Patents

Literature

53results about How to "Eliminate strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

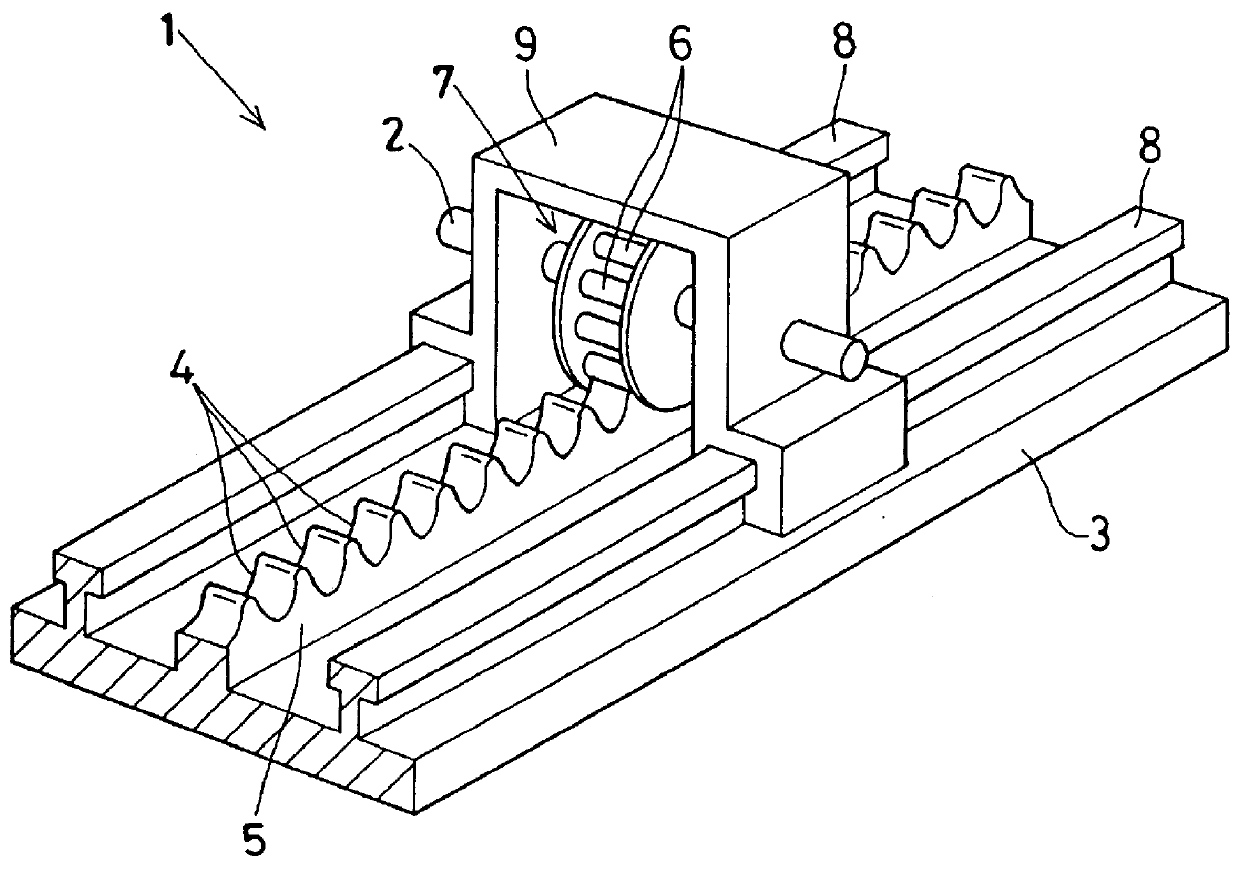

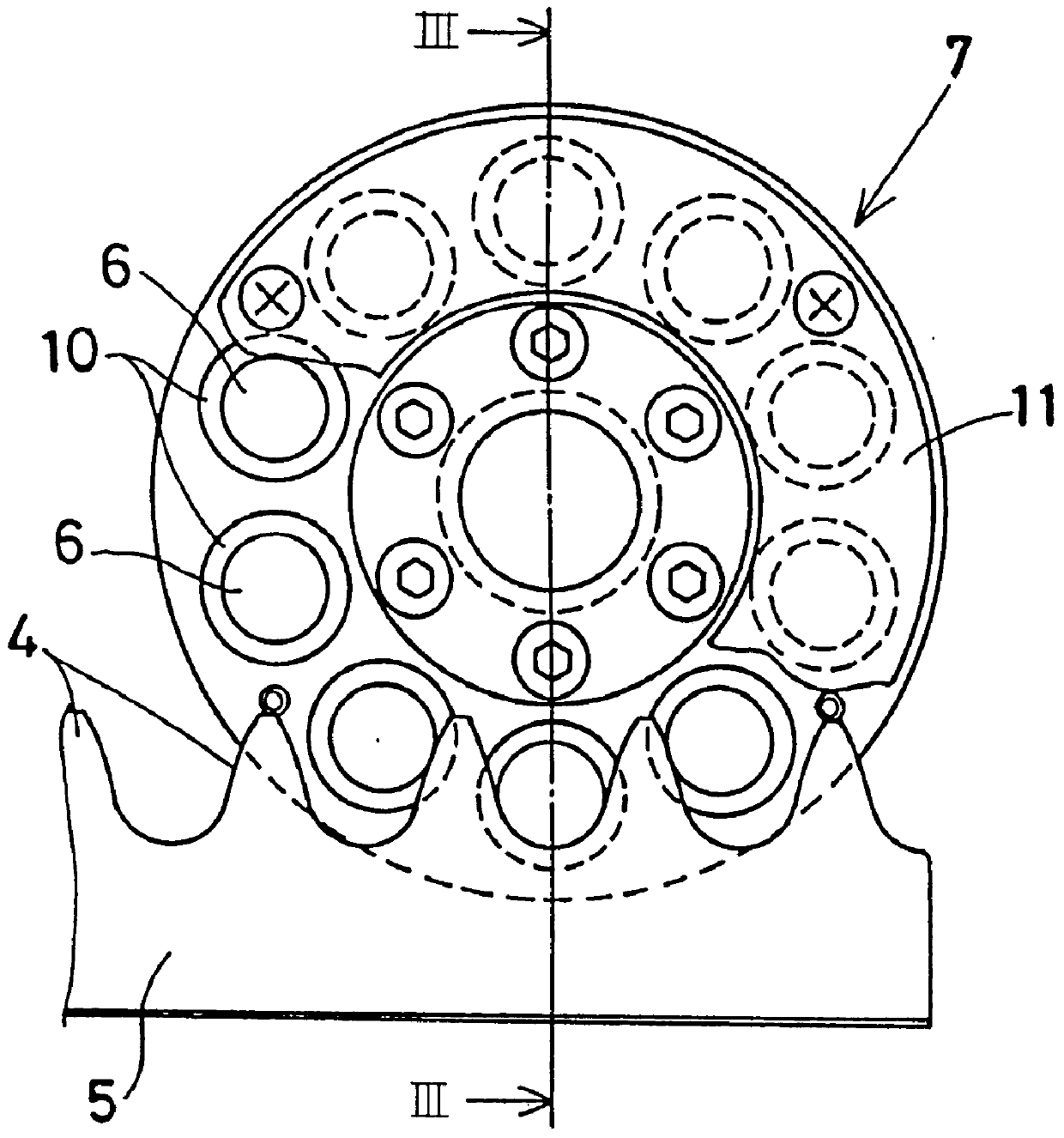

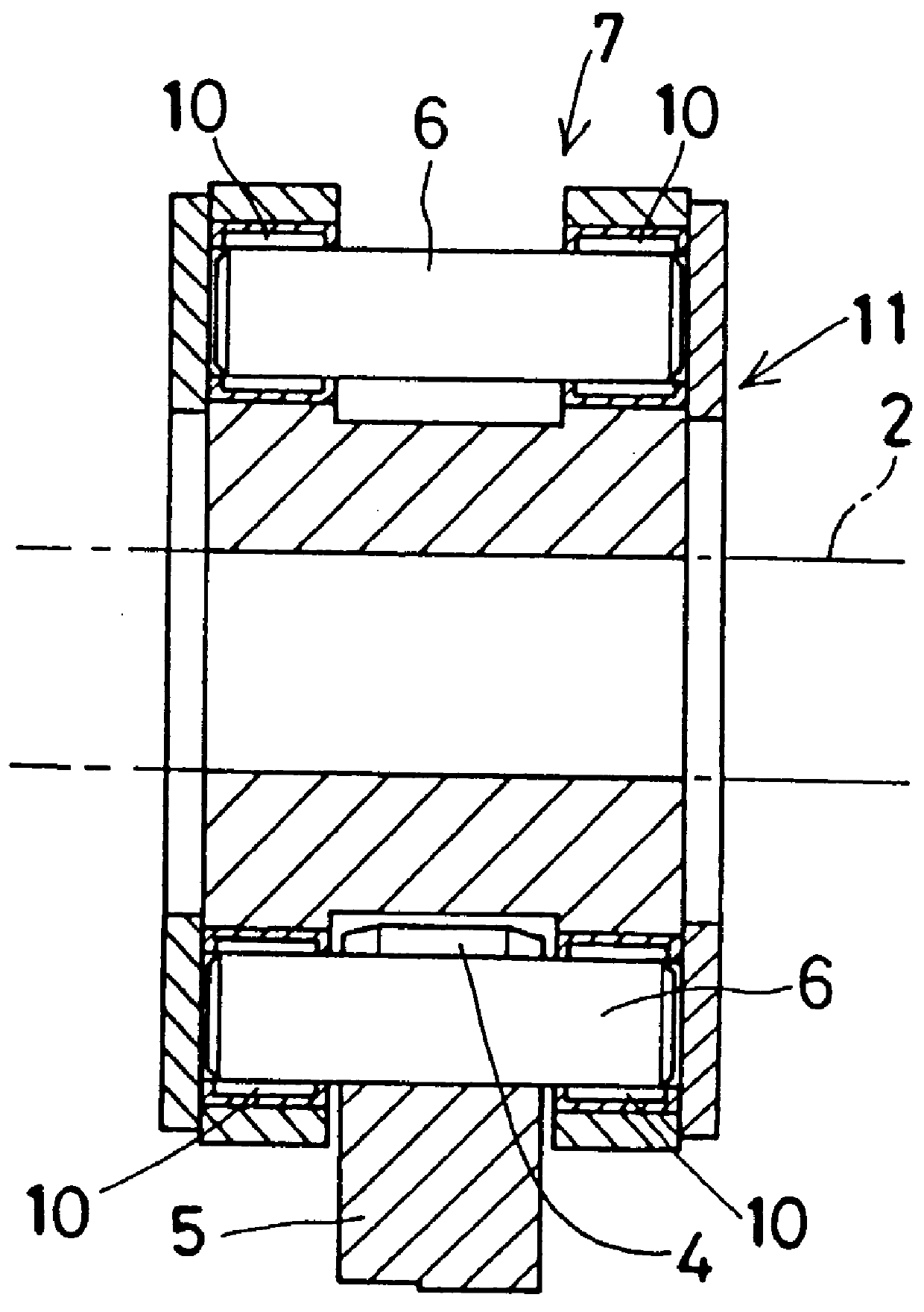

Transmission device for converting a torque between rotary movement and linear movement

InactiveUS6023989ASmooth meshingEliminate fluctuationsToothed gearingsPortable liftingLinear motionGear wheel

A transmission device for converting a torque from rotary to linear movement includes a rack having a plurality of teeth and a pinion having rollers which mesh with the teeth of the rack, with pressurization provided therebetween. The rack has an arcuate tooth flank diametrically greater than each of the rollers of the pinion. The rack also has a tooth face which has an approach profile progressively moving away from the path of contact of each of the rollers along which each of the rollers would otherwise engage with the tooth face. A plurality of each of the rollers of the pinion concurrently mesh with the corresponding teeth of the rack. Another embodiment converts a torque between rotary and linear movement and comprises a pinion having a plurality of teeth and a rack having a plurality of rollers to mesh with the teeth of the pinion. The device achieves reduced transmission resistance, a silent intermeshing movement with no substantial noise and vibration, as well as reduced wear on the teeth and rollers.

Owner:KAMOSEIKO

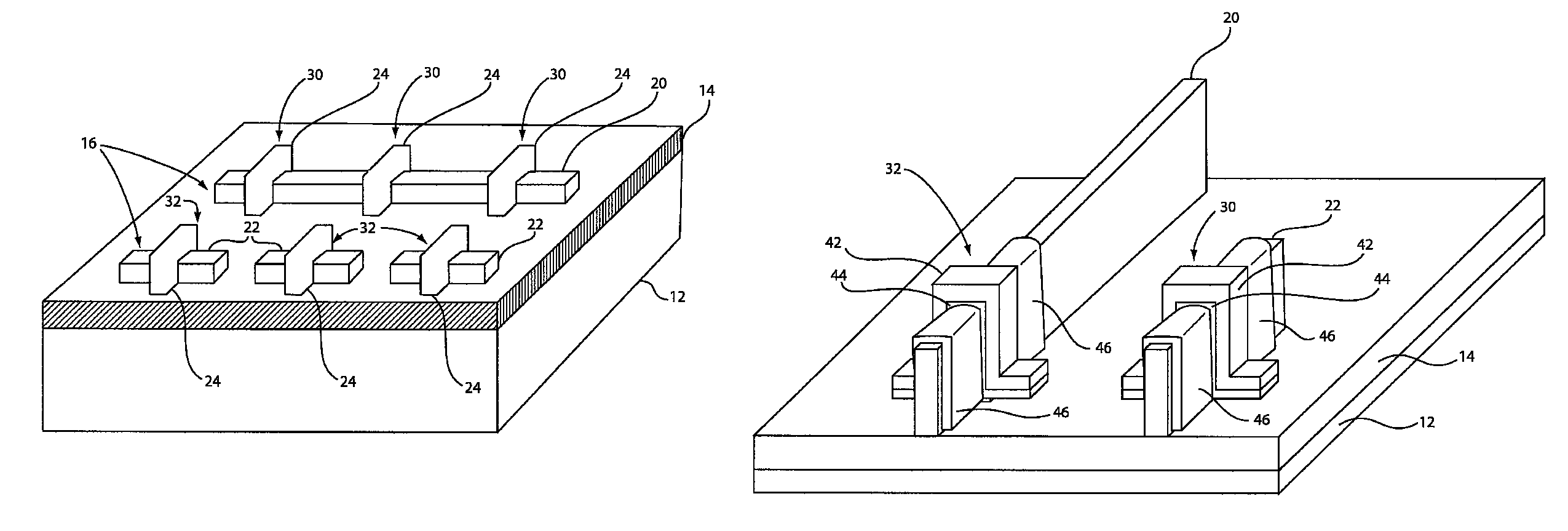

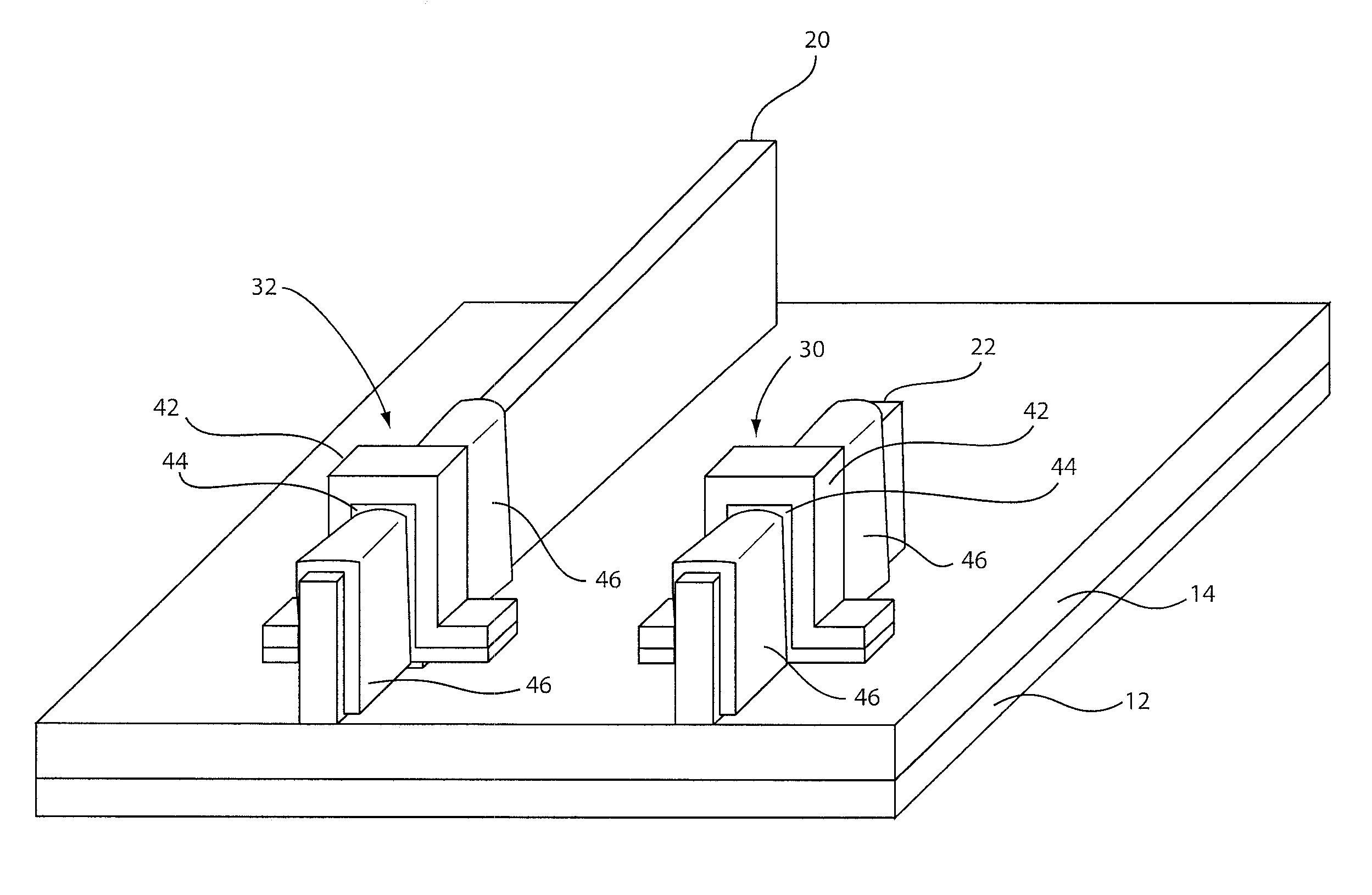

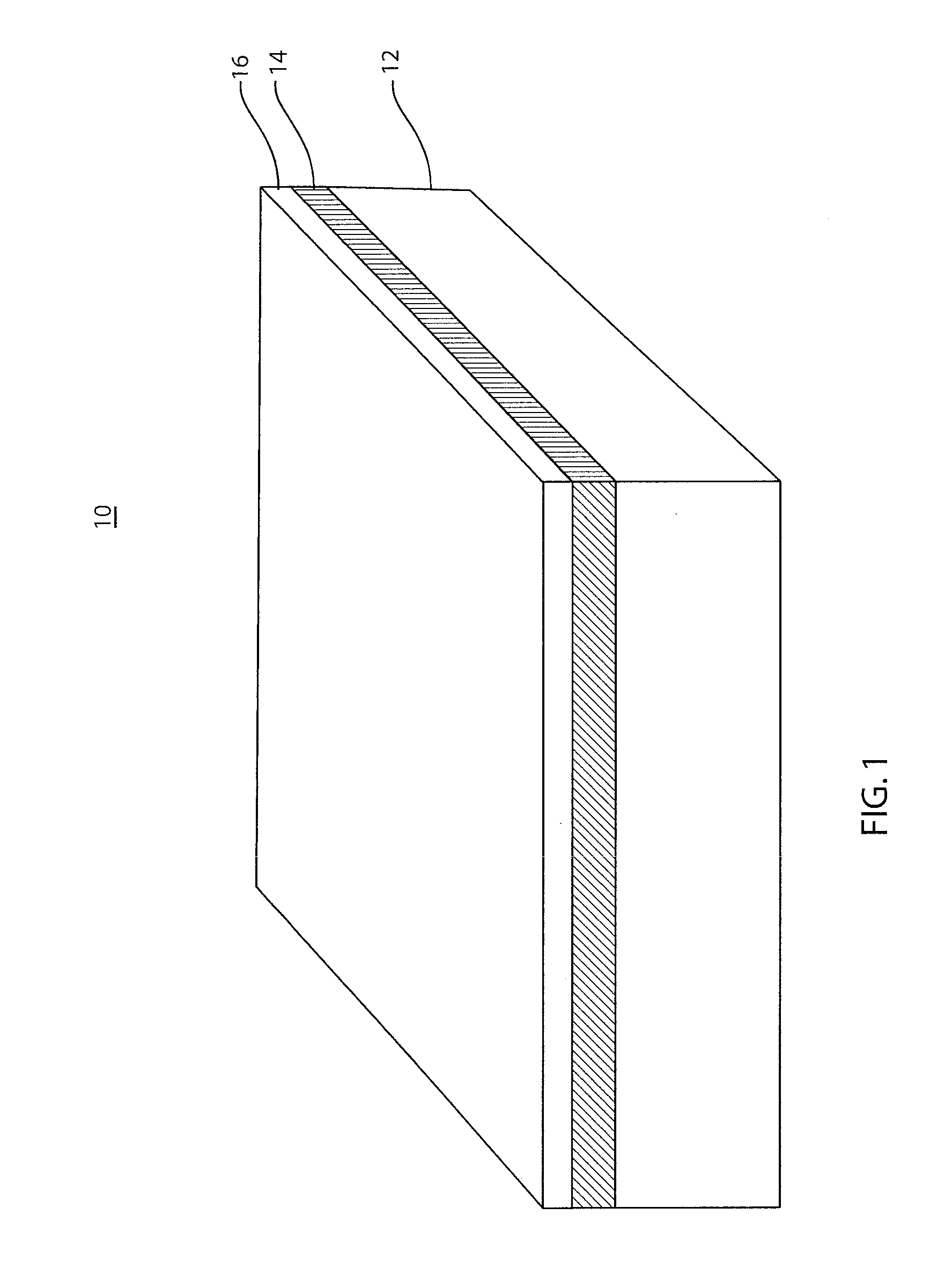

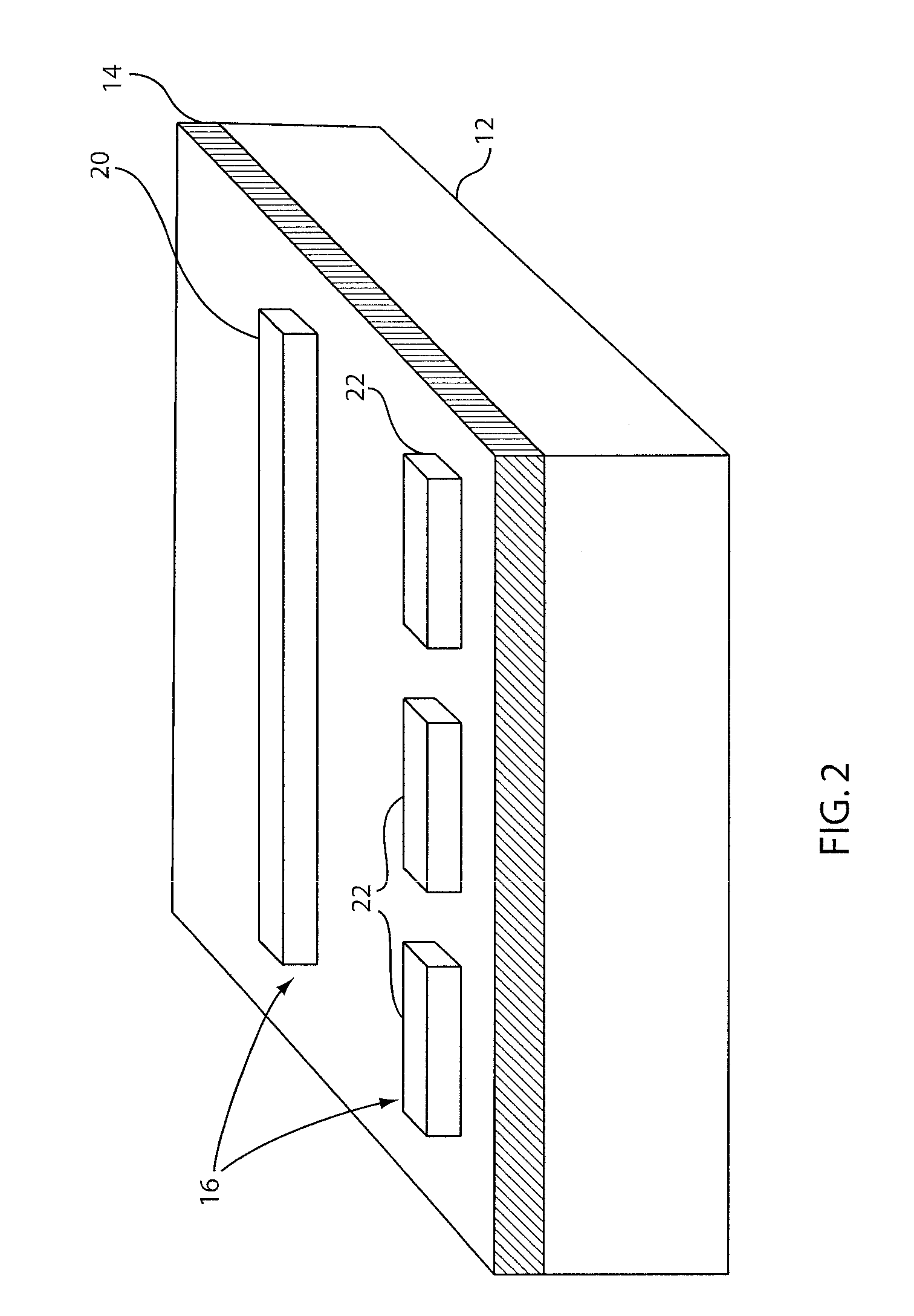

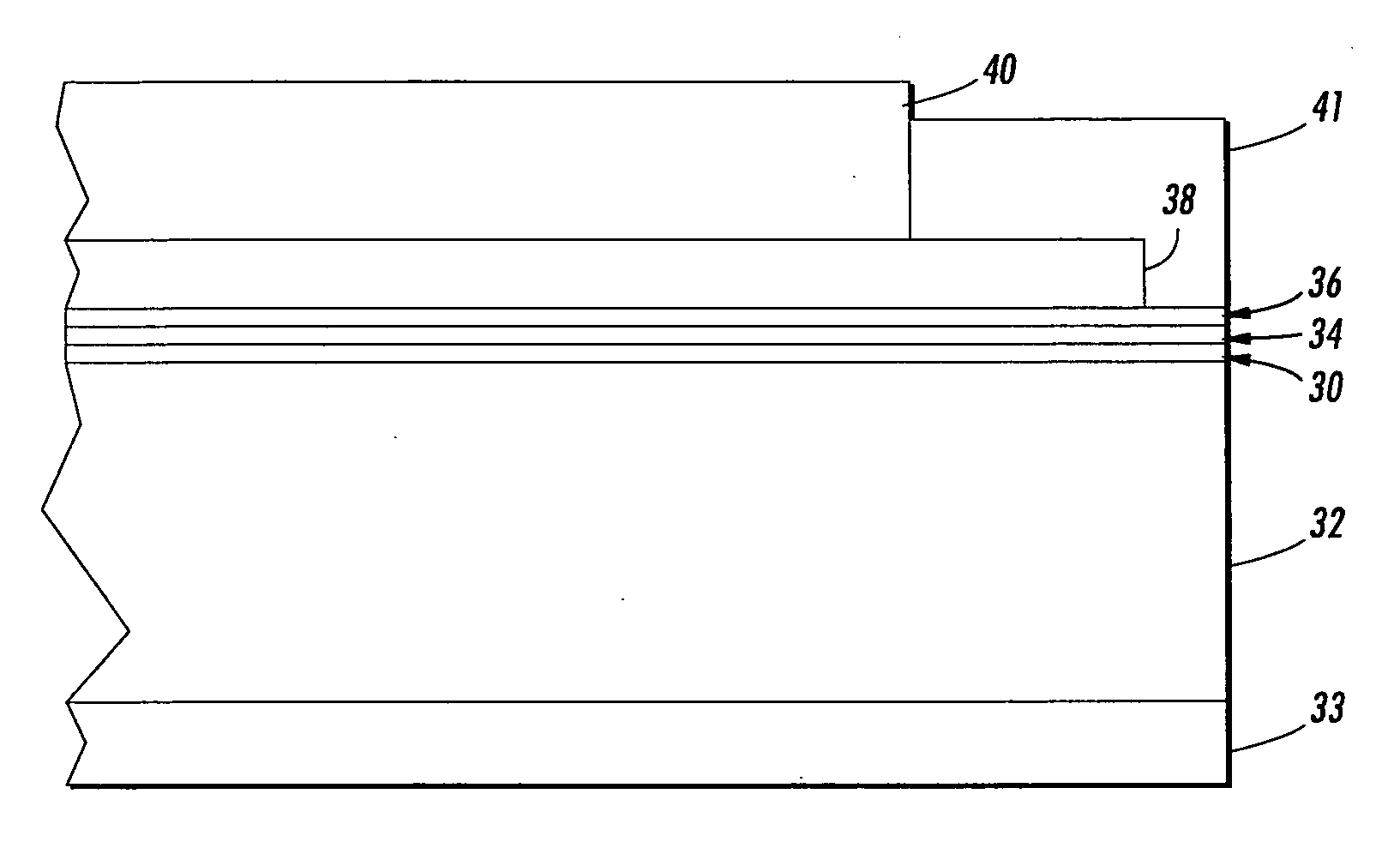

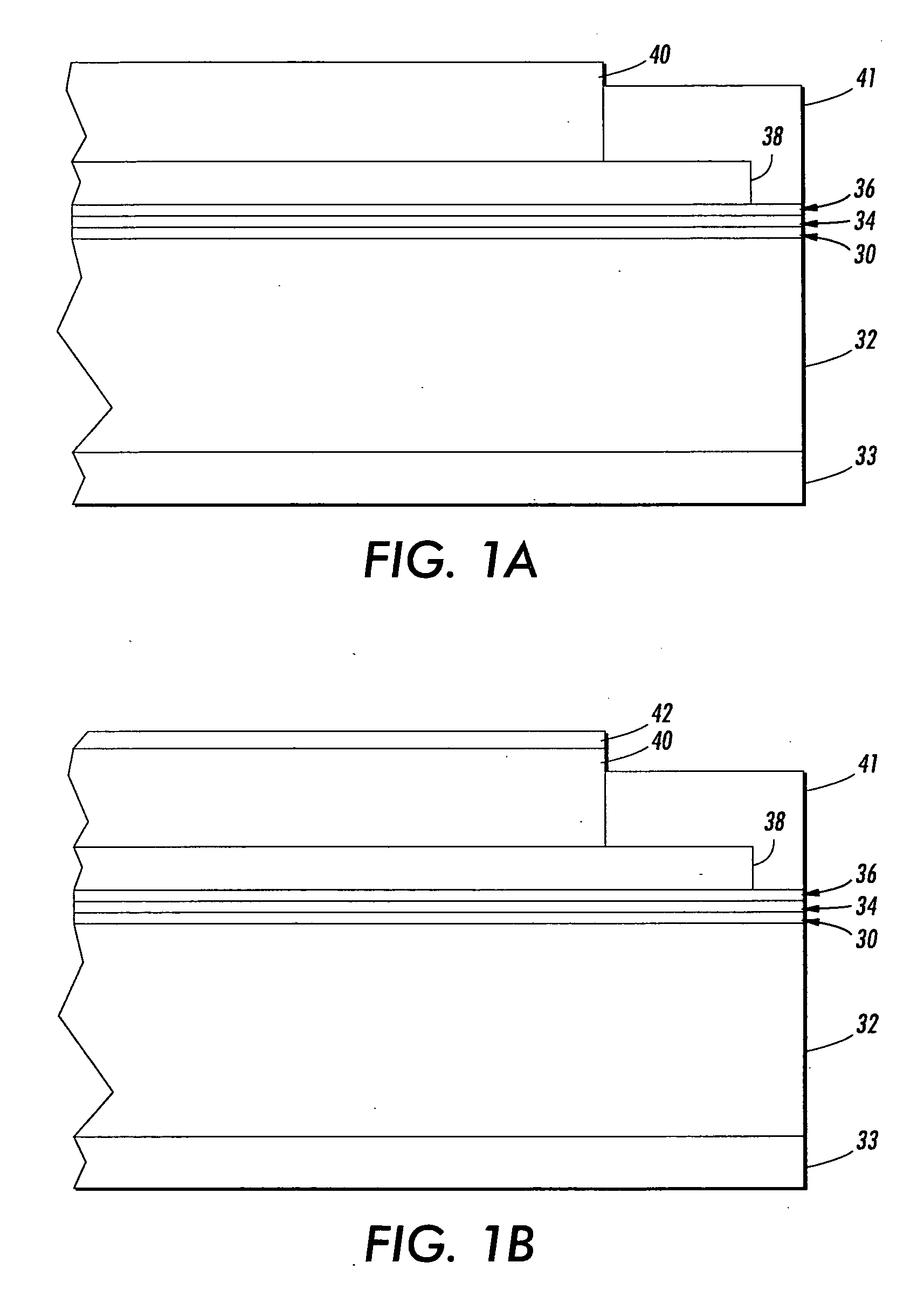

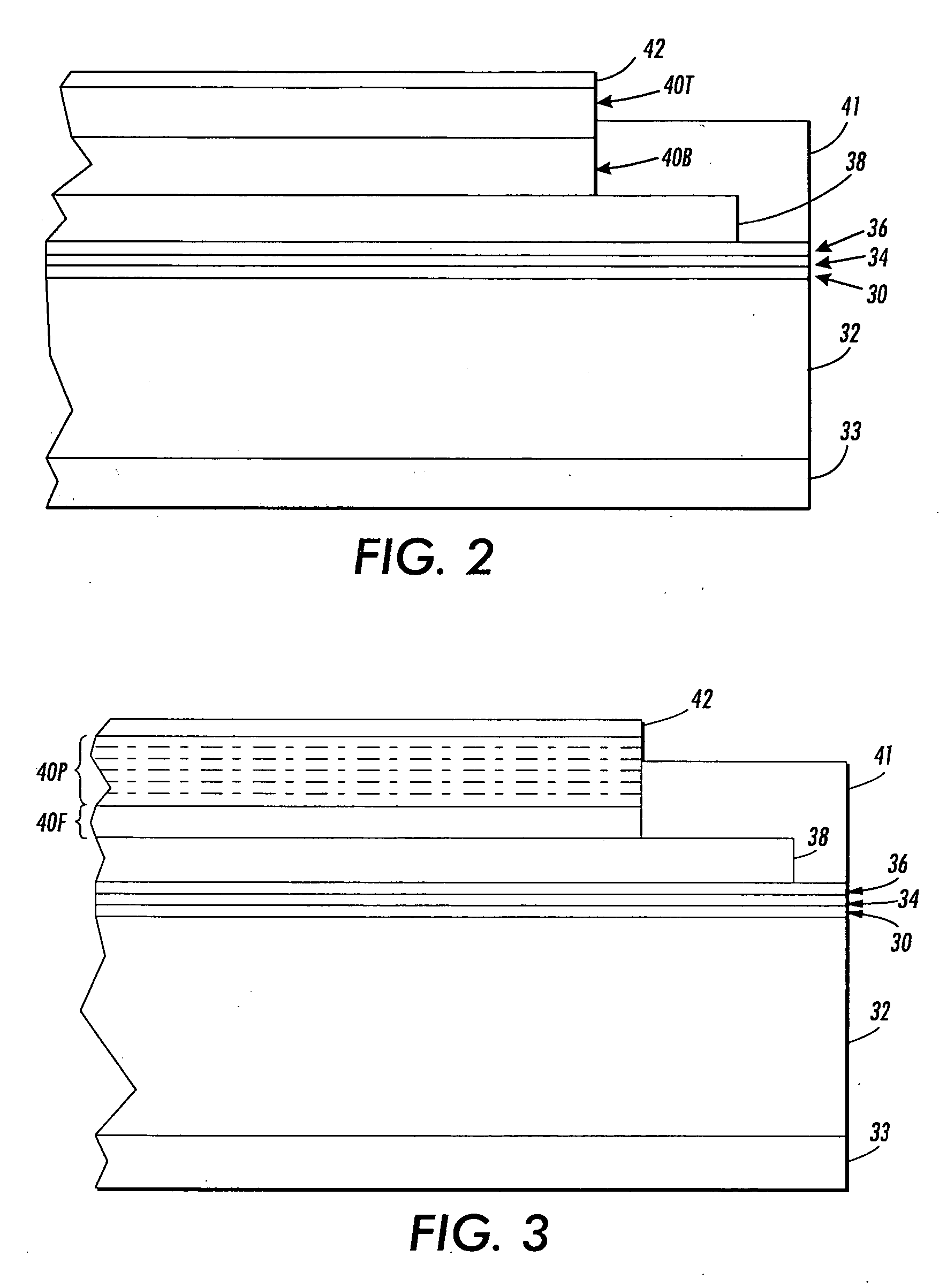

Strained CMOS device, circuit and method of fabrication

ActiveUS8169025B2Improve performanceEliminate strainSolid-state devicesSemiconductor/solid-state device manufacturingCMOSEngineering

A semiconductor device and fabrication method include a strained semiconductor layer having a strain in one axis. A long fin and a short fin are formed in the semiconductor layer such that the long fin has a strained length along the one axis. An n-type transistor is formed on the long fin, and a p-type transistor is formed on the at least one short fin. The strain in the n-type transistor improves performance.

