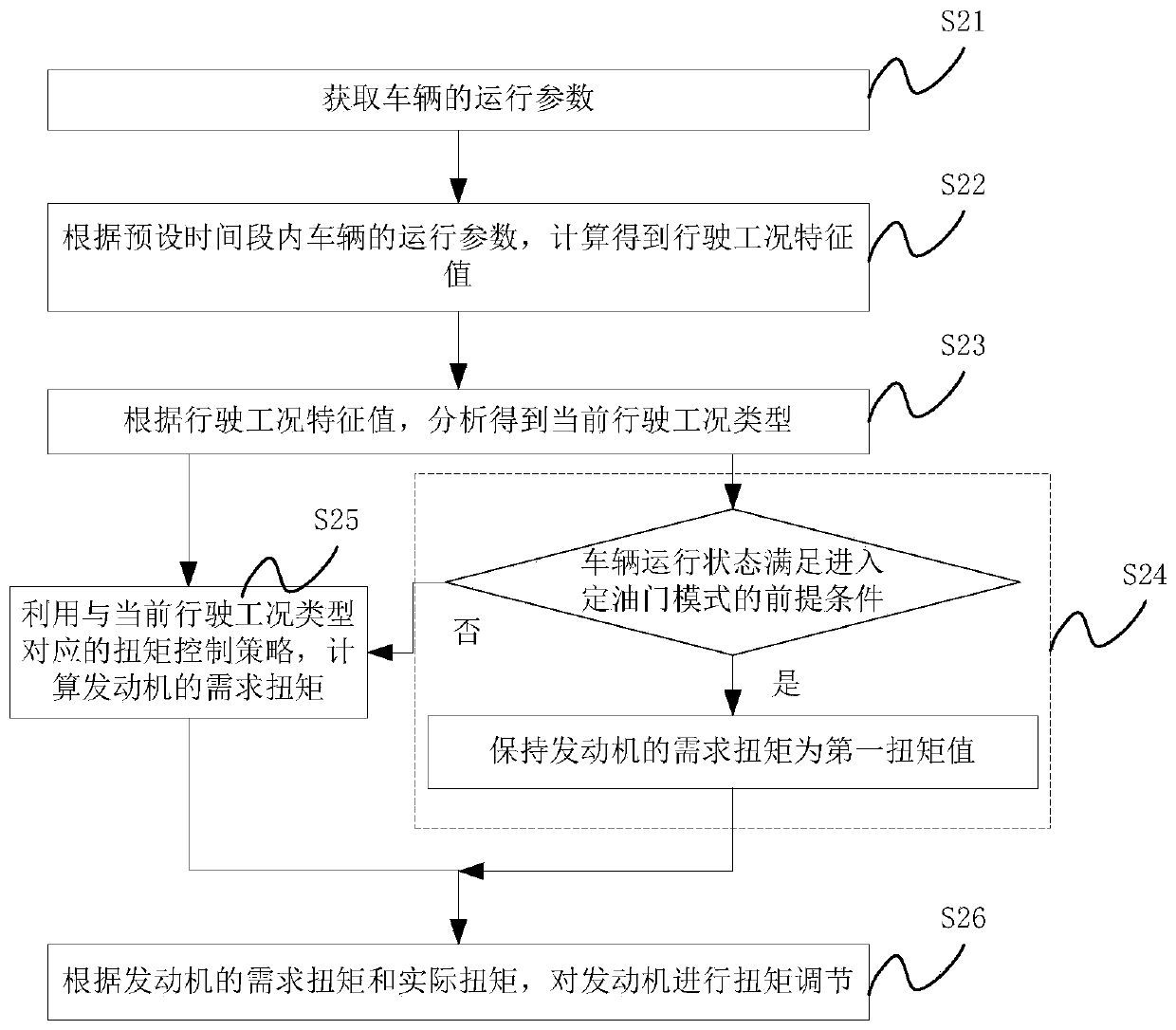

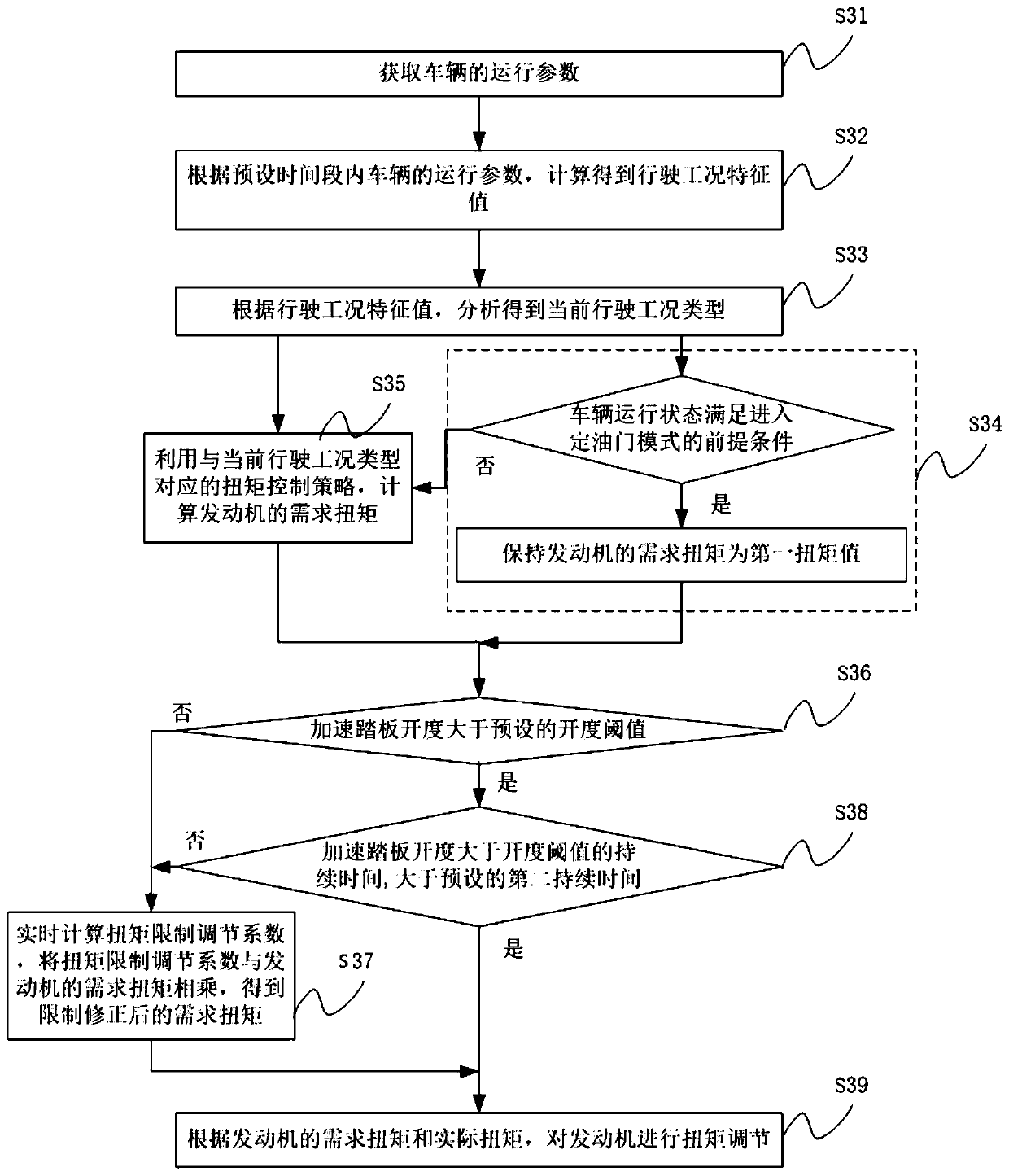

Engine torque control method and device

ActiveCN111379633AImprove adaptabilityImprove fuel saving effectElectrical controlMachines/enginesTorque regulationControl theory

Embodiments of the invention provide an engine torque control method and device. The engine torque control method comprises the steps that a current driving condition type of a vehicle is first obtained through analysis according to operating parameters of the vehicle, and then a corresponding relationship between the various preset driving condition types and torque control strategies is used forgetting the torque control strategy corresponding to the current driving condition type, the required torque of an engine is calculated, and then the torque of the engine is adjusted. The adaptability of the vehicle under complex and changing driving conditions is improved, the fuel saving effect of the vehicle is improved. further, when the vehicle operating state meets the preset conditions andenters the throttle fixing mode, the required torque of the engine can be kept at a fixed value to ensure that the engine torque remains stable, and the fuel saving effect of the vehicle can be further improved; and through the cooperation of an overtaking mode and a torque limiting mode, the economy and power of the vehicle are comprehensively guaranteed.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

Wing in ground effect vehicle with endplates

A Wing In Ground Effect Vehicle has a pair of supercavitating endplates ( 17 ) which extend below the fuselage ( 2 ) such that they can be immersed in water during flight thereover. The endplates have a nose ( 28 ) defining a leading edge ( 20 ) and adapted to generate a supercavity. The endplates ( 17 ) typically pivot about a pivot axis P to provide a stabilising weathercock-type effect.

Owner:КОСМОС ХОЛДИНГЗ ЛИМИТЕД

Methods and systems for engine starting

ActiveUS8352153B2Save fuelReduce exhaust emissionsAnalogue computers for vehiclesElectrical controlExhaust valveInlet valve

Methods and systems are provided for controlling a vehicle system including an engine that is selectively deactivated during engine idle-stop conditions and selectively reactivated during engine restart conditions. One example method comprises, during an engine restart from an idle stop, performing a first combustion event in a cylinder with a piston at an engine crankshaft position that is after a crankshaft position at which said cylinder's exhaust valve opens, and before a crankshaft position at which the cylinder's intake valve closes, during a cycle of said cylinder. In this way, inaccuracies in cylinder aircharge estimation may be reduced, thereby also reducing air-fuel ratio errors and improving the quality and repeatability of engine restarts.

