Transverse electric (TE) polarization mode AlGaInP/GaAs red laser diodes, especially with self-pulsating operation

a laser diode and transverse electric technology, applied in semiconductor lasers, optical resonator shape and construction, laser details, etc., can solve the problems of laser insensitive to feedback, large and heavier read head containing such optics, random fluctuations in laser output power, etc., to minimize or eliminate tensile strain of quantum wells, increase quantum confinement energy, and increase effective bandgap energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

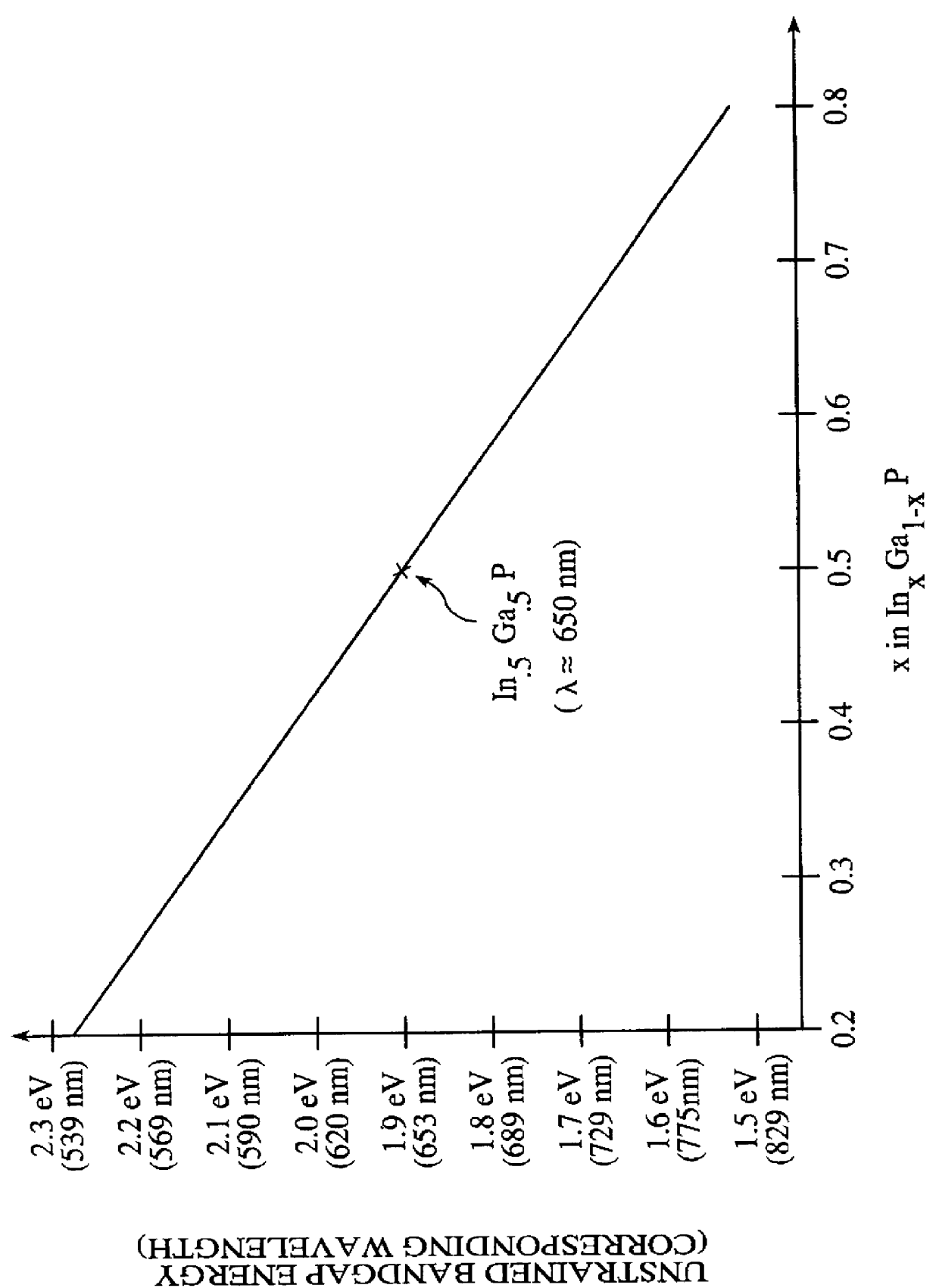

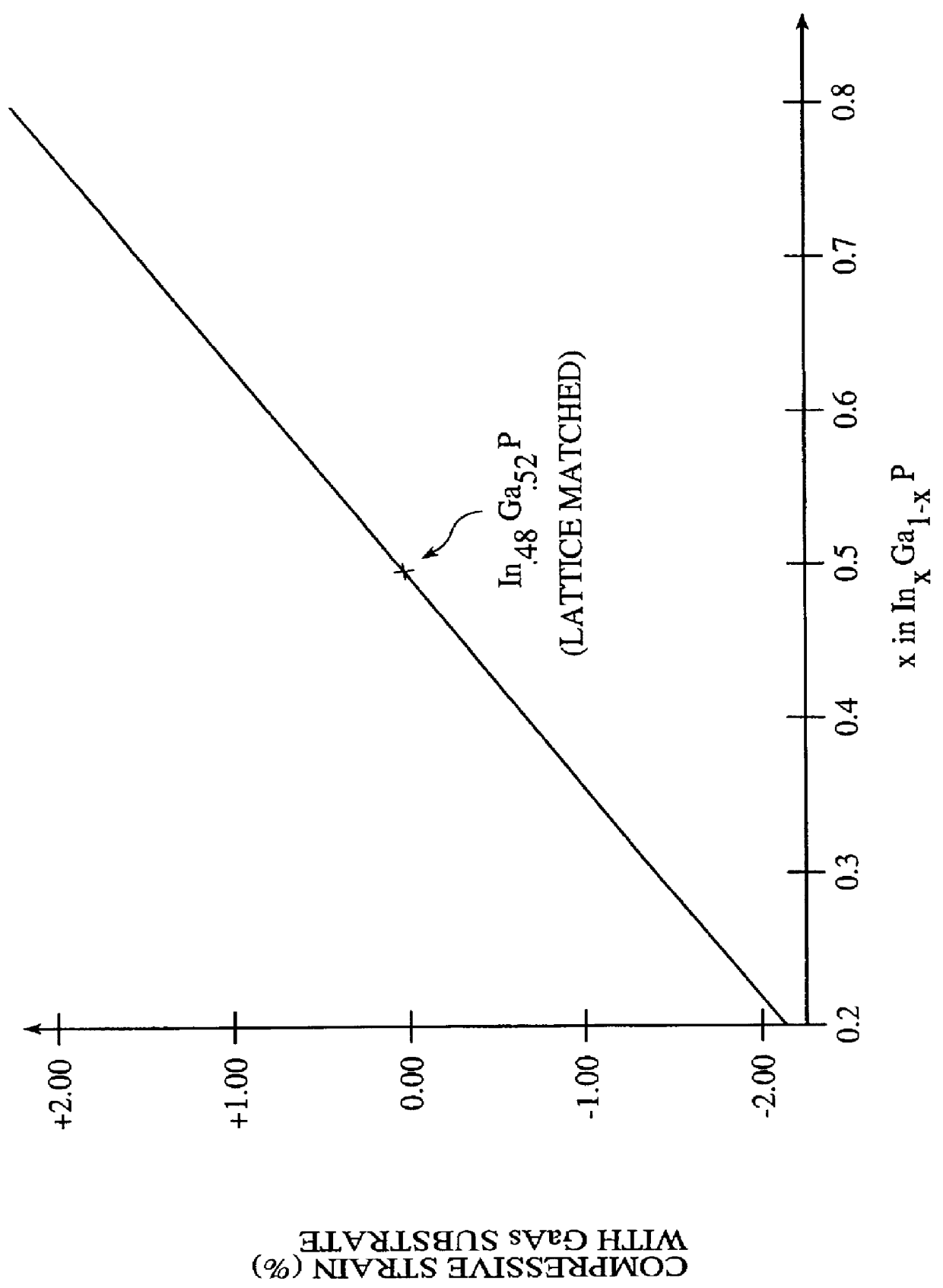

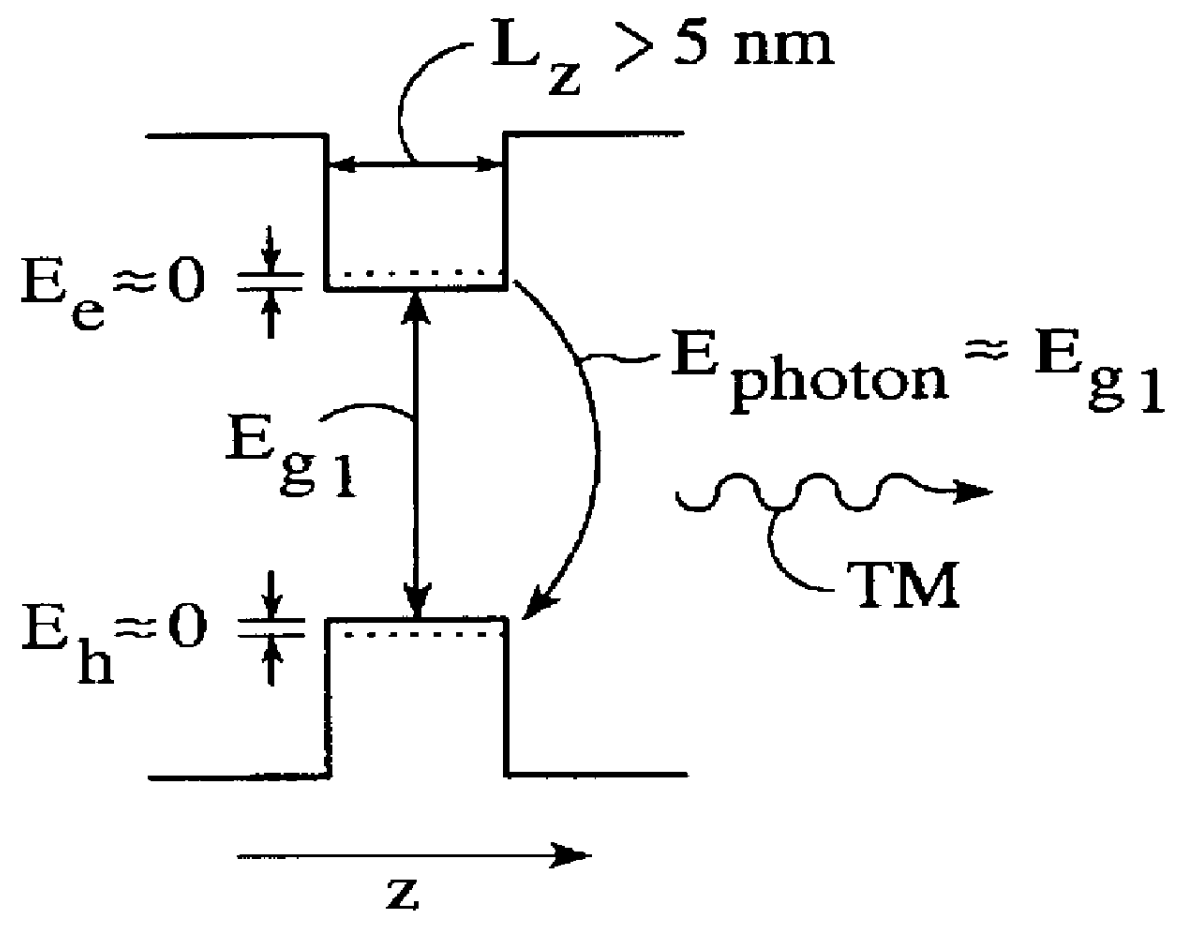

With reference to FIGS. 1 and 2, it has been seen that due to the constraints imposed by material composition, bandgap energy, lattice size and strain, prior laser diode devices of the AlGaInP / GaAs material type are limited to TM mode operation in the shorter 620-650 nm wavelength range. FIGS. 3A and 3B show how quantum confinement in narrow quantum wells is used in the present invention to simultaneously provide both compressive strain and high effective bandgap energies in the quantum wells to produce TE mode operation for wavelengths shorter than 650 nm. (For illustration purposes, the energy diagrams are not strictly to scale.) By cladding lower bandgap quantum well material between higher bandgap quantum barrier material, confinement of electronic carriers in the quantum well or wells is achieved. The quantum confinement in the wells allows discrete energy states for the carriers in which the carrier confinement energies are: ##EQU1## where m is the effective mass of the partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com