Owner:GLOBALFOUNDRIES US INC

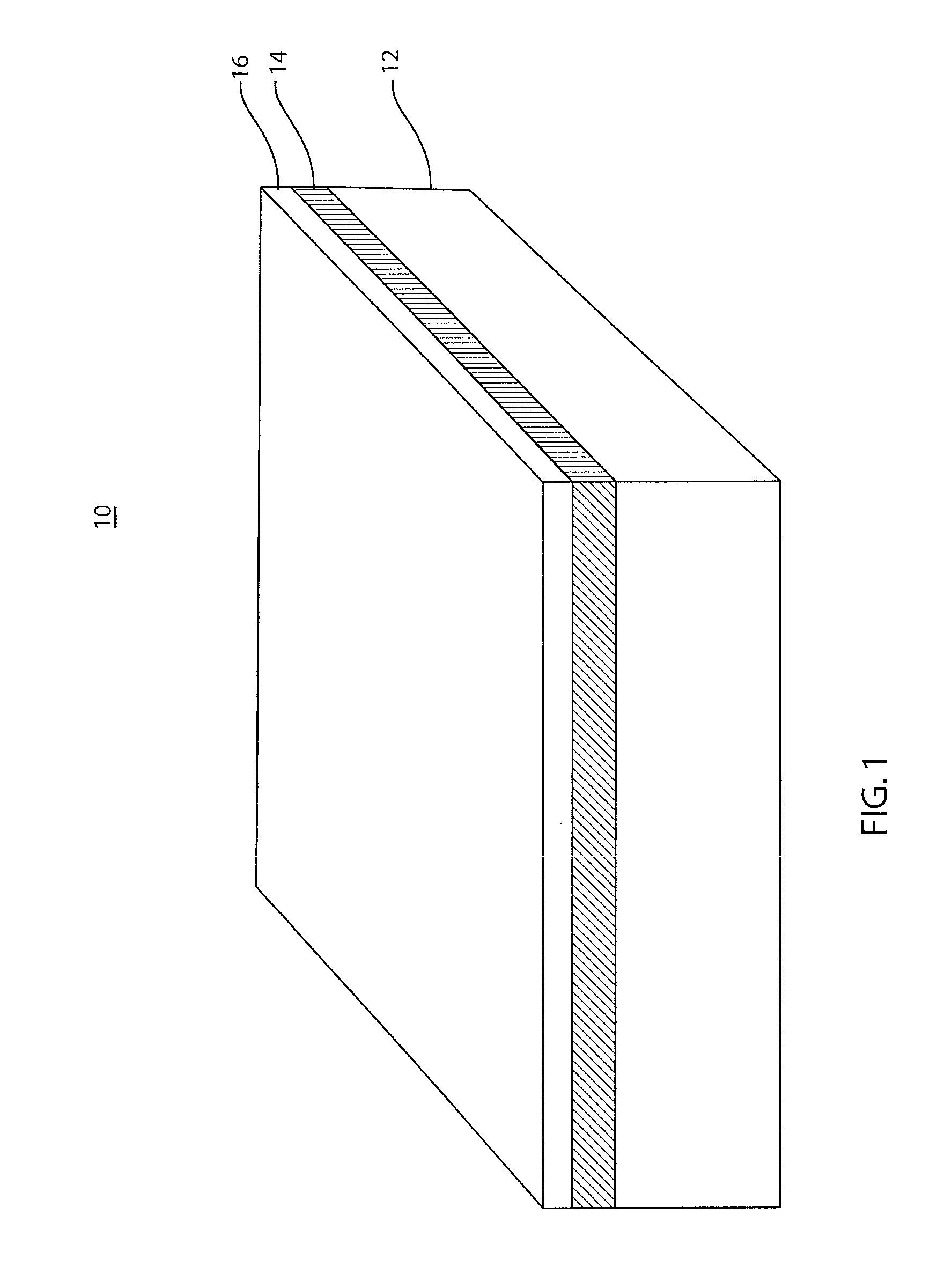

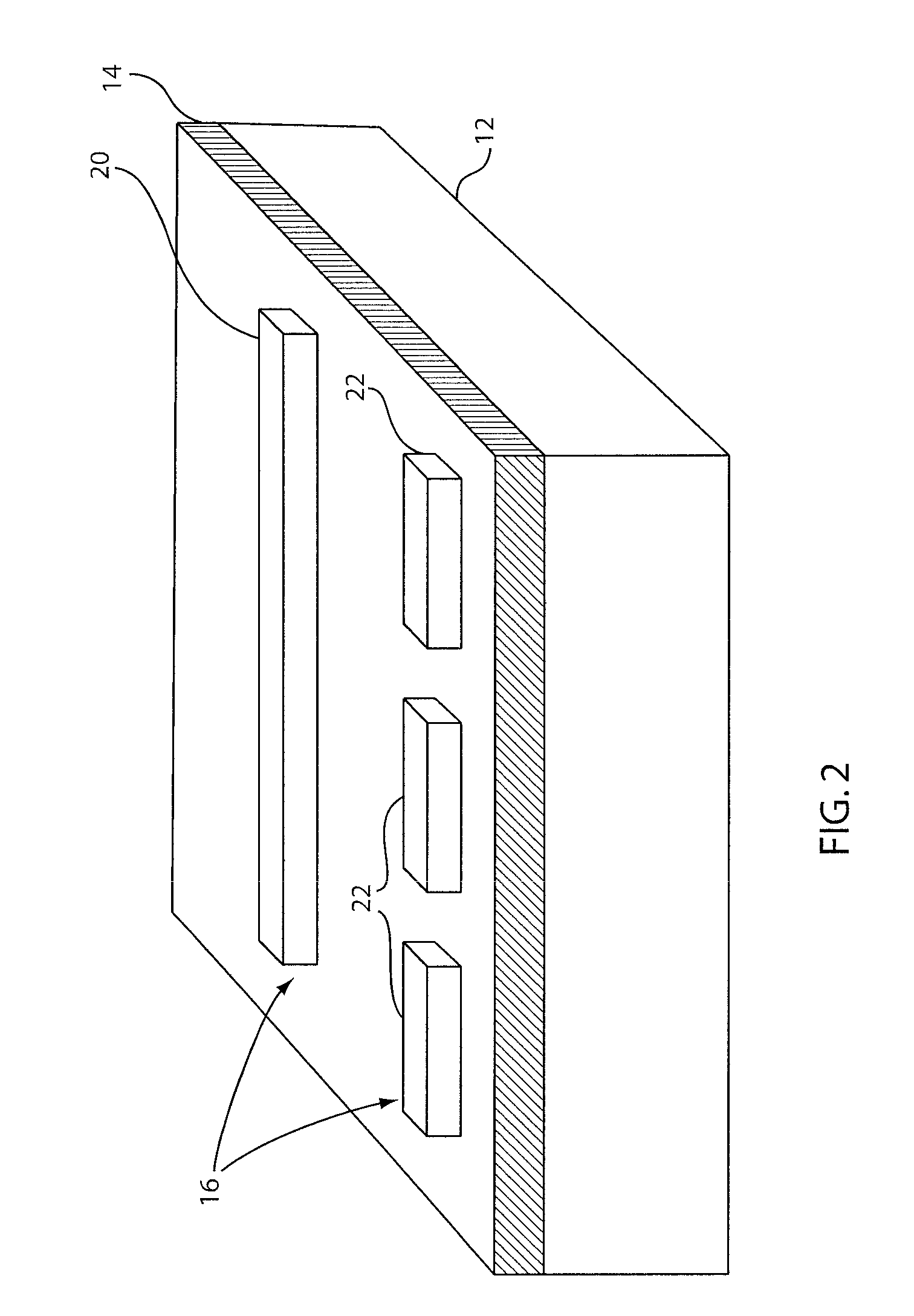

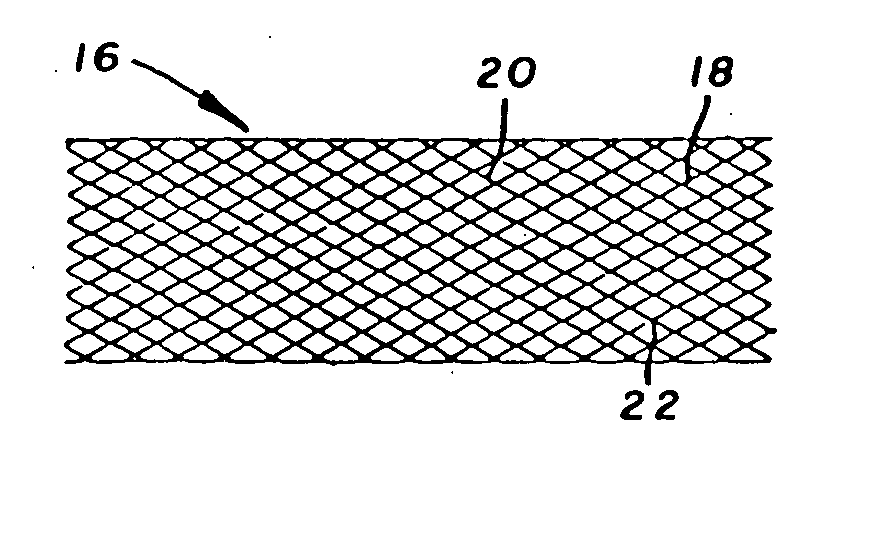

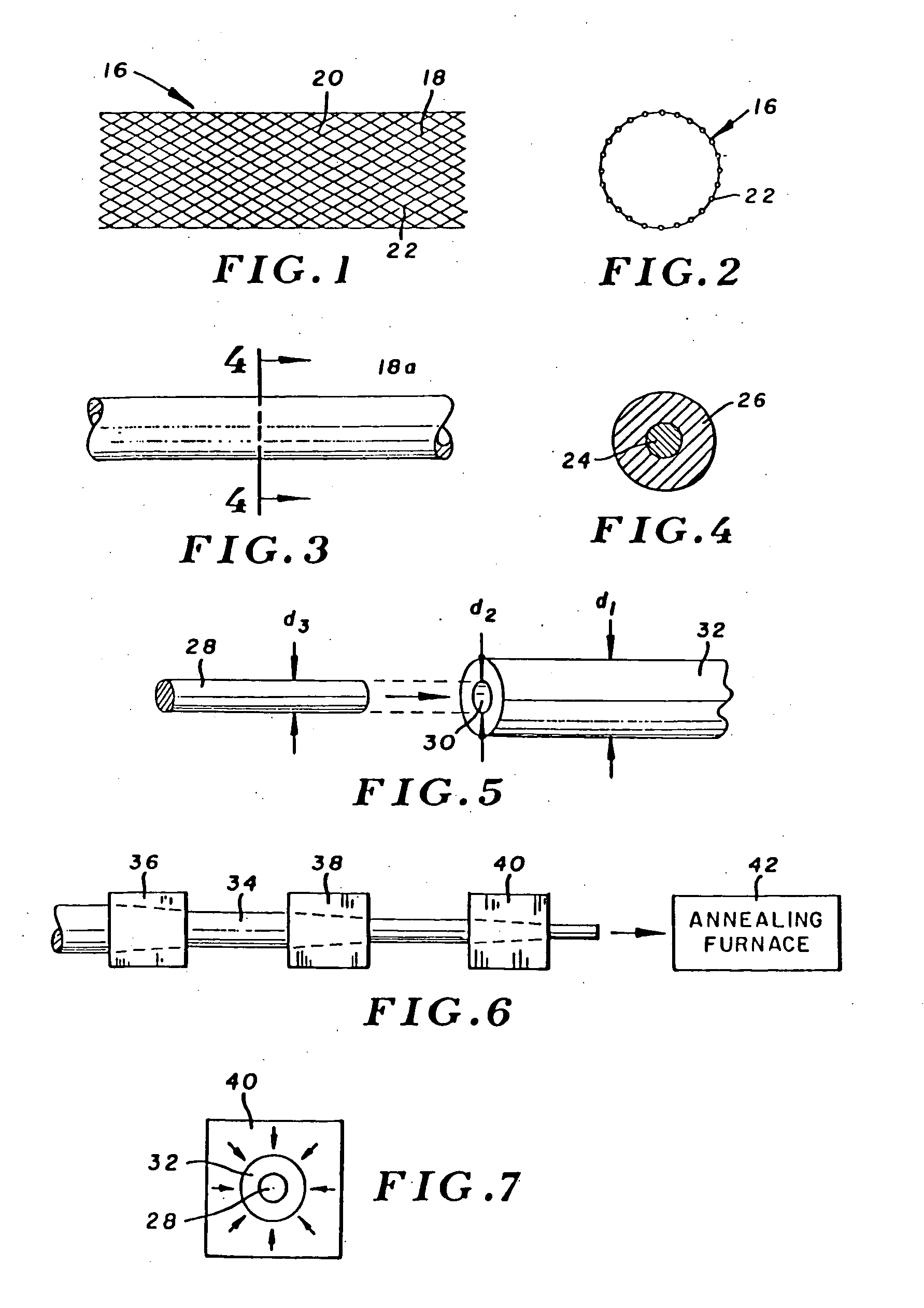

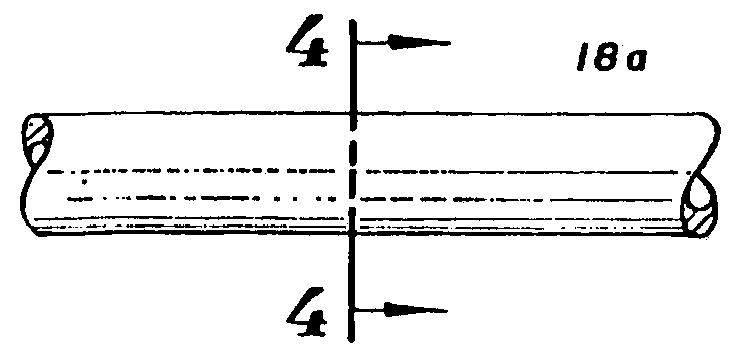

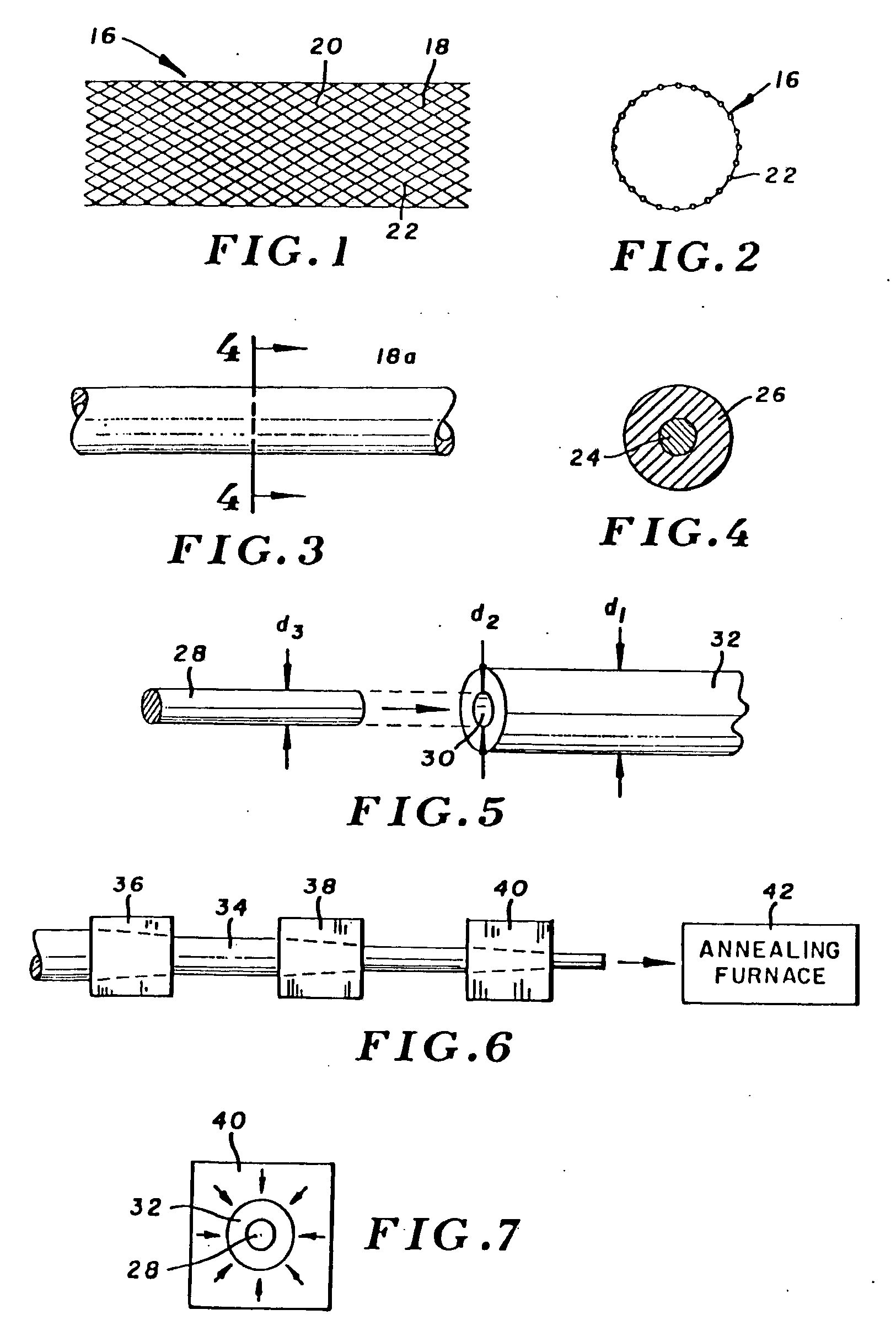

Clad composite stent

InactiveUS20050059889A1Reduce the cross-sectional areaEliminate strainStentsBlood vesselsPlatinumCobalt

A body compatible stent is formed of multiple filaments arranged in at least two sets of oppositely directed helical windings interwoven with one another in a braided configuration. Each of the filaments is a composite including a central core and a case surrounding the core. In the more preferred version, the core is formed of a radiopaque and relatively ductile material, e.g. tantalum or platinum. The outer case is formed of a relatively resilient material, e.g. a cobalt / chromium based alloy. Favorable mechanical characteristics of the stent are determined by the case, while the core enables in vivo imaging of the stent. The composite filaments are formed by a drawn filled tubing process in which the core is inserted into a tubular case of a diameter substantially more than the intended final filament diameter. The composite filament is cold-worked in several steps to reduce its diameter, and annealed between successive cold working steps. After the final cold working step, the composite filament is formed into the desired shape and age hardened. Alternative composite filaments employ an intermediate barrier layer between the case and core, a biocompatible cover layer surrounding the case, and a radiopaque case surrounding a structural core.

Owner:BOSTON SCI SCIMED INC

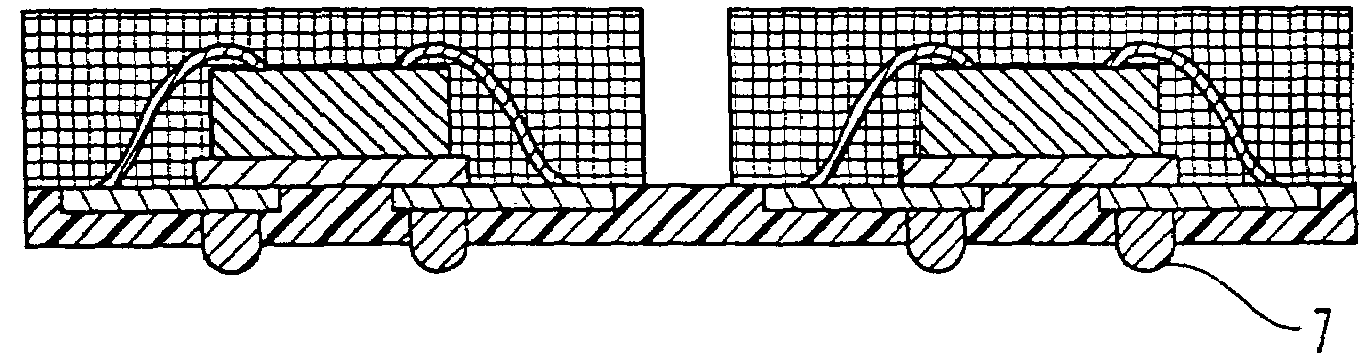

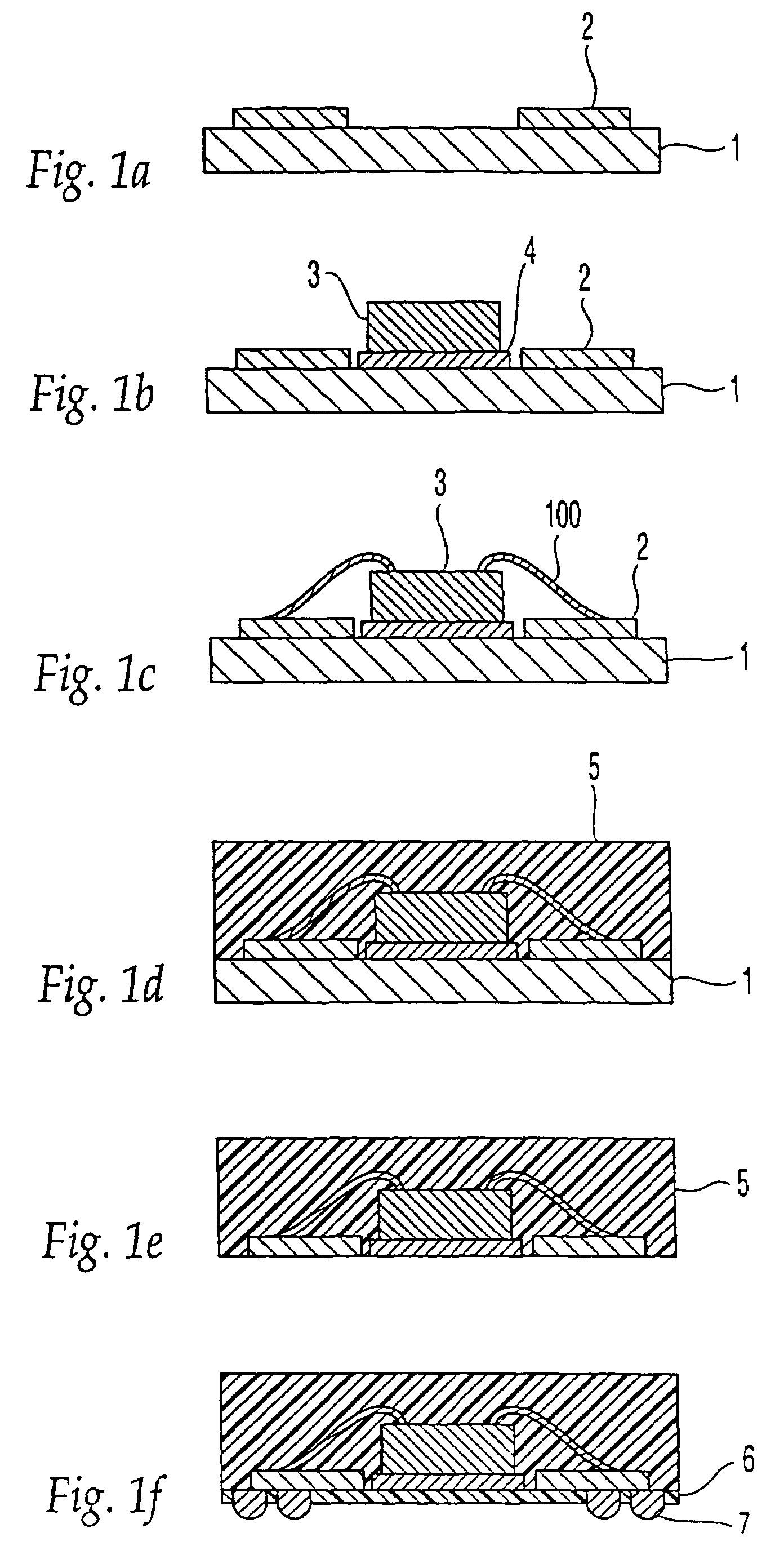

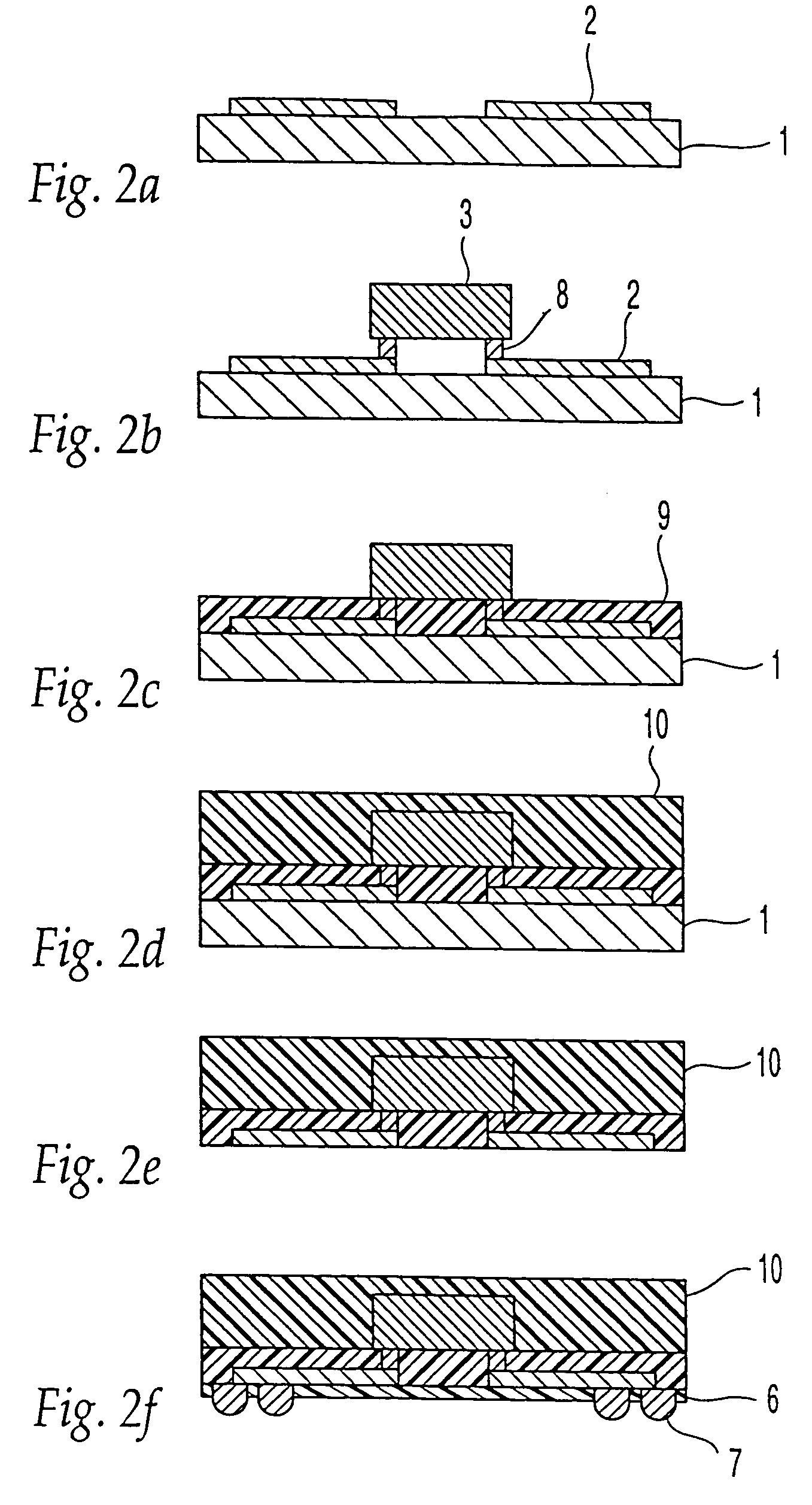

Fabrication process of semiconductor package and semiconductor package

InactiveUS7187072B2Removing residual strainReduce the impactPrinted circuit assemblingSemiconductor/solid-state device detailsResistEpoxy

A semiconductor package substrate is provided, which can meet the move toward high integration of semiconductors. A nickel layer is plated on an electroplated copper foil to form a wiring pattern. An LSI chip is mounted on the copper foil, and terminals of the LSI chip and the wiring pattern are connected by wire bonding, followed by sealing with a semiconductor-sealing epoxy resin. Only the copper foil is dissolved away with an alkali etchant to expose nickel. With a nickel stripper having low copper-dissolving power, the nickel layer is removed to expose the wiring pattern. A solder resist is coated, and a pattern is formed in such a way that connecting terminal portions are exposed. Solder balls are placed at the exposed portions of the wiring pattern and are then fused. The wiring pattern is connected to an external printed board via the solder balls.

Owner:HITACHI CHEM CO LTD

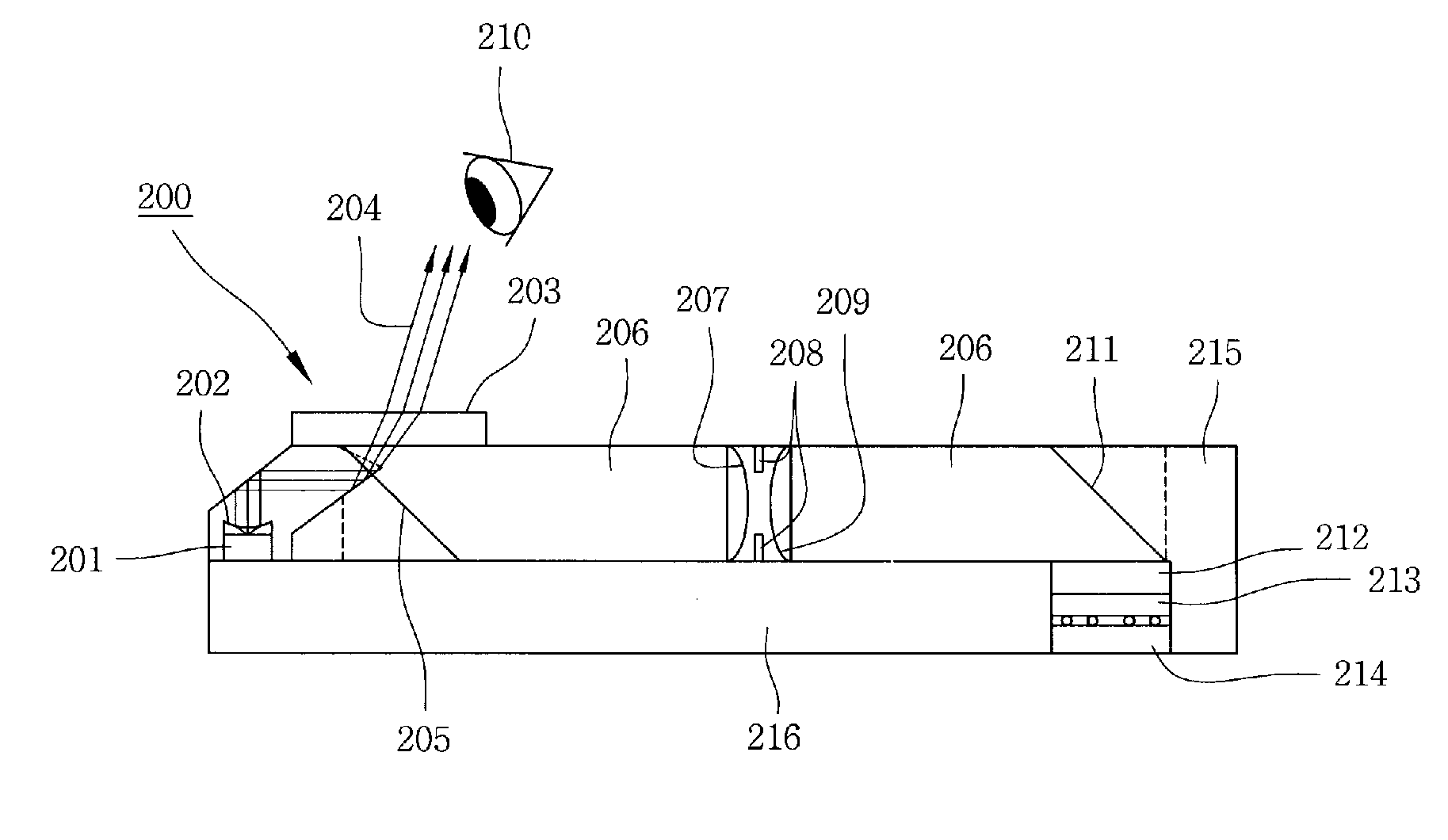

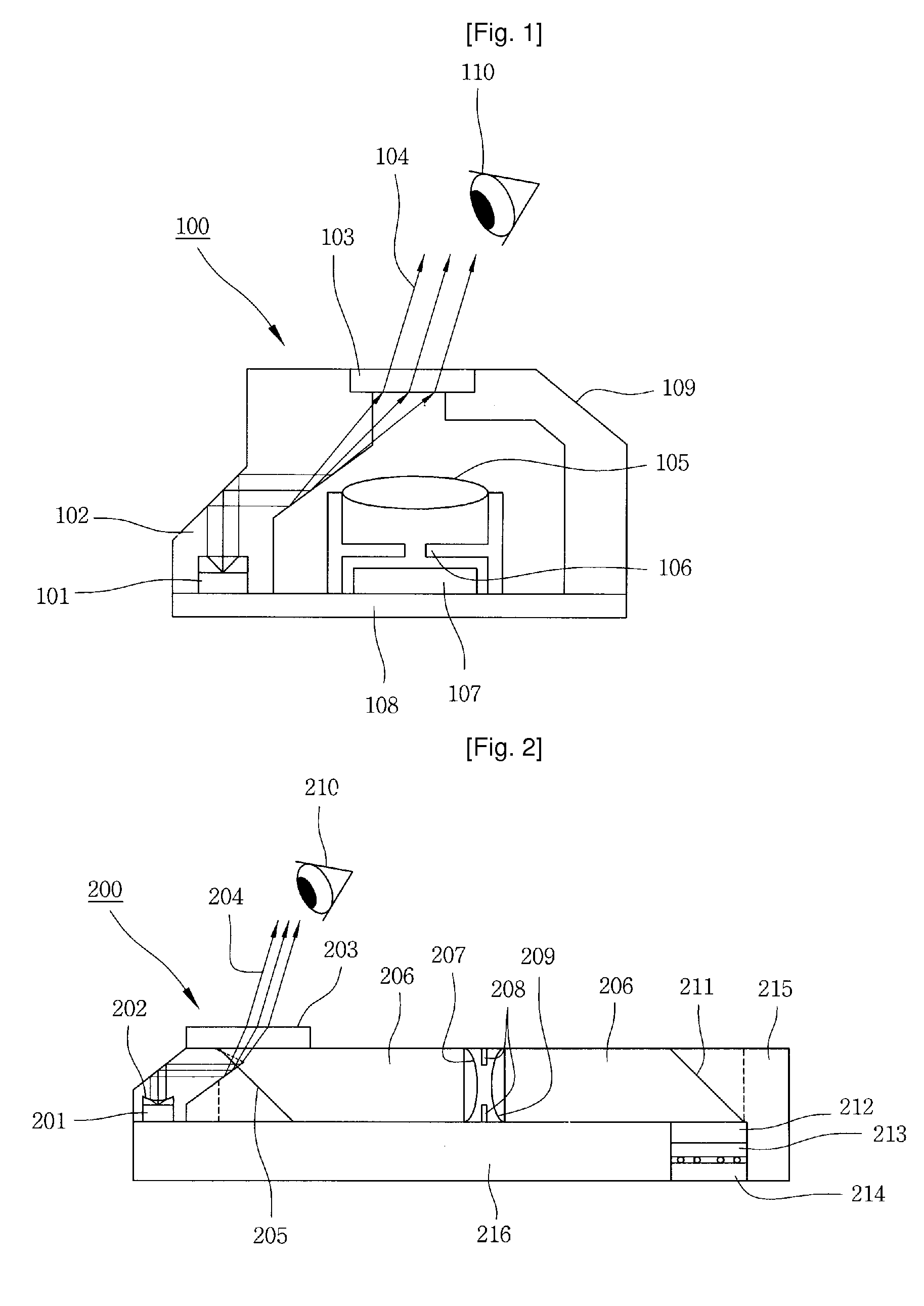

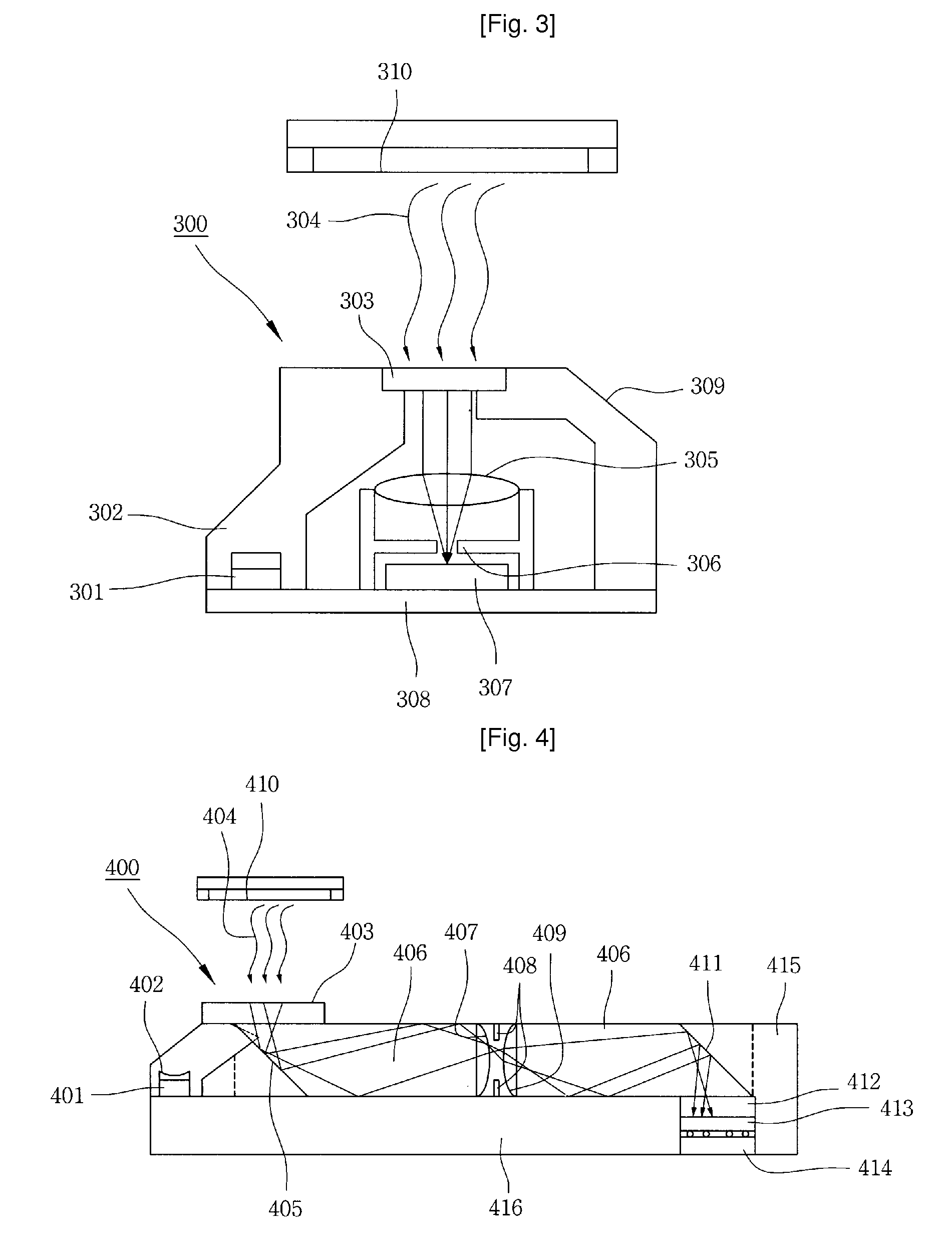

Ultra Thin Optical Pointing Device and Personal Portable Device Having the Same

InactiveUS20080218474A1Eliminate strainMinimize malfunctionCathode-ray tube indicatorsDetails for portable computersInfraredPlastic materials

The present invention relates to an ultra thin optical pointing device, and a personal portable device having the optical pointing device. The optical pointing device includes a PCB (508). An infrared LED (501) is provided on a side of the top surface of the PCB. A cover plate (503) detects motion of a finger, which is a subject. An illumination system (502) transmits light from the infrared LED to the cover plate. An image forming system lens (505) is placed below the cover plate to condense reflected light. An optical image sensor (507) receives a reflected image of the subject and detects motion of the subject. A body tube (509) is provided on a side portion over the PCB. The illumination system, the cover plate and the image forming system lens are made of an optical plastic material capable of passing only a wavelength band of infrared rays.

Owner:CRUCIALTEC

Strained CMOS device, circuit and method of fabrication

ActiveUS20110175166A1Improve performanceEliminate strainSolid-state devicesSemiconductor/solid-state device manufacturingCMOSEngineering

A semiconductor device and fabrication method include a strained semiconductor layer having a strain in one axis. A long fin and a short fin are formed in the semiconductor layer such that the long fin has a strained length along the one axis. An n-type transistor is formed on the long fin, and a p-type transistor is formed on the at least one short fin. The strain in the n-type transistor improves performance.