Owner:FORD GLOBAL TECH LLC

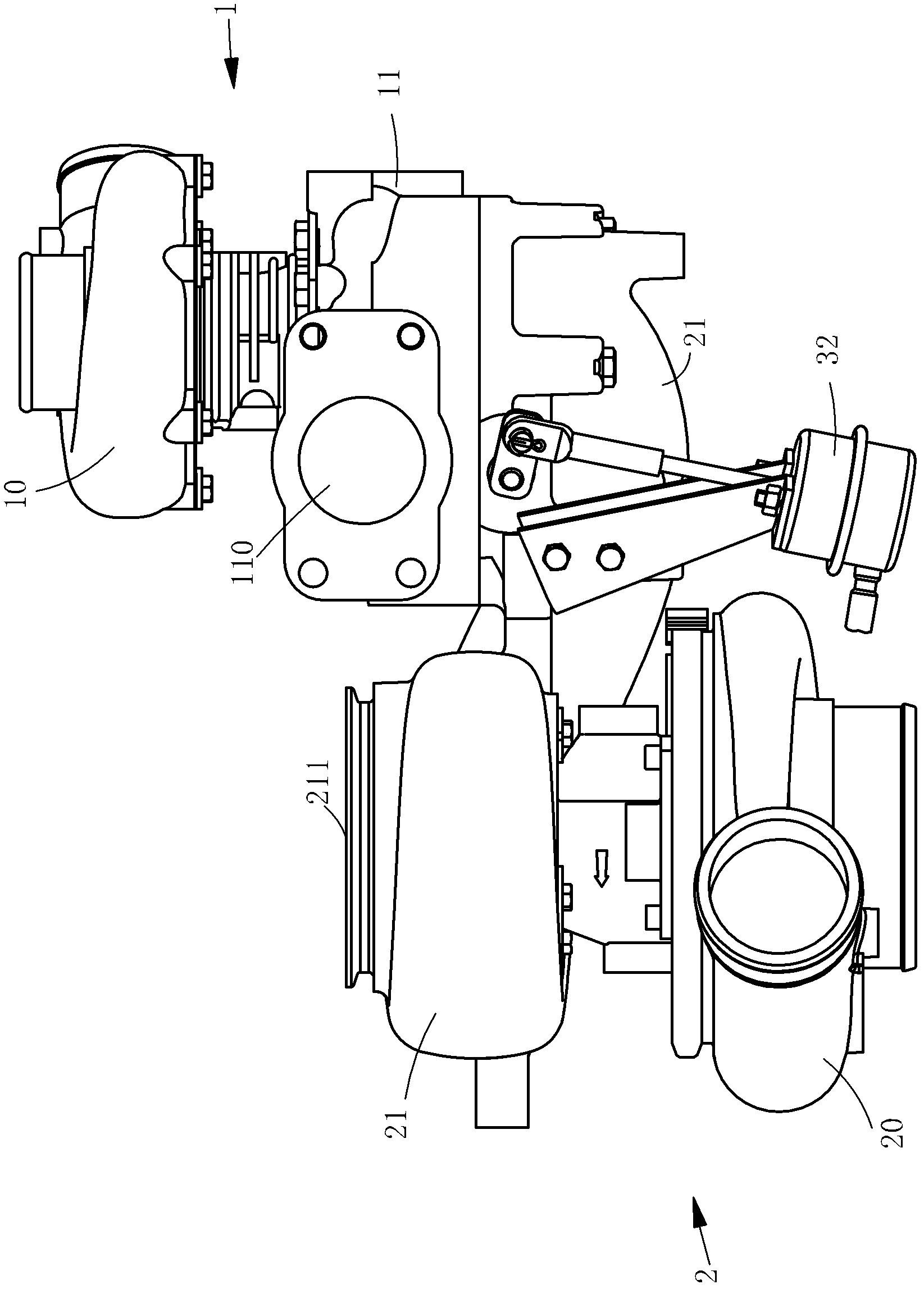

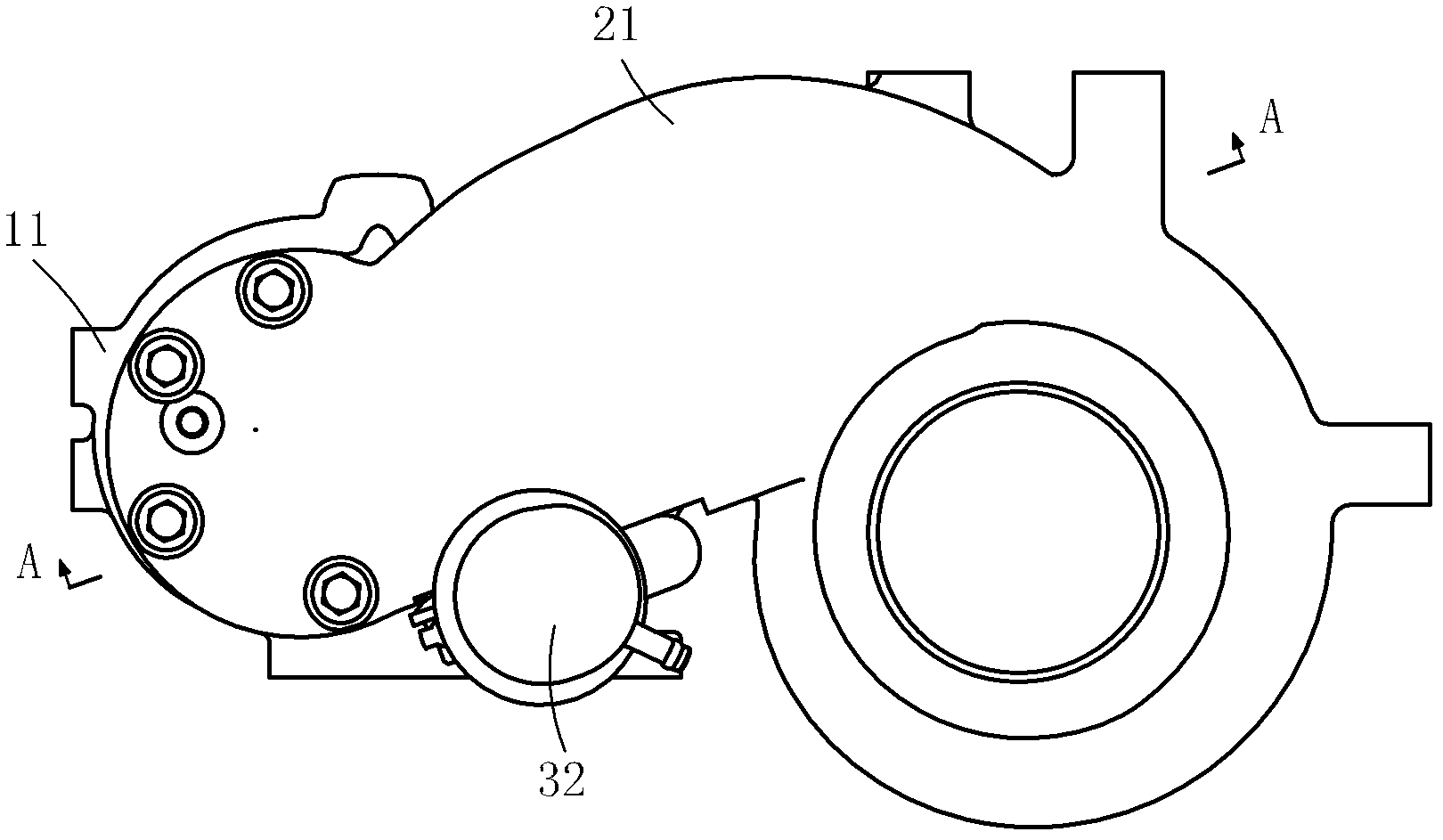

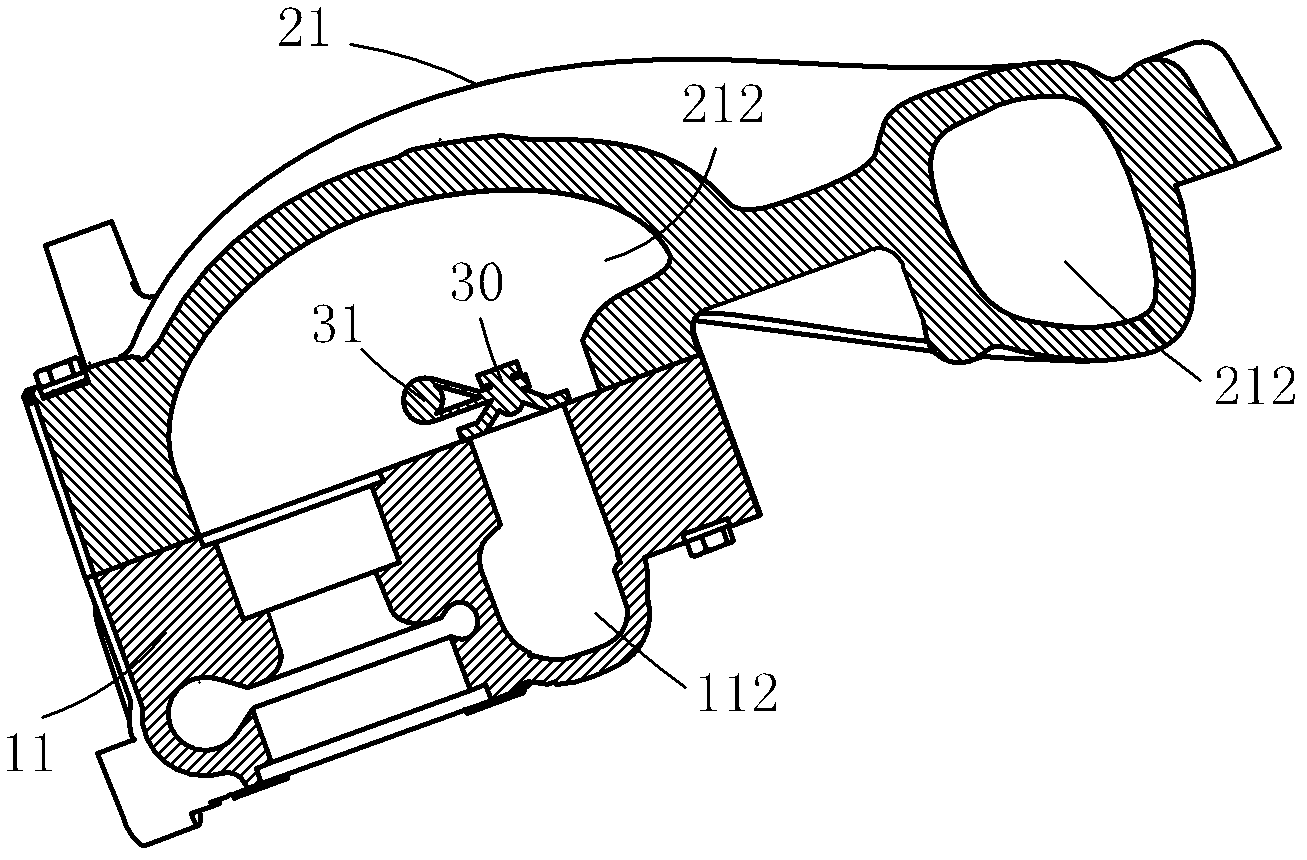

Turbocharger with two-stage supercharging function

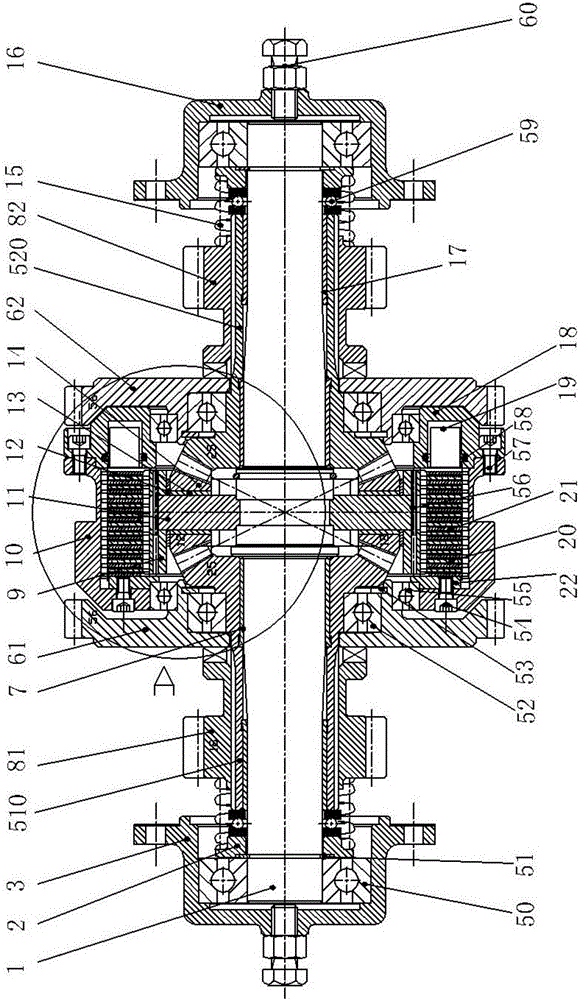

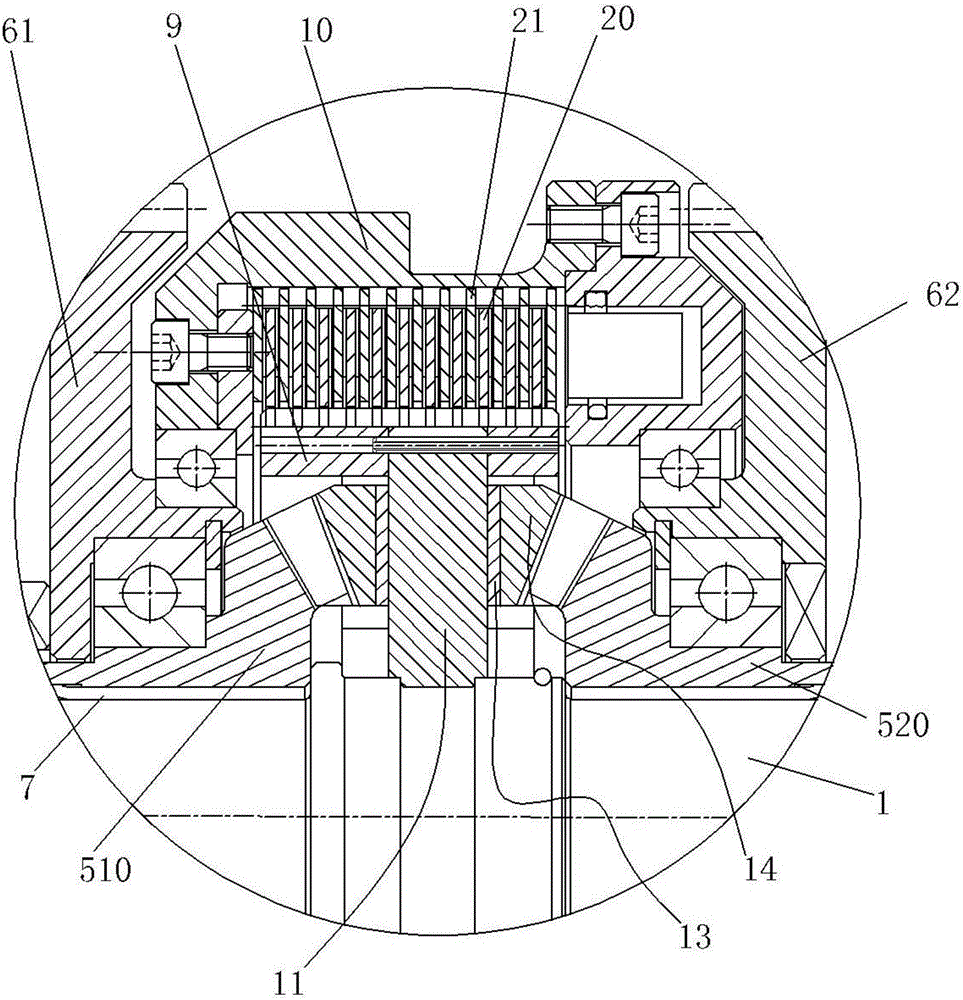

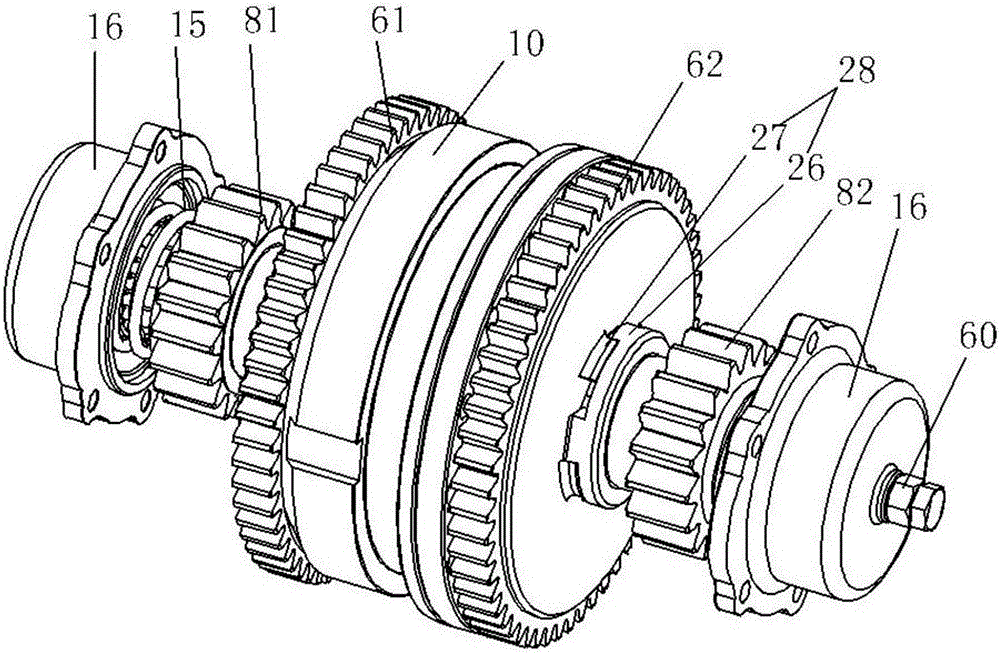

InactiveCN102606285AImprove reliabilityTorque stabilizationInternal combustion piston enginesCombustionTurbocharger

A turbocharger with a two-stage supercharging function relates to the technical field of turbocharger equipment of internal combustion engines of passenger motor vehicles and comprises a high-pressure turbocharger and a low-pressure turbocharger. An air channel which is communicated with a high-pressure turbine air inlet and a low-pressure turbine air inlet is arranged on a body of a high-pressure turbine shell, a flow control valve which is used for controlling airflow in the air channel is mounted on the air channel, a low-pressure turbine shell is integrally connected with the high-pressure turbine shell, and the low-pressure turbine air inlet is connected with a high-pressure turbine exhaust opening. The turbocharger with the two-stage supercharging function not only solves the conflict between high torque of a passenger motor vehicle an engine at a low rotation speed and maximization of power at a high rotation speed, but also is compact in structure, small in occupied space, fine in sealing performance, high in operational reliability and simple and convenient in production and installation, and has a high service value when used on passenger motor vehicles and the like with narrow engine spaces.

Owner:潍坊富源增压器有限公司

Orthostichous multi-cylinder pneumatic wave power generator

InactiveCN103994020AImprove power generation efficiencyTorque stabilizationMachines/enginesEngine componentsEngineeringWave power

The invention discloses an orthostichous multi-cylinder pneumatic wave power generator which comprises a wave energy collecting system, a wave energy converting system and a pressure regulating and stabilizing system, wherein the wave energy collecting system comprises multiple wave energy collecting cylinders, the wave energy converting system comprises a piston, a connecting rod, a crank shaft and a power generator body, and the pressure regulating and stabilizing system comprises a box, a pressure regulating rod and a hose and is used for making the crank shaft rotate continuously. According to the orthostichous multi-cylinder pneumatic wave power generator, the multiple cylinders operate at the same time, and therefore collected wave energy is rich; the multiple cylinders are divided into two groups through the pressure regulating and stabilizing system, the two groups of cylinders act alternately to guarantee that the crank shaft rotates continuously, the power generator body is made to output power uninterruptedly, and then power generation efficiency is improved; meanwhile, the shaking of the crank shaft during rotation can be overcome, and then vibration of the power generator body is reduced, and the whole wave power generator is made high in efficiency, adaptability and reliability and low in construction cost.

Owner:TIANJIN UNIV

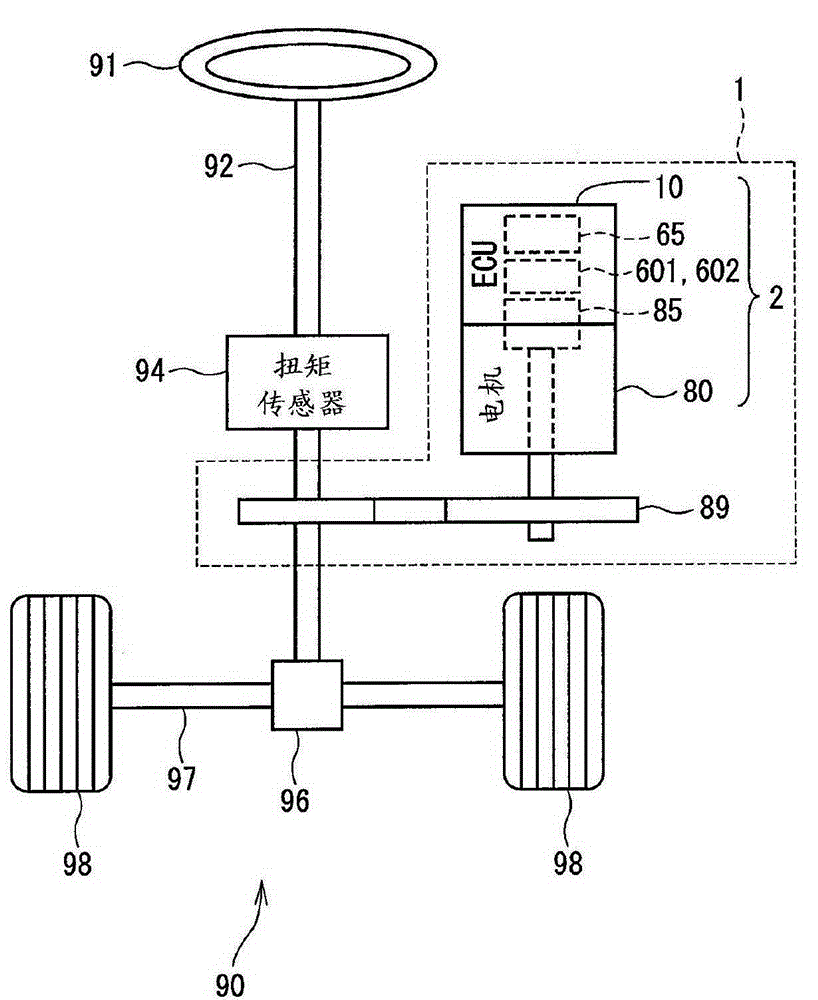

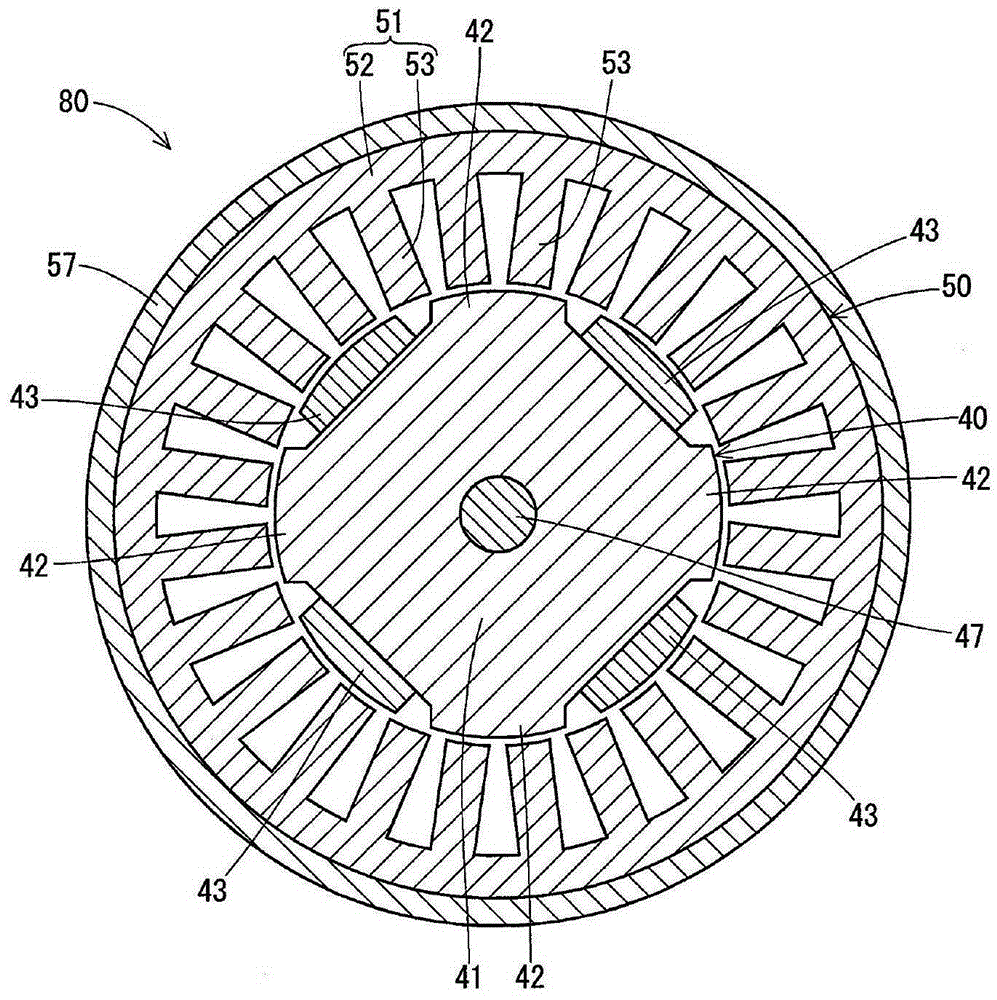

Brushless motor and motor control device

ActiveCN105553210AAvoid demagnetizationTorque stabilizationElectronic commutation motor controlAC motor controlElectric power steeringBrushless motors

A brushless motor (80) for an electric power steering device (1) that assists a steering operation includes: a stator (30) having a plurality of winding sets (801,802) for a plurality of systems respectively; and a rotator (40) having a ferrite magnet (43). In the motor, a maximum current flowing without any demagnetization at high temperature is large. Hence, the torque of the motor is easily ensured at high temperature. In particular, when a failure occurs in one system, it is easy to ensure the torque of the normal system even at high temperature.

