Patents

Literature

133results about How to "Ensure responsiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

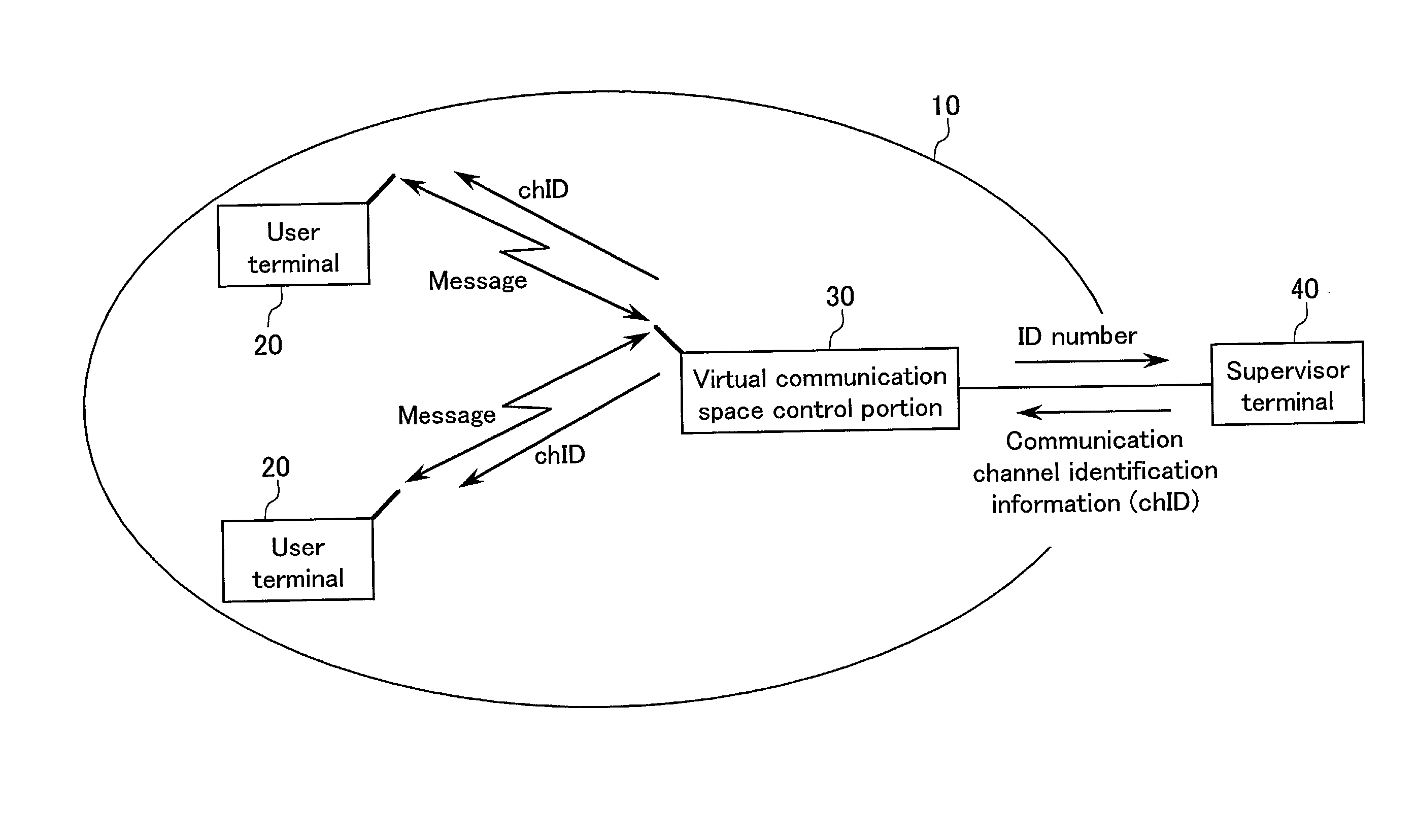

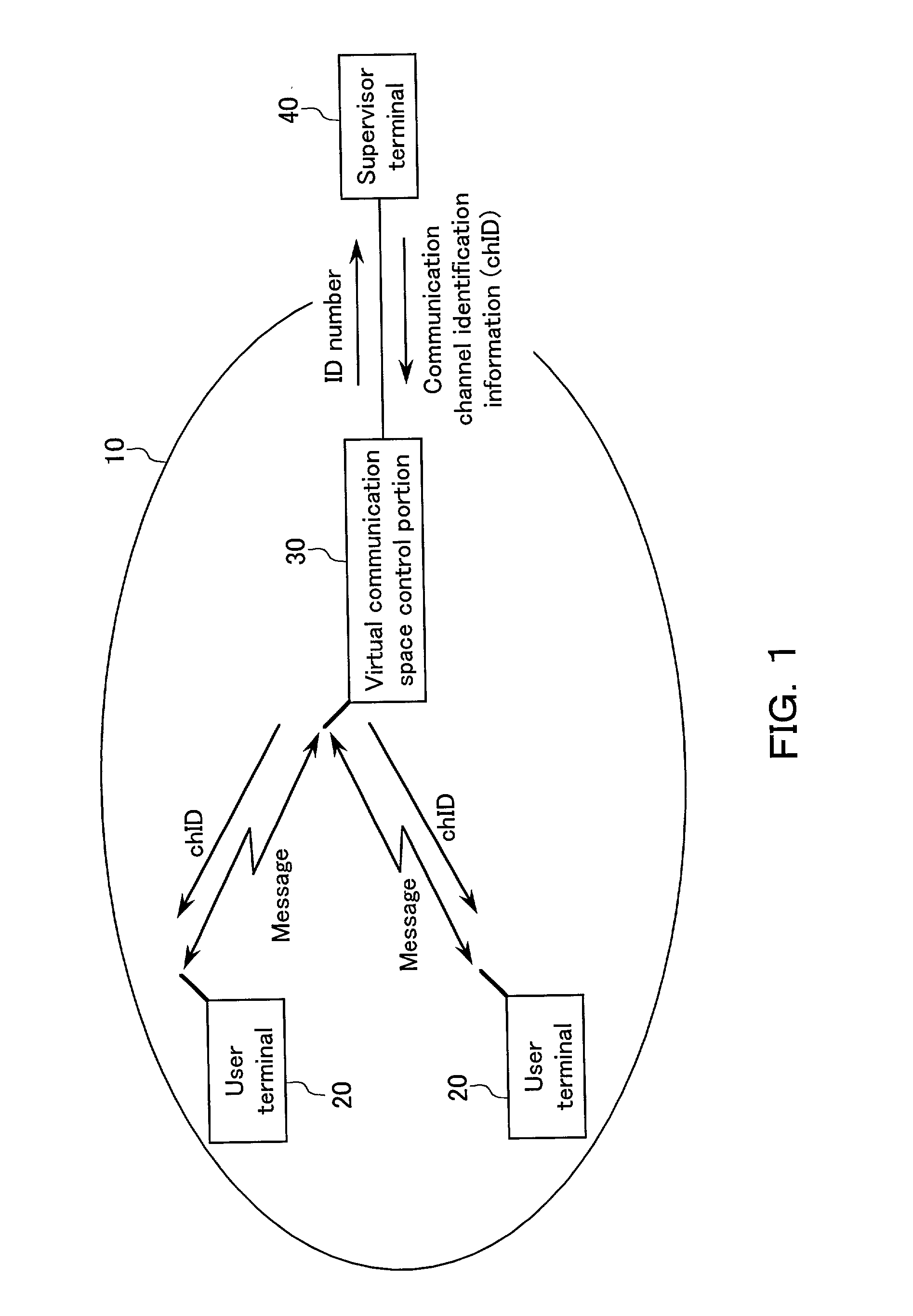

System for providing a virtual communication space corresponding to sensed information from the real world

InactiveUS20020032037A1Ensure convenienceEnsure responsivenessRadio transmissionSecuring communicationBulletin boardVirtual communication

A virtual communication space is constructed, in which people that actually see, hear or experience the same thing in the real world can exchange impressions or opinions in real-time. A user carrying a user terminal 20 moves in the real world and enters a predetermined space of the real world that is controlled and supervised by a virtual communication space providing portion 30. The virtual communication space providing portion 30 sends communication channel identification information with a communication channel identification information notifying means 32, and a communication channel identification information sensing means 21 of the user terminal 20 senses the communication channel identification information. Login into that communication channel is performed with a channel login / logout means 22. By logging in, the virtual communication space provided by the virtual communication space providing portion 30 is shared, and applications such as an electronic bulletin board and chat can be used. The supervisor terminal collects / analyzes a log of the conversation.

Owner:FUJITSU LTD

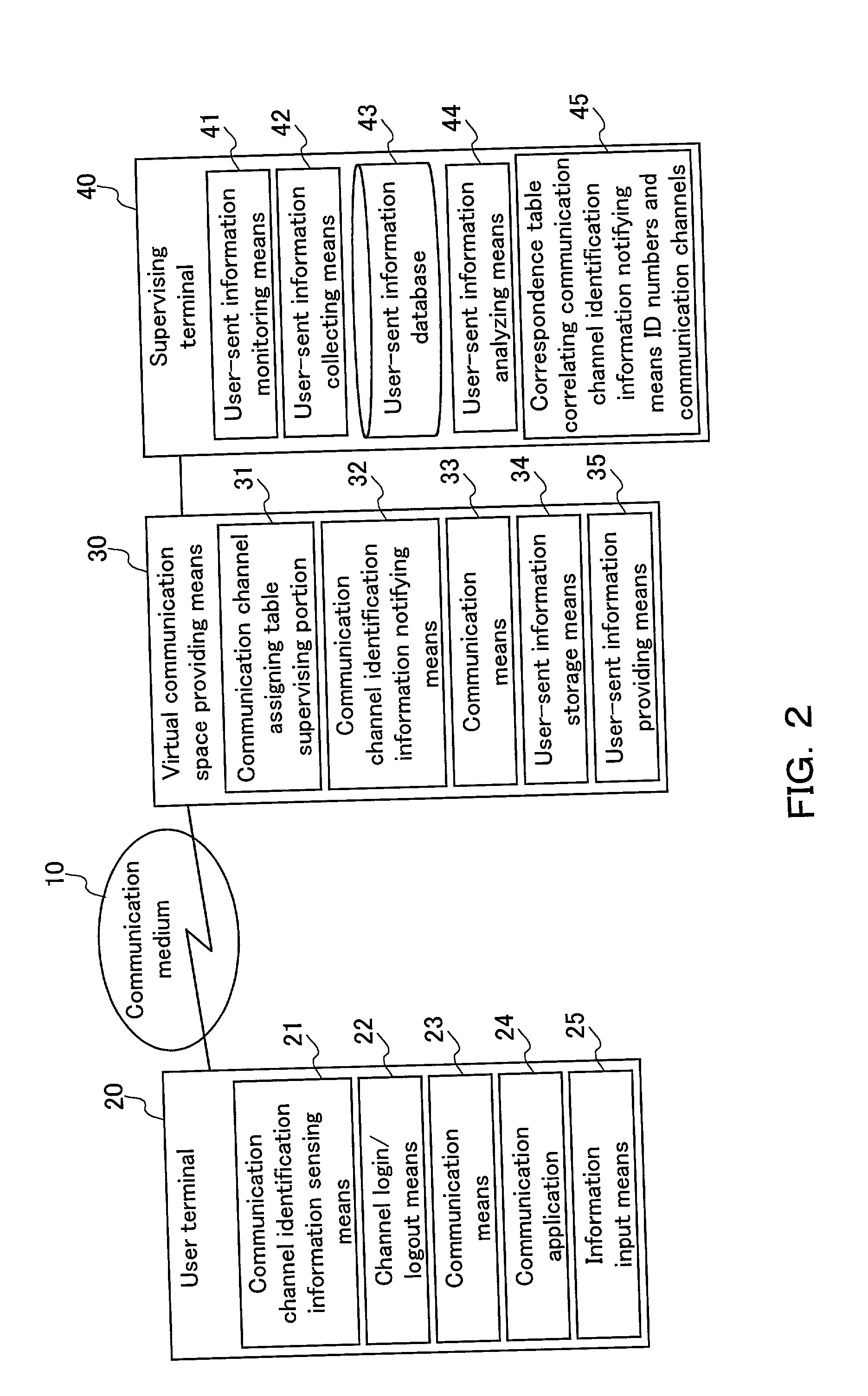

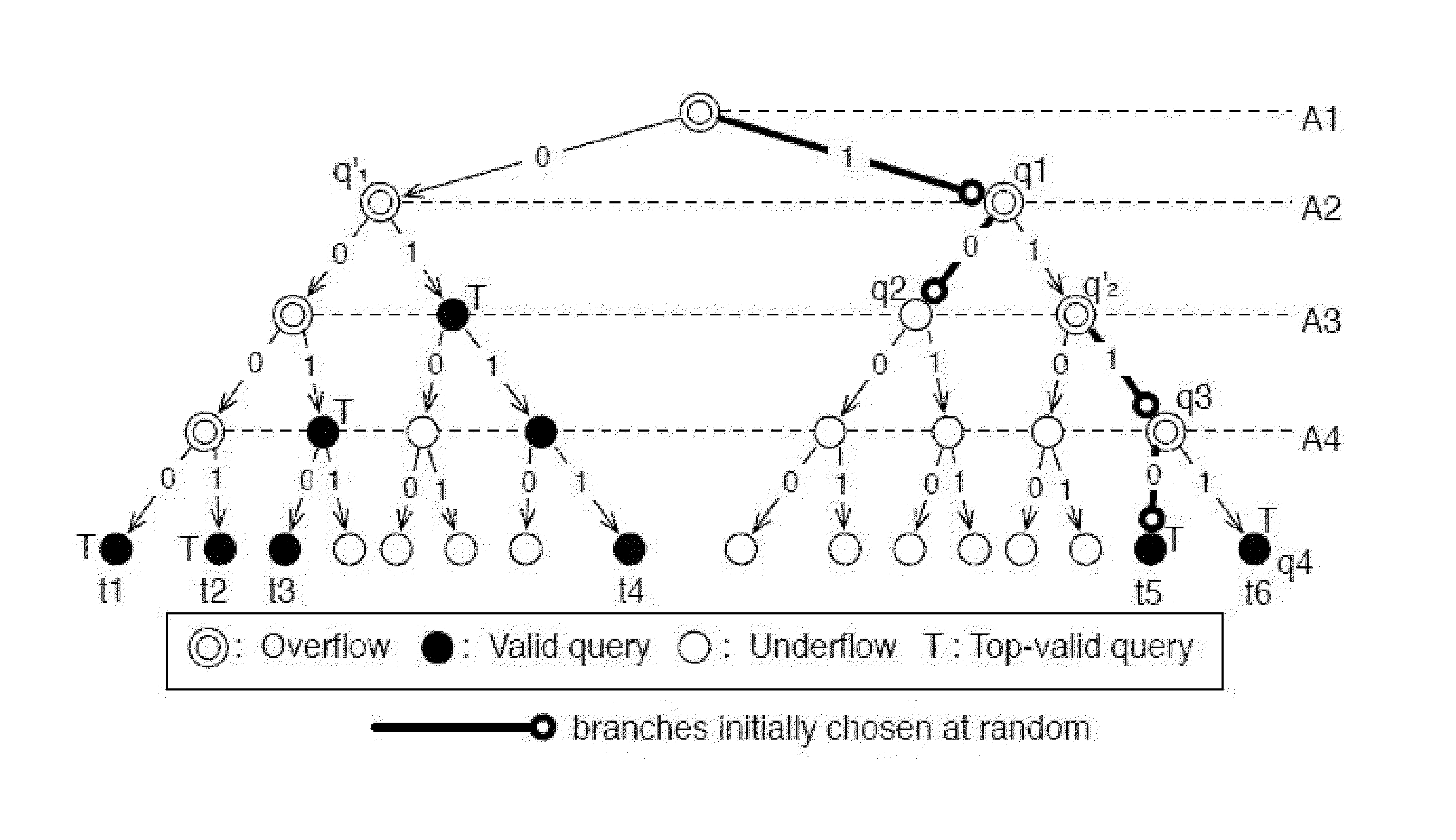

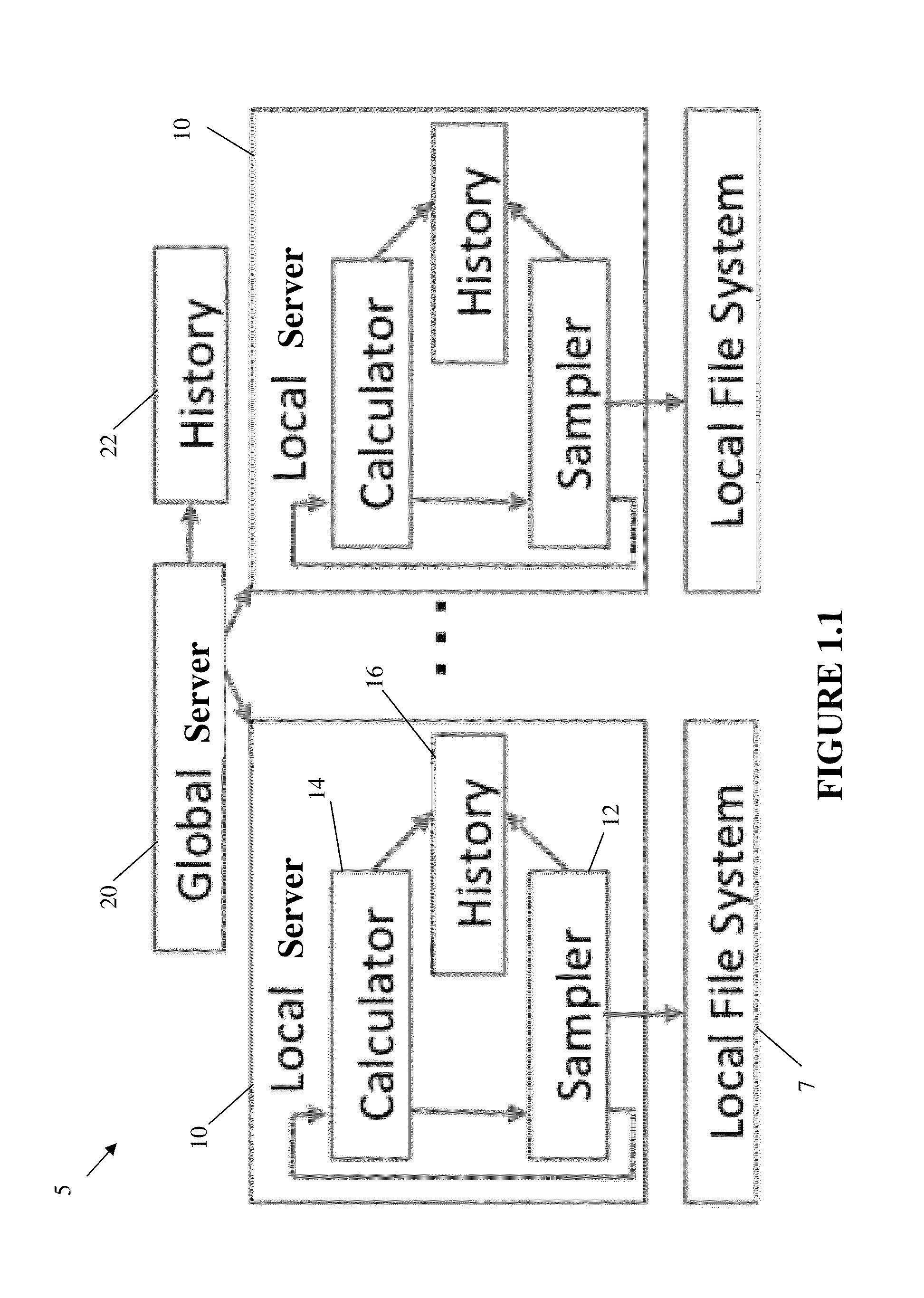

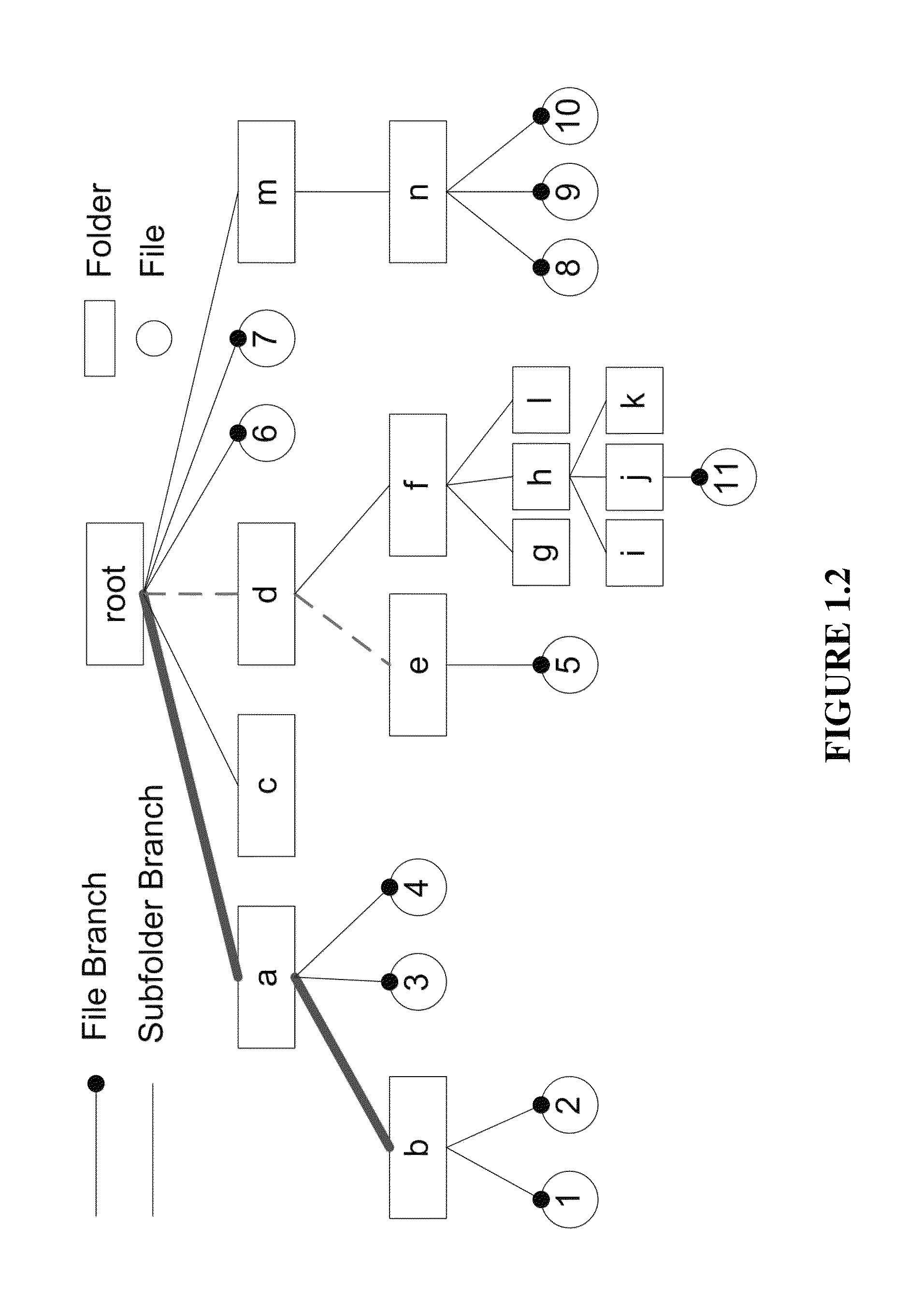

Just-in-time analytics on large file systems and hidden databases

ActiveUS9244976B1Easy to issueAccurate aggregate estimationDigital data information retrievalSpecial data processing applicationsHidden dataFile system

A just-in-time sampling-based system can, after consuming a small number of disk accesses or queries, produce extremely accurate answers for a broad class of aggregate and top-k queries over a file system or database without the requirement of prior knowledge. The system is efficient, accurate, and scalable. The system performs aggregate estimations of a hidden database through its web interface by employing techniques that use a small number of queries to produce unbiased estimates with small variance. It conducts domain discovery over a hidden database through its web interface by employing techniques which provide effective guarantees on the effectiveness of domain discovery. Systems and methods enhance forms used by mobile devices to access hidden databases. It employs data analytics to improve the usage of form fields, including providing context-sensitive auto-completion suggestions, highlighting selections in drop-down boxes and eliminating suggestions in drop-down boxes.

Owner:GEORGE WASHINGTON UNIVERSITY +1

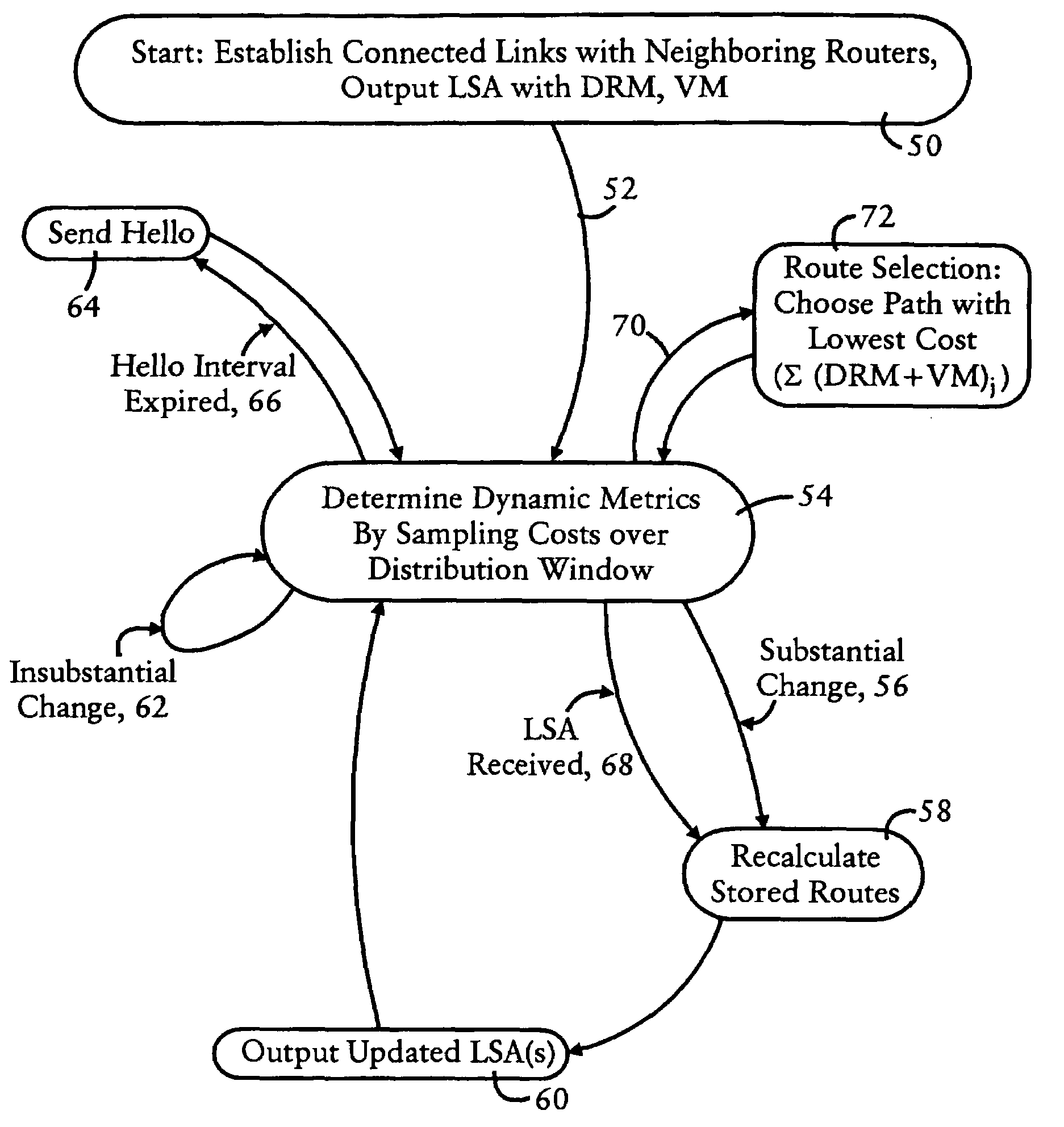

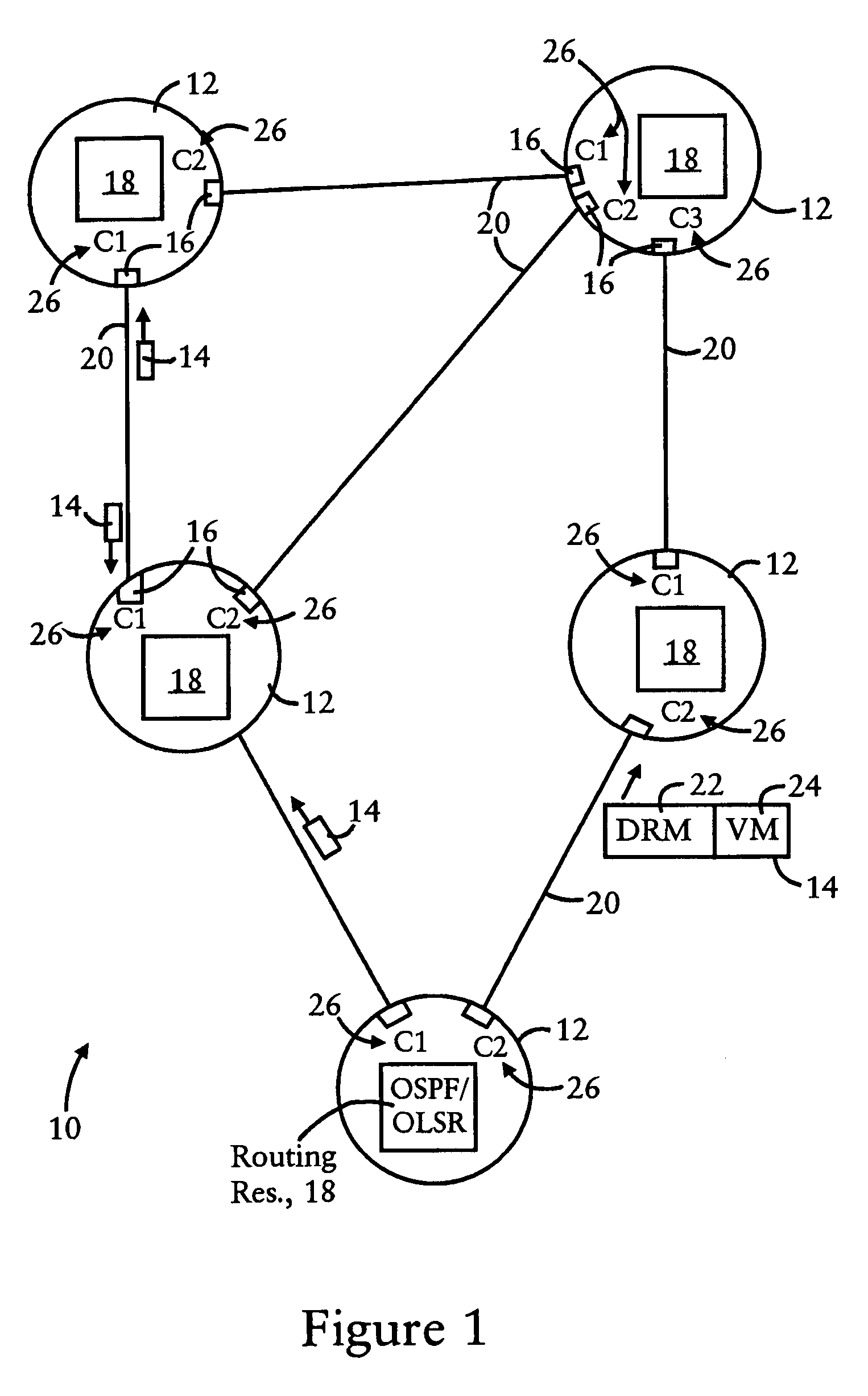

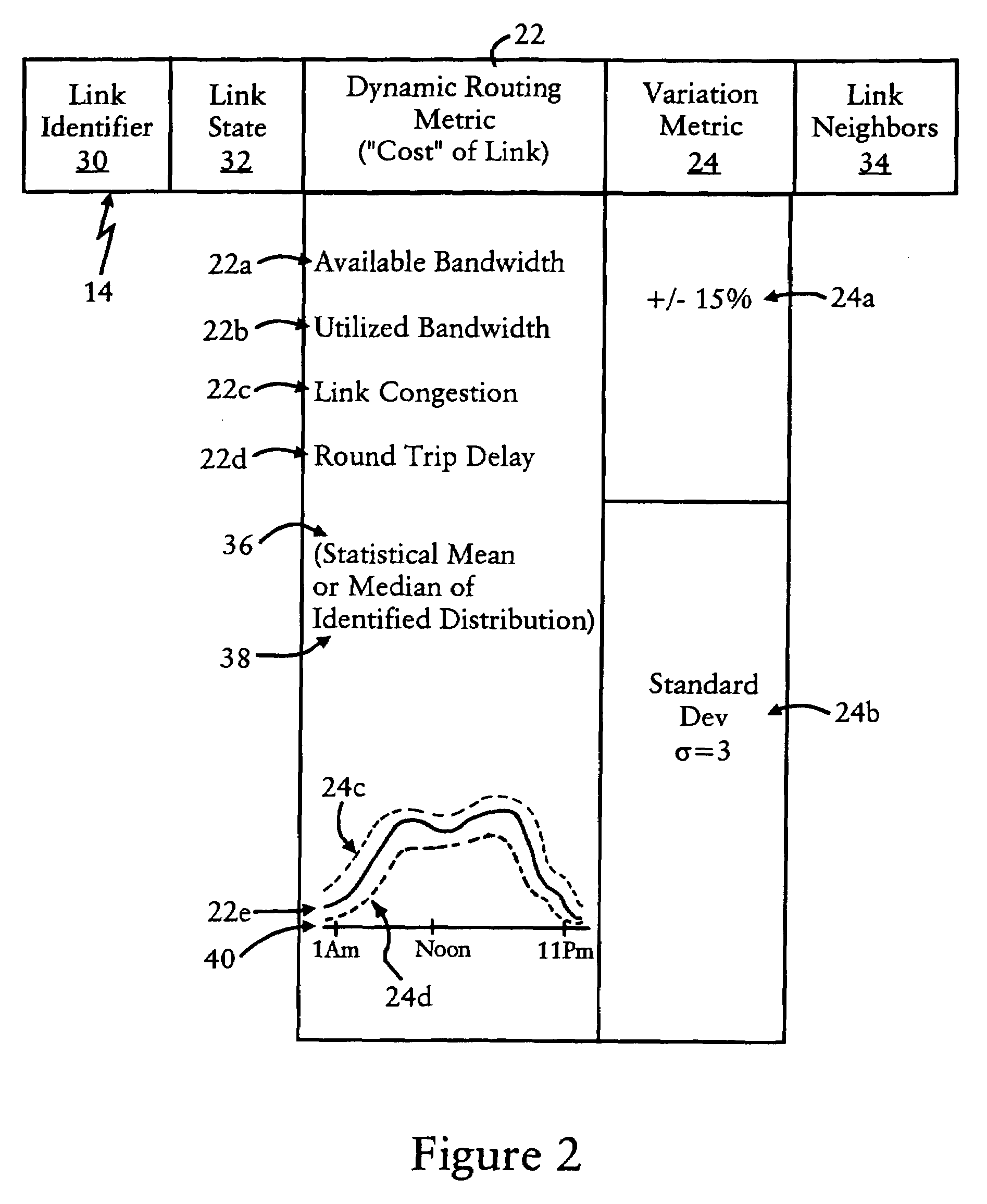

Link state advertisements specifying dynamic routing metrics and associated variation metrics and selective distribution thereof

InactiveUS7567577B2Introduce instabilityEnsure responsivenessDigital computer detailsData switching by path configurationLink-state advertisementAdaptive routing

Each router in a network is configured for executing a link state routing protocol based on outputting a corresponding first link state advertisement message describing a connected link of the router and that specifies a first dynamic routing metric identifying a first cost of the connected link, and a corresponding variation metric identifying a statistical variation of the dynamic routing metric. Each router also is configured for selectively outputting a corresponding second link state advertisement message describing the connected link and that specifies the corresponding variation metric and an updated dynamic routing metric identifying an updated cost of the connected link relative to the first cost, the second link state advertisement message selectively output based on the updated dynamic routing metric differing from the first dynamic routing metric by more than the variation metric, or the router having received another link state advertisement from another router in the network.