Owner:GLOBALFOUNDRIES US INC

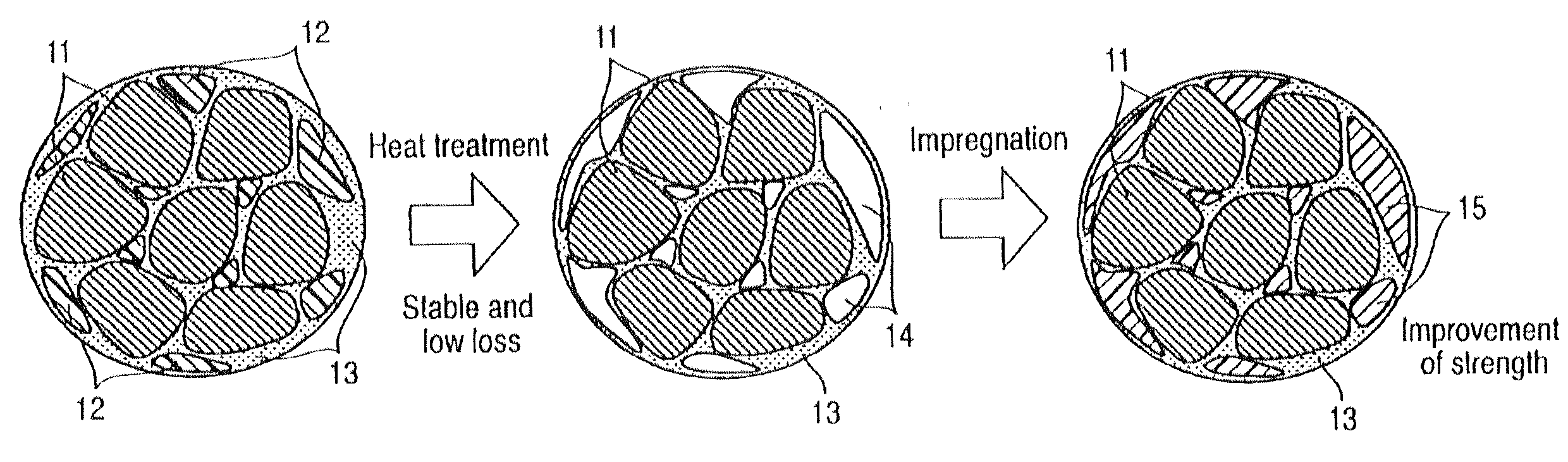

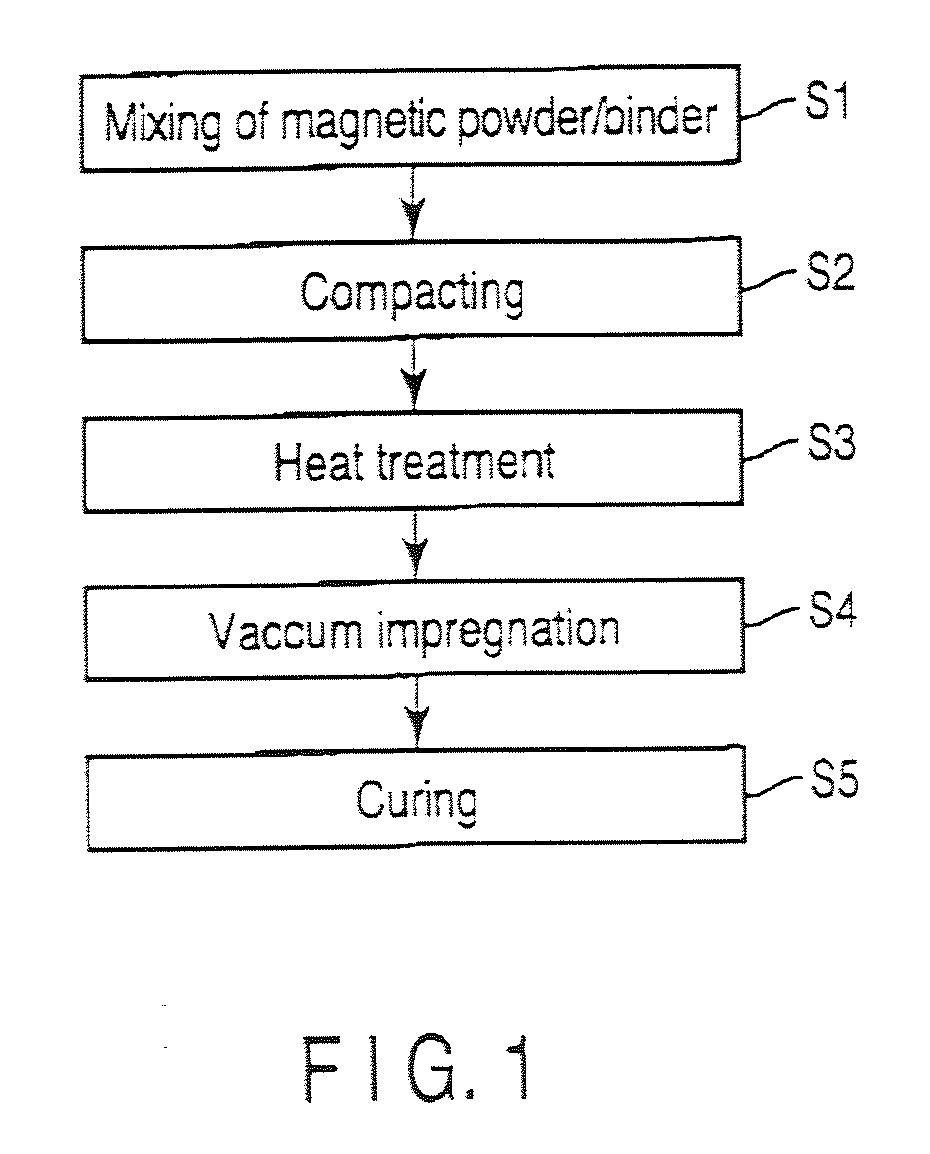

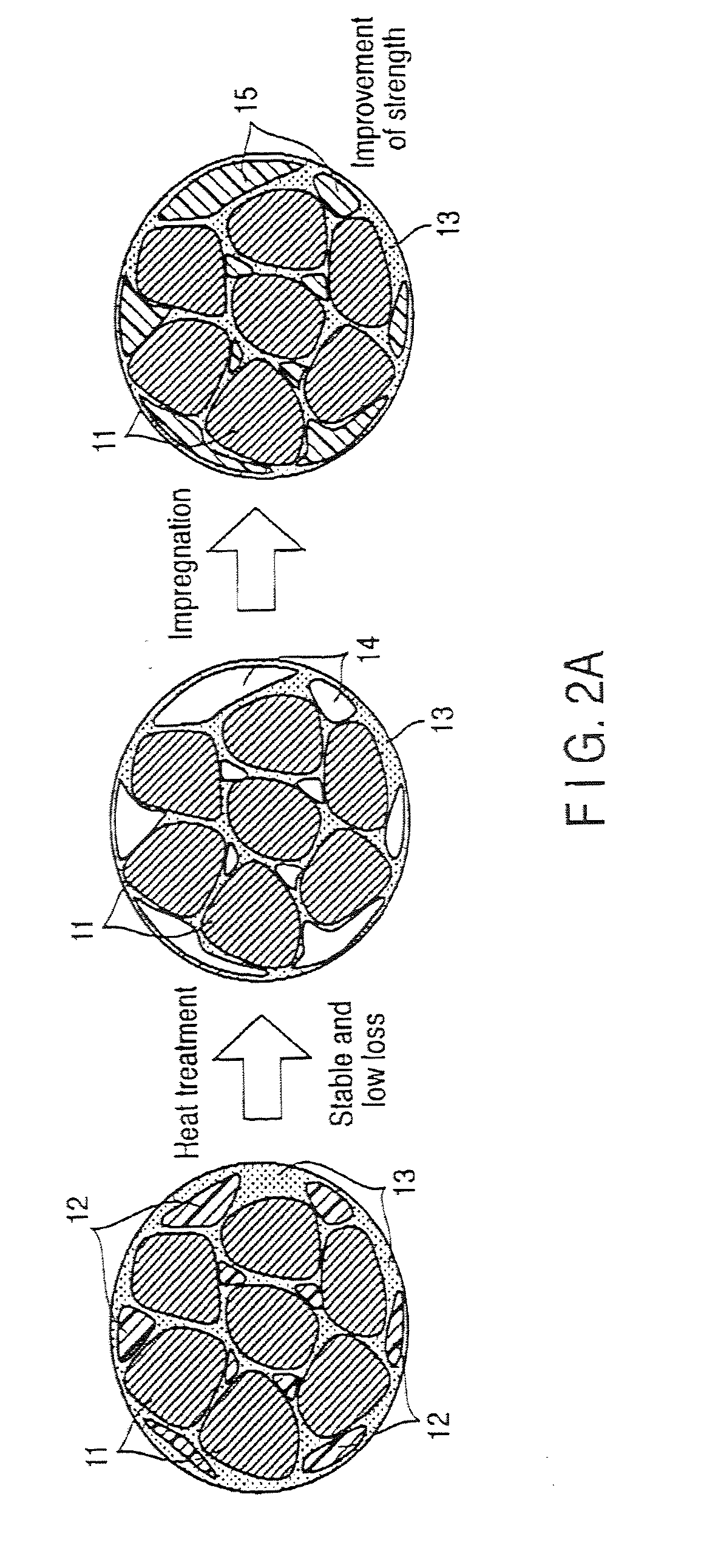

Composite magnetic material and method of manufacturing the same

InactiveUS20110024670A1Good molding effectReduce the amount requiredTransportation and packagingMetal-working apparatusSpherical shapedInductor

Certain embodiments provide a composite magnetic material for an inductor, wherein a non-magnetic material contains a first binder as a compacting additive, and is added to and mixed with the soft magnetic metal powder, and a second binder that is impregnated to a compact as a binder after the heat treatment of the compact obtained by adding the first binder to the soft magnetic metal powder and compacting it, and the soft magnetic metal powder contains 40% by mass or more (including 100%) of spherical particles of which the ratio L2 / L1 between a perimeter L1 of a particle cross-section in the two dimensional plane view and a perimeter L2 of a circle having equivalent cross-sectional area is 0.5 or more.

Owner:TOHO ZINC

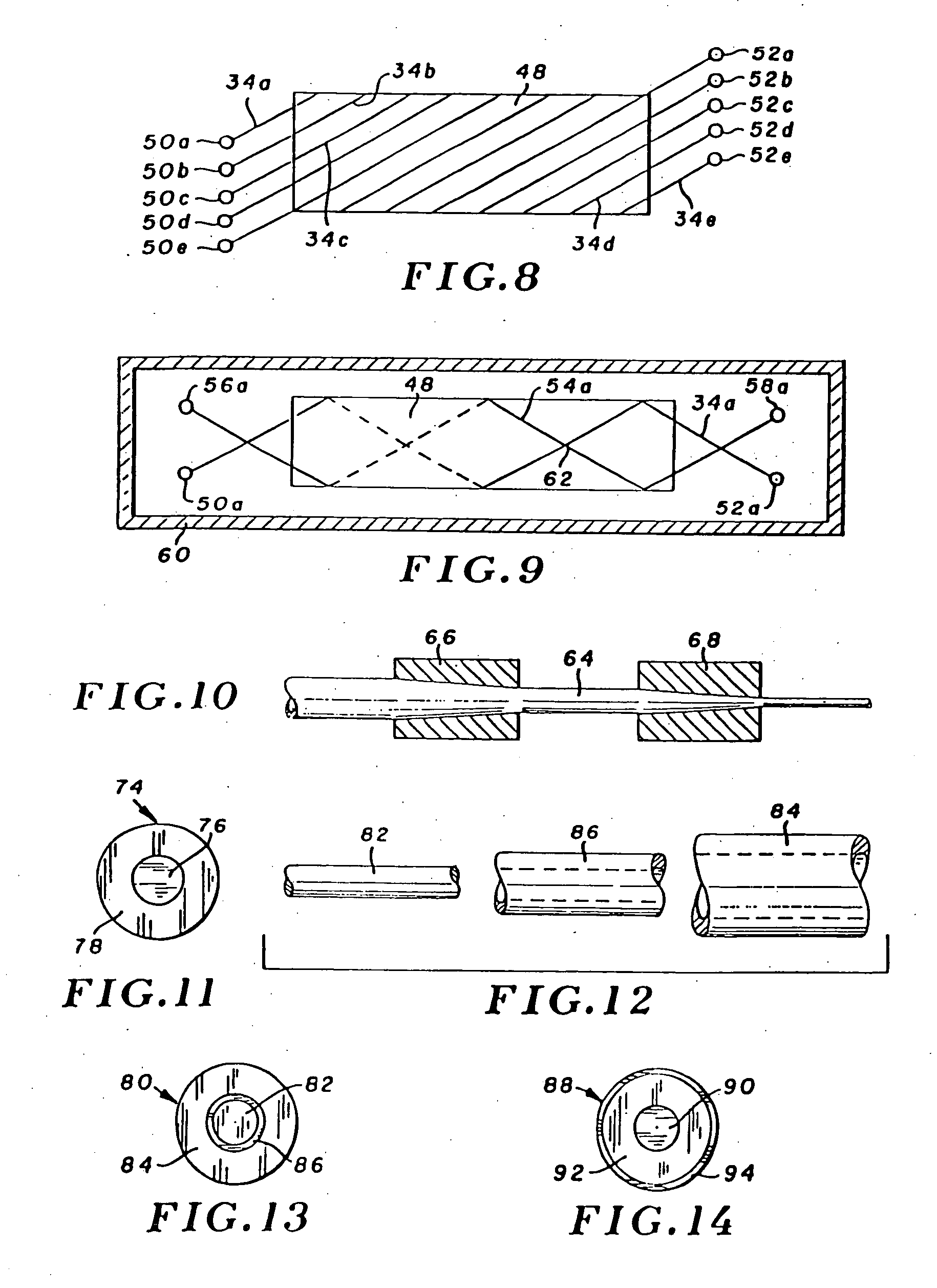

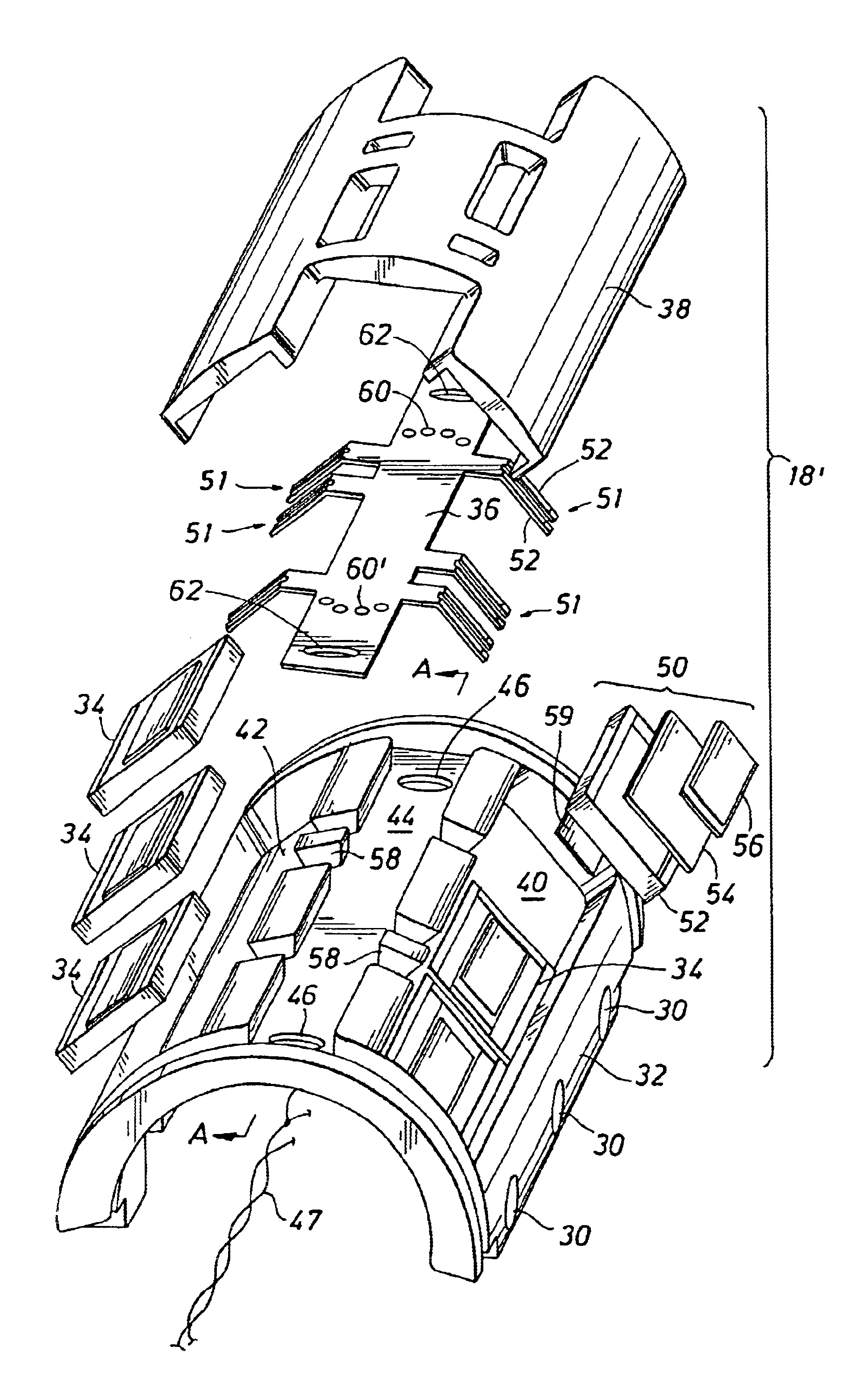

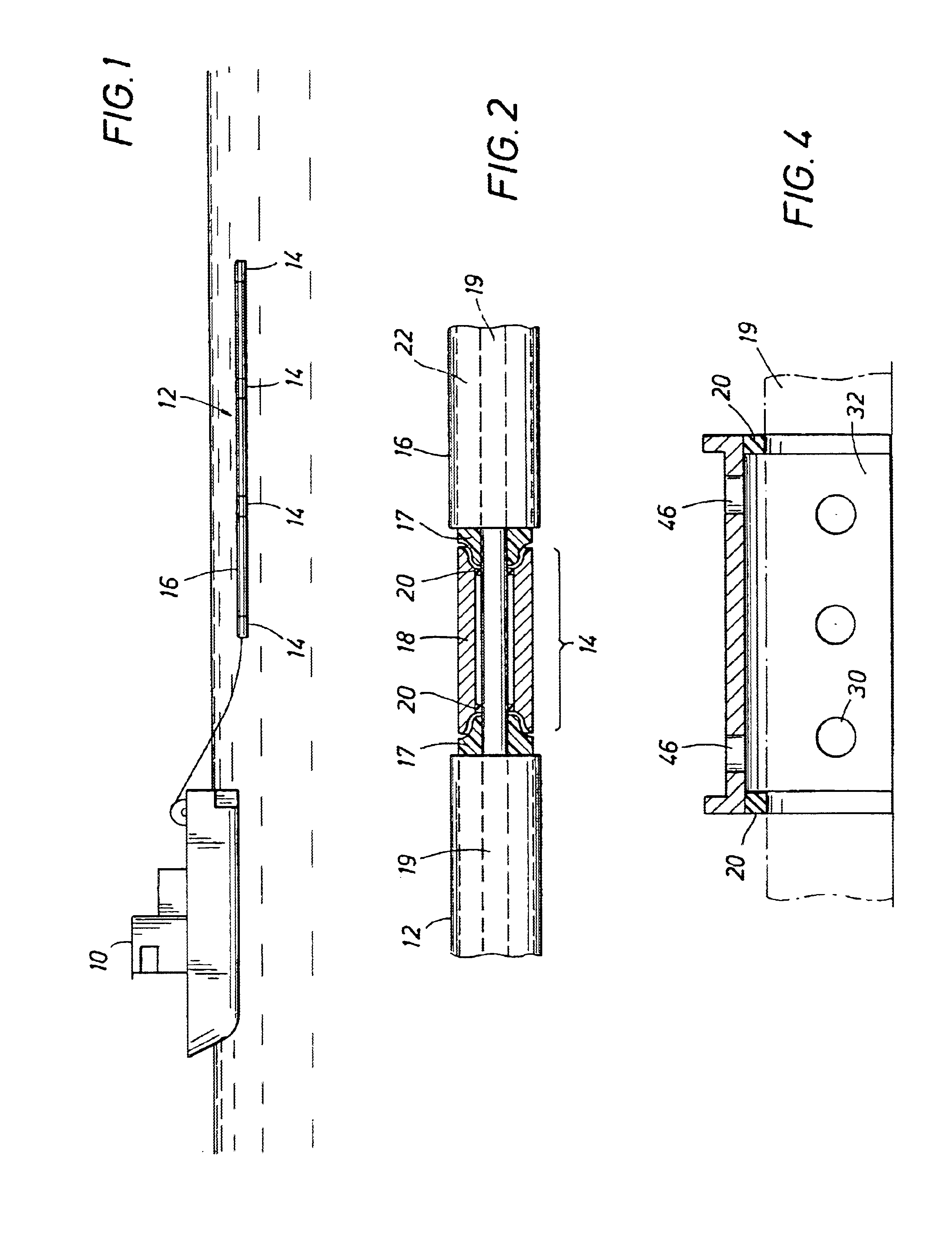

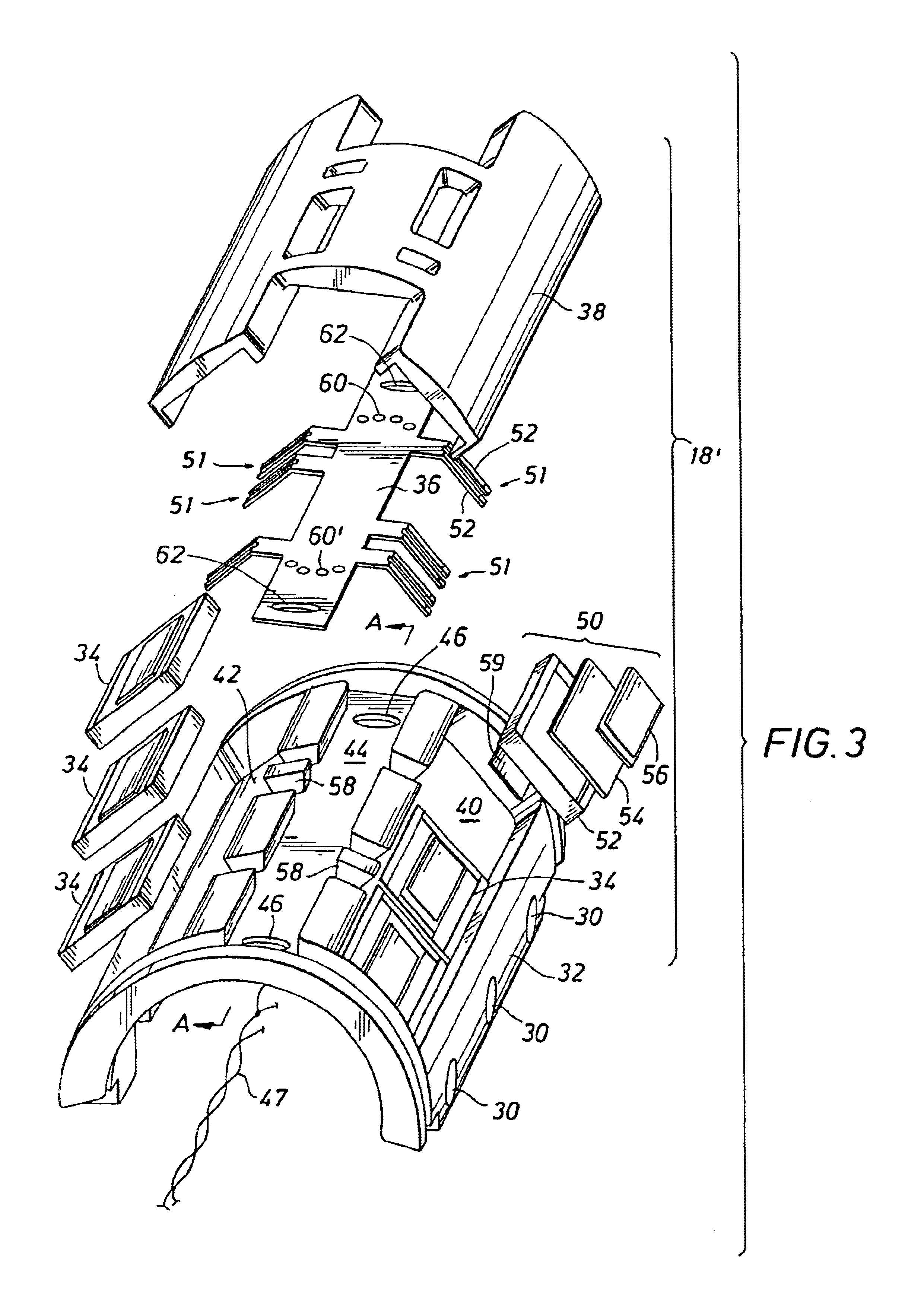

Solid marine seismic cable

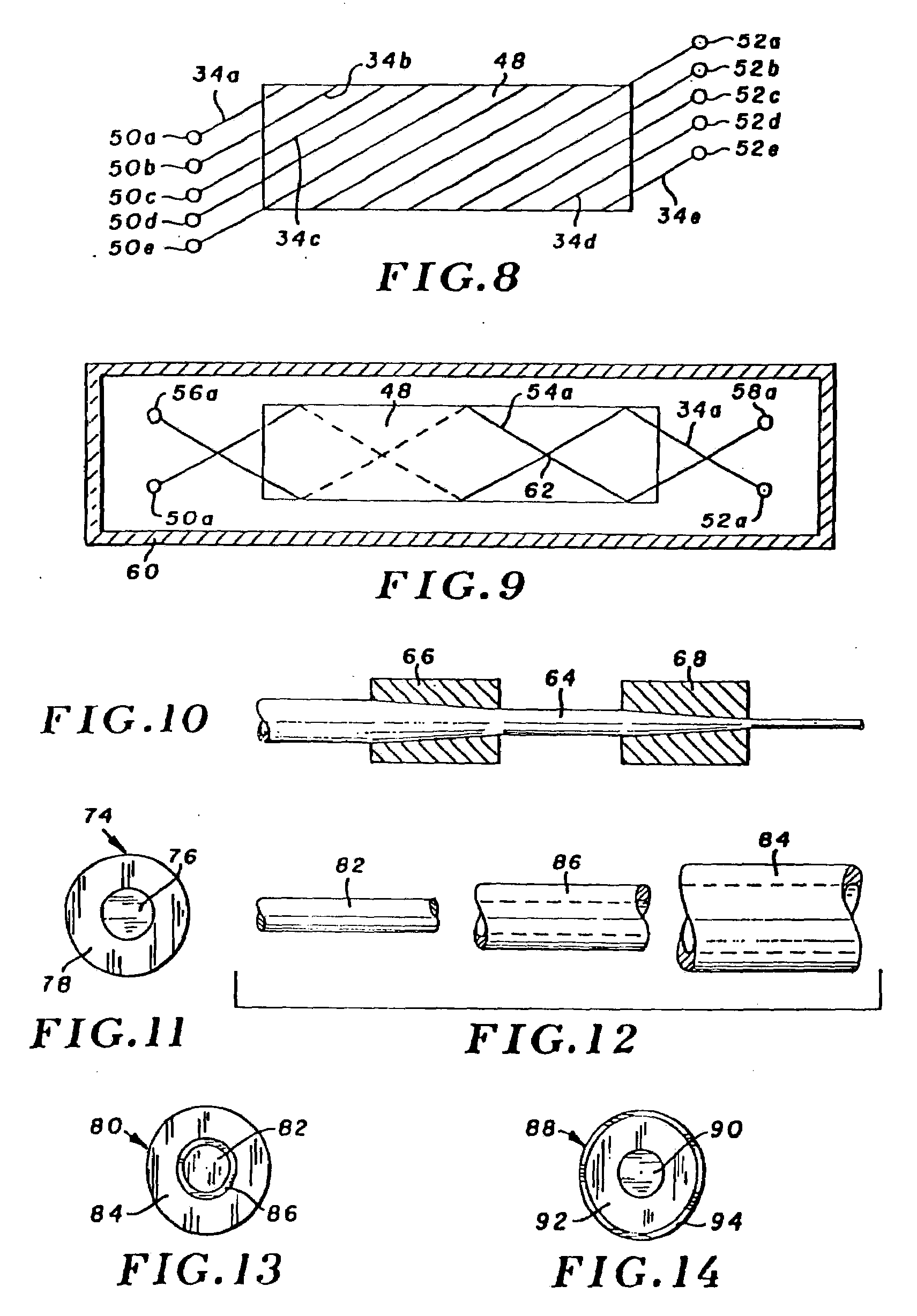

InactiveUS6853604B2Enhance total acoustic signal receivedGood effectSubsonic/sonic/ultrasonic wave measurementSeismic signal receiversFlexible circuitsAdhesive

A support structure for piezoelectric elements in a marine seismic cable is provided. The support structure comprises upper and lower cylindrical halves, each with channels formed therein. Two axial channels are adapted to retain three piezoelectric elements each. A third axial channel, positioned between the sensor element channels, is adapted to retain a flexible circuit. Transverse channels between the sensor element channels and the circuit channels accommodate extension from the flexible circuit. The piezoelectric elements are mounted within their respective channels with a resilient pad with adhesive on both sides. The piezoelectric elements are graded so that any group of three piezoelectric elements exhibits approximately the same sensitivity as any of the other three groups of piezoelectric elements on the support structure.

Owner:SERCEL INC

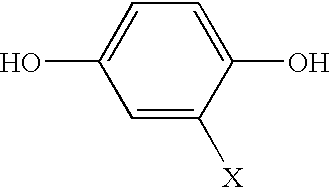

Imaging member

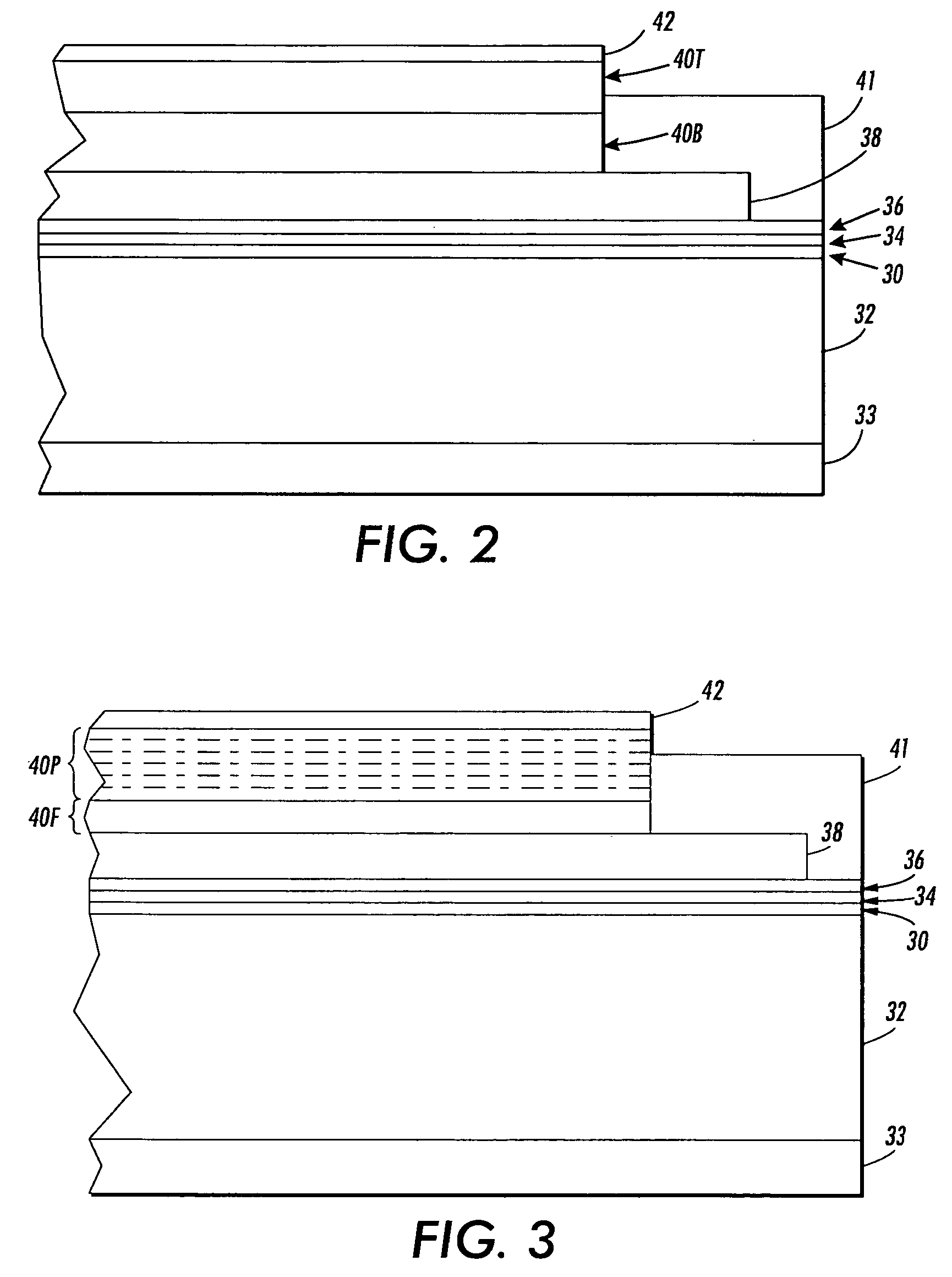

InactiveUS20060099525A1Reduce and eliminate presenceEliminates internal strainElectrographic process apparatusCoatingsEngineeringCarbonate

An electrostatographic imaging member formulated with a liquid carbonate is provided. The imaging electrostatographic member exhibits improved service life.