Owner:DENSO CORP

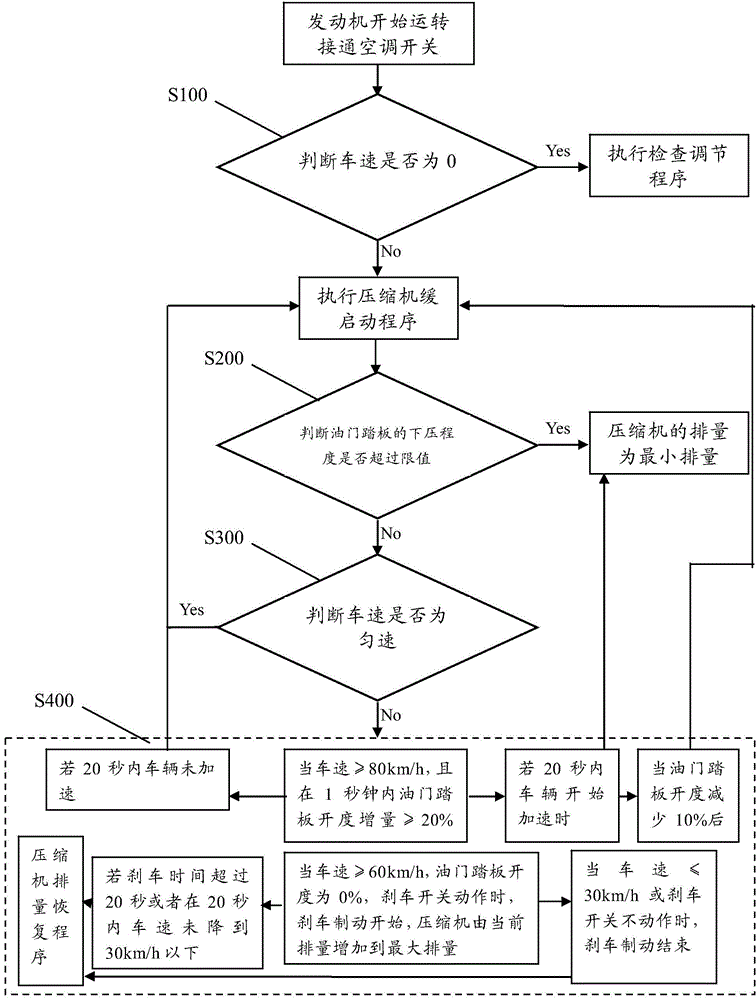

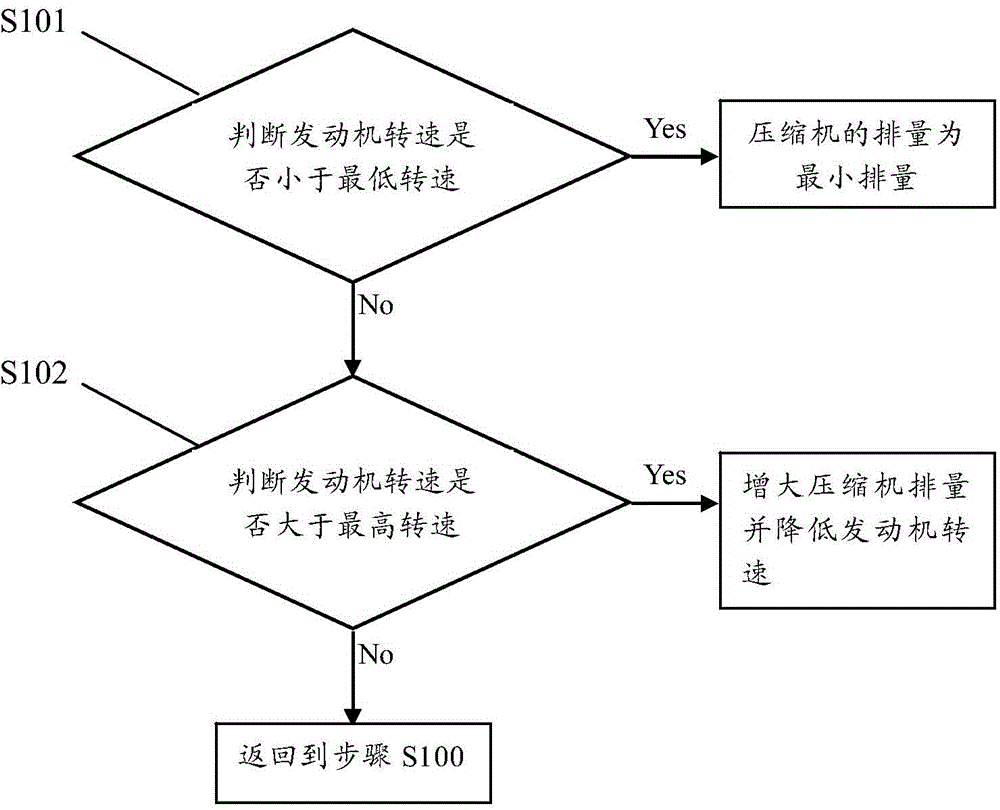

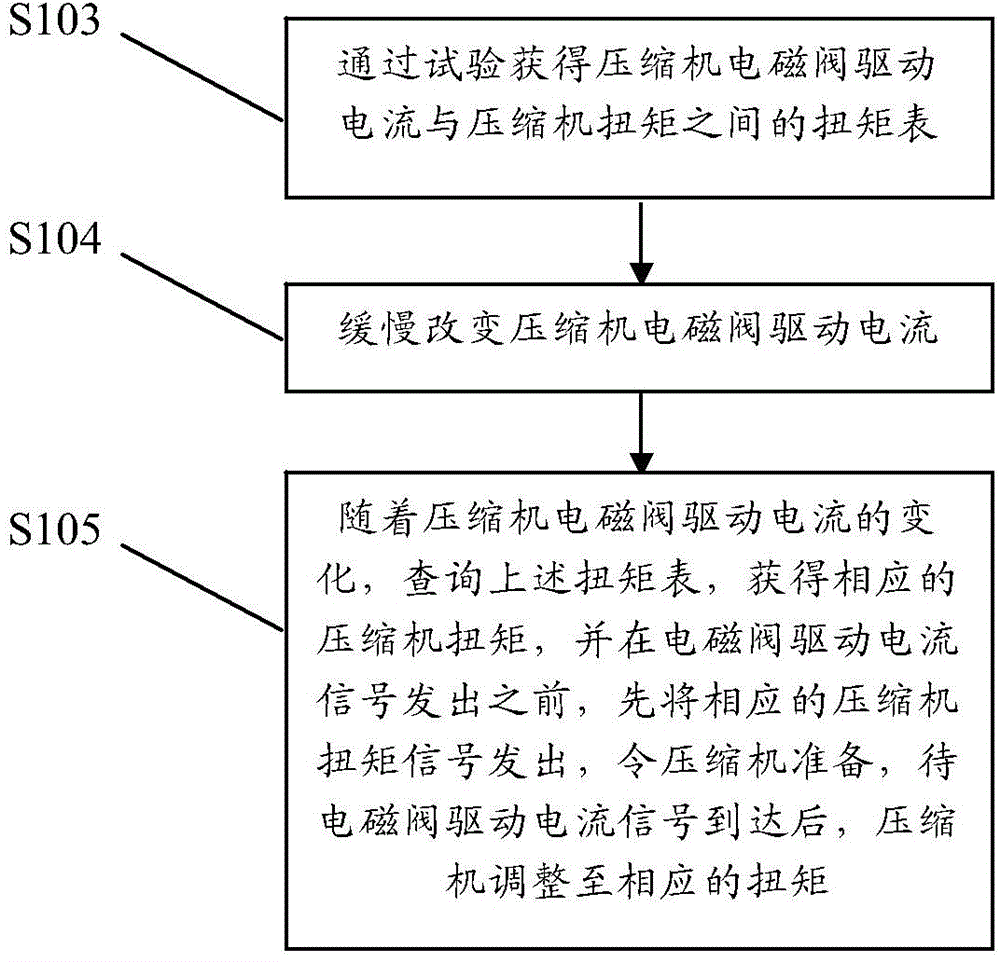

Method for controlling displacement of air condition compressor of automobile

ActiveCN104912783AImprove efficiencySmooth output torqueAir-treating devicesVehicle heating/cooling devicesSlow-startControl theory

The invention discloses a method for controlling the displacement of an air condition compressor of an automobile. According to the method, a compressor slow start program, the minimum displacement, the maximum displacement and a compressor displacement recovery program can be applied to the air condition compressor of the automobile according to different speeds of the automobile, and therefore the displacement of the air condition compressor of the automobile can be adjusted according to running conditions of the automobile in time, the utilization efficiency of the compressor is improved, and it is also guaranteed that an automobile engine stably outputs torque to the compressor in the running process.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

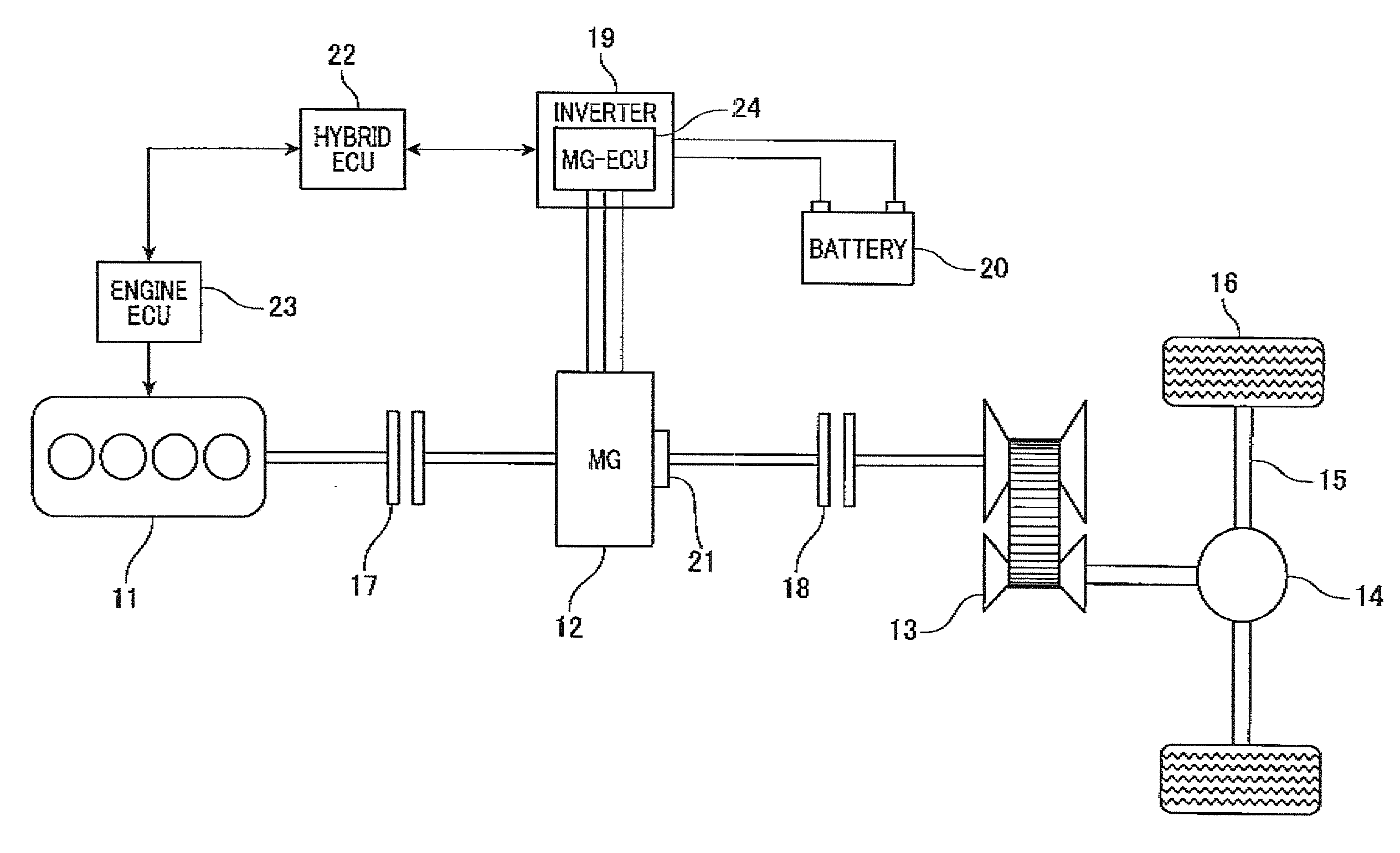

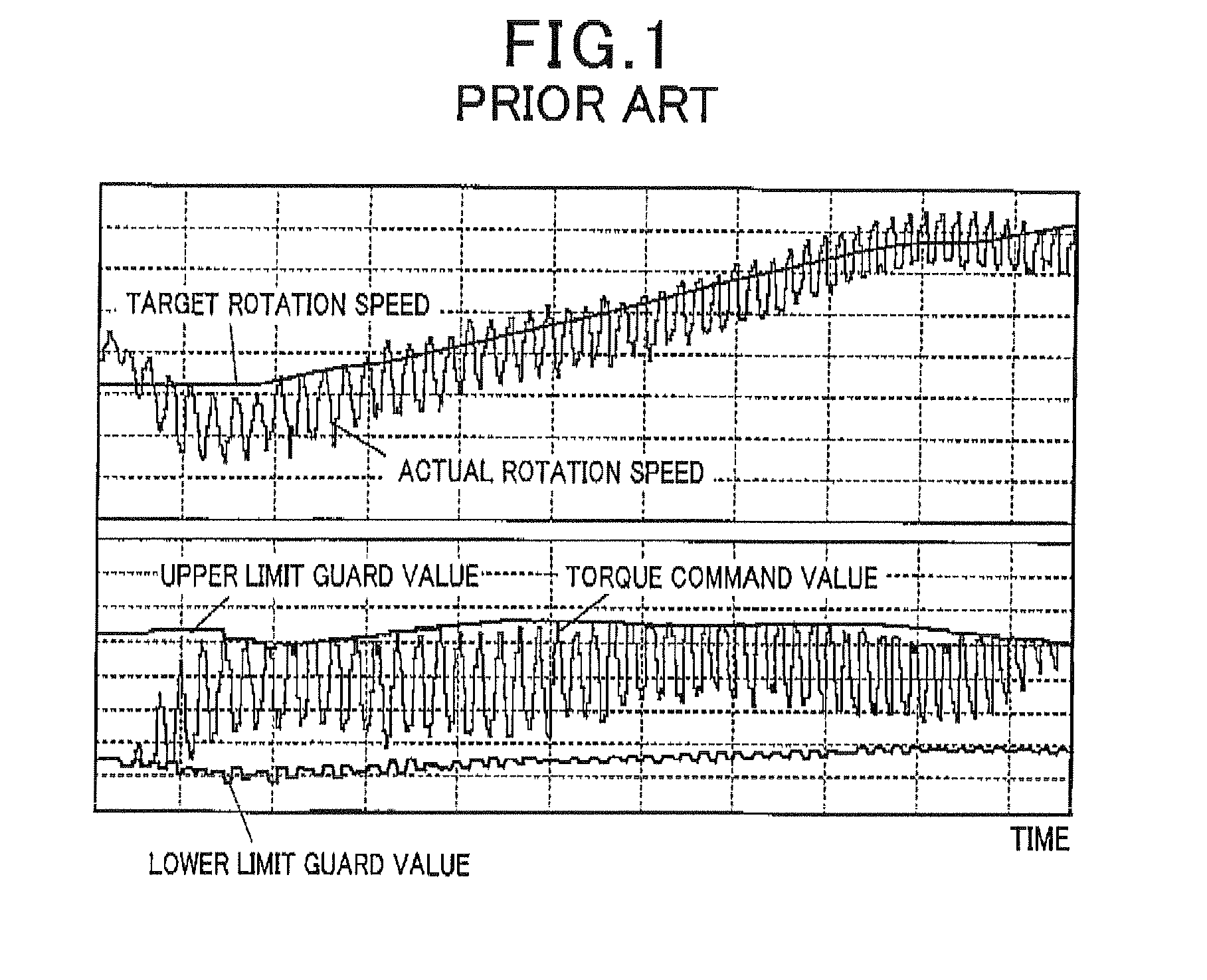

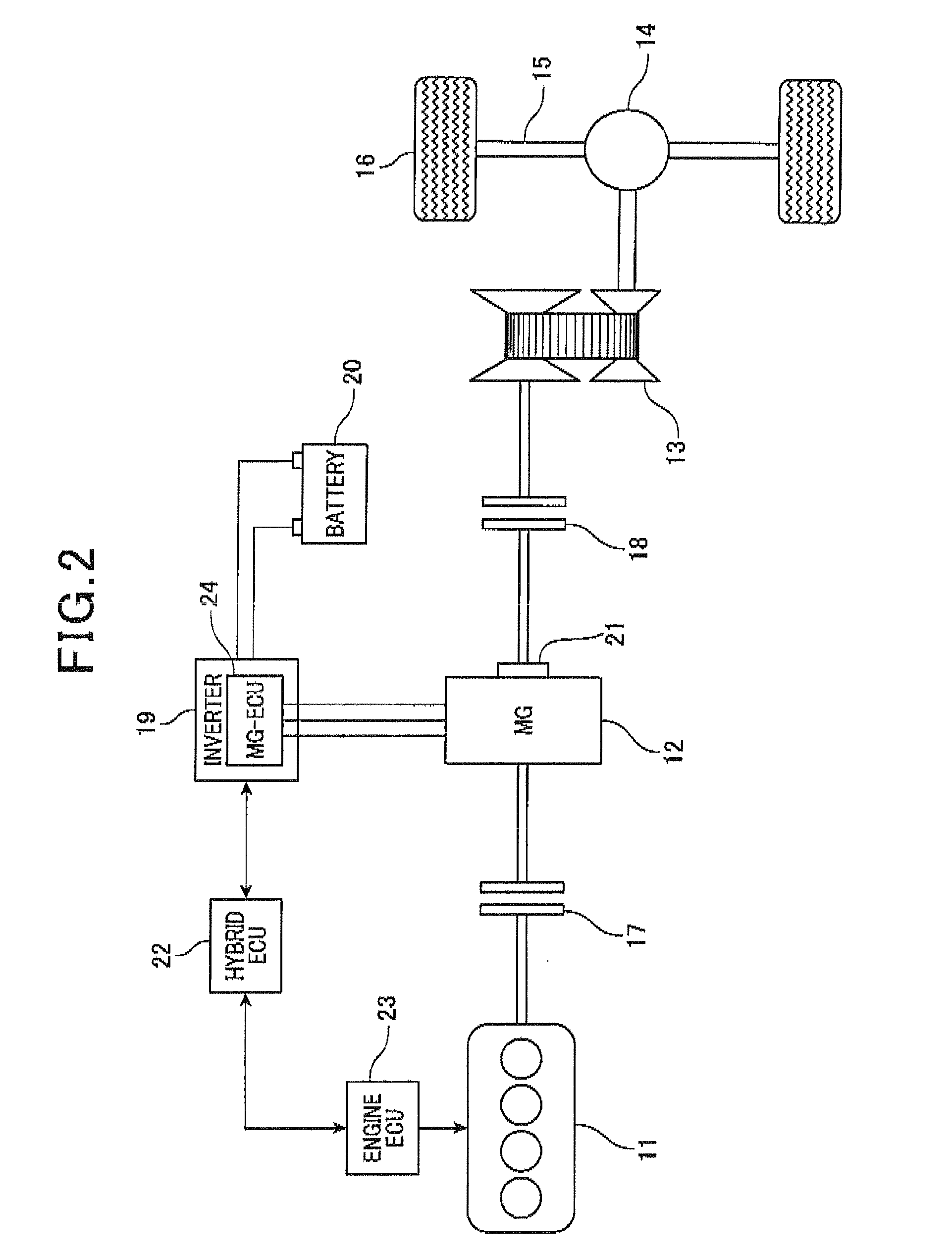

Motor control apparatus for hybrid vehicles

ActiveUS20140088808A1Ensure responsivenessTorque stabilizationHybrid vehiclesDigital data processing detailsRotational axisMotor control

An apparatus controls a motor equipped in a hybrid vehicle. In this apparatus, a basic torque command value of the motor is calculated so as to reduce a deviation between a target rotation speed and an actual rotation speed of the motor. A torque correction value for the motor is calculated based on a variation of the target rotation speed which is obtained per unit time and a value of inertia of a power train rotated integrally with the rotation shaft of the motor. Further, a torque command value finally supplied to the motor is calculated by correcting the basic torque command value with use of the torque correction value.

