High-power power electronic capacitor for elastic connection among core sets and copper bars

An elastic connection and power electronics technology, applied in multiple fixed capacitors, etc., can solve problems such as over-current performance damage, rigid solder joints being strained, copper strip deformation, etc. enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

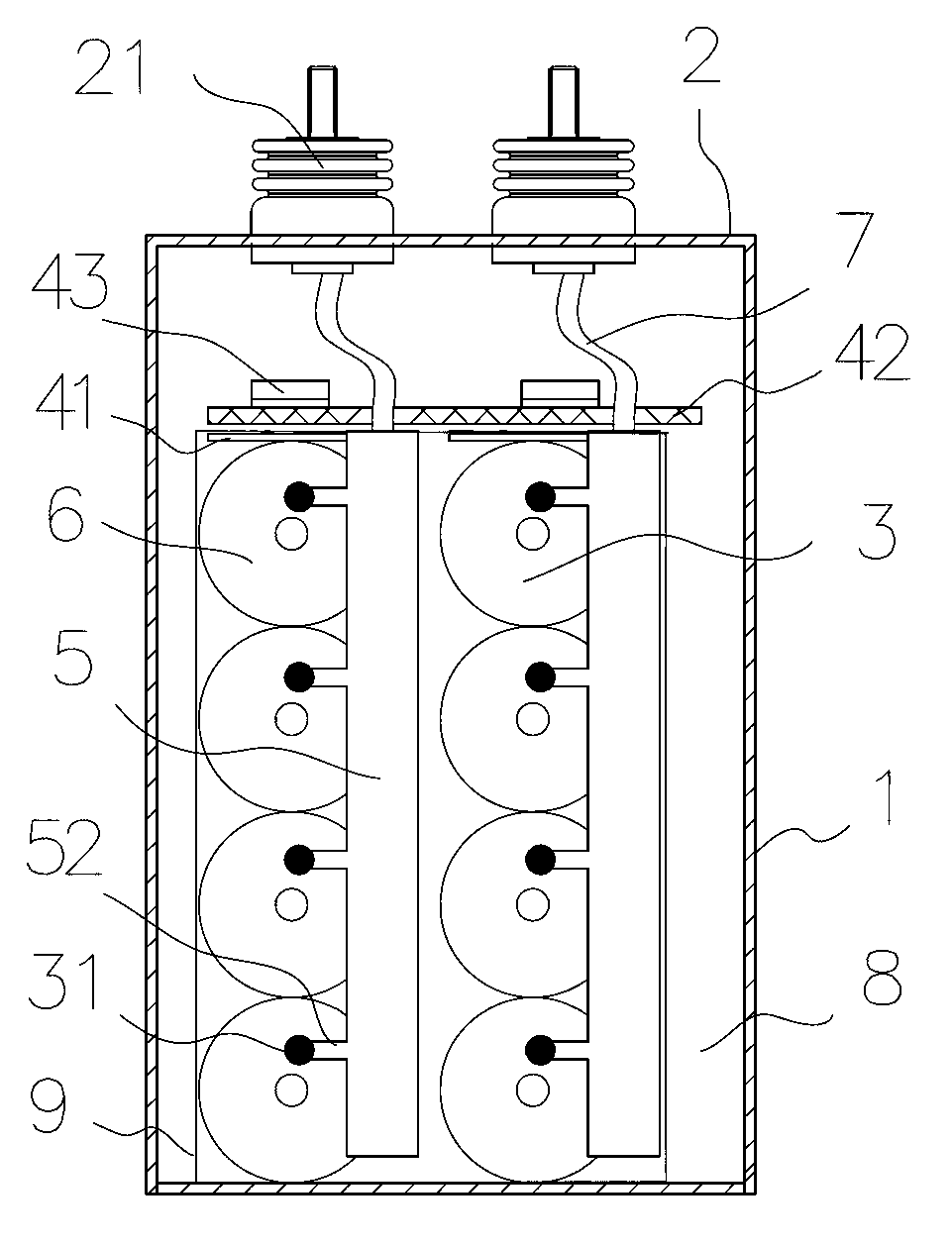

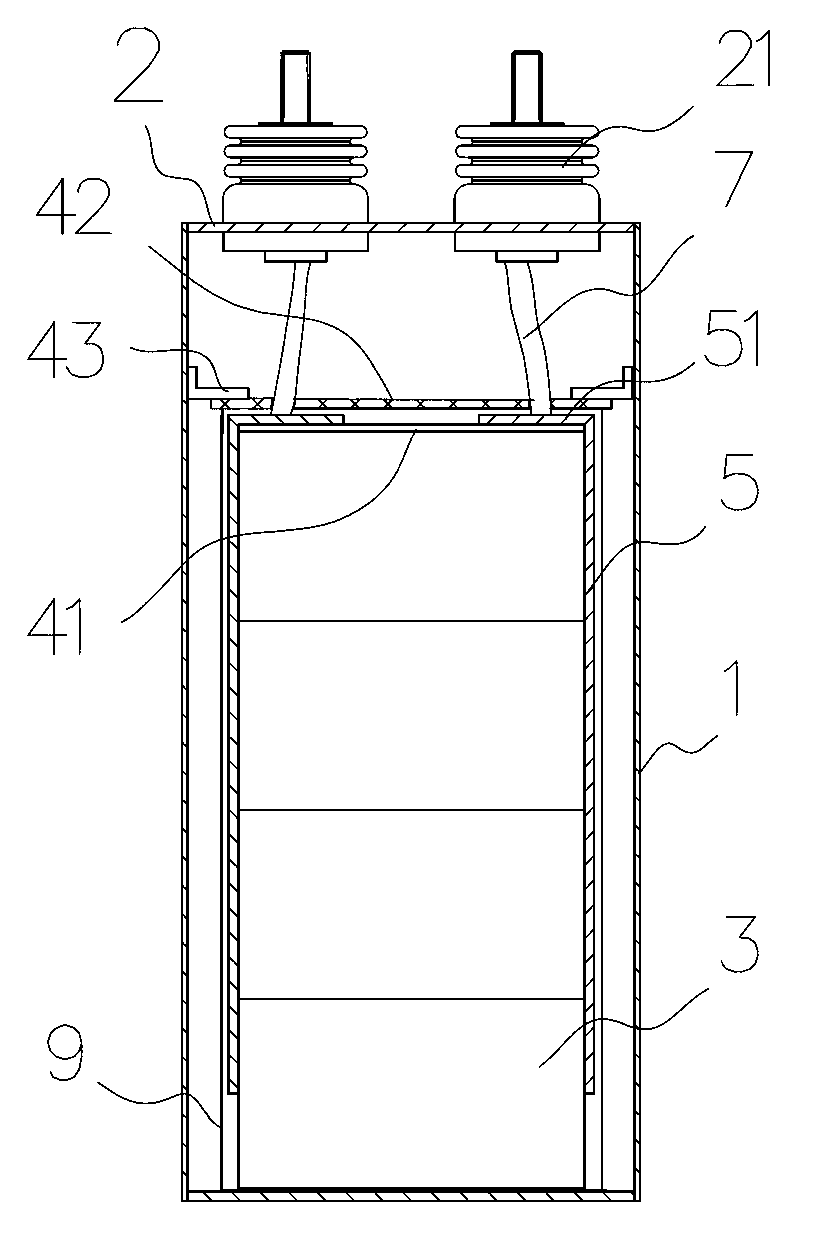

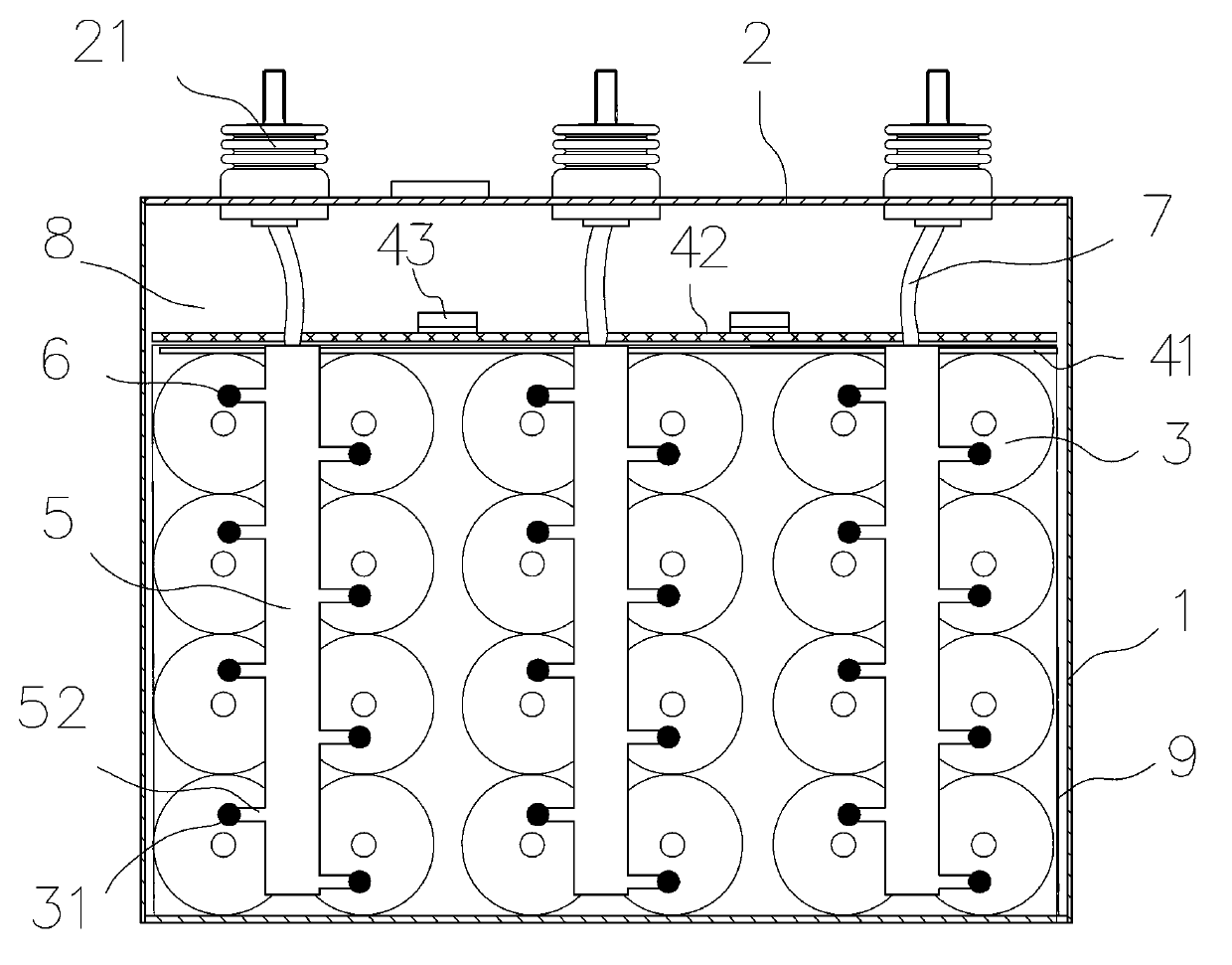

[0015] like figure 1 , figure 2 As shown, the present invention includes a cover plate assembly 2, a casing 1, and a core group 3; there are two sets of core groups 3, the core group 3 is fixed in the casing 1, and the inner cavity 8 can be filled with resin or liquid impregnating agent; each group of core groups 3 is composed of a row of multiple cylindrical capacitor cores superimposed up and down; each group of cores 3 is provided with lead-out copper strips 5 on the gold-sprayed surface on both sides, and the upper end of the lead-out copper strips 5 is bent to be used for welding and cover plate assembly 2 lead-out electrodes 51 of the lead wires 7 connected to the lead-out terminals 21; lead-out copper strips 5 are provided with elastic conductive sheets 52 extending to the gold-sprayed surface of each capacitor core of the core group 3, and the ends of each elastic conductive sheet 52 are connected to the corresponding capacitor The gold-sprayed surface of the core is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com