Control optimizing method for master controller of supercritical unit boilers

A supercritical unit and boiler master control technology, applied in the control system, steam generation, lighting and heating equipment, etc., can solve problems such as serious involvement, large overshoot, and reduced system output response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

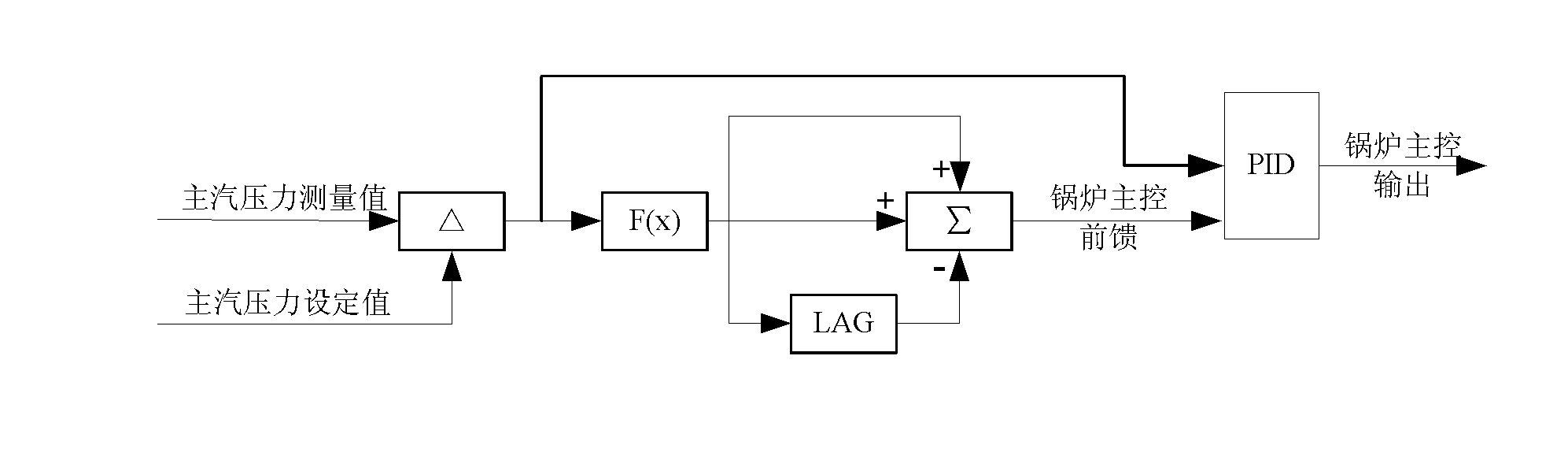

[0044] figure 1 It is a schematic diagram of the main control logic of the boiler:

[0045] The main steam pressure deviation is corrected by the function F(x) to generate two feedforward signals: one is equivalent to the proportional action, and the amplitude is directly output to the boiler main control; the other is the signal minus the value of the lagging link (LAG), Equivalent to the actual differential action.