Owner:DENSO CORP

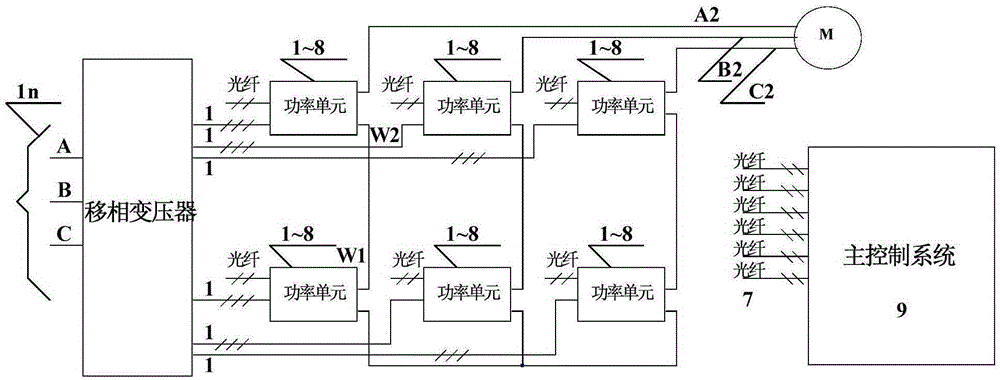

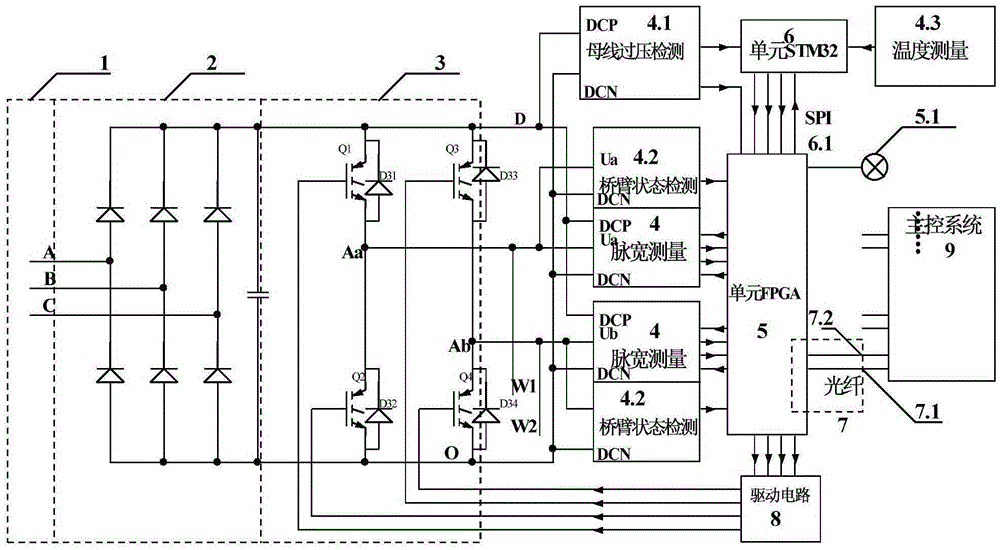

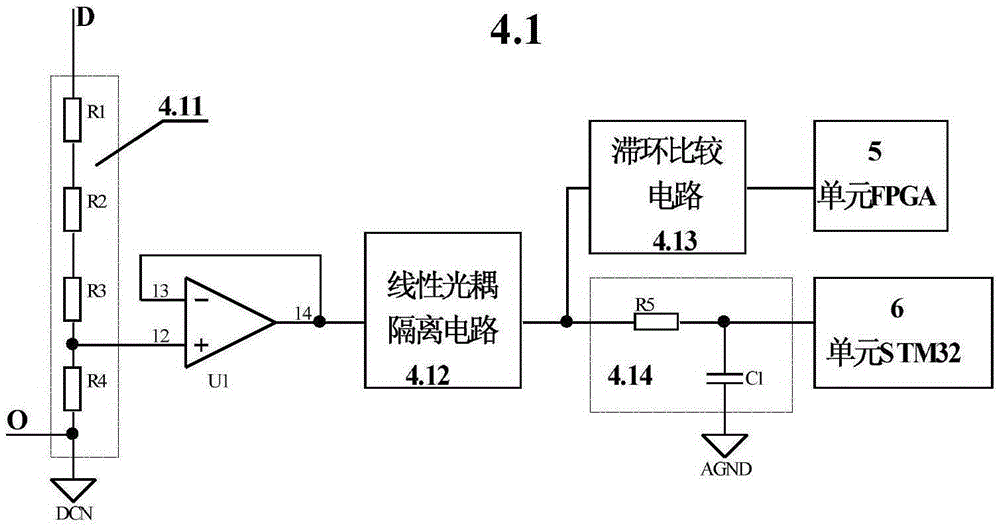

Intelligent power unit for high-power converter device and control method

ActiveCN105391310ASuitable for all-round controlLow costAc-dc conversionAc-ac conversionMicrocontrollerEngineering

The invention relates to an intelligent power unit for a high-power converter device and a control method, used for a high-voltage frequency converter and a photovoltaic inverter. The frequency converter is formed by a plurality of power units, each phase of which is arranged in multiple layers, in series; each power unit is provided with a unit field programmable logic array FPGA and a single chip microcomputer unit STM32; the unit field programmable logic array FPGA and the single chip microcomputer unit STM32 are connected through a serial interface SPI; bus over-voltage detection, temperature measurement, bridge arm open-circuit and short-circuit state detection having flash lamp indication, pulse wide measurement and the like are connected to the inlet of the FPGA; the outlet is connected to a driving circuit; a main control system comprises a central data controller and a layer controller on the same mainboard; bidirectional transmission between the main control system and the FPGA is realized through two optical fibres; the two have communication state detection; transmission is carried out according to a specified time sequence; therefore, the anti-interference performance is high; the real-time performance of fault response is ensured; dead-time compensation in pulse width measurement is carried out according to the real waveform; the compensation precision is the highest; a variable-frequency motor is constant in waveform and steady in torque; a test result shows that: the communication speed is high; the synchronization performance is good; the reliability is high; performances are comprehensively optimized and intelligentized; the cost is low; and the intelligent power unit is used for the driving power supply of the variable-frequency motor and the power supply of the photovoltaic inverter.