Owner:XEROX CORP

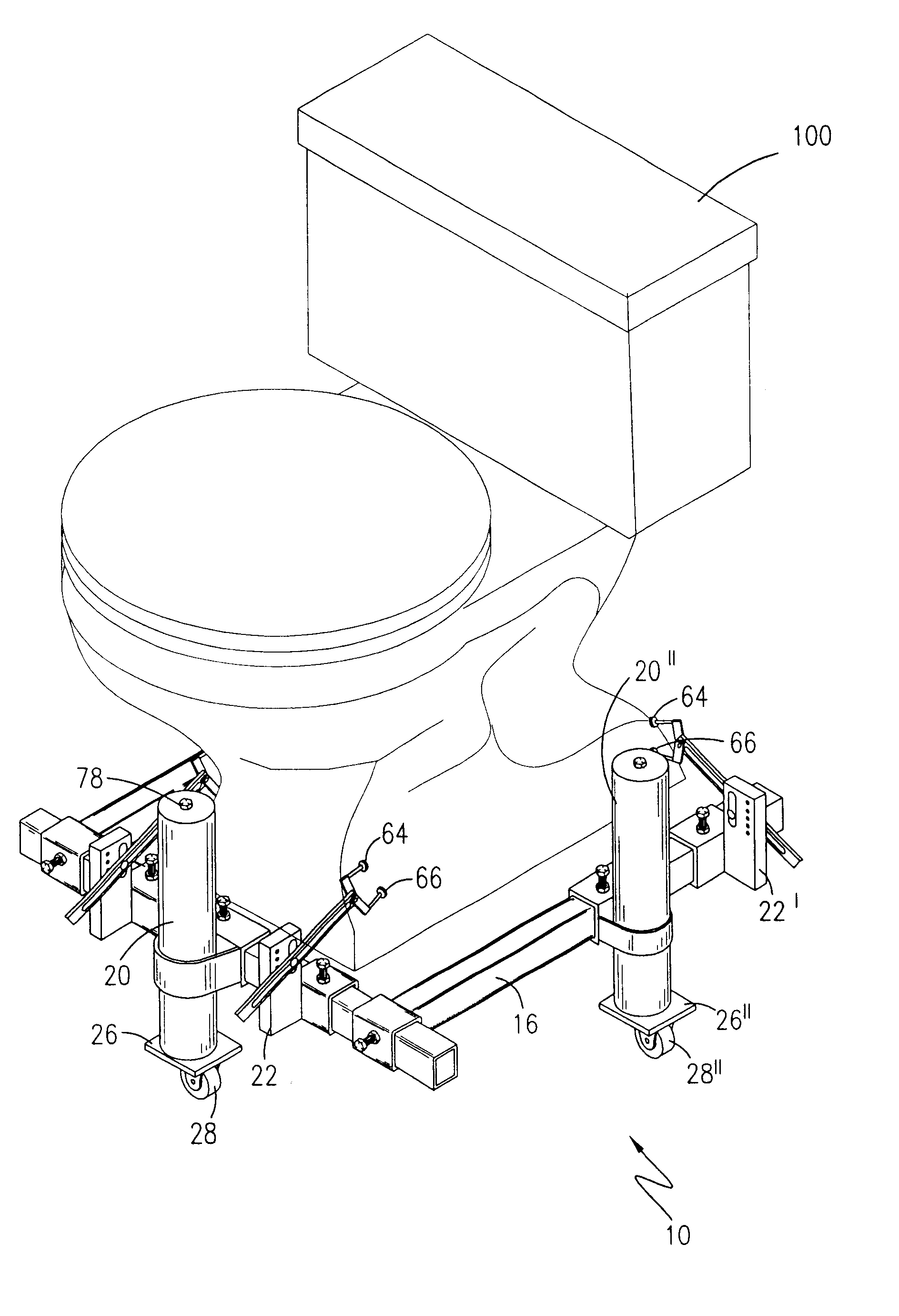

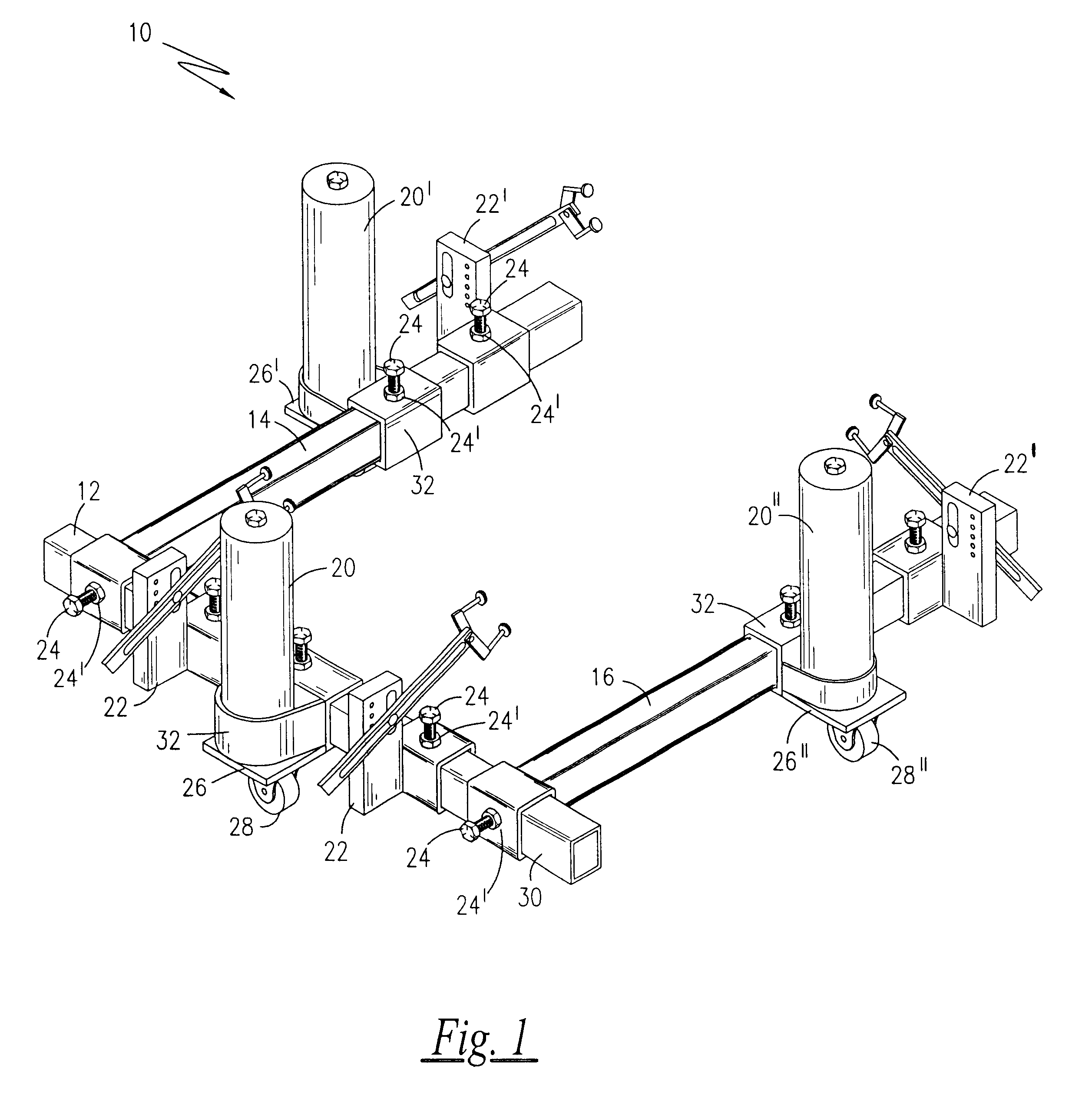

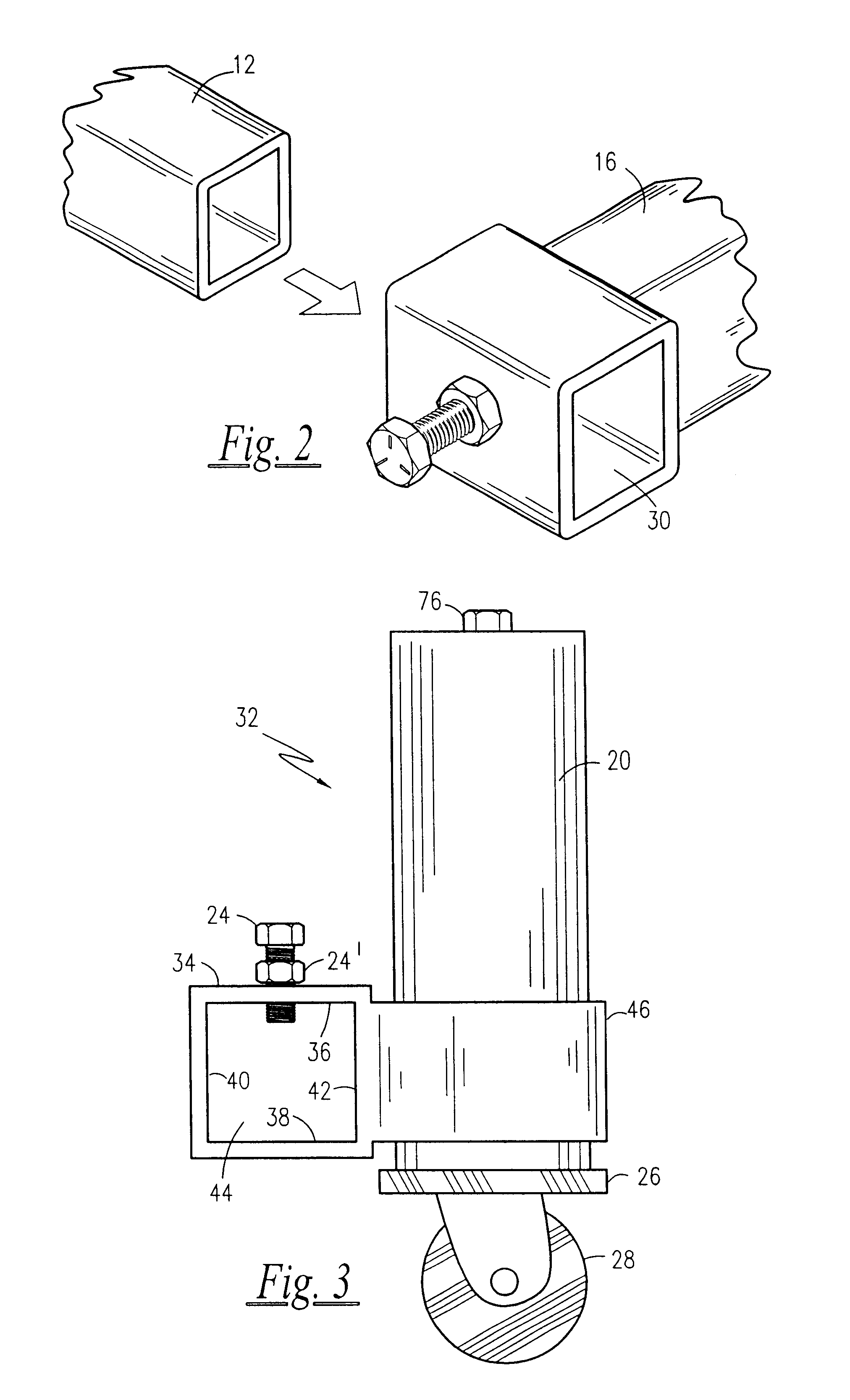

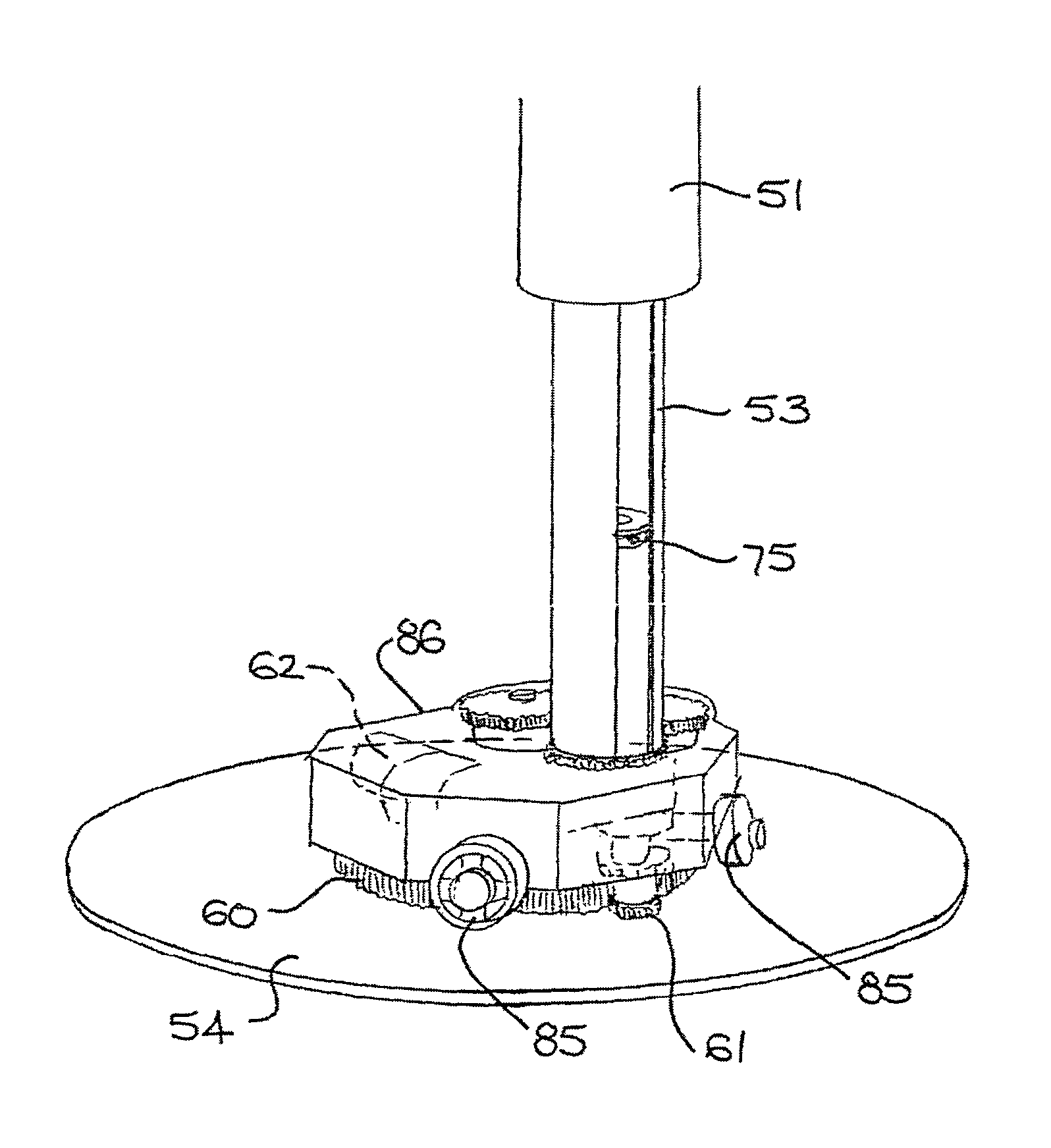

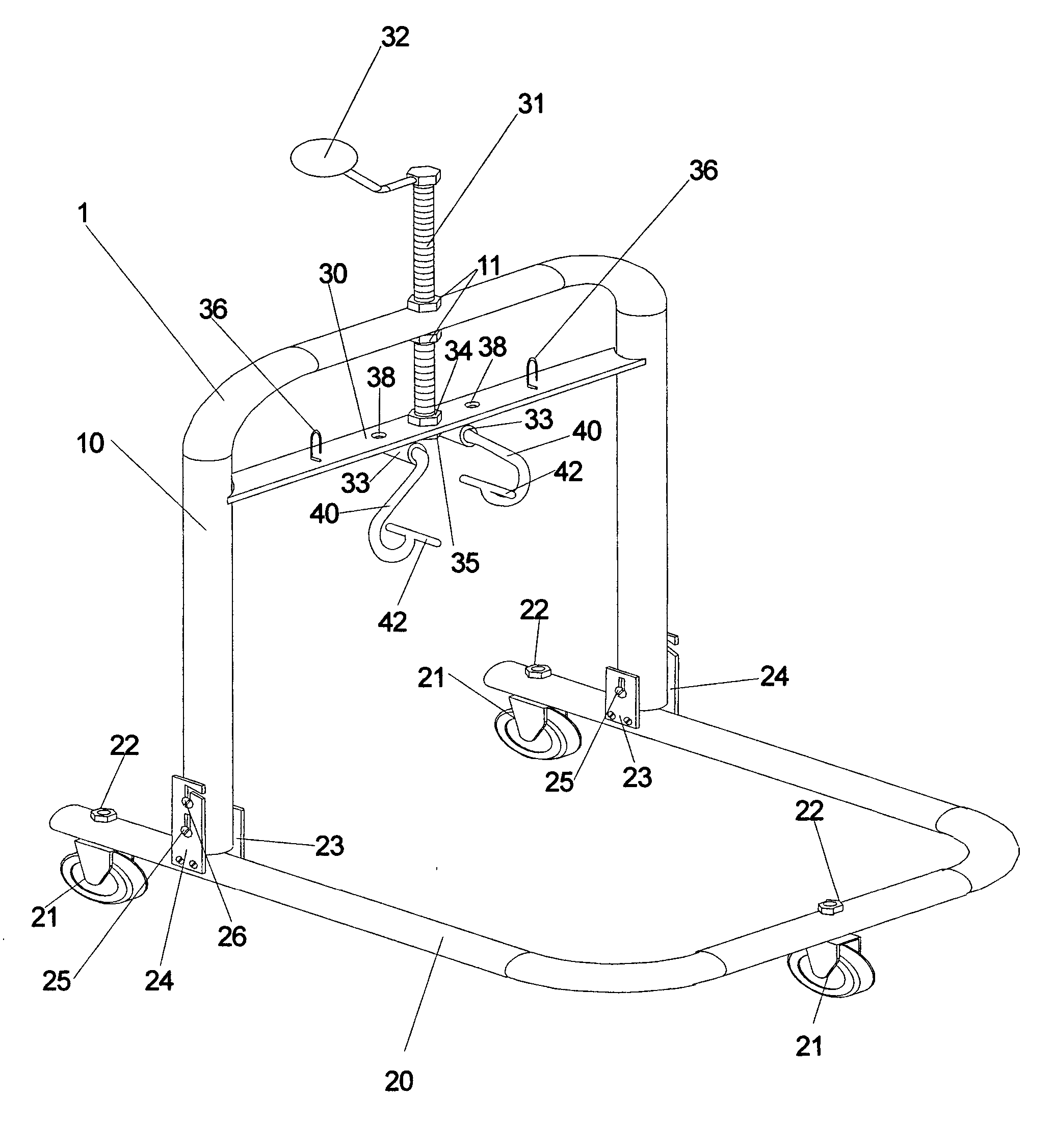

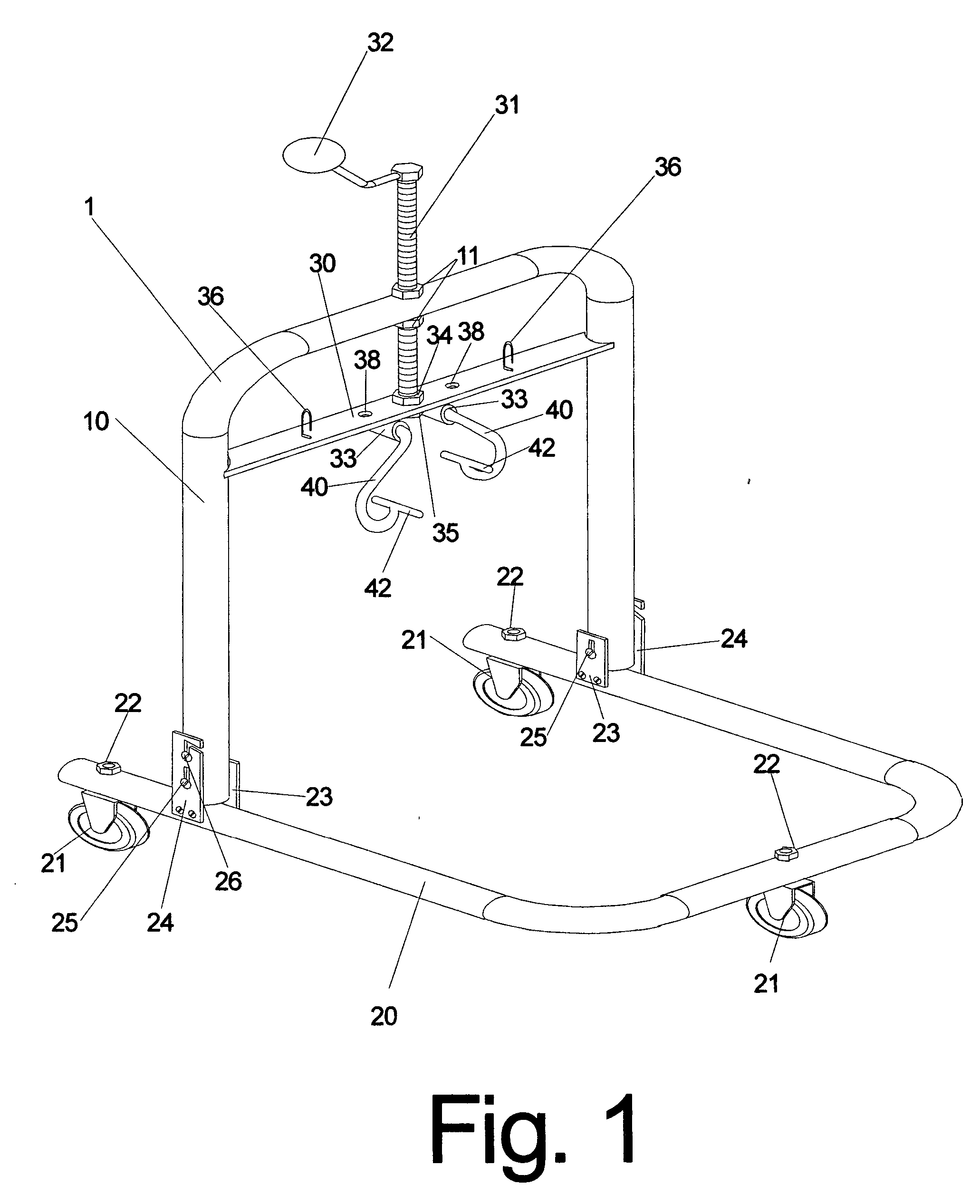

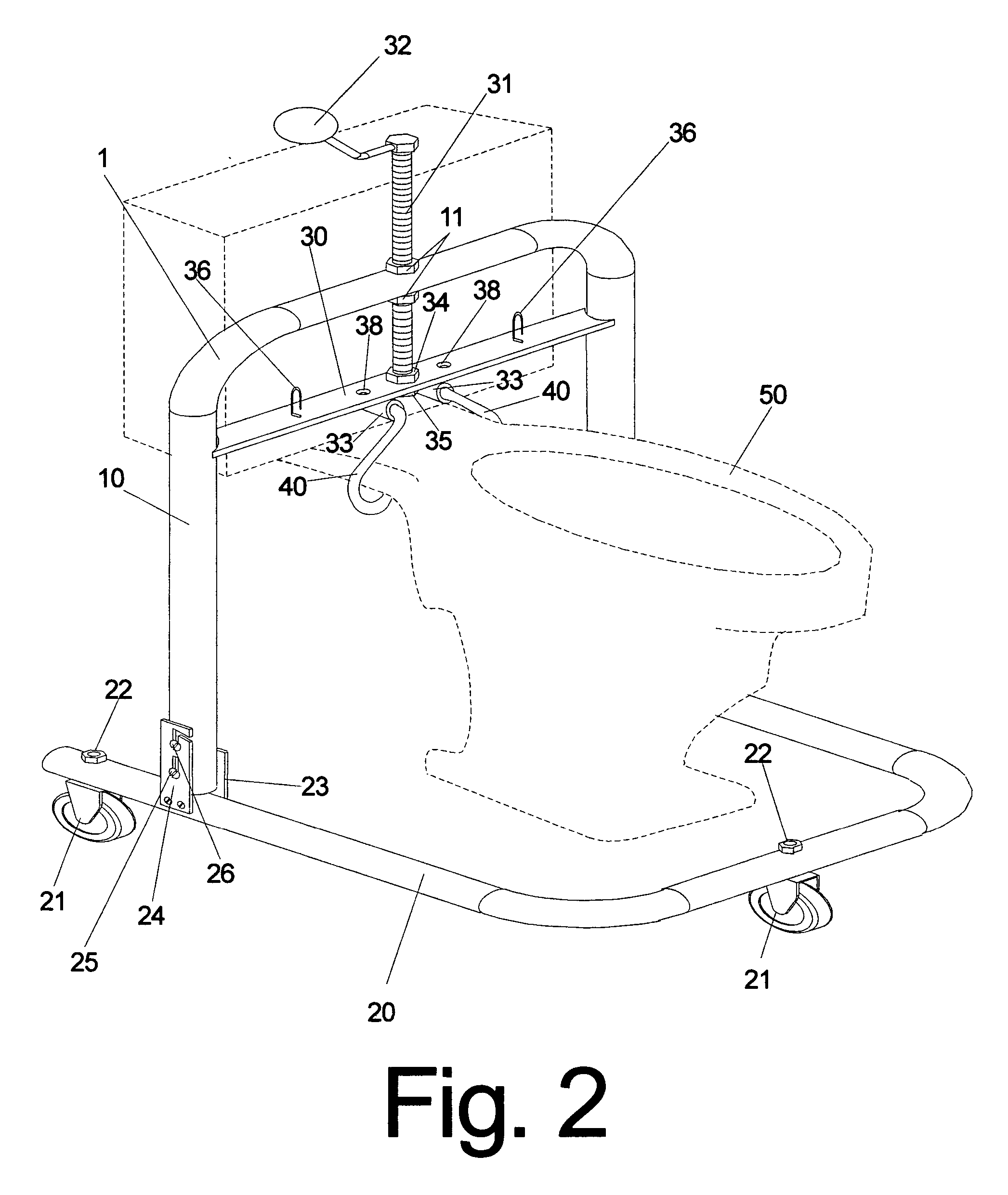

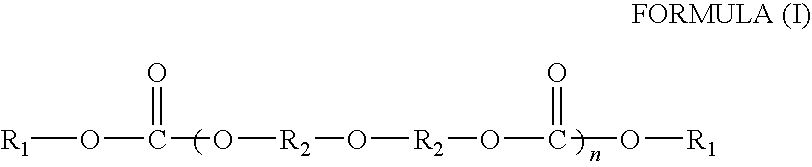

Adjustable toilet dolly

InactiveUS6752379B1Eliminating muscle strainAvoid Back InjuriesSupporting partsMobile jacksEngineeringToilet

A toilet dolly is a "U"-shaped frame that slide around either side of the toilet bowl. The frame comprises two arms that are adjustable to fit any size bowl or any difficult installation and are connected to a cross-arm. Padded lifting arms are provided to lock in place around the bowl. The two toilet mounting nuts removed, a series of three jack screws are raised in an alternating fashion to allow the bowl assembly to clear the floor-mounted fastening bolts. Once clear, the bowl can be rolled out of the bathroom. The bowl can be reinstalled by a similar but reverse process. The actually raising of the jack screw can be accomplished with an electrical drill, including cordless drills, and / or a ratchet.

Owner:WALL RICHARD L

Clad Composite Stent

A body compatible stent is formed of multiple filaments arranged in at least two sets of oppositely directed helical windings interwoven with one another in a braided configuration. Each of the filaments is a composite including a central core and a case surrounding the core. In the more preferred version, the core is formed of a radiopaque and relatively ductile material, e.g. tantalum or platinum. The outer case is formed of a relatively resilient material, e.g. a cobalt / chromium based alloy. Favorable mechanical characteristics of the stent are determined by the case, while the core enables in vivo imaging of the stent. The composite filaments are formed by a drawn filled tubing process in which the core is inserted into a tubular case of a diameter substantially more than the intended final filament diameter. The composite filament is cold-worked in several steps to reduce its diameter, and annealed between successive cold working steps. After the final cold working step, the composite filament is formed into the desired shape and age hardened. Alternative composite filaments employ an intermediate barrier layer between the case and core, a biocompatible cover layer surrounding the case, and a radiopaque case surrounding a structural core.

Owner:BOSTON SCI SCIMED INC

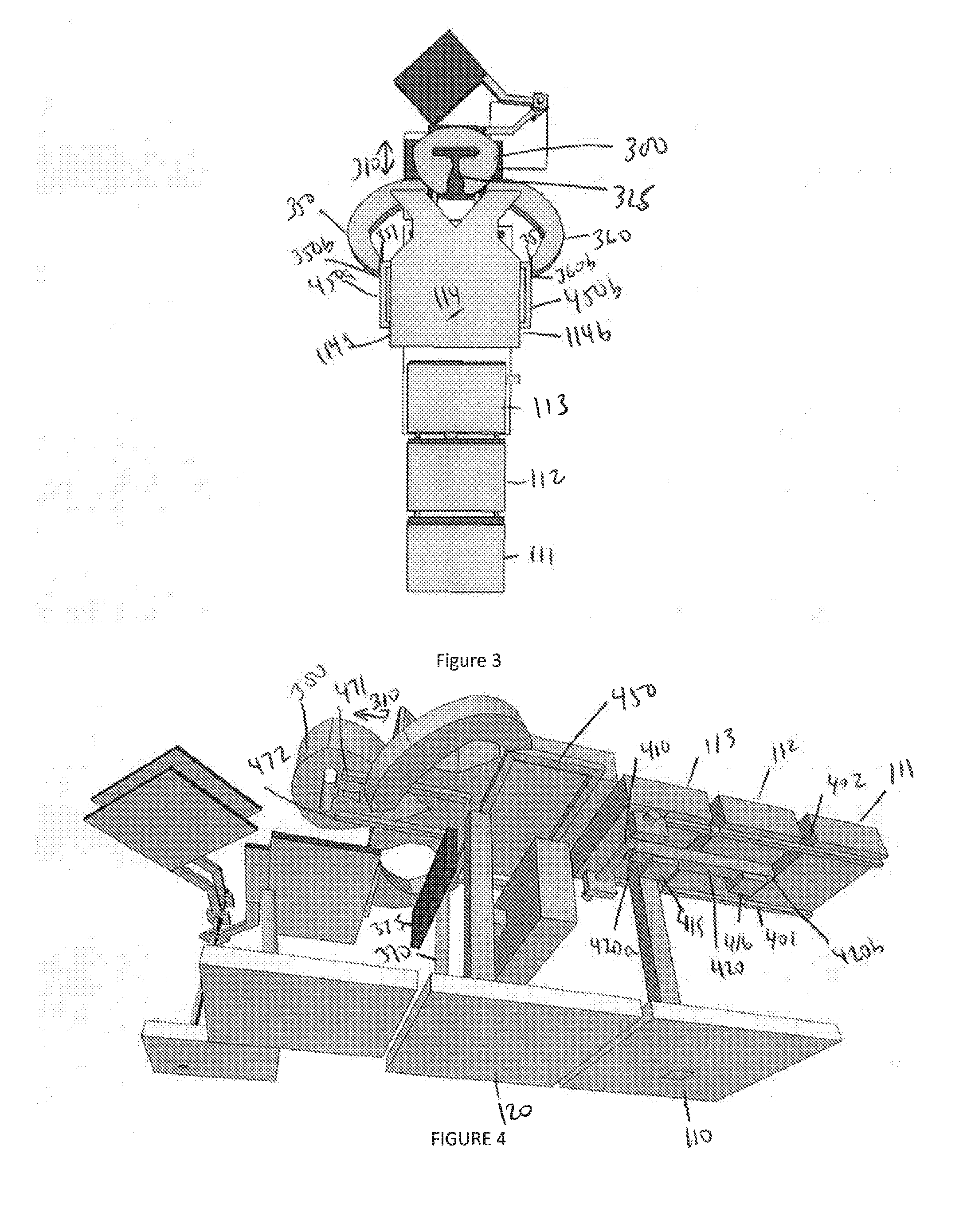

Freestanding self-propelled device for moving objects

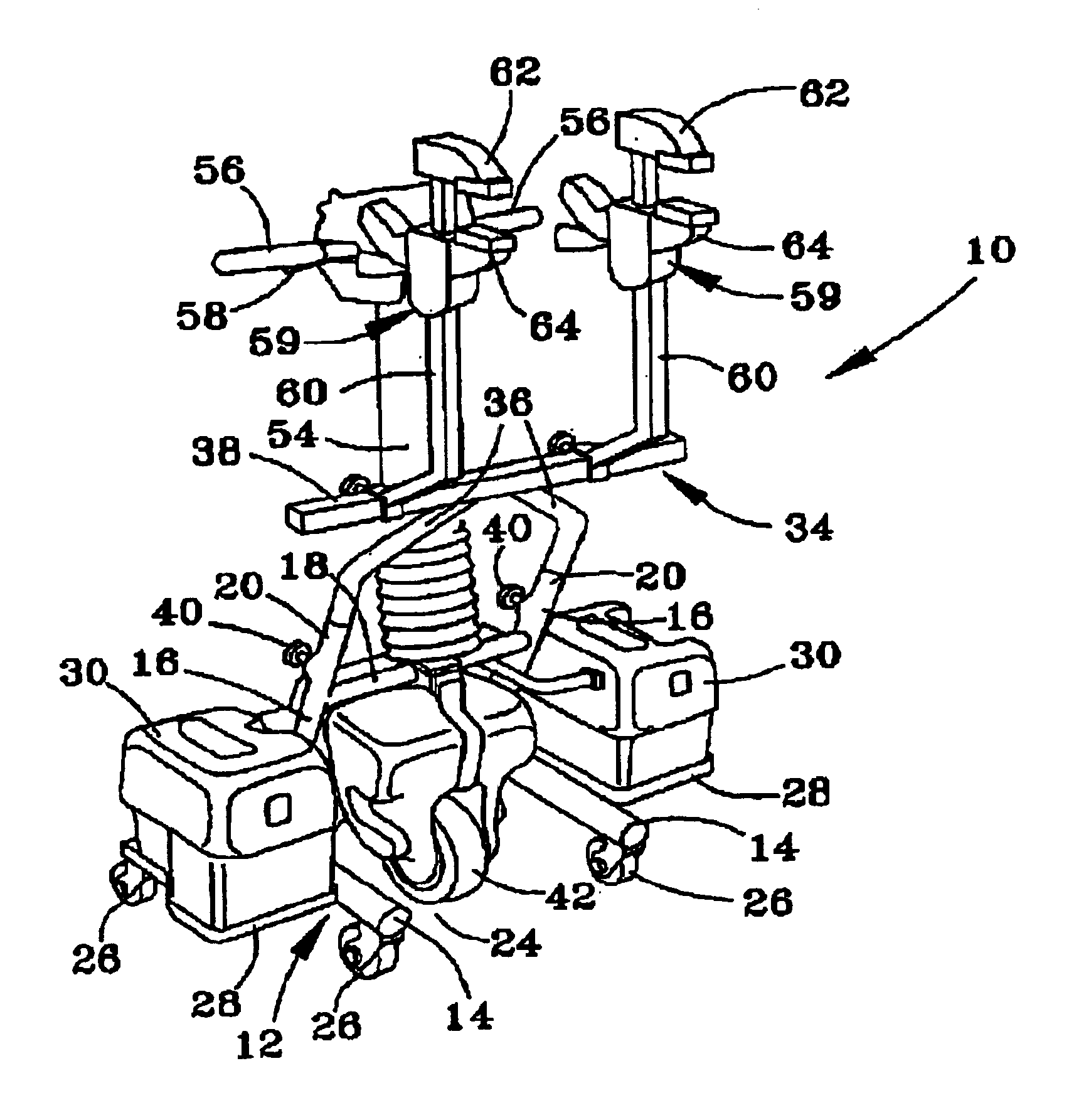

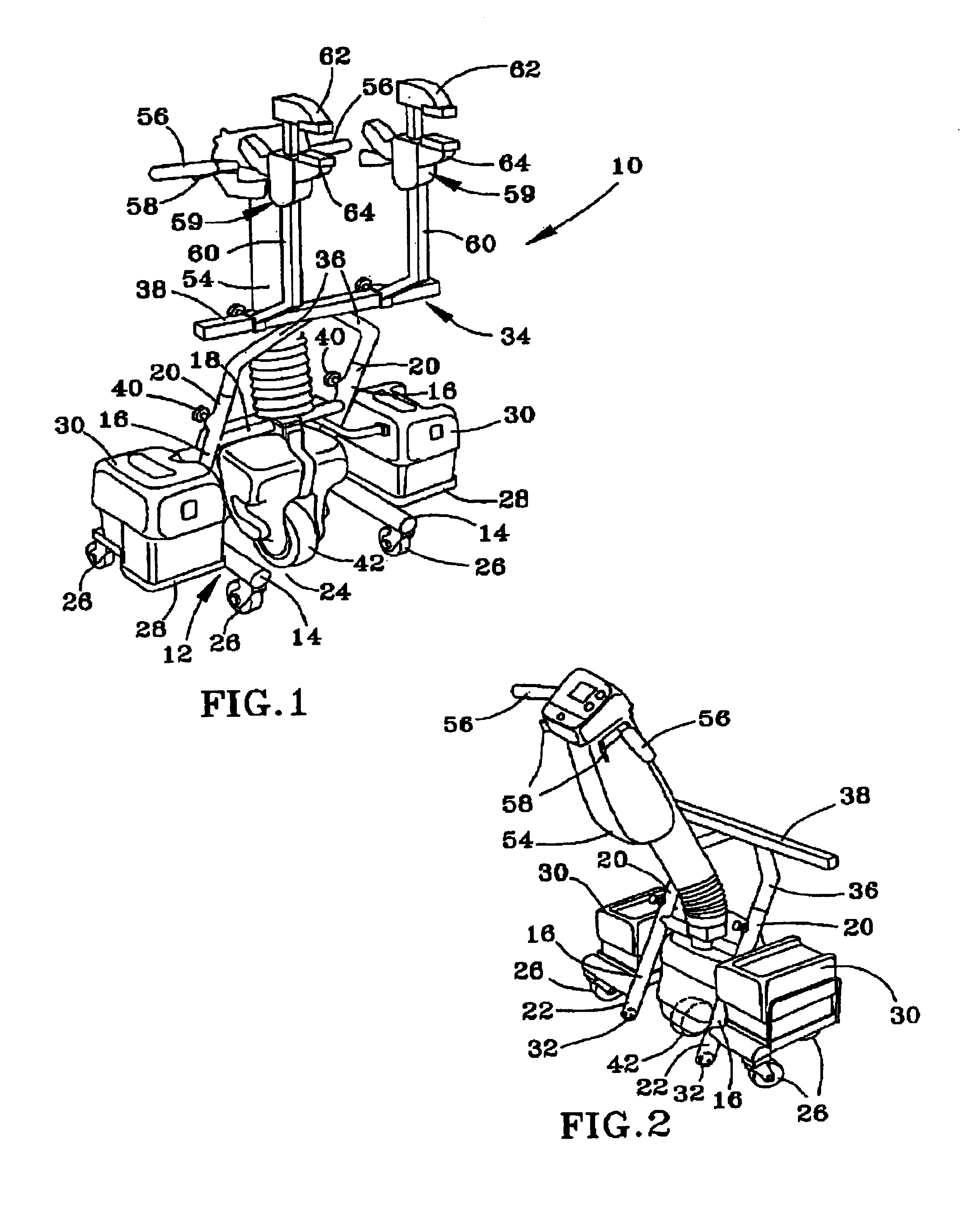

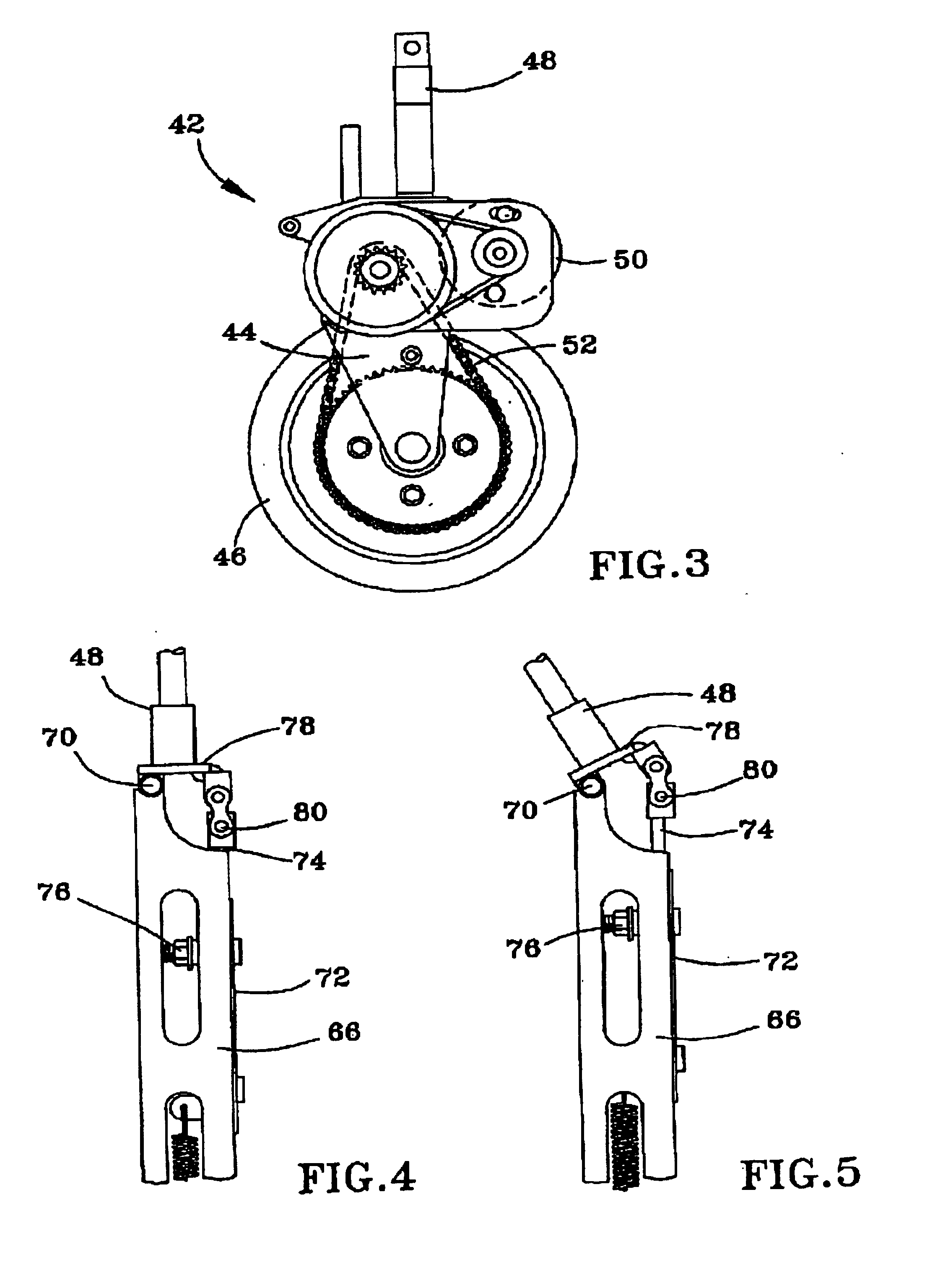

InactiveUS6938711B2Eliminate strainEasy to operateWheelchairs/patient conveyanceTractorsMotor driveDrive wheel

A freestanding self-propelled device for moving objects. The device includes a chassis having lower frame portions and upright frame portions. A single motor-driven drive wheel is centrally located between the lateral ends of the chassis and coupled to the chassis so as to be pivotable about a substantially vertical axis. The drive wheel is located between sets of support wheels coupled to the lower frame portion of the chassis. In combination, the drive wheel and the support wheels result in the device being freestanding. The drive wheel projects below the sets of support wheels so that the device is supported by the drive wheel and by only one of each set of support wheels at any given time, thereby establishing a three-point contact with the surface supporting the device. A tiller equipped with controls is pivotably coupled to the drive wheel for pivoting the drive wheel about its vertical axis.

Owner:PIPP MOBILE STORAGE SYST

Processing process of automobile engine crank shaft

The invention provides a processing process of an automobile engine crank shaft. The process comprises the following processing steps of (1) blank forging; (2) coarse tuning: coarse turning of a main shaft neck and a connecting rod neck is carried out; (3) coarse drilling: coarse drilling of a main oil hole is carried out; (4) annealing heat treatment; (5) semi-finish turning: semi-finish turning is carried out on the main shaft neck and the connecting rod neck; (6) tempering; (7) fine turning: fine turning is carried out on the main shaft neck and the connecting neck; (8) coarse and fine grinding: coarse and fine grinding is carried out on the main shaft neck and the connecting rod neck; (9) hole drilling: coarse drilling, expanding and reaming of balance block installing holes and inclined oil holes are carried out; (10) compounding reinforcing; (11) rolling processing: each processed hole is subjected to rolling pressing processing; (12): the main shaft neck and the connecting rod neck are subjected to polishing processing; (13) anti-rust processing; (14) inspection and packaging. The process solves three problems of low rigidity intensity, poor wear resistance and good lubrication performance in the existing automobile engine crank shaft production process, so that the finally produced crank shaft has the sufficient rigidity and intensity, good impact load bearing capability and good abrasion resistance and lubrication performance.