Owner:CISCO TECH INC

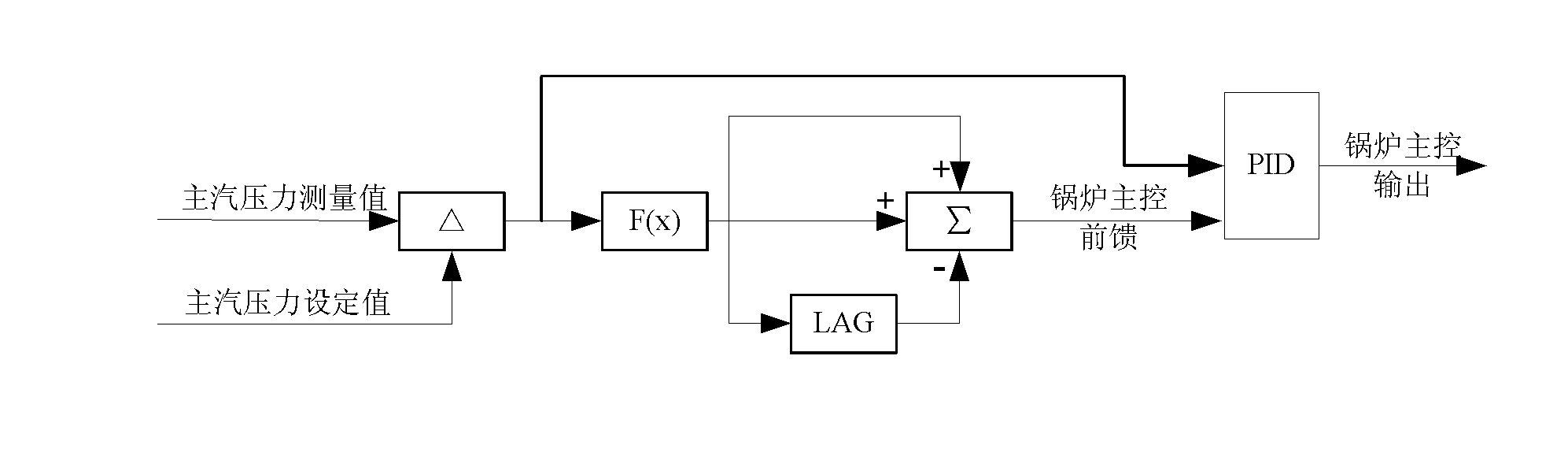

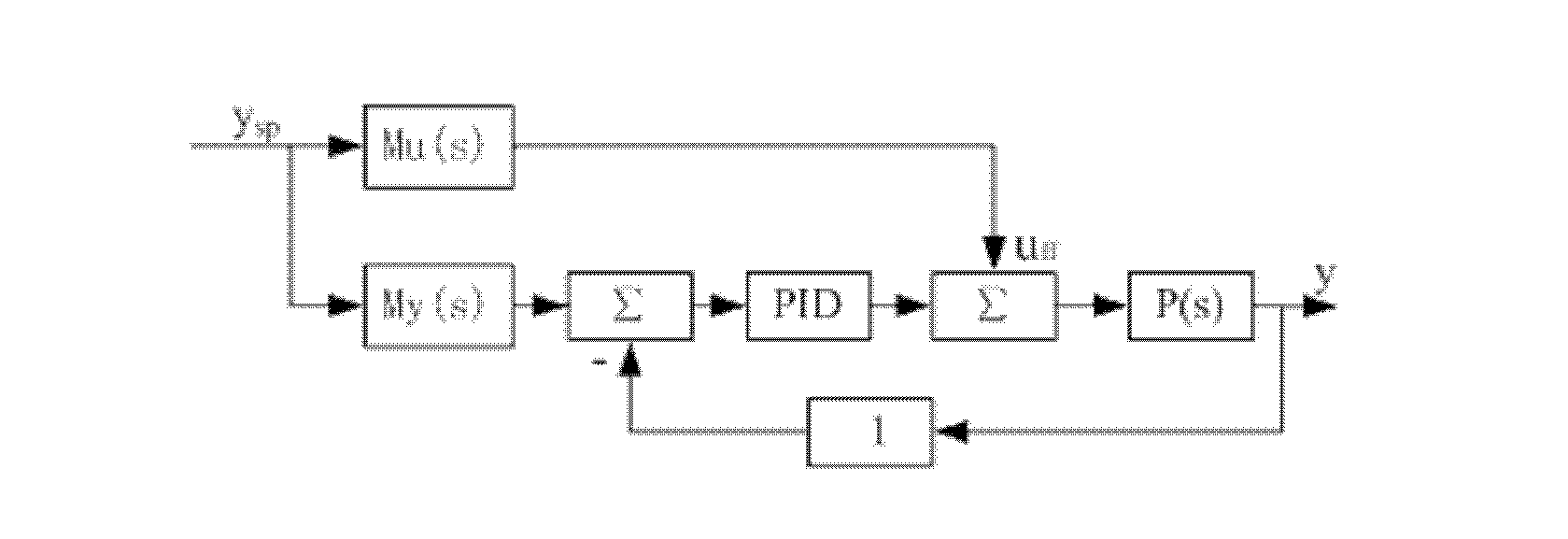

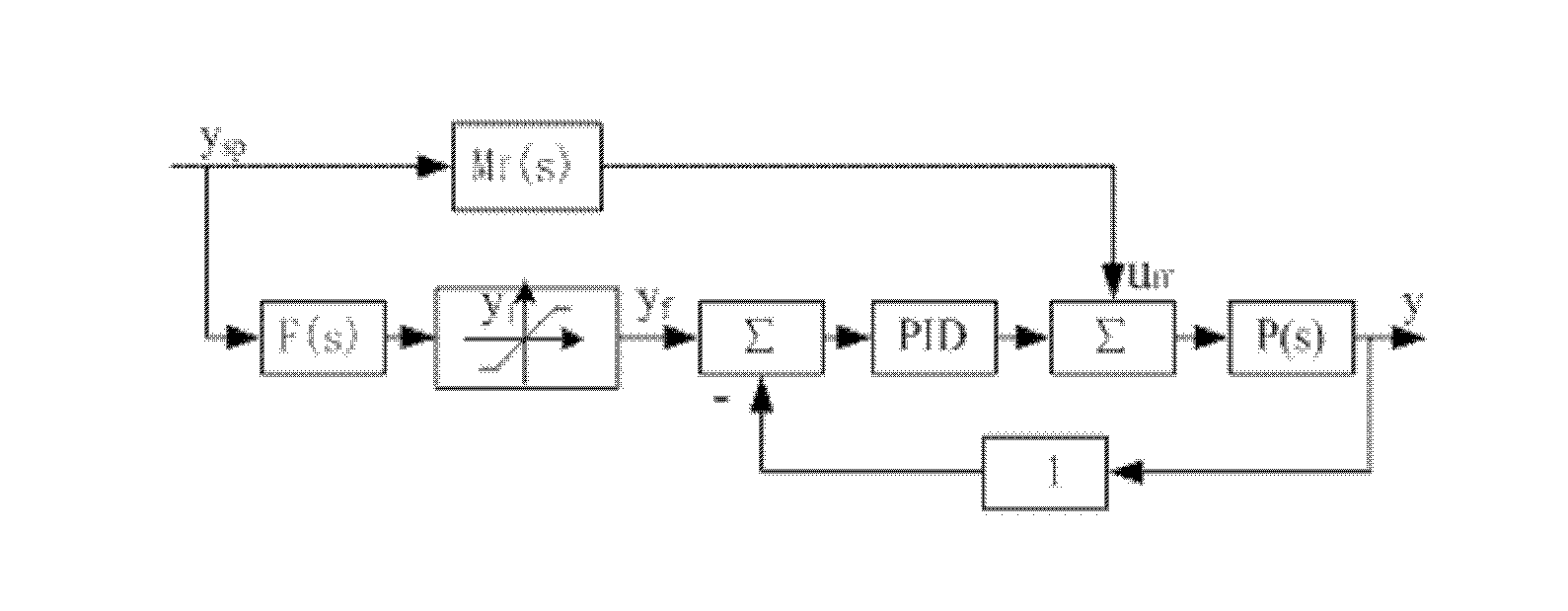

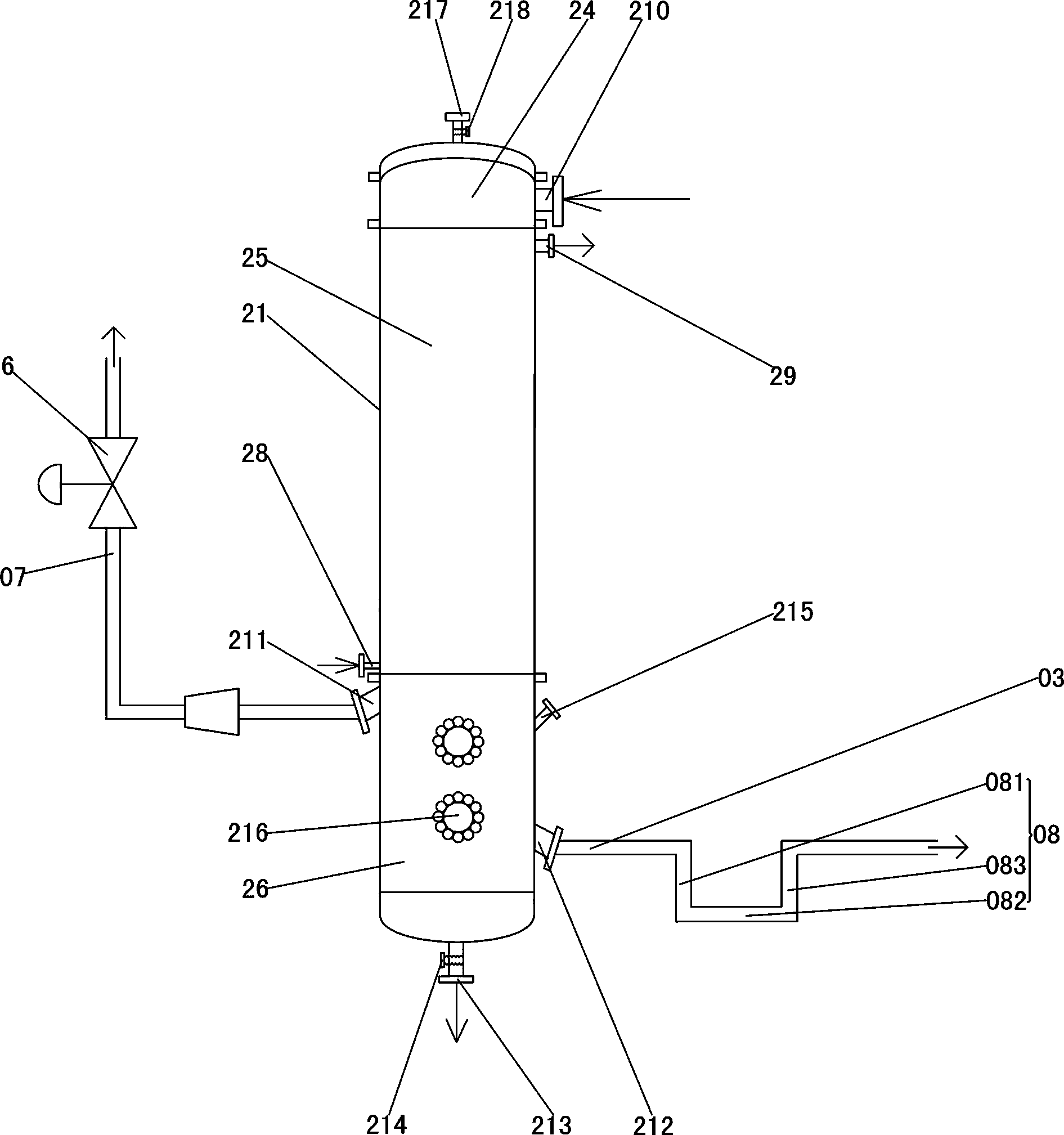

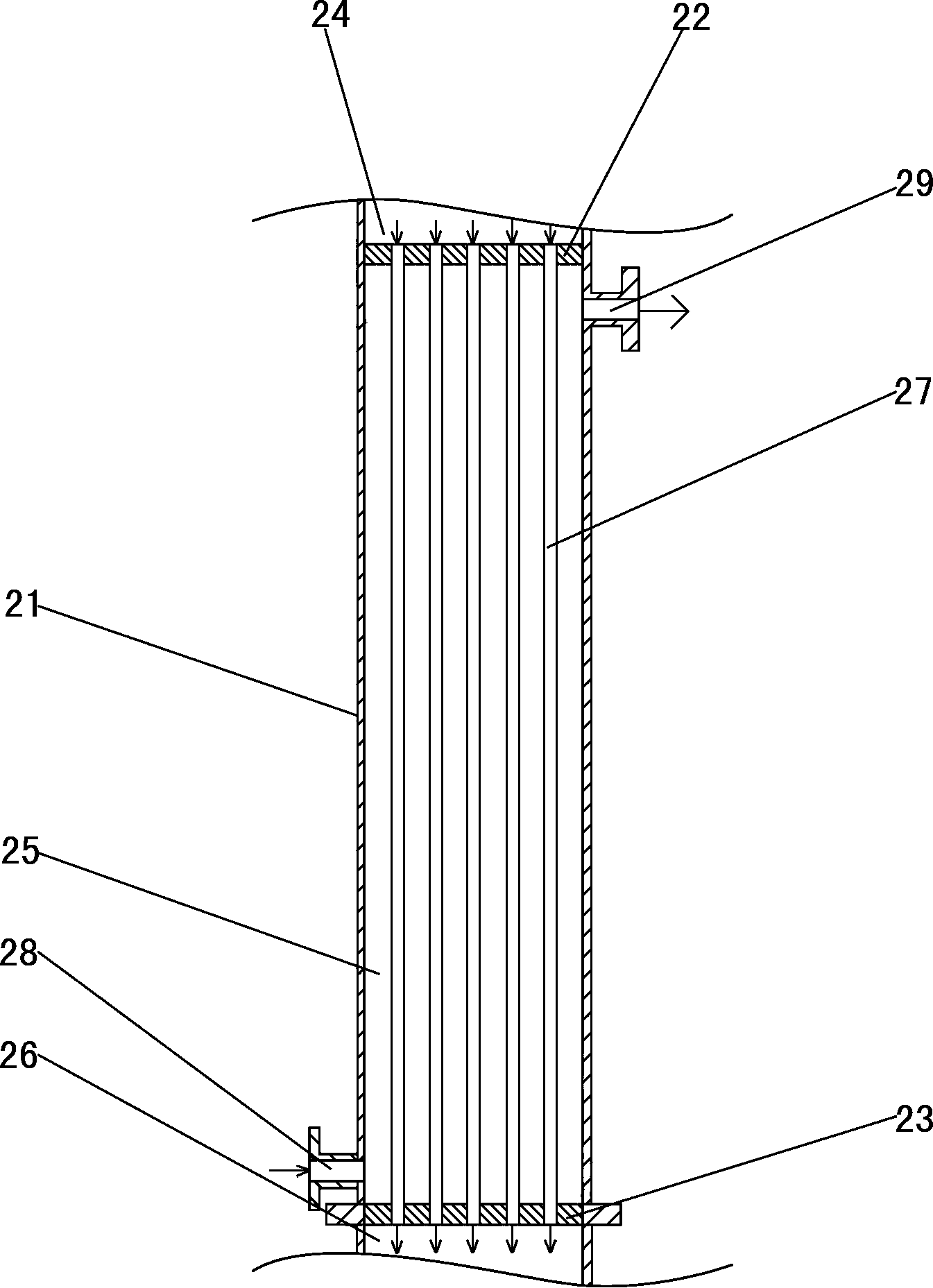

Control optimizing method for master controller of supercritical unit boilers

ActiveCN102563598AGuaranteed control effectEnsure responsivenessBoiler controlControl systemClosed loop

The invention discloses a control optimizing method for a master controller of supercritical unit boilers. The control optimizing method includes introducing an inertial element F(s) and a lagging element y1 into a feed-forward control branch to replace a modification function My(s) for a main vapor pressure input value ysp which is randomly set by an original system; providing input signals of the lagging element y1 by an element F(s), and leading reference signals yf outputted by the lagging element y1 to act on an input end of a closed-loop control element; and additionally optimizing a transfer function Mu(s) of the feed-forward control branch of an original boiler master control system into a pressure compensation transfer function Mf(s), meeting the requirement of parameter-variable running of a feed-forward function uff of the original boiler master control system, leading the uff and the yf to jointly act on the closed-loop control element, then controlling a follow-up executing mechanism and accordingly realizing master control for the boilers. The control optimizing method has the advantages that the master controller of the boilers can quickly and accurately output instructions to a fuel master controller and a water supply master controller, accordingly a main vapor pressure control effect is guaranteed, response characteristics of load are further ensured, and control quality of the unit and economical indexes are improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

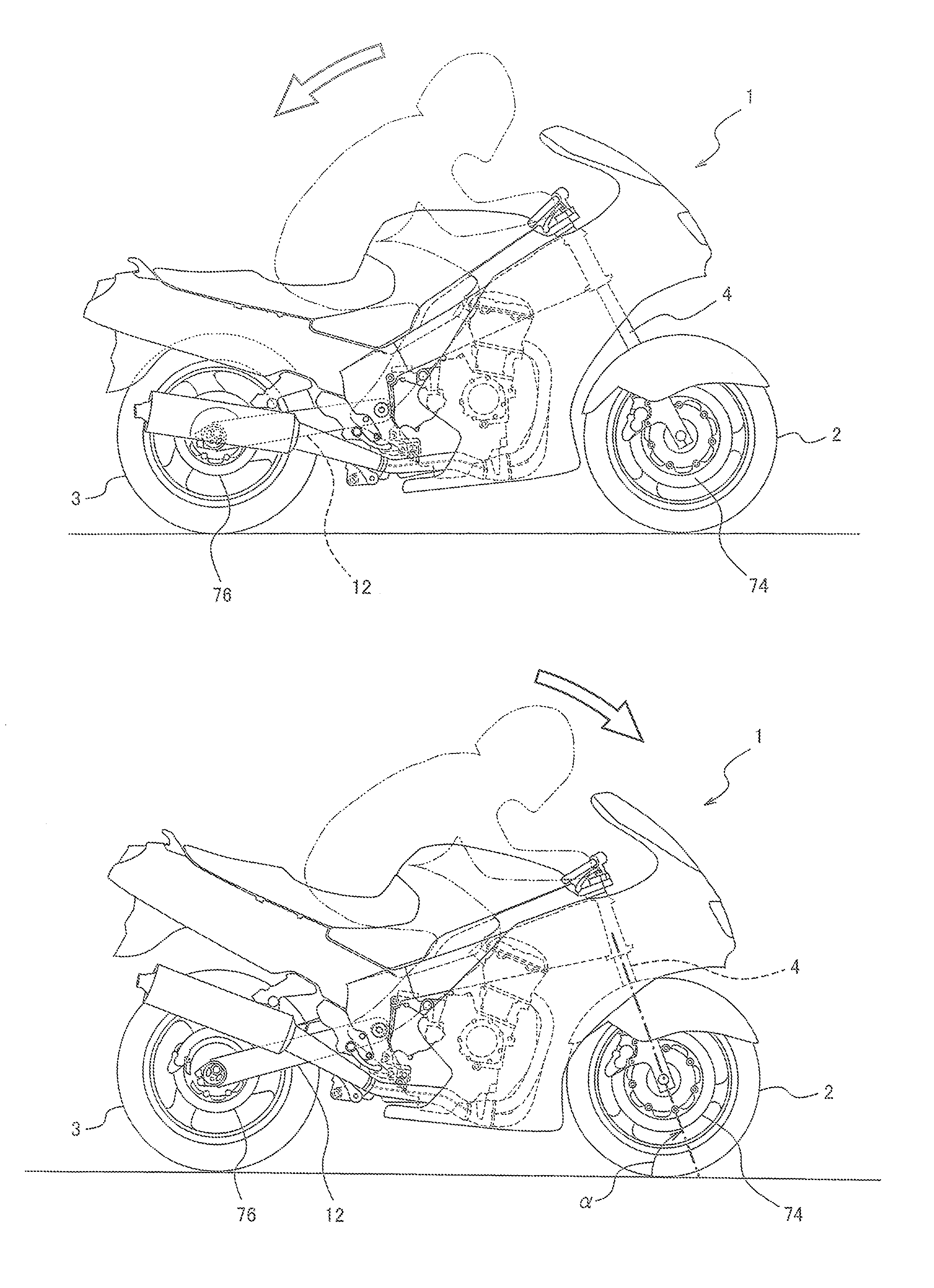

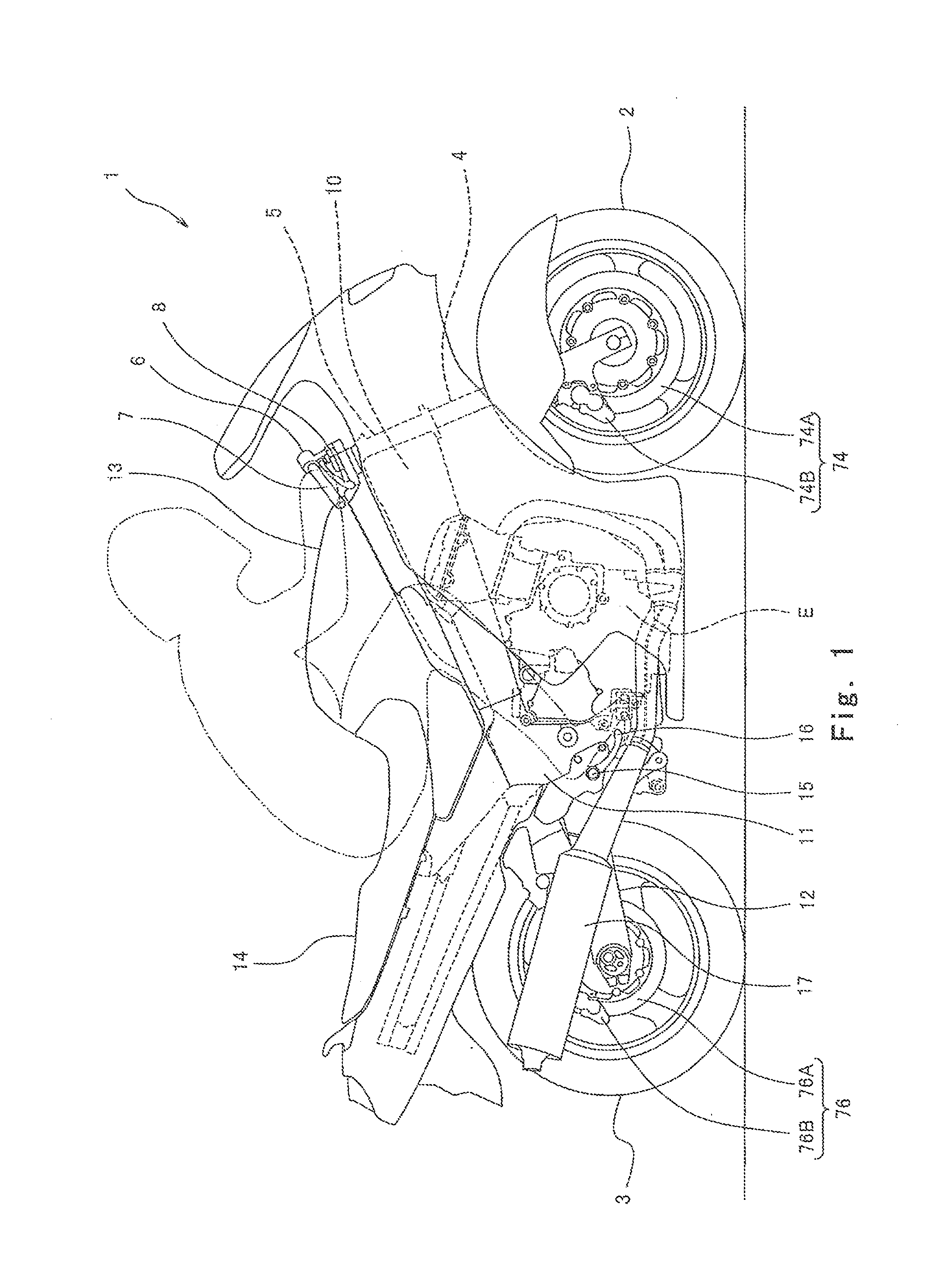

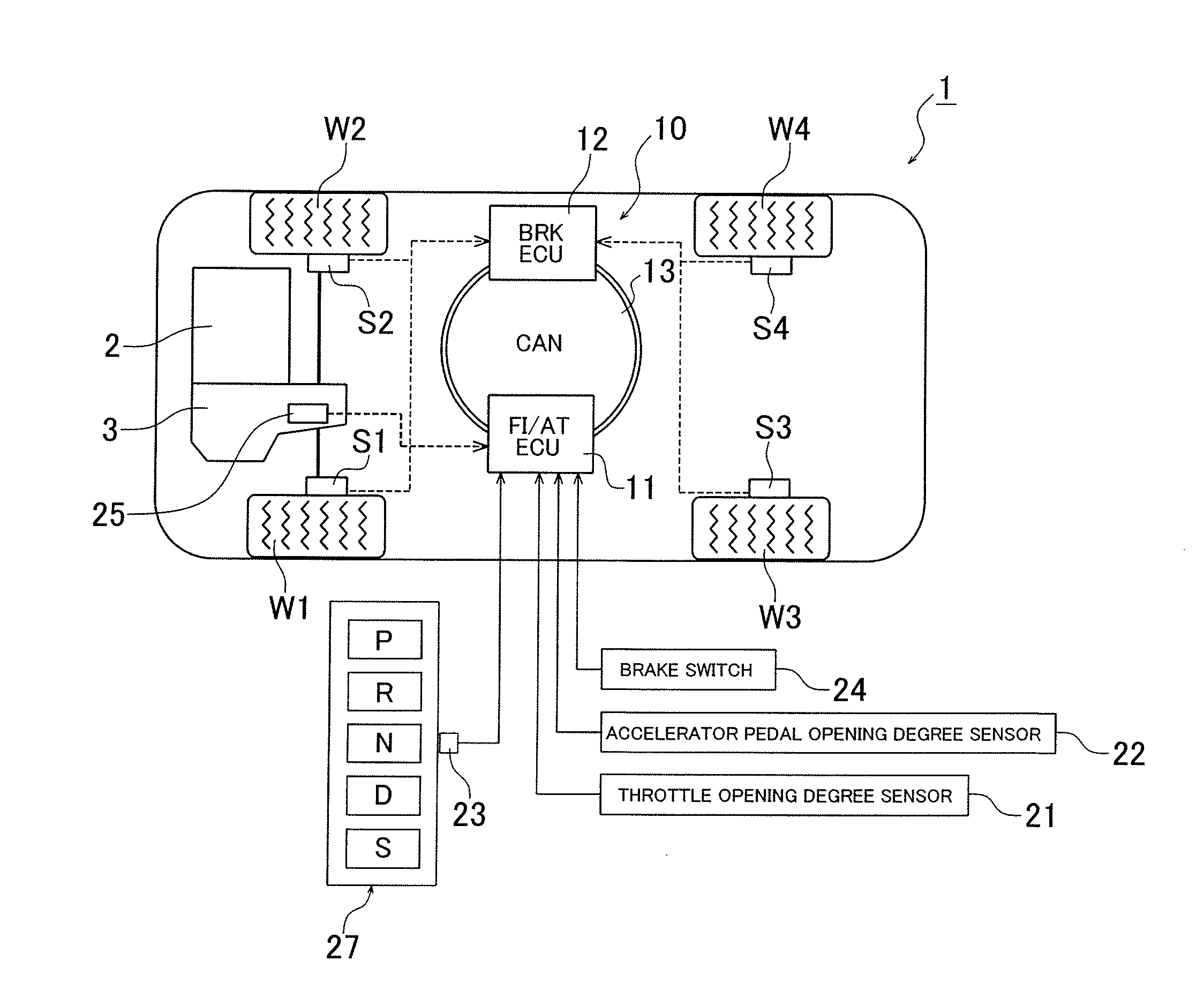

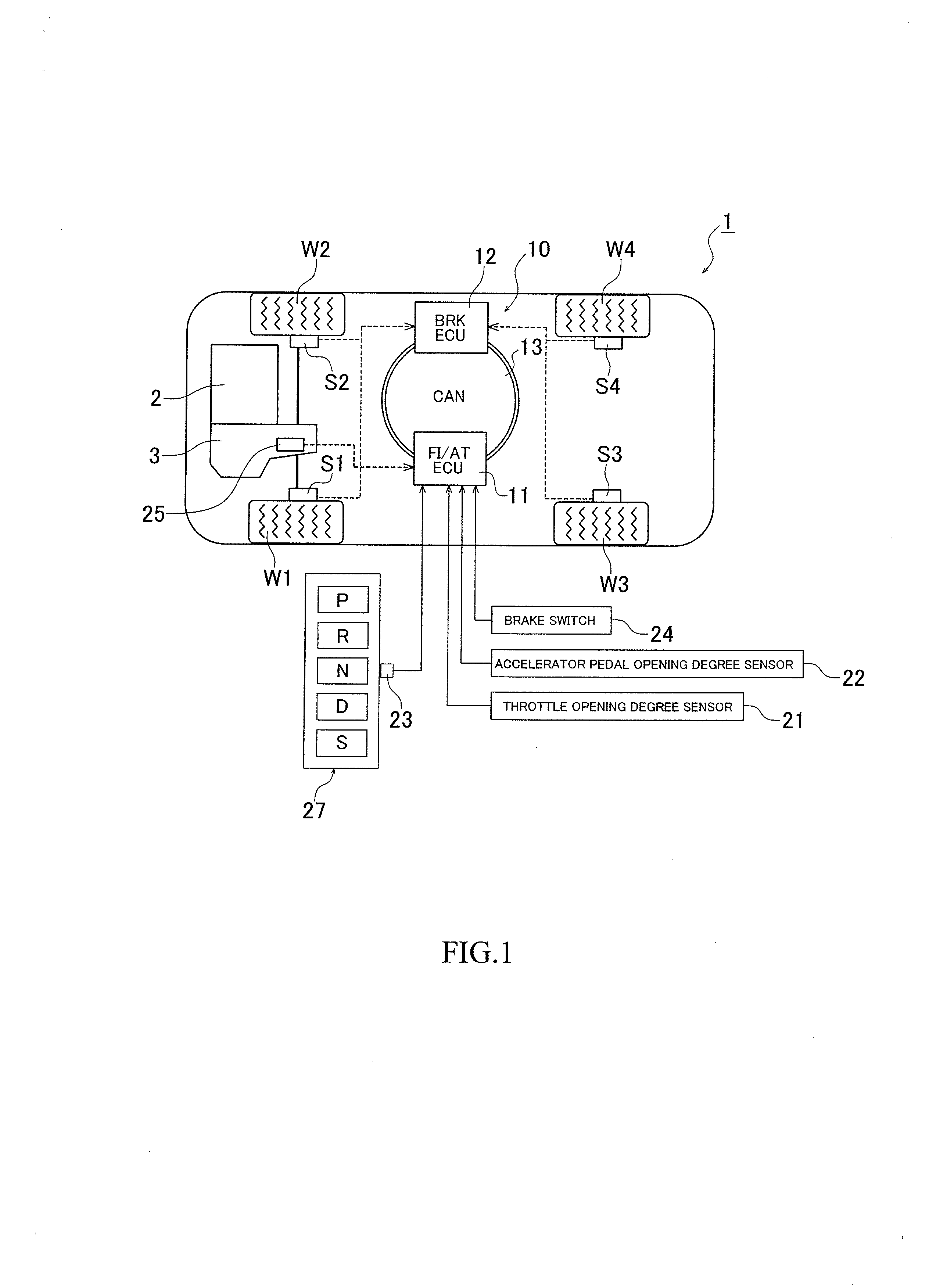

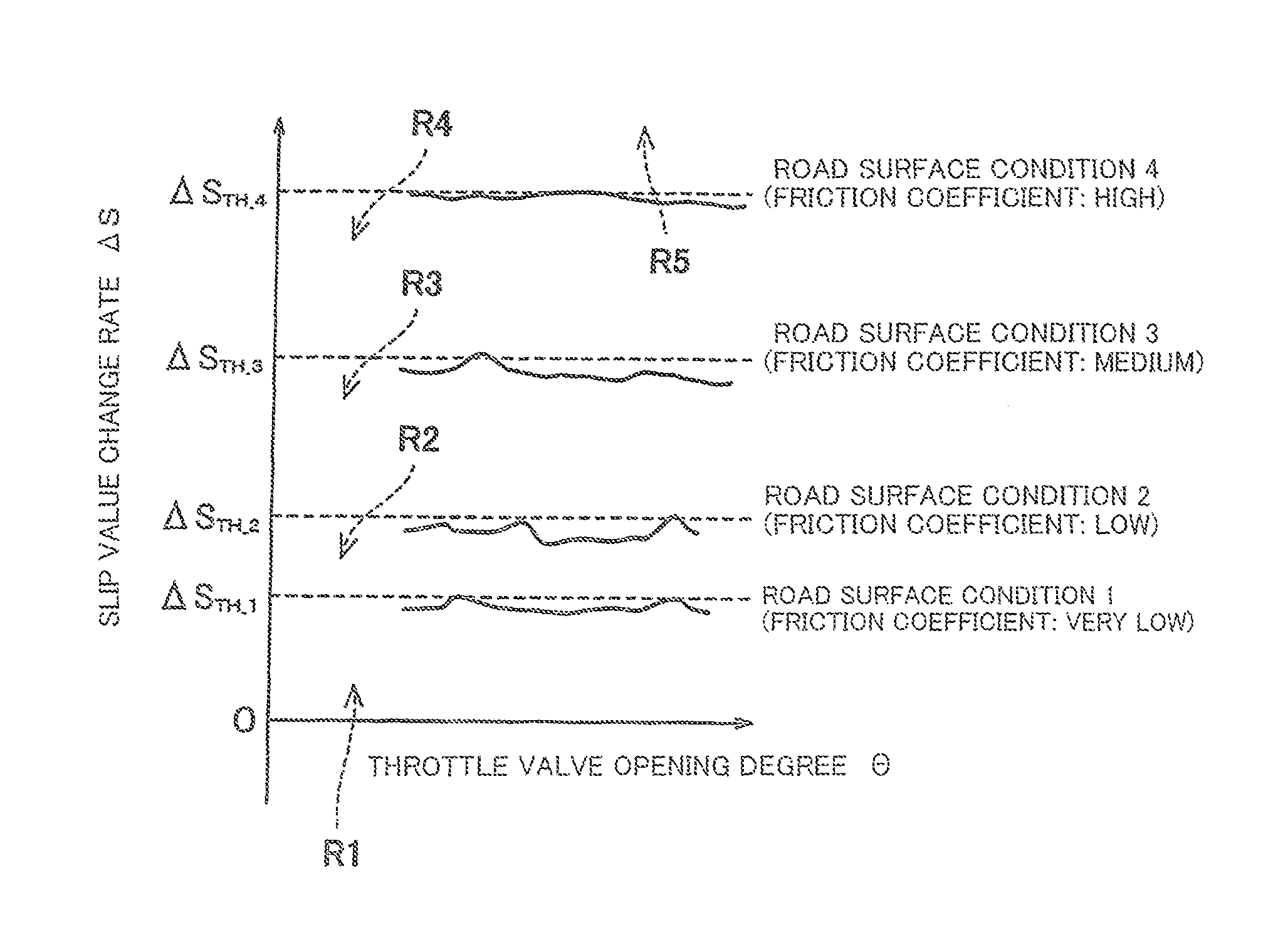

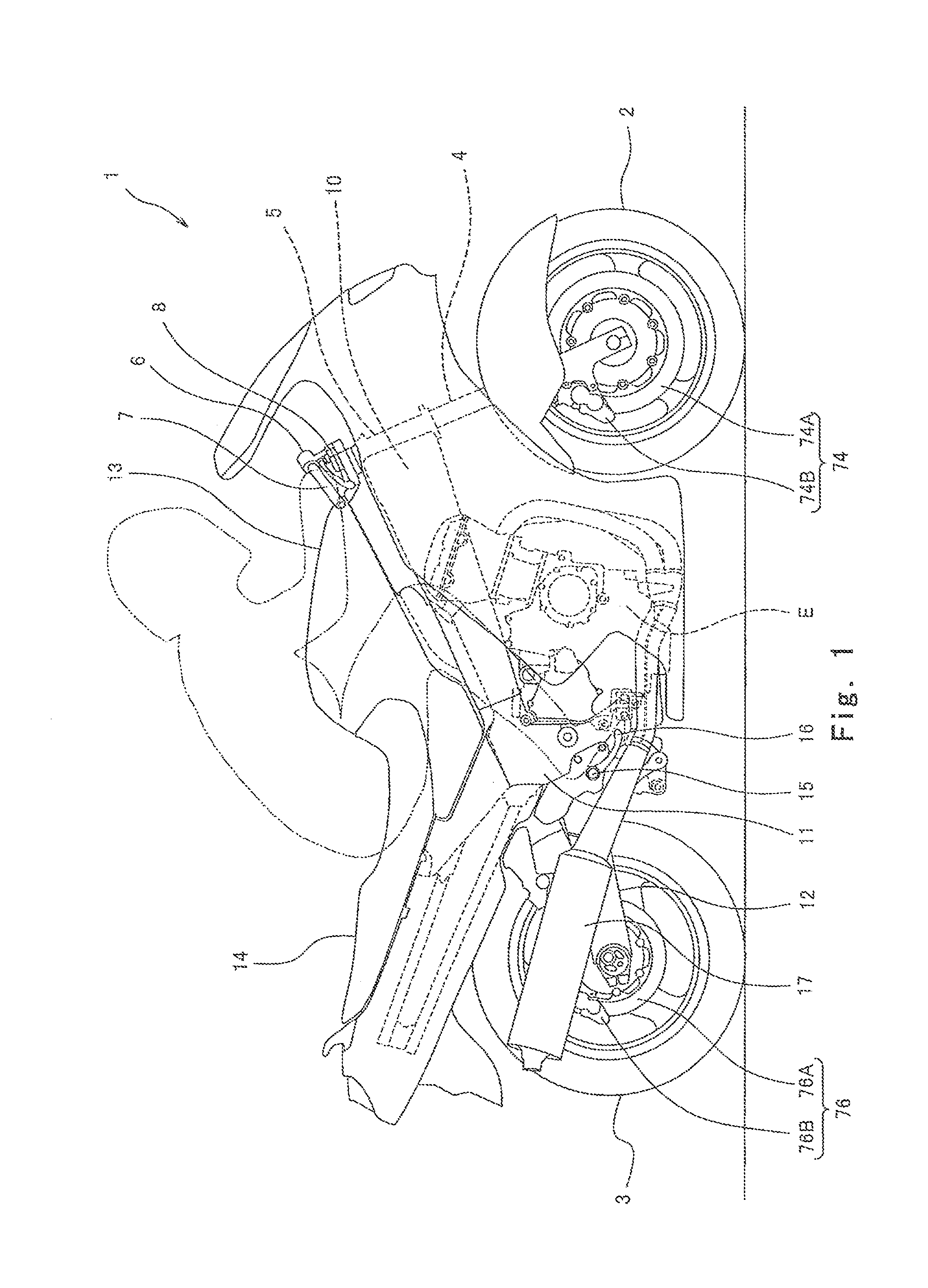

System and method for controlling straddle-type vehicle

ActiveUS20130030649A1Prevent slidingImprove driving power performance and braking performanceDigital data processing detailsAnimal undercarriagesControl systemStraddle

A control system in a straddle-type vehicle is provided. The control system includes front and rear wheels, comprises a load distribution changing section which changes a ground load distribution between the front and rear wheels during driving of the vehicle; a slip suppressing condition determiner section which determines whether or not a suppressing condition used to suppress a slip of one of the front and rear wheels is met, during driving of the vehicle; and a load distribution control section which controls the load distribution changing section to make the ground load of the one of the front and rear wheels greater when the slip suppressing condition determiner section determines that the suppressing condition is met, than when the slip suppressing condition determiner section determines that the suppressing condition is not met.