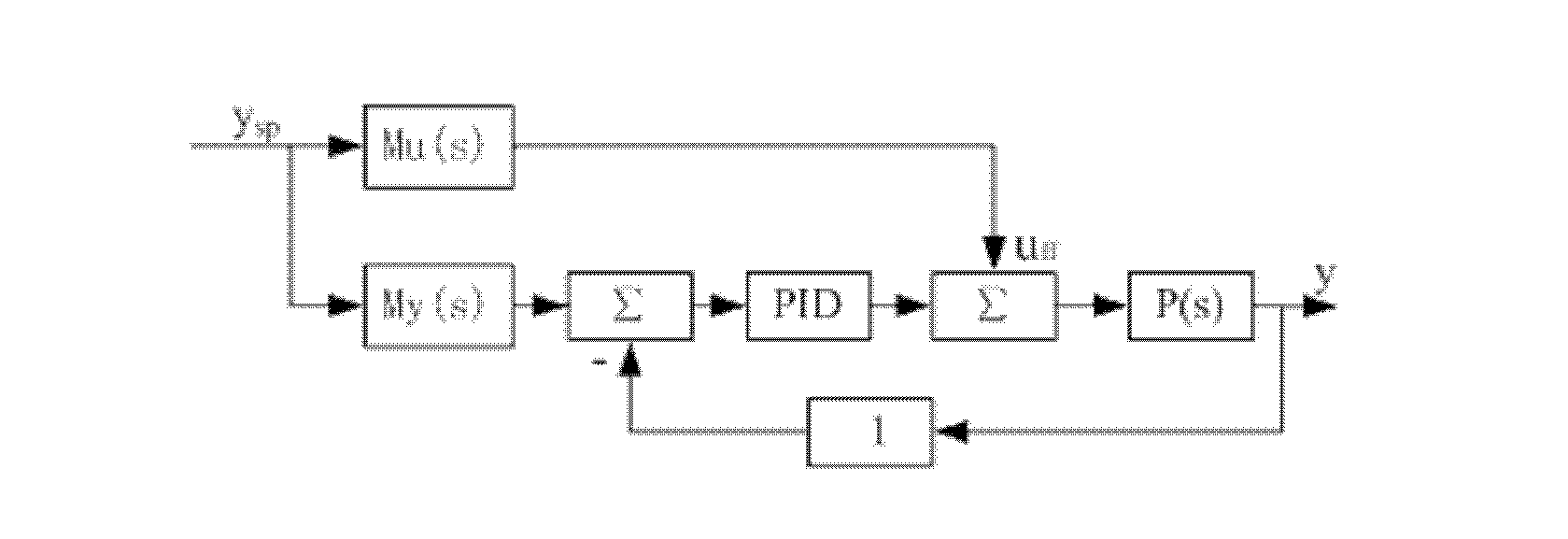

[0046] figure 2 Schematic diagram for conventional feedforward control:

[0047] M in the picture u (s) is the transfer function of the feedforward control branch; M y (s) is the setting value correction function, which corrects the setting value; P(s) is the functionalization of the actuator.

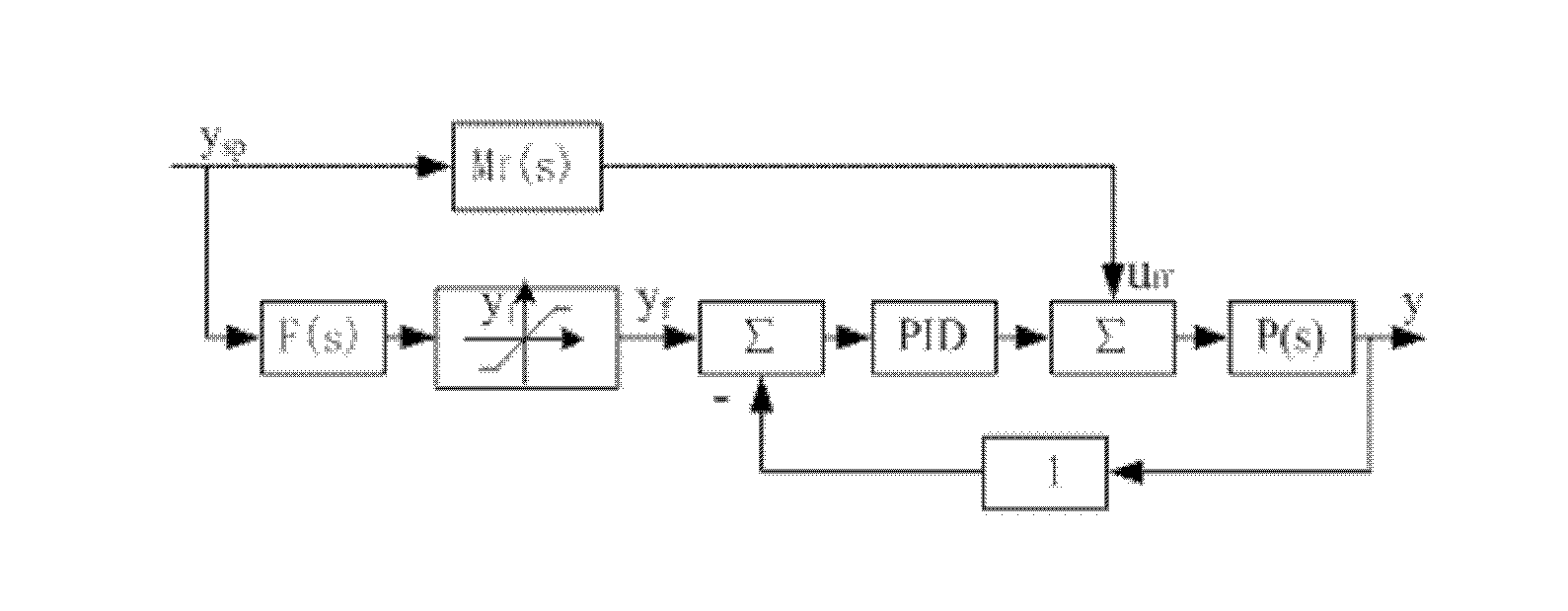

[0048] image 3 Feedforward control optimization schematic:

[0049] A supercritical unit boiler main control optimal control method, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com