Owner:ANHUI JINQINGLONG MACHINERY

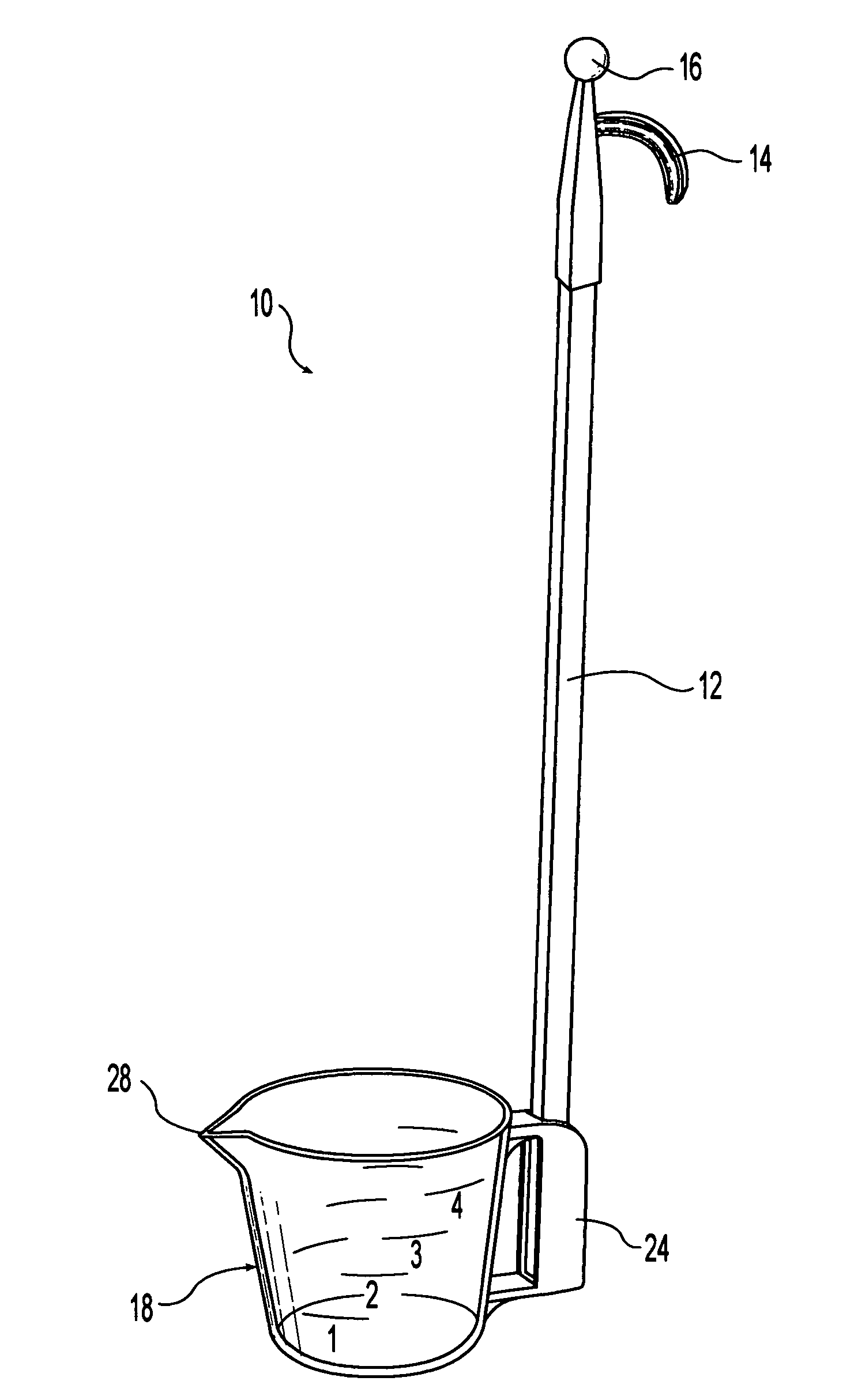

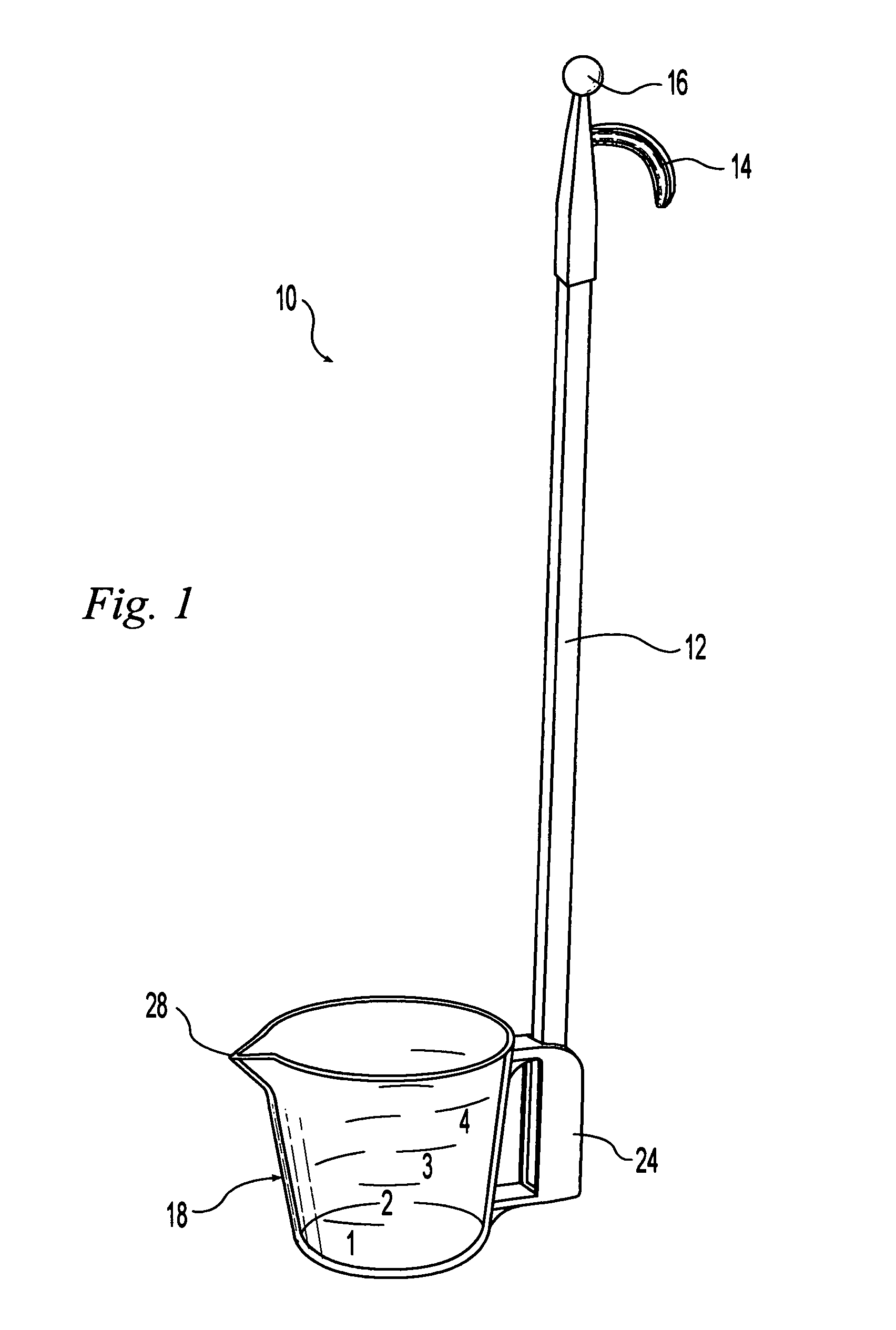

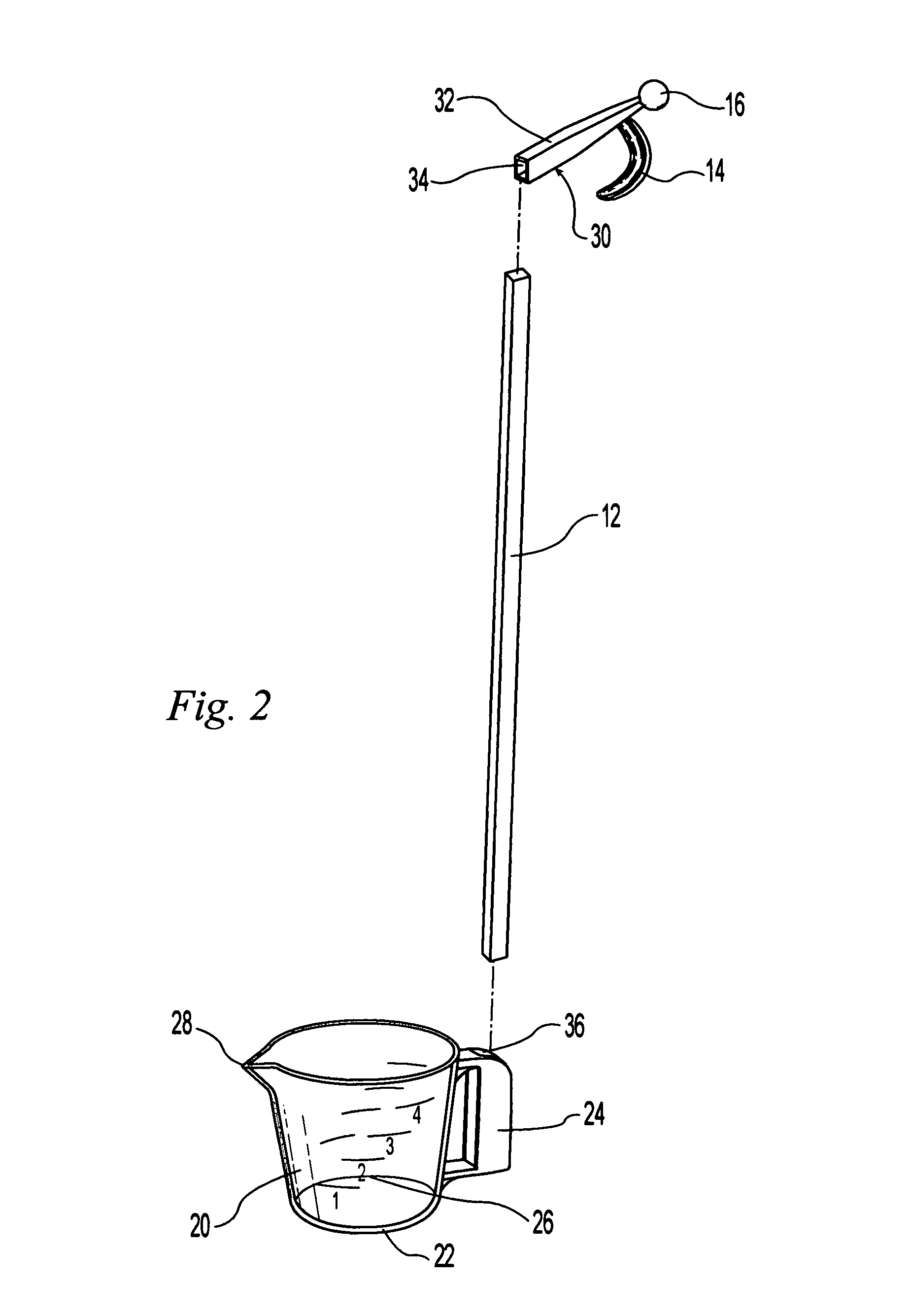

Pool maintenance device

InactiveUS7014231B1Eliminate strainEasily and efficiently manufactured and marketedWithdrawing sample devicesLifting devicesMarine engineeringWater pool

A pool maintenance device that can be used for several tasks including: sampling water at a predetermined depth below the water surface, removing a skimmer cover, moving objects within the pool, adding chemicals to the pool, and storing pool chemicals. The device is comprised of an elongated rigid rod having opposing first and second ends with an attached sampling container and hook assembly. The container is open at the top and has a discharge facilitation area. A handle extends laterally from the opposing side of the container. The hook assembly is comprised of a base, a curved hook, and a spherical element. The hook extends laterally from the base of the hook assembly and the spherical element extends upwardly from the base so as to be positioned essentially perpendicular to the hook.

Owner:CALLEN CHRIS D

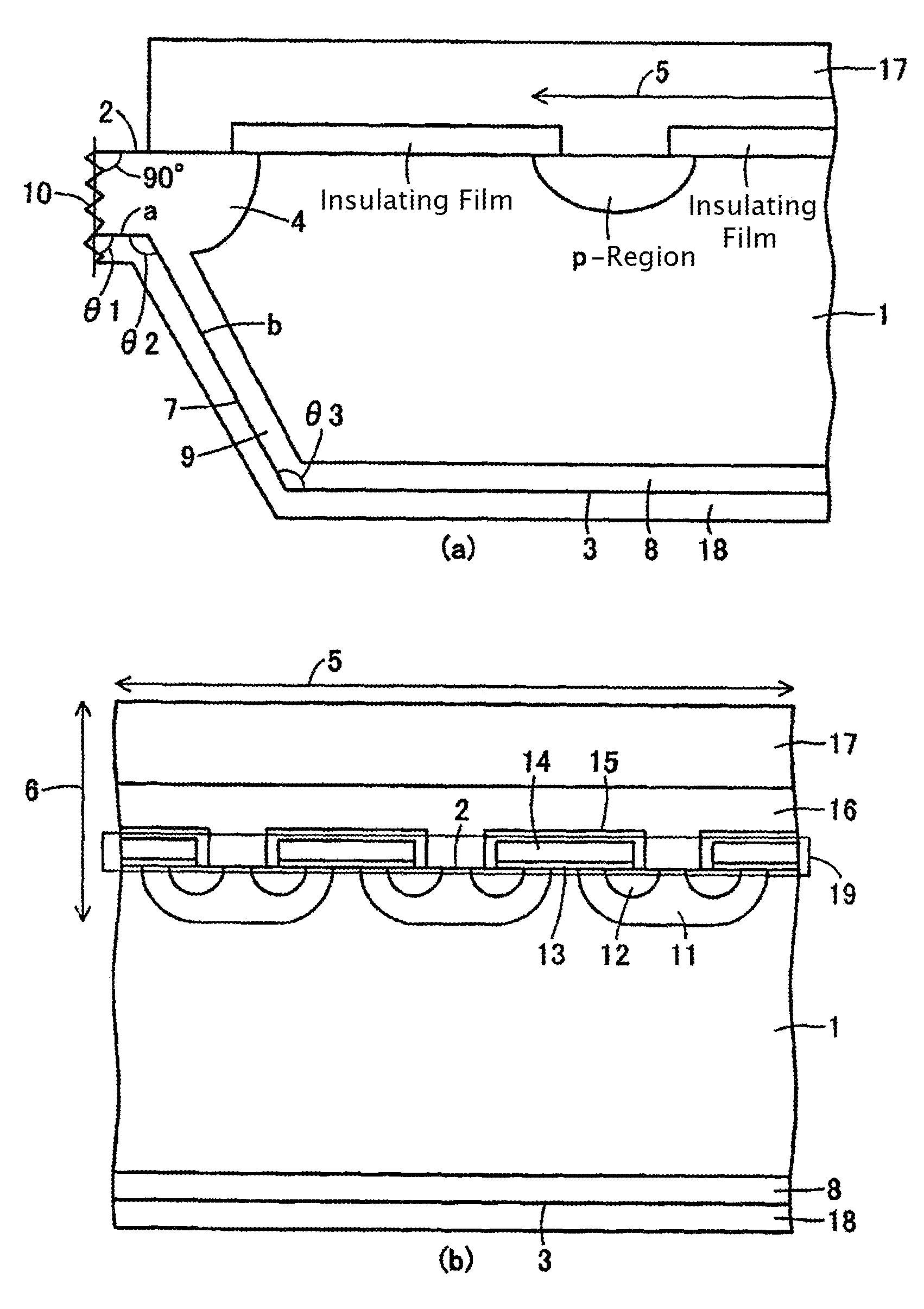

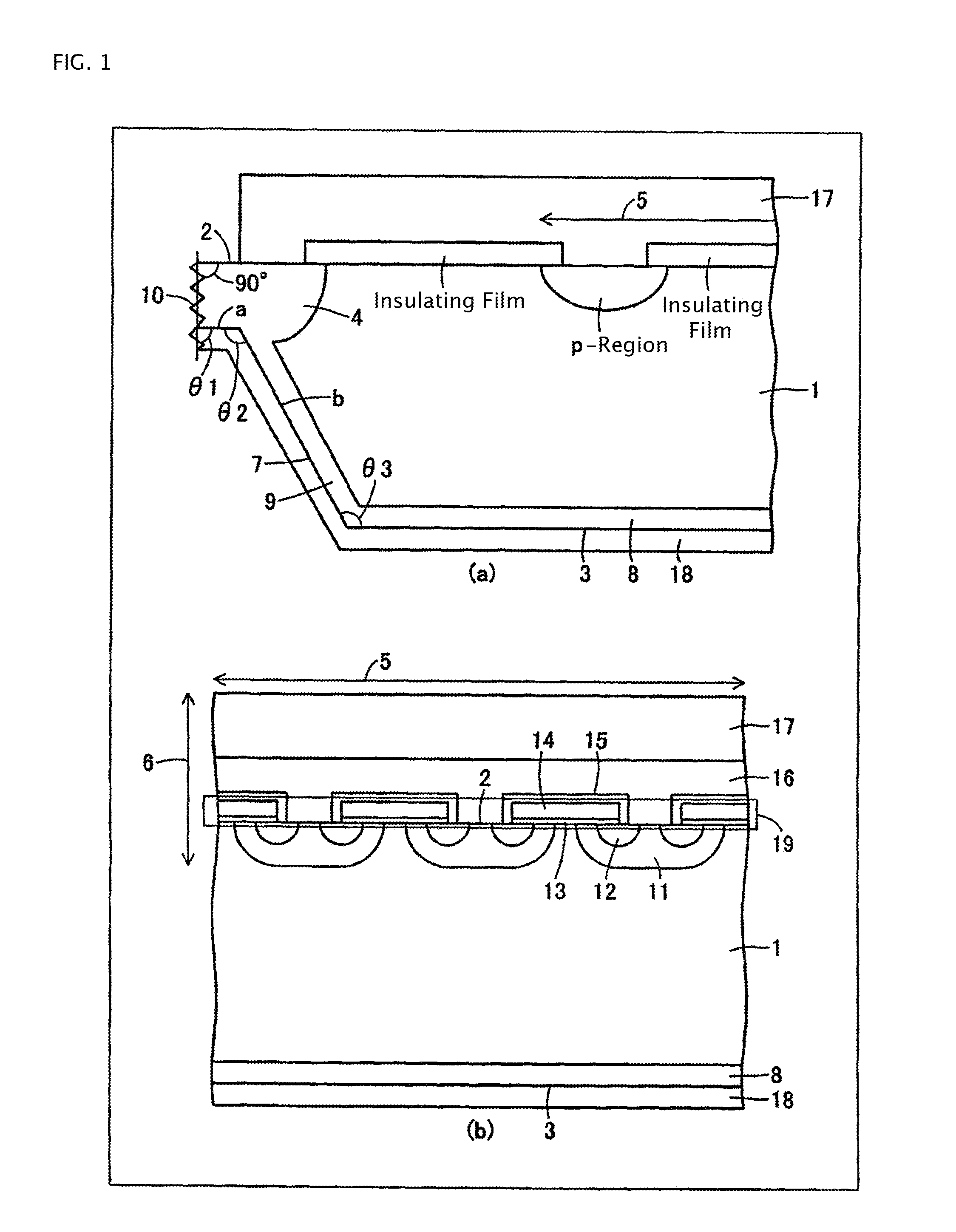

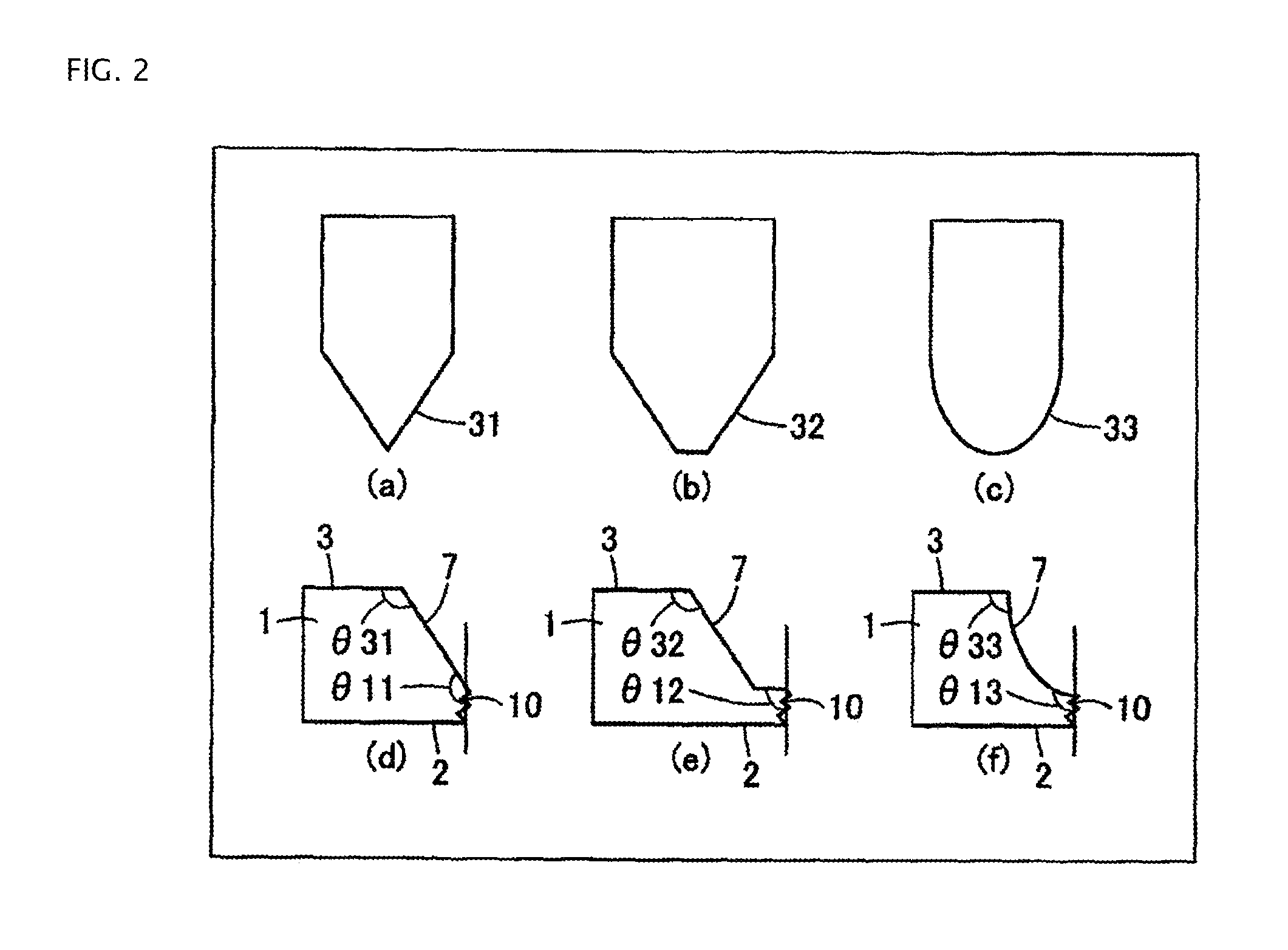

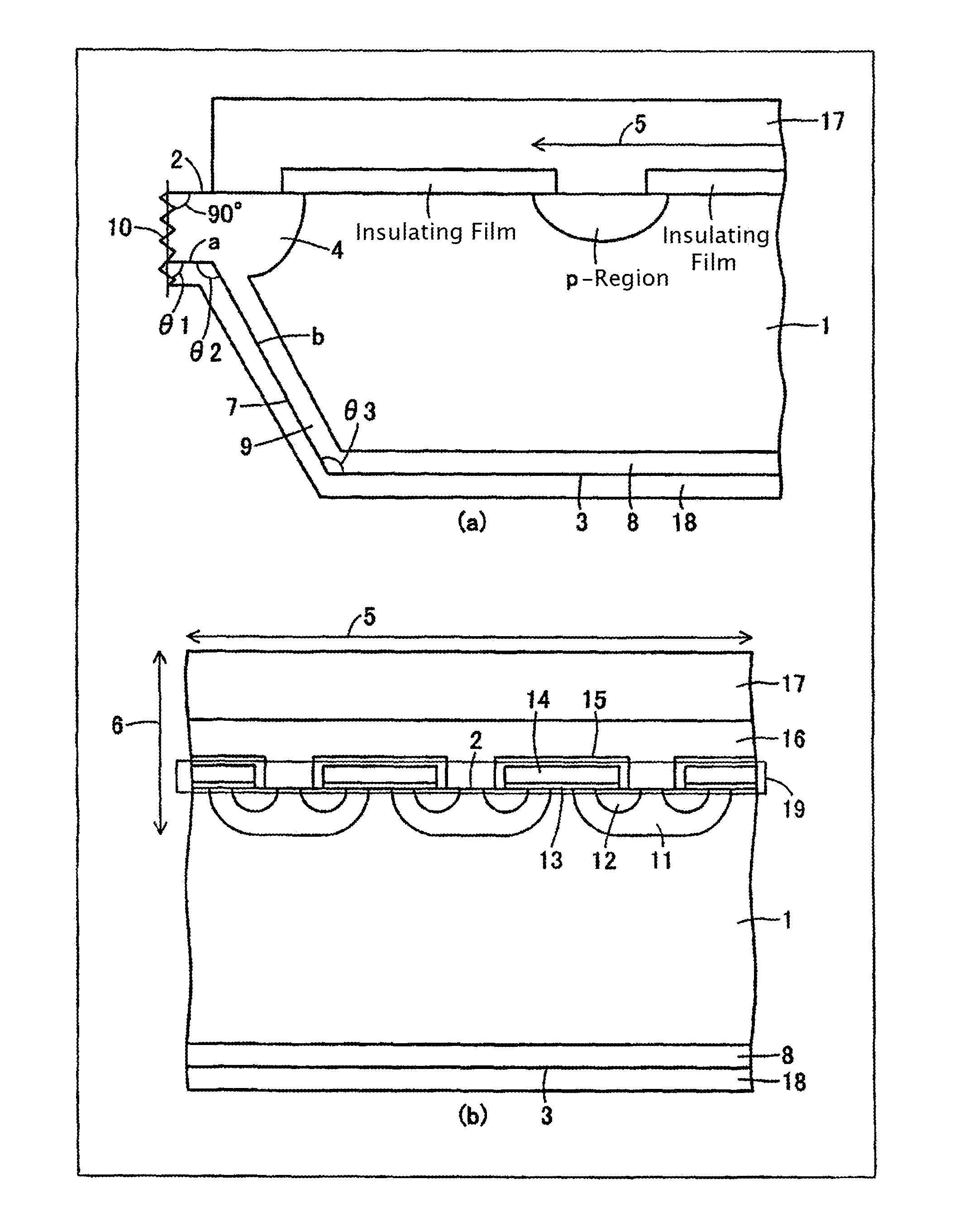

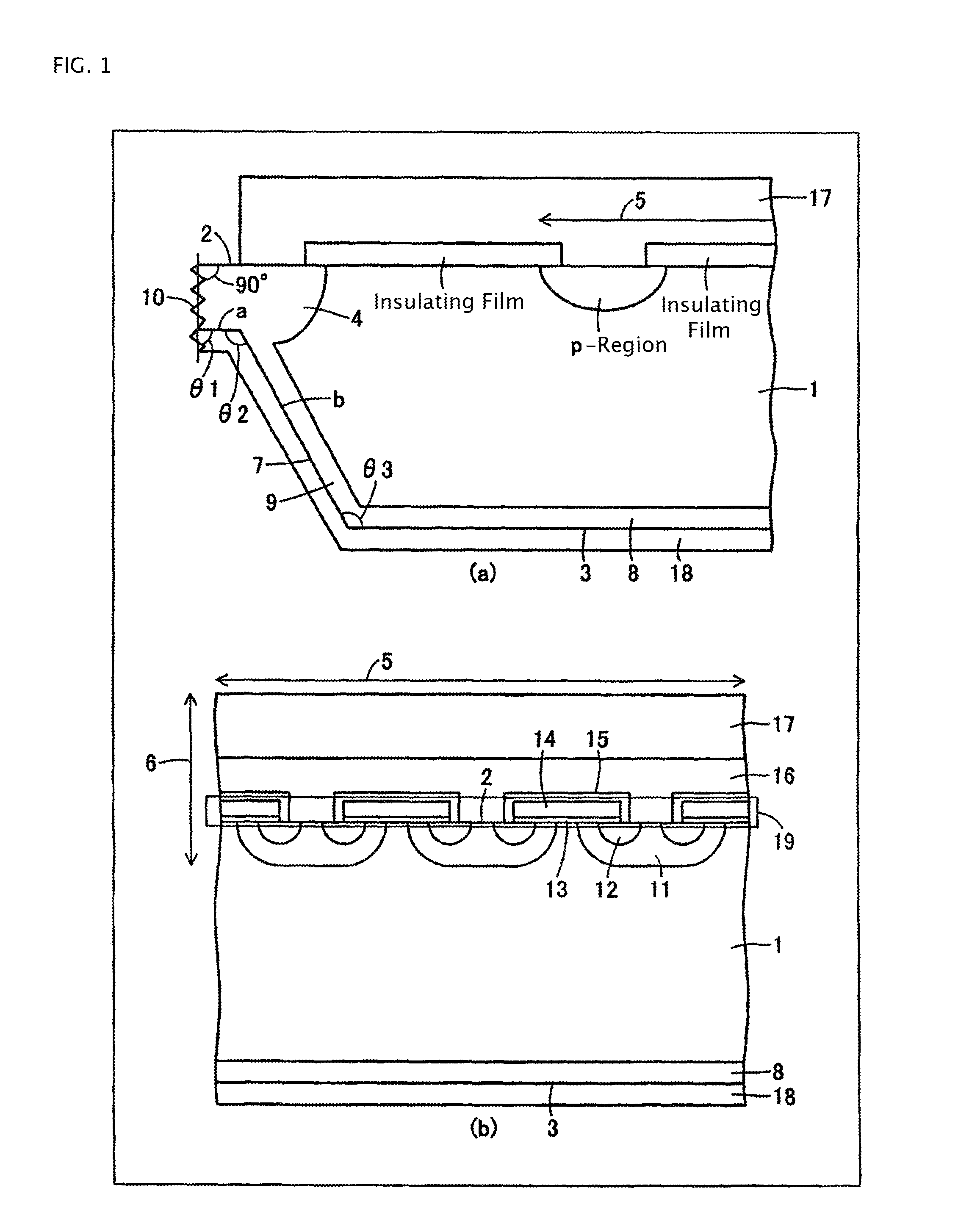

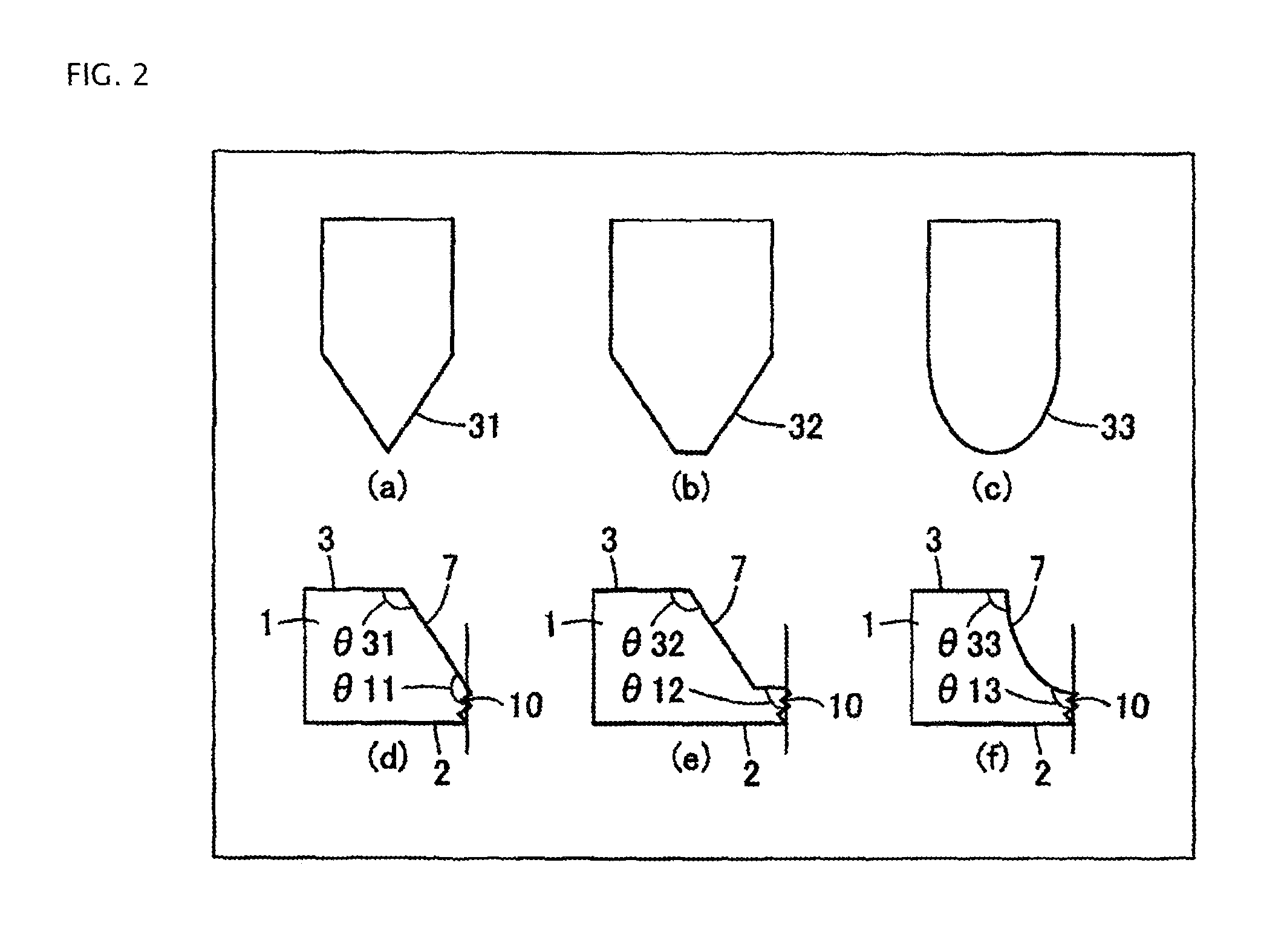

Semiconductor device and manufacturing method thereof

InactiveUS20110108883A1Low costEliminate strainSemiconductor/solid-state device detailsSolid-state devicesAdhesiveIsolation layer

Cutting work is performed on an n-semiconductor substrate (1) with an inverted trapezoid-shaped dicing blade to form grooves to be a second side walls (7). Bottom portions of the grooves are contacted with a p-diffusion layer (4) which is formed on a first principal plane (2) (front face) of the n-semiconductor substrate (1), so that the p-diffusion layer (4) is not cut. Then in the second side walls (7), a p-isolation layer (9) connected to a p-collector layer (8) and the p-diffusion layer (4) is formed. Since the p-diffusion layer (4) is not cut, a glass support substrate for supporting a wafer, and expensive adhesive, are not required, and therefore the p-isolation layer (4) can be formed at low cost.