Owner:KAWASAKI MOTORS LTD

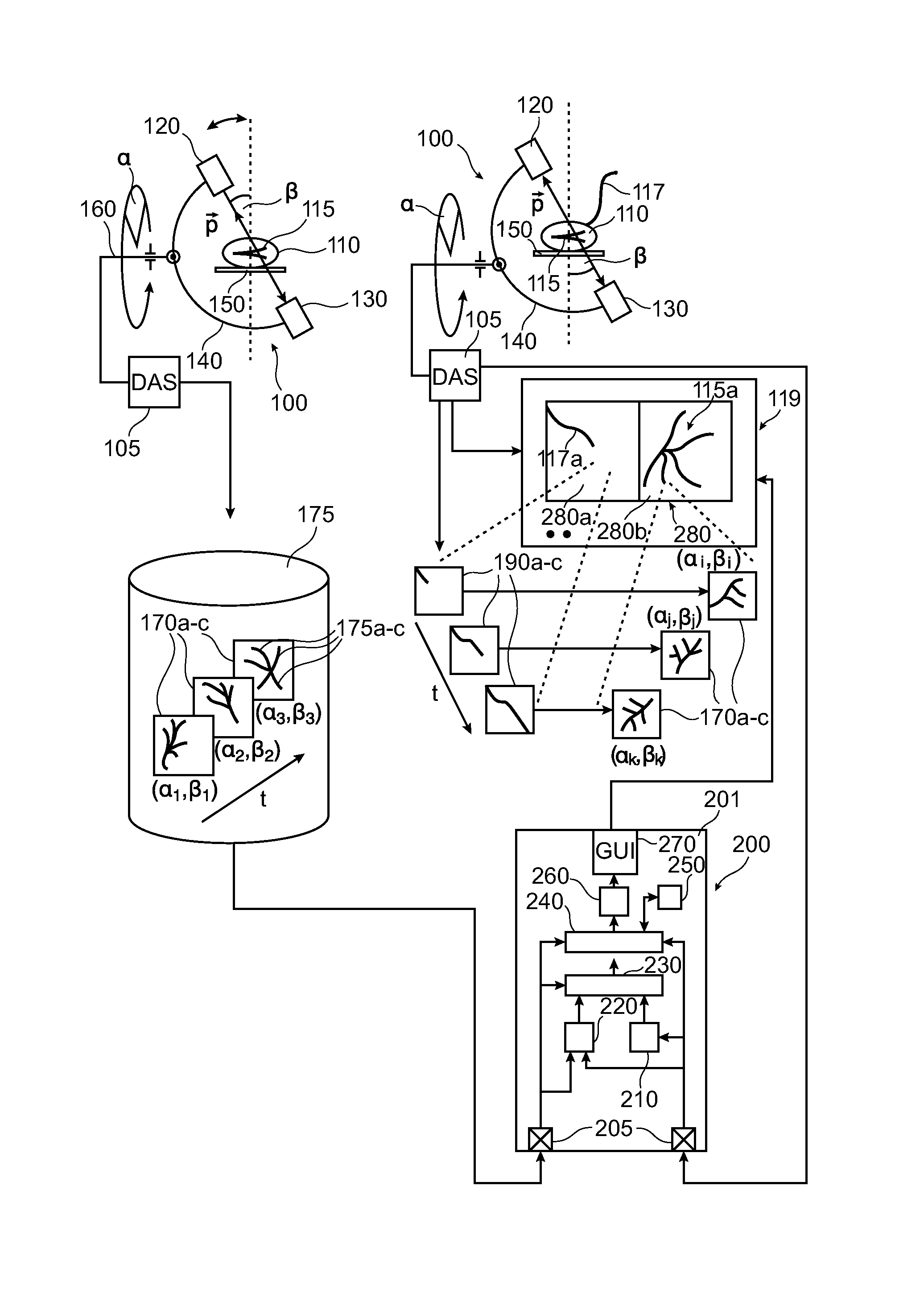

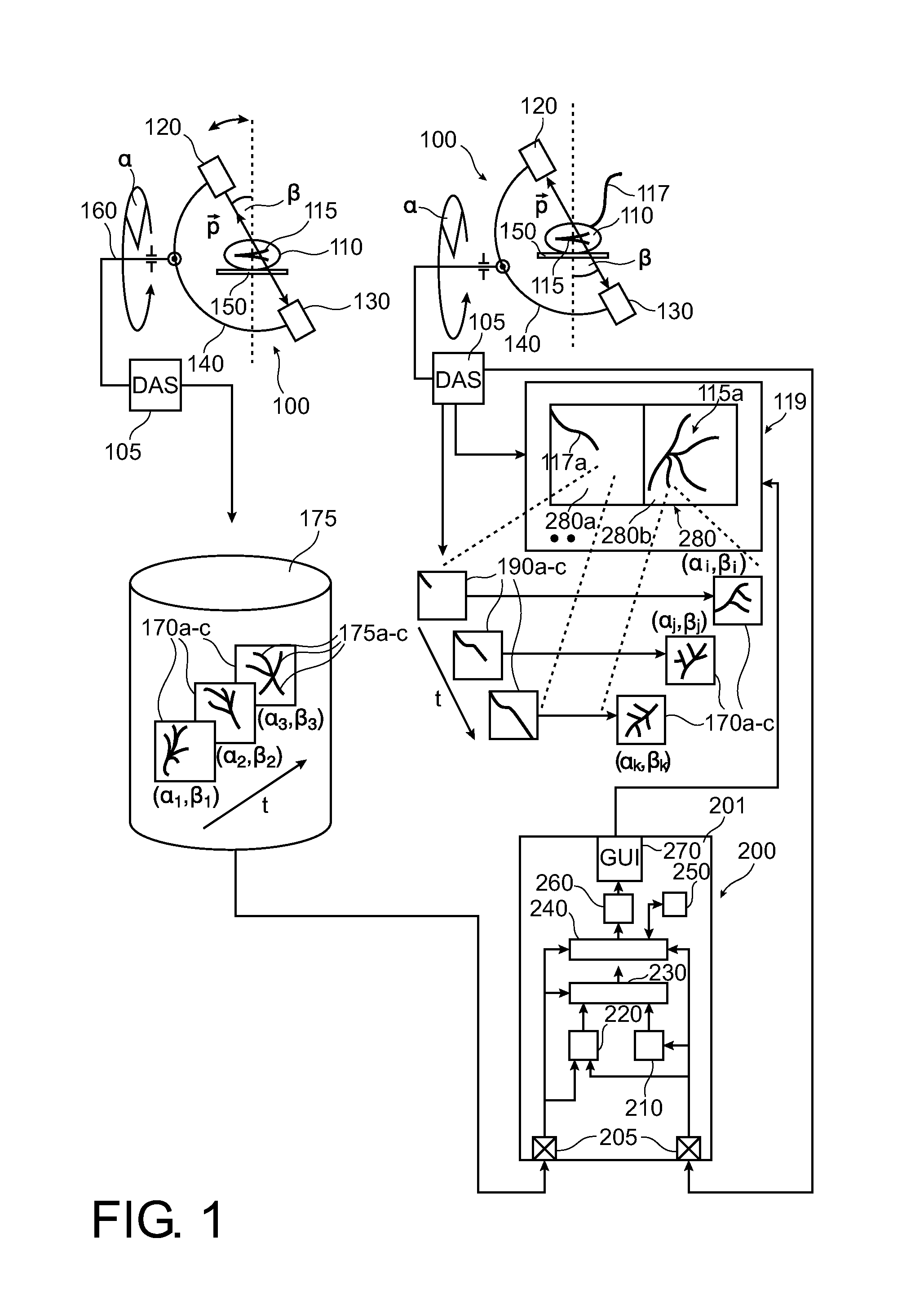

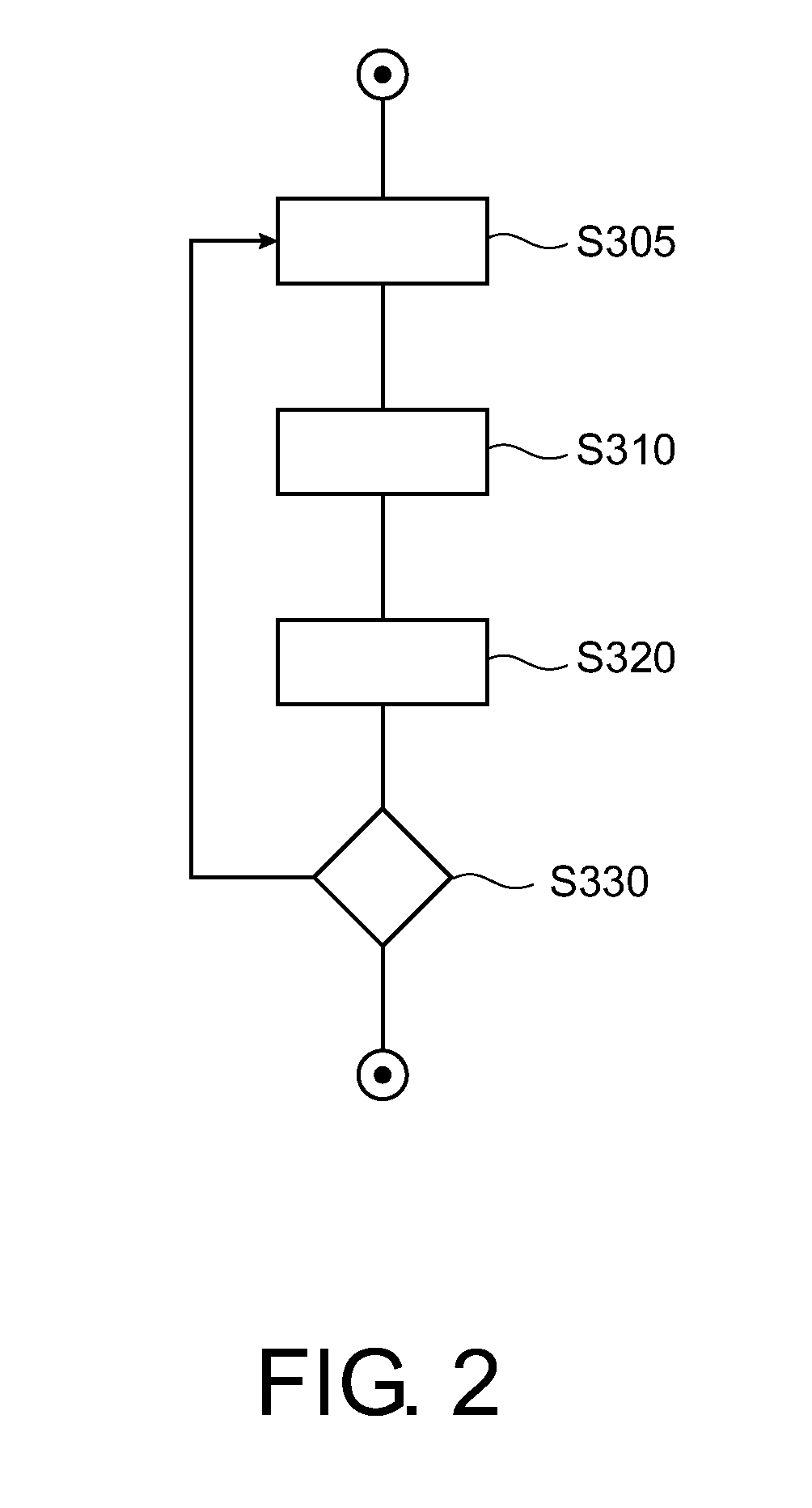

Real-time display of vasculature views for optimal device navigation

ActiveUS20140371578A1Easy to understandWell definedSurgical navigation systemsDiagnostic recording/measuringReal time displayMarine navigation

An apparatus configured to generate for display a plurality of vasculature (115) views (170a-c) alongside a live fluoroscopy image (190a). The views are selected in such a way that they allow visualizing the 3D structure of the vasculature segment in which the device (117) is currently navigating. The view is best relative to one or a weighted average of a plurality of goodness of view standards. As the device progresses and new fluoroscopy images (190b-c) are acquired, the views (170i-k) are updated accordingly.

Owner:KONINKLJIJKE PHILIPS NV

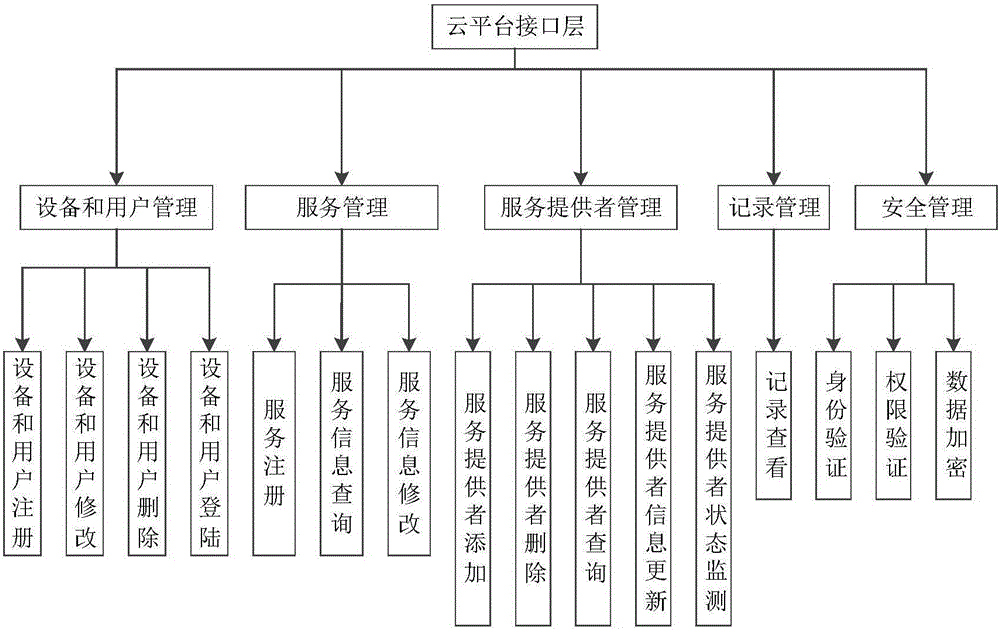

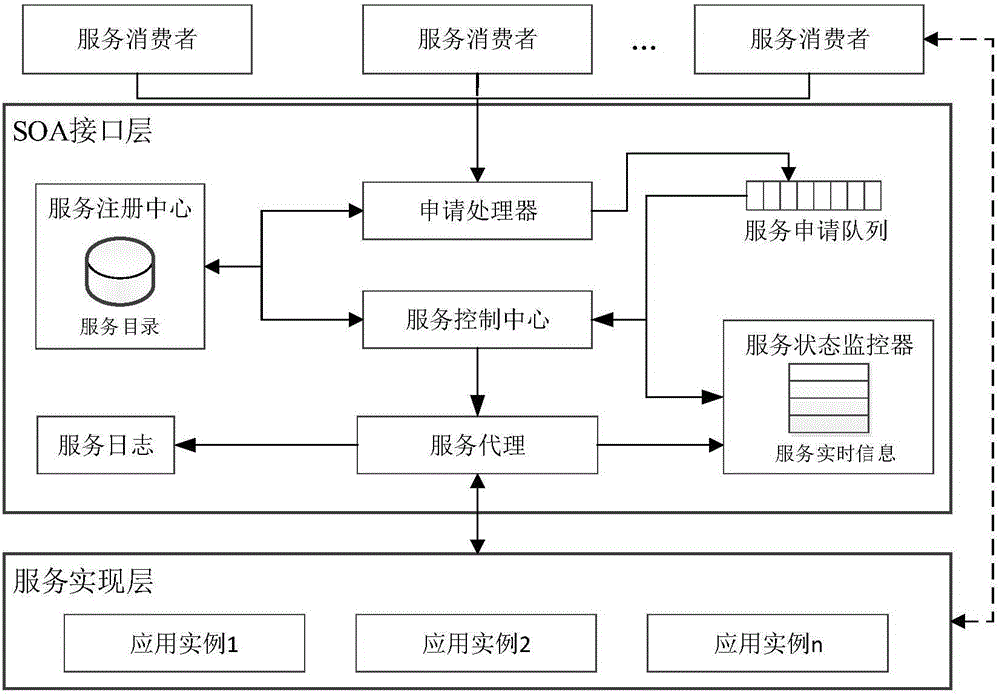

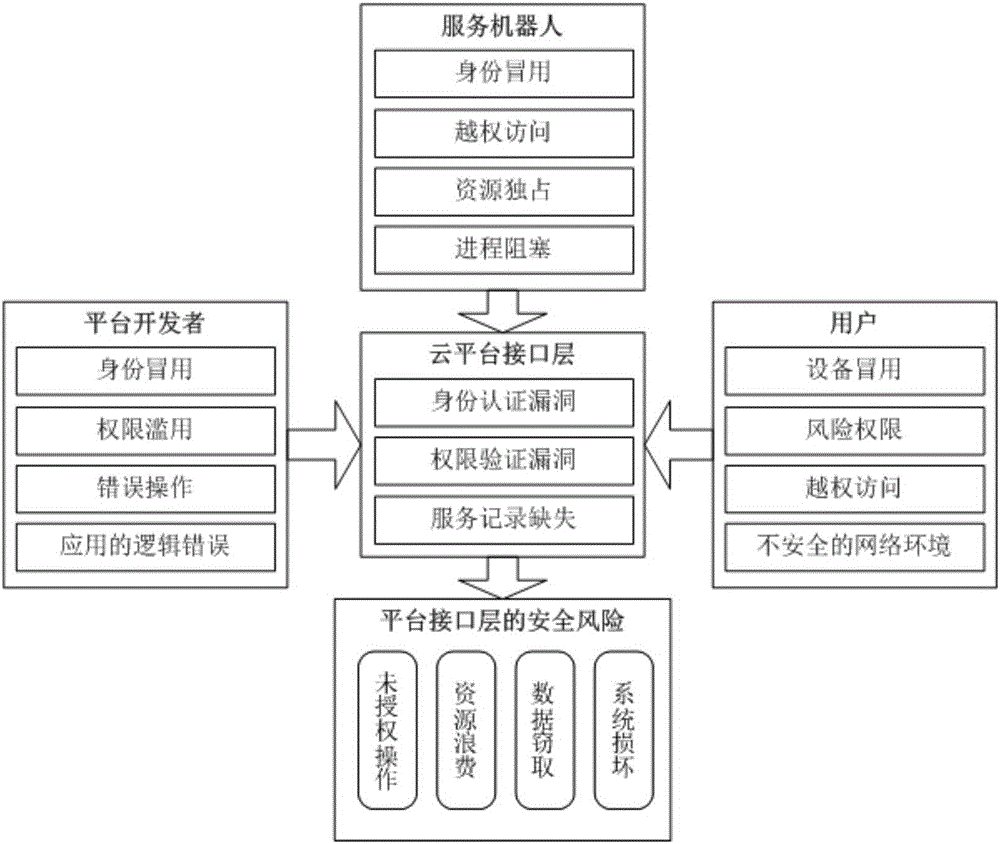

Service robot cloud platform interface system based on SOA and working method thereof

ActiveCN105872094AServices are independent of each otherWith control functionTransmissionInterface layerRequirements analysis

The invention discloses a service robot cloud platform interface system based on SOA and a working method thereof. The system comprises a service layer, an SOA interface layer and an application layer. The service layer issues a service request to the SOA interface layer, the SOA interface layer carries out corresponding service querying and scheduling according to the service request, service agent and remote procedure call are achieved, and the application layer provides coarse grain service based on calling of the SOA interface layer, and meanwhile provides service feedback and log interfaces for the SOA interface layer. According to the development situation of a robot and the using character of a current robot, in the design process of cloud computation, the requirements of a mobile client and robot developers are considered, requirement analysis is carried out on a cloud calculating platform, the design principle of the SOA is followed, the cloud calculating platform is designed, and service of the robot and service of the could computing platform can be independent from each other.

Owner:山东芯辰人工智能科技有限公司

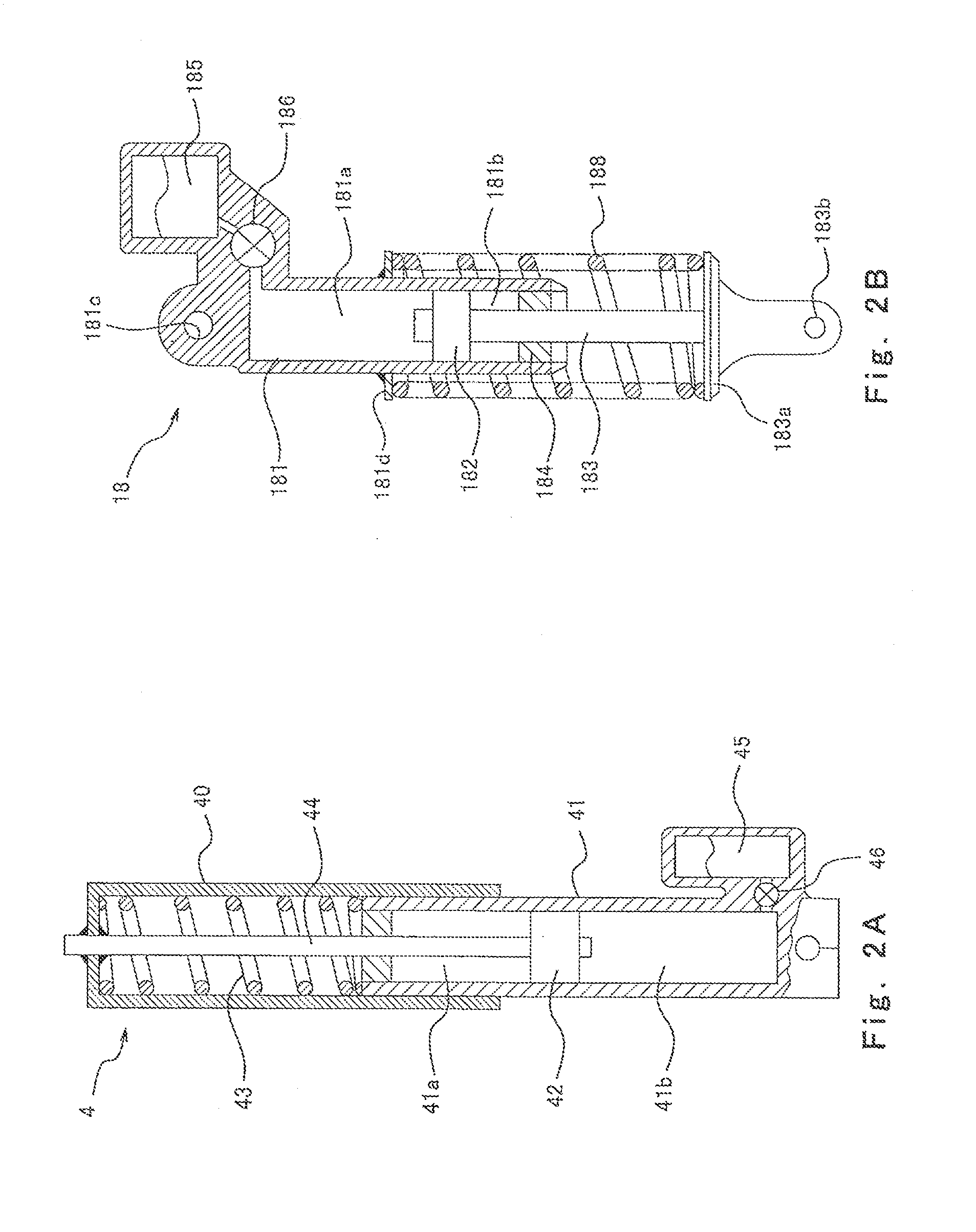

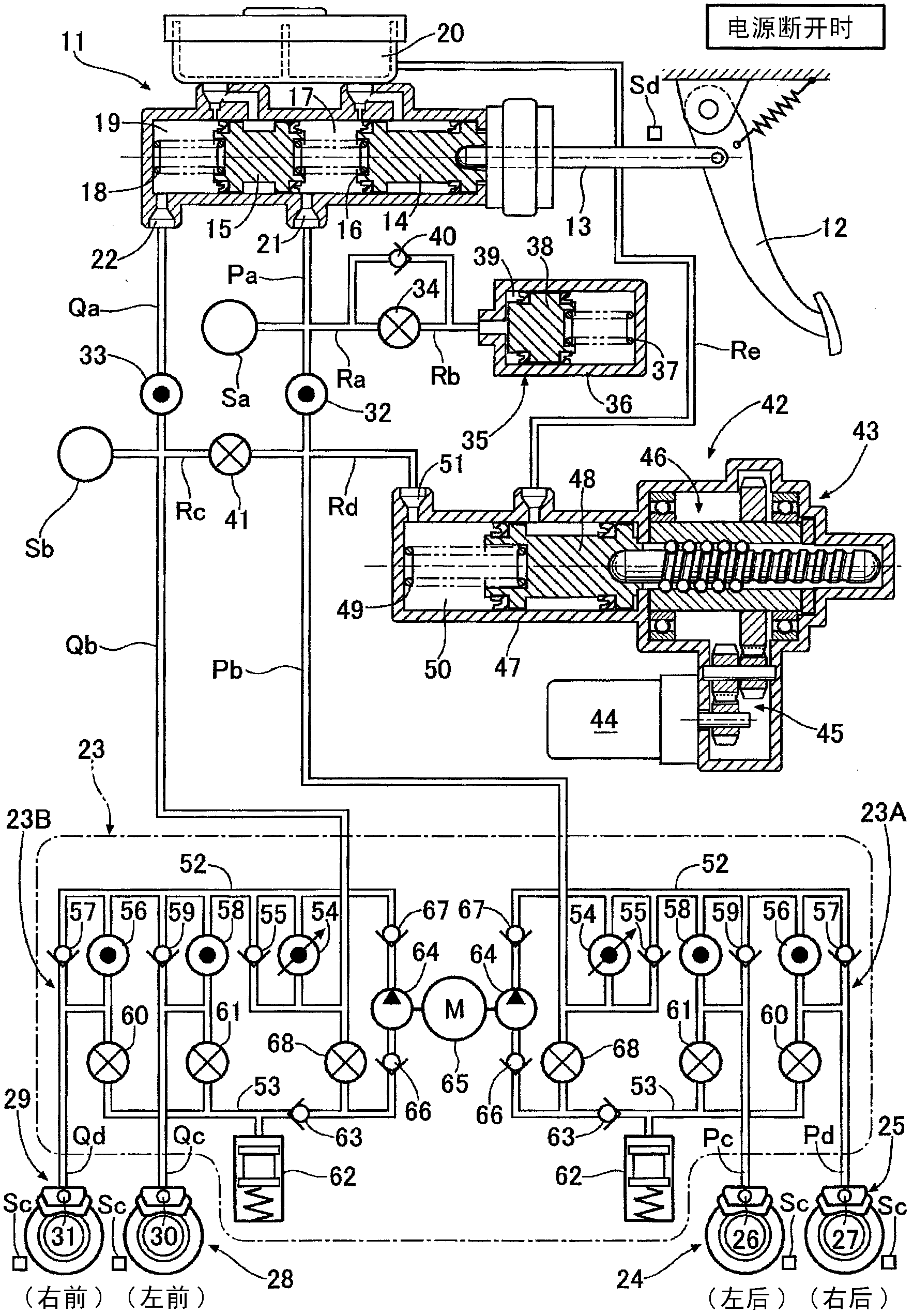

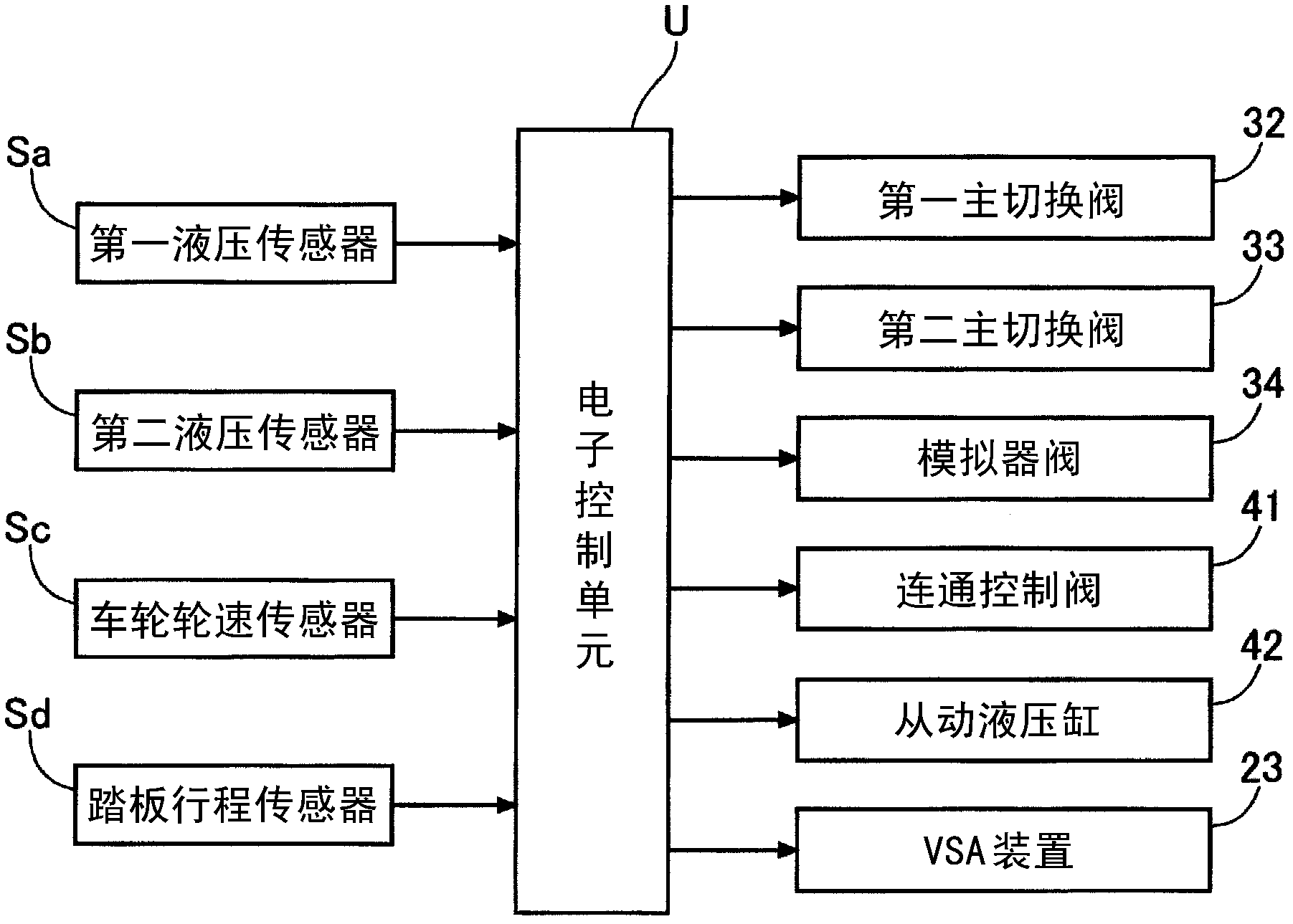

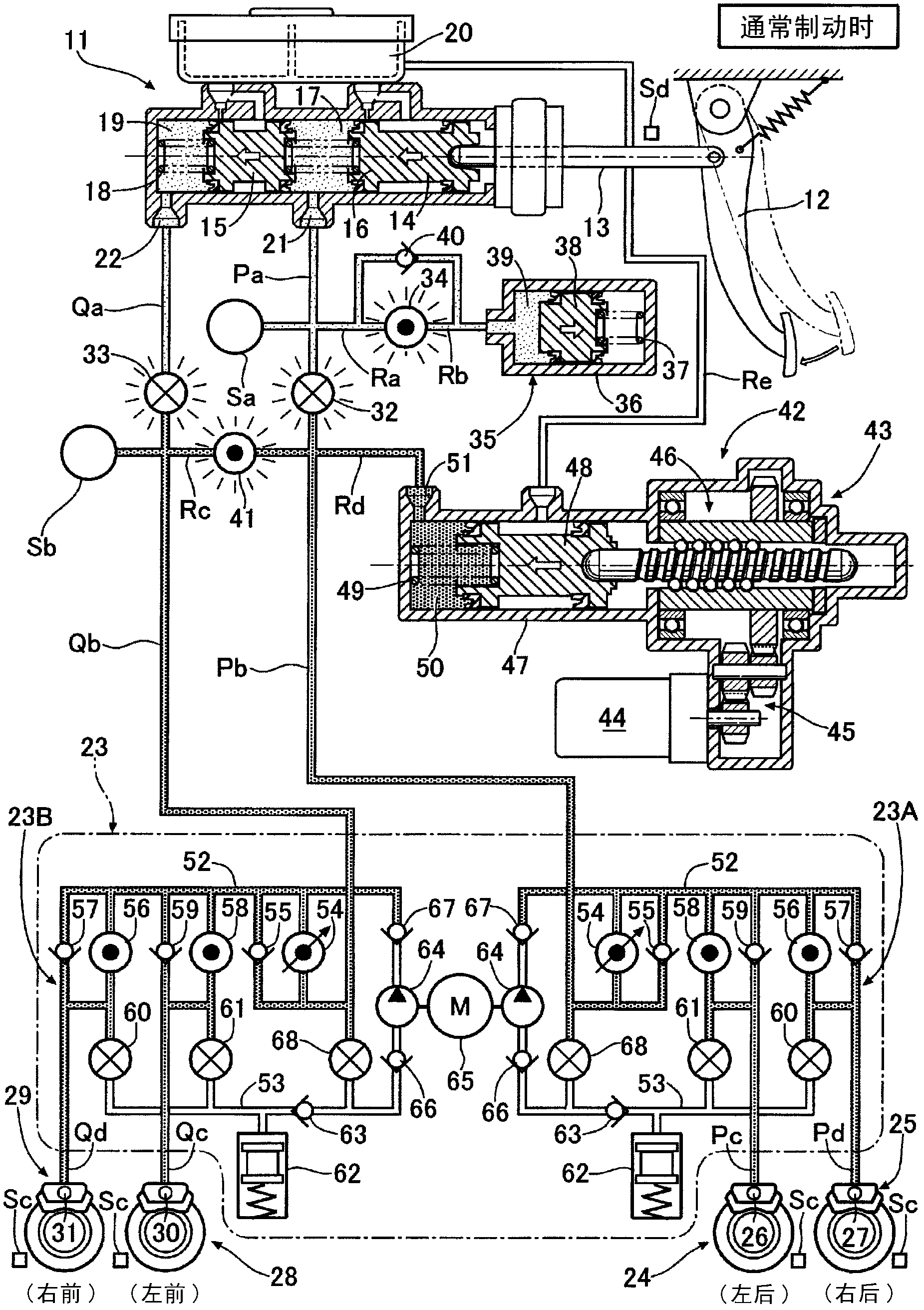

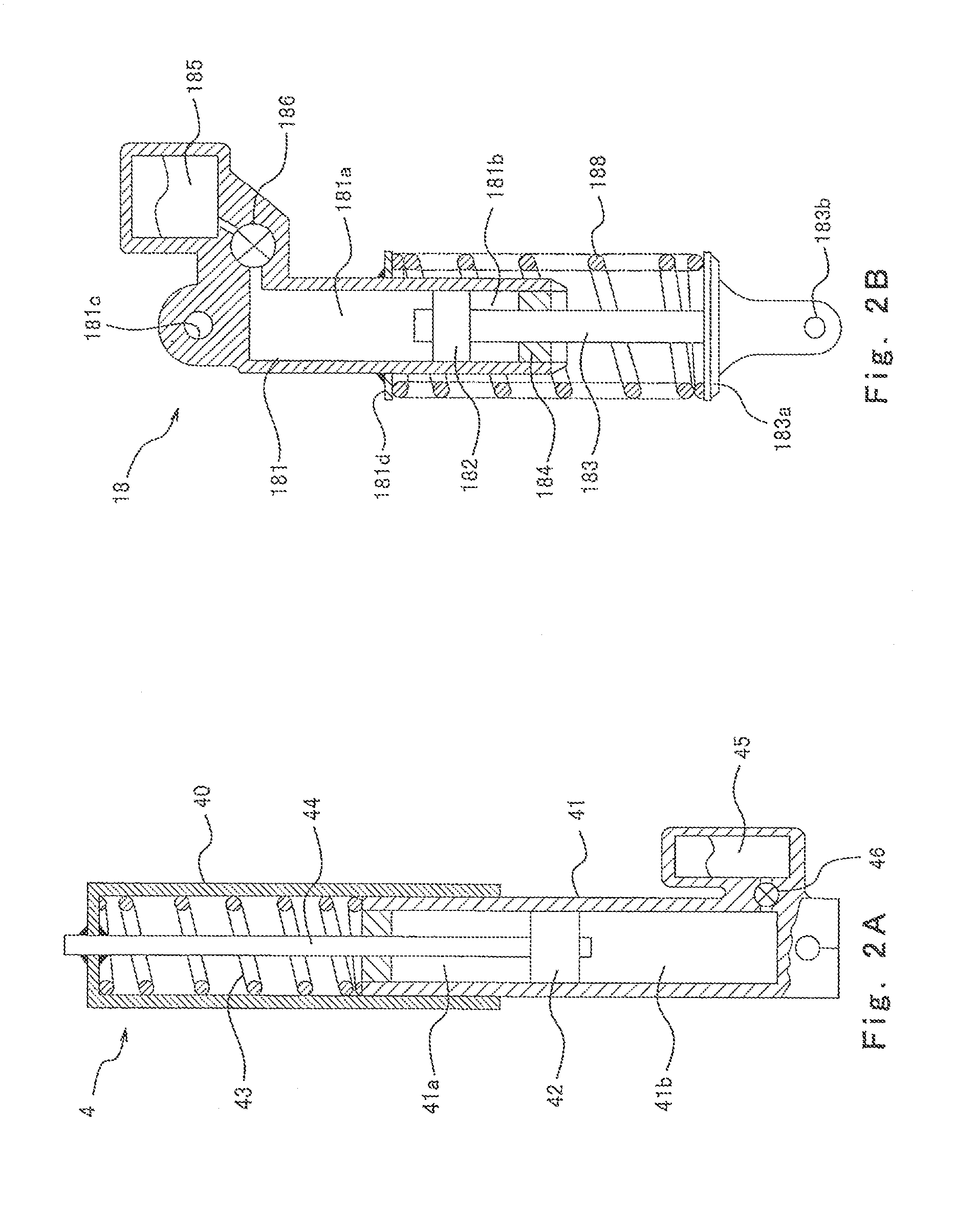

Vehicle braking apparatus

ActiveCN102556031AImprove responsivenessRealization of small size and light weightBraking action transmissionBrake action initiationsHydraulic cylinderMiniaturization

The invention provides a vehicle breaking apparatus having a hydraulic pressure source which can generate brake hydraulic pressure corresponding to a piston forward movement driven by an electric motor. The apparatus enables the electric motor small and light-weighted while the responsiveness of the brake hydraulic pressure generation is ensured. The hydraulic pressure source with BBW-type brake apparatus comprises: a slave hydraulic cylinder (42), generating brake hydraulic pressure by the forward movement of the piston (48) driven by the electric motor (44); a VSA apparatus (23), by using a pump (64), pressurizing on the brake fluid at the downstream side of the slave hydraulic cylinder (42). For the slave hydraulic cylinder (42) and the VSA apparatus (23) are selectively acted based on the operation amount of a brake pedal (12), the slave hydraulic cylinder (42) is acted when the high responsiveness of generating brake hydraulic pressure is not required, so that the miniaturization of the electric motor (44) is achieved and the VSA apparatus (23) is acted when the high responsiveness of generating brake hydraulic pressure is required, thereby ensuring the high responsiveness.

