Multi-dimension dynamic synergic movement control method of high-speed intelligent prototype

A technology of coordinated motion and control method, applied in the direction of digital control, electrical program control, etc., can solve problems such as difficult to improve synchronously, unsolved, and difficult to run electronic pattern machine at high speed and smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The jitter problem of the pattern machine under high-speed operation is mainly related to the two-dimensional plane motion controlled by the stepper motor, that is, the worktable.

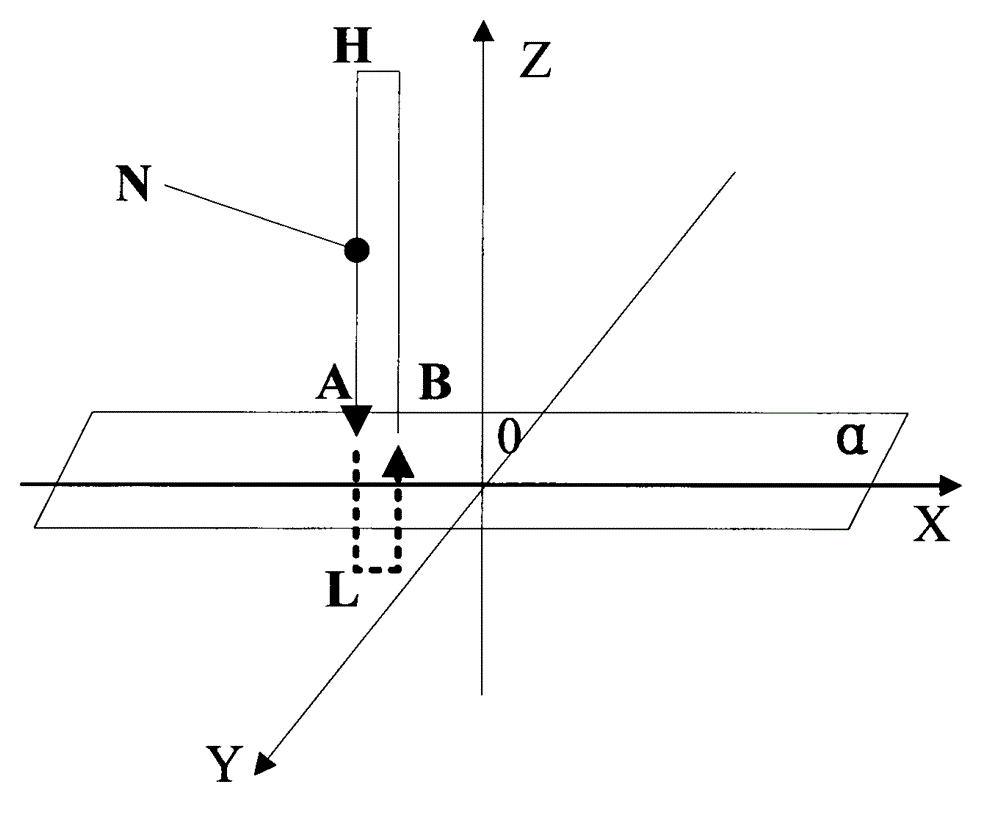

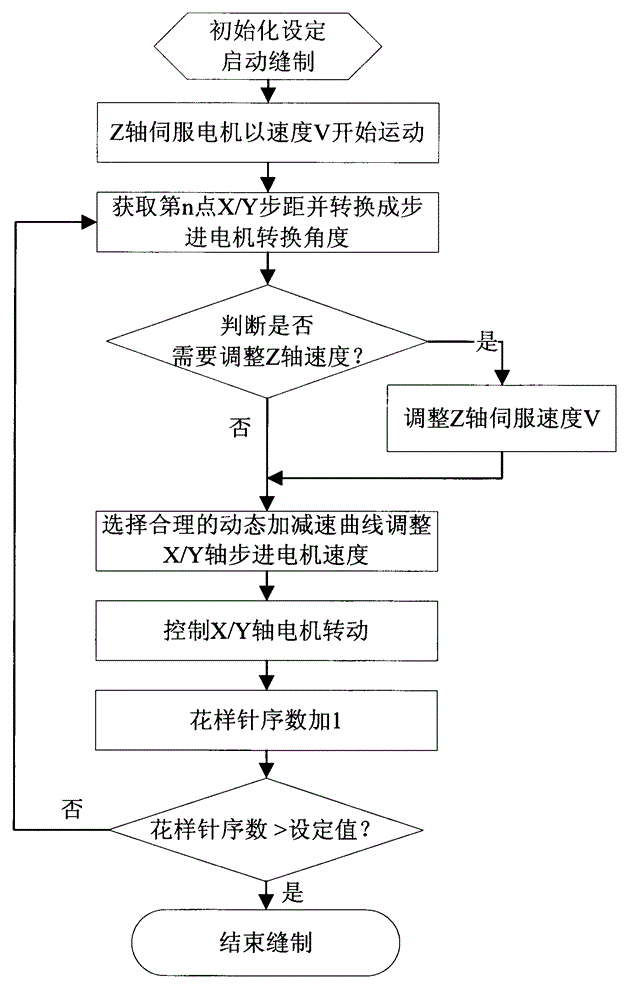

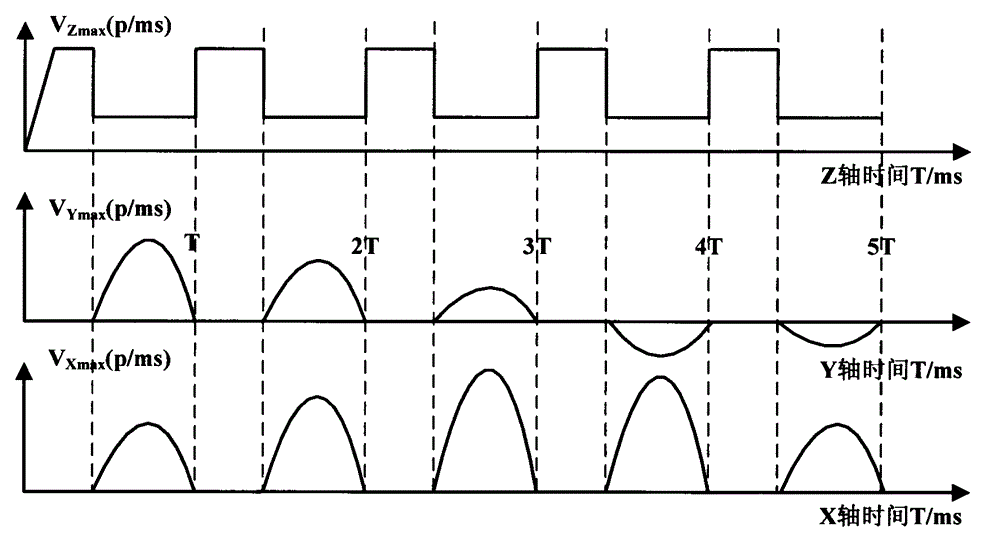

[0071] Subject to the requirements of the sewing function, the worktable that clamps the fabric on the XY plane moves a stitch length and then stops within a working cycle of the pattern machine. The Z-axis sewing needle passes through the fabric after the jumper (thread pulling, thread trimming, etc.) Remove the fabric and complete a stitch sewing; in this cycle, the worktable driven by the stepping motor starts to accelerate quickly, and then decelerates and stops immediately after the movement completes a stitch length; the movement time-space model is like figure 1 As shown, the mass point N-the end of the needle tip; plane α-feeding mechanism; A-the intersection point of the mass point N (needle tip) with the plane α when it moves downward; B-the intersection point of the mass point N (needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com