Owner:FUJI ELECTRIC CO LTD

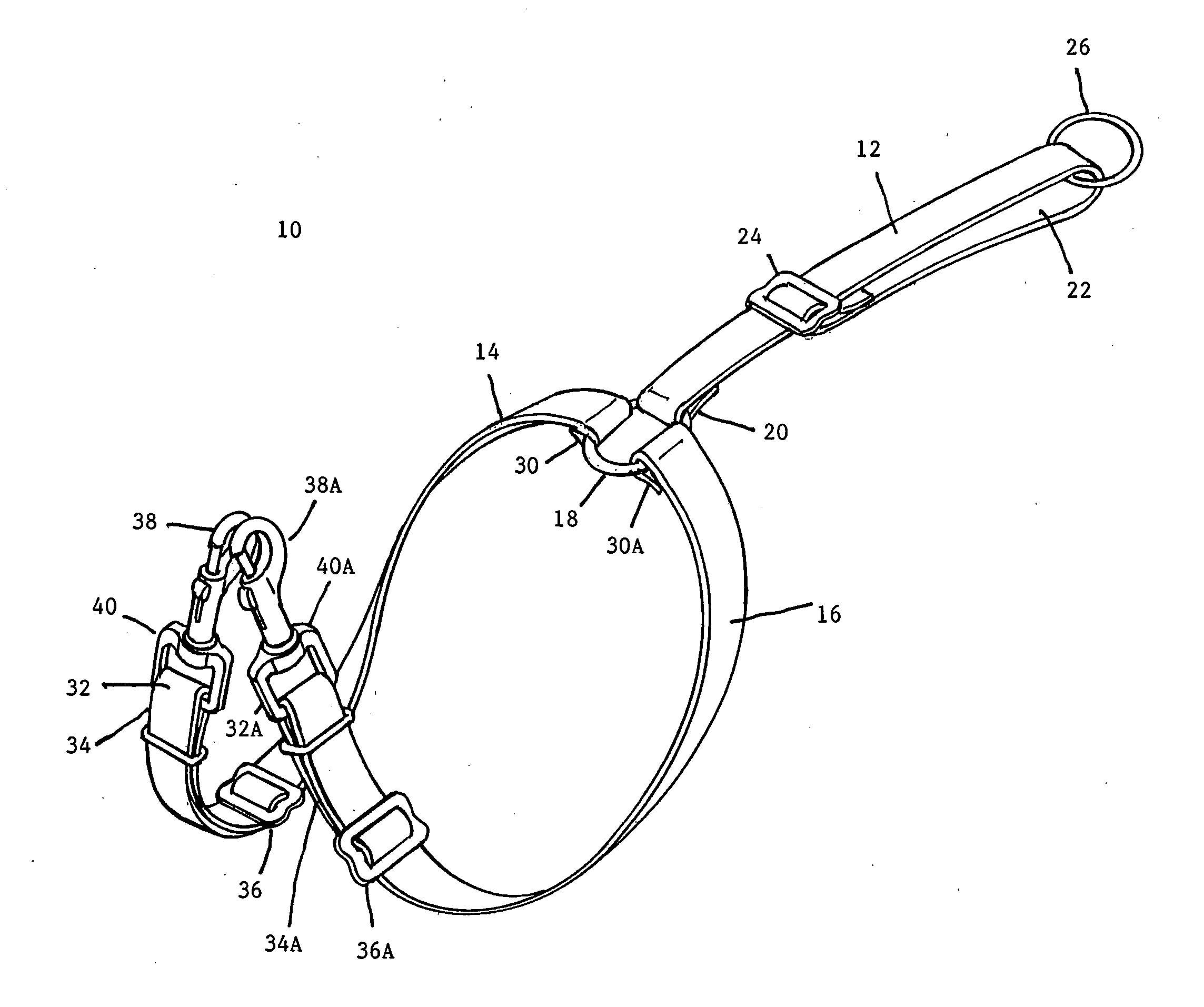

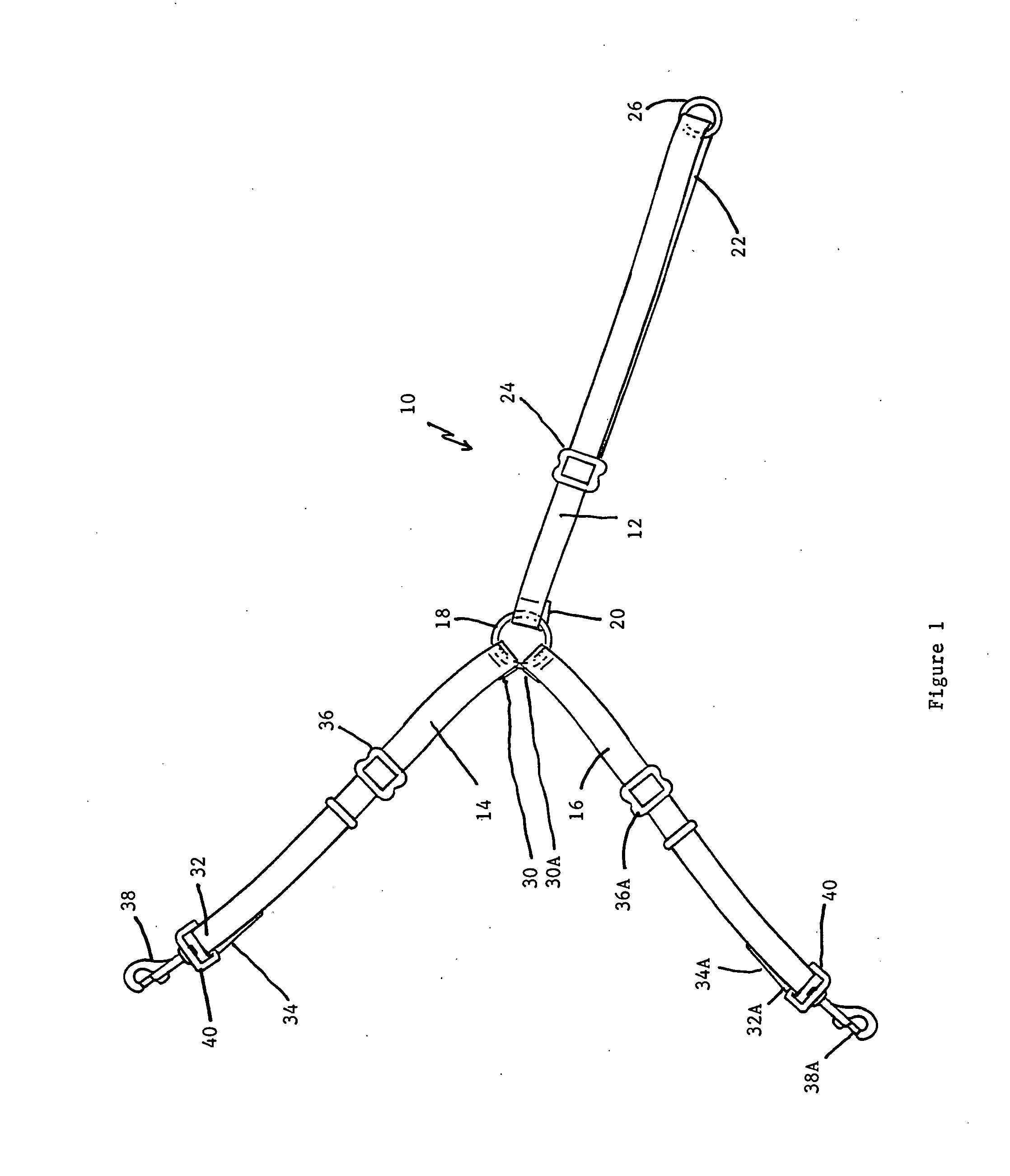

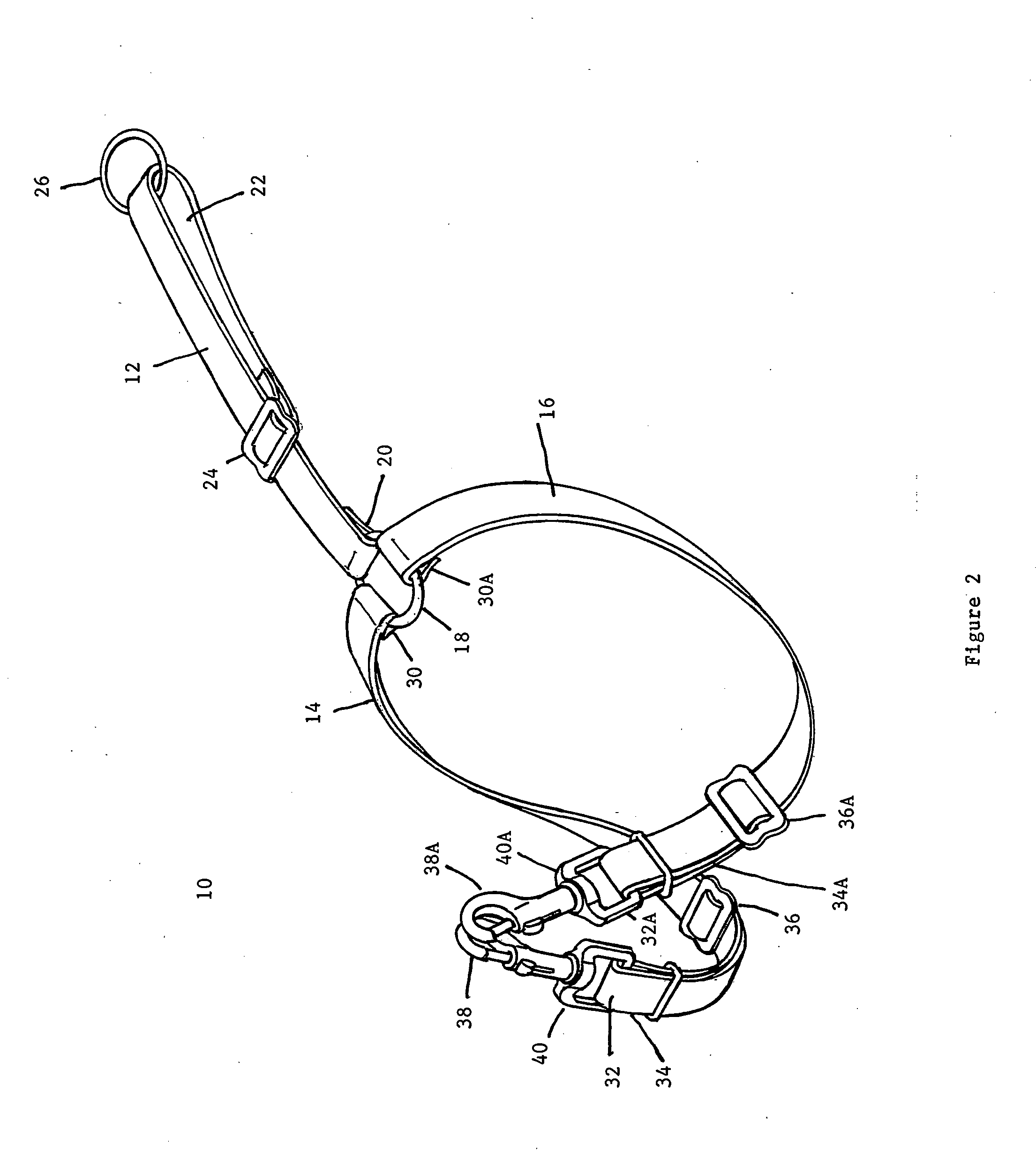

Dog harness

InactiveUS20150114311A1Eliminate pressureRemove tensionTaming and training devicesEngineeringCanis lupus familiaris

A dog harness comprising three flexible adjustable straps secured at a common midpoint, two adjustable flexible straps extending outwardly and under the forelegs of the dog and removably secured to a D-ring secured to the front of the collar of the dog underneath the dogs head, the third flexible adjustable strap having a D-ring secured to the end thereto for removable receipt of a leash, the harness controlling the pace and direction of the dog and also allowing the owner to control the head positioning of the dog without effecting a strain or choke to the dog's neck.

Owner:LYNCH WILLIAM

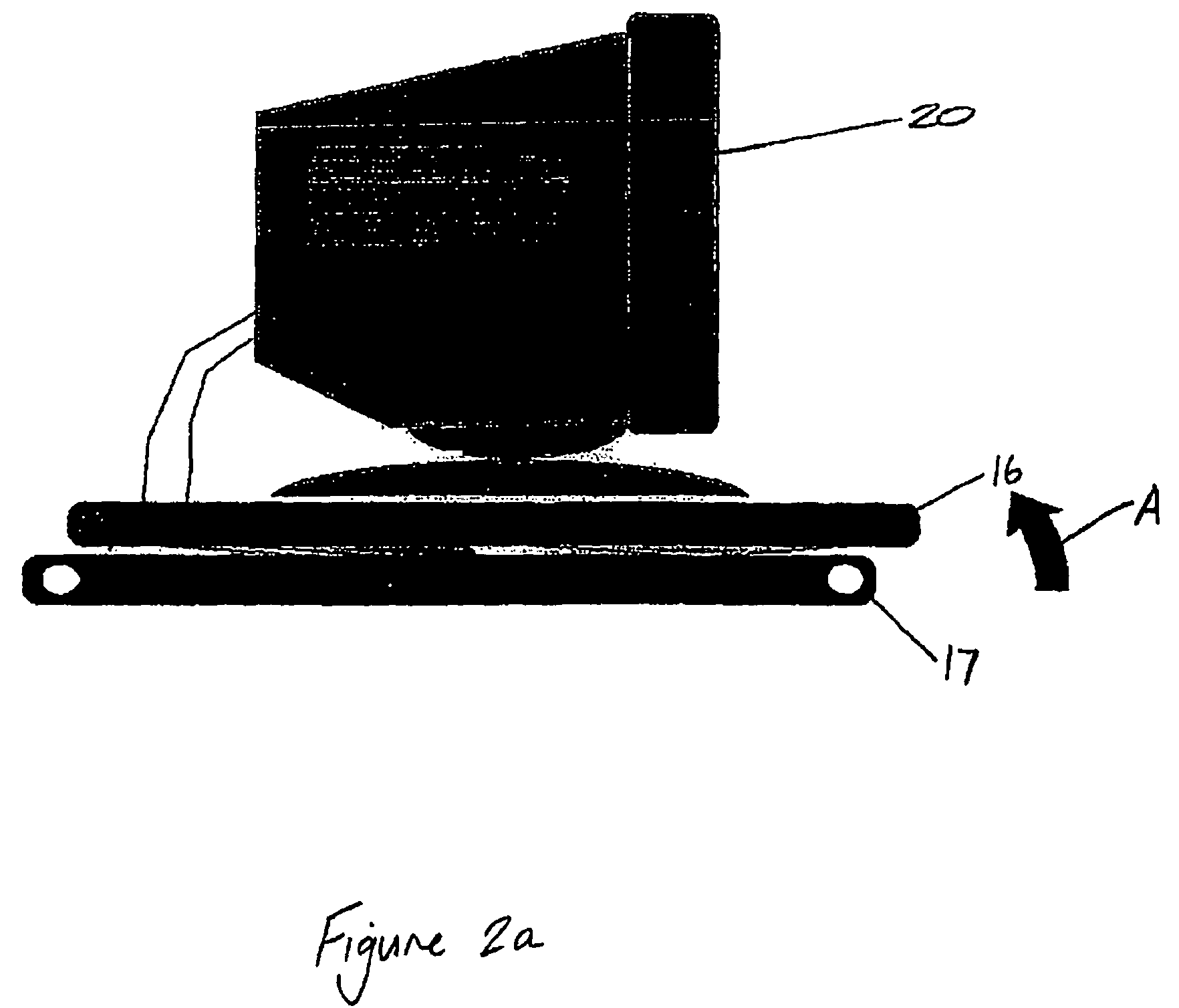

Automatically varying equipment support

InactiveUS8091842B2Reduce and eliminate eye strainReduce or eliminate musculo skeletal disorders (MSDs)Substation/switching arrangement detailsDigital data processing detailsReliability engineering

Owner:NIGEL GEOFFREY THOMAS +1

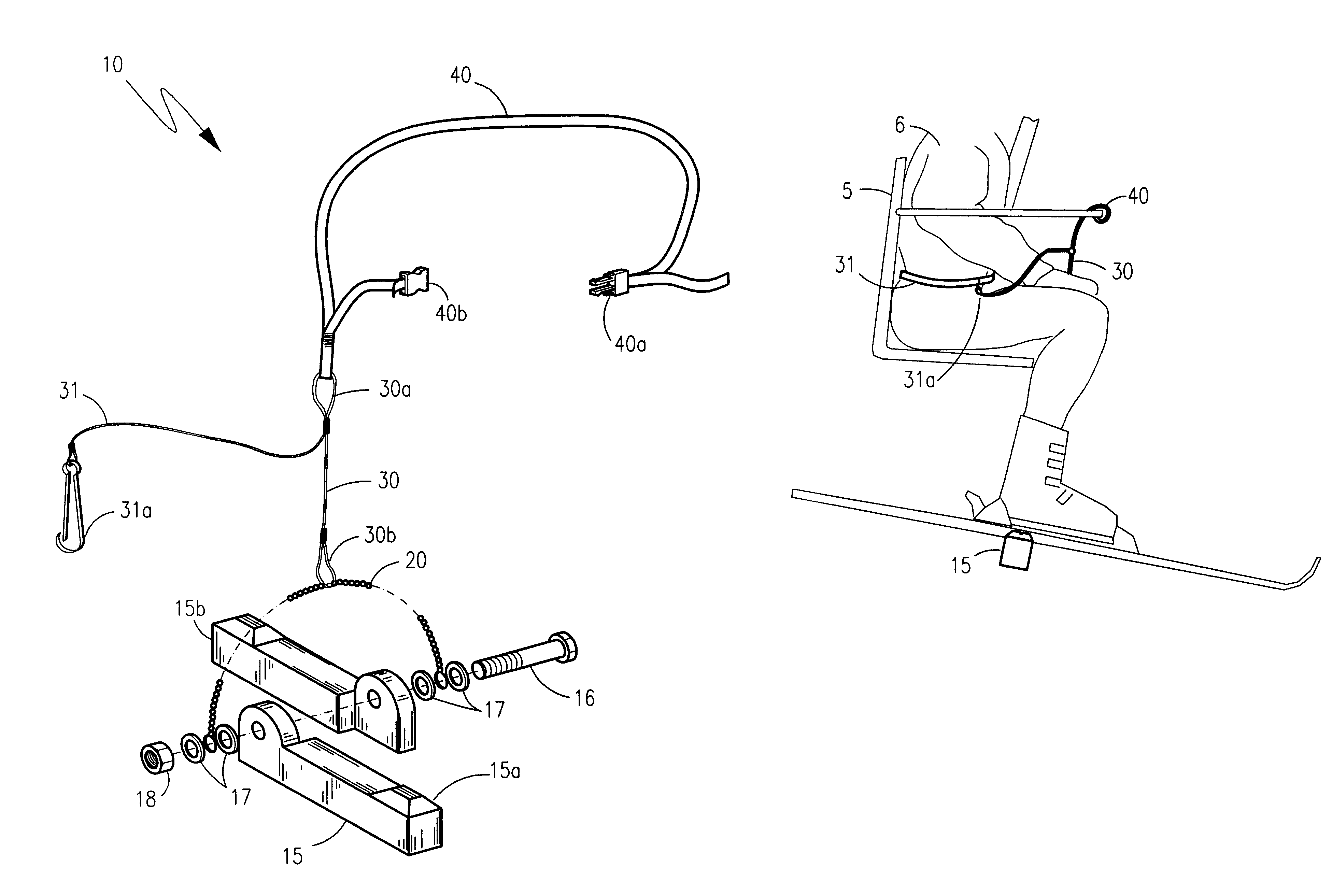

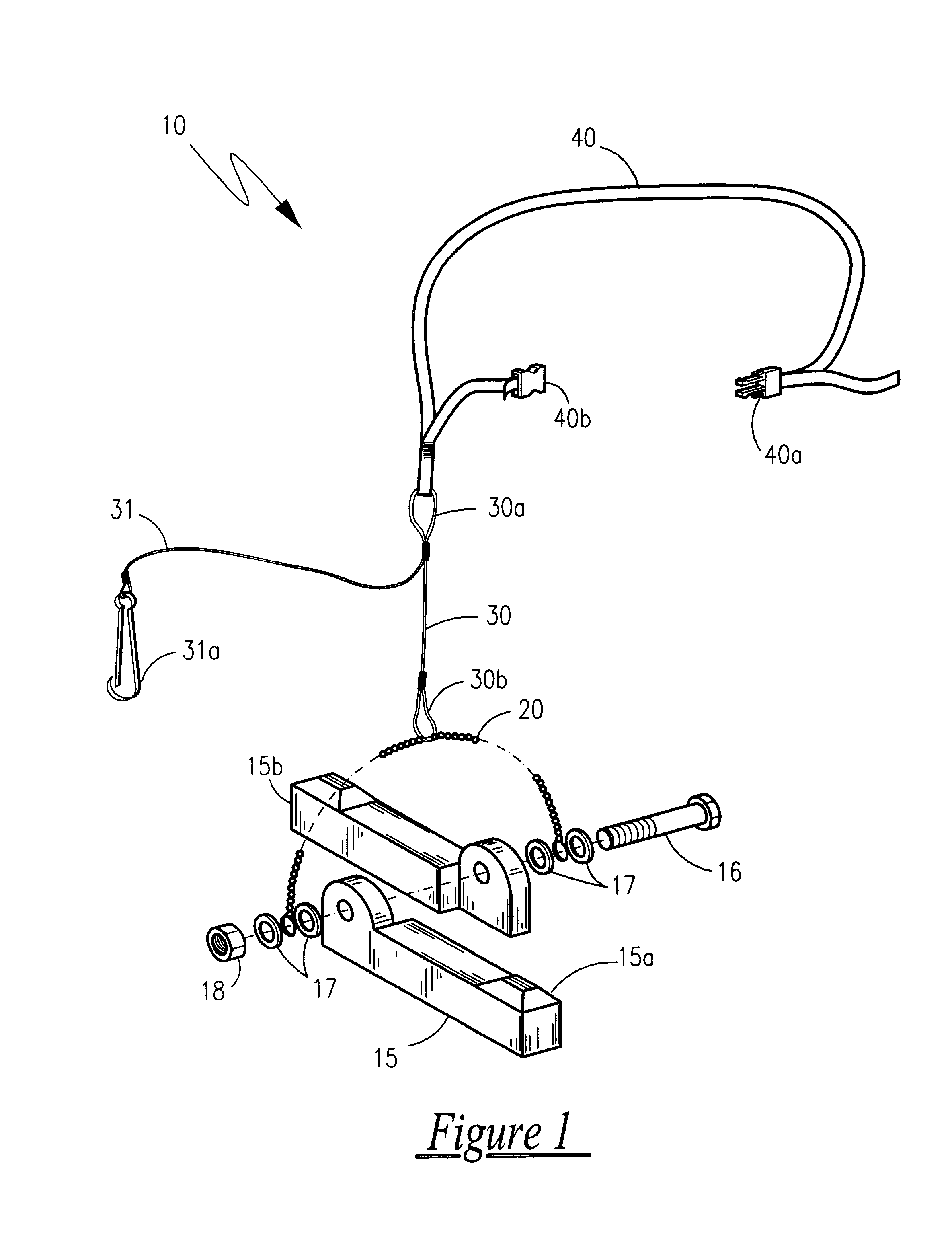

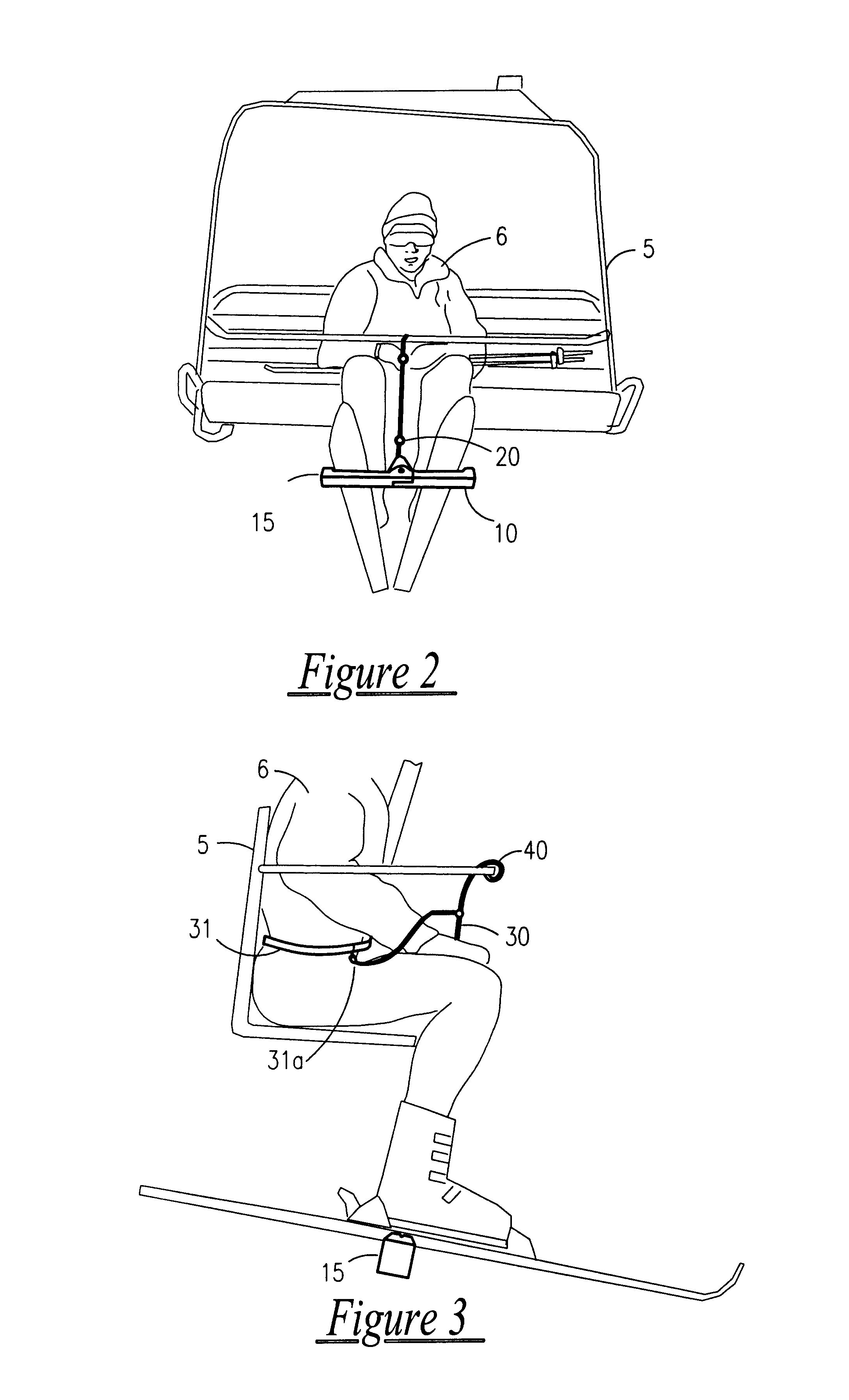

Ski lift ski rest

The invention is an apparatus that serves as a foot rest for ski lift chairs. The invention is designed to take stress off of the leg and back areas of the rider by providing them a place to rest their feet. The user simply fastens a nylon strap with a quick release buckle around the safety bar or arm rest of the ski lift chair. From the nylon strap, a cord hangs down where it connects to a harness supporting a foldable foot rest. Each segment of the foot rest folds thru an arc to provide a flat foot rest area that is approximately ten inches long. Each foot rest extension is connected thru its pivot point with a long screw. The screw, along with washers and nuts, also serves to fasten the foot rest to the harness. The user then rests his or her ski boot on the foot rest for the ride to the top of the ski slope. In an alternate preferred embodiment, a snow board harness is substituted for the cord, harness and foldable foot rest.

Owner:SHIA STEVEN S

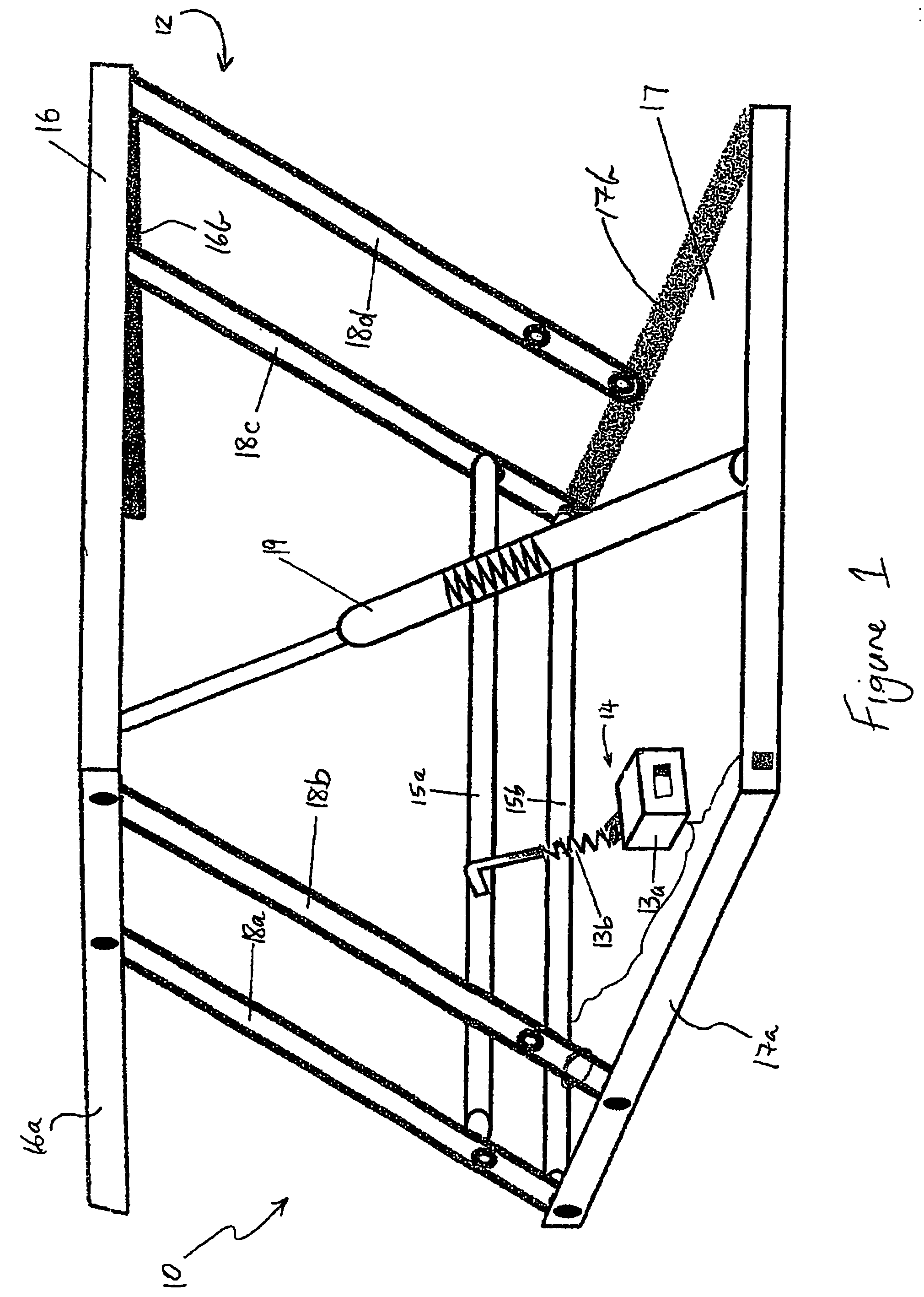

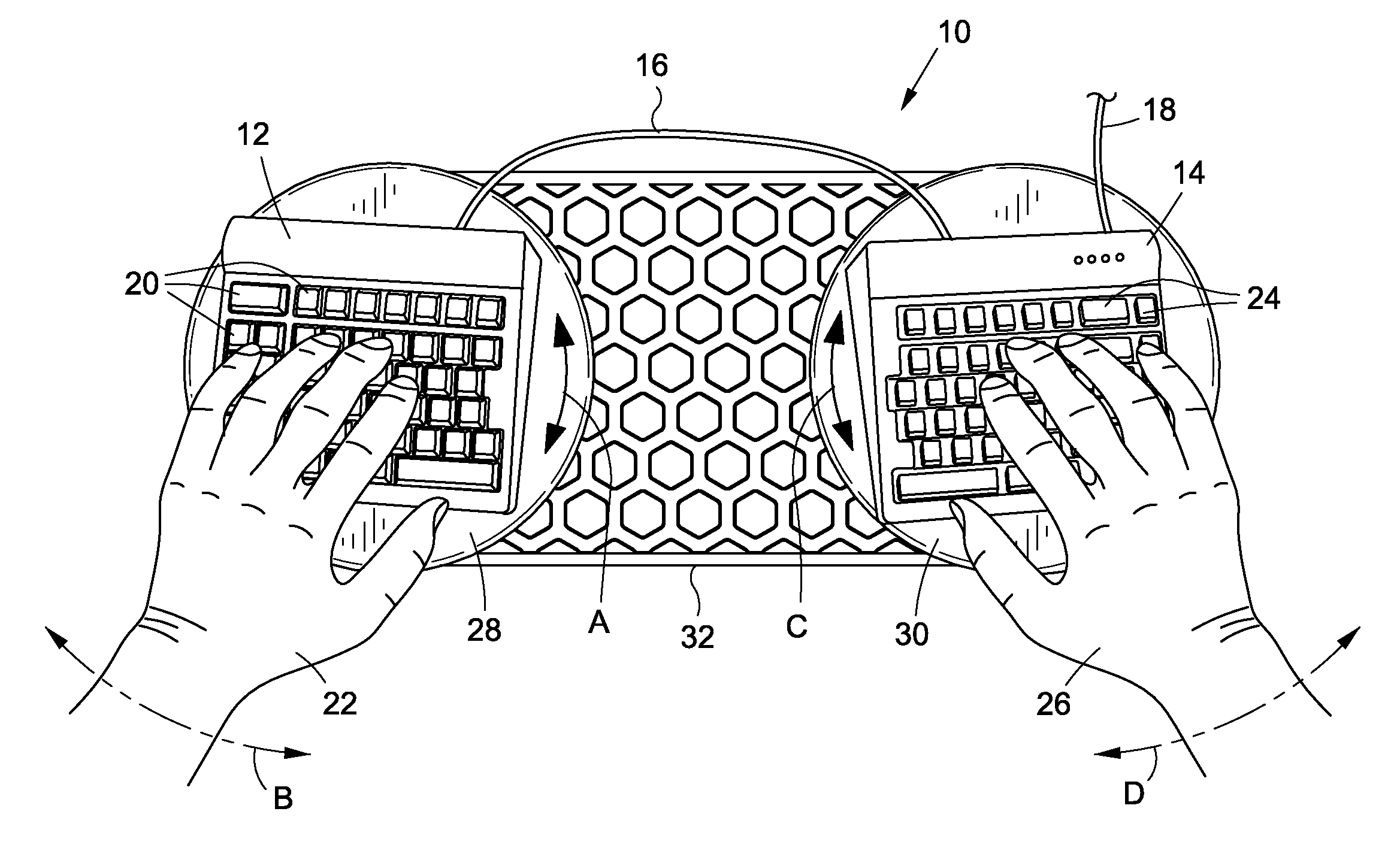

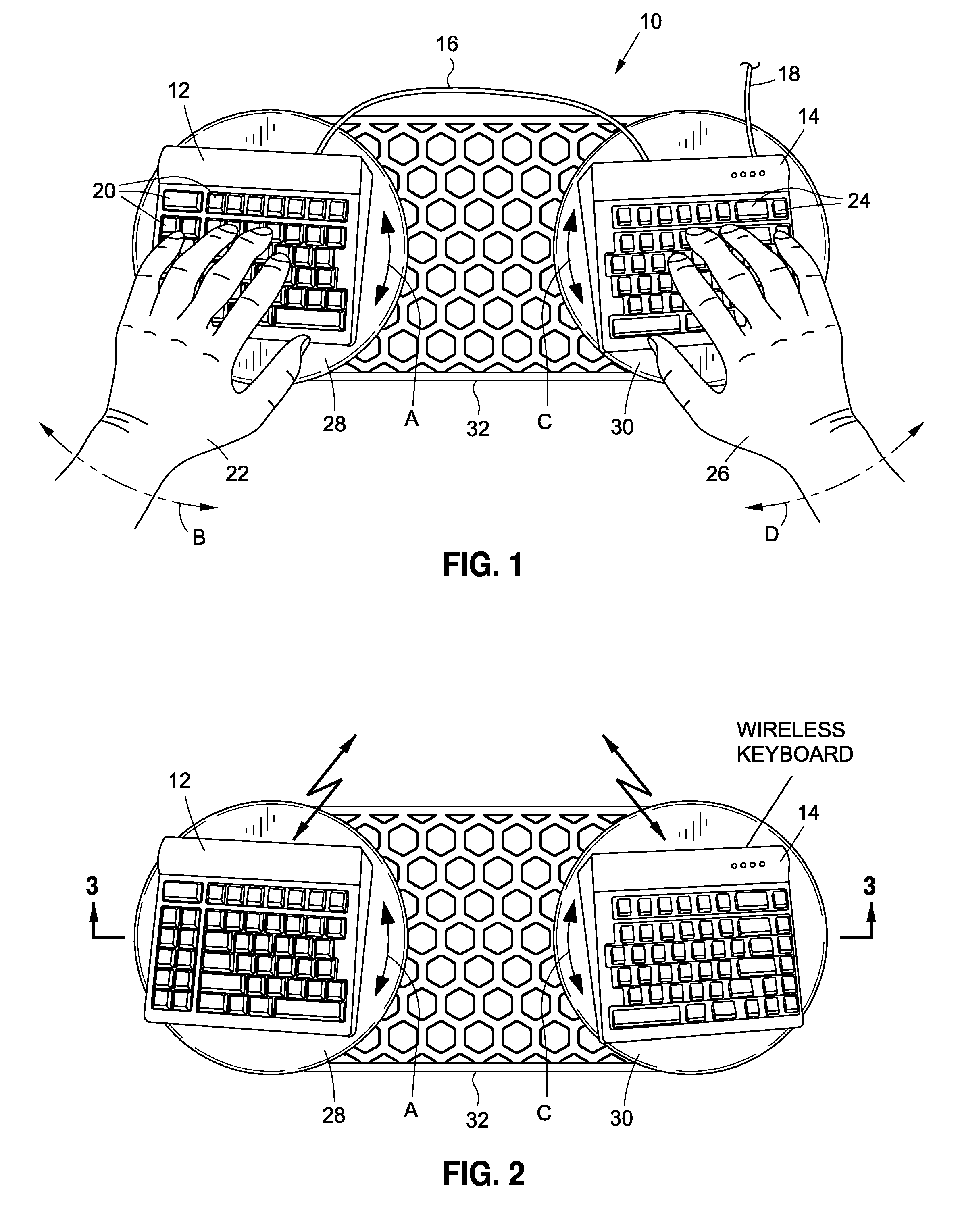

Split rotating keyboard system

ActiveUS20160139680A1Mitigates muscular fatigueMitigates compressive syndromeInput/output for user-computer interactionCathode-ray tube indicatorsCTS - Carpal tunnel syndromeEngineering

A split rotating keyboard system for use in easing muscle strain and mitigating the effects of carpal tunnel syndrome associated with the usage of conventional computer keyboards. The system comprises first and second computer keyboard sections, namely, a left-hand computer keyboard section and a right-hand computer keyboard section. Each respective computer keyboard section is mounted upon a dedicated rotating platform member that is operative to rotate in clockwise and counter-clockwise directions. According to a preferred embodiment, the rotating platform portions upon which the first and second keyboard sections are positioned may be secured upon a base member that is operative to maintain the first and second rotating platform members in fixed relation to one another. Another preferred embodiment includes elements that allow for a partially “spherical” motion upon which the first and second keyboard sections are positioned may be secured upon a base member that is operative to maintain the first and second spherical platform members in fixed relation to one another. Sensors embedded in the members can transmit motion, position, and pressure data back to the receiving device such as a computer, tablet, or gaming console.