Owner:HONDA MOTOR CO LTD

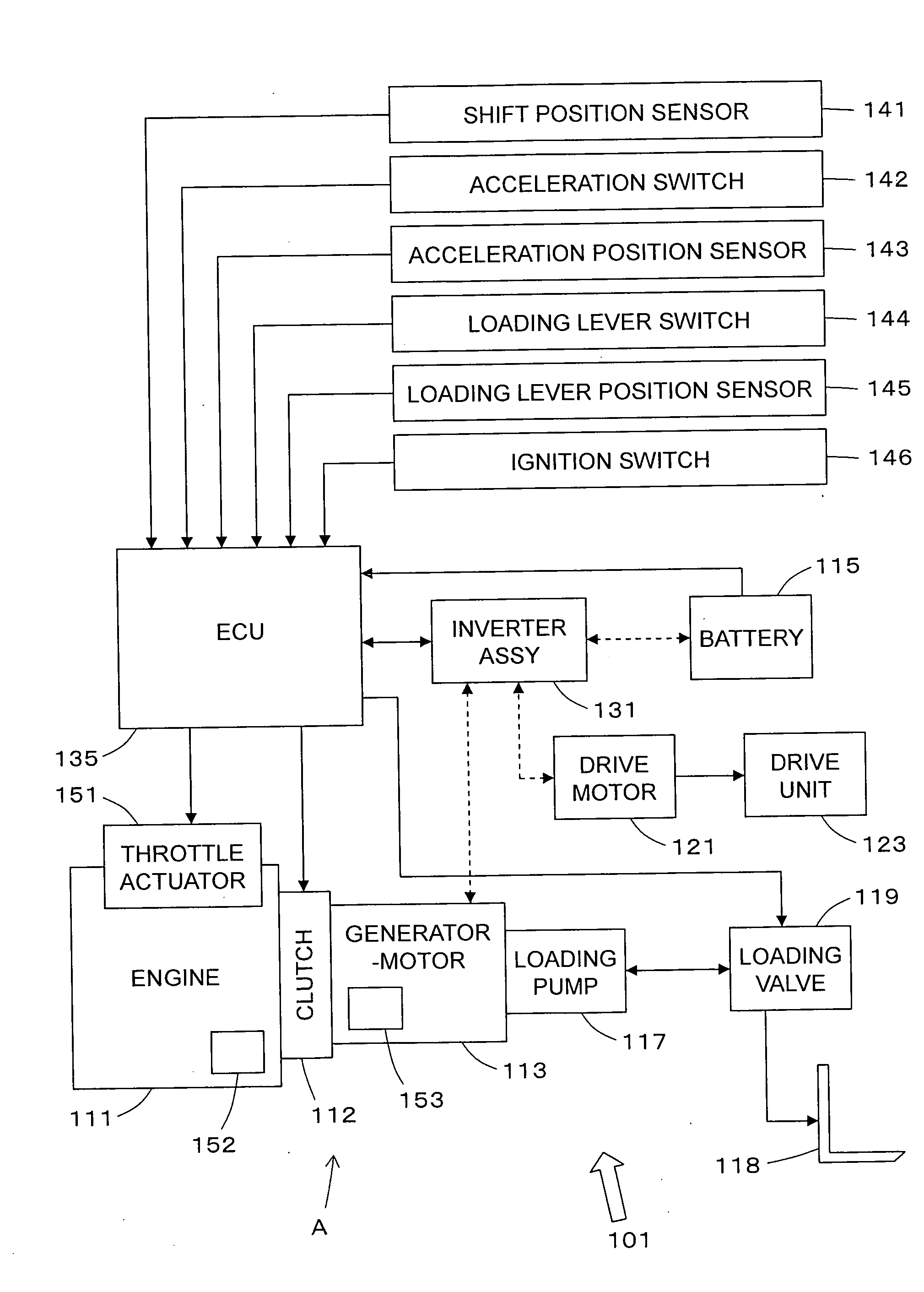

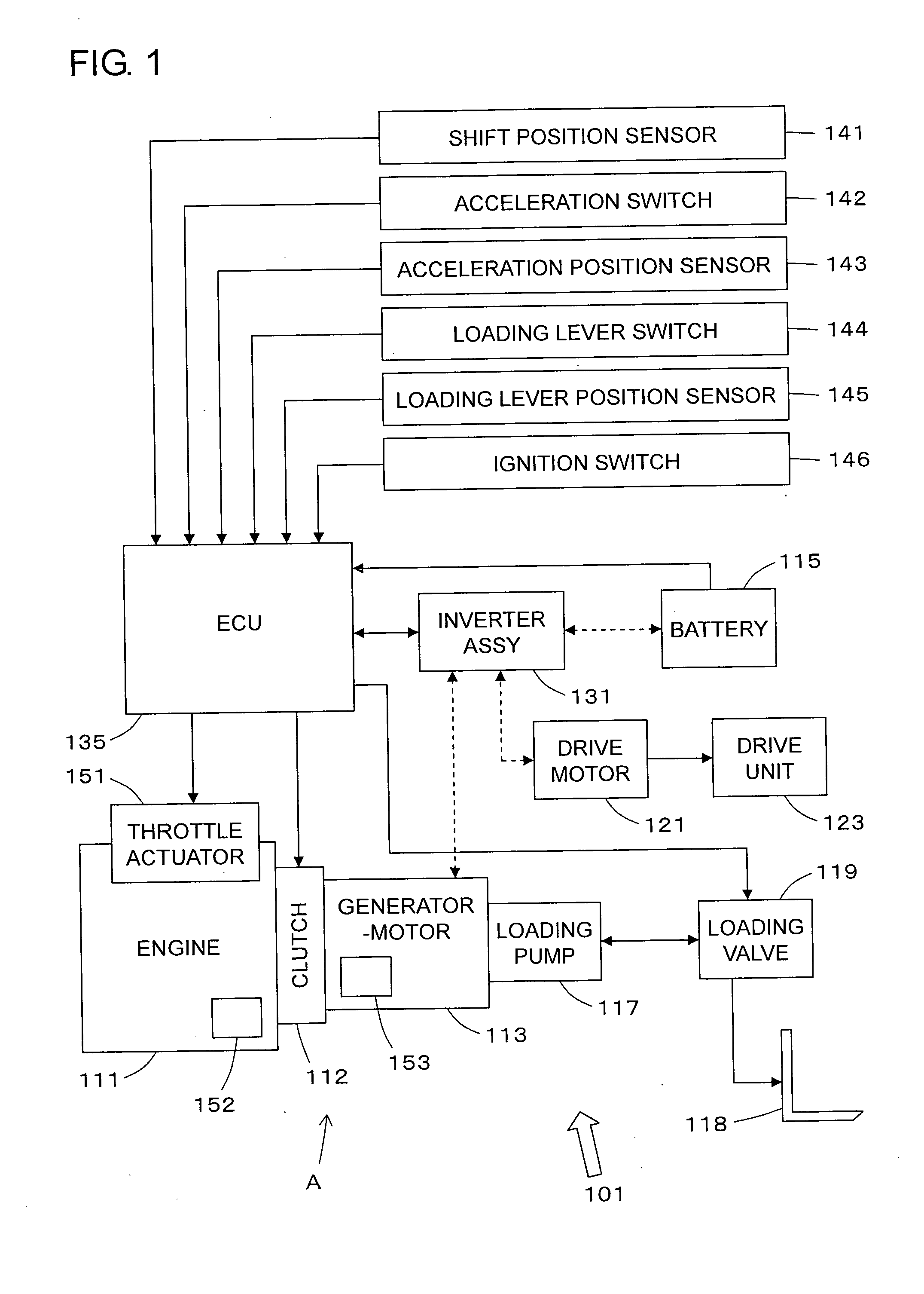

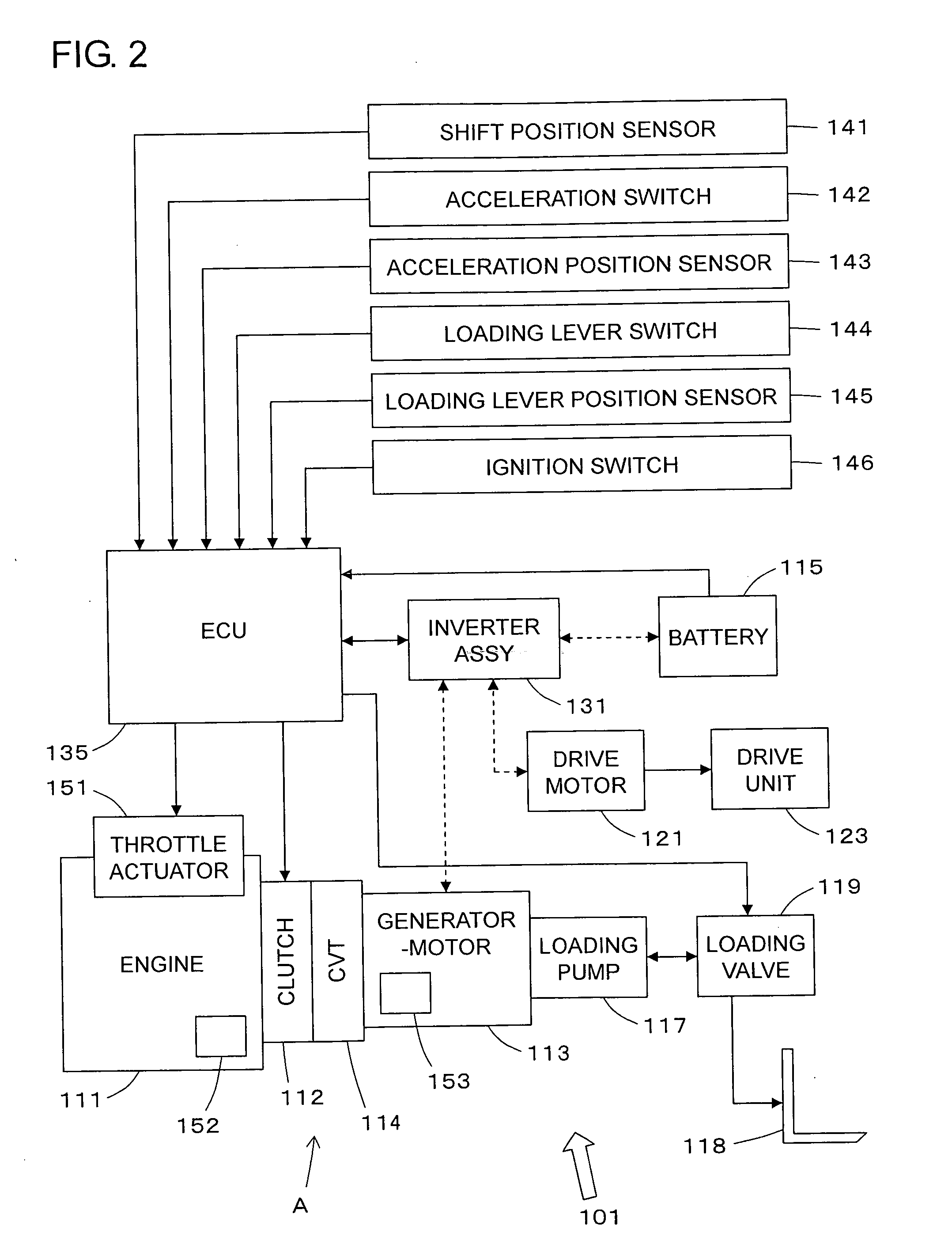

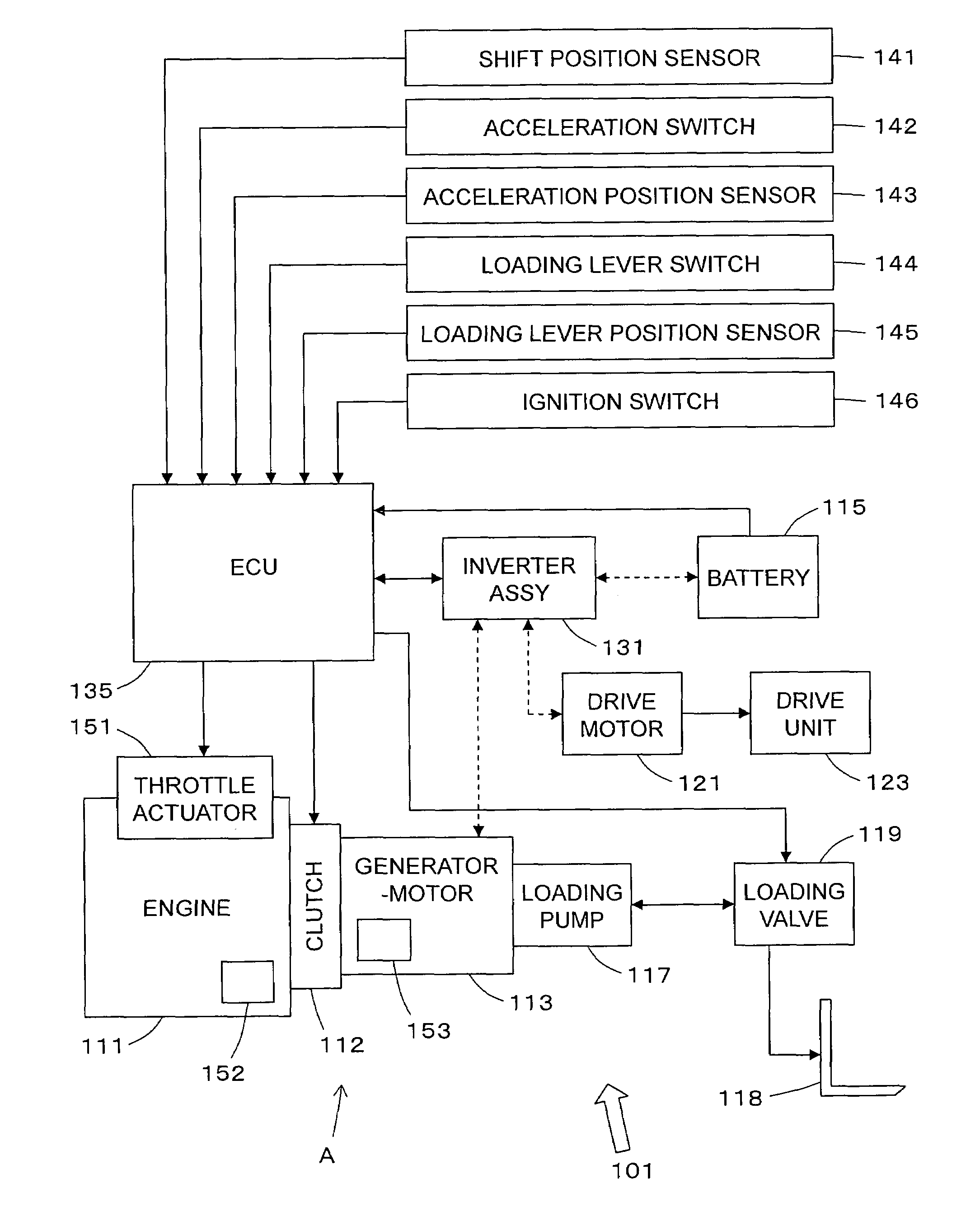

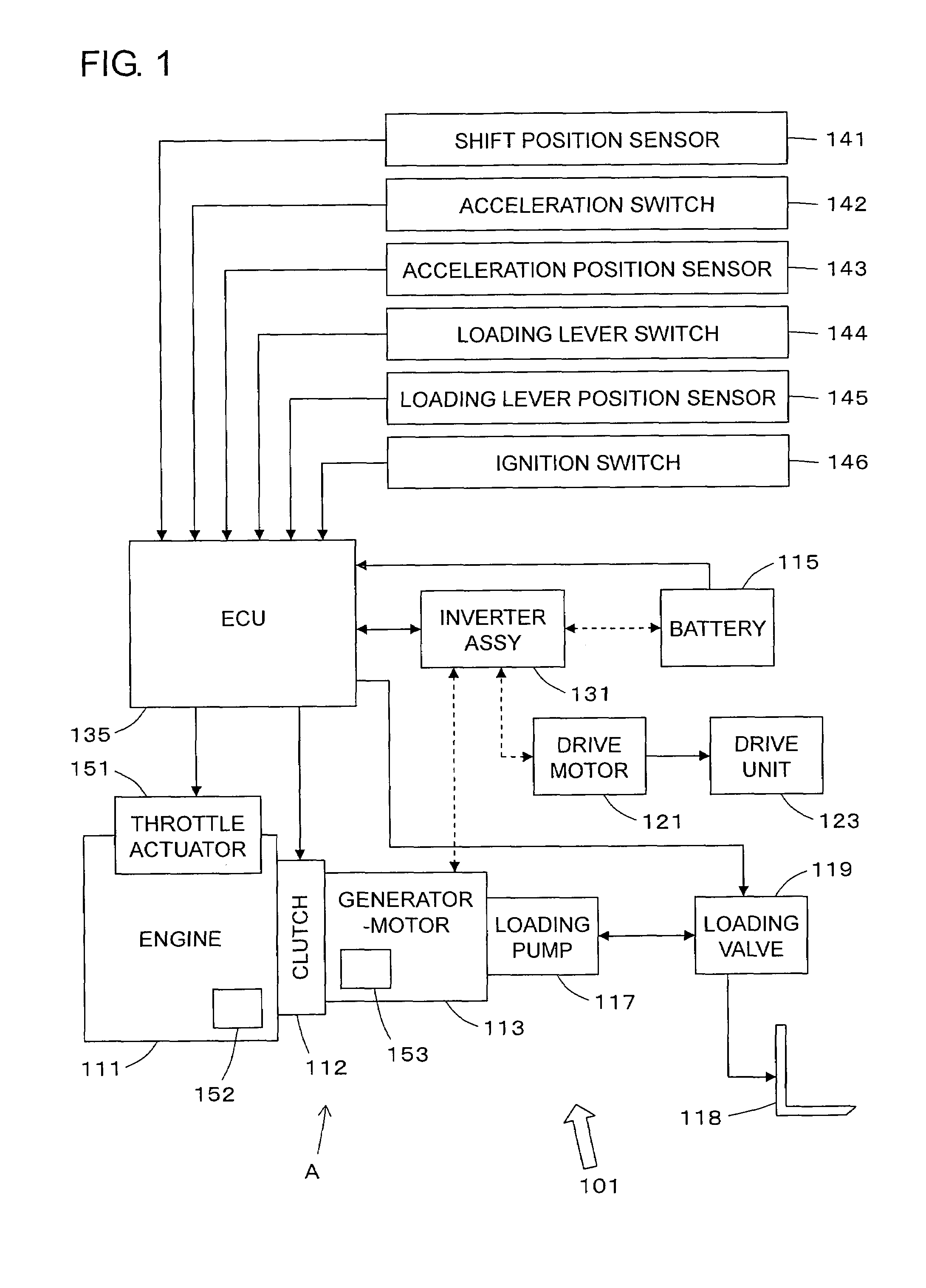

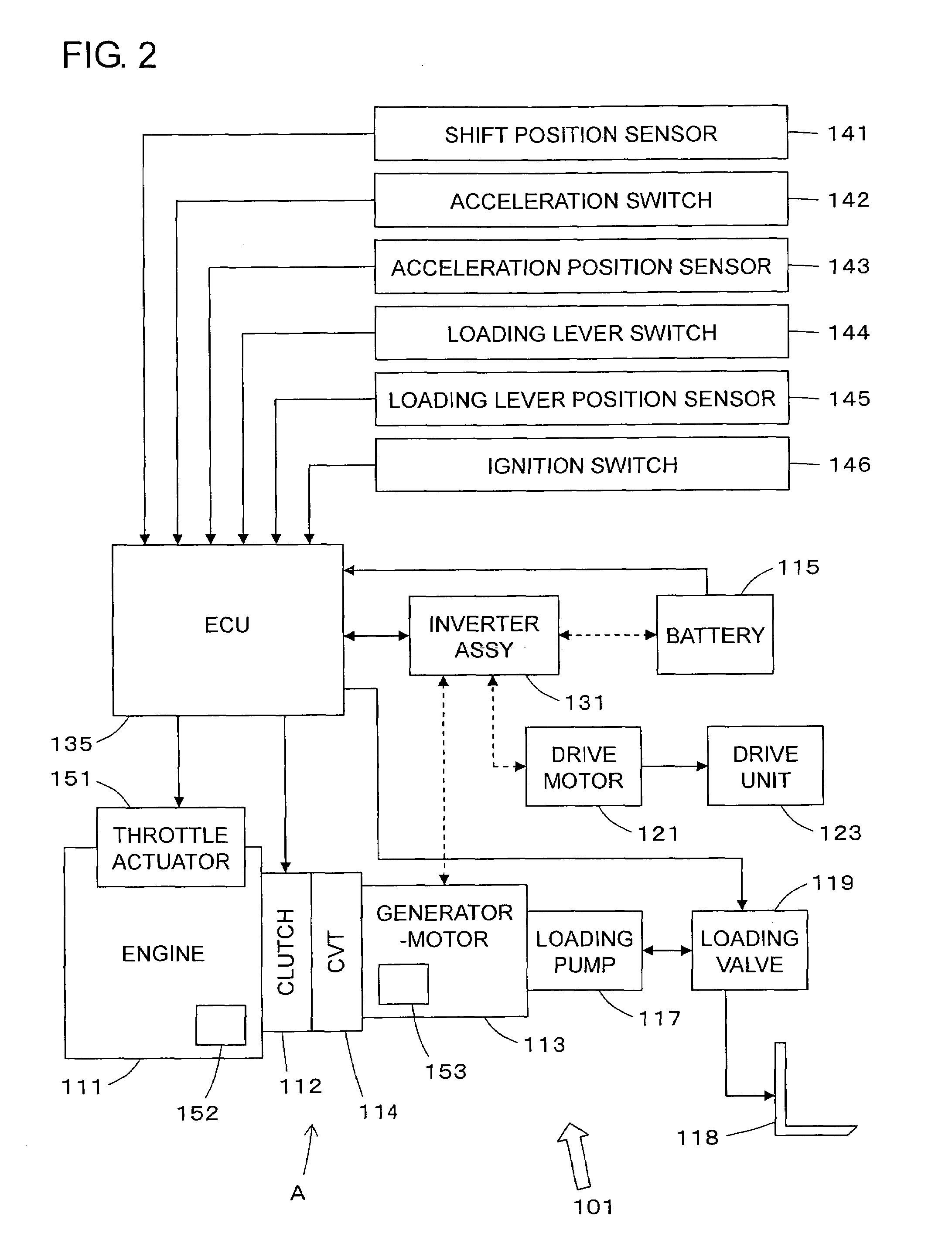

Cargo Handling Apparatus of Cargo Handling Industrial Vehicle

InactiveUS20080190703A1Improve energy efficiencyEnsure responsivenessGearing controlPlural diverse prime-mover propulsion mountingPosition sensorClutch

Provided are an engine 111, a generator-motor 113, a clutch 112 connecting / disconnecting power therebetween, a battery 115, and a loading pump 117 for driving a fork 118. The generator-motor 113 is set either in a generator mode or in a motor mode. When a cargo handling load (detected by a loading lever position sensor 145 and the like) is smaller than a predetermined value, the clutch 112 is set to a disconnection state, the engine 111 is stopped or idled, and the loading pump 117 is driven by the generator-motor 113 in the motor mode. When the load is increased to the predetermined value or more during cargo handling work in a state where the clutch 112 is released, an increase of the number of revolution of the engine is started while an output of the generator-motor 113 is being increased. When the number of revolution of the engine 111 is made equal to the number of revolution of the generator-motor 113, the clutch 112 is set to a connected state, and the loading pump 117 is driven by the engine 111.

Owner:TOYOTA IND CORP

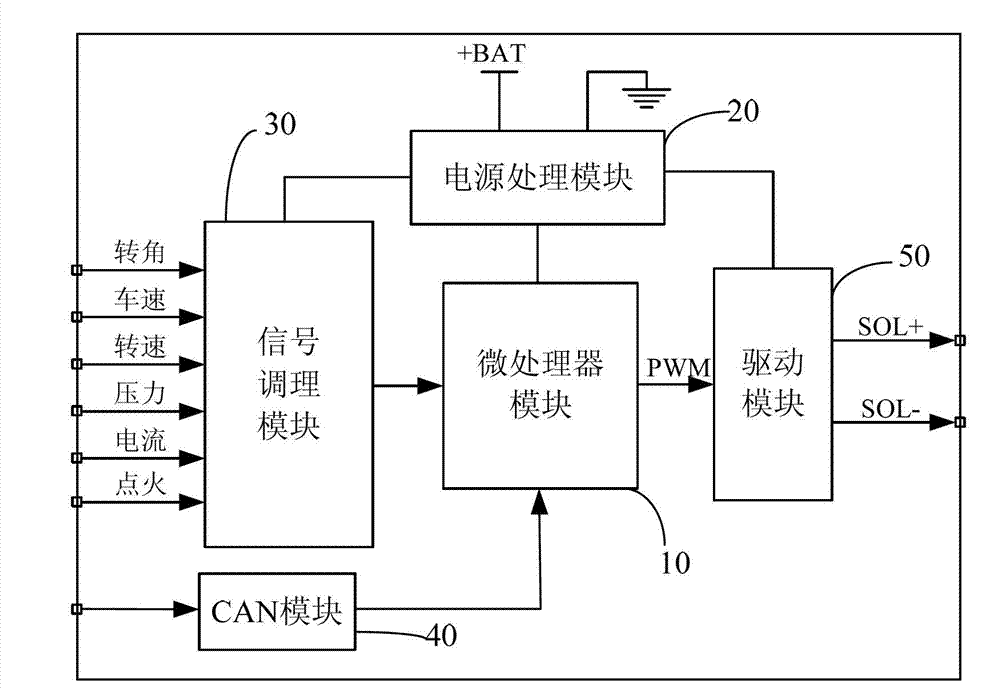

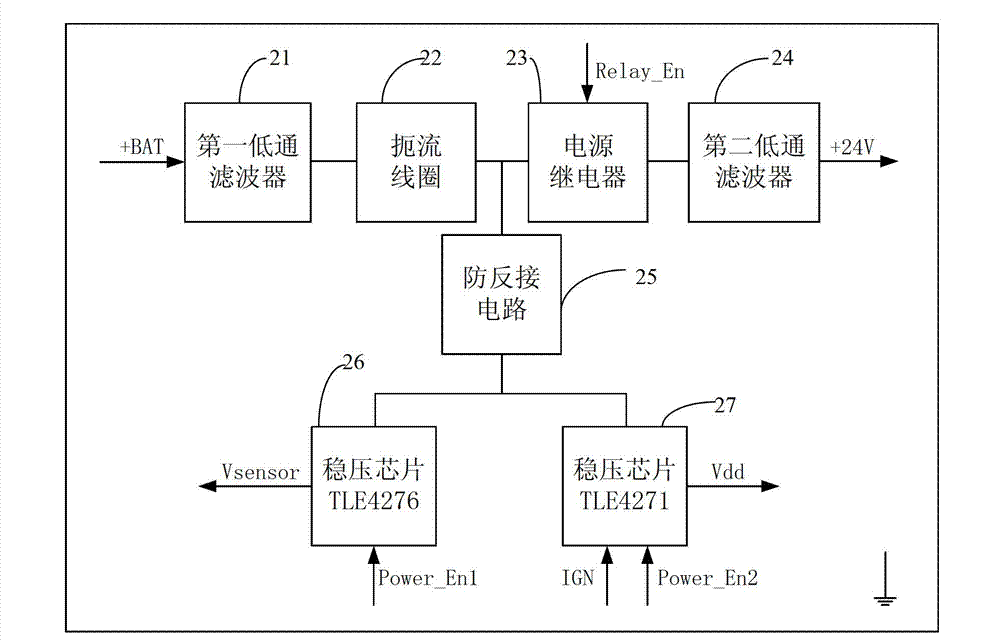

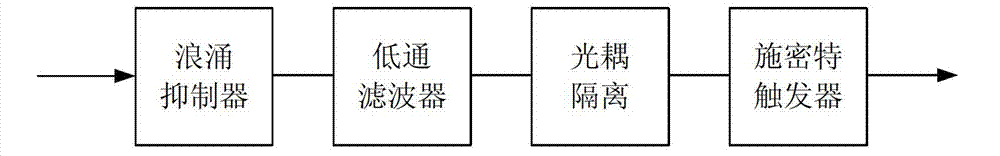

Electronic control hydraulic power steering system controller and control method thereof

ActiveCN102923185AImprove anti-interference abilityHandling Stability Requirements GuaranteeFluid steeringElectrical steeringMicrocontrollerMicrocomputer

The invention provides an electronic control hydraulic power steering system controller and a control method thereof. The controller comprises a microprocessor module, a power module connected with the microprocessor module, a signal conditioning module, a controller area network (CAN) module and a driver module. When a vehicle steers on site or at low speed, the controller meets the requirement for low-speed steering handiness. When the vehicle steers at high speed, the controller meets the requirement for high-speed handling stability. When the vehicle steers urgently, the controller ensures steering responsiveness. When the vehicle steers in full loading, the controller executes a control program according to assist characteristics of the vehicle at a speed lower than the current speed and enhances road feel in steering. A single chip microcomputer is adopted as a control core of the controller. Due to the fact that signals are transmitted mainly in a digital form, the controller is strong in anti-interference capacity and can enable control to achieve optimization by optimizing the curve the assist characteristics and control parameters.

Owner:JIANGSU UNIV

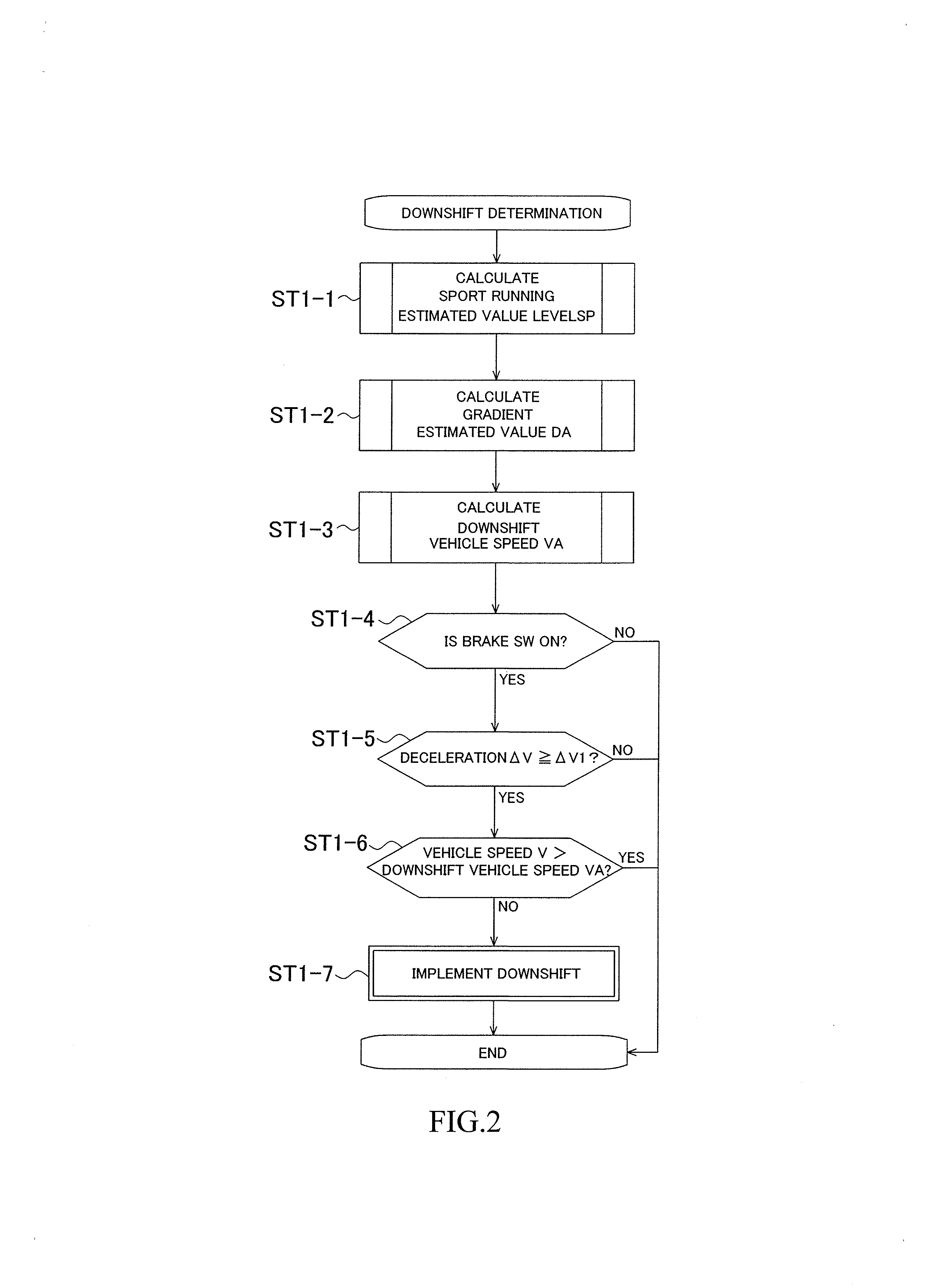

Control apparatus for vehicle automatic transmission

ActiveUS20130179044A1Improve drivabilityEnsure responsivenessRotary clutchesDigital data processing detailsAutomatic transmissionAcceleration Unit

A sport running estimated value LEVELSP obtained by searching a value on a map prepared in advance based on an average values AGYAVE of lateral accelerations GY of a vehicle and on average values of vehicle speed changes is calculated, and a vehicle speed on a shift map is searched based on the sport running estimated value LEVELSP and an estimated value DA of a vehicle gradient, whereby a downshift vehicle speed VA at which a downshift is implemented is calculated. Then, the downshift is implemented in a case where actuation of a brake is detected, deceleration of the vehicle is a predetermined value or more, and a current vehicle speed is a downshift vehicle speed VA or more. In such a way, running on a meandering road, for which the downshift and a subsequent shift hold should be implemented, is sensed appropriately.

Owner:HONDA MOTOR CO LTD

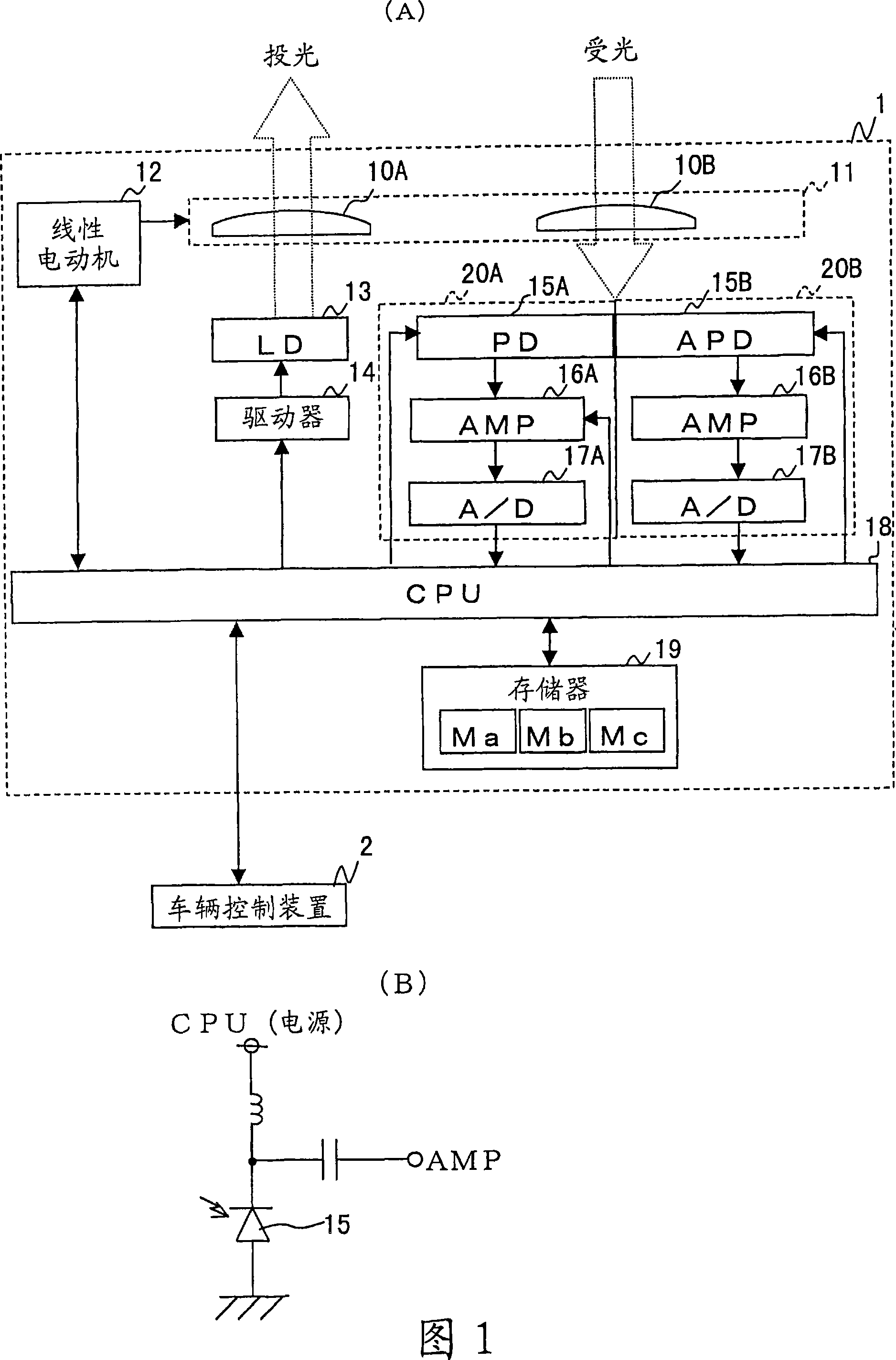

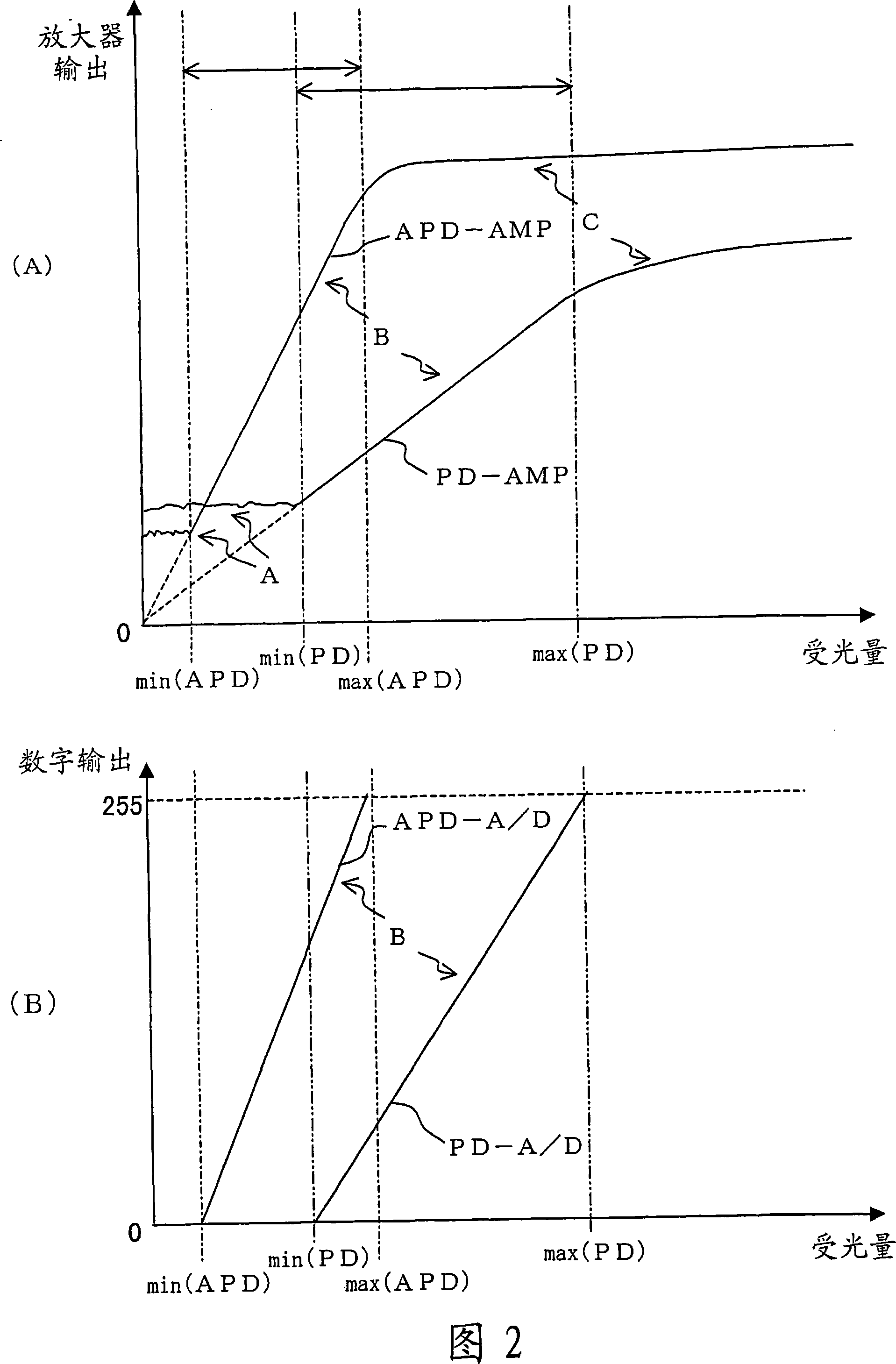

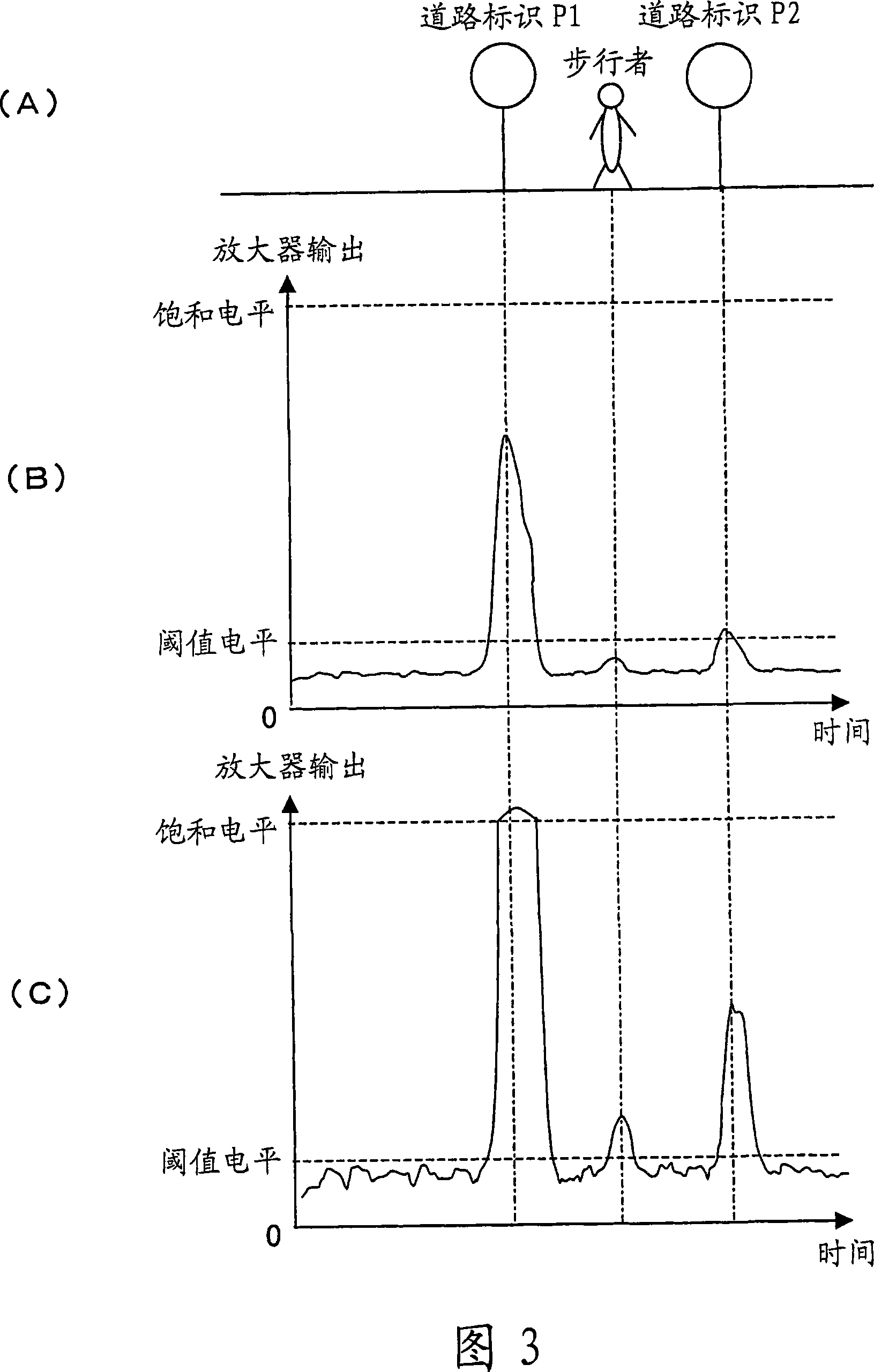

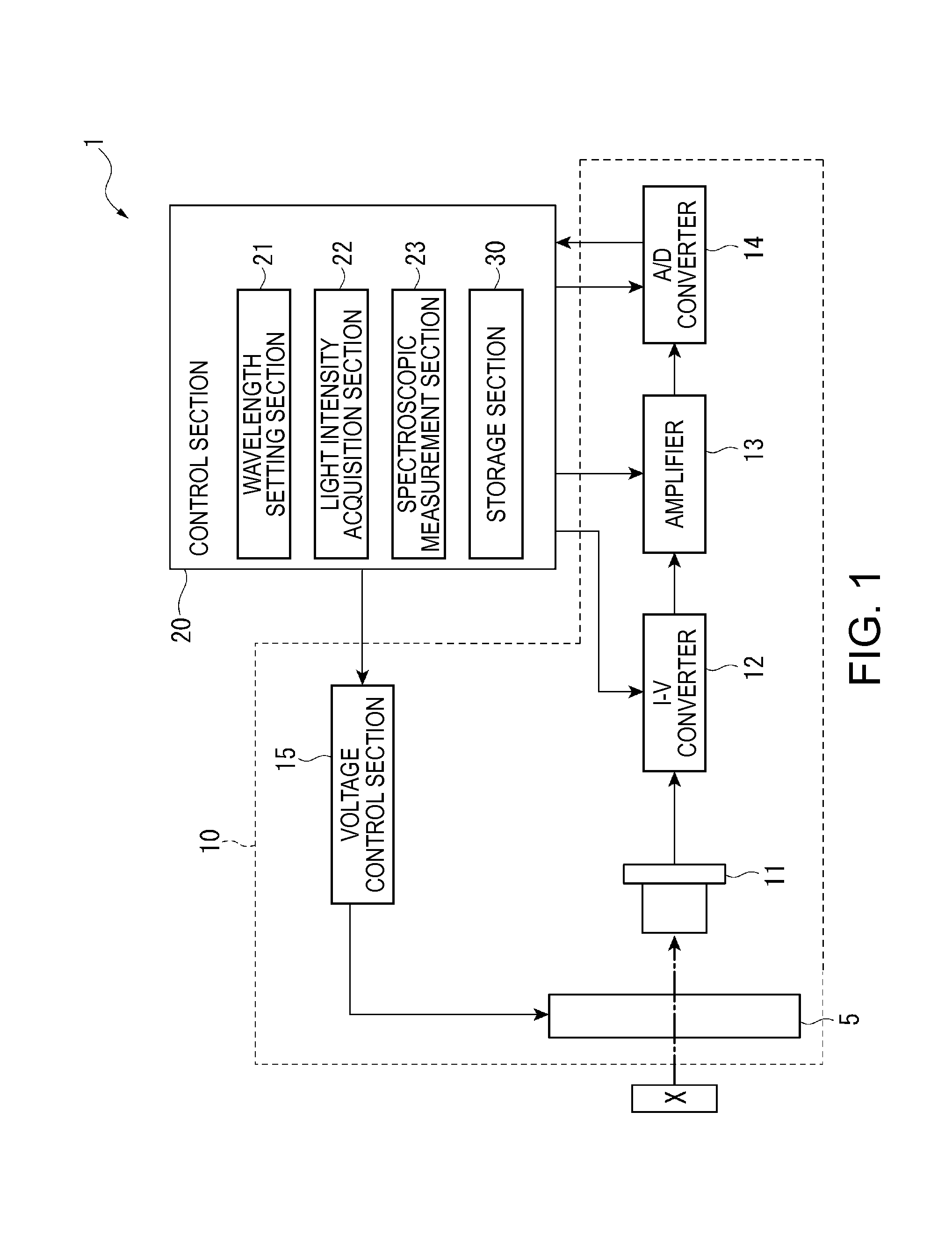

Radar device

InactiveCN101105531AAccurate detectionNo need to reduce biasElectromagnetic wave reradiationRadarPhotodiode

A radar device has a light projecting circuit for projecting light to an object. Reflected light from the object is received by a first light receiving circuit and a second light receiving circuit and converted into signals. The first and second light receiving circuits each have an activity range in which the outputted signal is proportional to the logarithm of the quantity of received light. The activity range of the first light receiving circuit is lower than the activity range of the second light receiving circuit.

