Wing in ground effect vehicle with endplates

An end plate and air cushion technology, applied in the field of WIG with end plates, can solve the problems of unrealistic thickness, wrong structure of end plate 57, lack of stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

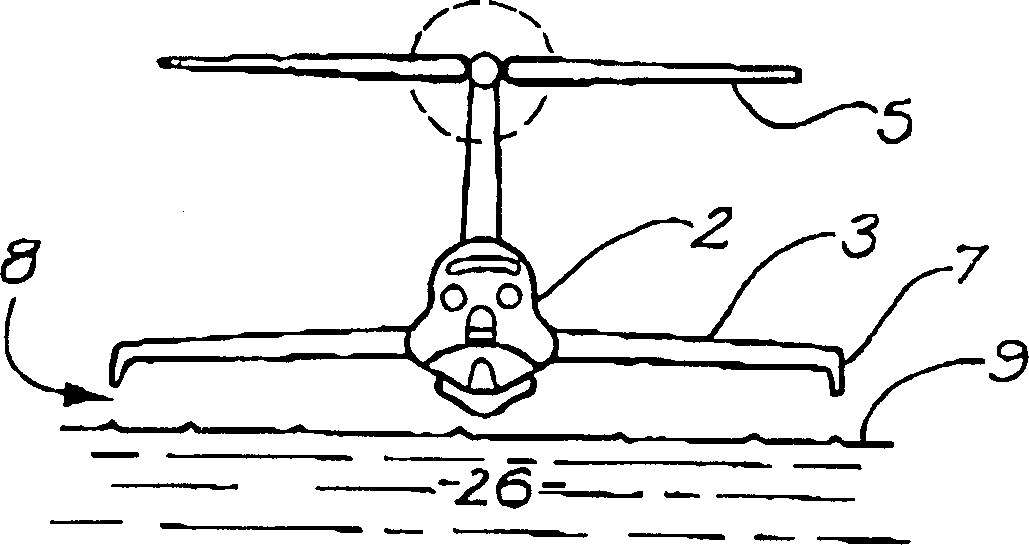

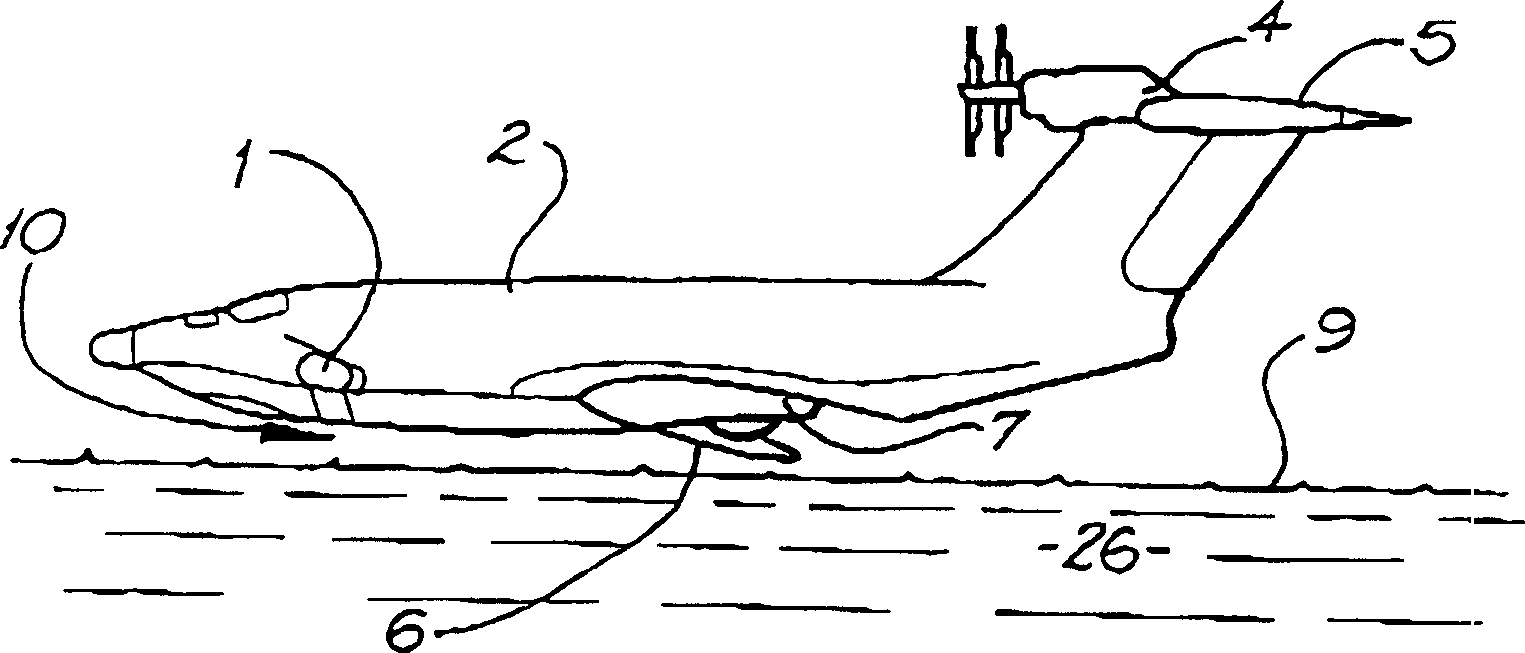

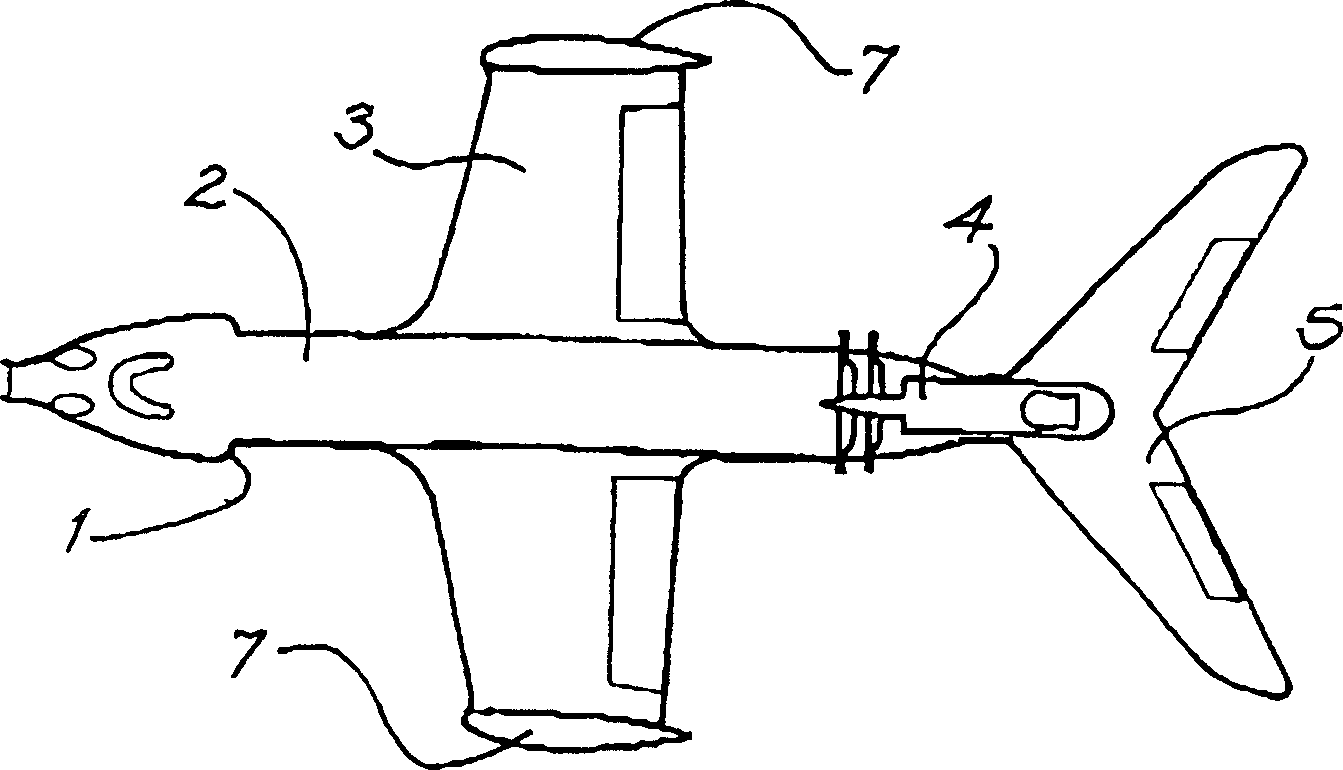

[0129] Figures 6(a) to 6(c) A winged hovercraft according to a preferred embodiment of the present invention will be described. The winged hovercraft has a fuselage 2 and a wing structure 3 with opposing wing tops. A pair of end plates 17, each end plate having a proximal base 33, a bottom or distal end 19, a leading edge 20 and a trailing edge 22, extend downward from the end plate wall 34 at the wing tip to the fuselage 2 and the machine. Below the wing structure 3. As shown in Figure 6(b), this allows the end plate 17 to be submerged in water 26 during flight while keeping the fuselage 2 and wing structure 3 in flight. In flight, the end plates are typically slightly submerged below the surface 9 of the water 26, even in the troughs 18 of the waves 21, as shown in the sectional view of Fig. 6(b). Since there is no air gap between the distal end 19 of the end plate 17 and the water 26, the WIG's induced drag is reduced, thereby increasing the WIG's lift / drag ratio. In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com