Owner:INFINITY KEYBOARD

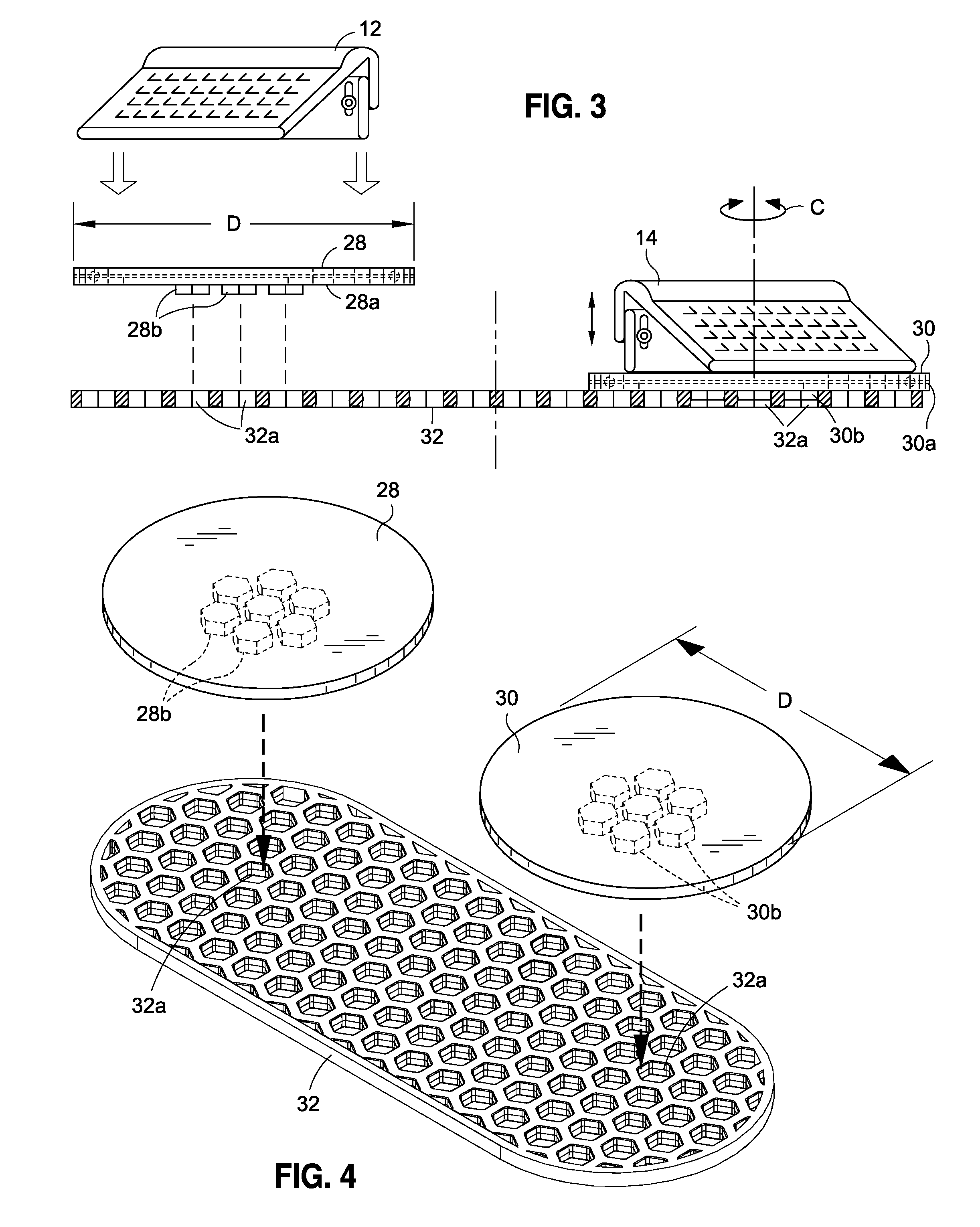

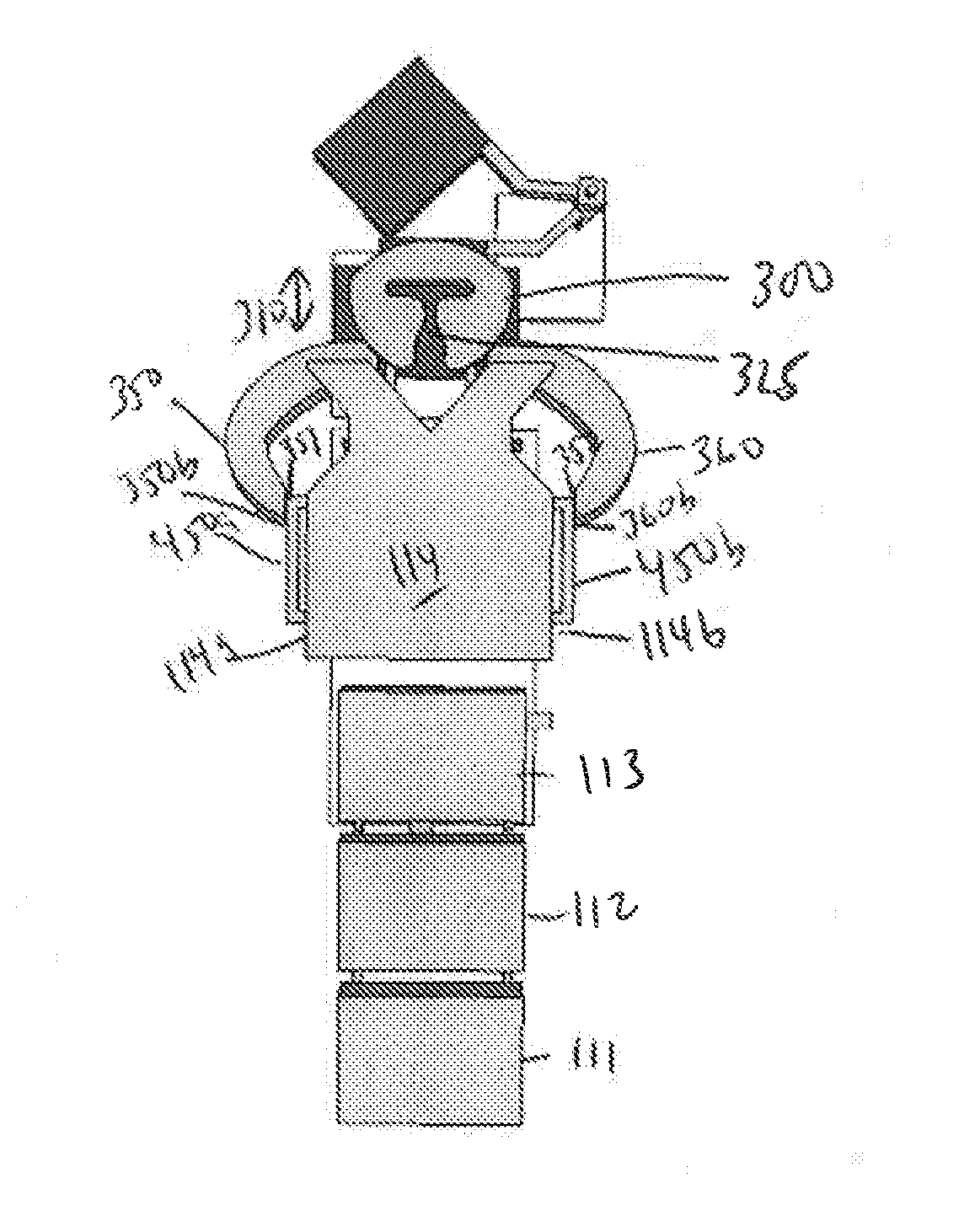

Desk and Recovery System

InactiveUS20130340766A1Eliminate stressEliminate strainOperating chairsDental chairsButtocksEngineering

The invention features a desk and recovery system that affords the user the ability to avoid stress and strain on the user's back, head and neck. The system features an upper body support featuring a torso or chest support which receives the stomach of the user for face-down support or face-down recovery. Adjustable arms are provided for an entertainment system, such as keyboard and monitor. The torso or chest, knee and buttocks supports can tilt, rotate and are height adjustable.

Owner:SEGER DANIEL E

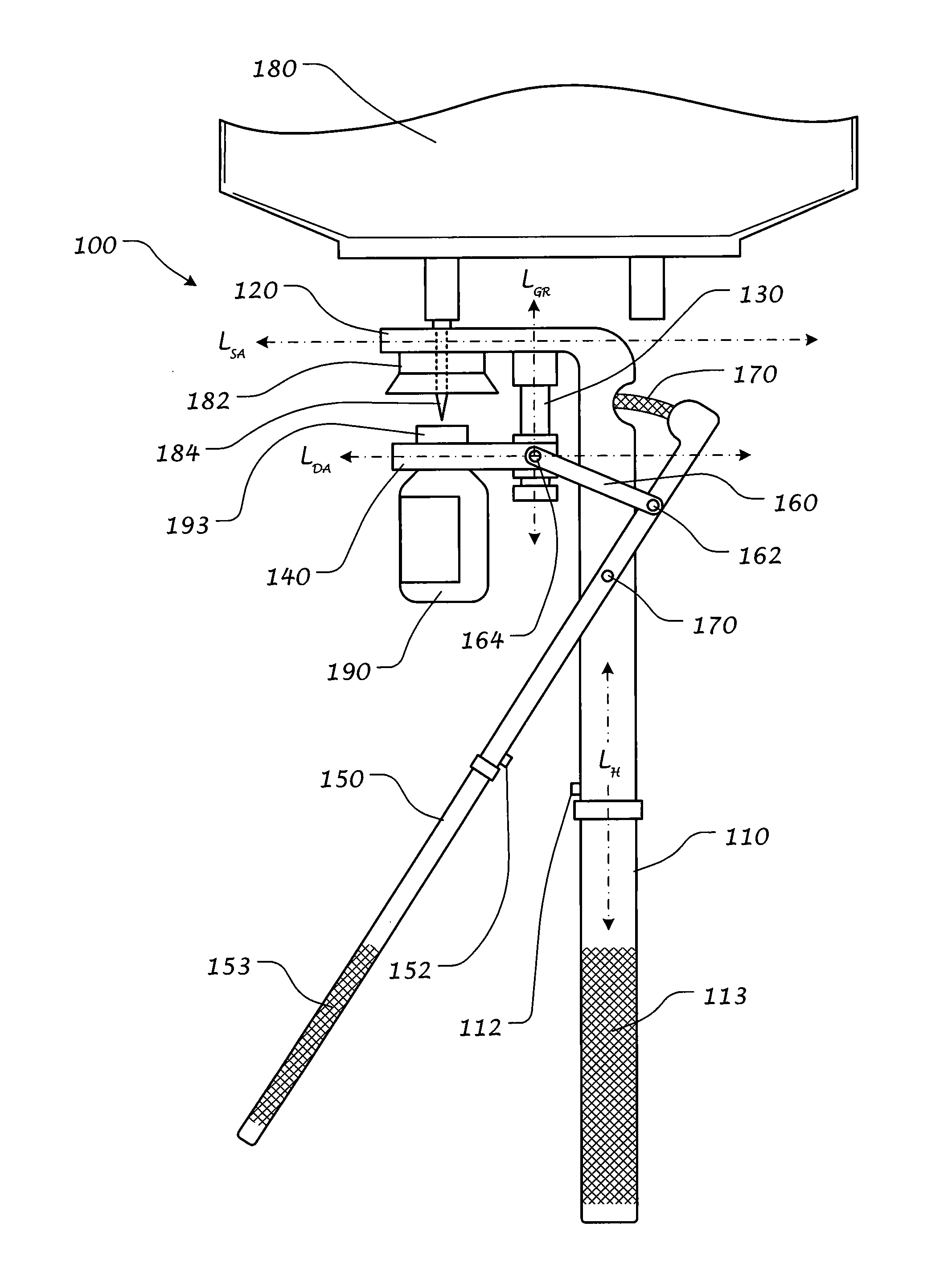

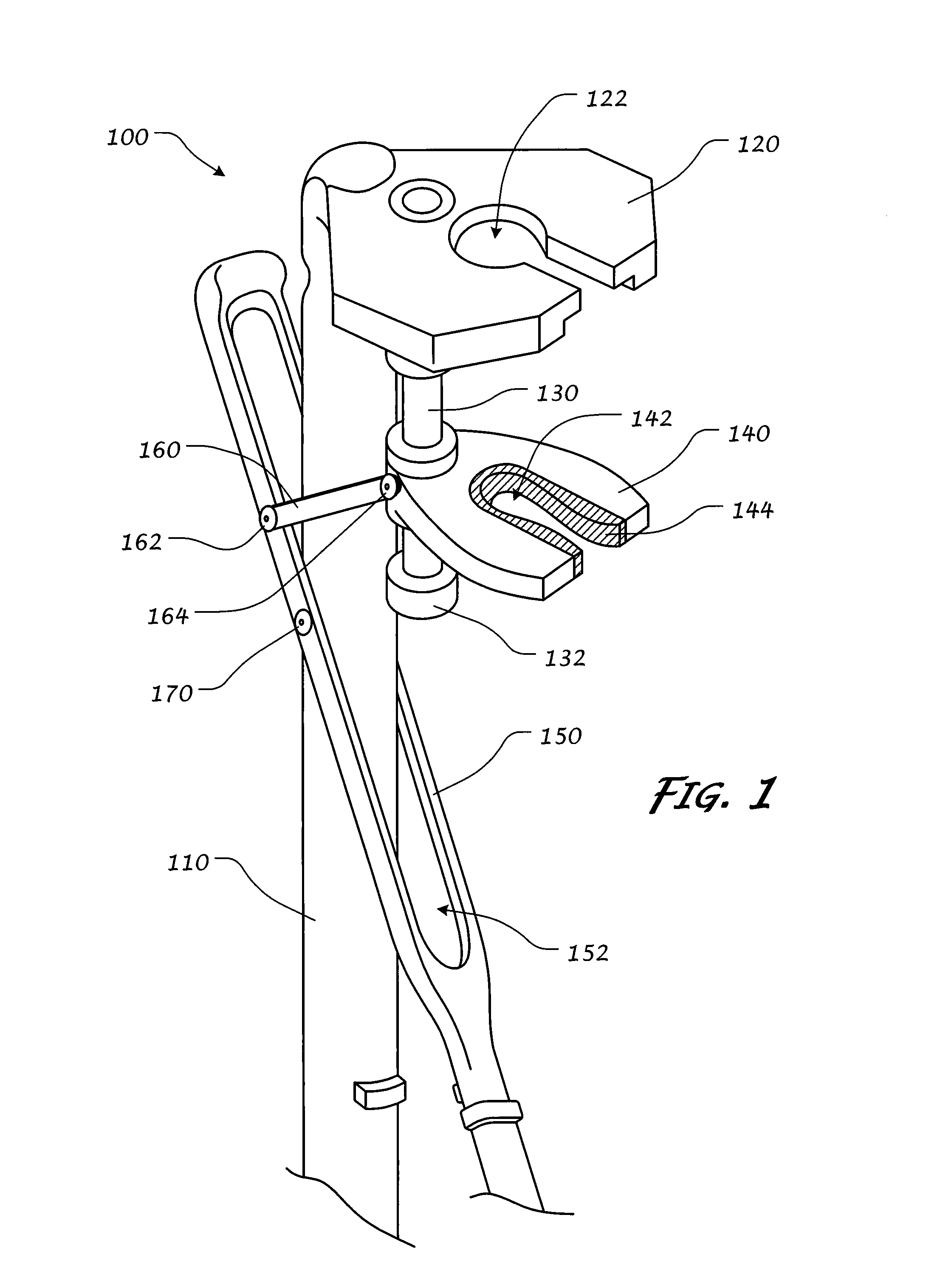

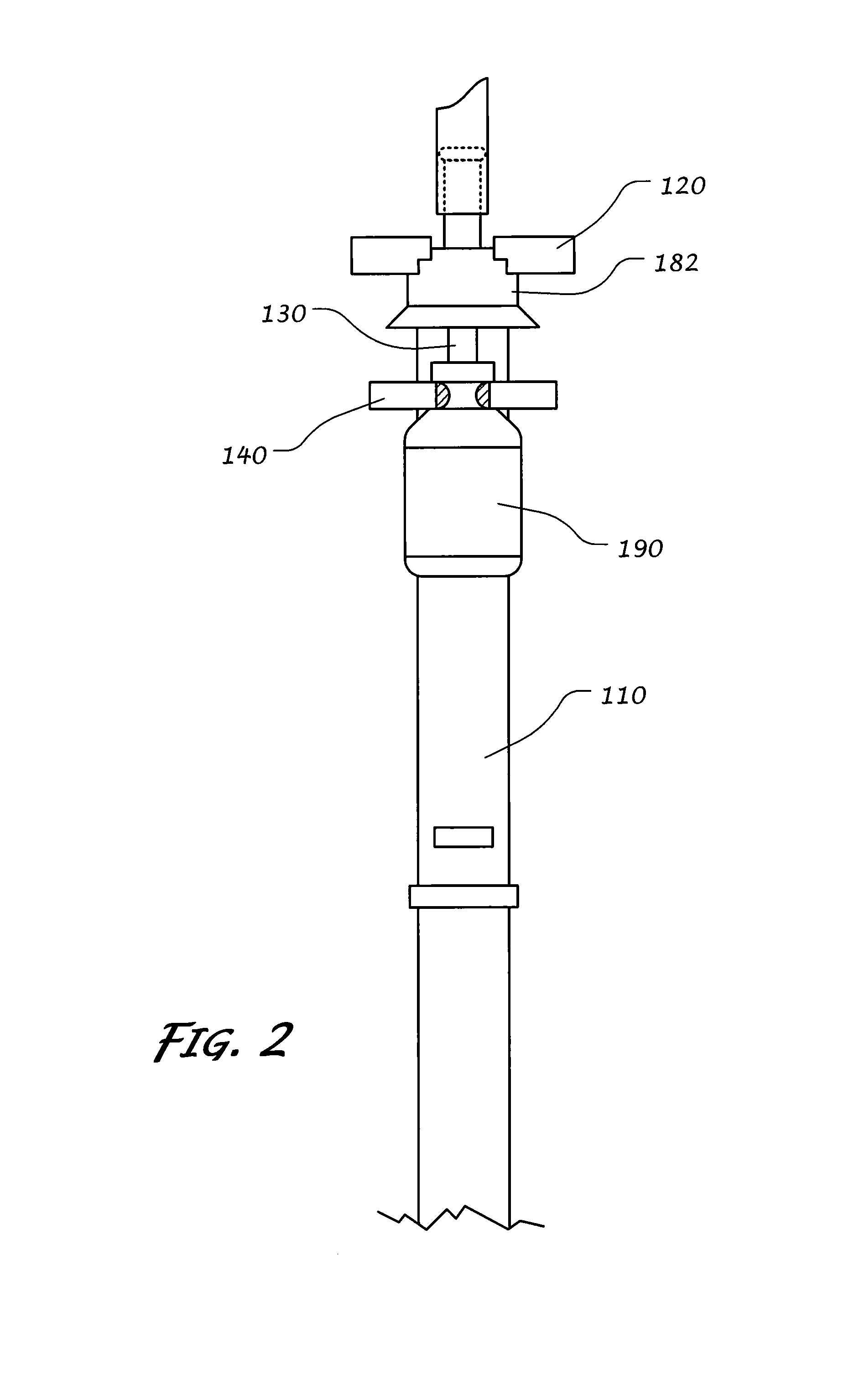

Commode lifting and transporting device

InactiveUS20070011807A1Eliminate strainReduce risk of damageWash-standsDomestic plumbingEngineeringAlternative methods

A method and apparatus for lifting, transporting, or installing a commode is disclosed. The commode lifting and transporting device includes a base frame, with an upright support frame designed to straddle and lift a commode at or near the commode's center of gravity. The lifting member includes a screw jack, a lifting bar guided by the upright support frame, and three methods of attaching the commode to the commode lifting device: a self-clamping mechanism for lifting and transporting standard commodes; a set of support hooks and chain for lifting and transporting non-standard commodes, and lifting bar holes used in conjunction with the commode's seat holes, two bolts and two nuts as an alternate method for lifting and transporting non-standard commodes.

Owner:HAMILTON LAWRENCE DALE

Imaging member

InactiveUS7592111B2Reduce eliminateEffectively flush-out residual solventElectrographic process apparatusCoatingsEngineeringCarbonate

Owner:XEROX CORP

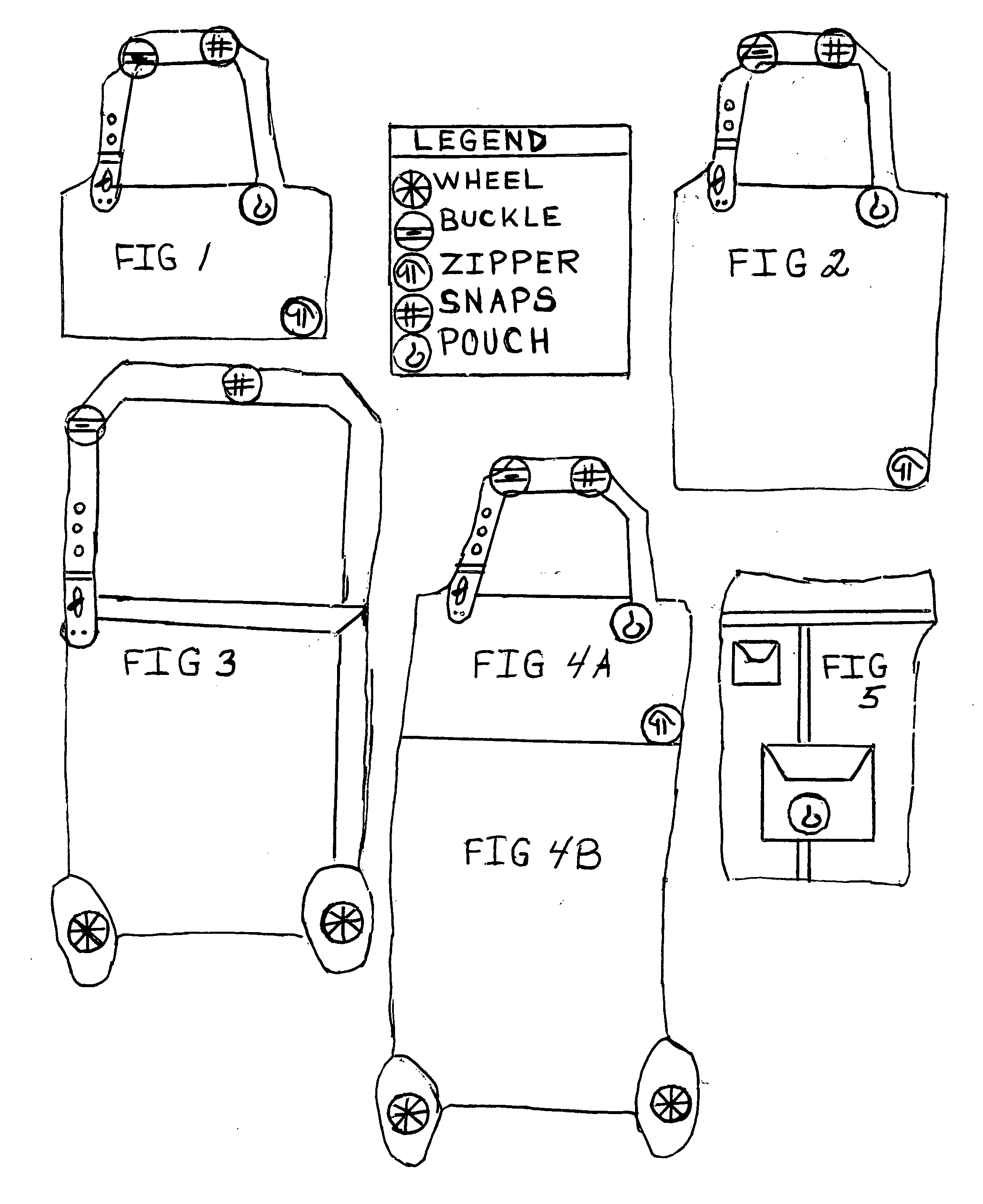

EZ BN green shopping bag with wheels

InactiveUS20090283990A1Eliminate strainEliminate stressSnap fastenersTravelling carriersEngineeringPhysical exercise

Owner:GRAHAM SANDRA LOUISE

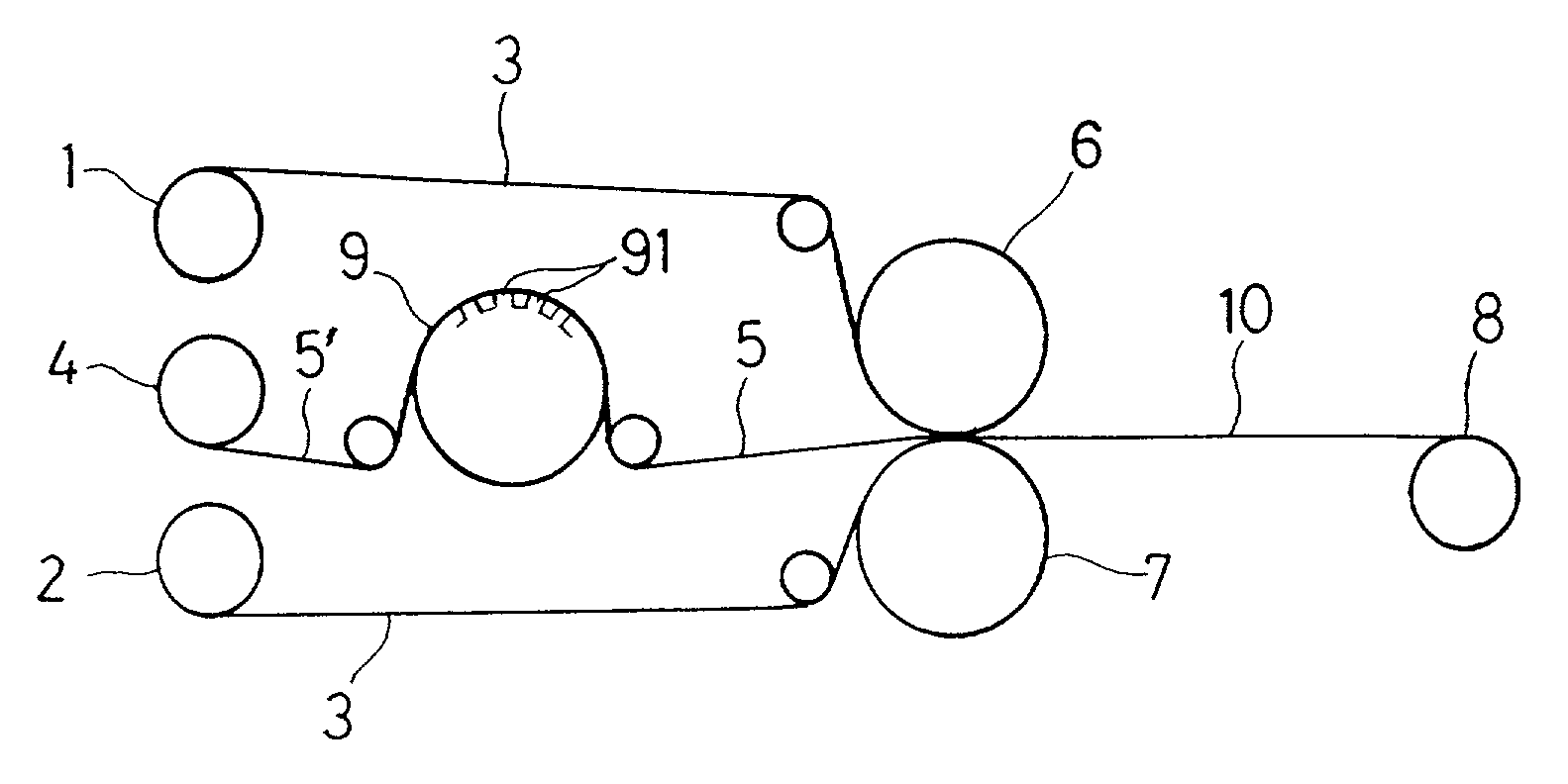

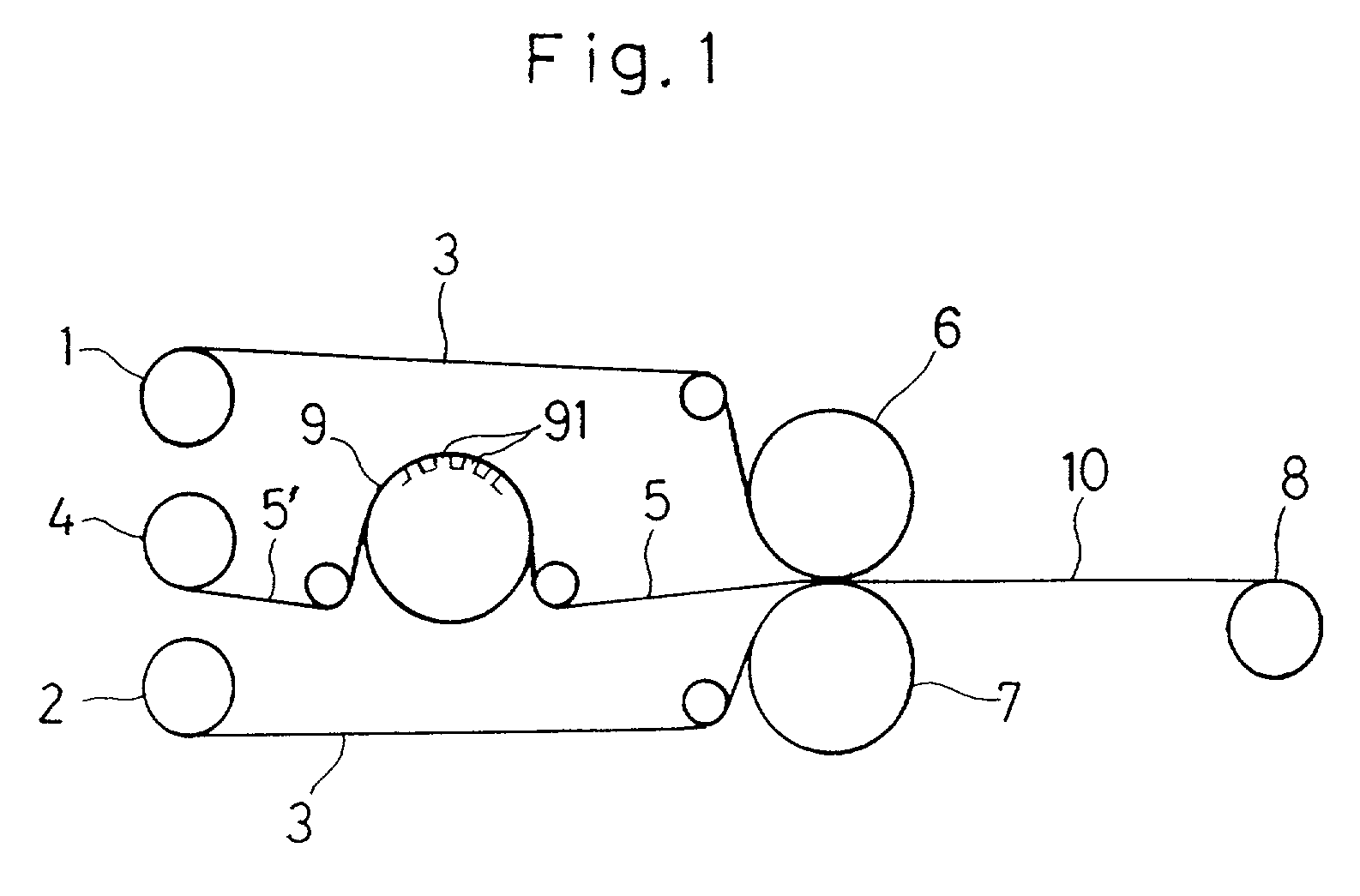

Method for producing metal laminate

InactiveUS7052574B2Removing residual strainGood dimensional stabilityAdhesive processesLamination ancillary operationsMetal sheetPolymer chemistry

To continuously produce a metal laminate having excellent dimensional stability and flatness, there is provided with a method of producing a metal laminate in which a thermoplastic liquid crystal polymer film (5′) capable of forming an optically anisotropic melt phase is heat-treated on a heat treatment roll having unevenness (91) on its surface and subsequently a metal sheet (3) is bonded to at least one side of the film (5′).

Owner:KURARAY CO LTD

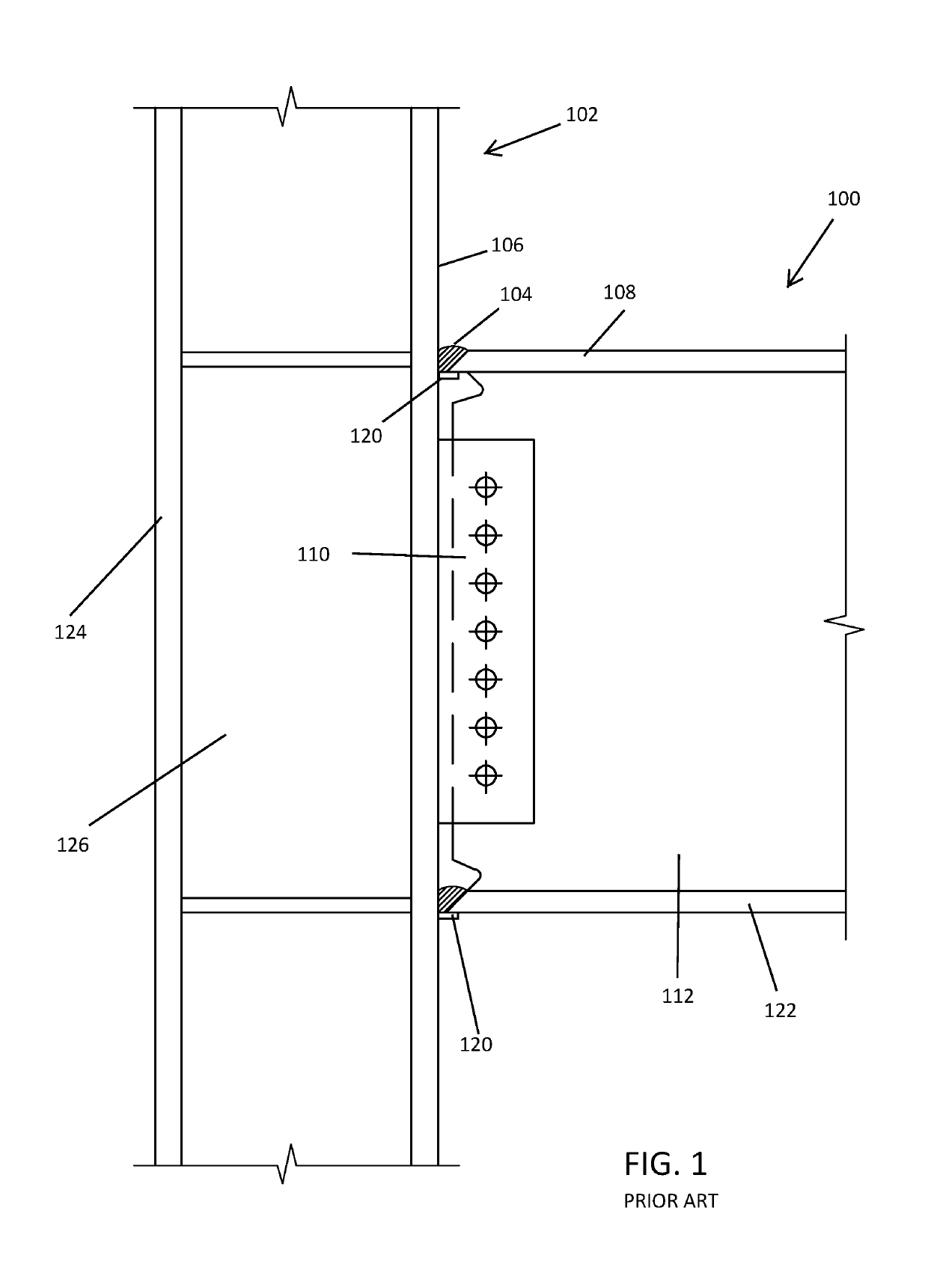

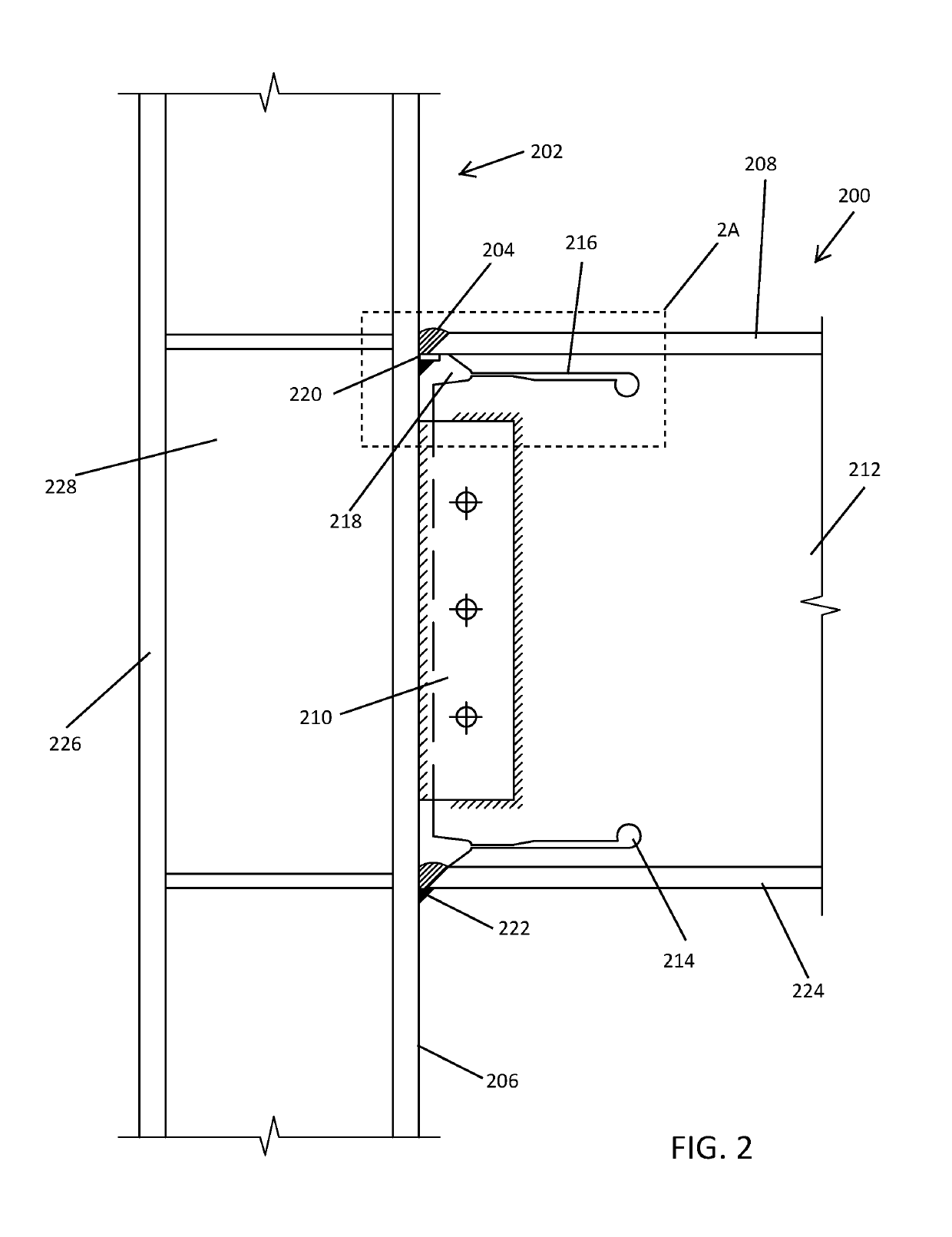

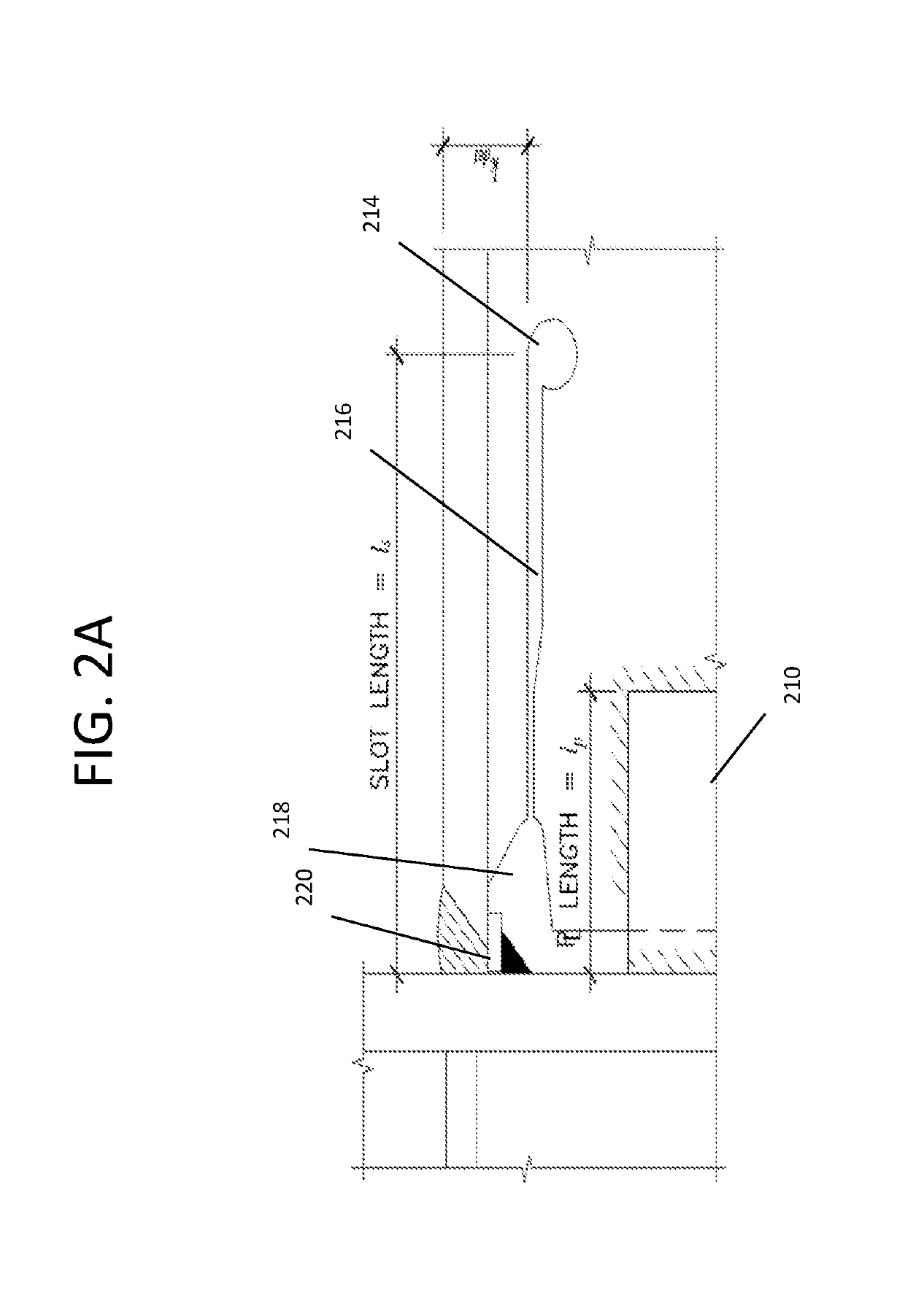

Retrofit designs for steel beam-to-column connections

ActiveUS20190330873A1Repair is necessaryEliminate clippingBuilding repairsProtective buildings/sheltersStress reliefFlange

A method of retrofitting a pre-Northridge type steel beam-to-column connection, includes welding the web of the beam to a flange of the column and slotting the beam web in the region of the connection and near the beam flanges. Stress relief holes are made into the web of the beam and slots are cut into the web of the beam. A top backup bar is welded to the flange of the column and a bottom backup bar is removed from the flange weld to the column. The method includes back gouging the flange of the column at a position of the removed backup bar and welding a bottom flange of the beam to the flange of the column.