Owner:ORMON CORP

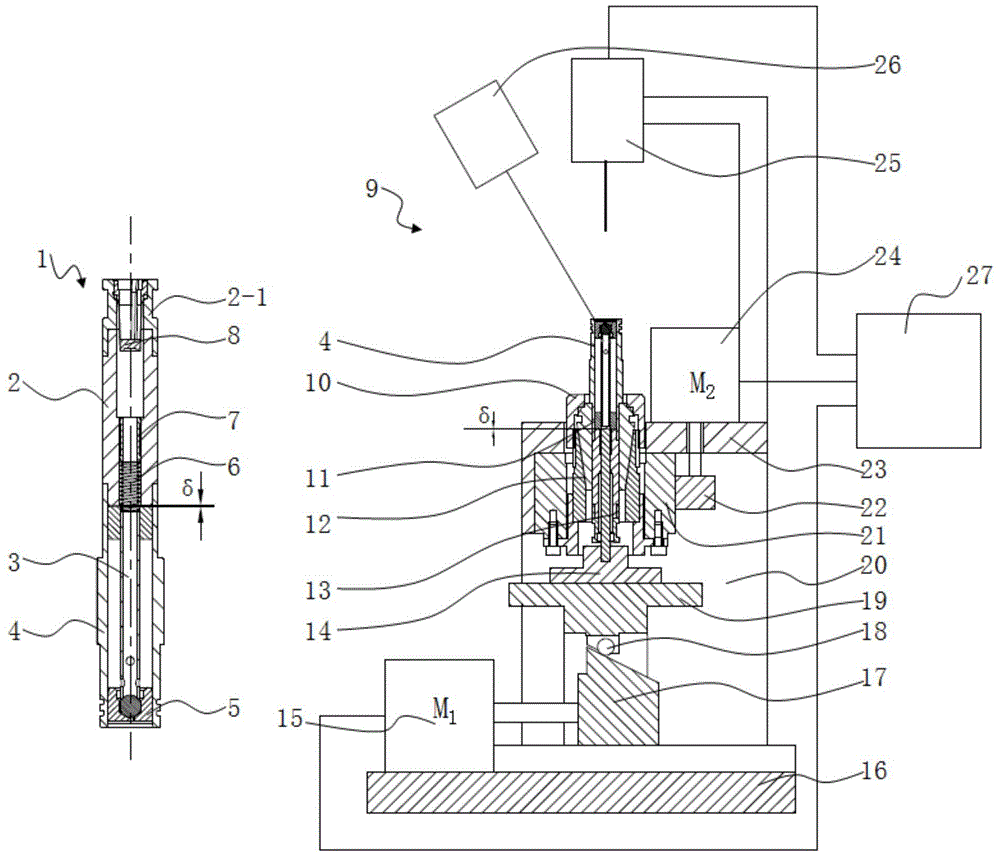

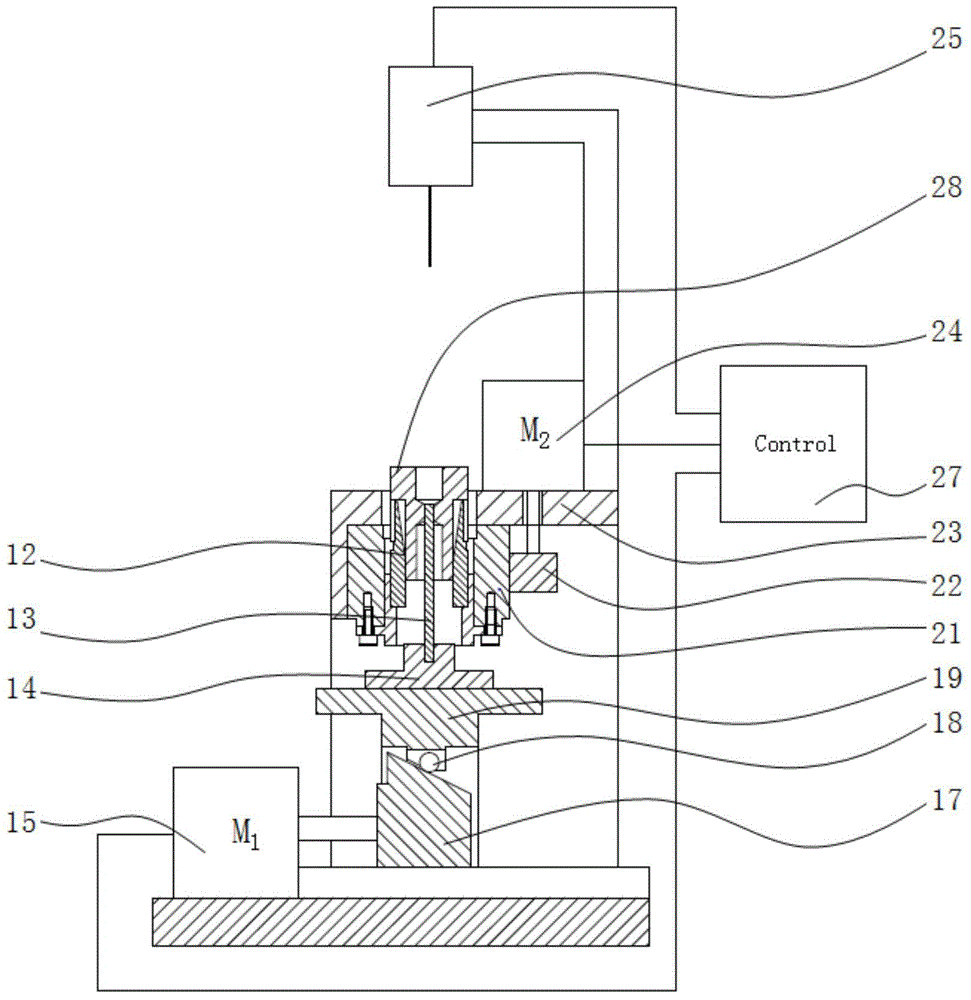

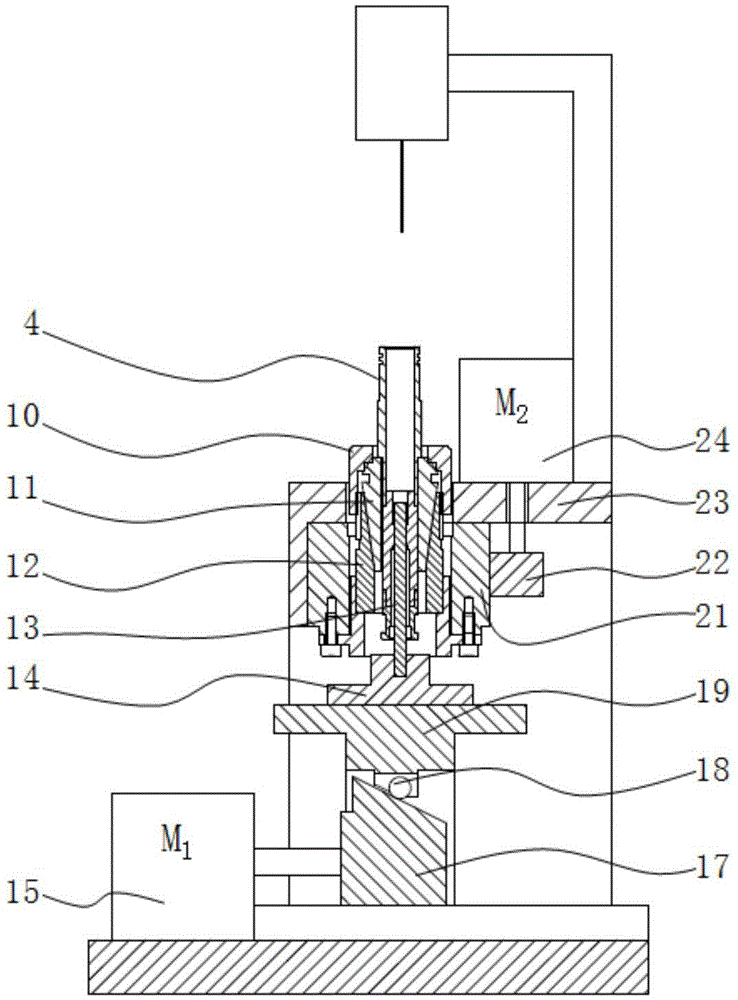

Assembly equipment and assembly method of fluid ejector

ActiveCN104858548AAvoid the problem of inaccurate lift adjustmentAvoid setpointLaser beam welding apparatusEngineeringDisplacement control

The invention discloses assembly equipment of a fluid ejector. The assembly equipment comprises a rack, a lifting mechanism, a clamping and rotating mechanism, a displacement sensor, a displacement controller and welding equipment, wherein the lifting mechanism is arranged at the lower part of the rack; the clamping and rotating mechanism is arranged above the lifting mechanism; the displacement sensor is arranged above the clamping and rotating mechanism; the welding equipment is arranged on one side of the clamping and rotating mechanism. The invention further discloses an assembly method of the fluid ejector. The assembly method comprises the following steps: firstly, pressing the other end, where an ejecting opening is formed, of a valve sleeve in the outer circumference at the top end of the a fixed iron core for welded fixing; secondly, adjusting the lifting range of a movable part through the displacement sensor and the displacement controller, and conducting welded fixing on a valve seat; finally, mounting the other parts. The assembly equipment and the assembly method have the advantages that the lifting range adjustment precision and the lifting range consistency of the movable part of the fluid ejector are obviously improved, so that the flow measurement precision and the responsiveness of the fluid ejector are guaranteed, and the assembly efficiency and quality are greatly improved; meanwhile, the allowable concentricity error ranges of armature and sealing parts can be widened, so that the difficulties of part processing and assembly are reduced.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +2

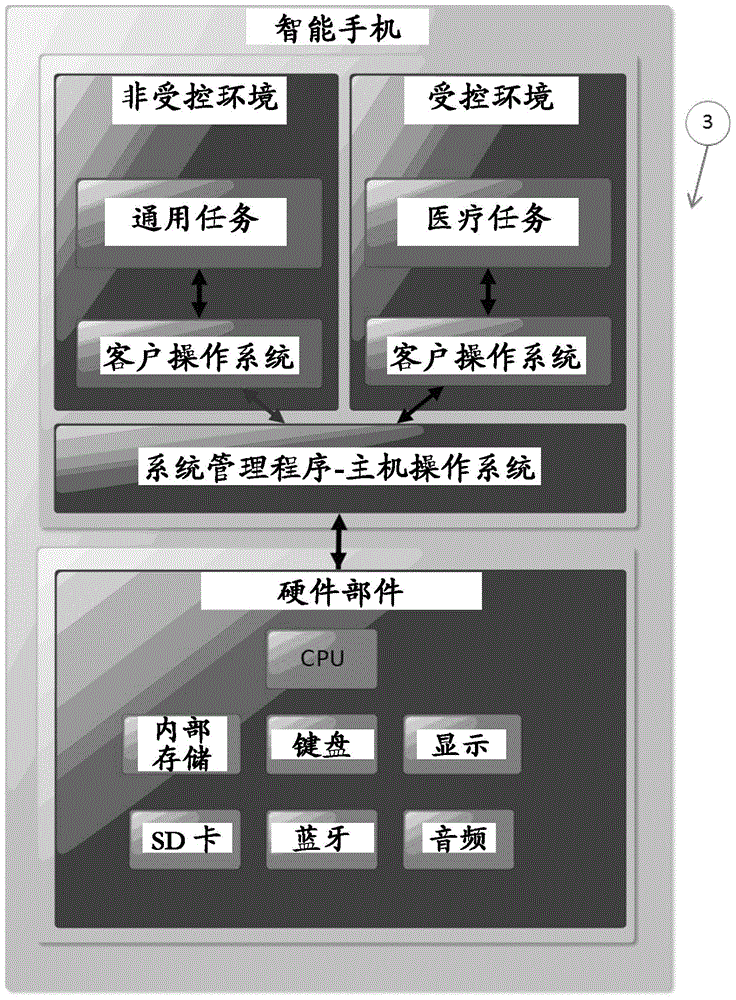

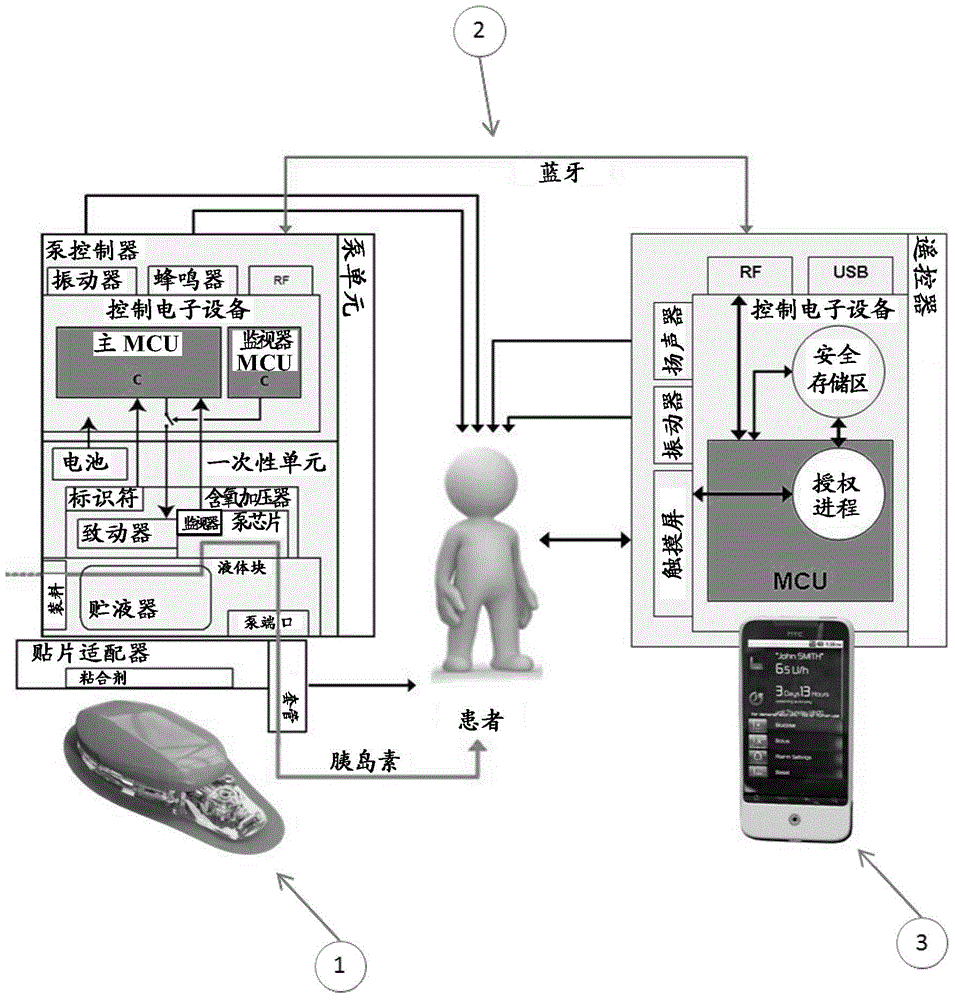

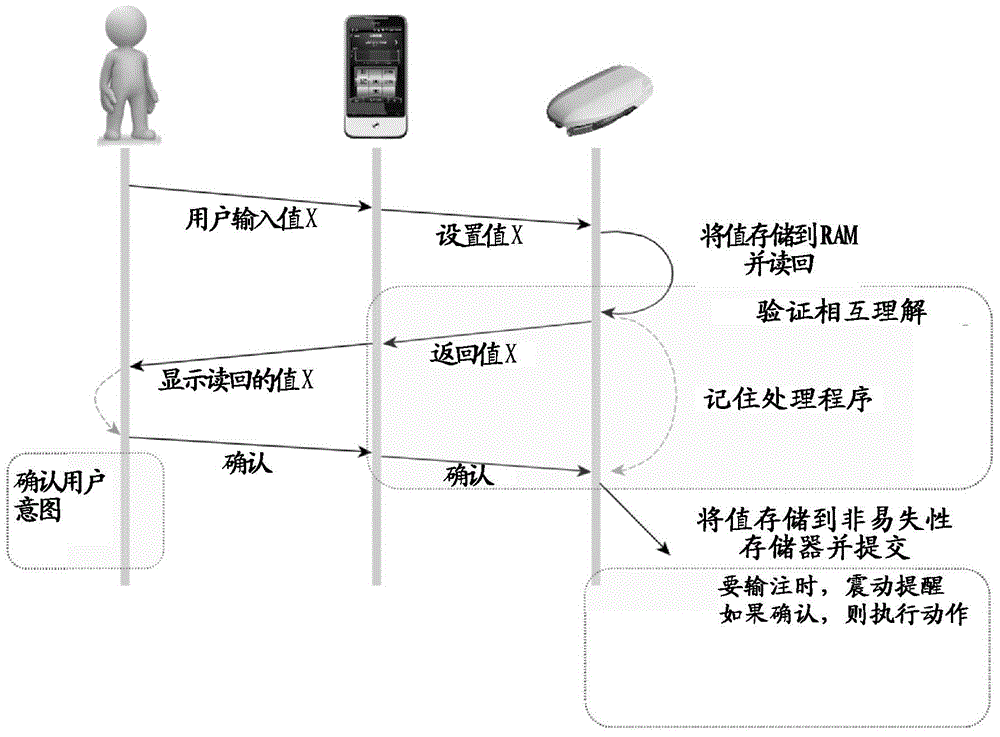

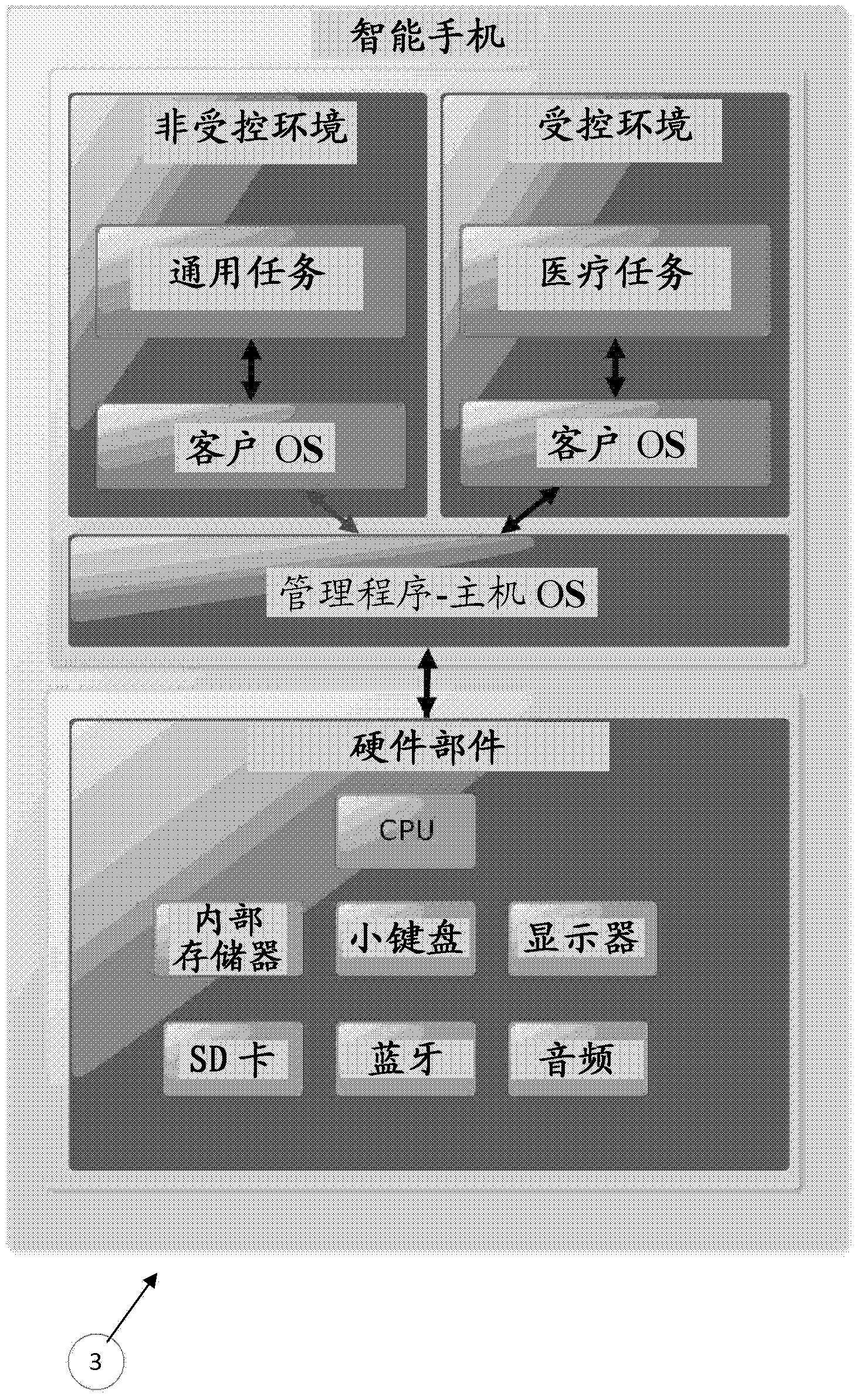

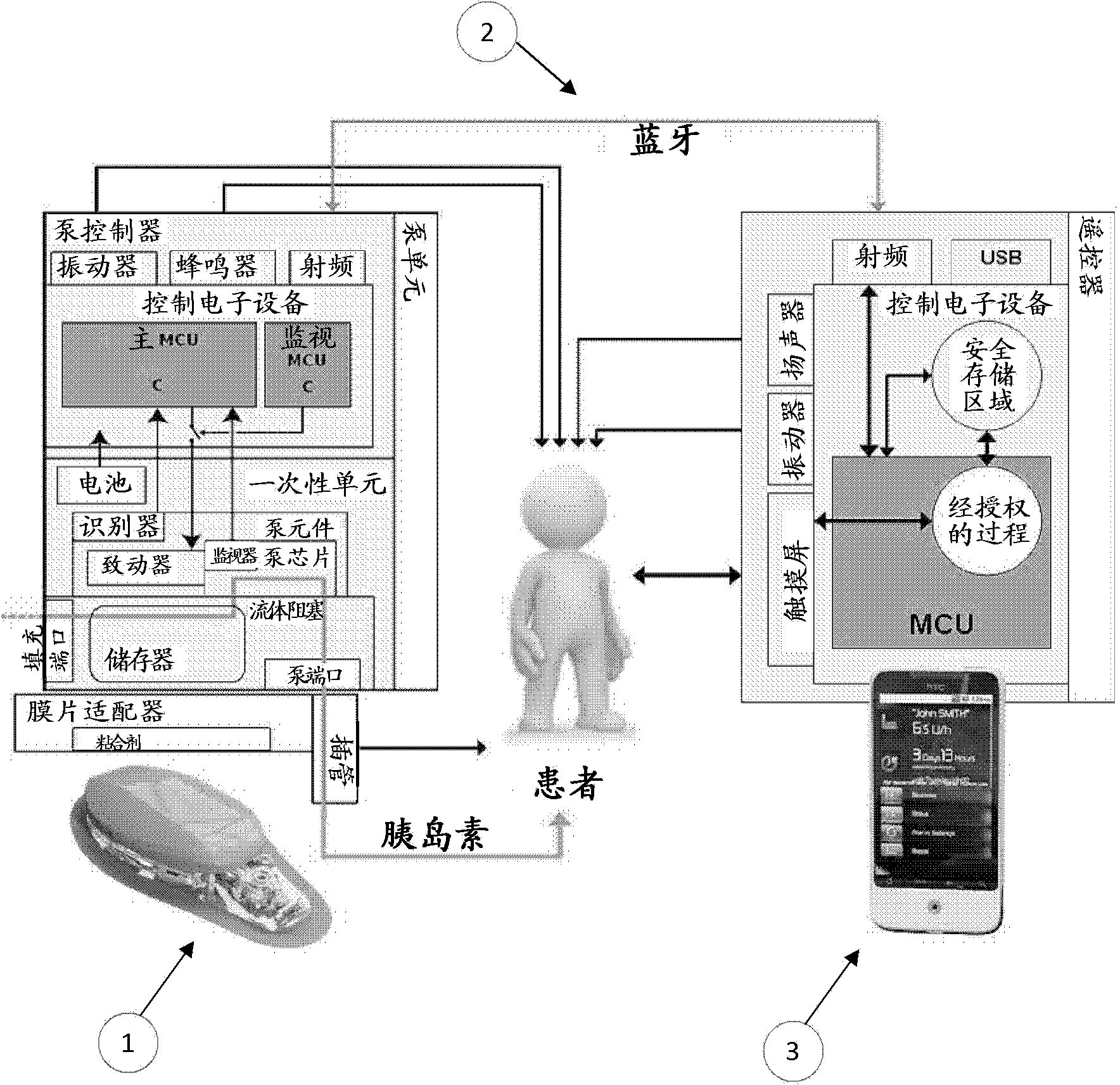

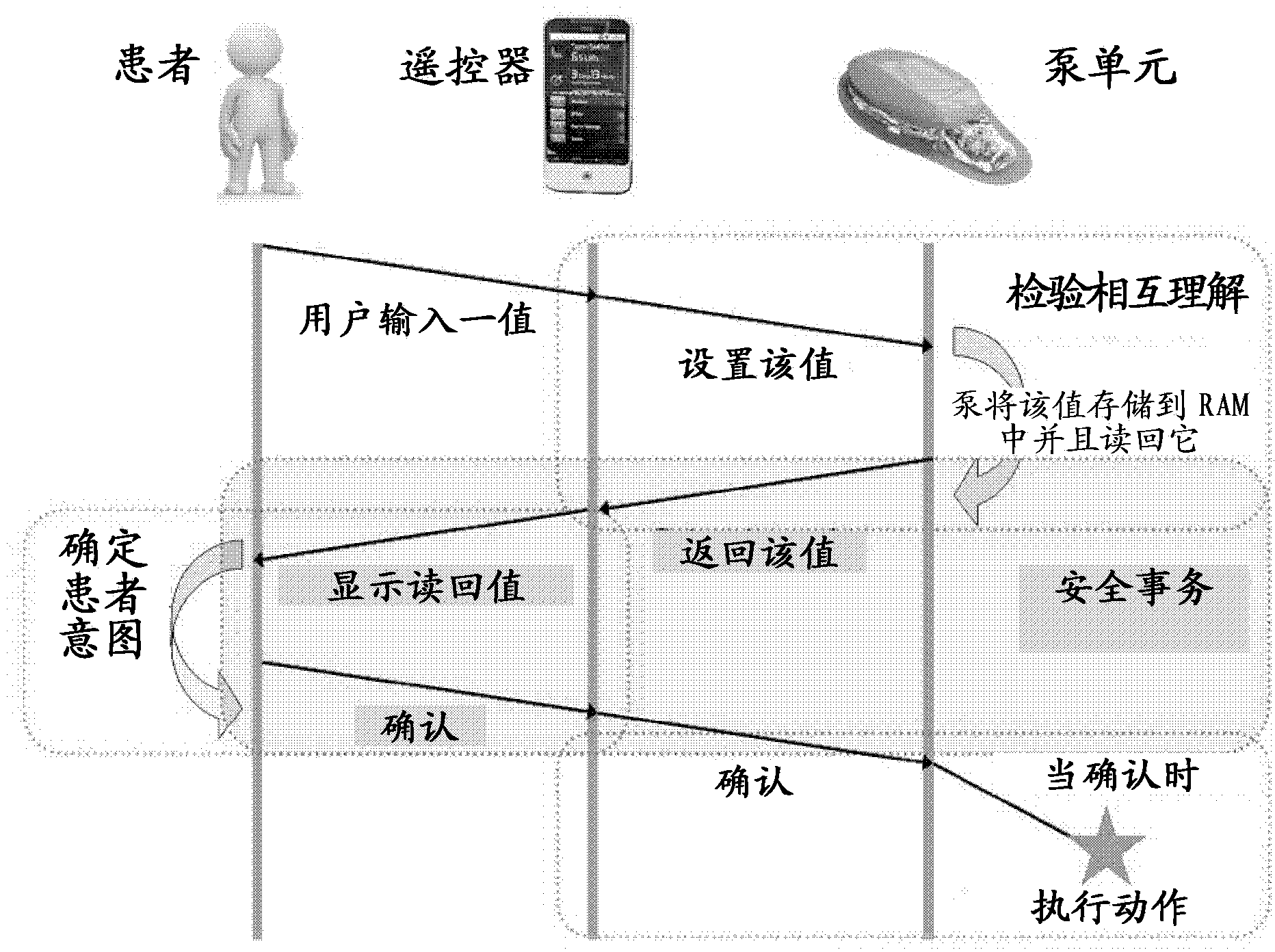

Communication secured between a medical device and its remote device

InactiveCN104641375AEnsure responsivenessIntegrity guaranteedTransmission systemsPublic key for secure communicationTelecommunicationsMedical device

Owner:DEBIOTECH SA

Cargo handling apparatus of cargo handling industrial vehicle

InactiveUS7464778B2Improve energy efficiencyEnsure responsivenessGearing controlPlural diverse prime-mover propulsion mountingCargo handling gearPosition sensor

Provided are an engine 111, a generator-motor 113, a clutch 112 connecting / disconnecting power therebetween, a battery 115, and a loading pump 117 for driving a fork 118. The generator-motor 113 is set either in a generator mode or in a motor mode. When a cargo handling load (detected by a loading lever position sensor 145 and the like) is smaller than a predetermined value, the clutch 112 is set to a disconnection state, the engine 111 is stopped or idled, and the loading pump 117 is driven by the generator-motor 113 in the motor mode. When the load is increased to the predetermined value or more during cargo handling work in a state where the clutch 112 is released, an increase of the number of revolution of the engine is started while an output of the generator-motor 113 is being increased. When the number of revolution of the engine 111 is made equal to the number of revolution of the generator-motor 113, the clutch 112 is set to a connected state, and the loading pump 117 is driven by the engine 111.

Owner:TOYOTA IND CORP

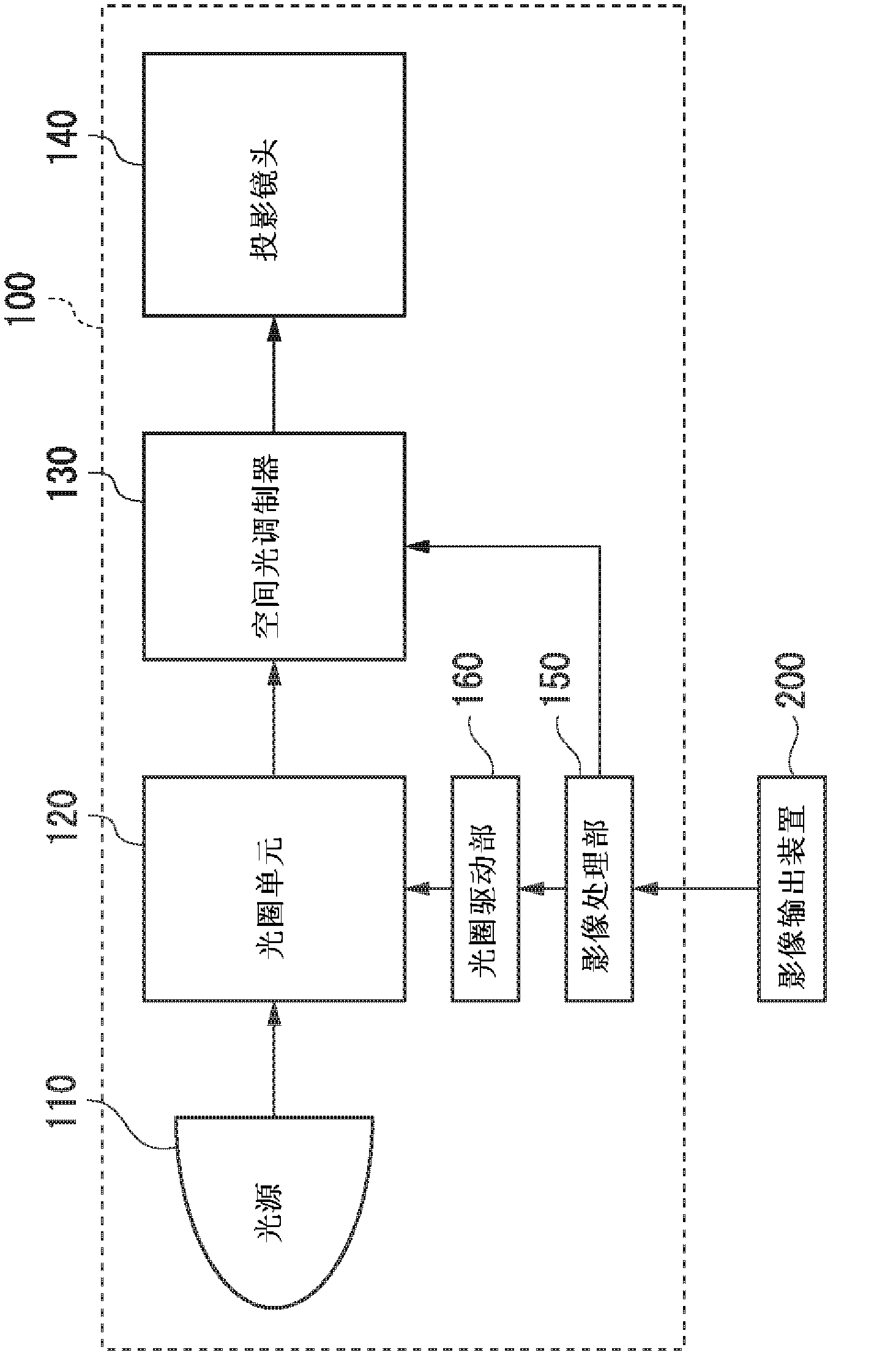

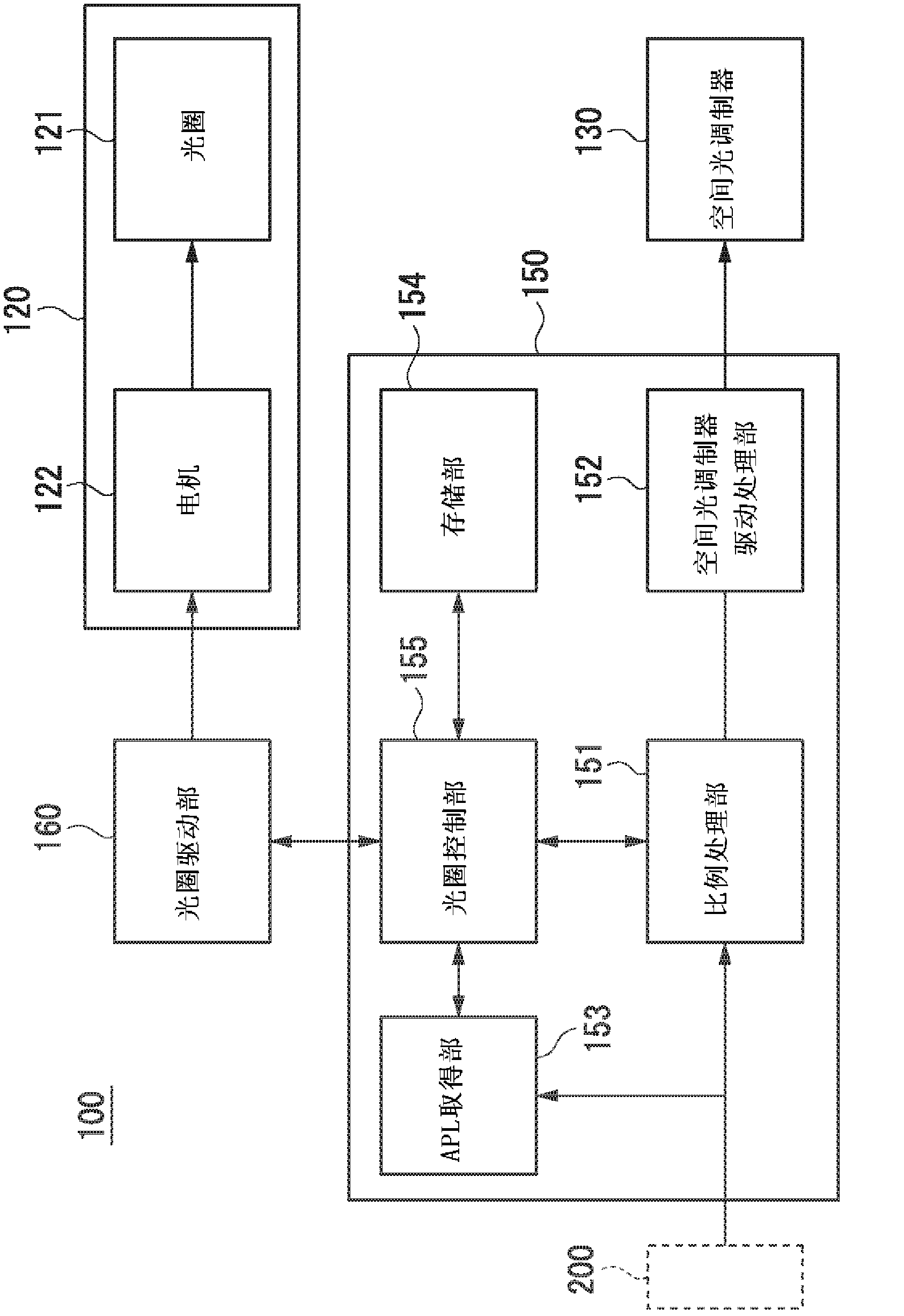

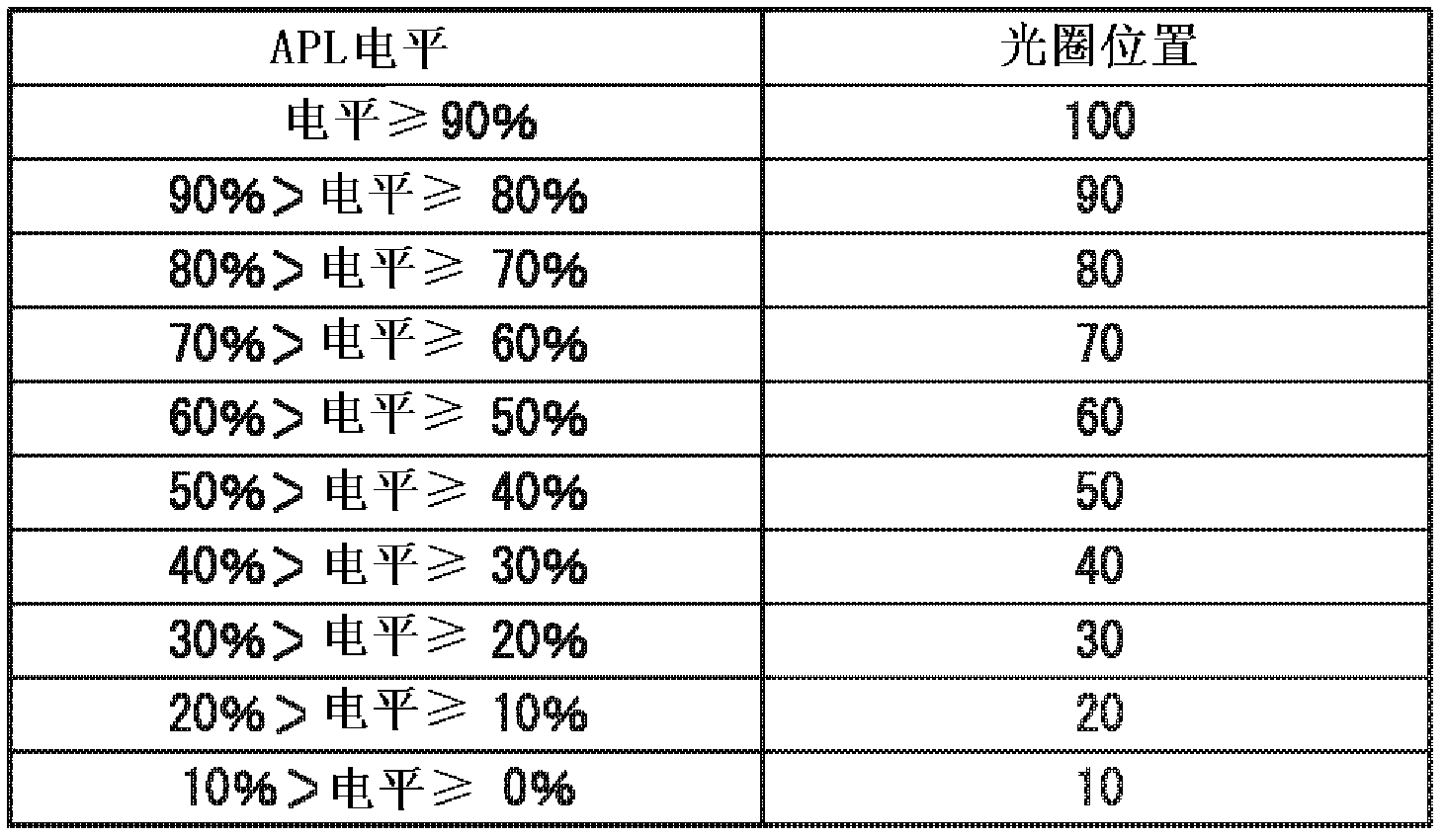

Diaphragm control circuit, projector device, diaphragm control program, and diaphragm control method

InactiveCN102472952AGuaranteed stabilityEnsure responsivenessProjectorsColor television detailsVideo processingEngineering

A video processing unit (150) has a diaphragm control unit (155) which uses a diaphragm (121) to limit the light quantity outputted in accordance with information indicating the brightness of the inputted video signal. Here, the diaphragm control unit (155) controls the open degree of the diaphragm (121) in accordance with a difference between the open degree of the diaphragm (121) detected by a diaphragm drive unit (160) which detects the open degree of the diaphragm (121) and a target open degree of the diaphragm (121) based on the information indicating the brightness of the inputted video signal.

