Mixing device for acetylene oven

A technology of a mixer and an acetylene furnace is applied in the field of mixer devices of an acetylene furnace, which can solve the problems that the safety and stable operation of the acetylene furnace cannot be satisfied, and achieve the effects of stable operation, increasing the degree of turbulence and shortening the distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

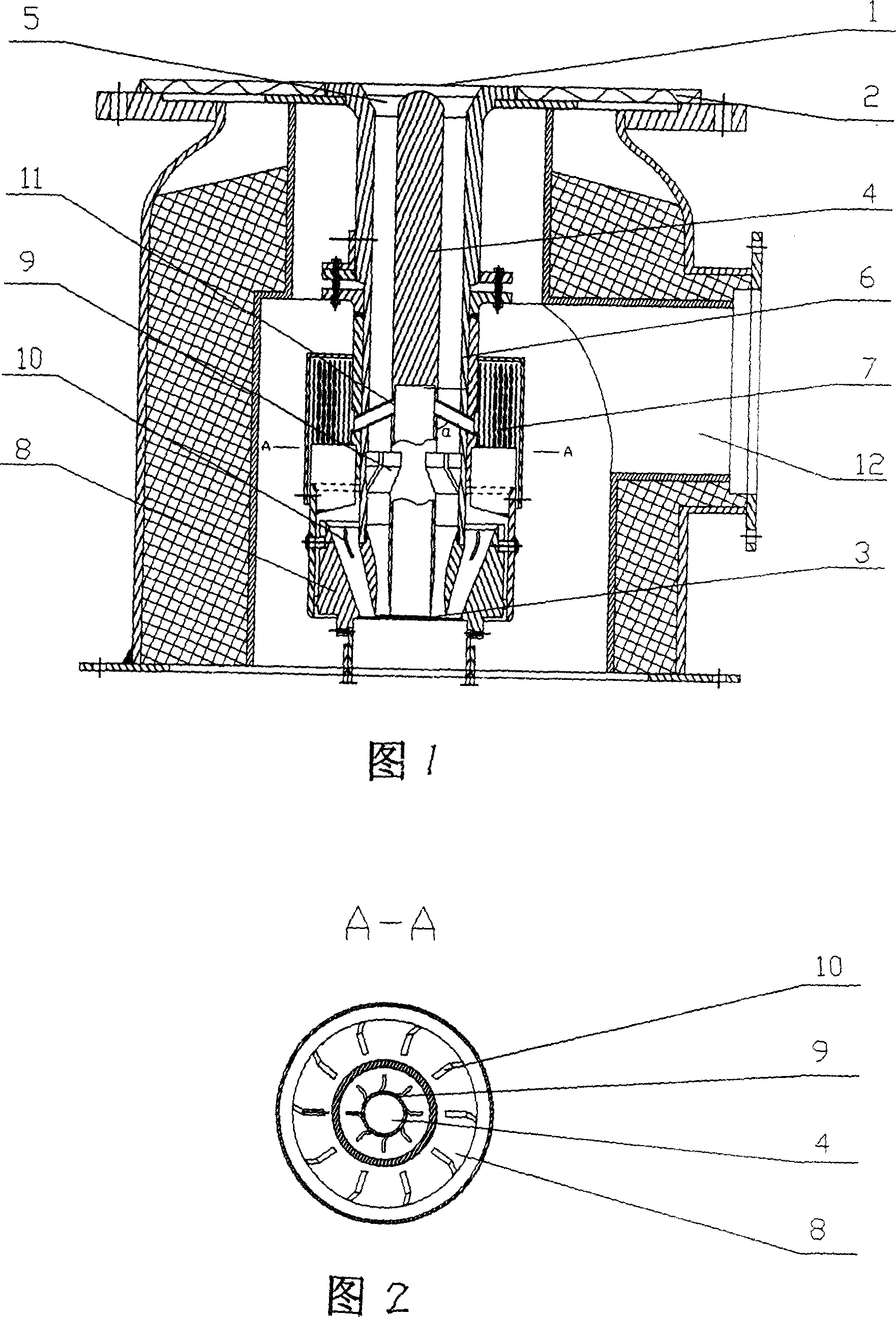

[0016] Embodiment: a kind of mixer device that is used for acetylene furnace, comprises natural gas inlet 12, is arranged on the corrugated plate 2 of oxygen inlet outer plane, and the oxygen nozzle 6 that is connected with oxygen inlet 1, in oxygen nozzle 6 by The vortexer positioning piece 5 is connected to the positioned vortexer 4, the oxygen swirl piece 9 uniformly fixed on the lower circumference of the vortexer 4, the natural gas nozzle 8 connected to the upper end of the mixed gas nozzle 3, one end connected to the upper end of the natural gas nozzle 8, and the other end The natural gas inlet filter screen 7 connected to the outside of the oxygen nozzle 6 is characterized in that: the through hole provided on the circumference of the oxygen nozzle 6 relative to the middle position of the natural gas inlet filter screen 7 passes through the connecting pipe 11 and the The through holes provided on the circumference of the swirler 4 communicate; on the inner circumference ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com