Hydraulic brake device for differential mechanism

A technology of hydraulic brakes and differentials, which is applied in the field of brakes and differential hydraulic brakes, can solve the problems of inability to turn on the spot, different driving torques, and large energy consumption loss, etc., and achieves a simple and reasonable structure, The effect of stability improvement and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment,

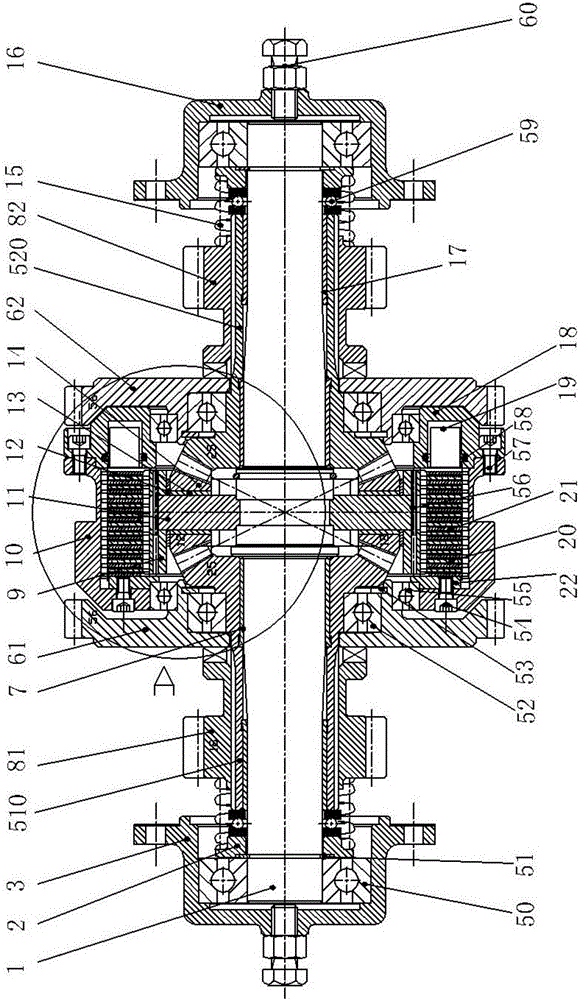

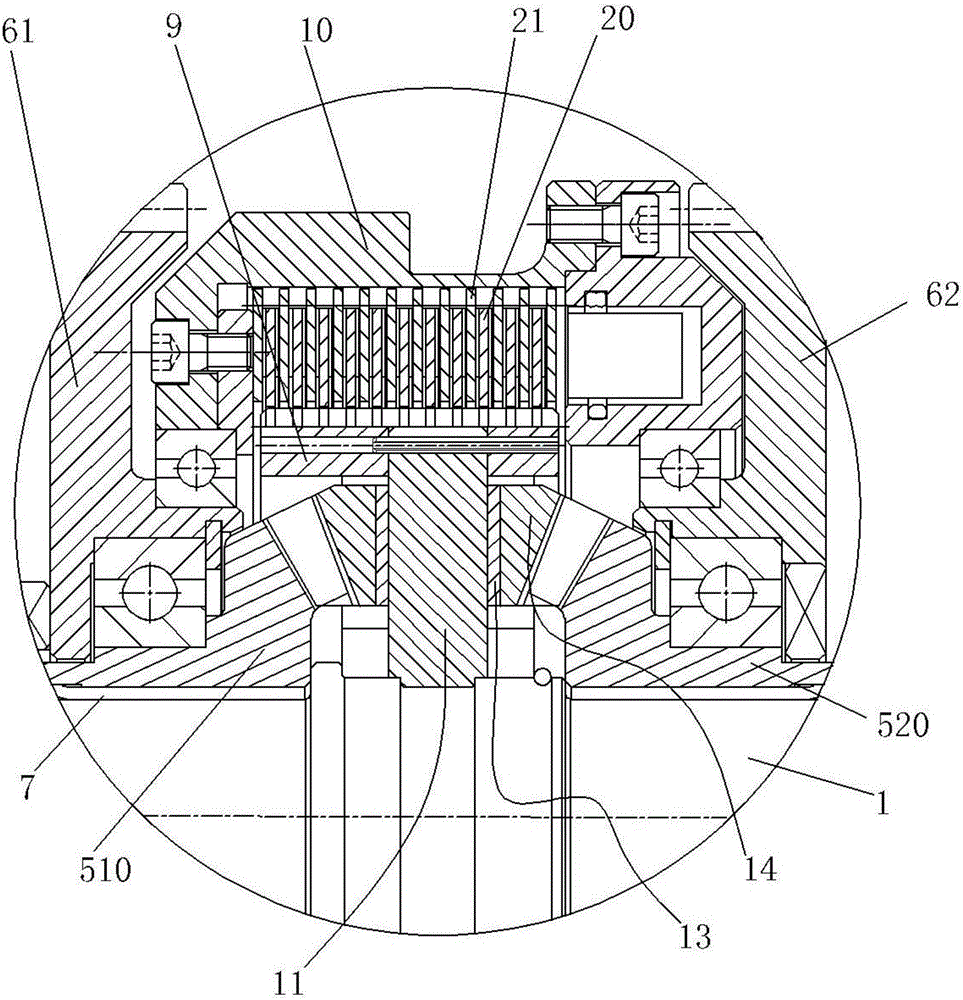

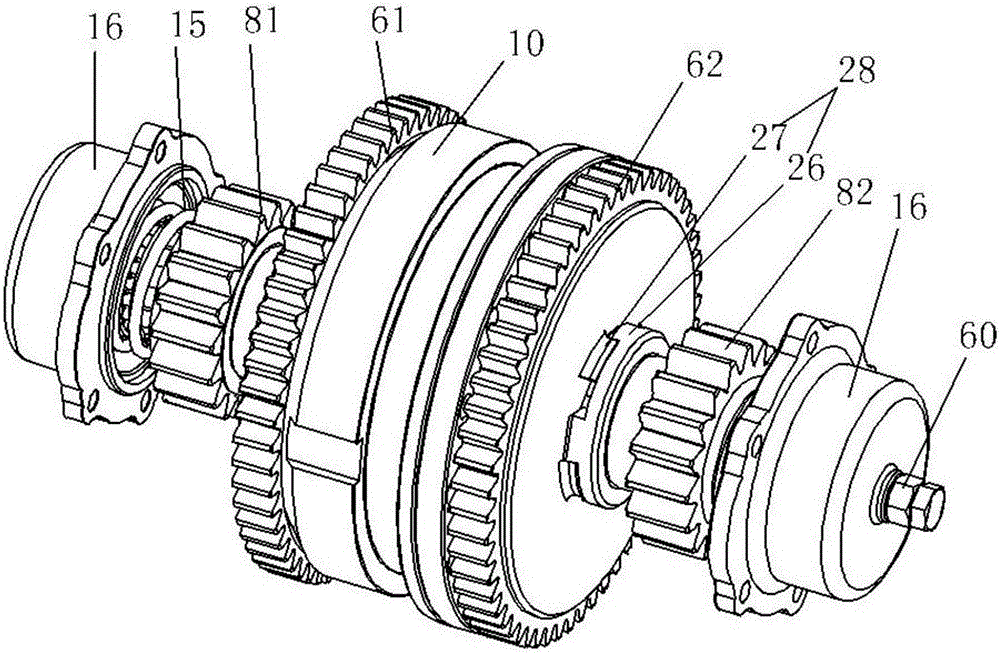

[0039] see Figure 1-8 : a differential hydraulic brake device, comprising a planetary gear differential and a hydraulic brake mechanism, the planetary gear differential and the hydraulic brake mechanism are meshed with each other; the hydraulic brake mechanism includes several separating plates 21, and the separating plate 21 and An inner disk 20 is arranged between the separation plates 21, and the inner disk 20 is movably arranged on the planetary gear differential, wherein the leftmost separation plate 21 is fixedly connected to the gear differential, and the rightmost separation plate 21 is on the right side. A hydraulic cylinder is provided to push the separating plate 21 and the inner disc 20 to be in close contact; the planetary gear differential is externally connected with a power device.

[0040] Including a case body 10 and a different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com