Owner:NEC DISPLAY SOLUTIONS LTD

Communication secured between a medical device and its remote device

InactiveCN103890768AEnsure responsivenessIntegrity guaranteedLocal control/monitoringUser identity/authority verificationMicrocontrollerSecure communication

The invention concerns a medical assembly which insures a secured communication between a medical device (like a insulin pump) and its remote control which manages the medical device. To this effect, said assembly use an external microcontroller (MCU) which contains the secured data and uses a cryptographic mechanism to communicate with the medical device. One single external microcontroller (MCU) is paired with only one medical device in such a way the patient can change several times of remote device although aware that the remote device, in which said external protected MCU is inserted, is the single remote device paired with the medical device. In said assembly, said medical device and said external microcontroller (MCU) comprise secured memories which contain the wireless communication configuration in such a way the devices know in advance the good configuration.

Owner:DEBIOTECH SA

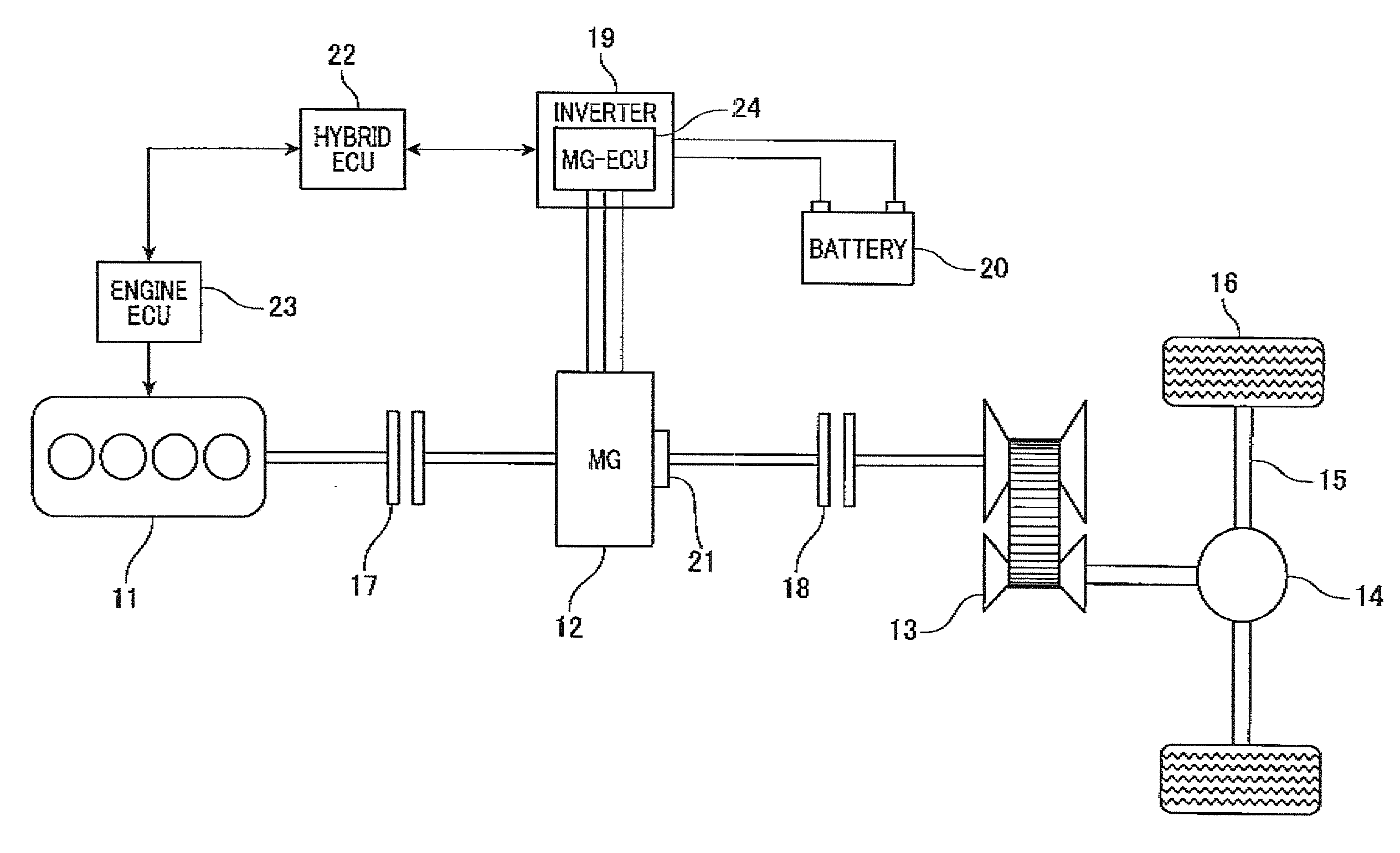

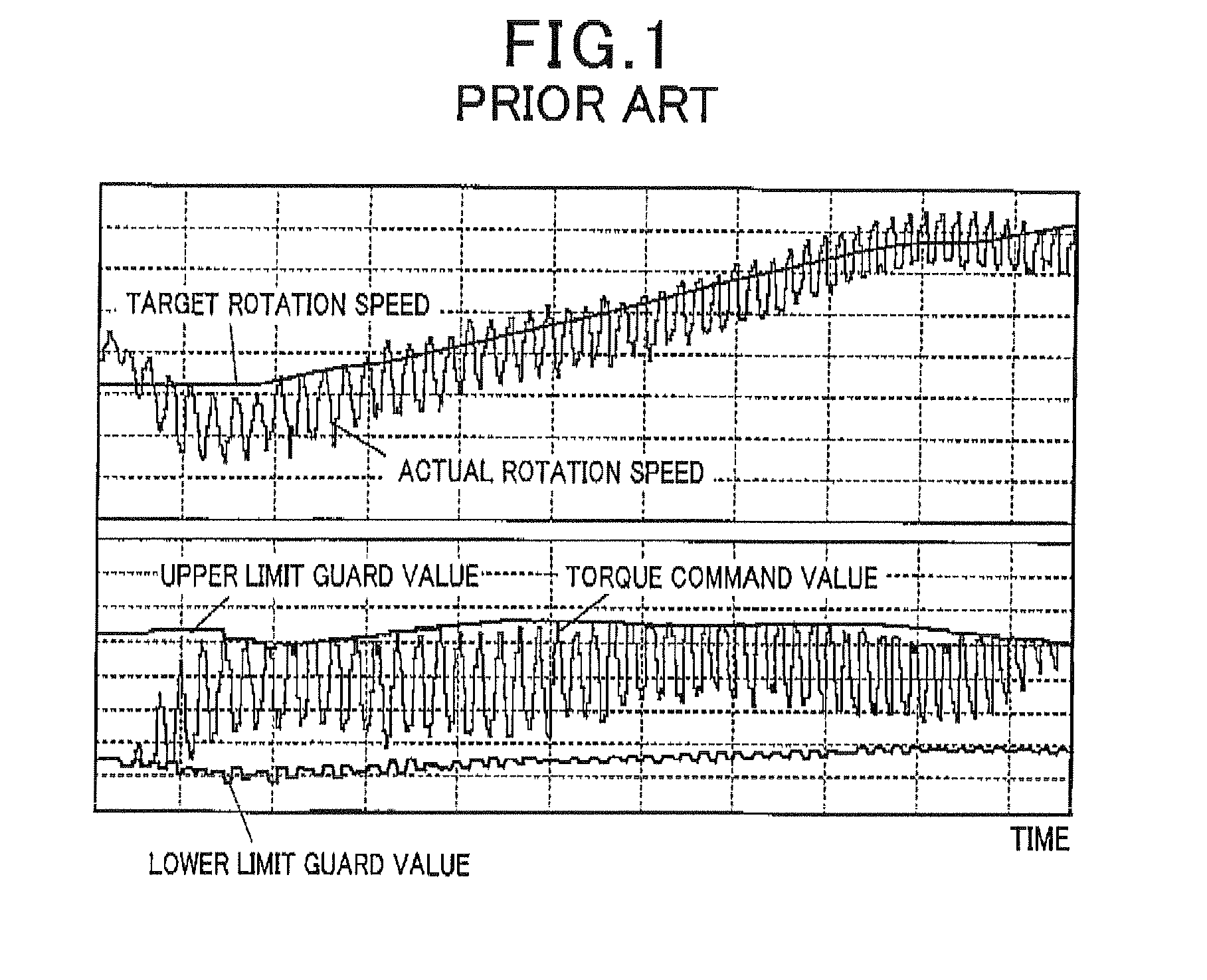

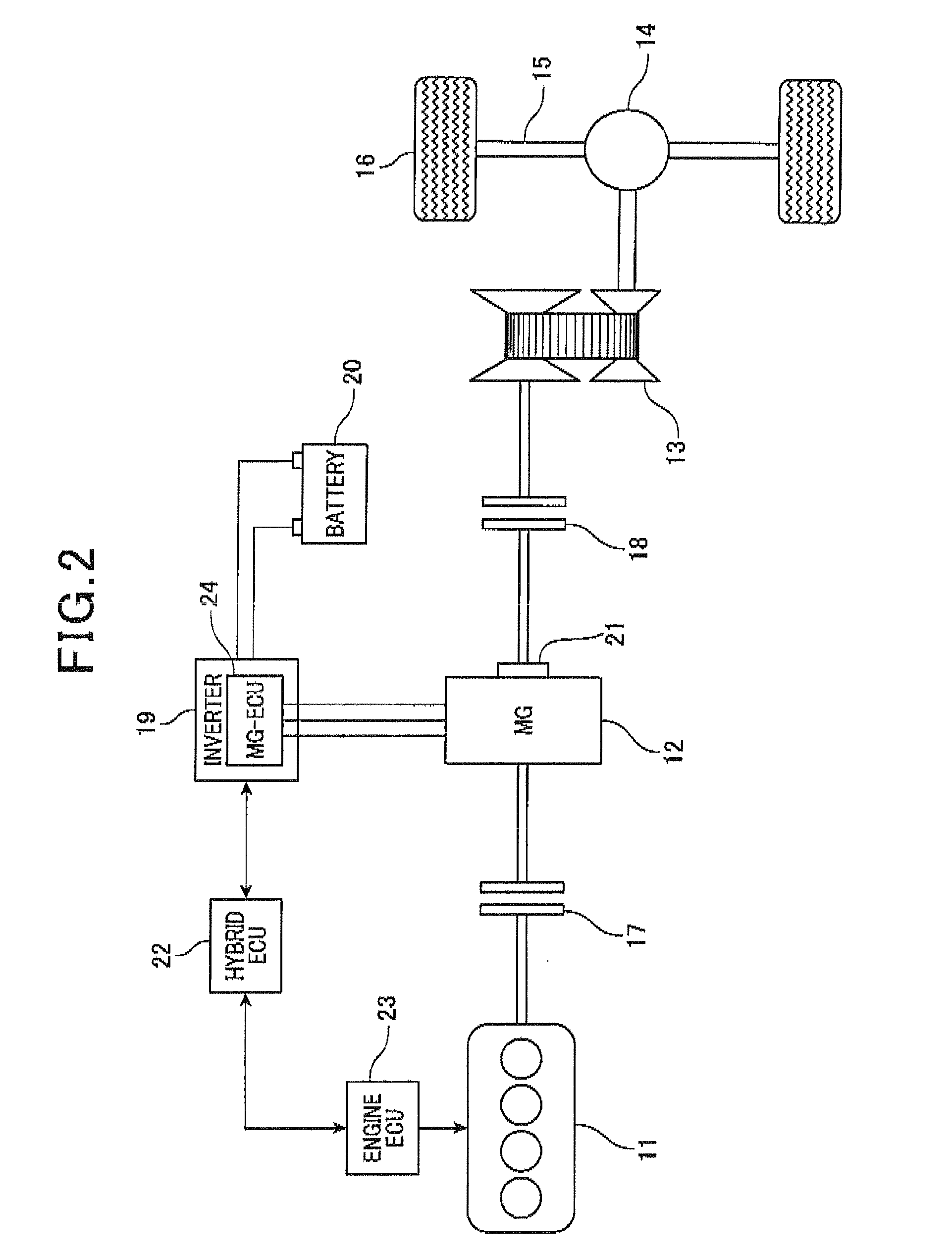

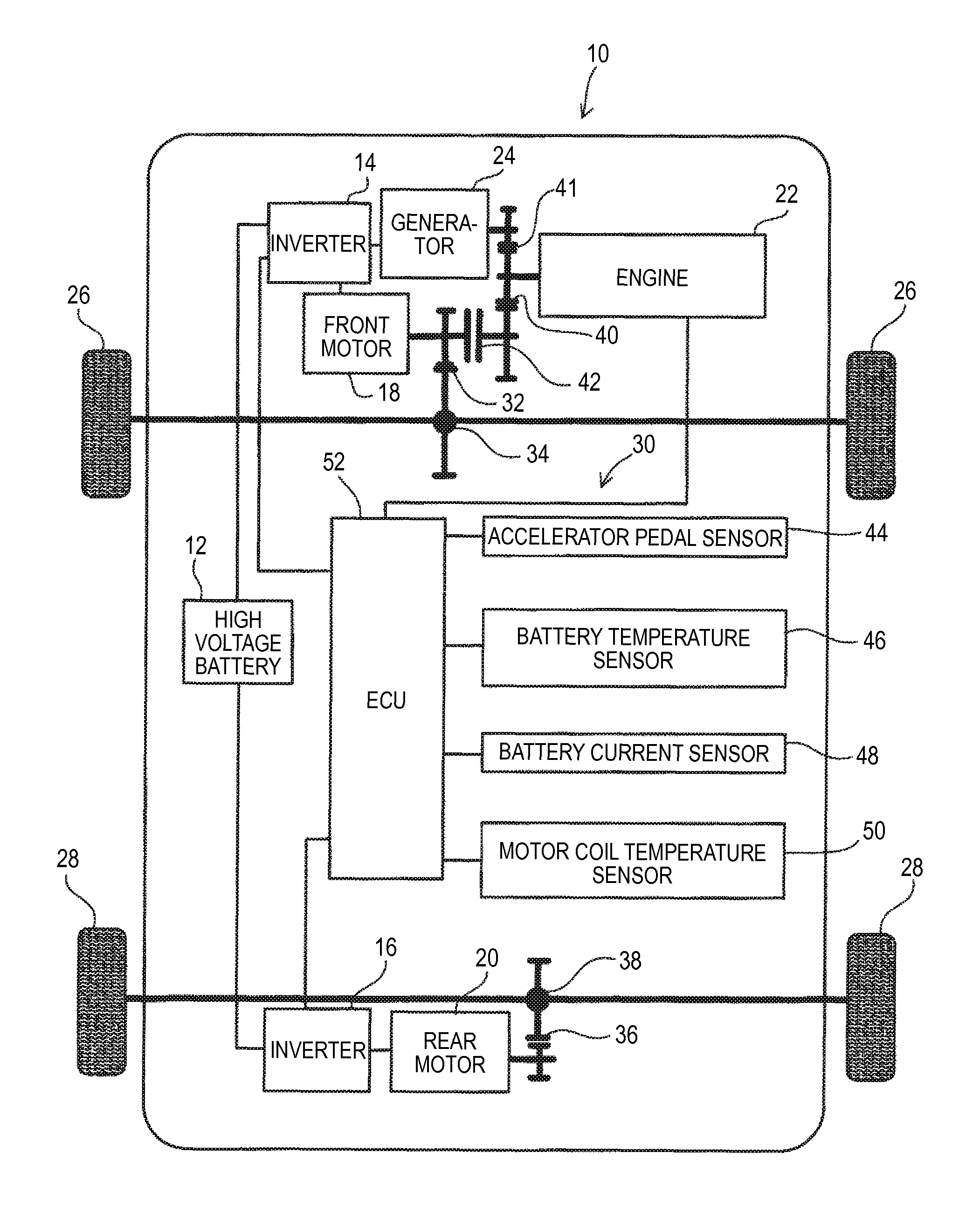

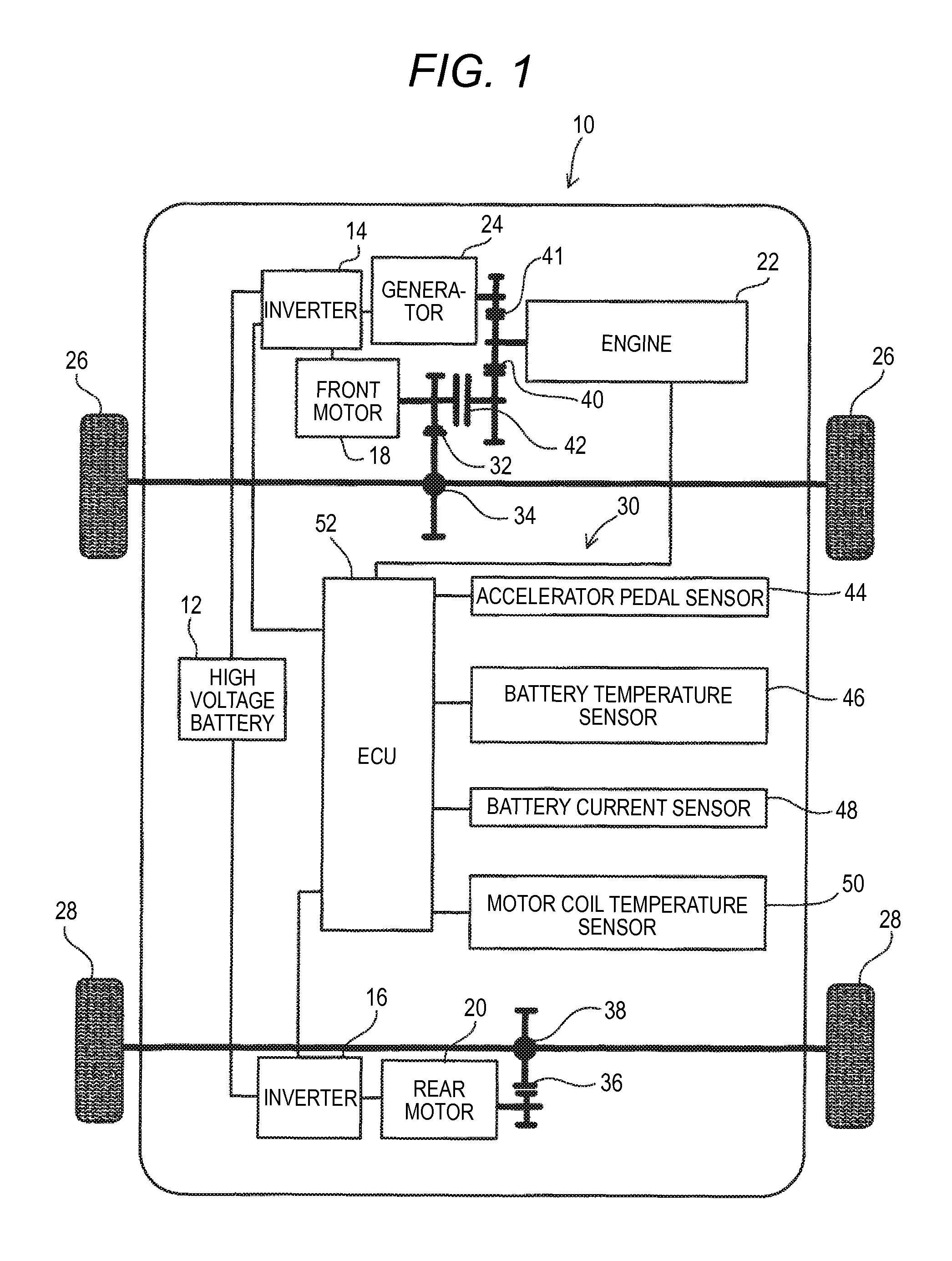

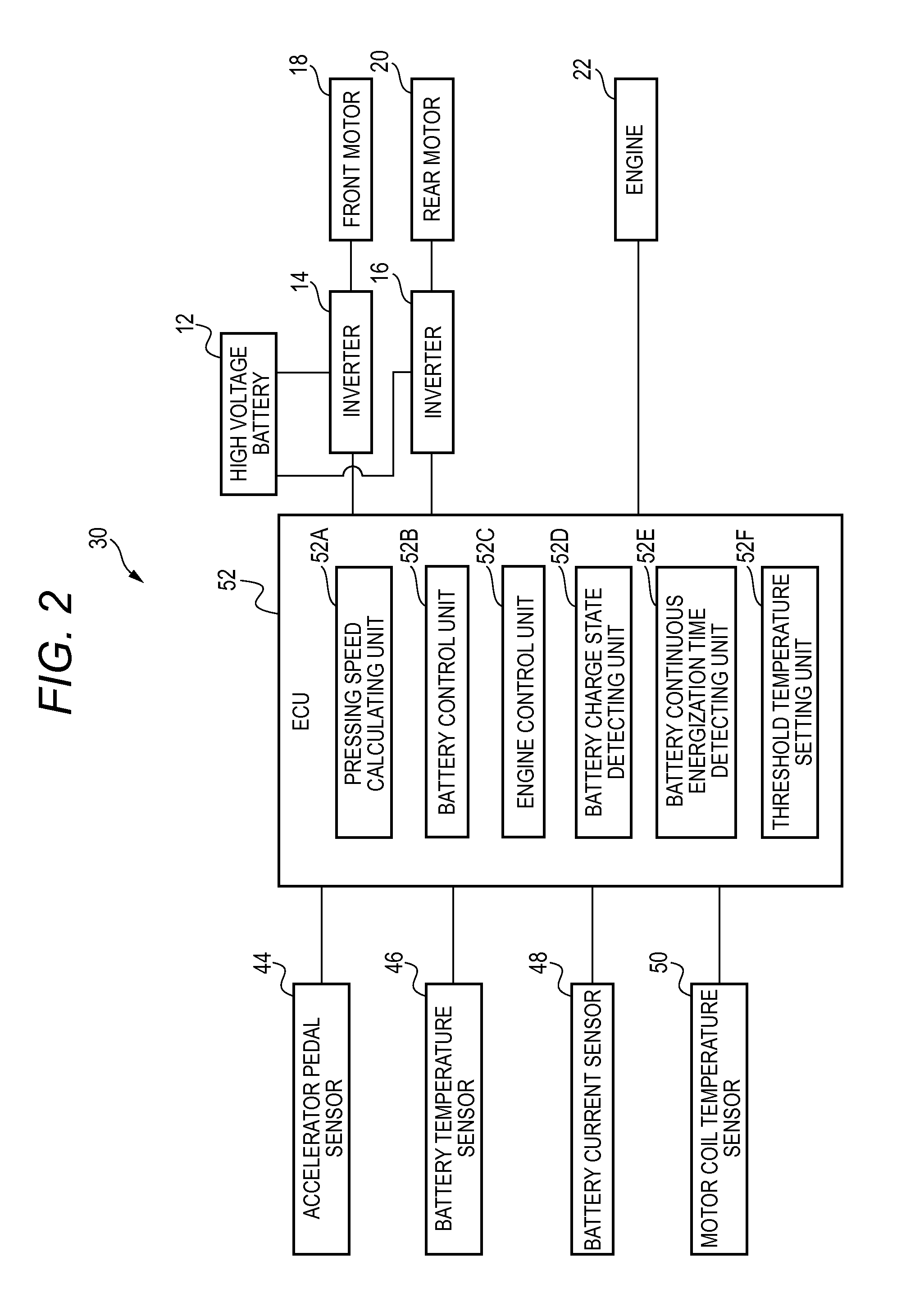

Motor control apparatus for hybrid vehicles

ActiveUS20140088808A1Ensure responsivenessTorque stabilizationHybrid vehiclesDigital data processing detailsRotational axisMotor control

An apparatus controls a motor equipped in a hybrid vehicle. In this apparatus, a basic torque command value of the motor is calculated so as to reduce a deviation between a target rotation speed and an actual rotation speed of the motor. A torque correction value for the motor is calculated based on a variation of the target rotation speed which is obtained per unit time and a value of inertia of a power train rotated integrally with the rotation shaft of the motor. Further, a torque command value finally supplied to the motor is calculated by correcting the basic torque command value with use of the torque correction value.

Owner:DENSO CORP

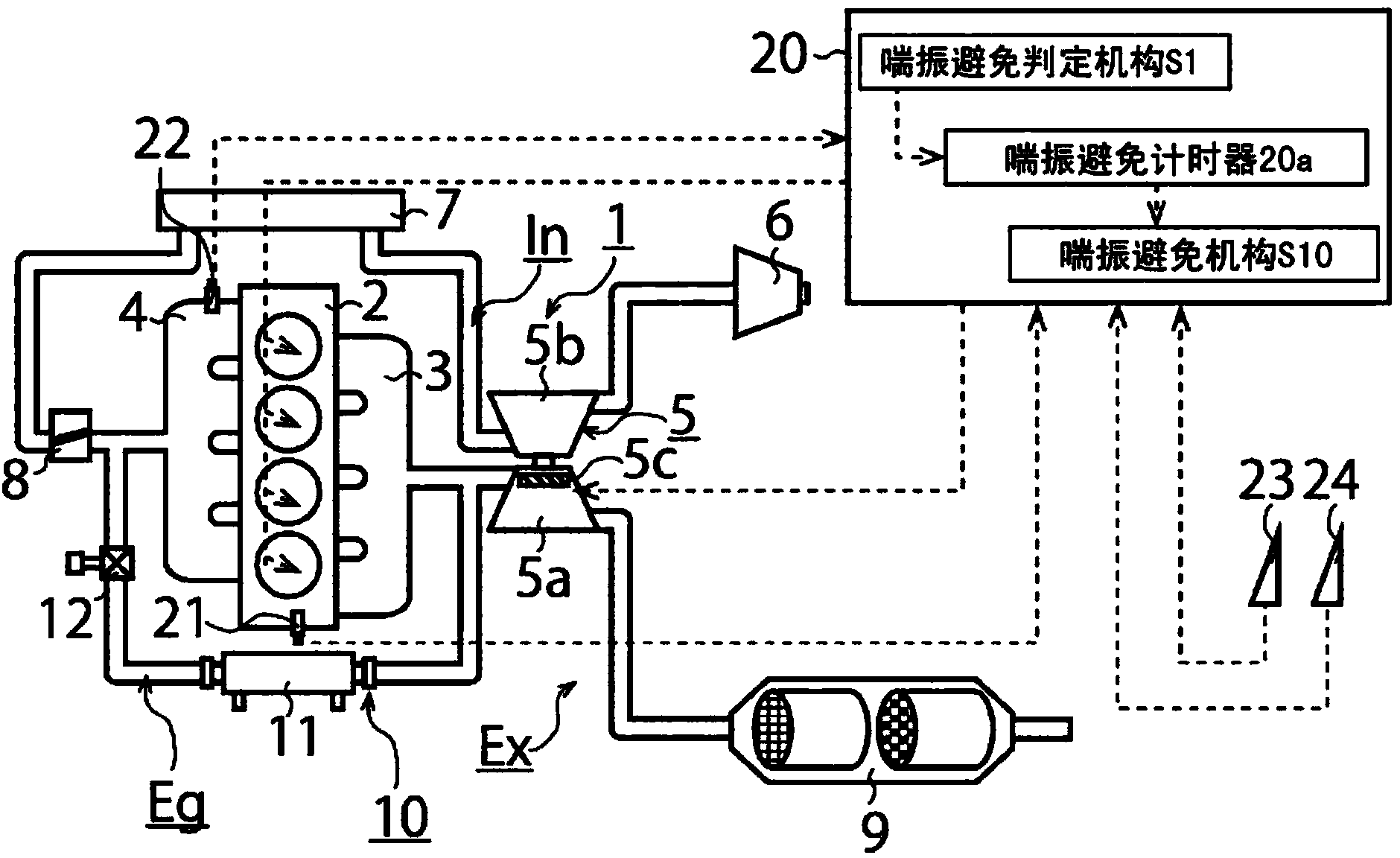

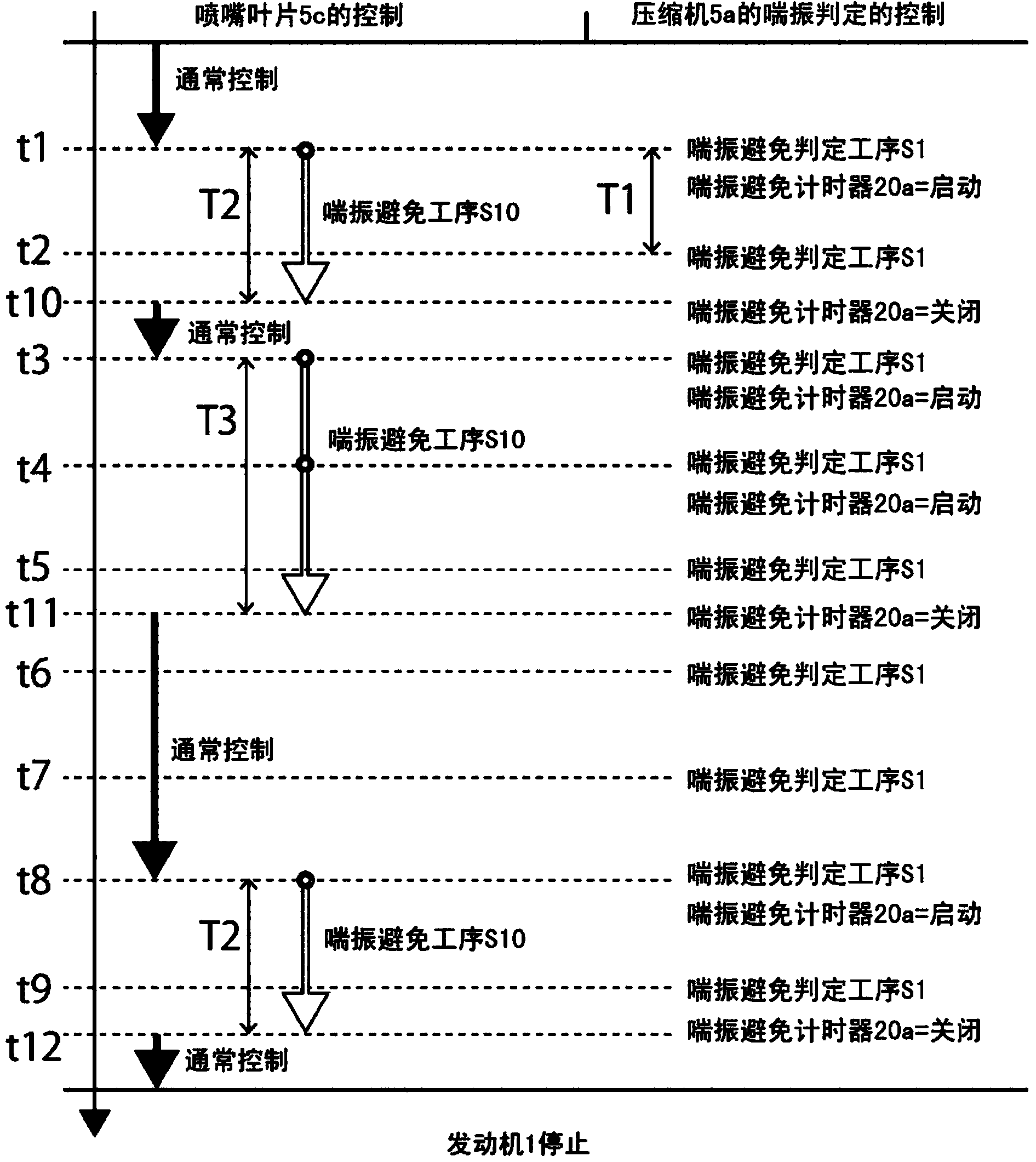

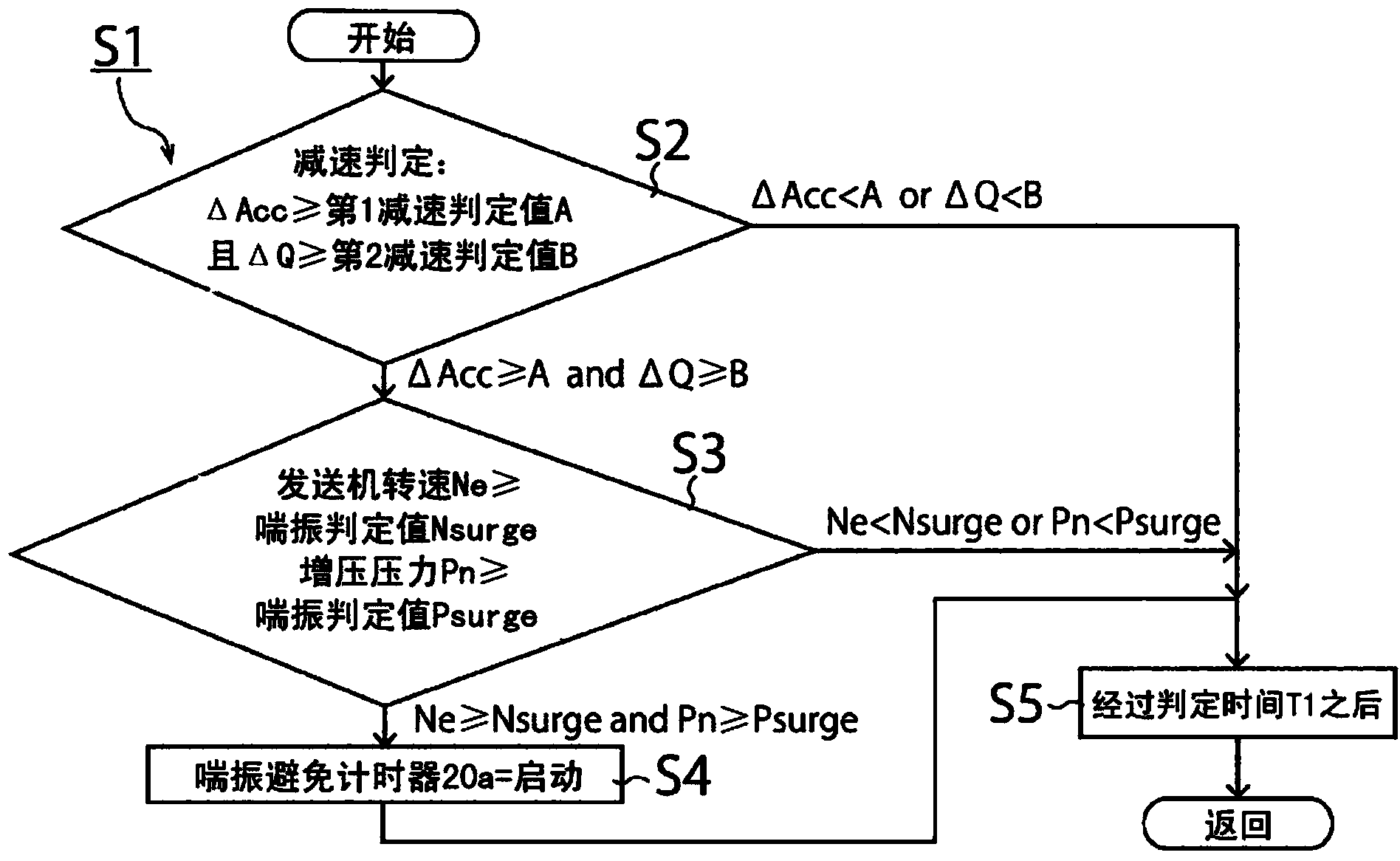

Internal combustion engine and control method thereof

ActiveCN104364500APrevent surgePrevent blowback soundElectrical controlInternal combustion piston enginesTurbochargerInternal combustion engine

In order to avoid a surge state of the compressor (5b) of a turbocharger (5), an ECU (20) is configured to be provided with a surge avoidance means (process) which, during vehicle deceleration, determines whether or not the compressor (5b) of the turbocharger (5) enters a surge state; if the compressor (5b) is determined to enter a surge state, then, as surge avoidance control, the surge avoidance means acquires a first target opening degree (TAn) of the nozzle vane (5c) of a turbine (5a) of the turbocharger (5) based on the driving state and a first opening degree map (M1); if the first target opening degree (TAn) is less than a pre-set surge avoidance first target opening degree (TAx), then the surge avoidance means controls the nozzle vane (5c) to the surge avoidance first target opening degree (TAx), and if the first target opening degree (TAn) is greater than or equal to the surge avoidance first target opening degree (TAx), controls the nozzle vane (5c) to the first target opening degree (TAn).