Owner:四川中大华瑞能源技术有限公司

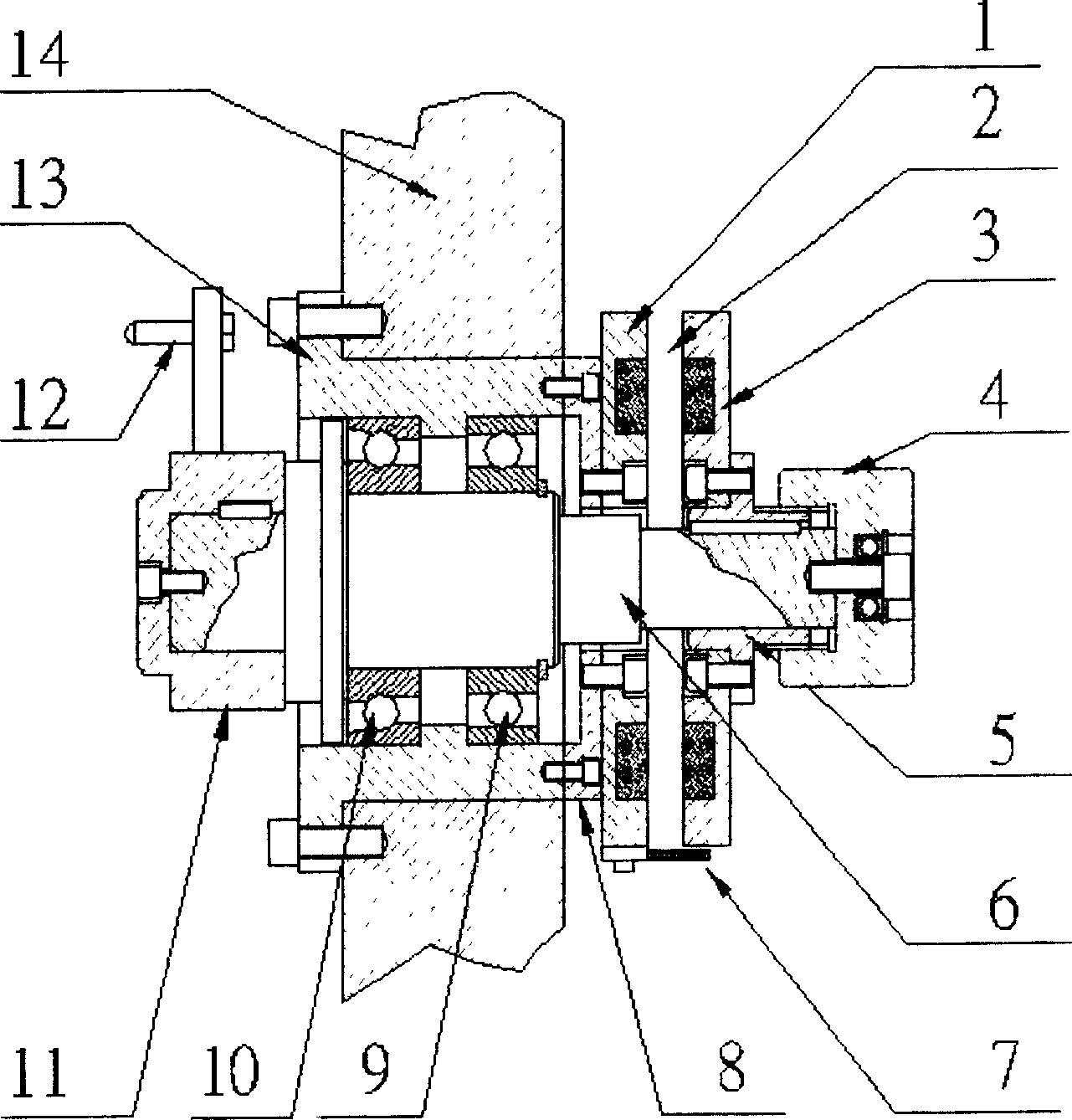

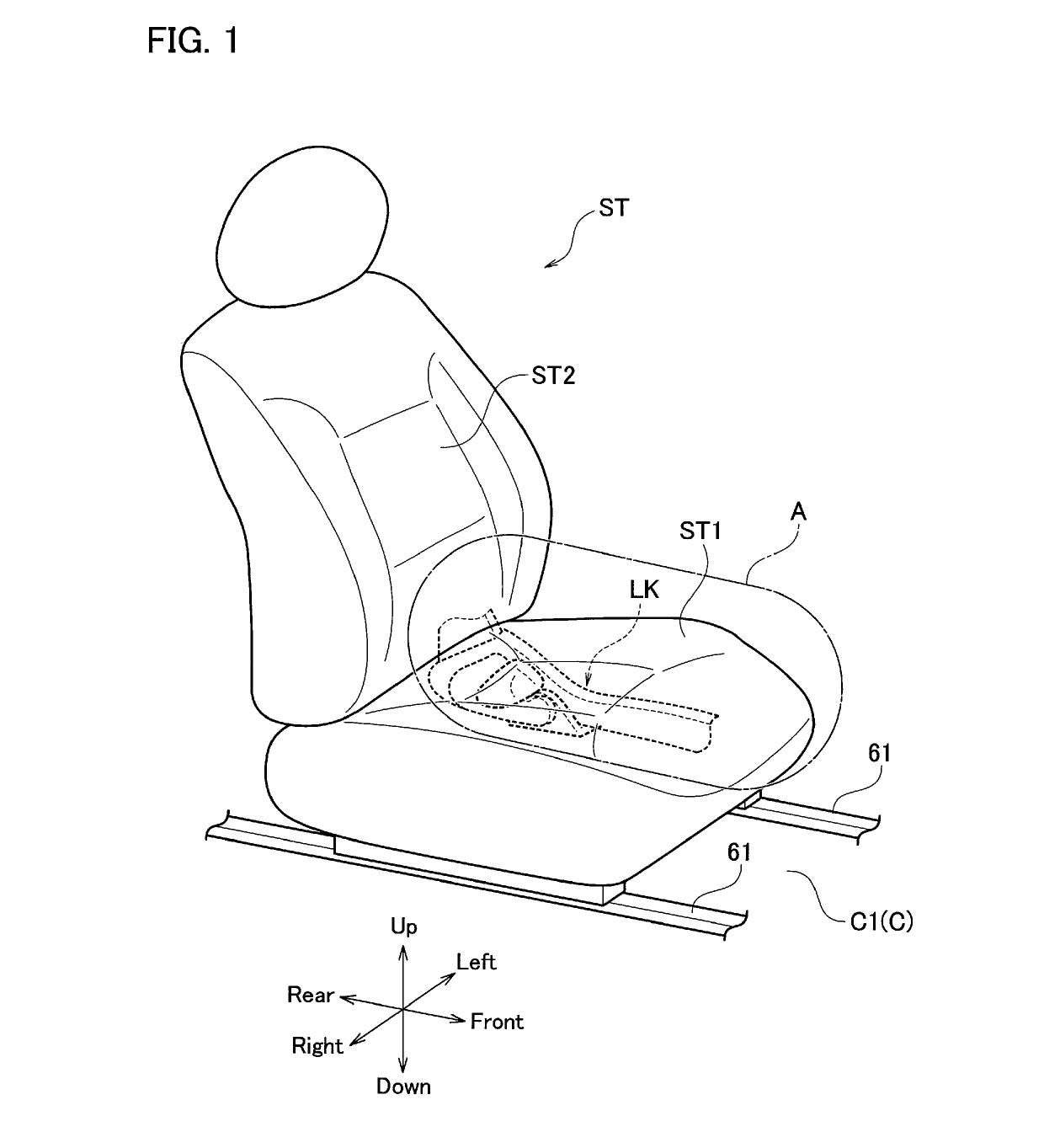

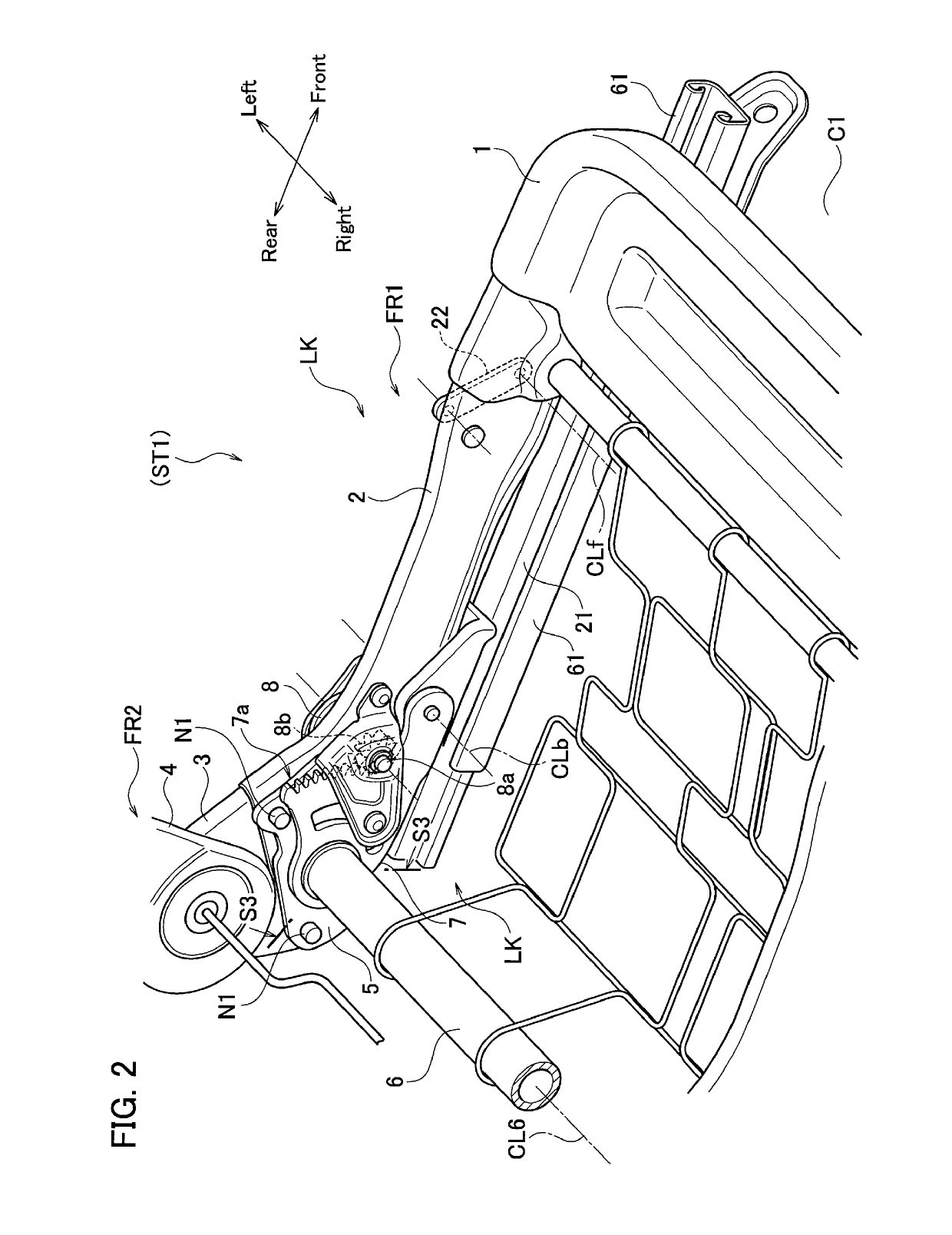

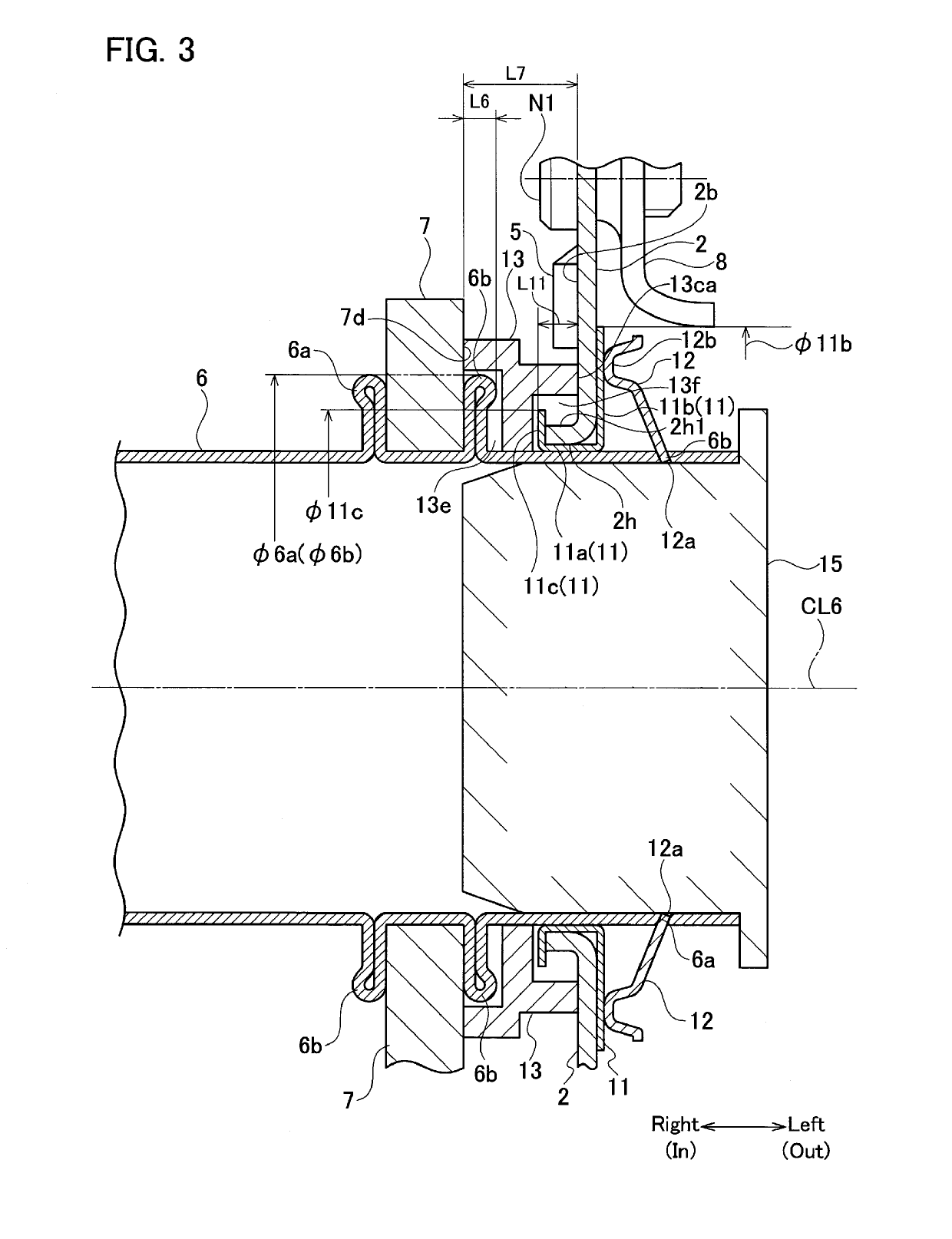

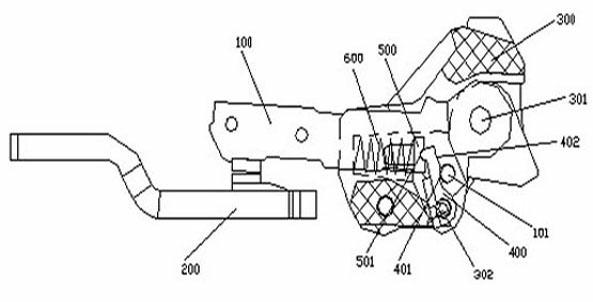

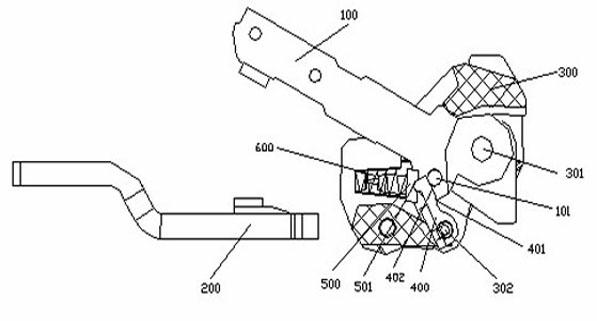

Seat lifter structure and vehicle seat equipped with the same

A seat lifter structure which can obtain a rotation of a sector with stable torques is provided. It is equipped with a sector (7) supported to be rotatable by a support member (21), arranged to be facing with a side frame (2) by being pinched and fixed by a pair of expanded portions (6a, 6b) of a tubular shaft member (6) that is supported to be rotatable by the side frame (2), and rotating along the side frame (2) at a time of raising or lowering the side frame (2); a ring shaped spacer (13) having a first ring shaped abutting surface (13da) facing with the sector (7) and having a first outer diameter (ϕ13d2), and a second ring shaped abutting surface (13ca) facing with the side frame (2) and having a second outer diameter (ϕ13c2) different from the first outer diameter (ϕ13d2), which is installed between the sector (7) and the side frame (2) with an axial line (CL6) as a center; and a biasing member (12) that biases and abuts the sector (7) to the first abutting surface (13da) and biases and abuts the side frame (2) to the second abutting surface (13ca) by biasing the sector (7) and the side frame (2) to approach.

Owner:HONDA MOTOR CO LTD +1

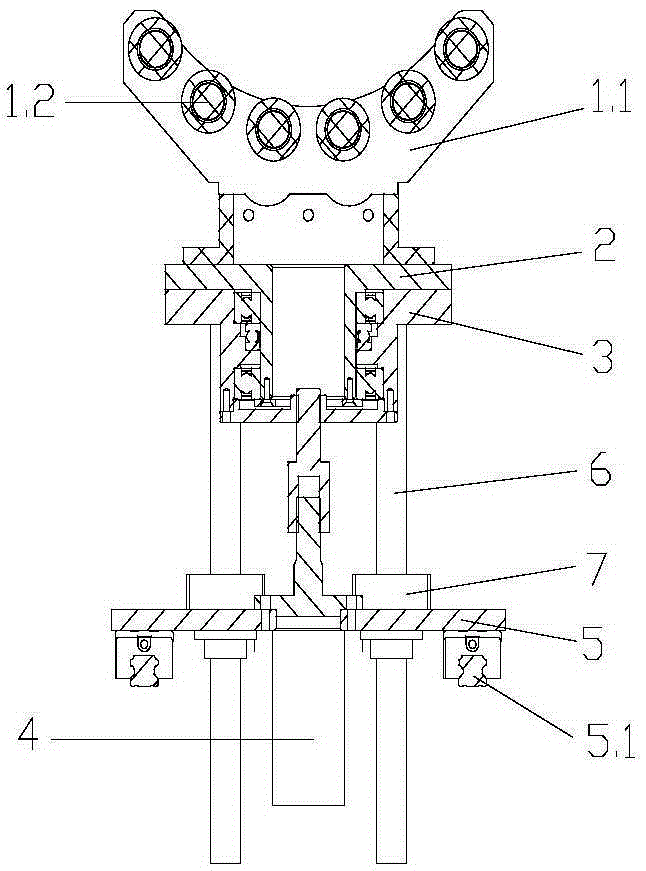

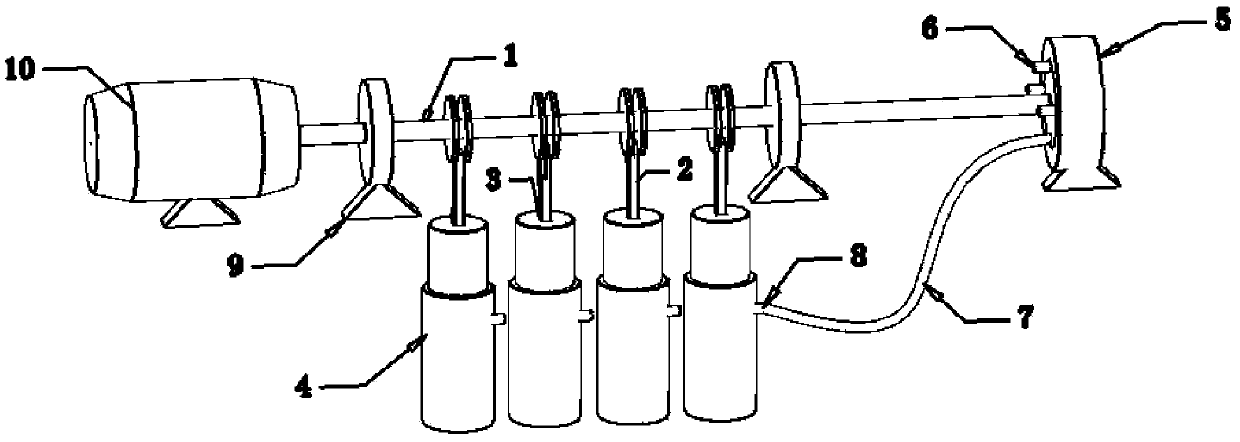

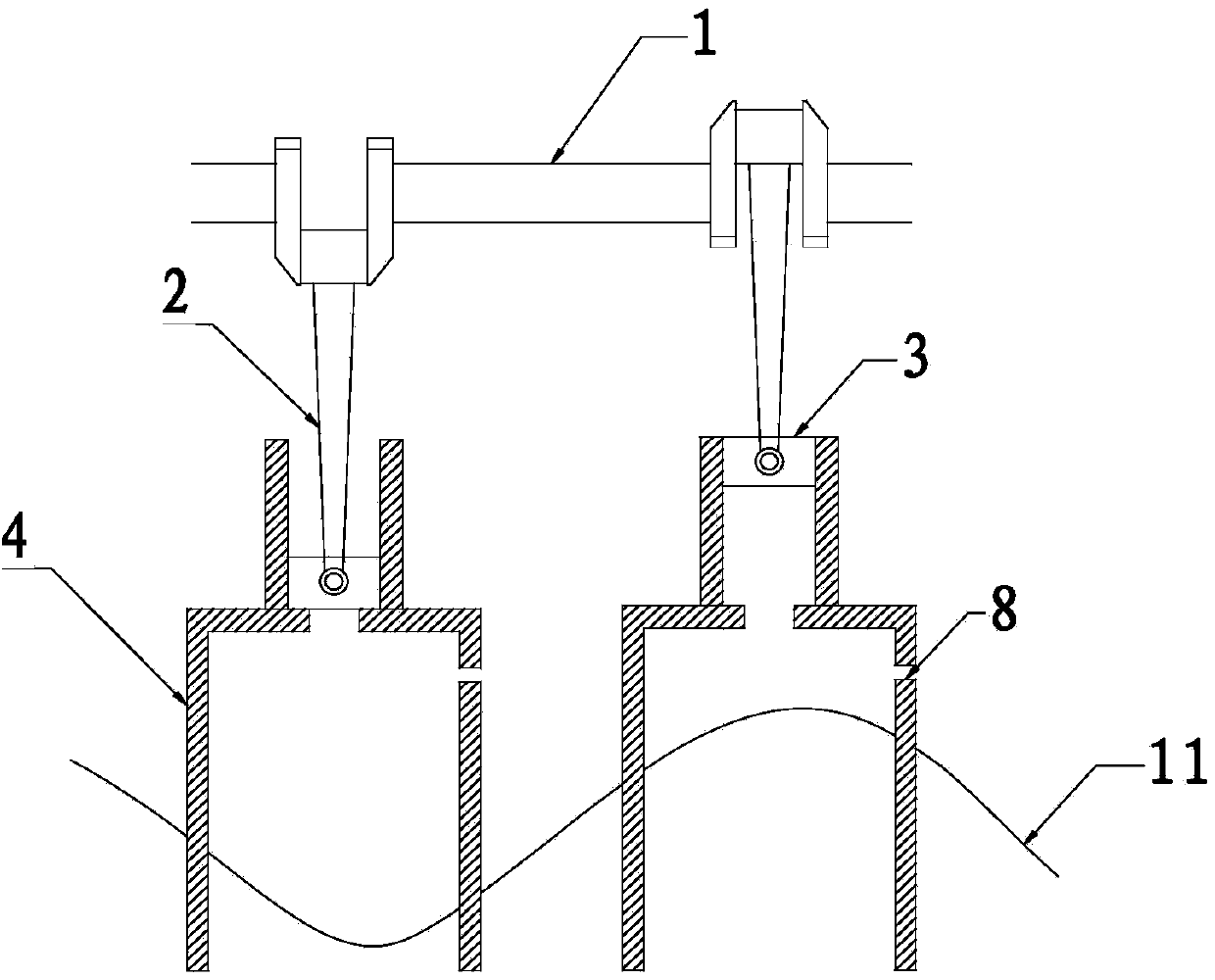

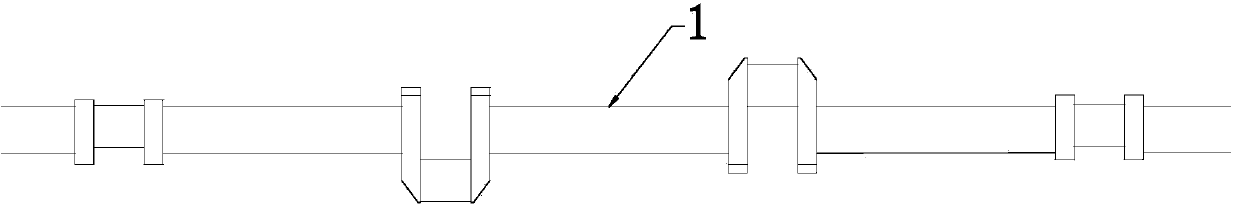

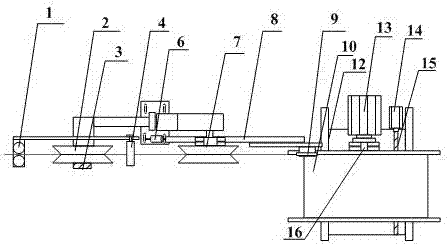

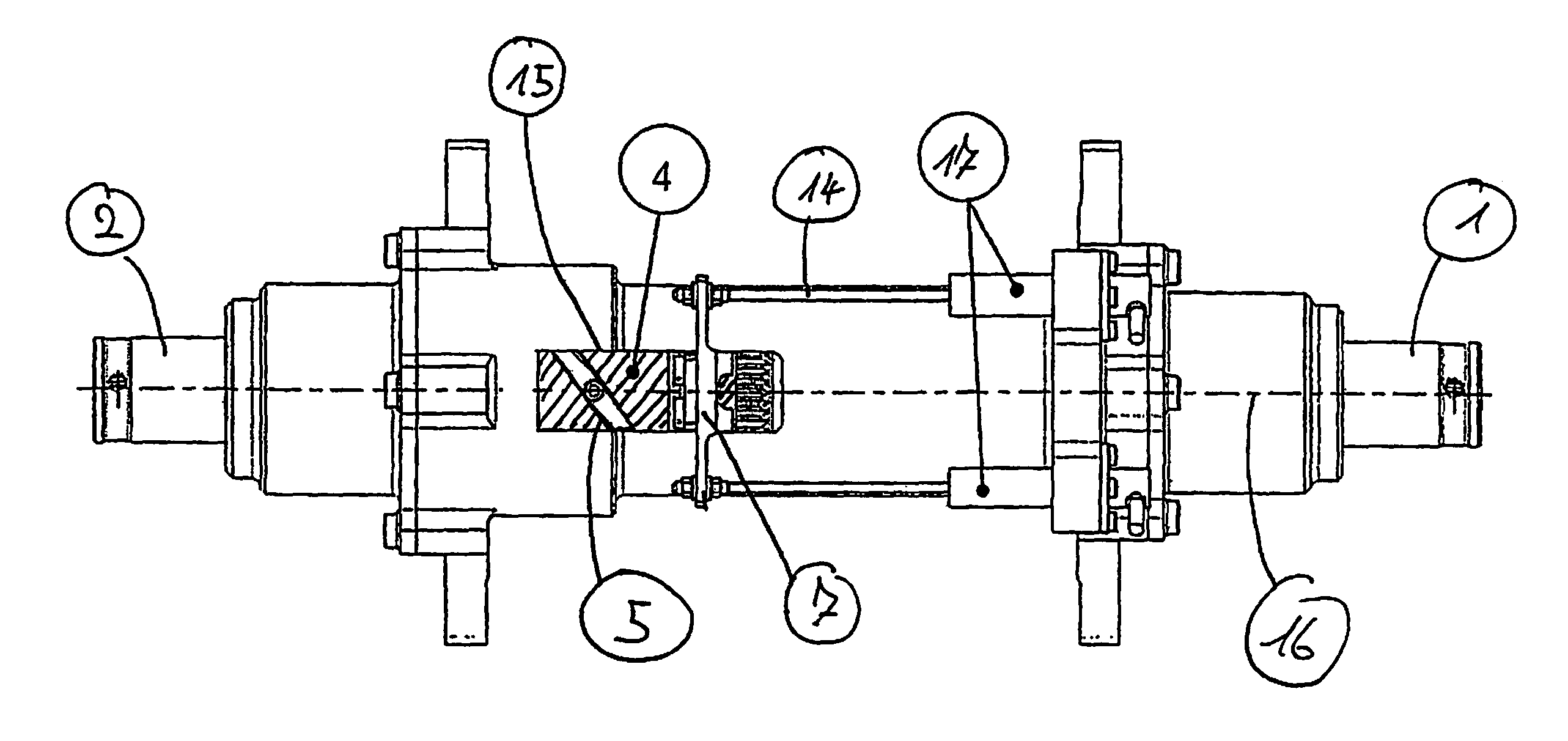

Testing apparatus for service life of load of valve execution mechanism and using method thereof

The invention provides a testing apparatus for a service life of a load of a valve execution mechanism and a using method thereof. The testing apparatus comprises a rack, a rotating mechanism and a loading mechanism. The rack is supported between a top plate and a bottom plate by support posts. A testing plate covers the top plate. Rotating shafts are installed in bearings between the top plate and the bottom plate and the upper ends of the rotating shafts pass out of the top plate and a mounting plate. More than one rotating plate is installed on the rotating shafts horizontally and rotates with the rotating shafts. The loading mechanism includes friction plates and hydraulic systems; through holes are formed in the friction plates and the friction plates sleeve the support posts through the through holes. One friction plate is arranged below each rotating plate; and the friction plates are separated by sleeving rings arranged on the support posts. The hydraulic systems are installed on the bottom plate and mandrils of the hydraulic systems support the bottom friction plates; under pushing of the mandrils, upward contact with the rotating plates is realized and the last friction plate is pushed upwardly by the sleeving ring and is in contact with the rotating plate arranged on the friction plate; and the rotating plates and the friction plates in close contact with the rotating plates respectively generate friction and the friction forces are transformed into torques by the rotating shafts, thereby realizing testing of the service life of the load of the valve execution mechanism.