Owner:SEISMIC STRUCTURAL DESIGN ASSOC

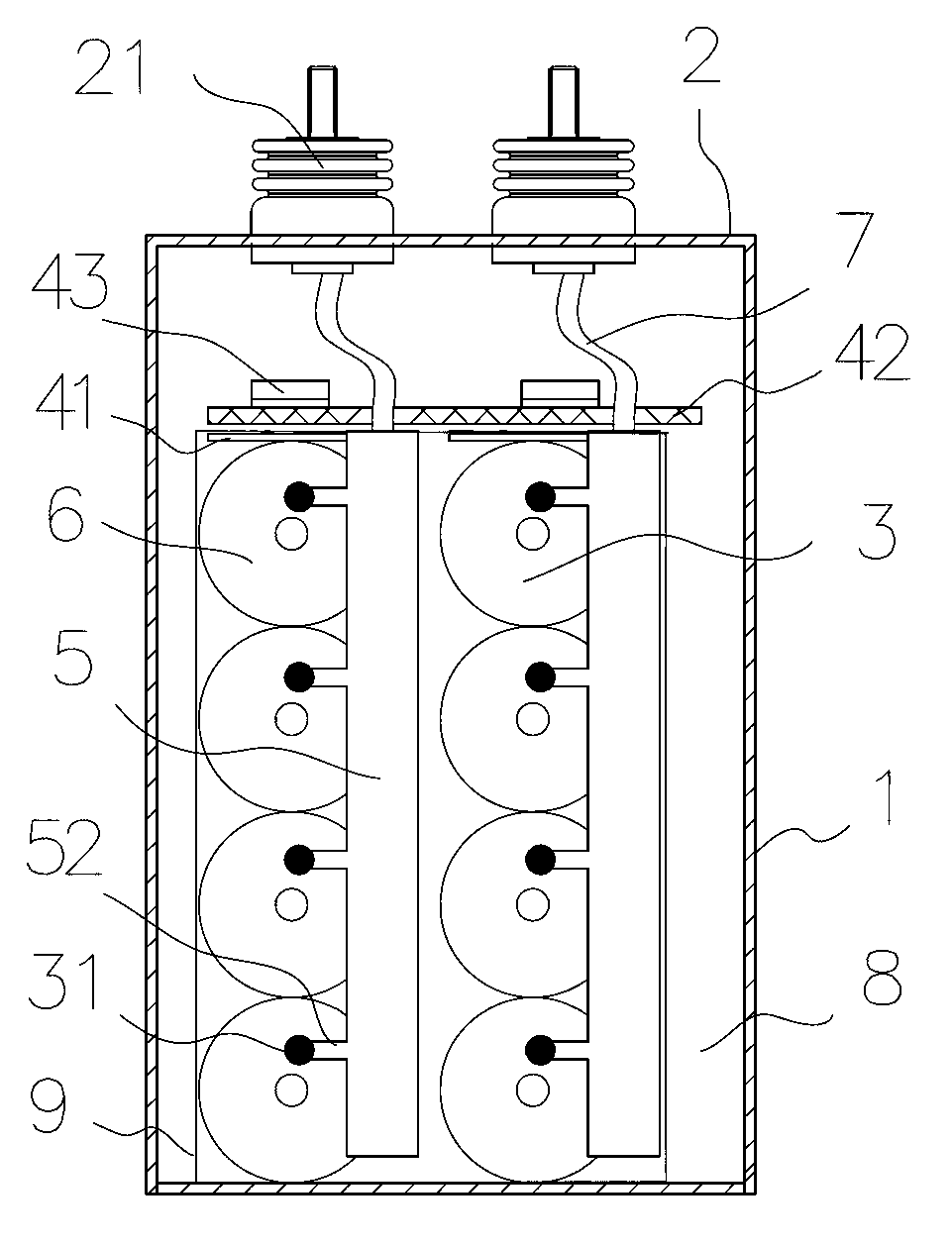

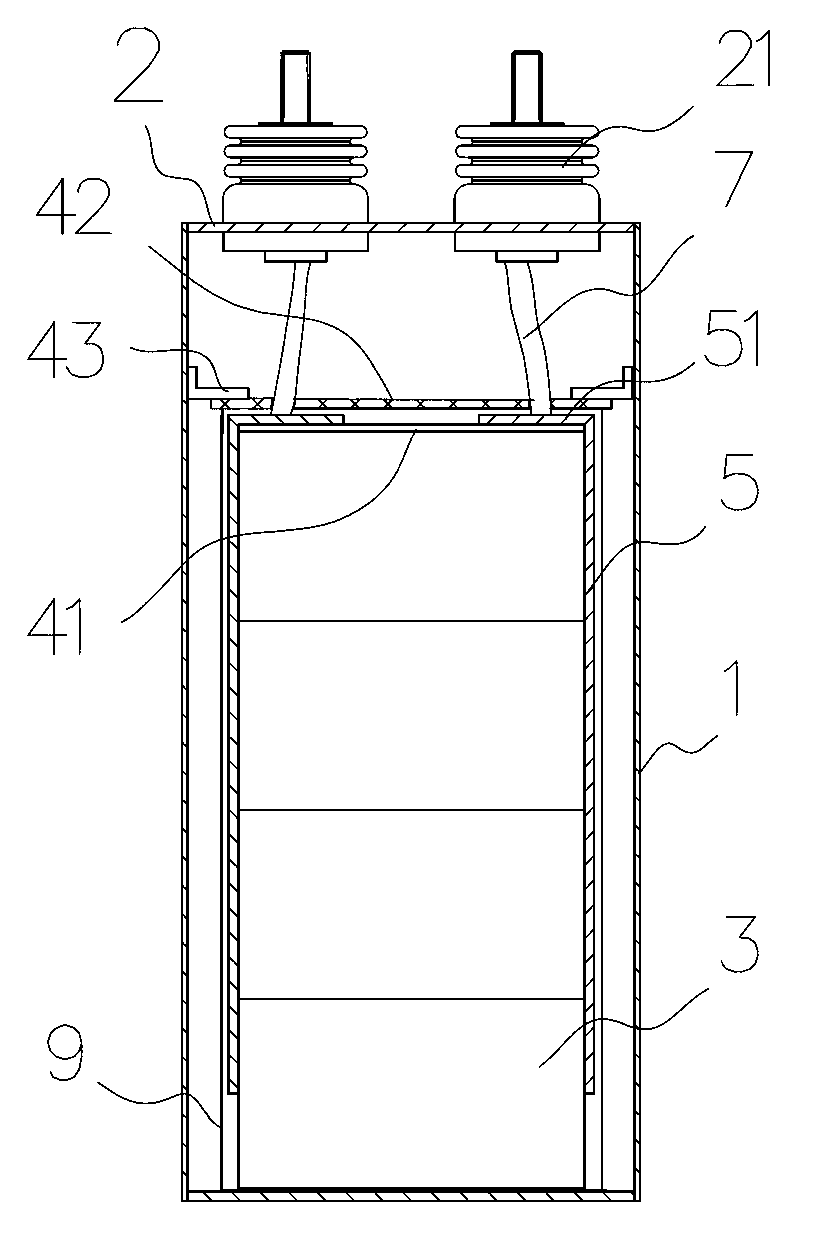

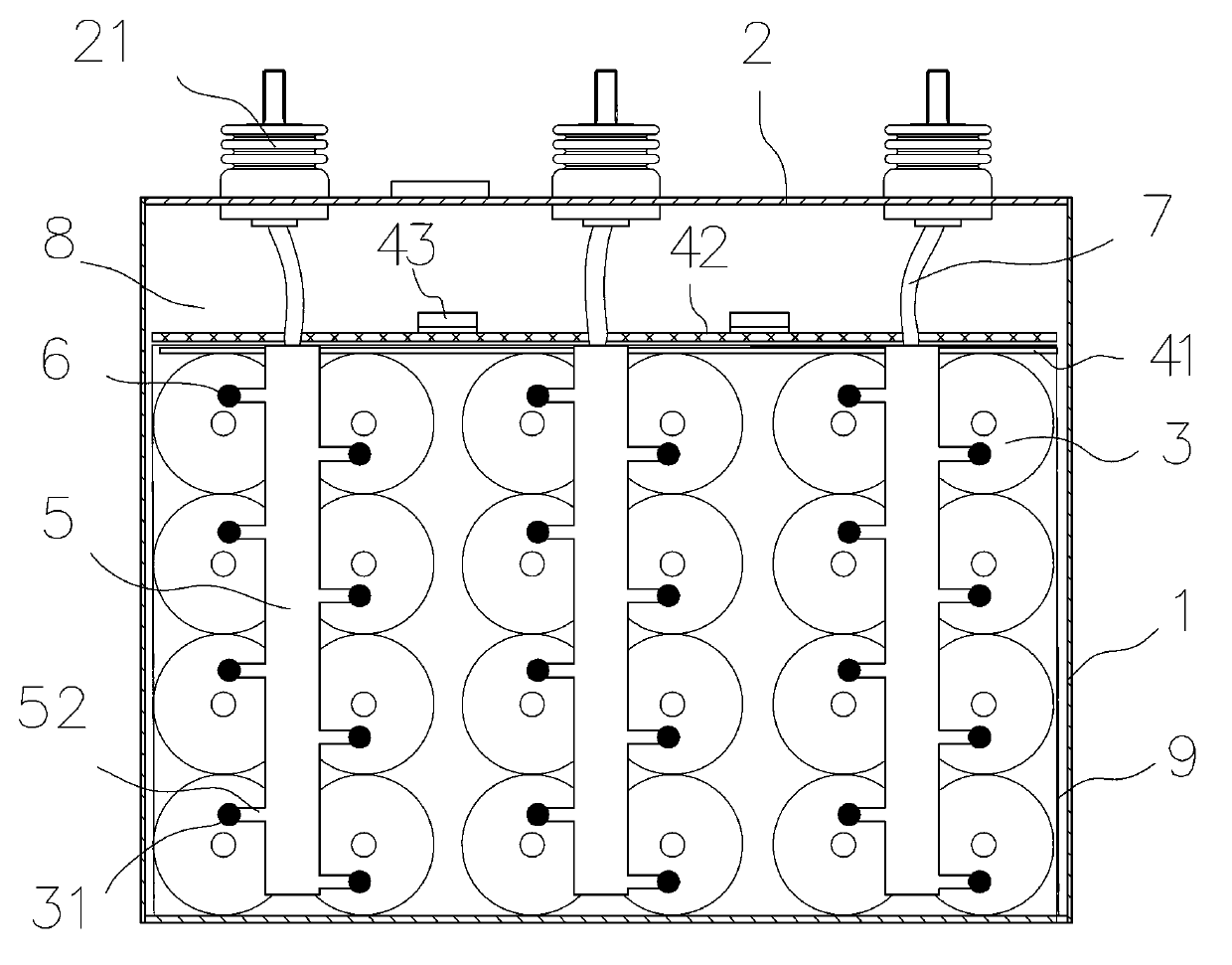

High-power power electronic capacitor for elastic connection among core sets and copper bars

The invention relates to a high-power power electronic capacitor for elastic connection among core sets and copper bars. The high-power power electronic capacitor comprises a cover plate assembly, an outer shell and the core sets. The core sets are fixed in the outer shell, leading-out copper strips are arranged on the two metal sprayed faces of each core set respectively, and bent leading-out electrodes are arranged at the upper ends of the leading-out copper strips and used for being electrically connected with leading-out terminals of the cover plate assembly through welding. Elastic conducting plates are arranged on the leading-out copper strips and extend to all capacitor core metal sprayed faces of the core sets, and the tail end of each elastic conducting plate is electrically connected with the corresponding capacitor core metal sprayed face through the welding. The core sets are connected with the leading-out copper strips in an elastic mode. The force, adhering to the elastic conducting plates, of welding points is strengthened. The situation that the leading-out copper strips have sufficient properties of current passing can be guaranteed, and in addition, the situation that the displacement of the core sets causes the welding points to be strained can be eliminated, so that the welding points are not prone to loosening and disengaging.

Owner:ANHUI TONGFENG ELECTRONICS

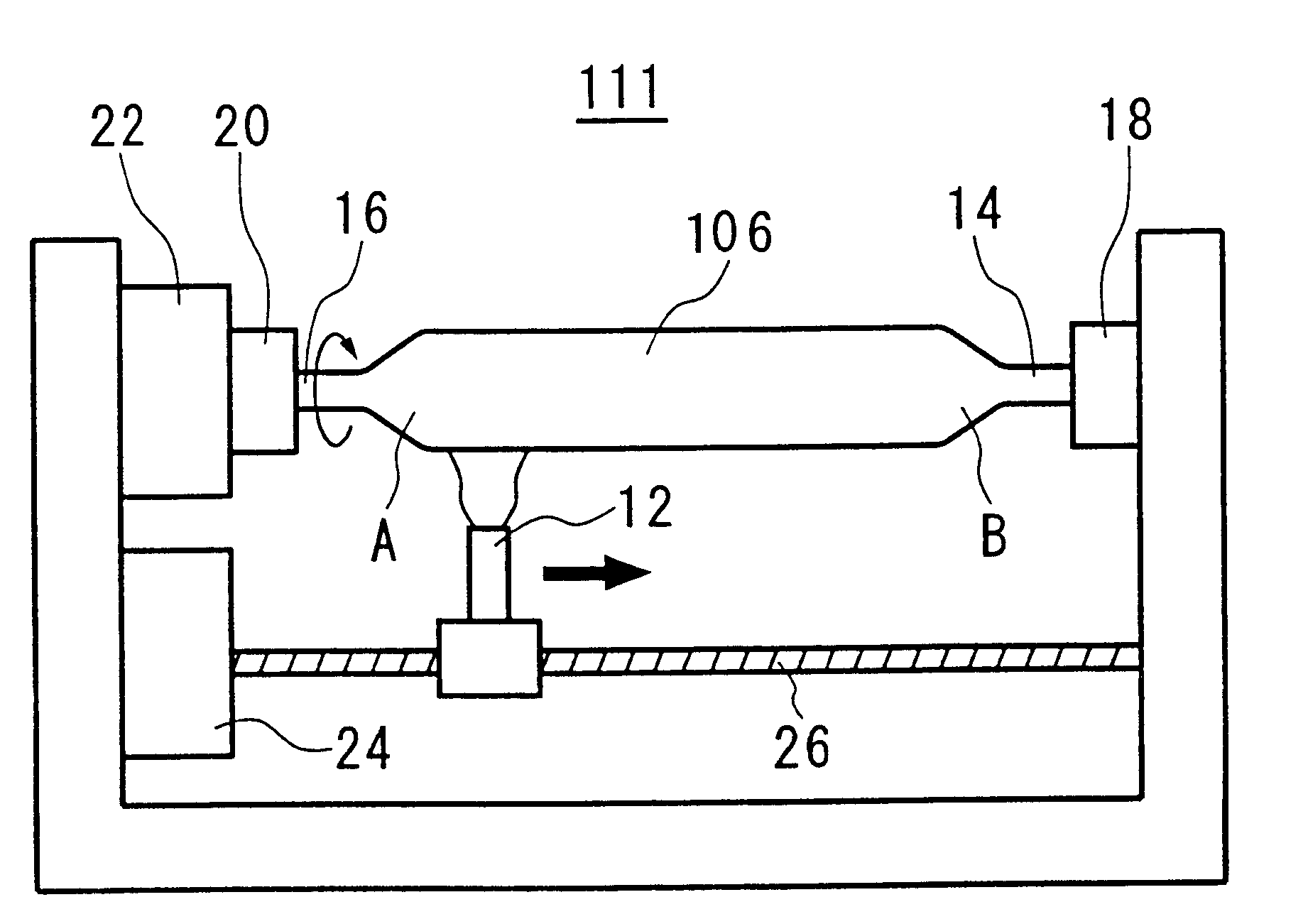

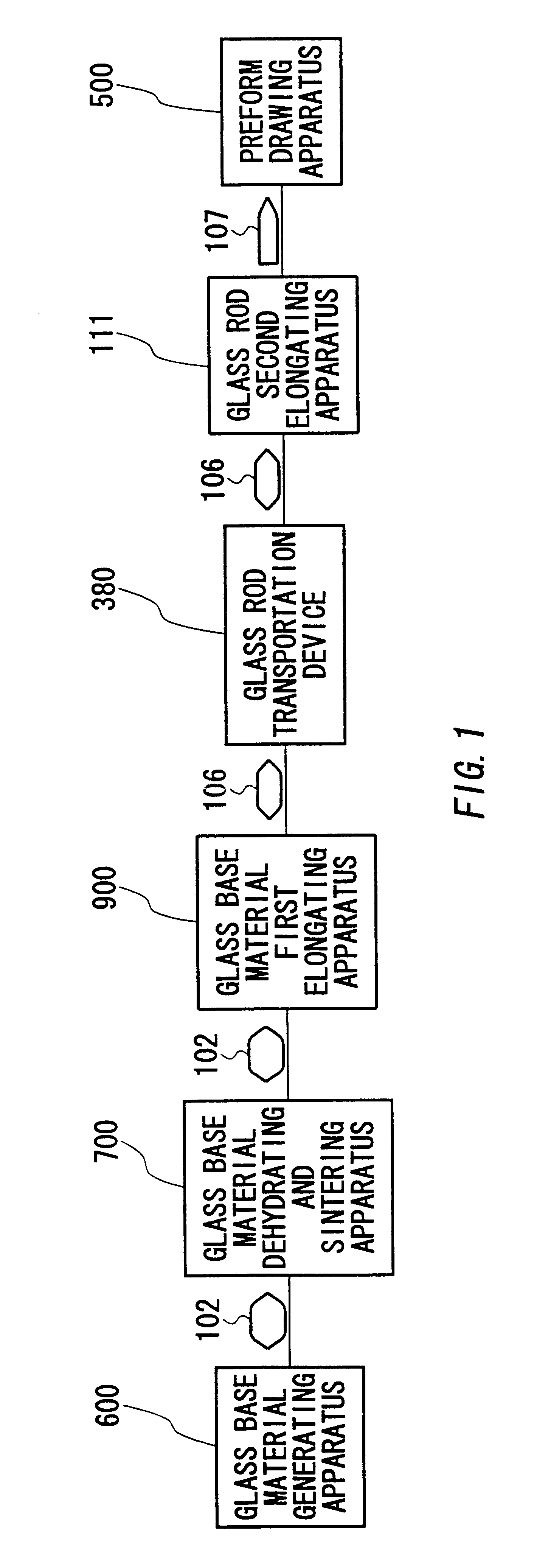

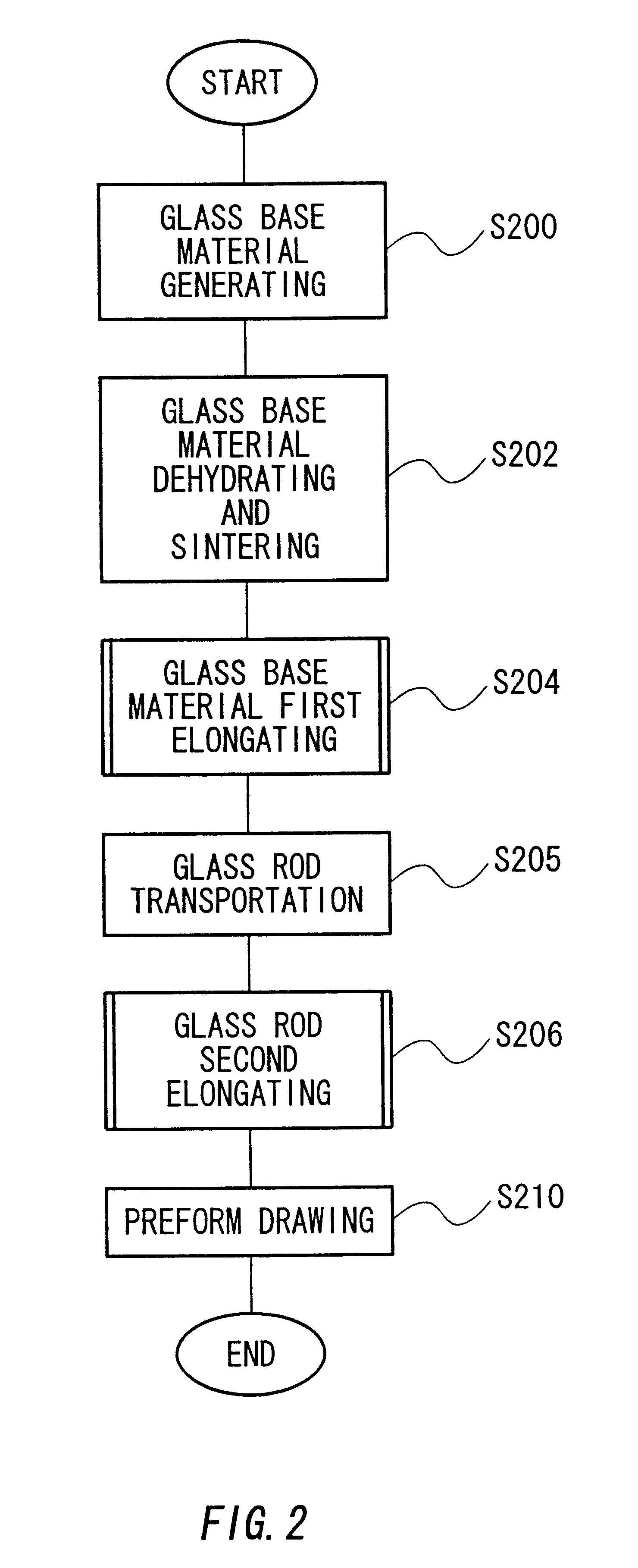

Double flame polishing method for fiber preforms

Owner:SHIN ETSU CHEM IND CO LTD

Semiconductor device manufacturing method thereof

InactiveUS8507327B2Low costEliminate strainSemiconductor/solid-state device detailsSolid-state devicesAdhesiveIsolation layer

Cutting work is performed on an n-semiconductor substrate (1) with an inverted trapezoid-shaped dicing blade to form grooves to be a second side walls (7). Bottom portions of the grooves are contacted with a p-diffusion layer (4) which is formed on a first principal plane (2) (front face) of the n-semiconductor substrate (1), so that the p-diffusion layer (4) is not cut. Then in the second side walls (7), a p-isolation layer (9) connected to a p-collector layer (8) and the p-diffusion layer (4) is formed. Since the p-diffusion layer (4) is not cut, a glass support substrate for supporting a wafer, and expensive adhesive, are not required, and therefore the p-isolation layer (4) can be formed at low cost.

Owner:FUJI ELECTRIC CO LTD

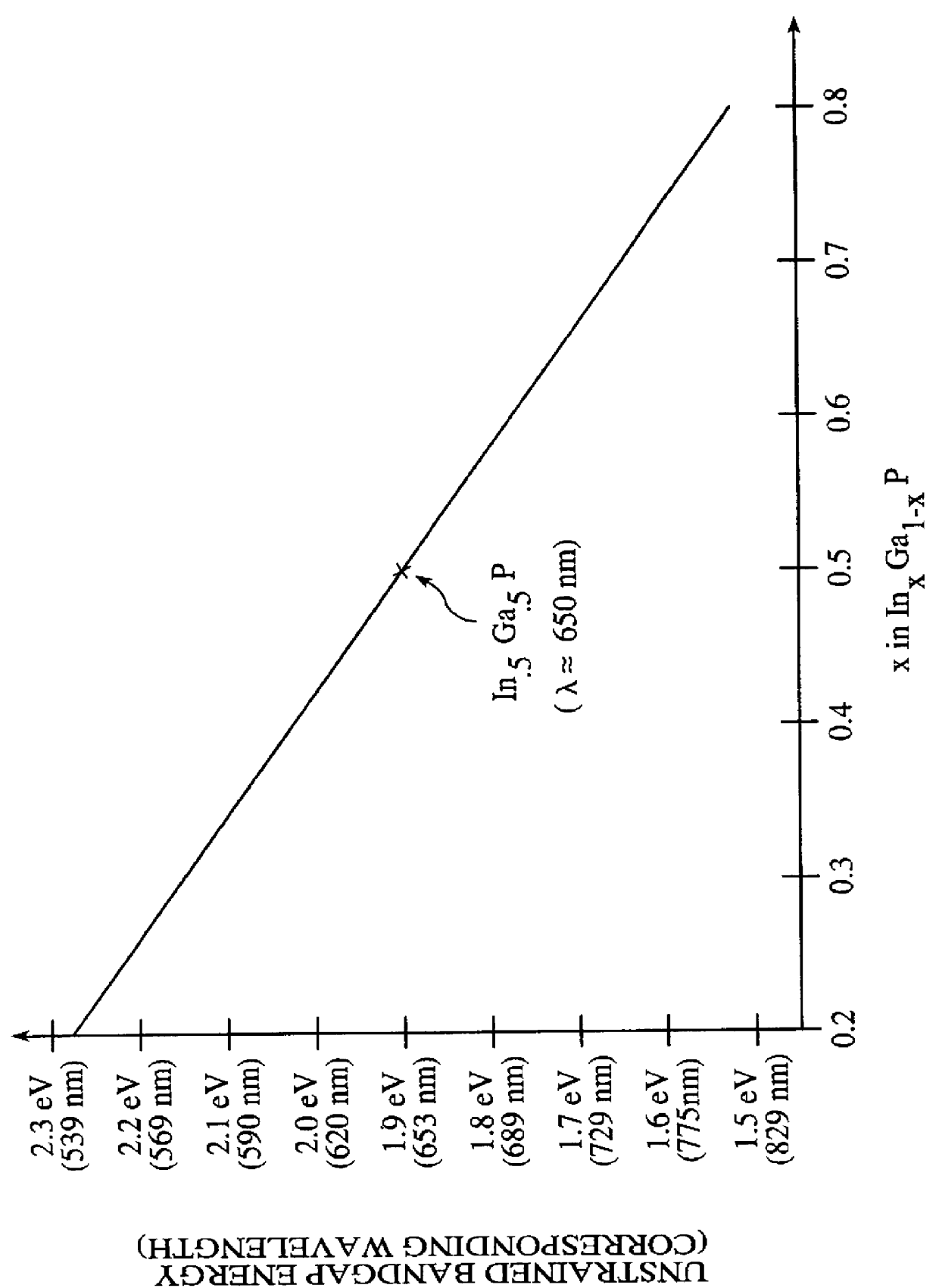

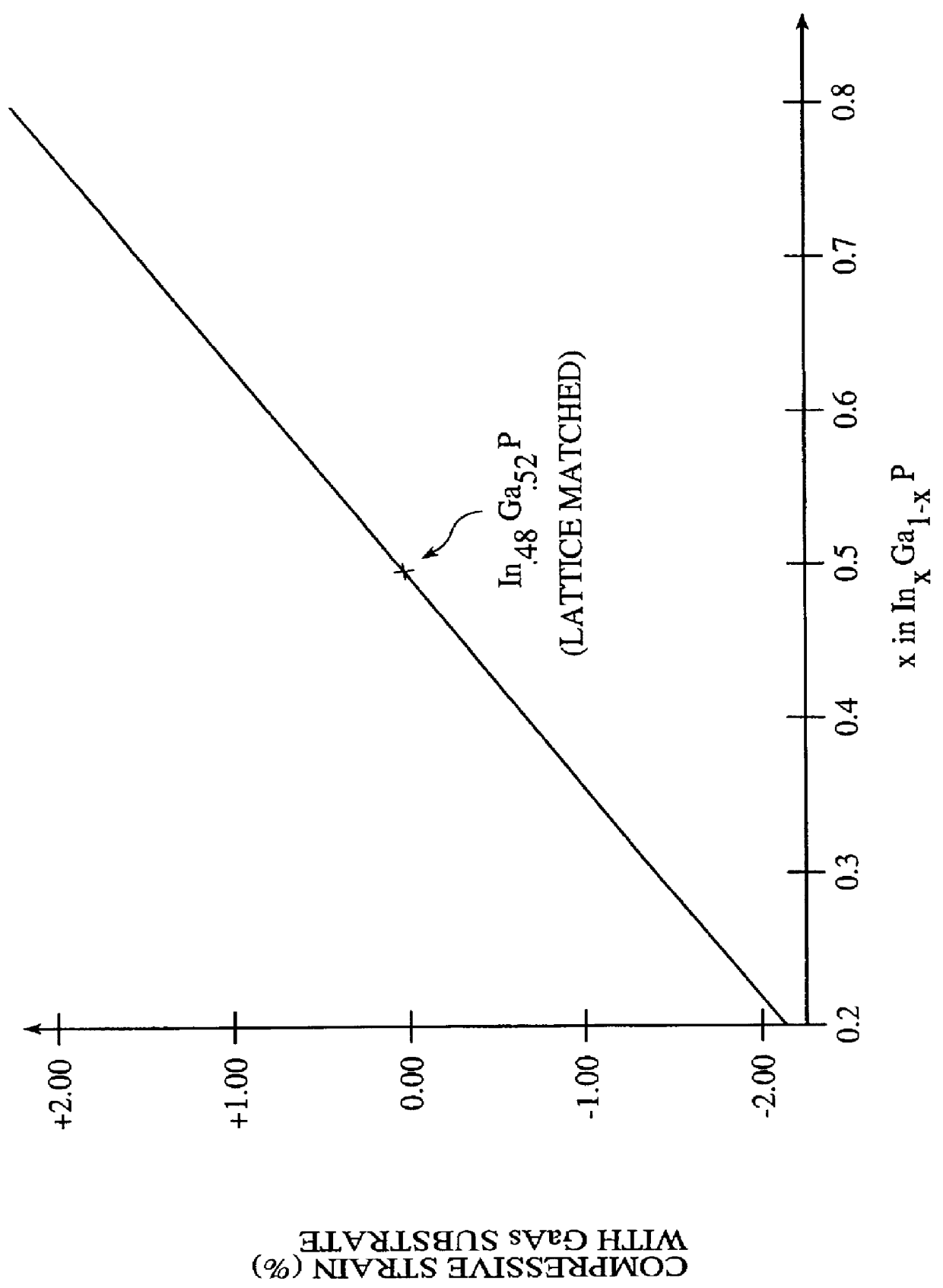

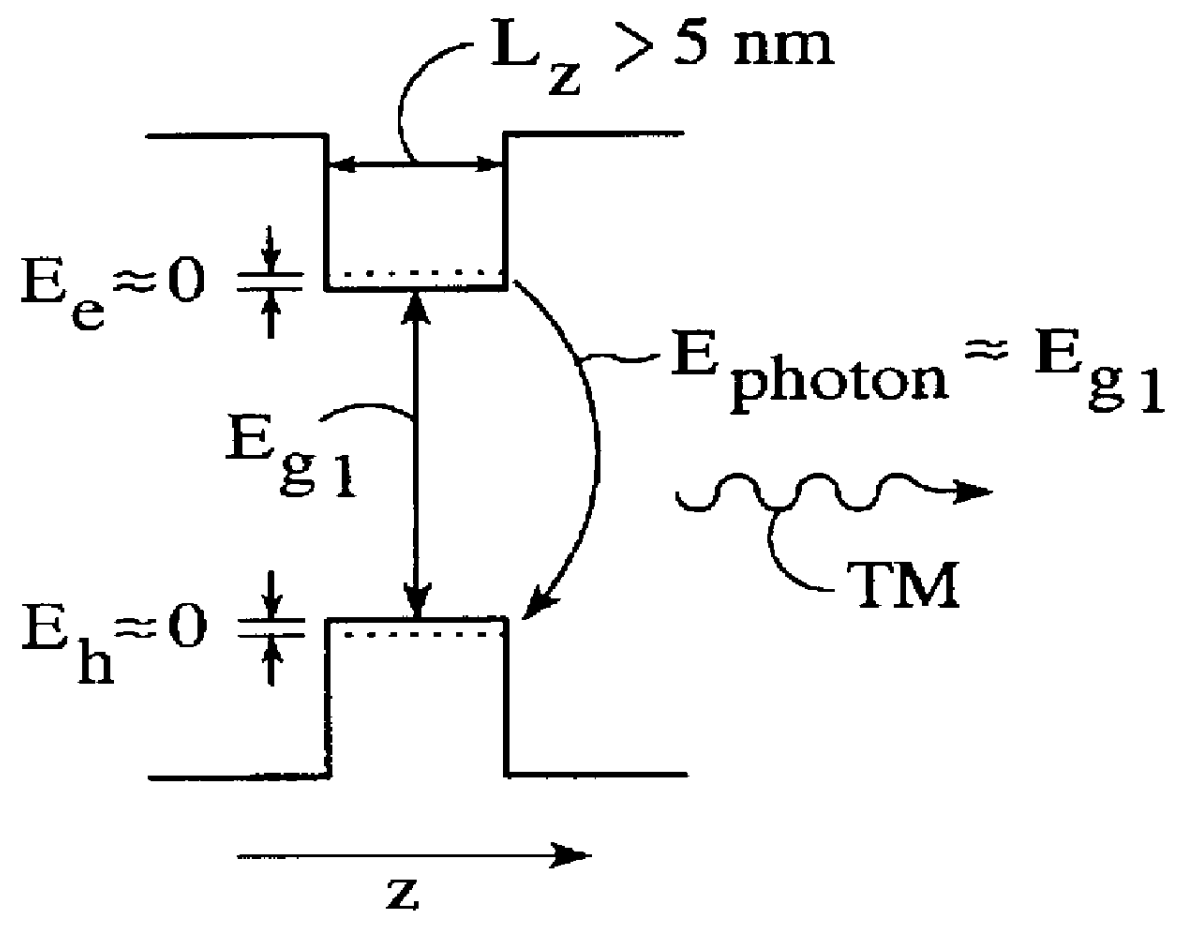

Transverse electric (TE) polarization mode AlGaInP/GaAs red laser diodes, especially with self-pulsating operation

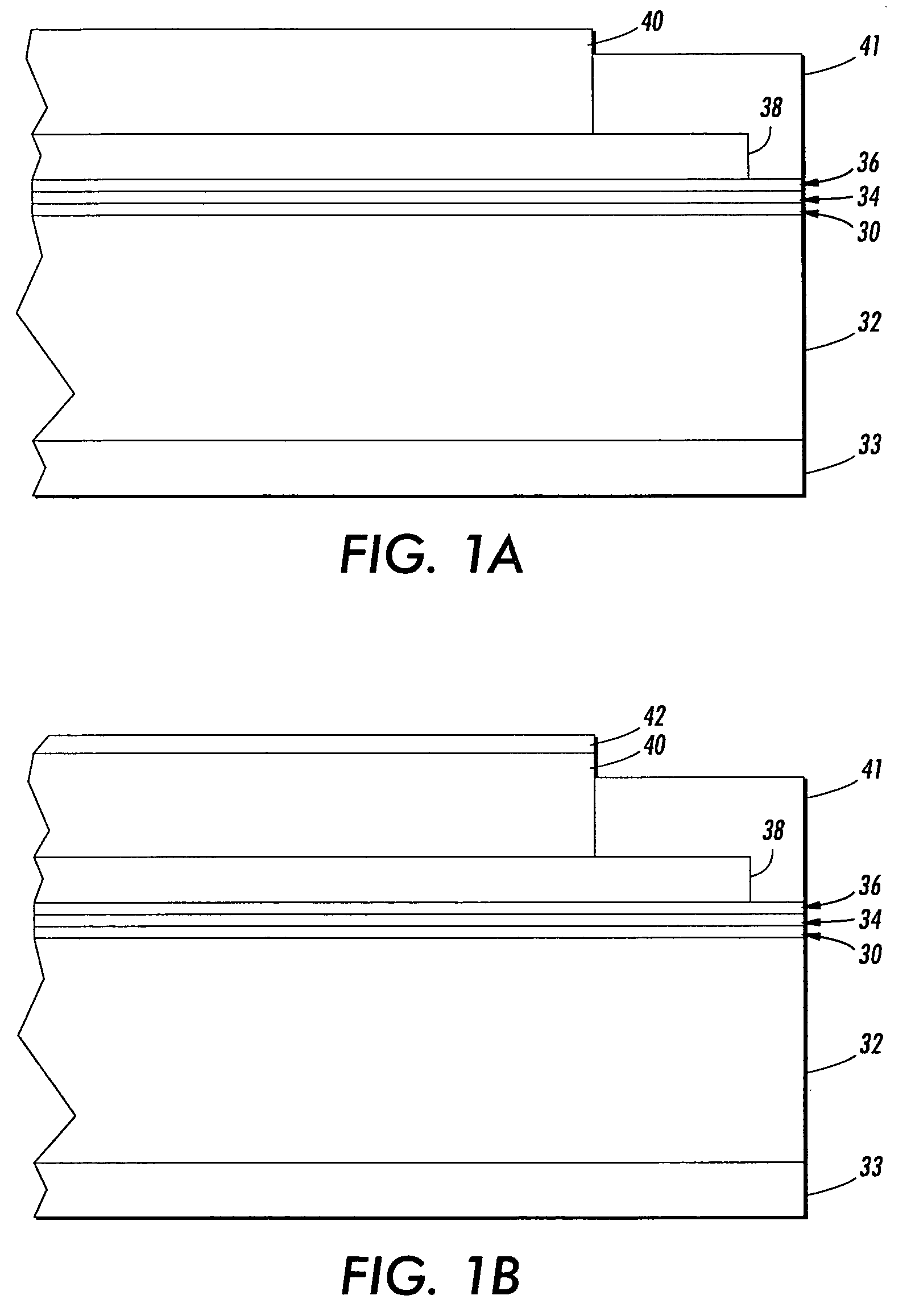

InactiveUSRE36802E1Increased effective bandgap energyMinimize and eliminate tensile strainLaser active region structureOptical resonator shape and constructionDiffusionCharge carrier

An AlGaInP / GaAs laser diode is disclosed in which the active region is made up of quantum wells that are sufficiently thin (less than 5 nm thick) that the transition energy increase due to quantum confinement of the carriers becomes significant. This allows the quantum well material composition to be selected for compressive strain so that the laser operates in the TE polarization mode, while still obtaining a transition energy of from 1.9-2.0 eV for 620-650 nm laser emission. Quantum barriers have sufficient thickness to confine carriers to the quantum wells. Self-pulsation may be obtained in a heterostructure that also includes a saturable absorption layer proximate to the active region and a ridge structure transversely confining absorption produced carriers in the central section of the absorber layer, while allowing lateral carrier diffusion to side regions where carriers are allowed to leave the absorber layer.

Owner:JDS UNIPHASE CORP

Vial attachment pliers

Vial attachment pliers that include a handle; a static arm that includes a recessed vial adapter slot and extends from the handle such that the longitudinal axis of the static arm is substantially perpendicular to the longitudinal axis of the handle; a guide rod that extends from the static arm such that the longitudinal axis of the guide rod is substantially perpendicular to the longitudinal axis of the static arm; a dynamic arm having a vial slot that is slidably attached to the guide rod; a lever pivotably attached to the handle; and a connector bar connecting the lever to the dynamic arm, such that as the lever pivots relative to the handle, the dynamic arm is urged to slide along the guide rod.

Owner:FORBES VINCENT C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com