Owner:ISUZU MOTORS LTD

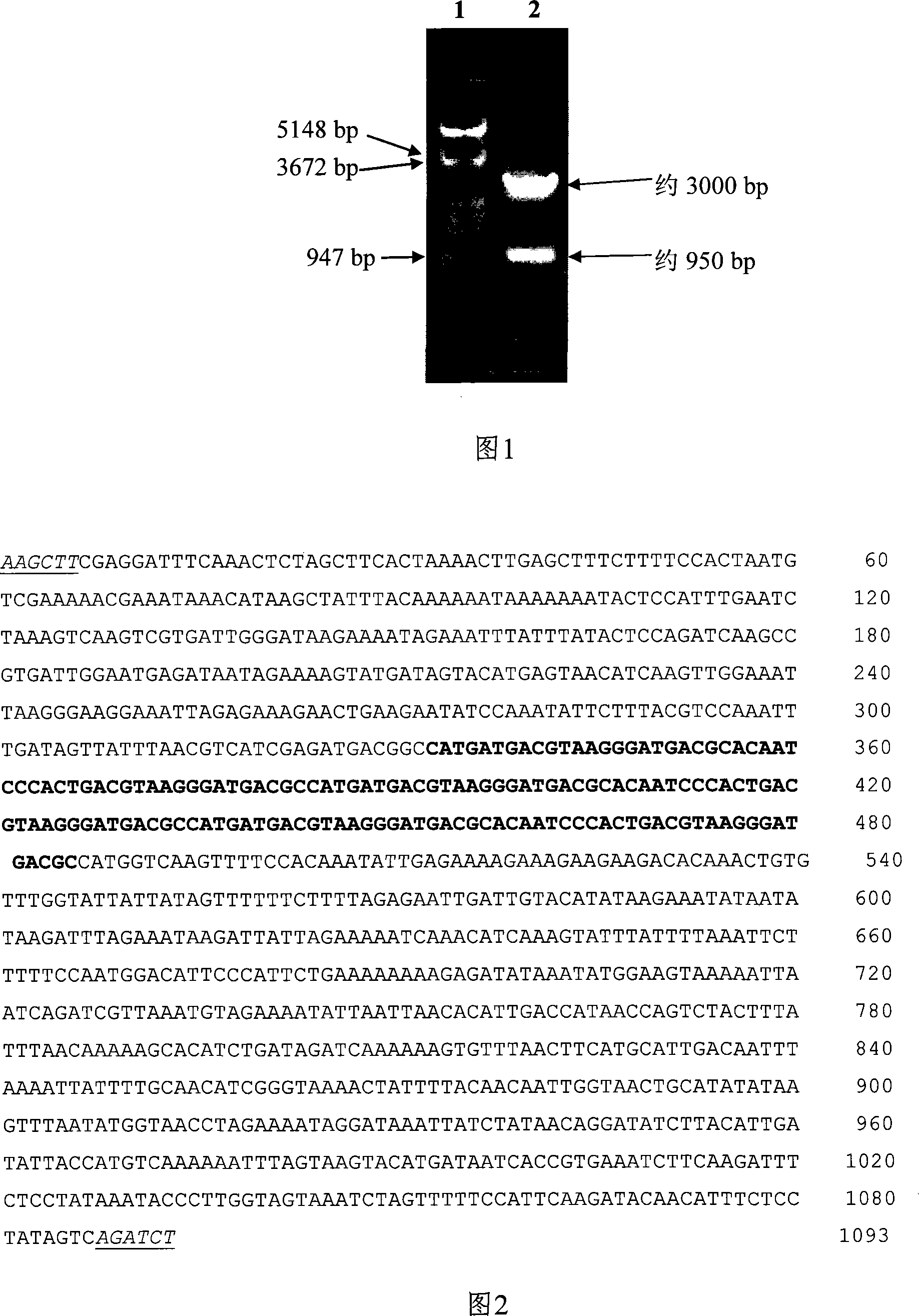

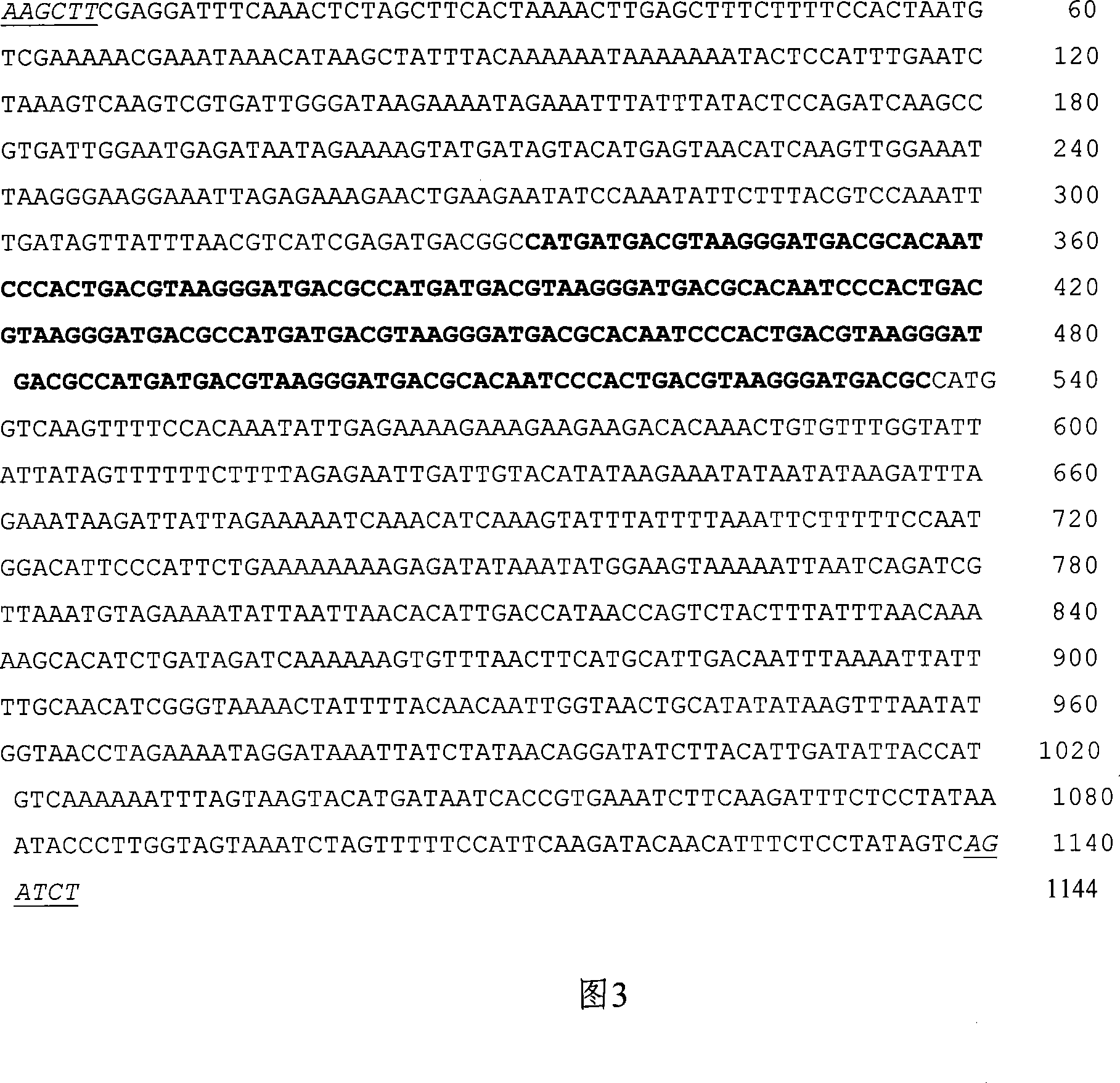

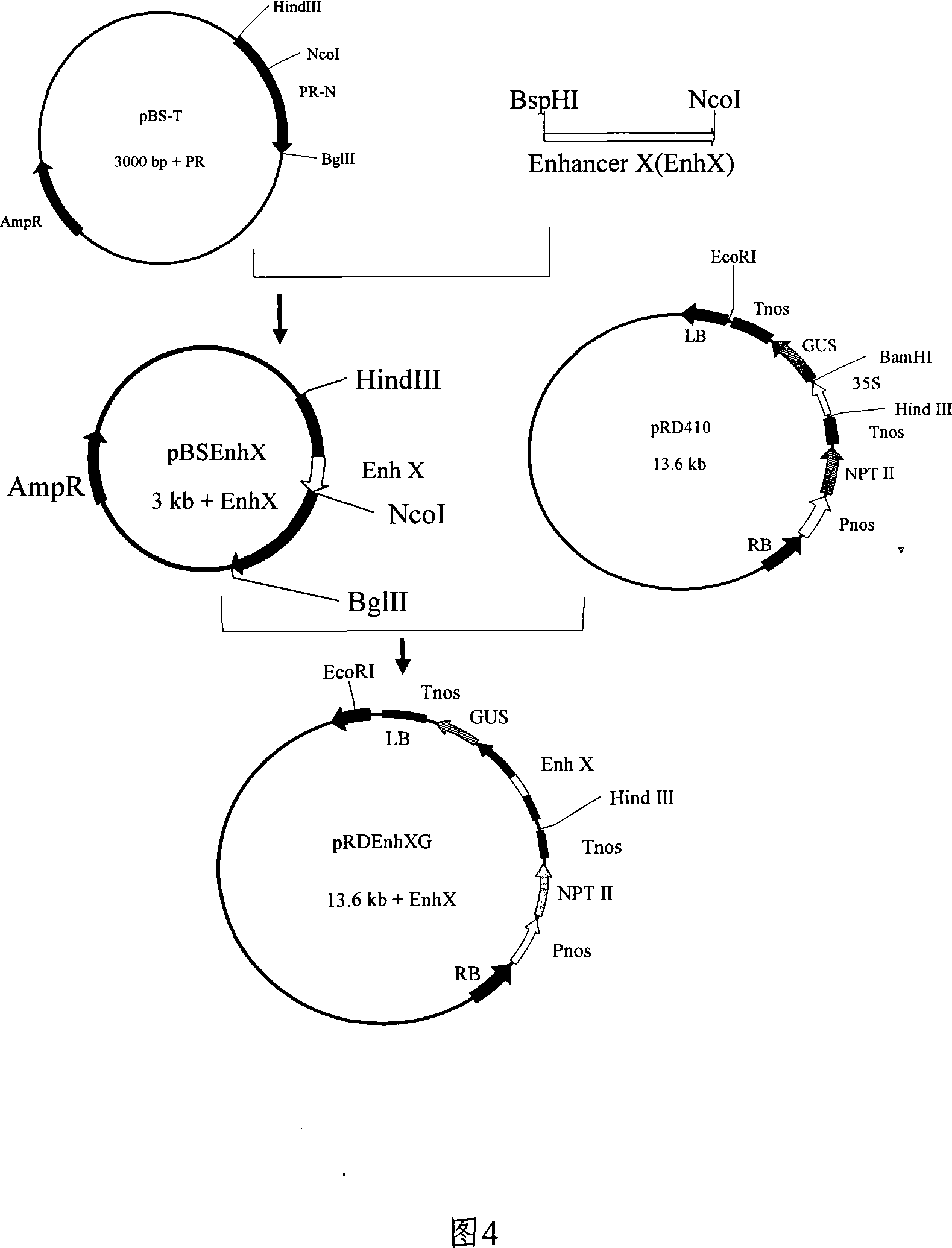

Inducing reinforced composing type promoter and uses thereof

InactiveCN101182530AEnsure responsivenessImprove responsivenessVector-based foreign material introductionDNA/RNA fragmentationNucleotidePlant cell

The invention discloses a plant-inducible and enhanced super-strong constitutive promoter and its application. The promoter has the following nucleotide sequence: the nucleotide sequence described in sequence 4 or 6 in the sequence listing, and a nucleotide sequence capable of hybridizing with the nucleotide sequence under stringent hybridization conditions. The promoter of the present invention can drive the constant expression of genes in plant cells, and at the same time has the ability to respond to chemical inducers. Under the induction of inducers, it can drive the superexpression of genes. Under the condition of no inducer, its driving ability is about It is twice that of the CaMV 35s promoter; after induction by chemical inducers, its driving ability is about 5 times that of the CaMV 35s promoter.

Owner:CHINA AGRI UNIV

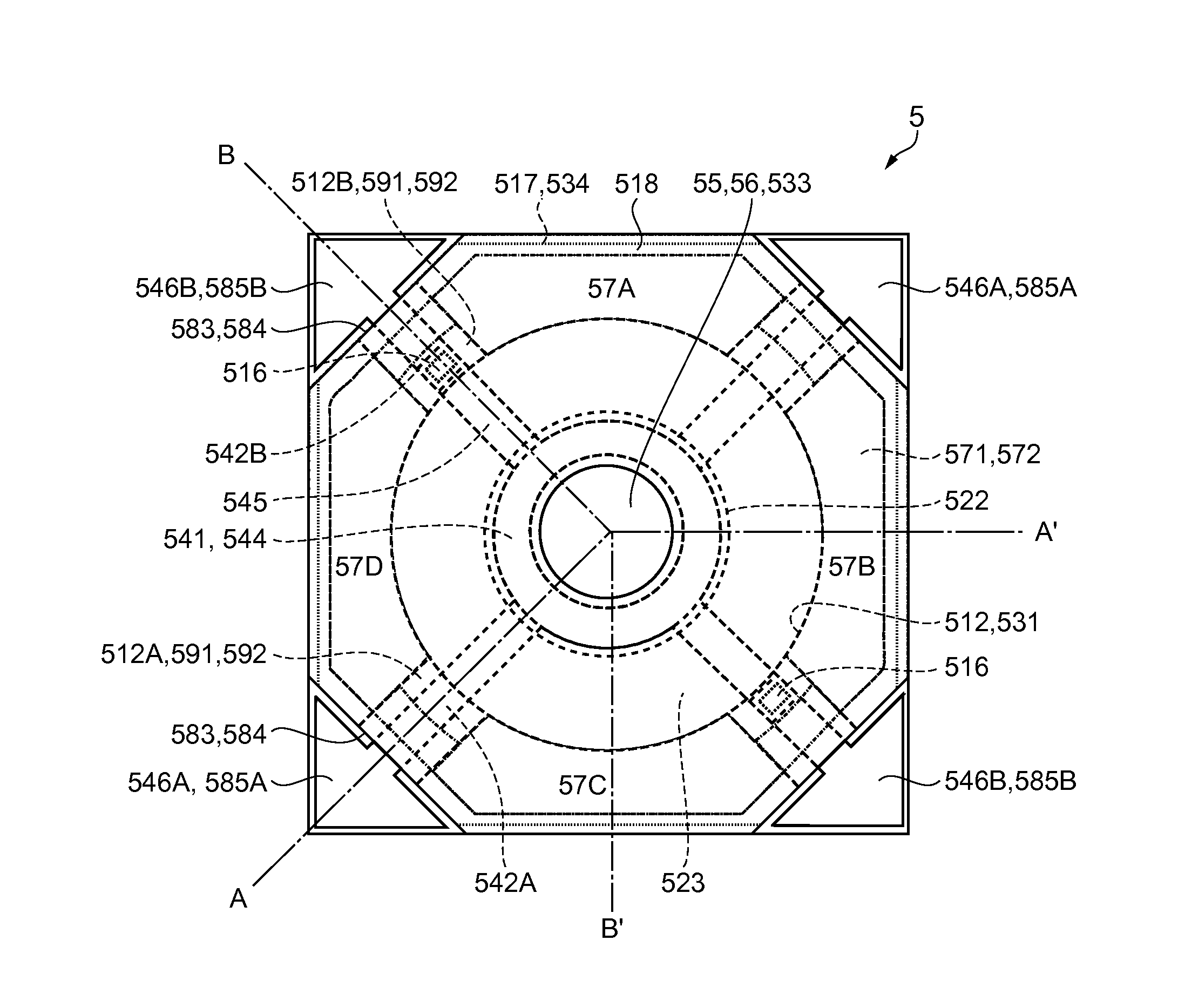

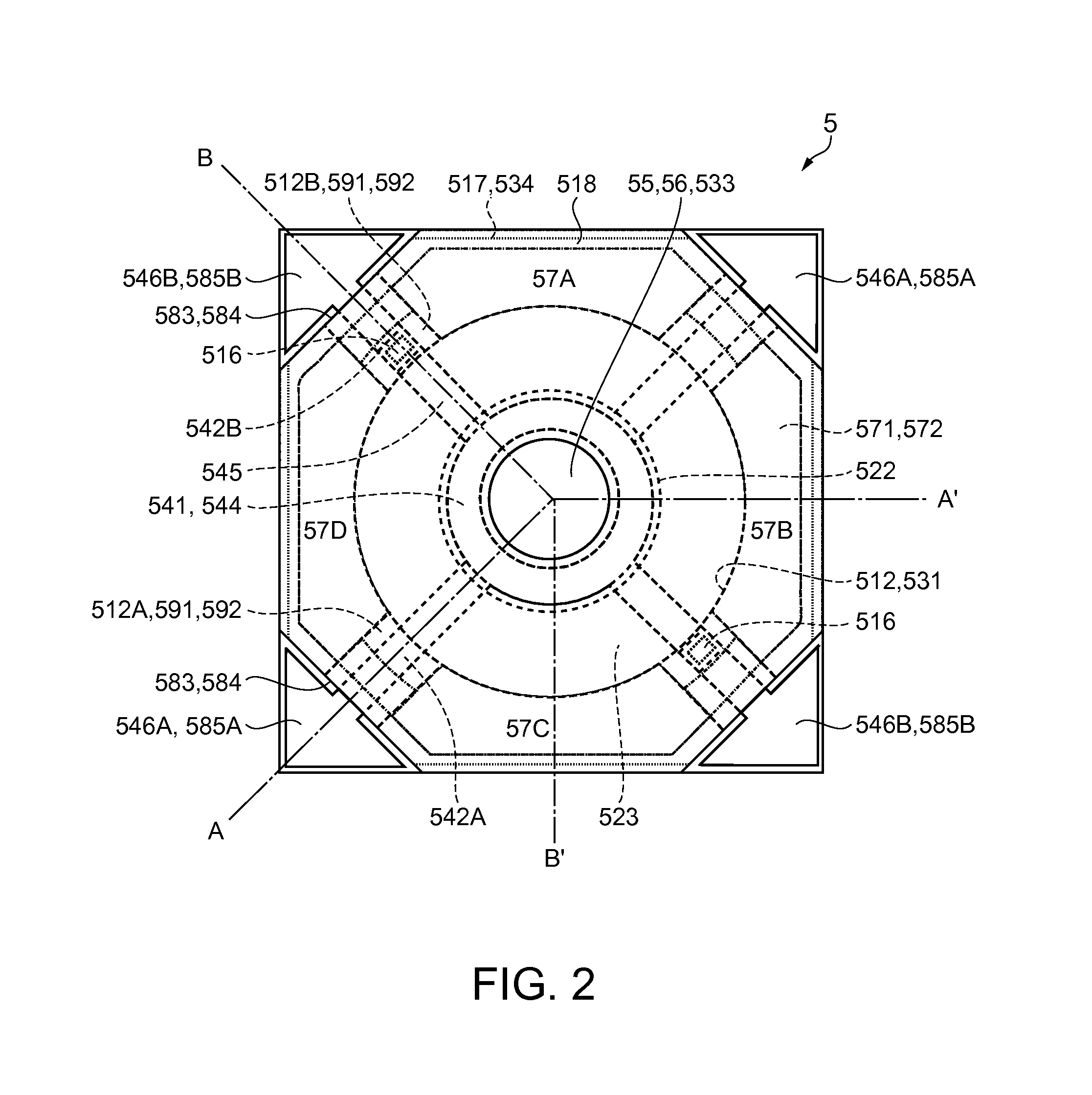

Variable wavelength interference filter, optical module, electronic apparatus, and method of manufacturing variable wavelength interference filter

ActiveUS20140063501A1Improve production efficiencyImprove responsivenessLamination ancillary operationsLaminationOptical ModuleLength wave

A variable wavelength interference filter includes a first substrate having a stationary mirror, a second substrate bonded to the first substrate and provided with a movable section and a movable mirror fixed to the movable section, and a third substrate bonded to the second substrate on an opposite side to the first substrate, and is provided with a first inner space sandwiched by the first substrate and the second substrate, a first gap, through which the first inner space communicates with the outside, a second inner space sandwiched by the second substrate and the third substrate, and a second gap, through which the second inner space communicates with the outside, and the first gap and the second gap are each sealed by a sealing member.

Owner:SEIKO EPSON CORP

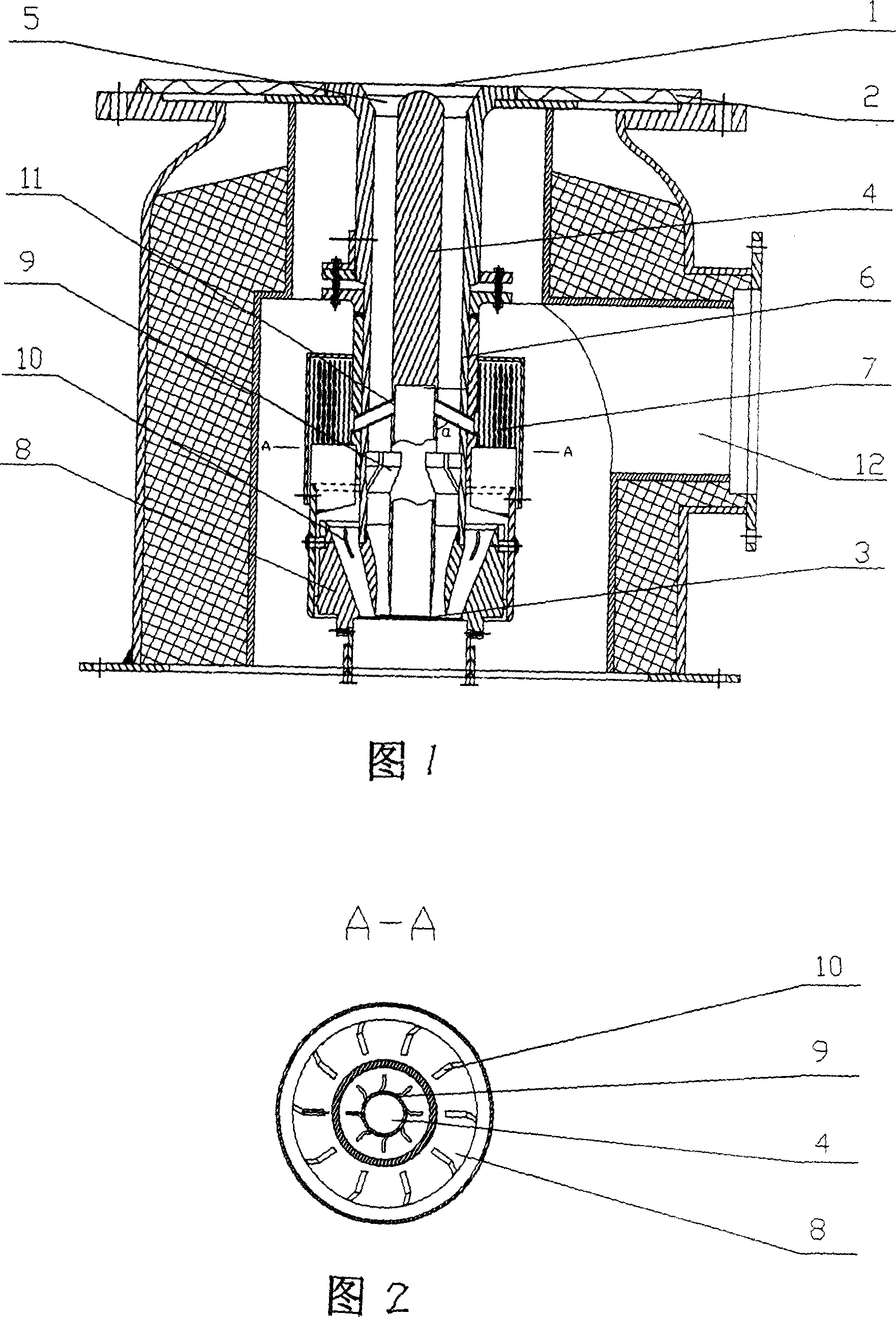

Mixing device for acetylene oven

ActiveCN1951885AGuaranteed uptimeIncreased turbulenceTransportation and packagingMixersSprayerEngineering

The invention discloses a mixer device of acetylene furnace, which comprises the following parts: oxygen spraying pipe (6) in connection with oxygen inlet (1), vortex tool (4) located by vortex locating piece (5) in the oxygen spraying pipe (6), oxygen vortex piece (9) fixed on the lower circumference of vortex tool (4) evenly, natural gas sprayer (8) in connection with the upper end of composite gas injector (3), wherein the through-hole on the circumference of oxygen spraying pipe (6) interconnects the through-hole on the circumference of vortex tool (4) through interconnecting pipe (11); the natural gas vortex piece (10) is set on the inner circumferential side of upper end of natural gas injector (8) with the opposite direction corresponding to the oxygen vortex piece (9). The gaseous hydrocarbon reactant is preheated with large amount of oxygen in the three-inlet mixer, which is mixed completely to guarantee the effect and manufacturing safety.

Owner:CHINA PETROCHEMICAL CORP +1

System and method for controlling straddle-type vehicle

ActiveUS8560173B2Prevent slidingImprove driving power performance and braking performanceDigital data processing detailsAnimal undercarriagesControl systemStraddle

A control system in a straddle-type vehicle is provided. The control system includes front and rear wheels, comprises a load distribution changing section which changes a ground load distribution between the front and rear wheels during driving of the vehicle; a slip suppressing condition determiner section which determines whether or not a suppressing condition used to suppress a slip of one of the front and rear wheels is met, during driving of the vehicle; and a load distribution control section which controls the load distribution changing section to make the ground load of the one of the front and rear wheels greater when the slip suppressing condition determiner section determines that the suppressing condition is met, than when the slip suppressing condition determiner section determines that the suppressing condition is not met.

Owner:KAWASAKI MOTORS LTD

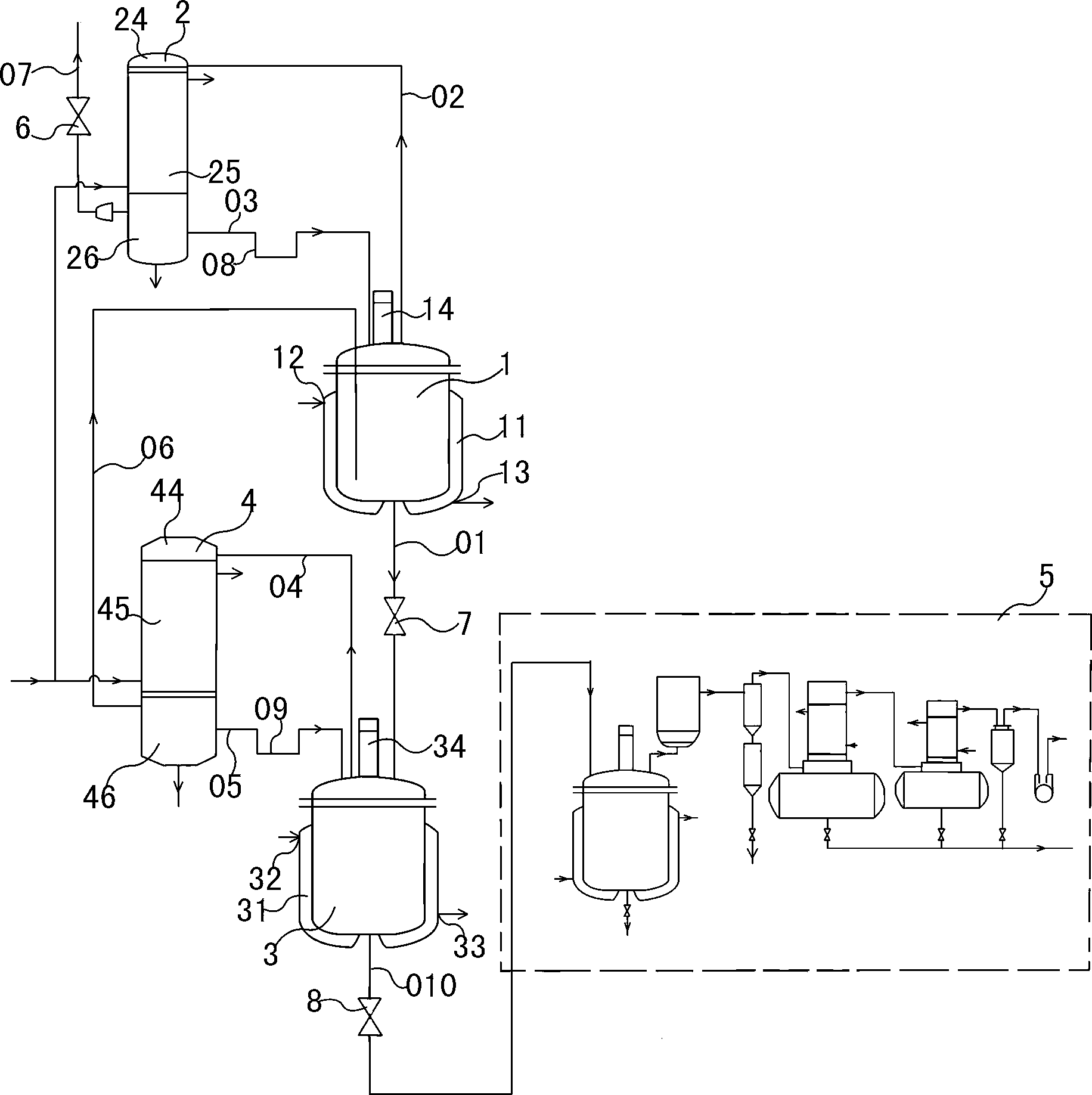

Phthalocyanine compound synthesizer

InactiveCN103638887AAchieve exclusionAchieve recyclingOrganic chemistryChemical/physical/physico-chemical stationary reactorsRefluxPhthalocyanine

The invention discloses a phthalocyanine compound synthesizer. The phthalocyanine compound synthesizer comprises a first reaction kettle, a first condenser, a second reaction kettle and a second condenser, wherein the first reaction kettle is communicated with the second reaction kettle by a first material conveying tube; a first gas inlet, a first gas outlet, a first solvent reflux opening and a first water outlet are formed on the first condenser; the first reaction kettle is communicated with the first gas inlet by a first mixed gas conveying tube; the first solvent reflux opening is communicated with the first reaction kettle by the first solvent reflux tube; a second gas inlet, a second gas outlet, a second solvent reflux opening and a second water outlet are formed on the second condenser; the second reaction kettle is communicated with the second gas inlet by the second mixed gas conveying tube; the second solvent reflux opening is communicated with the second reaction kettle by the second solvent reflux tube; and the second gas outlet is communicated with the first reaction kettle by a third mixed gas conveying tube. The phthalocyanine compound synthesizer disclosed by the invention effectively controls generated moisture, improves ammonia gas yield, recycles a carrier solvent and ensures safety and continuity of operation.

Owner:FUJIAN HUATIANYU SCI & TECH DEV

Control apparatus for hybrid electric vehicle

InactiveUS20130066497A1Curb fuel consumptionEnsuring responsiveness of drivingHybrid vehiclesInternal combustion piston enginesElectrical batteryElectric power system

A control apparatus for a hybrid electric vehicle, includes: a temperature detector configured to detect a motor temperature of the electric motor; a pressing speed detector configured to detect a pressing speed of an accelerator pedal; an electric current detector configured to detect a value of the electric current supplied to the electric motor from the battery; and an engine controller configured to allow, when the motor temperature detected by the temperature detector is equal to or lower than a threshold temperature, the engine to be started based on the pressing speed detected by the pressing speed detector, so that the generator generates the electric power, and configured to allow, when the motor temperature is higher than the threshold temperature, the engine to be started based on the value of the electric current detected by the electric current detector, so that the generator generates the electric power.

Owner:MITSUBISHI MOTORS CORP

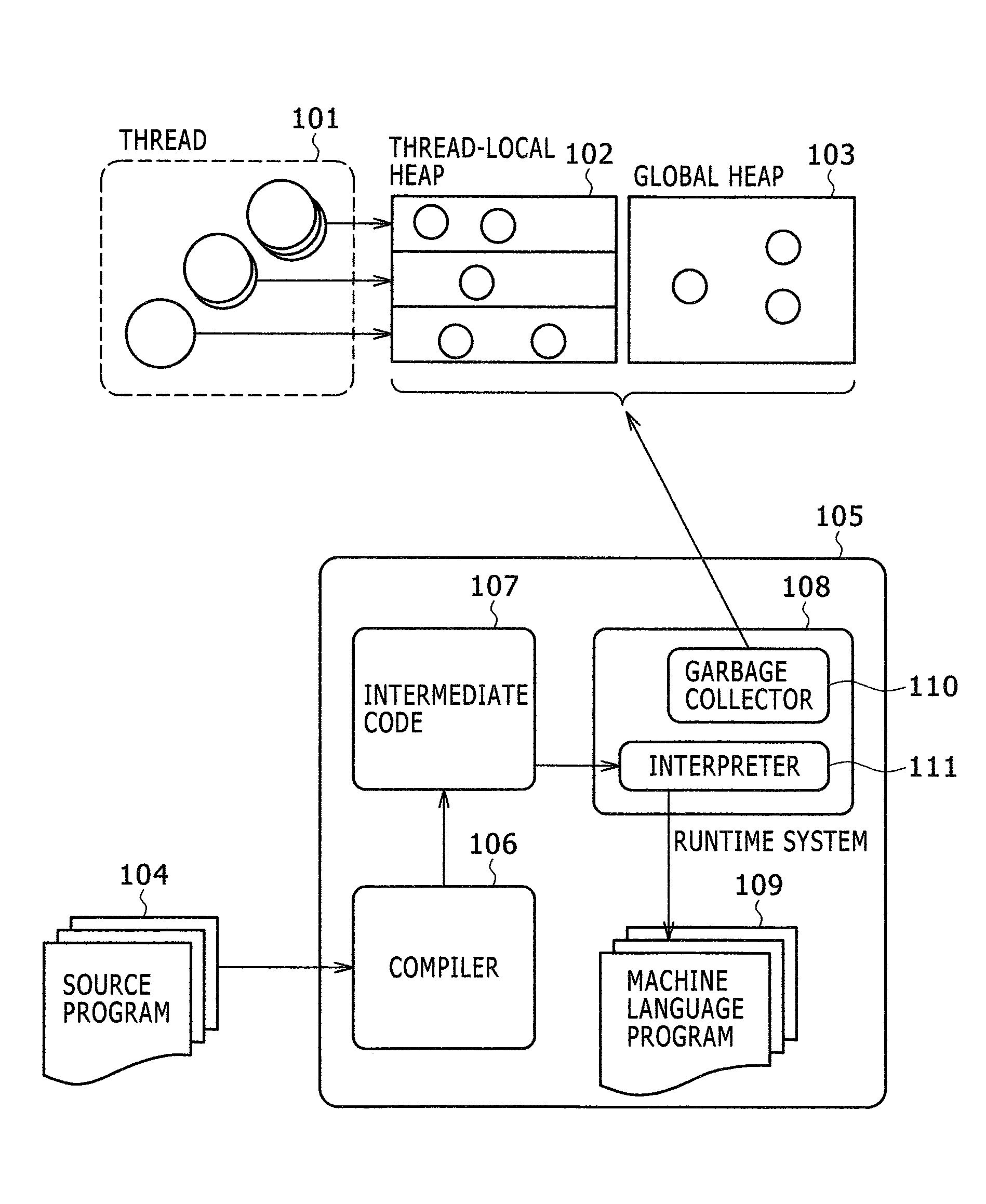

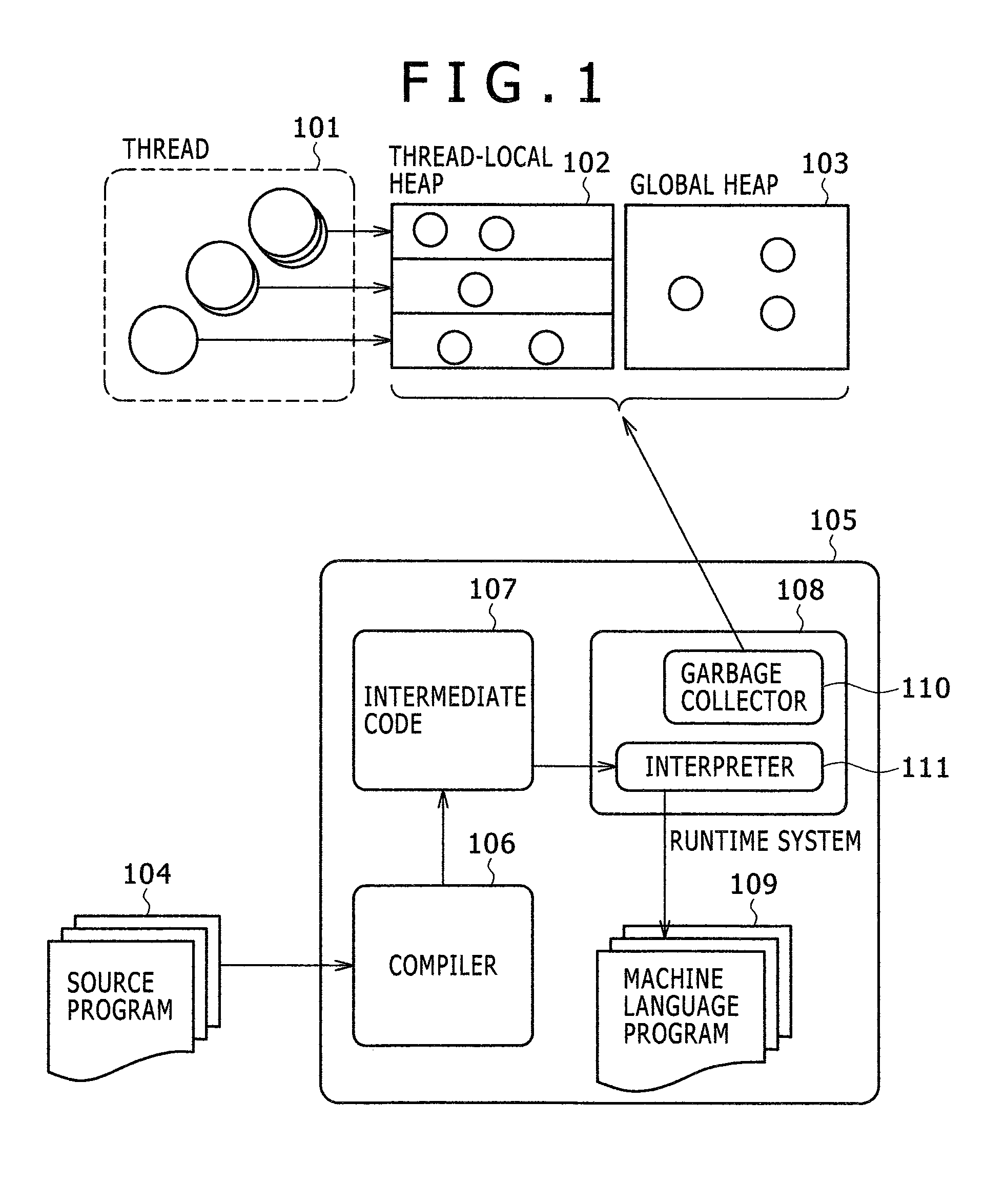

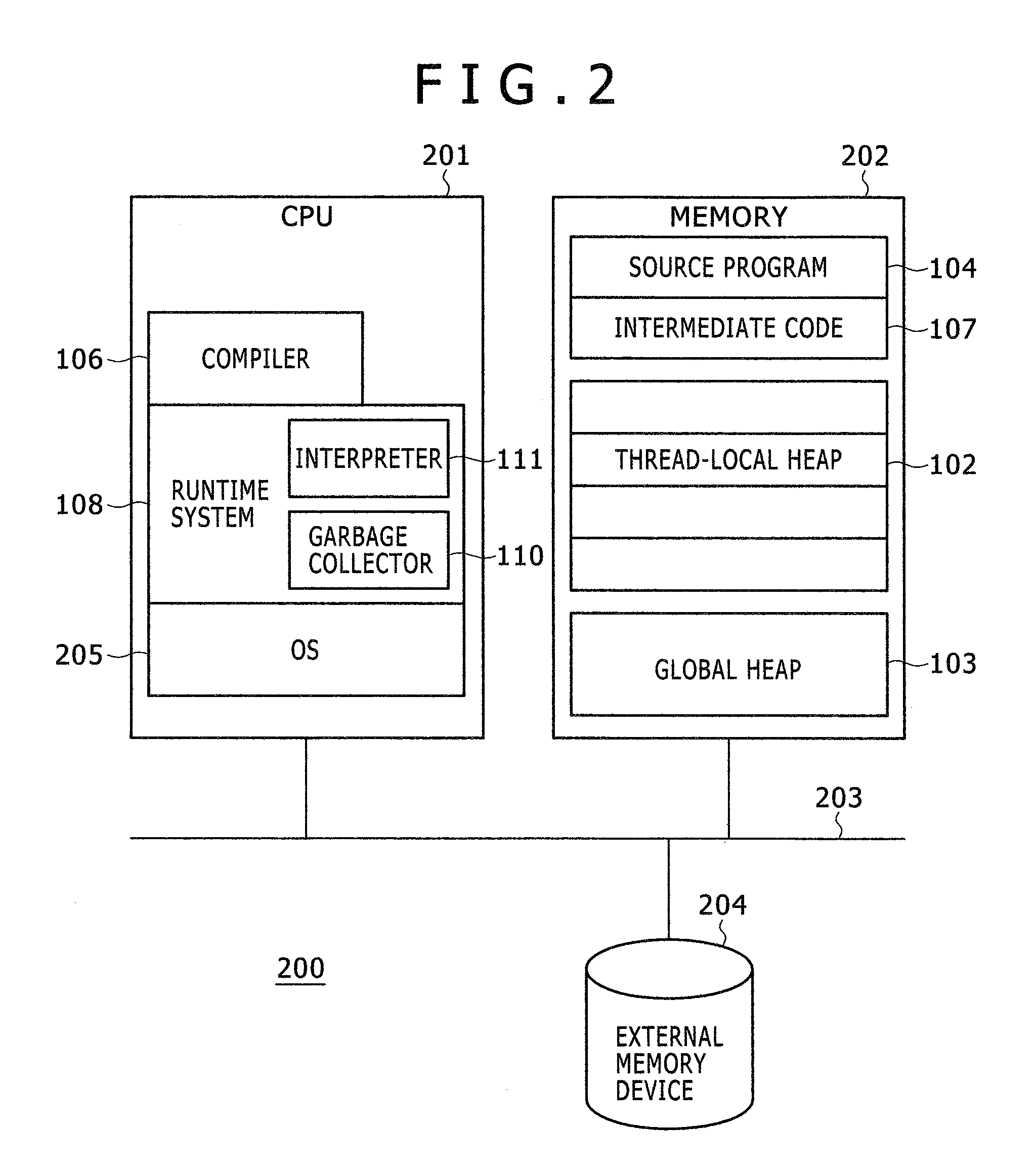

Method and system for managing memory for a program using area

InactiveUS20090037501A1Reduce areaEnsuring processing responsivenessMemory adressing/allocation/relocationMultiprogramming arrangementsOperating system

If garbage collection is executed in every thread-local heap in order to secure processing responsiveness, a memory area may be fragmented or collectable areas may be reduced as the program execution proceeds. To overcome such problems, memory is divided into an area where thread specific data is allocated and an area where referenceable data from other threads is allocated, and is managed separately. More specifically, data that is referenced specifically by each thread is allocated to a thread-local heap, while data that is referenced from other threads is allocated to a global heap.