Owner:TEFULONG SHANGHAI TECH CO LTD

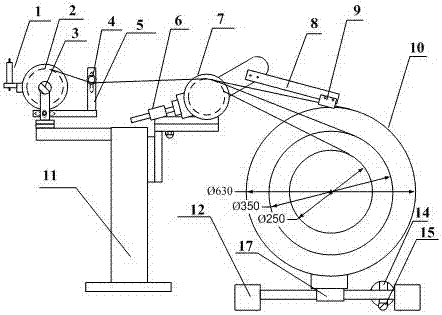

High-speed dense-arrangement wire winding machine used for wire and composite in-channel superconducting wire material

ActiveCN107187934ATorque stabilizationPrevent left and right deviationFilament handlingWinding machineWire rod

The invention discloses a high-speed dense-arrangement wire winding machine used for a wire and a composite in-channel superconducting wire material. The high-speed dense-arrangement wire winding machine comprises a wire feeding system, a rotating servo system controlled by stable torque and a traverse moving platform servo system controlled by high precision displacement. A structure mode that rotating torque controls a servo motor to control wire winding torque to be matched with a wire pressing swinging arm and a counterweight weight is adopted, torque stability of the wire material in the wire winding process is guaranteed, meanwhile, the wire and the composite in-channel superconducting wire material are stably pressed on a wire wheel through a special wire arranging and pressing device, and thus precision of wire arranging is guaranteed. In the transverse moving direction, a transverse moving servo motor is adopted to be matched with a high precision ball lead screw to realize transverse movement of a whole transverse moving platform, and meanwhile a wire speed is fed back into a servo control system through a wire speed detection encoder to guarantee precision of wire arranging. Irreversible damage of torsion of the cross sections produced by the wire and the composite in-channel superconducting wire material to the yield of the superconducting wire material and a superconducting magnet due to the fact that control of a general wire winding machine is unstable is avoided.

Owner:XIAN JUNENG EQUIP TECH CO LTD

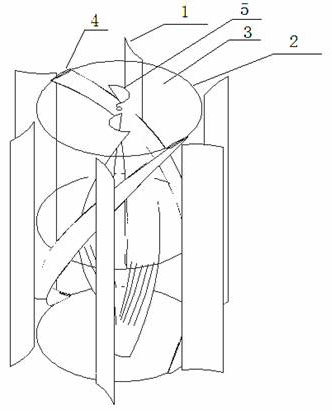

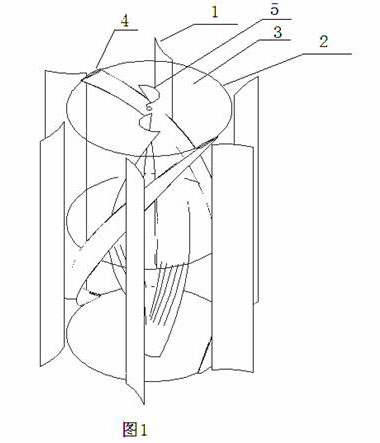

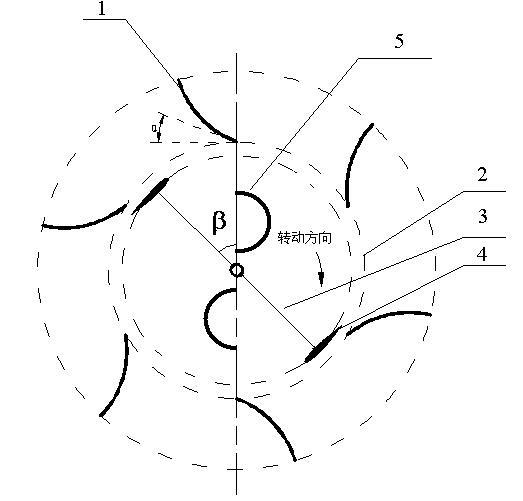

Energy-collecting speed-increasing reverse-rotating lift-drag composite type vertical shaft wind power machine

InactiveCN102094752ALarge starting torqueTorque stabilizationMachines/enginesRenewable energy generationPhase differenceEngineering

The invention relates to an energy-collecting speed-increasing reverse-rotating lift-drag composite type vertical shaft wind power machine which comprises an energy-collecting plate and a vertical shaft wind wheel, wherein the energy-collecting plate is a panel or an arc-shaped panel; the energy-collecting plate is installed at the periphery of the wind wheel; the distance between the energy-collecting plate and the outer diameter of the wind wheel is 0.0001-0.2 time of the diameter of the wind wheel; at the same time, the included angle alpha of the energy-collecting plate and the tangent line of the inscribed circle of the energy-collecting plate is 50 degrees-75 degrees; the vertical shaft wind wheel is provided with a 'twist type' lift-power type blade rotating reversely based on a dip angle and a 'twist type' resistance force type blade rotating reversely based on a certain dip angle; and a certain phase difference beta minus 45 degrees-45 degrees is formed between the lift-power type blade and the resistance force type blade. The wind power machine is suitable for the wind directions of any incoming flow direction, the flow speed can be improved greatly through contracting the flow channel, the energy consumption of the reverse side of the wind wheel can be reduced by a shield plate, and the high effective utilization of wind energy can be realized.

Owner:SHANGHAI UNIV

Oxidation coloring process for watch hairspring

InactiveCN1896290ATorque stabilizationAppearance hasSolid state diffusion coatingSal ammoniacNitrogen

The present invention discloses a oxidation and coloring technology of watch hairsprings that includes: Step 1, washing: washing the hairspring in detergent and cooking in the mixed solution of oleic acid and ammonia; Step 2, oxidation and coloring: placing the washed hairsprings in the quartz tube, putting into the heat treatment furnace and treating for 2-12 minutes at 380DEG C-450DEG C in the air medium to form a colorized oxide layer of 20-200nm thin on the hairspring surface; Step 3, curing: treating the hairspring at 180-200DEG C for 5-6 hours in the medium of nitrogen or oxygen in the curing oven to cure the oxide layer. There are some advantages as follows: the hairspring is passivated during oxidation and coloring and completes torsional moment drift in a short time; the hairspring presents yellow, red, blue or black color to increase the additional value.

Owner:TIANJIN SEAGULL WATCH CO LTD

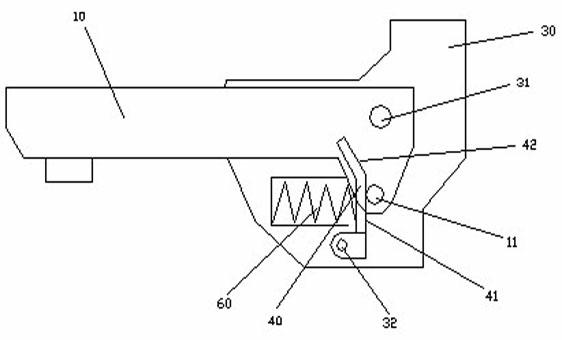

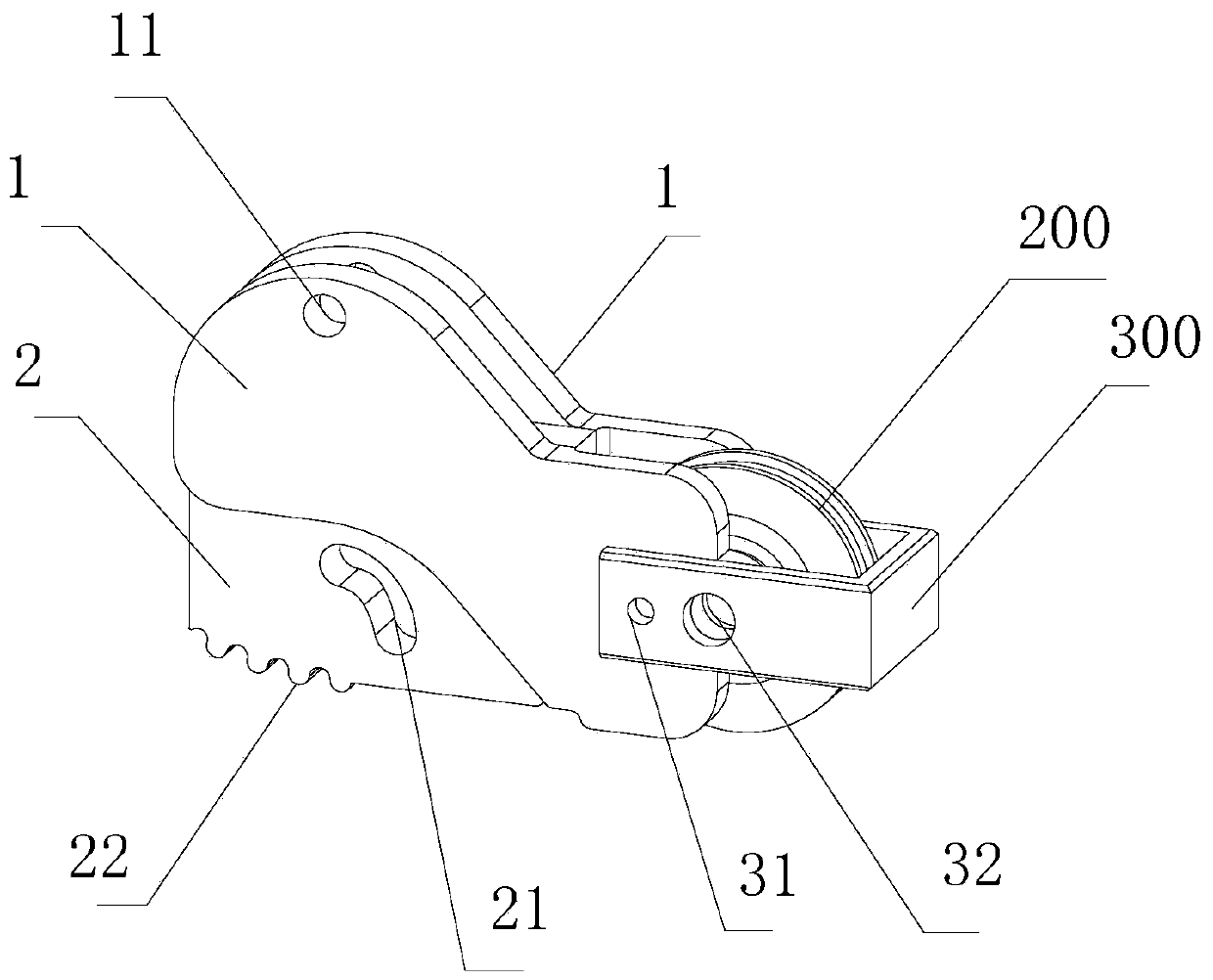

Contact pressure control mechanism for molded case low-voltage circuit breaker

ActiveCN102427001AControl pressureReduce volumeProtective switch operating/release mechanismsEngineeringCircuit breaker

The invention discloses a contact pressure control mechanism for a molded case low-voltage circuit breaker. A rotating end is connected with a rotating shaft through a first rotary central shaft; a shaft which is positioned below the first rotary central shaft and is in parallel to the first rotary central shaft is arranged on a movable contact; a second rotary central shaft which is positioned below the shaft and is in parallel to the second rotary central shaft is arranged on the rotating shaft; the second rotary central shaft is connected with the lower end of a lever which can rotate around the second rotating central shaft; a spring is arranged in a groove in the rotating shaft; the front side surface at the upper end of the lever is acted on one end of the spring; the rear side surface at the upper end of the lever is pressed against the shaft; the rear side surface at the upper end of the lever is provided with two continuous curved surfaces; the first curved surface is close to the second rotary central shaft; the second curved surface is a circular arc curved surface; when the first curved surface is pressed against the shaft, the shaft is positioned at the front side of an axis connecting line of the two rotary central shafts; when the second curved surface is pressed against the shaft, the circle center of the second curved surface is the first rotary central shaft; and the pressure of the contact can be controlled within the whole rotating range of the rotating shaft, and thus the opening speed of the movable contact is increased.

Owner:EATON HUINENG LOW-VOLTAGE ELECTRICAL (JIANGSU) CO LTD

Torque sensor

ActiveUS8109156B2Simple structureTorque stabilizationWork measurementTorque measurementCouplingControl theory

The present invention relates to a torque sensor comprising a torsion spring having first and second sides which are rotated with respect to one another by a torque applied to the torque sensor, wherein a mechanical coupling apparatus is provided between the first and second sides of the torsion spring and includes a movement element which is moved in the axial direction by a rotation of the first side with respect to the second side. In addition, a measuring apparatus is provided for the measurement of the axial movement of the movement element.

Owner:LIEBHERR AEROSPACE LINDENBERG

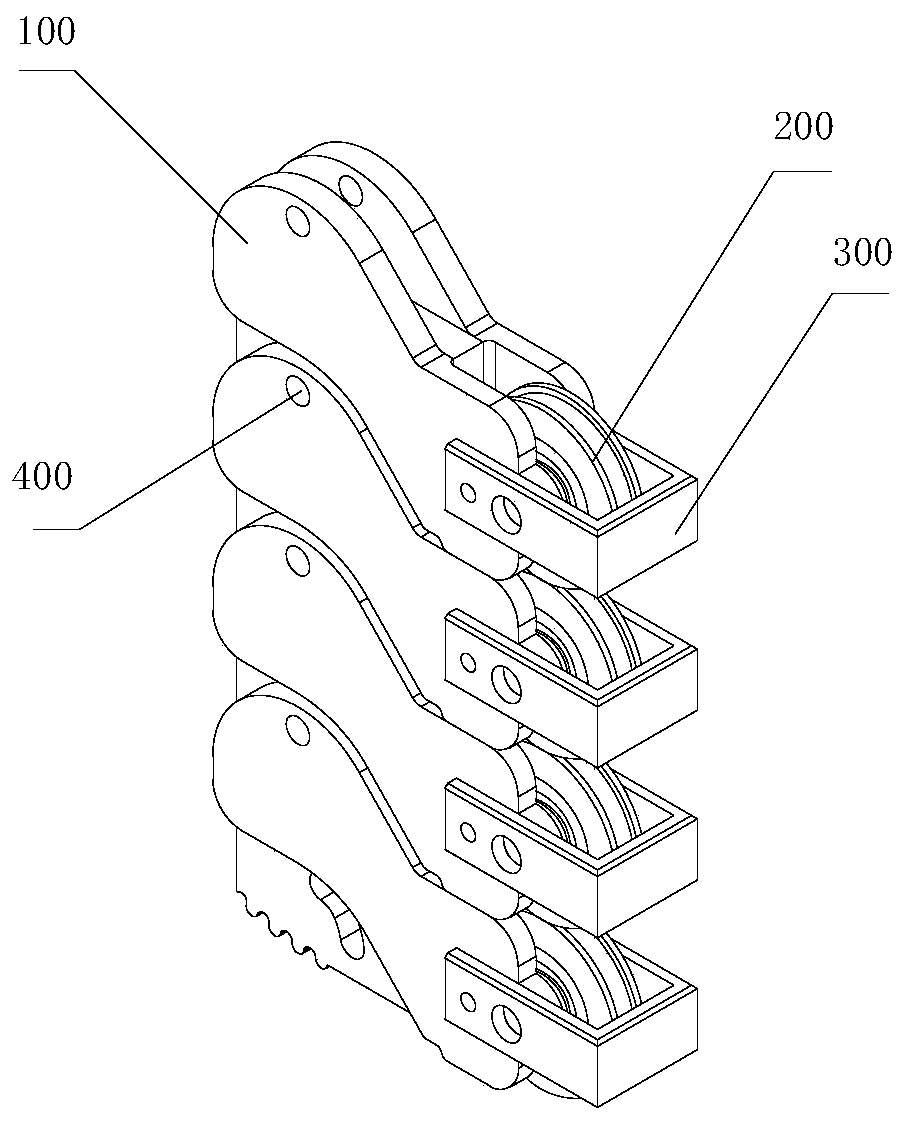

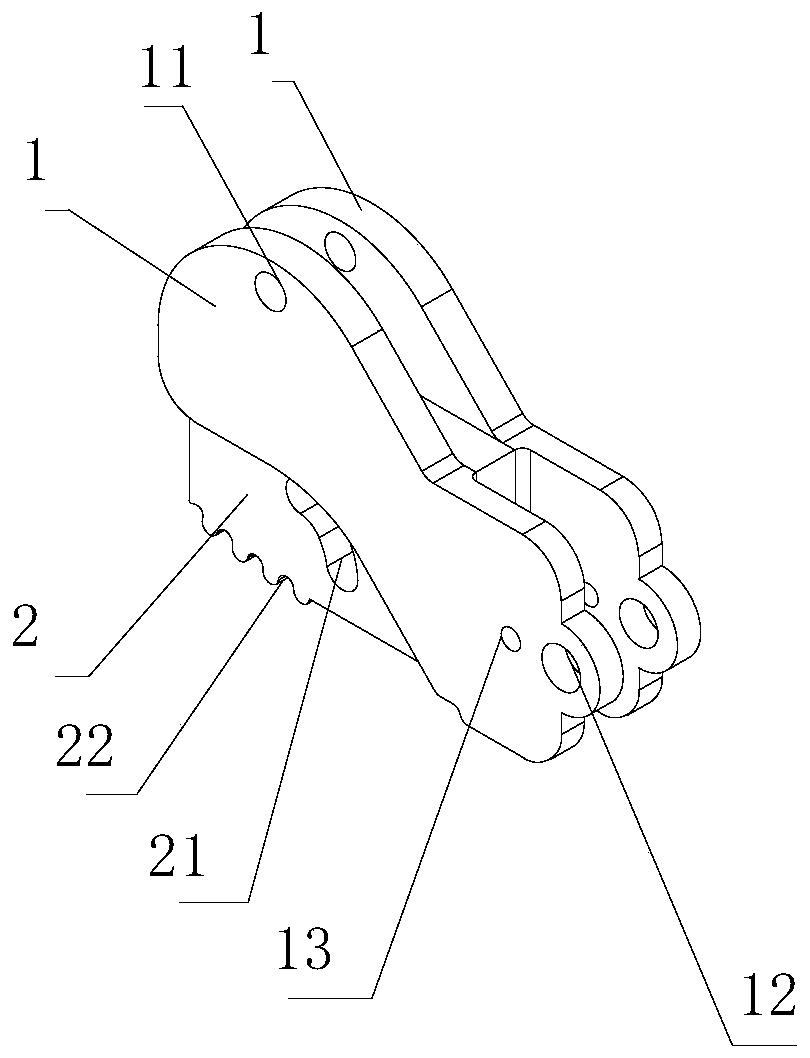

Knee joint mechanism for wearable external skeleton

PendingCN110421592AStable torqueReduce energy lossProgramme-controlled manipulatorJointsKnee JointLower tooth

The application provides a knee joint mechanism for a wearable external skeleton. The knee joint mechanism for the wearable external skeleton comprises at least two connection units connected in series in the up-down direction, wherein each connection unit comprises a connection piece and a steel rope pulley installed on the connection piece, each connection piece comprises two first connection sheets oppositely arranged and a second connection sheet clamped between the two first connection sheets, each first connection sheet comprises a first protruded part protruded upwards relatively to thecorresponding second connection sheet, each second connection sheet comprises a second protruded part protruded downwards relatively to the two corresponding first connection sheets, an installing gap is formed between the first protruded parts of the two first connection sheets oppositely arranged on each connection unit, a poisoning pin hole is formed in each first protruded part, an arc slidechute is formed in each second protruded part, an upper tooth part is arranged on the upper edge of each second connection sheet, and a lower tooth part is arranged on the lower edge of each second connection sheet.

Owner:MEBOTX INTELLIGENT TECH SUZHOU CO LTD

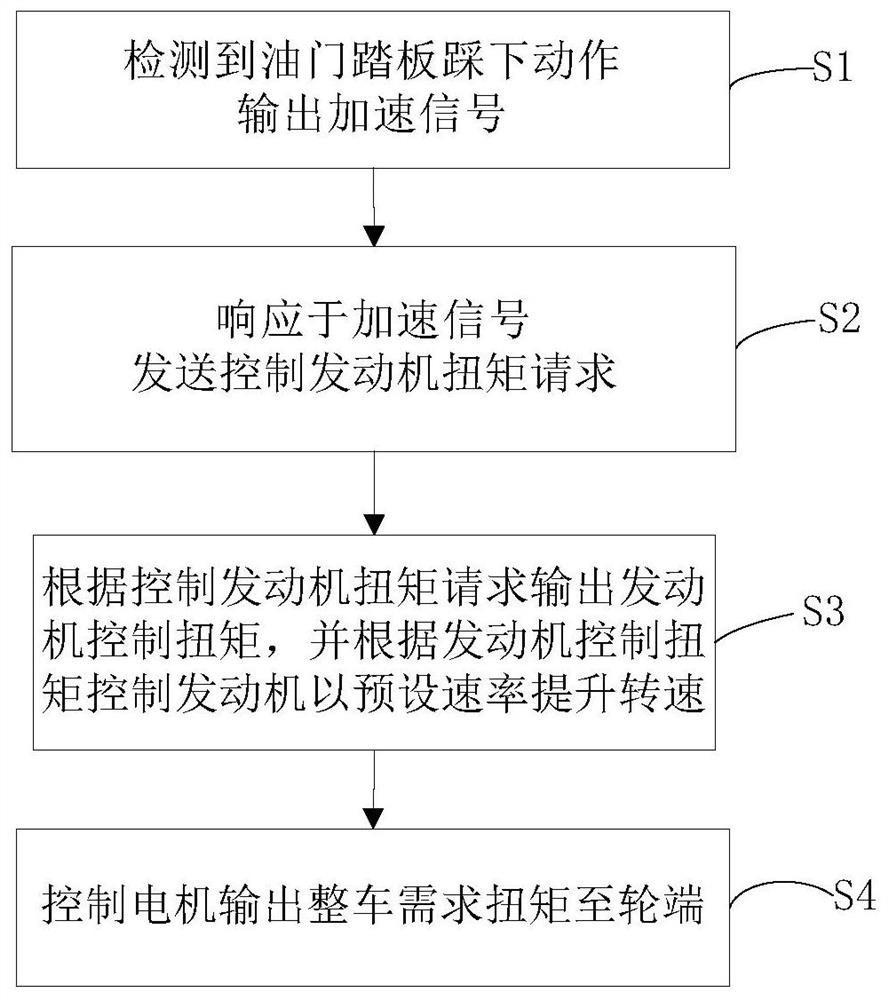

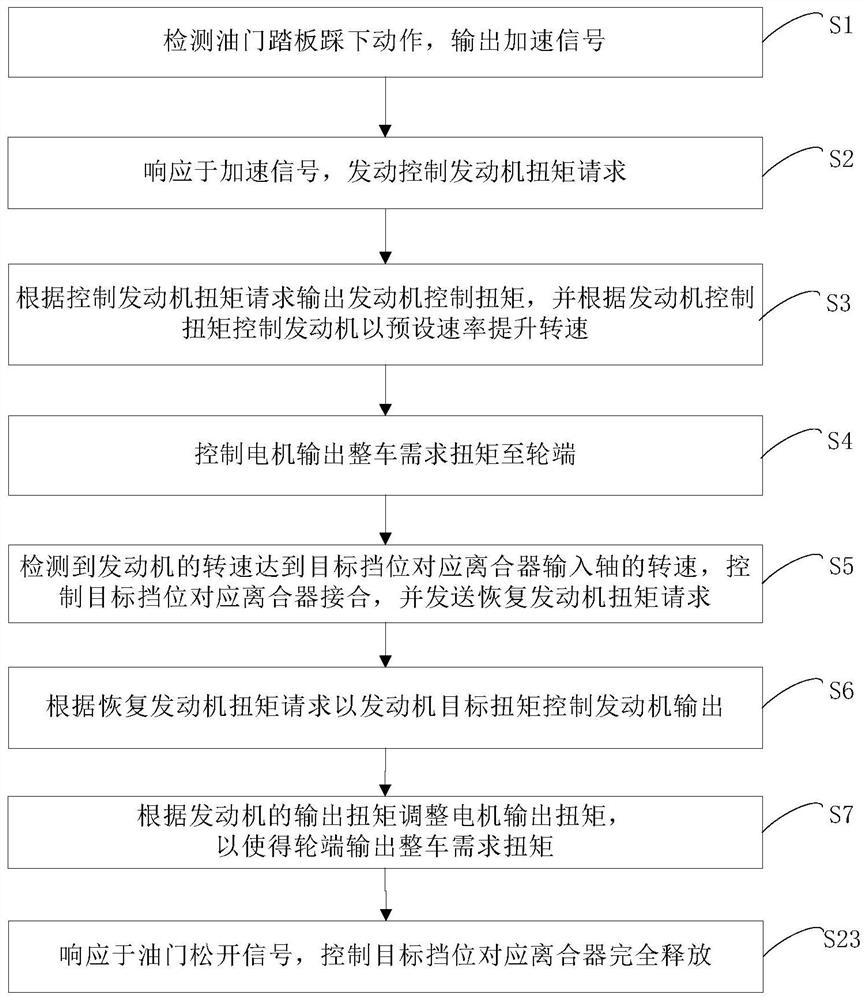

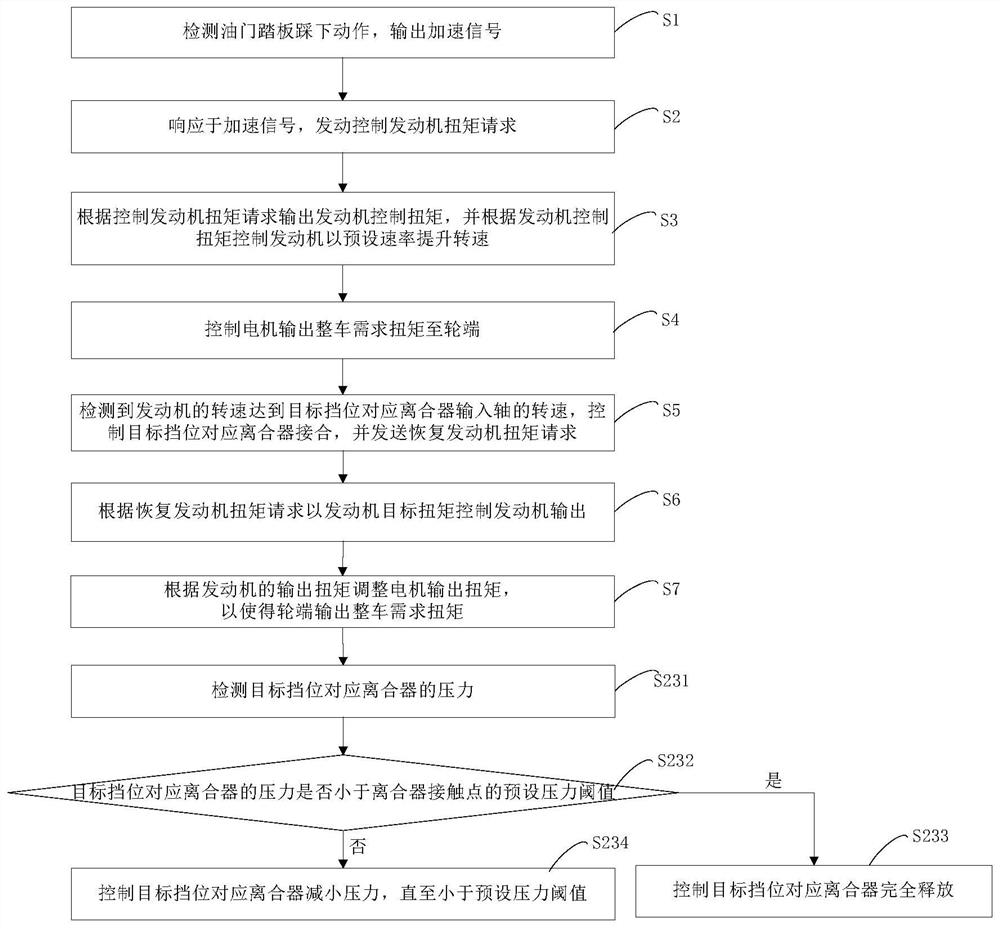

Hybrid vehicle, control method and control system thereof and storage medium

The invention discloses a control method and a control system of a hybrid vehicle, the vehicle and a medium. The method comprises the steps of detecting an accelerator pedal treading action, and outputting an acceleration signal; in response to the acceleration signal, controlling an engine to increase the rotating speed, and controlling a motor to output the whole vehicle required torque to the wheel end; when detecting that the rotating speed of the engine reaches the rotating speed of the clutch input shaft corresponding to the target gear, controlling the clutch corresponding to the targetgear to be combined; distributing engine target torque according to the whole vehicle operating parameters and the whole vehicle required torque, and controlling engine output torque according to theengine target torque; and adjusting the motor output torque according to the engine output torque, so that the wheel end outputs the whole vehicle required torque. According to the control method ofthe hybrid vehicle, the rotating speed and the output torque of the engine can be controlled under the refueling working condition of the vehicle, the target gear clutch is combined, and the vehicle pause phenomenon caused by inconsistency of the rotating speed of the engine and the rotating speed of the target gear input shaft is avoided.

Owner:BYD CO LTD

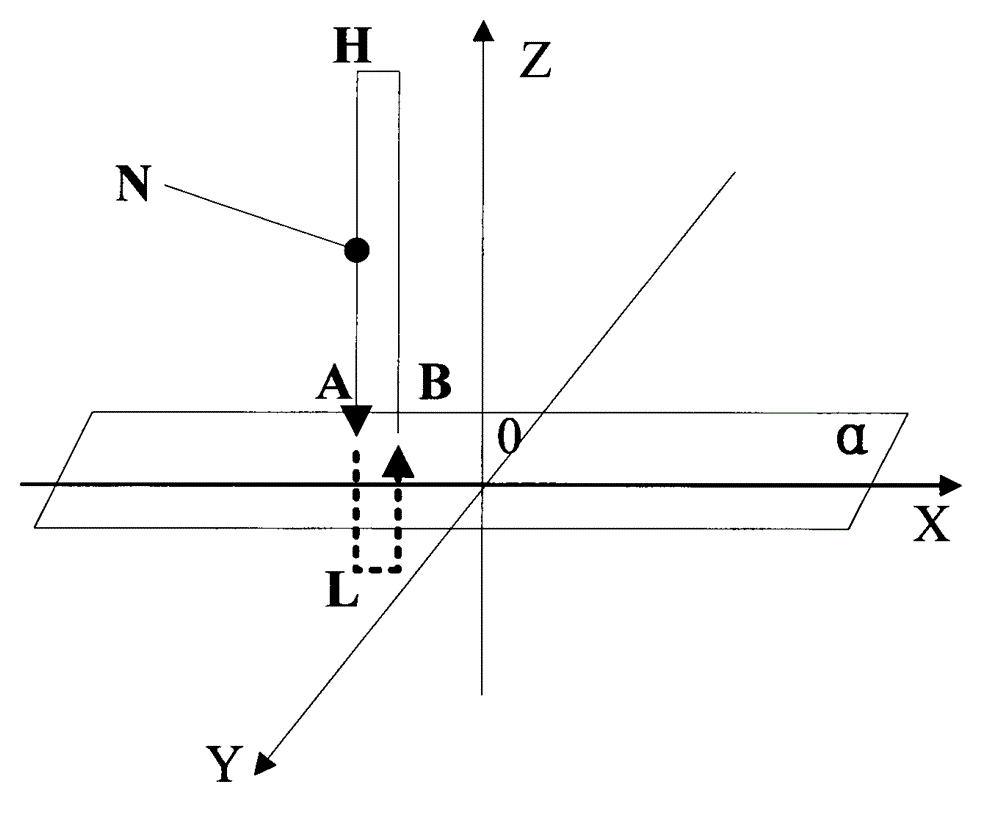

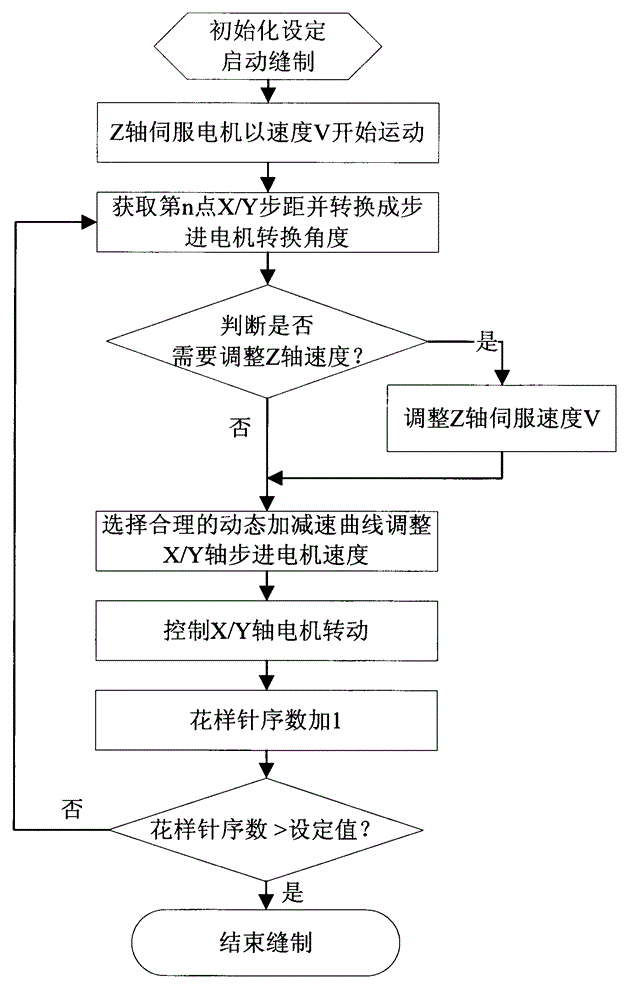

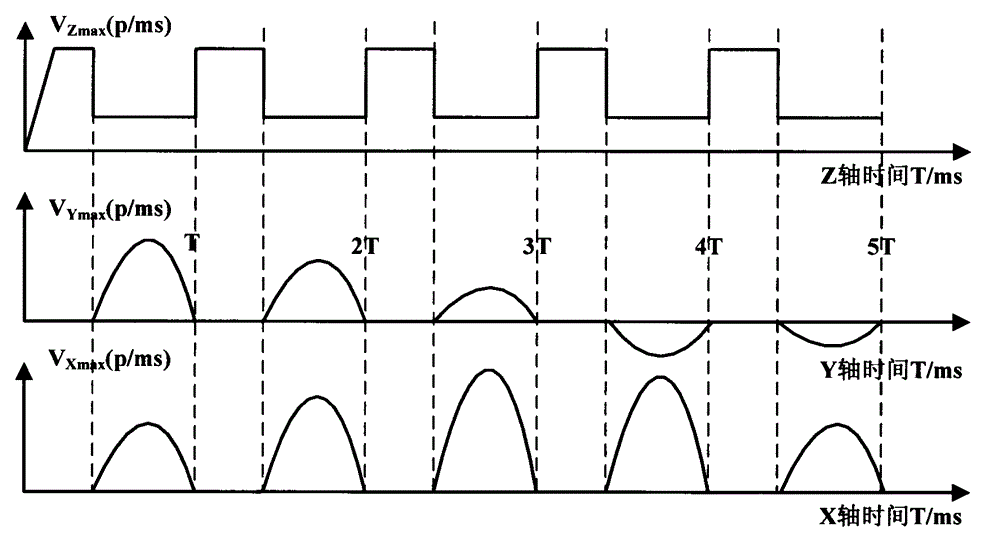

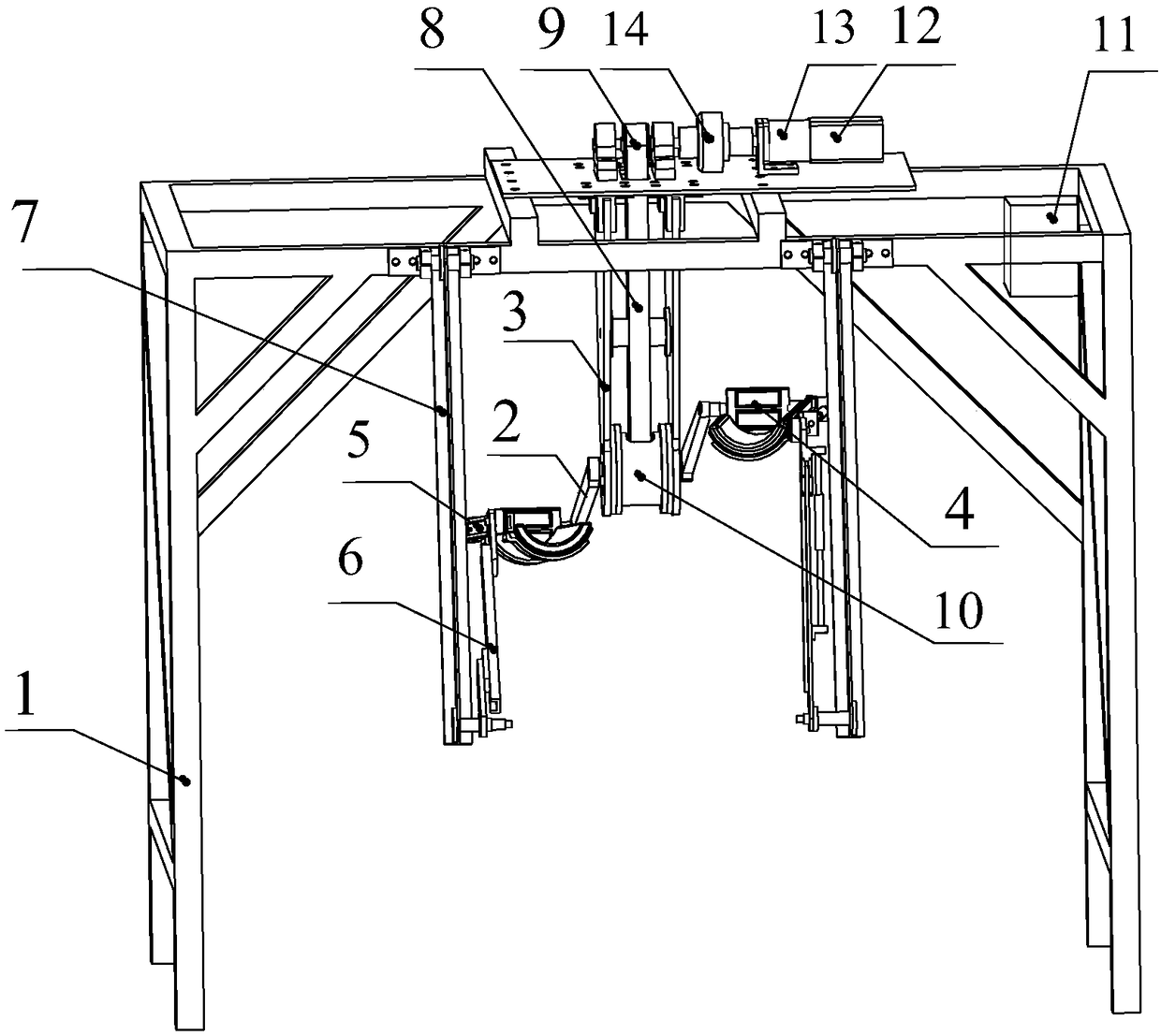

Multi-dimension dynamic synergic movement control method of high-speed intelligent prototype