Owner:HITACHI LTD

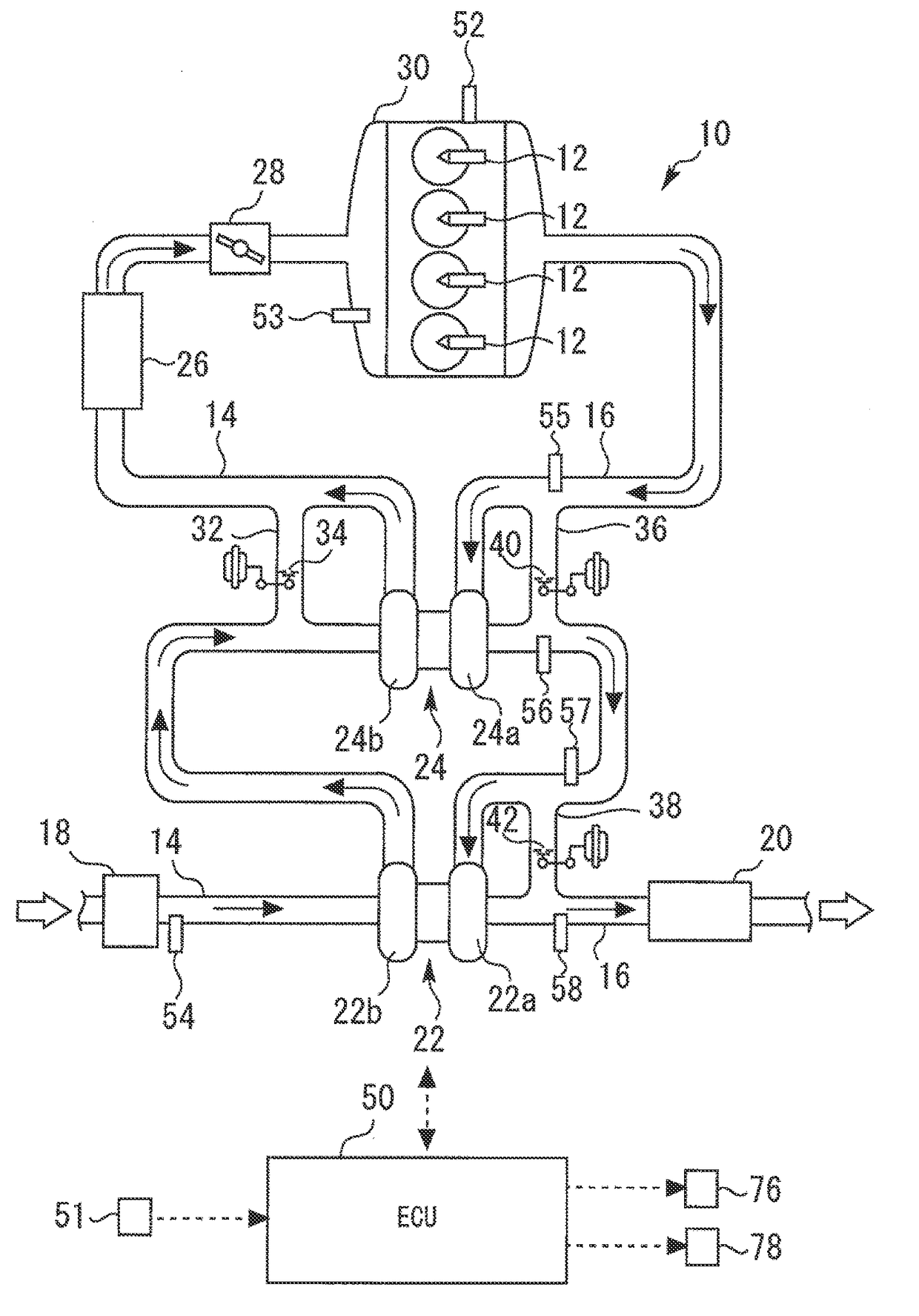

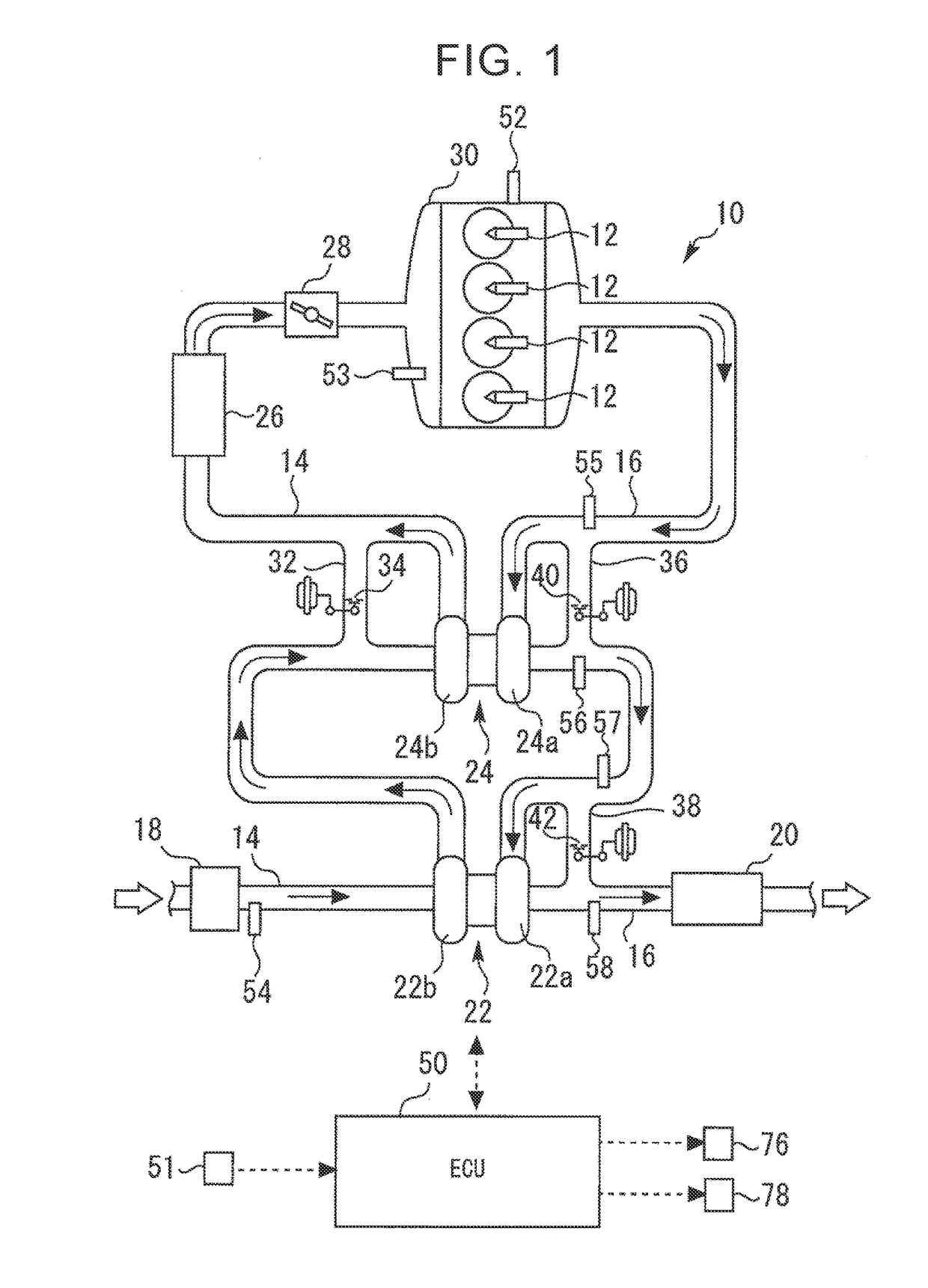

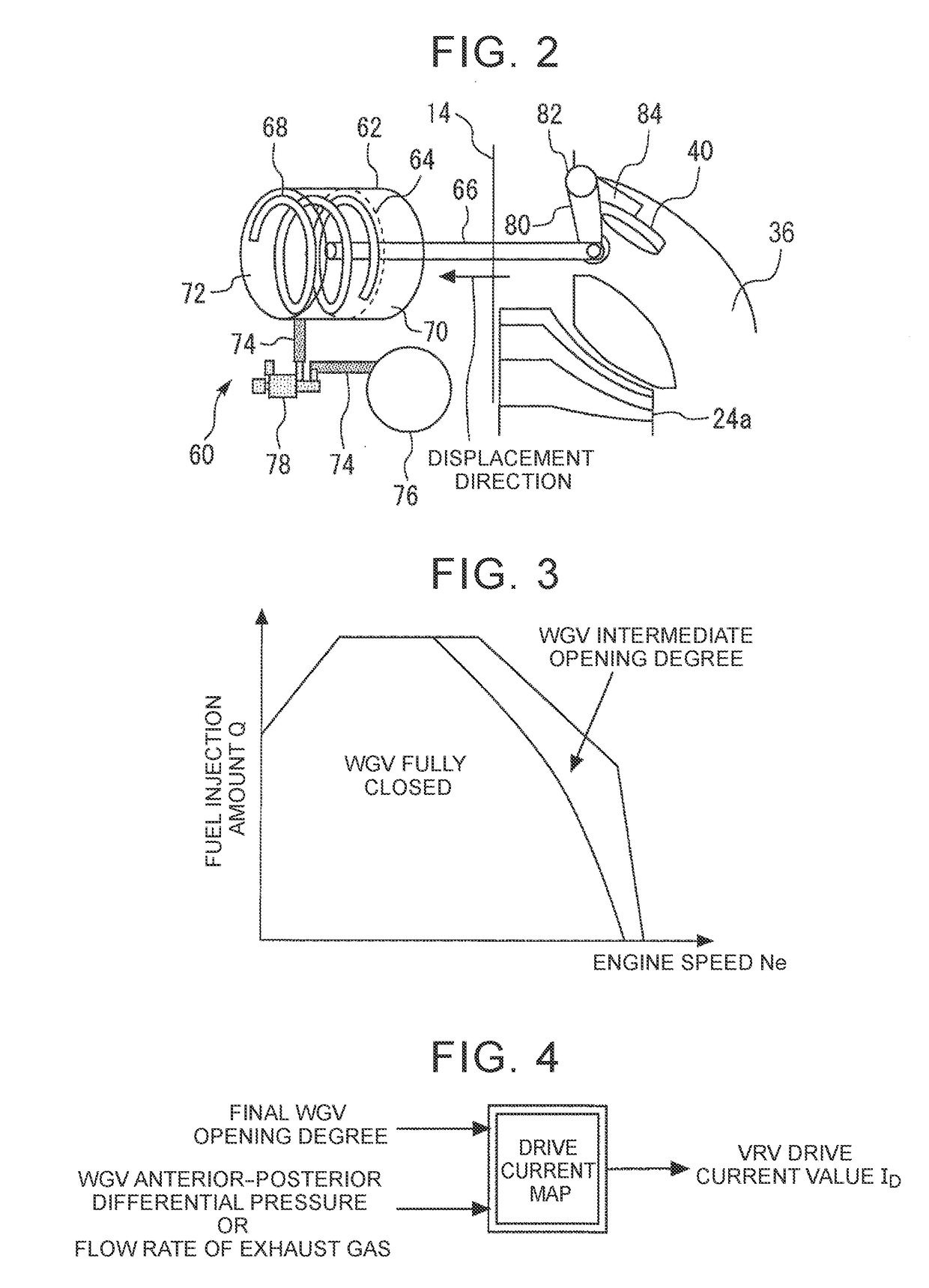

Control device for internal combustion engine including turbocharger

ActiveUS20180328269A1Minimize changesEnsure responsivenessElectrical controlInternal combustion piston enginesDriving currentTurbocharger

A control device for an internal combustion engine including a turbocharger and a negative-pressure waste gate valve includes an electronic control unit configured i) to apply a first drive current value to a pressure regulation valve so as to maintain an opening degree of the waste gate valve in a fully closed state in a case where an actual boost pressure is lower than a target boost pressure and a boost pressure difference between the actual boost pressure and the target boost pressure is equal to or larger than a threshold, and ii) to apply a second drive current value that is smaller than the first drive current value to the pressure regulation valve in a case where the actual boost pressure is lower than the target boost pressure and the boost pressure difference is smaller than the threshold.

Owner:TOYOTA JIDOSHA KK

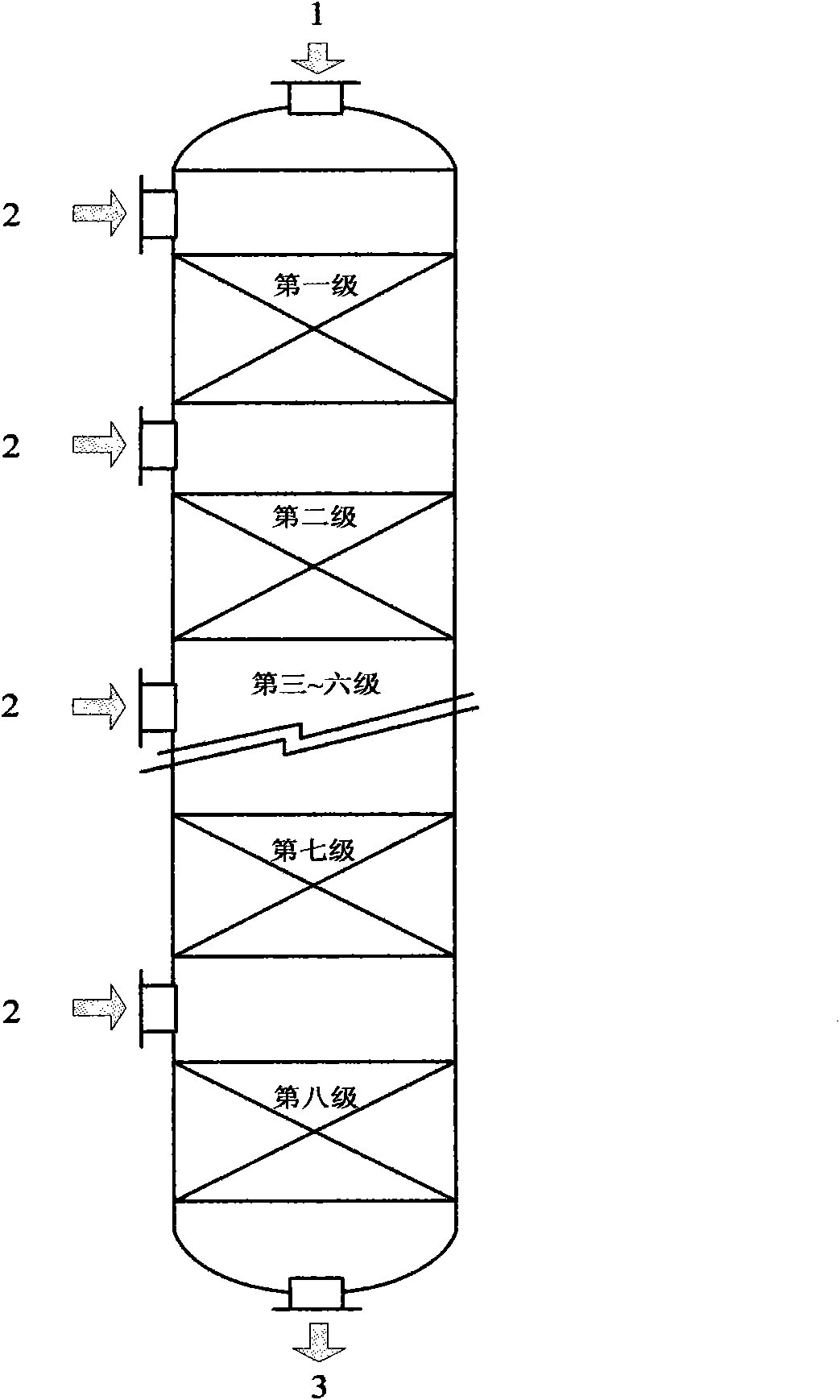

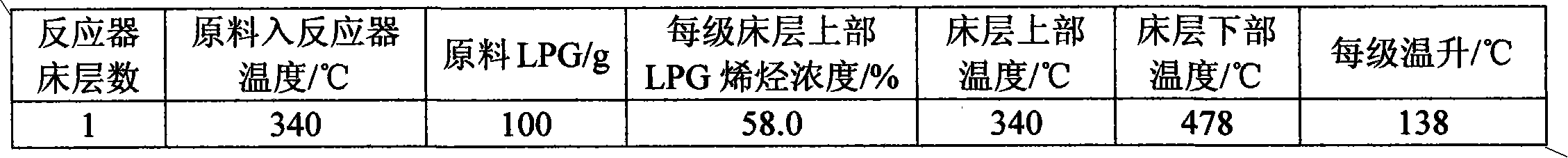

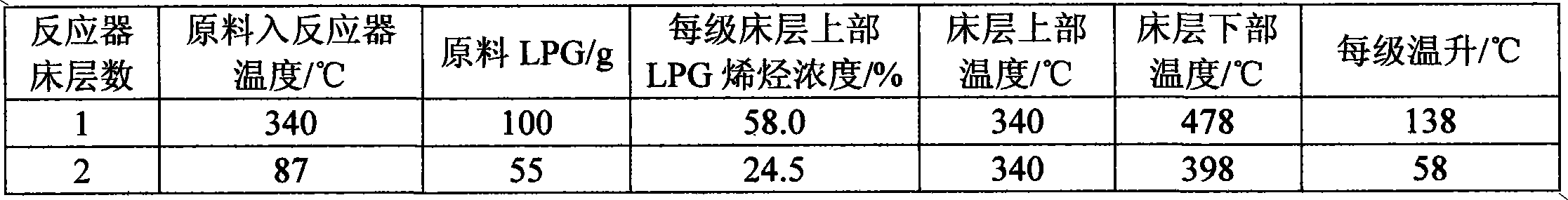

Fixed bed multistage reactor for aromatizing reaction of olefin-containing liquefying gas

InactiveCN101892072AEnsure responsivenessHigh selectivityLiquid hydrocarbon mixtures productionFixed bedAlkene

The invention aims to provide a fixed bed multistage quench-type reactor for an aromatizing reaction of olefin-containing liquefying gas, which is characterized in that: the stage number of the fixed bed multistage reactor is determined according to the circulation quantity of saturated hydrocarbon entering the reactor and bed temperature rise in beds controlled in advance by the catalyst beds in the reaction process; and the saturated hydrocarbon is introduced to control the olefin content of the olefin-containing liquefying gas so as to control the temperature rise in the reactive catalyst beds. In the aromatizing reaction of the olefin-containing liquefying gas, the reactor can control the temperature rise in each stage of catalyst bed, so the appropriate reaction performance is obtained, the utilization rate of catalysts is improved, the service life of the catalysts is prolonged, and secondary reactions are reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

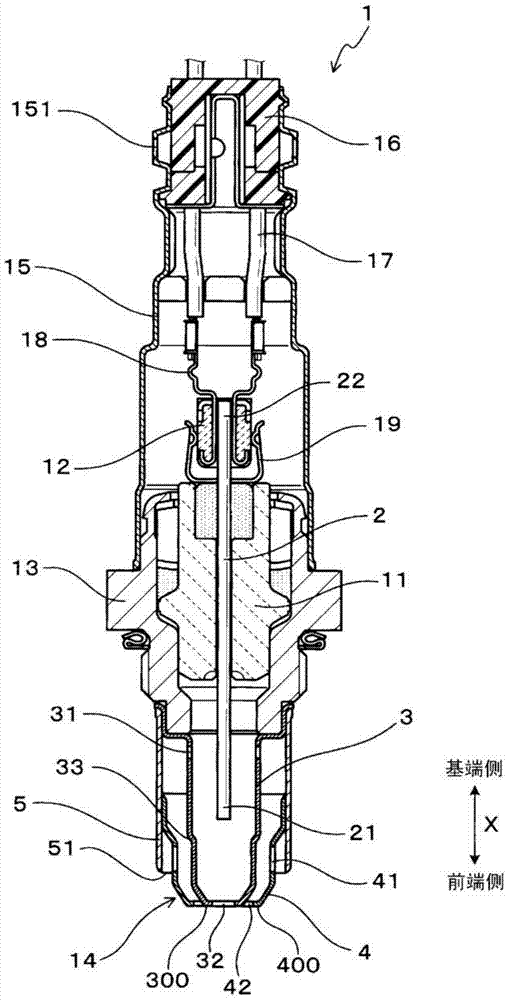

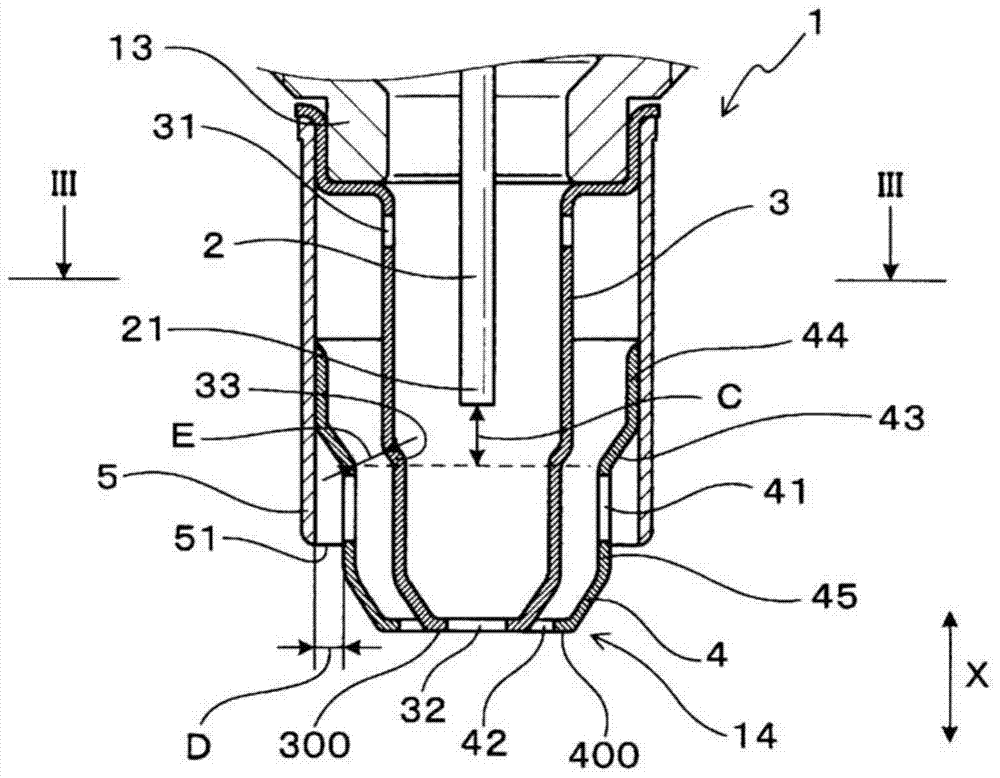

Gas sensor

ActiveCN104246487APrevent intrusionIncrease temperatureMaterial analysis by electric/magnetic meansEngineeringElectrical and Electronics engineering

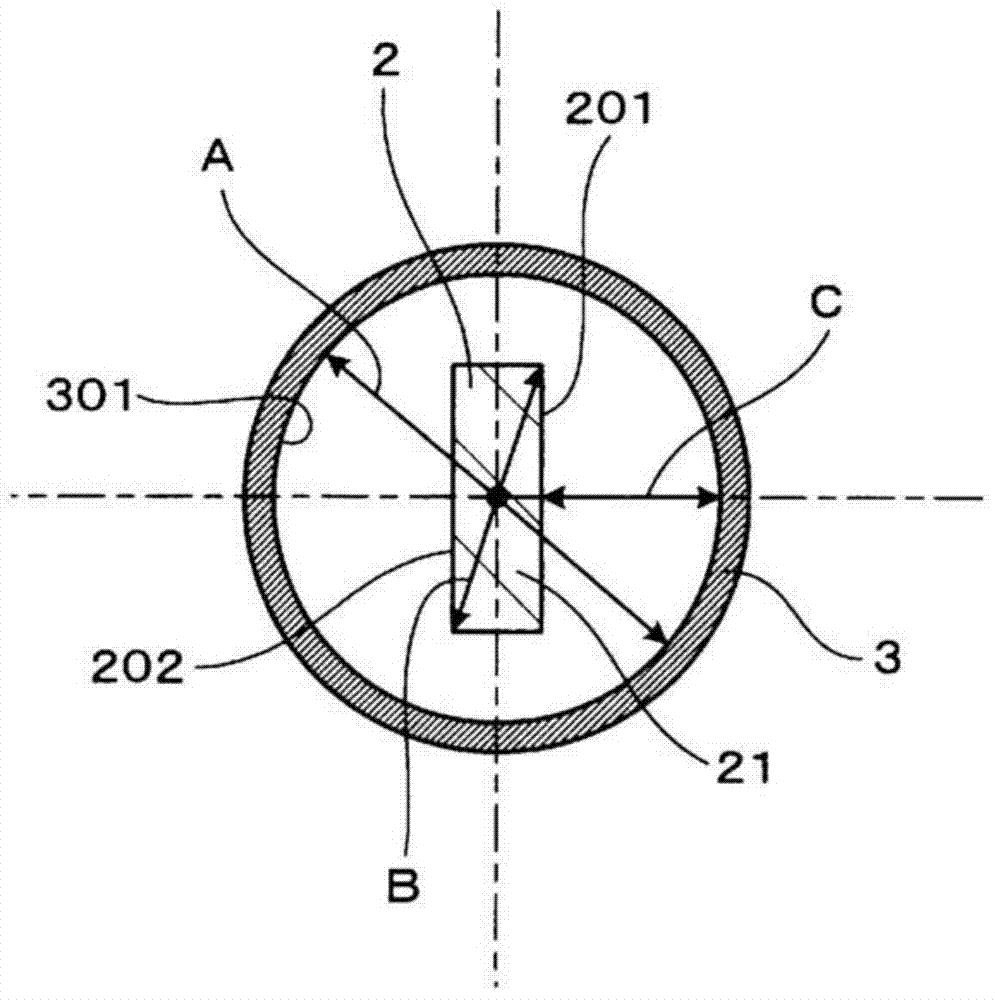

A gas sensor (1) is provided with a sensor element (2), a housing (13), and an element cover (14). The element cover (14) has an inner cover (3) and an outer cover (4). The outer cover (4) has an outer introducing port (41) and an outer discharge port (42). The inner cover (3) has an inner introducing port (31) and an inner discharge port (32). On the diameter direction outer side of the outer cover (4), a protection cover (5) having the leading end side thereof opened is disposed to cover the outer introducing port (41), and a predetermined interval is provided between the outer cover (4) and the protection cover (5). The inner cover (3) is provided with a diameter reducing step portion (33) having the diameter thereof reduced toward the leading end side. The diameter reducing step portion (33) is positioned between the outer introducing port (41) and the inner introducing port (31) in the axis direction X. When the inner diameter of the inner cover (3) is represented by A, and the diameter direction maximum length of the leading end portion (21) of the sensor element (2) is represented by B, the relationship of A / B<=2.1 is satisfied.

Owner:DENSO CORP

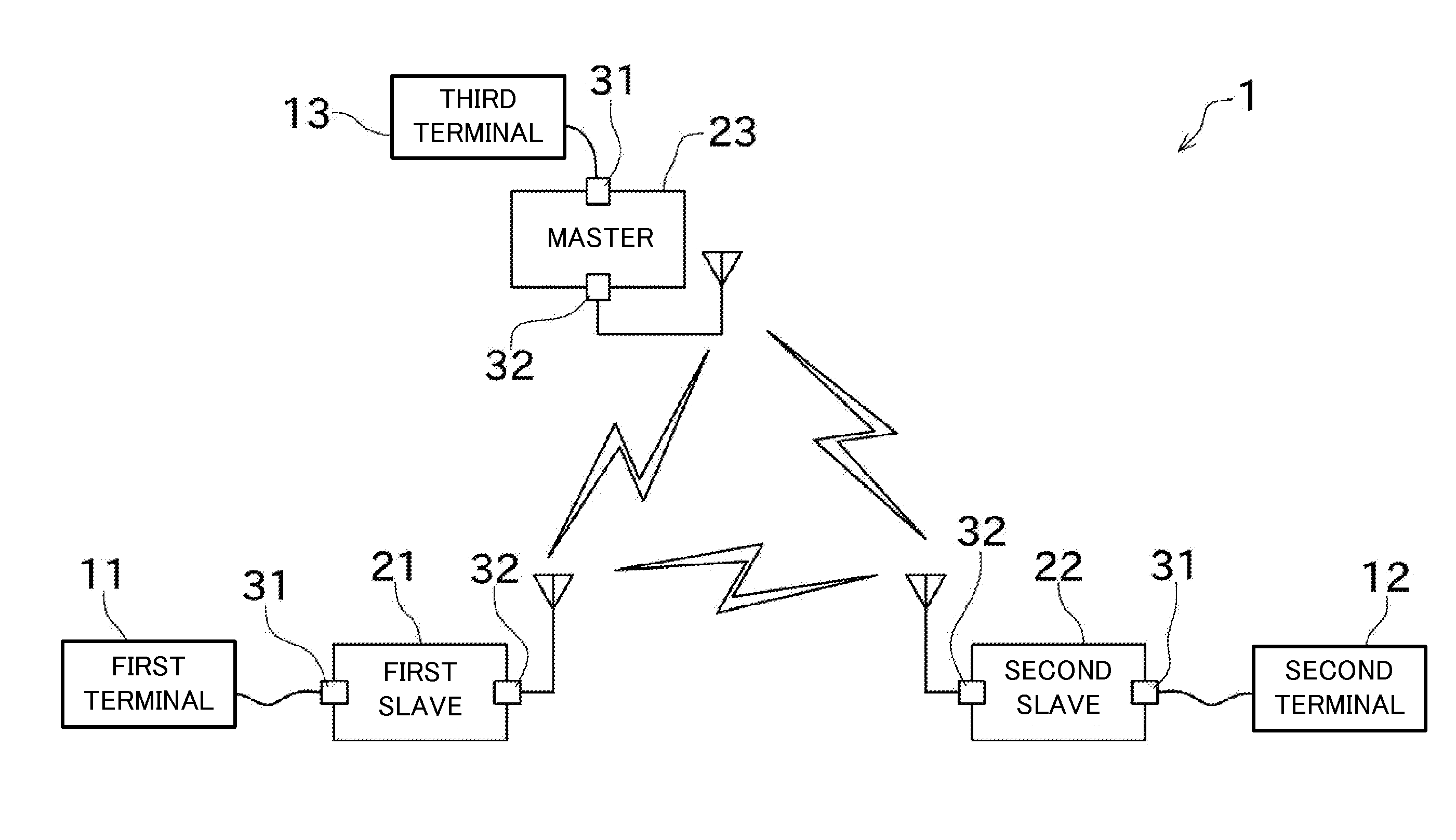

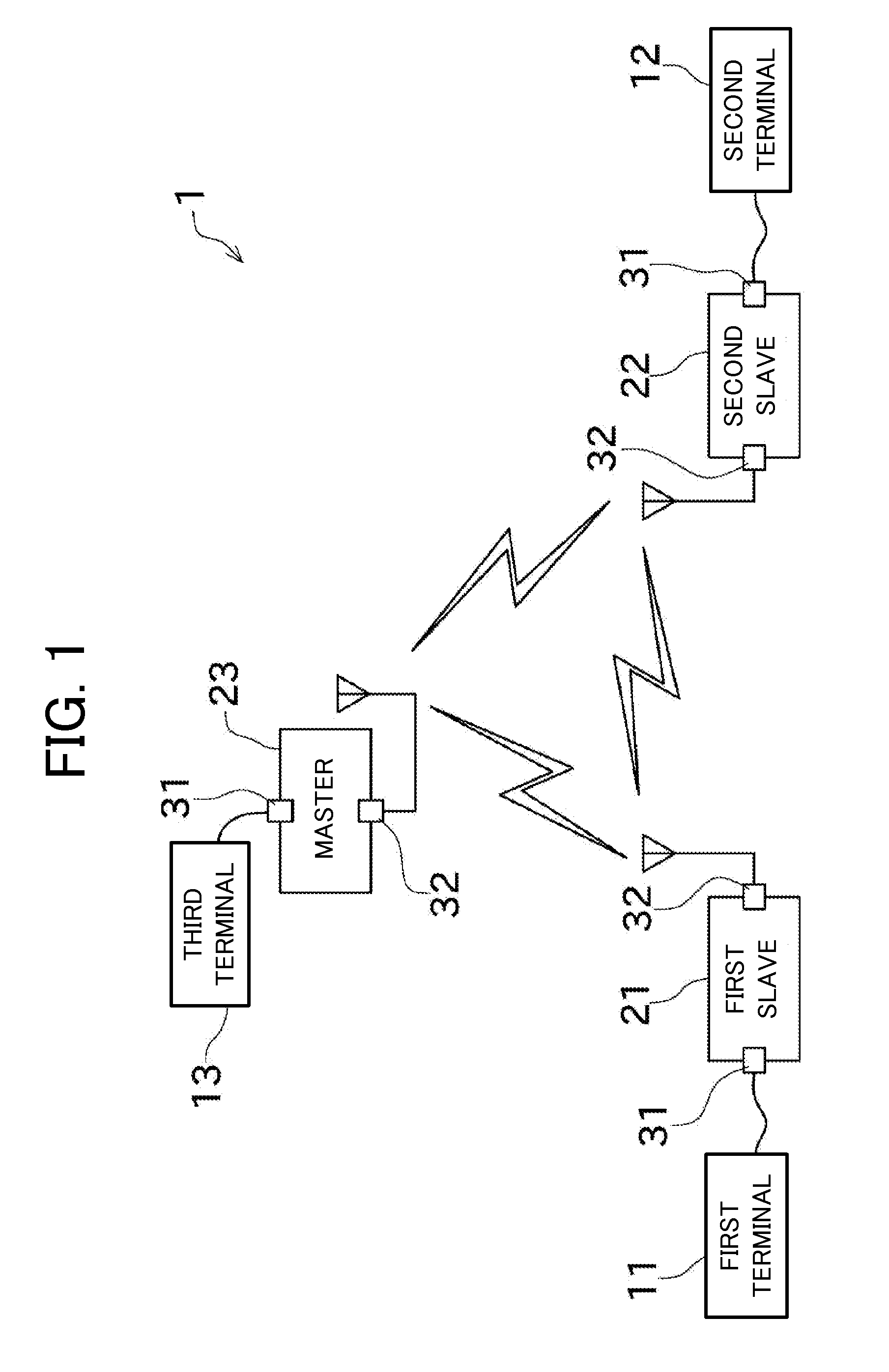

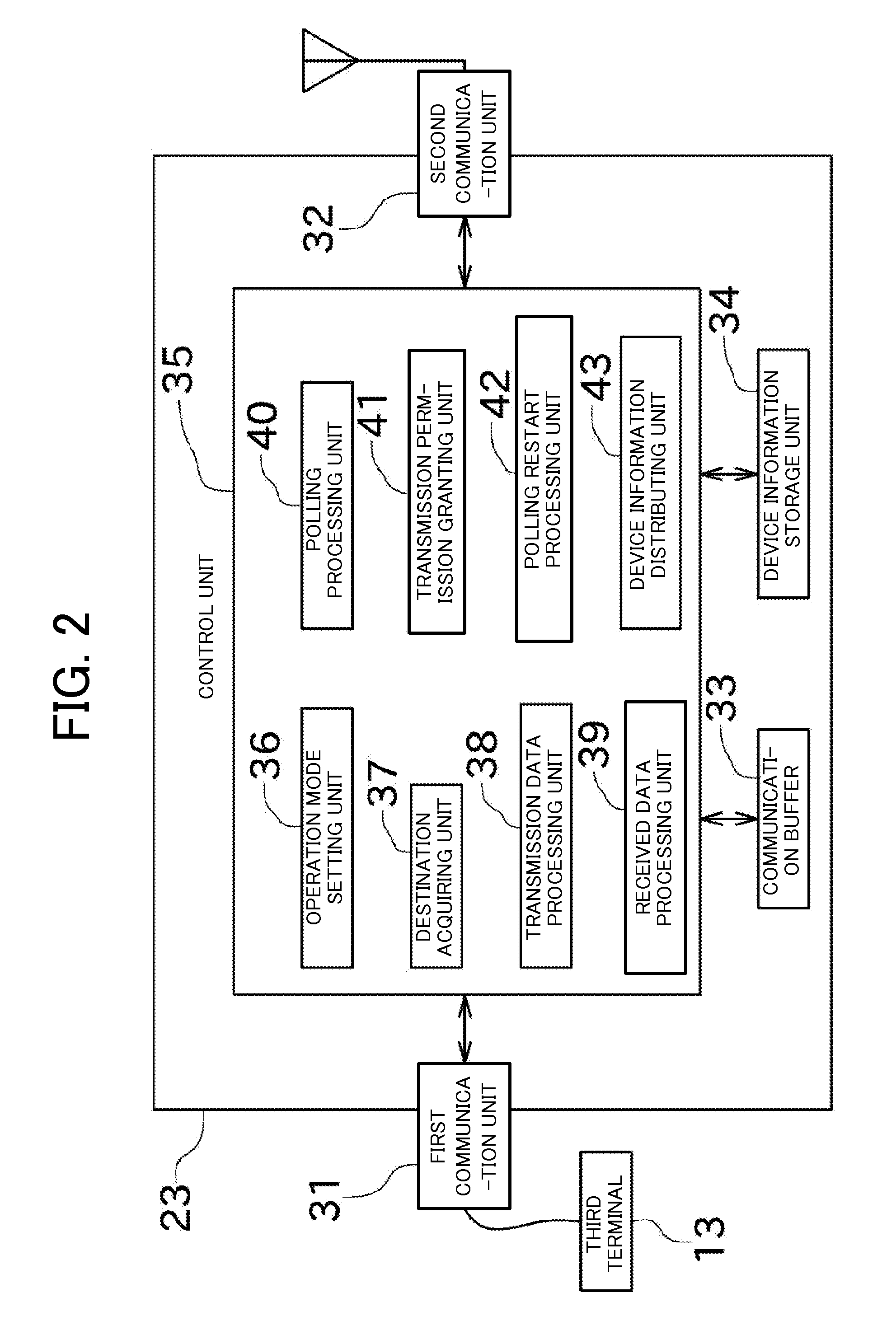

Relay communication system and relay communication device

InactiveUS20140003325A1Avoid collisionLow costFrequency-division multiplex detailsTime-division multiplexComputer hardwareCommunications system

A relay communication device includes a first communication unit, a second communication unit, and a communication buffer. When receiving data in the first communication unit, each relay communication device temporarily accumulates the data in the communication buffer. The relay communication device functioning as a master asks the relay communication device functioning as a slave if there is data in the communication buffer. The master grants transmission permission to the slave that has returned a reply indicating that there is data. The slave that has received the transmission permission transmits the data to a slave that is a destination of the data. The master makes an inquiry into a next slave in the case where the slave which has been granted the transmission permission completes the transmission of the data from the second communication unit. The allowed amount of data transmitted by each relay communication device at one time is limited.

Owner:MURATA MASCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com