ActiveCN103064339AImprove performanceLess chance of losing synchronizationNumerical controlMotor driveMovement control

The invention relates to a multi-dimension dynamic synergic movement control method of a high-speed intelligent prototype. According to the pre-time servo motor movement speed, available moving duration of current the X axis and the Y axis, namely, the time dimension, and the cloth delivery distance of nest stitch of the X axis and the Y axis, namely, the spatial domain can be worked out. In the whole accelerating and decelerating process, variable accelerating and decelerating parameters are applied, and conflict between speed increase and stable performance is avoided. A dynamic variation acceleration curve are applied to an X-axis stepping motor and a Y-axis stepping motor, the speed in the process of the acceleration is higher than normal fixed acceleration curve, and the deceleration has the same characteristic of the acceleration process. Under the condition that the dynamic variation acceleration curve satisfies a motor drive torque equation, the driving frequency smoothly changes, and torque overmeasure is stable. Compared with the fixed acceleration curve, the dynamic variation acceleration curve is provided with no inflection point, the out-of-step possibility of the motor is reduced, and stability is improved. The dynamic variation acceleration curve is worked out according to self torque frequency characteristics of the motor used by the system and mechanical system characteristics, and therefore the whole performance is enabled to be optimal.

Owner:SUZHOU UNIV OF SCI & TECH

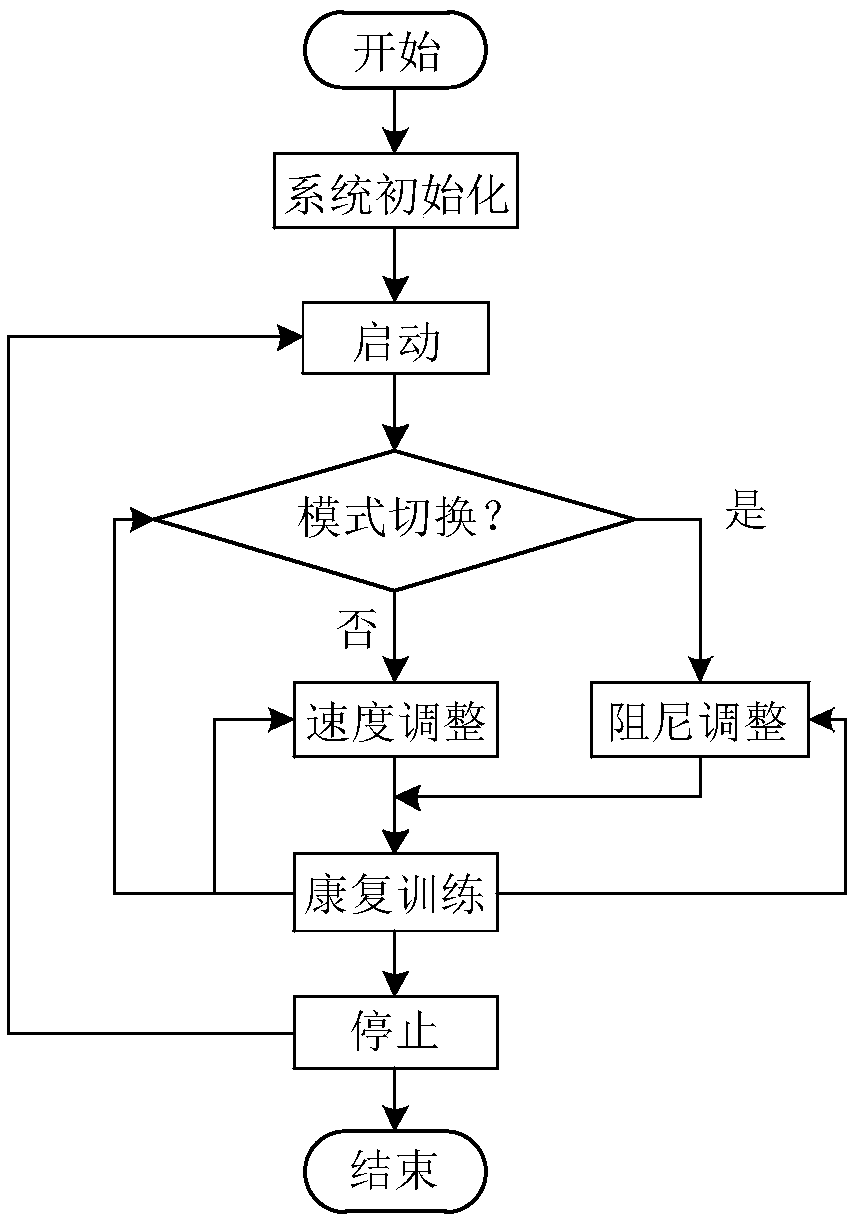

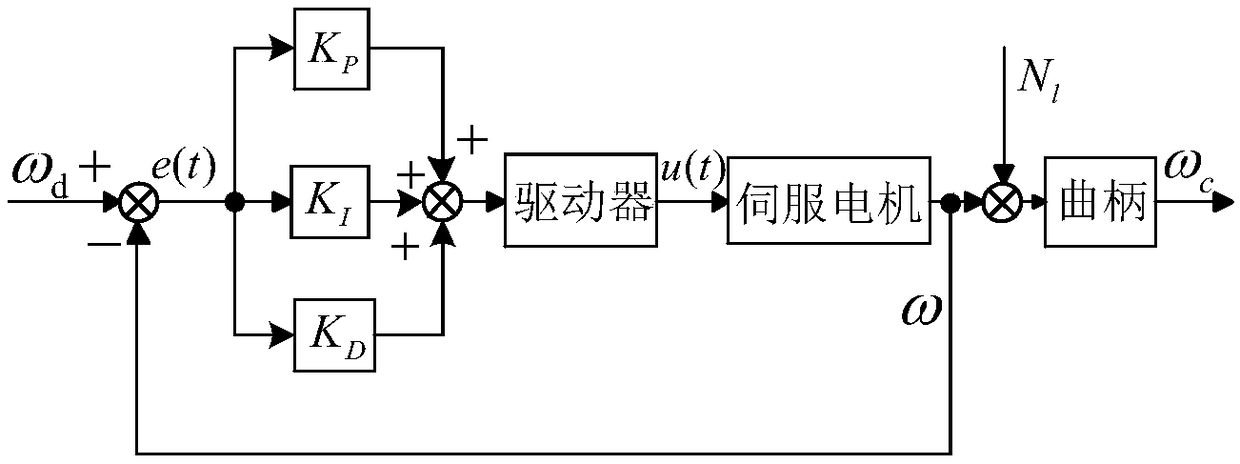

Leg muscle trainer and control method thereof

InactiveCN109364427APromote circulationStable speedMovement coordination devicesMuscle exercising devicesLeg muscleEngineering

The invention discloses a leg muscle trainer and a control method thereof. The leg muscle trainer comprises an outer frame, a crank, a crank shaft support, a pedal, a connecting rod, a rocker, a rocker support, a synchronous belt, a first synchronous pulley, a second synchronous pulley, a controller, a servo motor and a servo driver; the control method based on the device comprises the steps thatleg rehabilitation training is divided into a passive training mode that the servo motor provides power to drive leg movement and an active movement mode that the servo motor provides damping and needs legs to generate movement; bedridden patients can conduct leg muscle training and exercise leg joints on a sickbed, leg blood circulation is promoted, the passive mode and the active mode are alternatively used, the training method suitable for the patients can be adjusted continuously in the training process, and proper training mode adapting to the patients can be achieved in different rehabilitation phases.

Owner:SOUTHEAST UNIV

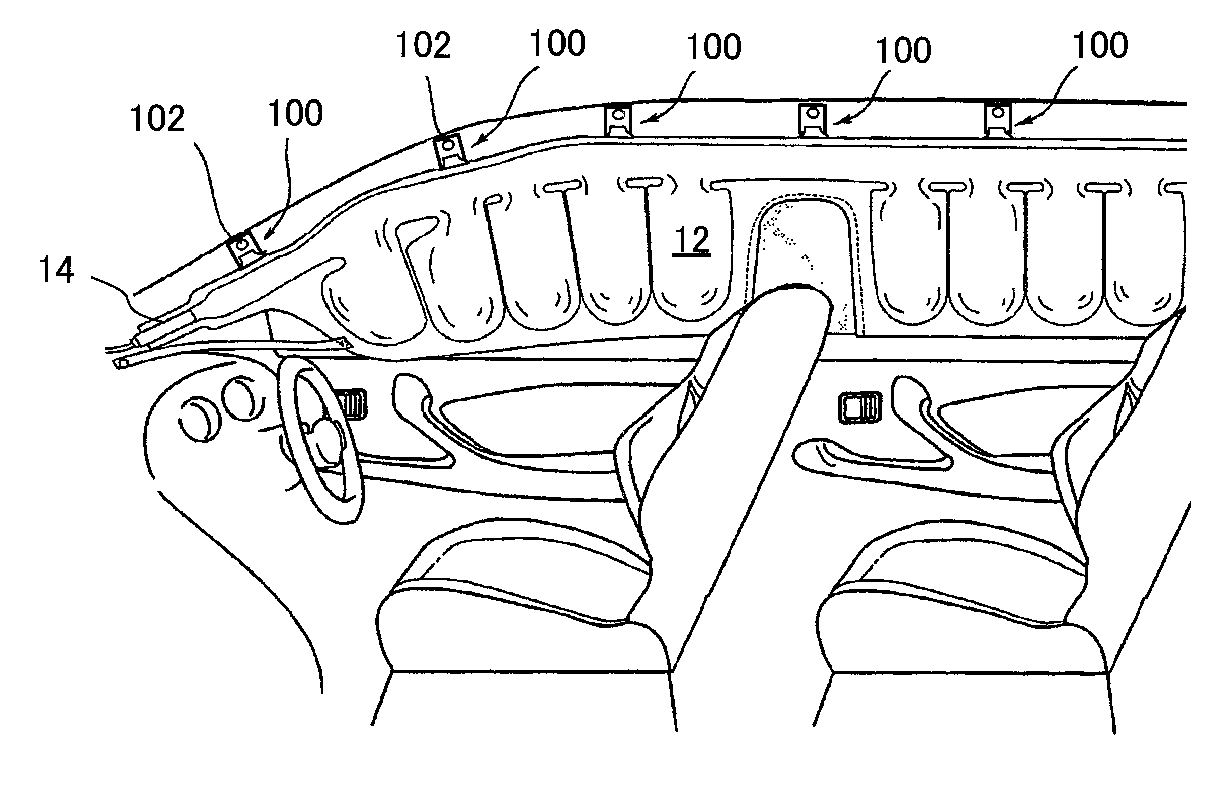

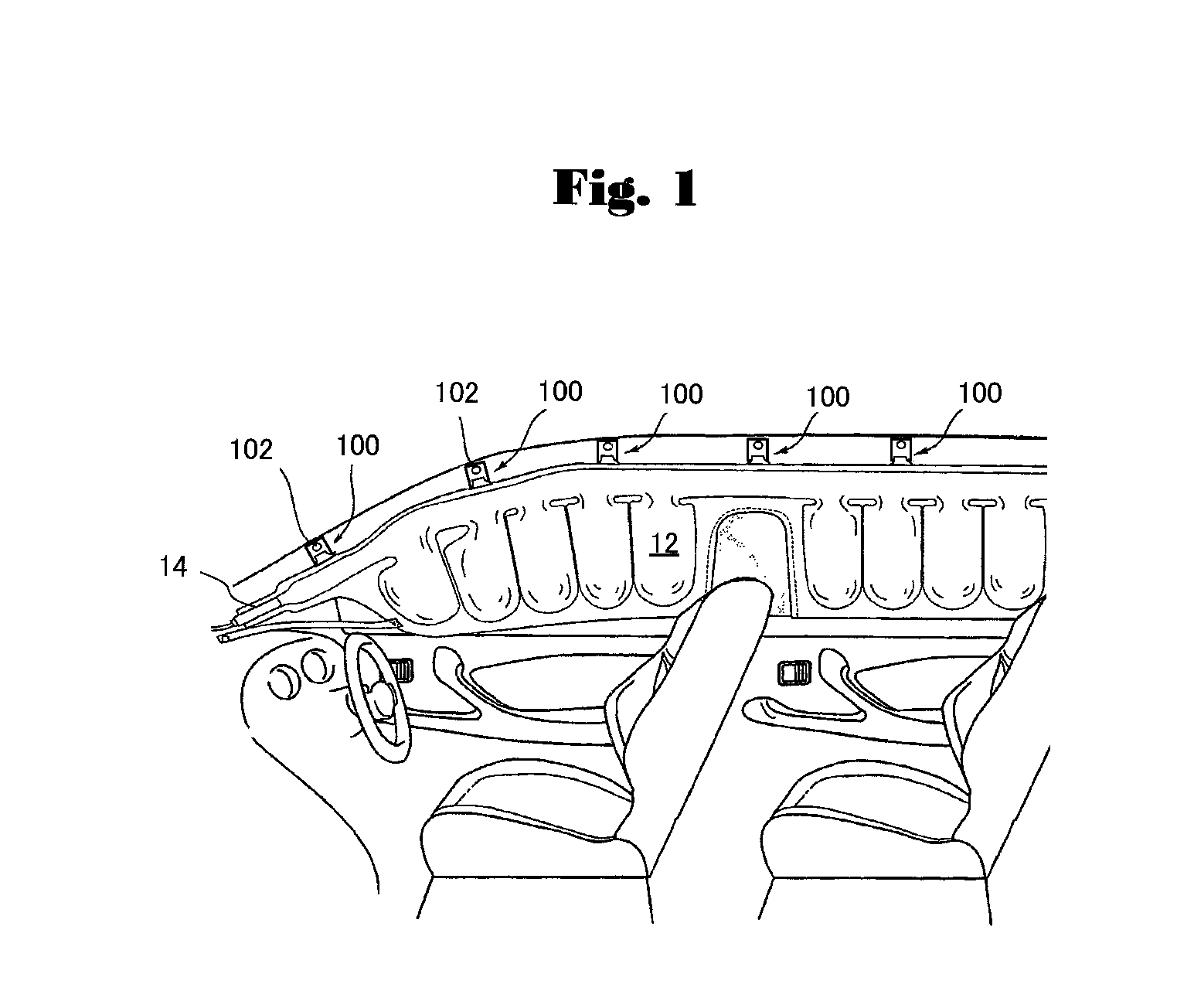

Curtain airbag device and method of manufacturing the same

ActiveUS8562016B2Torque stabilizationEnhanced couplingPedestrian/occupant safety arrangementMetal working apparatusCouplingAirbag

In at least one embodiment of the present invention, an airbag capable of maintaining a stable attachment to a vehicle for a long period and a method of manufacturing the airbag are provided. The curtain airbag device comprises an airbag body accommodated to a window upper edge of a vehicle for expanding and inflating toward inside of the vehicle in a compressed state when it is deployed. A plurality of strip-shaped coupling members are coupled with the airbag body. A plurality of brackets are coupled with the airbag body for fixing the airbag body to the vehicle. Each bracket has a coupling hole through which each strip-shaped coupling member is inserted and a fixing hole into which a tightening member is inserted. The airbag body is coupled with the brackets by the strip-shaped coupling members as well as the airbag body is fixed to the vehicle through the brackets by the tightening members.

Owner:AUTOLIV DEV AB

Hydraulic brake device for differential mechanism

ActiveCN105864389ASimple structureThe output speed is convenientDifferential gearingsHydraulic cylinderEngineering

The invention belongs to the field of differential mechanisms and in particular relates to a hydraulic brake device for a differential mechanism. The hydraulic brake device for the differential mechanism comprises a planetary gear differential and a hydraulic brake mechanism which are mutually meshed; the hydraulic brake mechanism comprises a plurality of separating plates, an inner disc is arranged between the separating plates, the inner disc is movably arranged on the planetary gear differential, the leftmost separating plate is fixedly connected with a gear differential, and a hydraulic cylinder which is used for pushing the separating plates and clings to the inner disc is arranged at the right side of the rightmost separating plate; a power device is connected outside the planetary gear differential, and rotating speed of an output end of the planetary gear differential and steering are controlled by virtue of the hydraulic brake mechanism. The hydraulic brake device for the differential mechanism has the advantages that structure is simple, in-situ steering can be realized, output rotating speeds of the left side and the right side can be conveniently adjusted, and power output is stable.

Owner:ZHEJIANG LIULIN AGRI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com